Abstract

Manufacturing and the further utilization of biogas is an efficient way of complementing or replacing primary energy resources. Ukraine has followed the global tendency to substitute fossil energy sources with renewable ones, which particularly includes biogas. Considering the experience of European countries, as well as the potential and needs of Ukraine, the necessity of biogas plant building implies three main factors: obtaining the energy sources, selling agricultural products and by-products of biogas production, and managing the environmental issues surrounding biogas generation. The growth dynamics of biogas plants and their productivity were analyzed for the period of 2012–2019. In doing so, the capacity and potential capabilities of biogas production in Ukraine by means of biological waste and agricultural raw materials were assessed. The article focuses on the importance of resolving the issues of sanitary and technogenic protection in biogas plant building and biogas manufacturing. It also points out the reasons that prevent Ukraine from going forward with biogas projects, as well as the main factors that affect biogas plant viability and efficiency. Based on the statistical data of previous years and regression analysis, the authors calculated the production output and biogas transformation. Herein, the trend model and Excel software were applied.

1. Introduction

The overall development of a country depends on the production output of its industrial, agricultural, and service sectors. Nevertheless, an extensive increase in production is not always beneficial in terms of social and economic welfare. In a situation of constant deterioration of the ecological state in the entirety of a nation, region, or a local community, the minimization of the negative influence on the natural environment becomes the bottom line. A modern solution to the problem of economic development in a country such as Ukraine is transiting to resource-efficient, environmentally safe, low-waste technologies. However, this process is complex, capital intensive, and implies the rejection of more traditional means of manufacturing [1].

Thus, great attention is paid to searching for new technologies and improving the current ones by enhancing their economic efficiency level and expanding their scope of use. One of the most prominent directions of energy development in the world is making the best possible use of renewable energy sources and, hence, increasing their share in the overall energy resource supply. This last is predicated by the necessity of decreasing the number of harmful emissions in the atmosphere and reducing dependence upon imported energy sources [2].

In recent years, renewable energy sources have become one of the main criteria of energy security throughout the world. The principal reasons are the prospected depletion of fossil fuels, the rapid price increase of energy sources, uncertainty of stability of supply, and reliability of procurement. Moreover, the negative effect on the environment is leading to grave consequences that concern society in more ways that are becoming explicit. In many countries, renewable energy utilization significantly augments current energy capacities, thus, delivering security and enhancing the social and economic situation. Ukraine, unfortunately, may be listed among those that are dependent on energy resource imports. Consequently, the development of renewable energy is crucial to expanding its state of energy security. A reduction in expensive energy source imports will lead to a decrease in Ukraine’s dependency upon other nations and prevent instability related to ongoing energy crises [2].

One further reason for the increased utilization of renewable energy sources is that in order to ensure economic development, overall energy consumption has become higher since the normal functioning of industrial enterprises, thermal power stations, and transport activities need a constant flow of energy inputs. The main sources of energy are coal, natural gas, gasoline, kerosene (paraffin), and mazut (which are derived from petroleum). Meanwhile, vehicle engines, industrial facilities, and thermal power stations increase carbon dioxide emissions (a greenhouse gas). The reduction of CO2 emissions by transitioning to the use of renewable energy sources and lowering the energy capacity of businesses is the primary means of combating climate change. Renewable and ecologically safe energy sources are recognized as being the most auspicious way to accomplish this goal [3].

The production of renewable energy becomes especially significant in the context of global alterations of climate conditions. However, some countries possess certain features that expand the role of ecologically beneficial energy. Ukraine can be mentioned as an example of a nation that is not self-sufficient in terms of energy delivery and is heavily dependent on weakly diverse energy source imports. This systematically leads to socio-economic tensions with geopolitical consequences [4].

In recent years, due to the global energy crisis, agricultural production and waste have come to be perceived as potential fuel sources. Waste products of plant production are, for example, created in enterprises that process agricultural crops. In Ukraine, the utilization of plant by-products began in the year 2000 with the construction of a pilot plant generating electricity by burning straw. This had a capacity of 980 kW/h. The technology was based on the Danish experience. In the short time since, the Ukrainian company UTEM has begun to produce similar boilers using a license agreement made with the Danish firm BWSC [5].

Nowadays, it is impossible to anticipate ecological crises and not make use of modern eco-biotech technologies involving the processing of solid and fluid waste generated during agro-industrial production. However, the prospects for the successful development of the biogas industry need more fundamental analysis, wherein economic, ecological, and sociological factors are taken into consideration [6].

Obtaining biogas from organic leftovers that come from the agricultural sector is considered to be an important vector of renewable energy development. The potential of Ukraine in terms of biogas production is enormous since the country has a well-developed agro-industry, the leftovers of which generate a perfect raw material base. The energy that is received from biomass, therefore, can become a tangible substitute for ‘traditional’ carbohydrate fuel.

Biogas can be used in different ways. It can be burned in heating installations, for example, or, in its enriched form, it can be employed in vehicle engines as a fuel. Moreover, cogeneration plants can produce electricity, which then can be sold or used in the manufactories’ own production. Biofuel production requires a biogas complex, an engineering and technical facility that processes organic waste into biomethane. Ukraine has great raw material opportunities and favorable tariffs for electricity from renewable sources, so biogas is promising for the development of renewable energy [7].

Ukraine has highly developed agricultural sectors that annually produce a large number of wastes and residues [8]. Today, agricultural waste is considered a valuable secondary energy resource. Developed agricultural production has a strong potential for biogas production, which can be produced from a wide range of organic substrates of both animal and plant origin. The advantage of biomass is its renewability and relatively cheap cost compared to traditional fuels. The benefits of using the potential of biomass and household waste are quite significant because raw materials in the form of litter and various types of waste are available throughout Ukraine. It is also important that modern biofuel plants are relatively compact and can employ different types of raw materials. This versatility allows them to be placed in close proximity to facilities that are planned to provide energy or heat from these resources [2].

Considering all the features and specific conditions, a properly designed biogas complex is able not only to recoup the cost of its construction but also, in the long run, to bring additional income from the sale of electricity at a green tariff. Today, renewable energy shows an annual increase of 1% in market share, which will only increase with time. In addition to the impact on the environment in the form of reducing carbon emissions and disposal of livestock and crop waste, the development of the biogas market will reduce dependence on fossil fuels, hasten biotechnical and bioengineering development, and smooth peak loads in the grid by connecting additional cogeneration facilities [9].

The benefits of using biogas are not only found in the production of alternative energy but also in that it is the solution to a myriad of environmental problems because, through proper disposal and processing of agricultural and household waste, biogas production can prevent methane emissions into the atmosphere. In addition, the uncontrolled growth in household and industrial waste leads to problems of land and water pollution due to loss of containment in landfills and implies a considerable cost for disposal. Given that the cost of fossil resources is growing and that they are a limited resource, the development of alternative energy is inevitable. This is driven not only by the ever-deteriorating environmental situation but also by economic expedience. Each new biogas complex reduces dependence on purchased fuel and, ultimately, indirectly affects the country’s economy [3].

These factors are relevant, have practical significance, and have determined the choice of the research topic. In this context, the study aims to analyze the current state and prospects of biogas production and use in Ukraine and assess the economic, environmental, and social effects and benefits of biogas production. The materials used in the study are the following: information from the State Agency for Energy Efficiency and Energy Saving of Ukraine, the State Statistics Committee of Ukraine, and scientific articles of domestic and foreign scientists on the research topic.

Recently, the problems of production and use of biogas have been the subject of numerous researches by foreign and domestic scientists. Accordingly, one of the promising areas of energy saving in agricultural enterprises is the production of biogas as a type of renewable energy source. The main advantage of biogas production is the opportunity to make use of available and inexhaustible sources of industrial, domestic, and agricultural waste raw materials [10].

Implementation of biogas projects in Ukraine will bring about moderate structural changes; initially, these will take the form of a slowdown in coal production, natural gas, steam, and hot water supply. In the longer term, the largest change will be observable in the case of coal, the demand for which is declining due to its replacement with solid and gaseous biofuels. However, expanded use of biogas projects requires significant modernization of existing energy networks and infrastructure [11].

In the European Union (EU), the use of biogas is mainly aimed at producing electricity and heat. However, there are cases of converting biogas into biomethane, which is introduced into the natural gas network or used as biofuel in vehicles. In this last direction, the current reality in several countries of the north-central part of the European Union deserves attention, as these have implemented effective policies to promote the use of biomethane for public and private transport [12].

2. Materials and Methods

Biogas production mainly depends on the availability of appropriate raw materials. Ukraine has a well-developed agriculture sector, the waste of which provides an excellent raw material base. However, biogas plants for biogas production must be installed and conditions created to ensure their operation. To assess the dynamics of biogas production in some EU countries and Ukraine, in this paper, data on the availability of biogas plants and their capacity were collected. The main sources of data used in the study were published materials of the State Agency for Energy Efficiency and Energy Saving of Ukraine and the Bioenergy Association of Ukraine [13]. The use of graphical research methods allowed bringing to light the technical potential of biogas production in Ukraine compared to some EU countries. In analyzing the dynamics of biogas production in some EU countries and Ukraine, we can see a different range of opportunities for biogas production. In Germany, for example, this process has developed steadily and yielded high results, as evidenced by the indicators of installed capacity and their use for the development of biogas production.

Based on the data of the State Agency for Energy Efficiency and Energy Saving of Ukraine, it is determined that the main beneficiaries of the biogas energy market in Ukraine are its large sugar factories, as they have a large number of raw materials. This means, in addition to sugar production, they can produce electricity from cellulose and earn money by selling it. Biogas production can also be carried out on small livestock farms, provided that energy crops are grown on small plots and added to livestock waste. In general, the larger the farm, the greater the capacity of the biogas complex it can economically build. The payback period of biogas plants is important here. Investors are interested in facilities with a payback period of 2 to 3 years, which can be provided by installations with a capacity of 2.5–3 MW. For a 1 MW installation, the payback period will be up to 4 years, but the farm must have a sufficient raw material base. Such an agribusiness venture could be a farm for 10,000 head of cattle [14]. The Biogas Association of Ukraine demonstrates, however, that agricultural biogas plants with a capacity of 100–300 kW cannot be repaid in fewer than 6 or 8 years, and special credit programs for farms do not yet exist. It is noted that at the end of 2019, of the planned 290 MW of electricity capacity, only 86 MW was brought about via biogas (29.7%) [15].

According to the materials of the State Information and Analytical Center, economic, environmental, and social aspects of biogas production and use are characterized by the need to develop and implement biogas technologies. The analysis of the positive effects obtained from the implementation of biogas projects reveals that each new biogas complex reduces dependence on purchased fuel and indirectly affects the country’s economy. The economic, ecological, and social effects of the implementation of biogas projects have been researched and assessed as positive. The potential for biogas production was estimated at 9633.4 million m3/h. However, currently, almost no biogas plant in Ukraine has achieved the desired efficiency of electricity production [16].

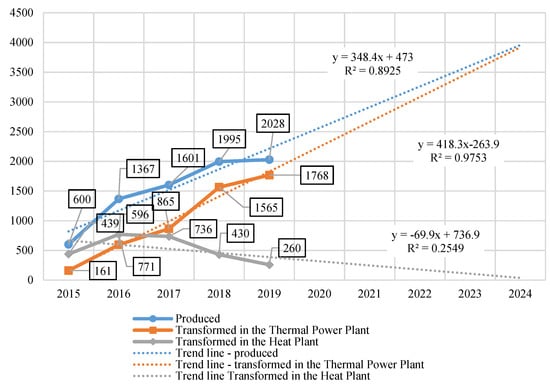

Using the Ordinary Least Squares regression (OLS) method, we analyzed the dynamics of biogas production and conversion at thermal power plants (TPP) and heat plants (HP) and calculated the forecast indicators of biogas production and conversion. This made it possible to compile a linear equation that best corresponds to a set of ordered pairs by finding the values for (a) and (b), the coefficients in the equation of the line.

The study used a dependence that describes the linear trend equation y = a + bx, which assumes a linear relationship between the input variables (x) and the single output variable (y) and the slope of the regression equation (a), the constant of equation (b).

The resulting graphs of the linear trend illustrate the relationship between the periods and volumes of output and converted products and the coefficient of determination (R2). This made it possible to estimate the density of the relationship between the studied phenomena, which is determined by a quantitative value.

The coefficient of determination was calculated by the formula:

where R2—coefficient of determination;

RSS—sum of squares of residuals;

TSS—total sum of squares.

The closer R2 is to 1, the more reliable the trend line, i.e., a better-defined relationship is generated that reflects the relationship between values and the trend towards positive or negative changes. For the trend line of biogas production, the linear equation of the trend y = 348.4x + 473, R2 = 0.8925, which determines a high level of density of connection between values. For the trend line of conversion to thermal power plants, y = 418.3x − 263.9, R2 = 0.9753 characterizes the relationship between values as a significantly high degree of reliability, i.e., linear regression equation corresponds to the sample data. For the trend line of biogas conversion to heat plants, y = −69.9x + 736.9, R2 = 0.2549, which confirms the weak bond density and predicts a decrease in these indicators in the future.

The forecast of biogas production and conversion was calculated on the basis of data from previous periods using regression analysis and Excel spreadsheet editor, which allowed assessing the degree of relationship between variables and predicting the value of a variable based on known values. The resulting trend lines are a geometric reflection of the average values of the analyzed indicators, which, with the help of regression analysis, were expanded beyond the available data to predict future values until 2024. Statistics on biogas production and conversion for the period 2015–2019 helped obtain graphs showing the forecast values of biogas production for 2020–2024.

3. Results

The modern world is faced with the need to solve the problem of providing individual countries and regions with energy resources. Presently, the production of energy from renewable resources is globally relevant. Renewable energy has long been a worldwide trend. Wind, solar, and biogas production can not only replace expensive natural gas but also provide solutions to environmental problems. Given the constant demand for fuel resources, one of the priority areas and ways to overcome energy problems is the development of bioenergy and, in particular, the production and use of biogas, which is formed by appropriate technologies and is an effective way to supplement and replace traditional fuel and energy resources. Biogas is the general name for a mixture of combustible gases obtained as a result of the process of natural decomposition of various organic substances, i.e., methane fermentation. In the natural environment, the decomposition process takes a long time, but to obtain biogas in industrial conditions, it can be significantly accelerated, primarily by creating optimal conditions for the bacterial ‘engines of change’. To ensure the efficient flow of the methane fermentation process, it is important to maintain an optimal temperature that will stimulate the activity of these bacterial cocktails. Depending on the type of substrate, it can range from +25 °C to +75 °C, so in winter (at low temperatures), the meta tank must be heated. There are more than 60 listed and patented technologies for biogas manufacturing. This is due to the fact that to ensure the maximum output of biogas for each type of feedstock, a different technology is applied [17].

Biogas consists of a mixture of several gases. These are:

- -

- methane—(CH4) is the main source of energy, the share of which is equal to 60–70%, and its content is determined by the choice of source material (bio substrate);

- -

- carbon dioxide (CO2)—its share is from 25% to 40%;

- -

- hydrogen (H2), ammonia (NH3), and hydrogen sulfide (H2S)—A total of 2–5% [17].

Of note: the theoretical potential of biohydrogen from crop-based biomass in Ukraine is 77 billion m3 over a 3-year period (25.6 billion m3 on average) [18].

The development of bioenergy is very important for Ukraine as it has a significant potential of biomass that is available for energy production. Indeed, this biomass is enough to replace most imports of gas, gasoline, and coal (about 23 million tons oil equivalent) [15]. The obtained biogas, after appropriate technological separation, is superior to natural gas in terms of calorific value. It can be used for heating or for electricity production. It has a great advantage over sun or wind energy generation, as biogas plants can run on schedule, start up, and shut down quickly. This makes it possible to use them in order to balance the voltage in the grid [14].

In analyzing the dynamics of biogas production in certain EU countries and in Ukraine, one may notice a different range of biogas production opportunities. In Germany, for instance, this process has gained stable development and delivered high results, as evidenced by the indicators of installed capacity and their use for the development of biogas production (Table 1). The development indicators of this industry in Poland are much lower, but they are characterized by stability and annual growth.

Table 1.

Dynamics of biogas production development.

In Ukraine, the installation of biogas plants began only in 2012, and production was launched in 2013. At that time, European countries were already increasing their potential and biogas production. Although having a sufficient number of natural resources for biogas production, Ukraine lags far behind many European countries, and therefore, conducting research and studying their experience is important for the development of biogas production in the country [13]. According to IRENA, the share of electricity generated from biofuels in the world is growing, although it still remains smaller when compared to solar and wind energy [13]. The prospects for biogas production in Europe, however, indicate a tenfold increase in production by 2030 [19].

Energy production is the main source of anthropogenic greenhouse gas emissions in the world, and therefore, the introduction of renewable energy sources, energy efficiency, and energy conservation play key roles [9]. Considering the state and possibilities of biogas production in Ukraine, it is worth paying attention to the significant potential due to the available biological waste and agricultural raw materials. Production of biogas may use as raw material:

- -

- agricultural waste—corn silage, grass, straw, chicken manure, cattle manure [3,20,21,22];

- -

- food industry waste—beer pellets, post-alcoholic bard, pulp (sugar beet processing residues), milk processing waste (whey, lactose), fruit, berry, grape and apple extracts, rotten potatoes, pulp, syrup [10,23];

- -

- technical glycerin and other waste materials from the production of biofuels (biodiesel);

- -

- food waste [3,16,24,25];

- -

- wastewater and fecal masses;

- -

- waste generated from the slaughter of animals on poultry farms, pig farms, livestock enterprises [13,25].

Studies conducted by specialists from different countries have indicated the estimated amount of biogas output during waste processing (Table 2) [3].

Table 2.

Biogas yield from different types of raw materials.

The production of biogas from garbage is also promising. In Ukraine, about 10 million tons of waste are generated annually, and there are almost 5.5 thousand landfills. About 3 million m3 of landfill gas, which contains about 50% of pure biomethane, can be extracted per year from more than 1 million tons of refuse. In late 2018, 20 biogas plants with a total capacity of 18 MW were already operating in landfills. One successful project is a 659 kW biogas complex at a landfill in Khmelnytskyi, where UAH 34 million has been invested in the project. The complex can produce about 5 million kWh of electricity per year at a “green” tariff of 12.4 Eurocents per kWh. This amount of electricity is enough for lighting the streets of the city. Thanks to this biogas plant, the city of Khmelnytskyi received:

- -

- an increase in the generation of “clean” electricity;

- -

- a reduction of CO2 emissions into the atmosphere;

- -

- minimization of fires in the landfill and reduction of volume thereof;

- -

- a gain in taxes to the local budget [26].

For the previously indicated raw materials, for biogas production, the most common technologies applied are:

- -

- obtaining energy from biomass by anaerobic fermentation in biogas plants;

- -

- applying methane fermentation technology, which allows acquiring, in addition to the energy source in the form of biogas, high-quality fertilizers and protein-vitamin feed additives and is essentially waste-free [10].

Biogas energy production is not harmful to the environment, as it does not cause additional greenhouse gas emissions of CO2, and it reduces the amount of organic waste. In addition, biogas can be obtained regardless of climate and weather conditions. In contrast to fossil energy sources, the potential for biogas production in Ukraine from waste from agricultural companies, the food industry, landfills, and wastewater is up to 3.2 billion m3 of methane (CH4) per year [3].

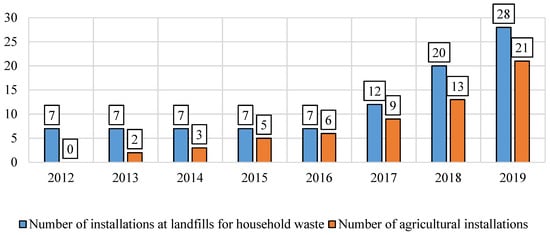

Creating a generation running on biogas has become a new direction for Ukraine. Until 2012, there were only seven biogas complexes in Ukraine installed at solid waste landfills. However, the potential is not exhausted, as there are many landfills where biogas plants can be installed, work on biogas produced by these landfills, and provide clean energy to the country’s energy system. In 2013, the first biogas plants began to be put into operation by agricultural enterprises. In 2018, 33 biogas plants were operating [24].

At present, the number of biogas plants in Europe exceeds 18,000. Among the leading countries are Germany, which has more than 11,000 biogas plants, and Italy, where there are about 1700 plants. France has 837, the United Kingdom has 715, while Switzerland has 634 biogas plants [27,28,29].

According to the State Agency for Energy Efficiency, 28 biogas plants and 21 biogas plants for agriculture were already operating at household waste landfills in 2019 (Figure 1).

Figure 1.

Dynamics of growth in the number of biogas plants in Ukraine, 2012–2019, in units. Source: own.

The owner of one of the most powerful biogas complexes in Ukraine is the company MHP Agroholding, which has an existing complex, “Oril-Leader”, in the Dnipropetrovsk region. This steadily generates 5.5 MW per day. It was built in 2013. In 5 years, the complex has utilized 300,000 tons of chicken manure, produced 100 million m3 of biogas, and generated 200 million kW of electricity. In 2018, the biogas complex reached its maximum capacity and contributed roughly 40 million kW of green energy to the grid [15,30].

Large sugar factories remain the major beneficiaries in the biogas energy market in Ukraine, as they possess huge amounts of raw materials. So, in addition to sugar production, they can produce electricity from the pulp and earn money from its sale. In 2017, a 5.1 MW biogas plant operating on the territory of the Teofipol Sugar Plant was established in the village of Teofipol. A year later, a new unit of 10.5 MW was put into operation. The total installed capacity of the station is 15 MW. The raw material for the production of electricity from biogas is beet pulp from sugar beet and corn silage taken from the same sugar factory [14].

This scale of possibility also exists with regard to small livestock holdings, provided that energy crops are grown on small plots and added to their livestock waste. In general, the larger the farm, the greater the capacity of the biogas complex it builds. However, the payback period of biogas plants is important here. Investors are interested in facilities with a payback period of 2 to 3 years, which may provide installations with a capacity of 2.5–3 MW. For an installation of 1 MW, the payback will be up to 4 years, but for this, the farm must have a sufficient raw material base. According to research, payback makes economic sense for a farm of 10,000 head of cattle [31].

Ecodevelop has built and launched an experimental low-power biogas complex of 333 kW. The project cost EUR 1.5 million and has an estimated payback period of 6 to 8 years. The raw material base is comprised of its own farm for 950 cows. In addition, the company buys 8 tons of silage per day. The daily production of biogas is 3600 m3, and the plant can produce 2.64 MW/h of electricity and 3.16 MW/h of heat per year. Moreover, additional income will be generated from the production of liquid and solid fertilizers—up to 28,000 tons per year [15].

The task of Demis-Agro’s low-capacity biogas plant at 100 kW was primarily to solve an environmental problem related to a pig farm located next to a residential area. The project was implemented before the introduction of the “green” tariff for electricity from biogas in 2013 and has paid off in 6 years. However, as the experience of members of the Biogas Association of Ukraine shows, such examples are quite rare. Unfortunately, farm biogas plants with a capacity of 100–300 kW cannot be repaid in less than 6 to 8 years, and special credit programs that would be available to farms do not yet exist [15].

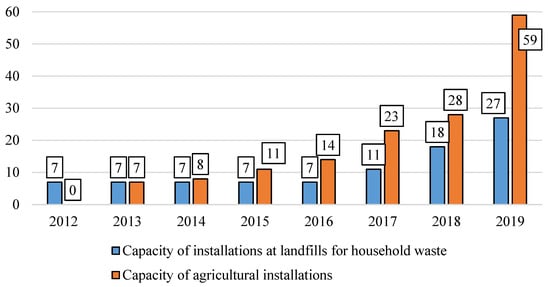

The State Agency for Energy Efficiency (Figure 2) has revealed that, in 2019, 49 plants produced energy from biogas at a “green” tariff. In the study period, the installed capacity increased from 7 MW in 2012 to up to 86 MW in 2019, of which 59 MW are generated from agricultural waste and 27 MW from solid waste. The total investment in this sector was EUR 140 million during 2012–2019. The National Commission for State Regulation of Energy and Utilities (NKREKP) states that, in 2019, biogas plants generated 247 million kWh of electricity [14].

Figure 2.

Dynamics of biogas capacity growth in Ukraine, 2012–2019, MW. Source: own elaboration, based on data from The State Agency for Energy Efficiency and Energy Saving of Ukraine [9].

Biogas production in 2019 increased by 3.3 times compared to 2015, and its use in thermal power plants by 9.7 times. In Ukraine’s heating plants, during 2016 and 2017, the use of biogas expanded. However, in 2018 it contracted by almost 1.7 times as compared to 2015 [32,33,34,35] (Table 3).

Table 3.

Dynamics of production and conversion of biogas, GJ.

Production and energy use of biogas has a number of reasonable and proven world practice advantages; among others, a wide range of raw materials can be used for biogas production. This means that biogas plants can be built basically everywhere in areas of concentration of agricultural production and technologically related industries. The universality of methods of energy use of biogas, both for production of electric and/or thermal energy at the place of its formation, allows any site that is connected to a network of natural gas (in the case of supply of purified biogas to the natural gas network) to be used, while it can also be applied as a vehicle motor fuel. In addition, the stability of annual electricity production from biogas allows it to cover peak loads in the network, especially taking into account the operation of unstable sources, such as solar and wind power plants [15,36].

Biogas plants are characterized by the possibility of modern waste-free production in agriculture, as they allow partial or complete use of organic waste from the farm while reducing harmful greenhouse gas emissions into the environment. It is important to note that biogas plants make it possible to dispose of agricultural residues and produce energy near waste disposal sites. In addition, it is possible to generate manufactured organic fertilizers for organic farming. Biogas plants can also be installed as treatment facilities on farms, poultry farms, distilleries, sugar factories, and meat processing plants. A biogas plant can replace a veterinary factory where dead animals are disposed of [13,37]. Biogas projects, therefore, create new jobs, provide cheap heating, reduce the need for imported natural gas, and reduce methane emissions.

Biogas is used as a fuel for the production of electricity, heat, steam, or as a motor fuel. Each new biogas complex reduces the dependence on purchased fuel and indirectly affects the country’s economy. However, the large-scale implementation of biogas projects is currently hampered by high initial investment costs, lack of working capital and investment, and wasteful treatment of biomass residues [38].

The economic effects of biogas production and the benefits of its use, thus are:

- -

- obtaining fuel that can be applied for the production of electricity, heating, and other industrial and domestic needs of industrial complexes that are suppliers of biosubstrates;

- -

- enhancing the economics of treatment plants;

- -

- minimizing the cost of raw material delivery—biofuel plants are usually placed directly next to the raw material supplier;

- -

- solving the issue of waste disposal, meaning instead of the cost of their removal and disposal, the company receives additional income;

- -

- converting biosubstrate residues into fertilizers [13].

The ecological influence of biogas production has great importance. This is the environmentally friendly processing of biomass, organic waste, and by-products of animal origin through methane fermentation. As indirect environmental effects, we can identify the prevention of contamination of groundwater, surface water, and soil. Electricity production as a result of biogas combustion in cogeneration plants allows maximum use of the received thermal and electric energy, but the most essential environmental effect is that biogas plants solve the problem of utilization of agricultural waste [39].

The conversion of organic residues into biogas occurs as a result of a sequence of complex biochemical transformations (biomass fermentation). Fermentation residues formed during biogas production in biogas plants are high-quality fertilizers that can be sold or used instead of mineral fertilizers. These pure liquid or solid biofertilizers do not contain weed seeds, nitrates, or a number of other negative components [3].

The most significant environmental impact is exerted by raw materials of animal origin. Currently, in Ukraine, there is an acute issue of utilization and safe processing of the wastes of poultry farms, pig farms, and cattle farms. In contrast, the anaerobic processing of livestock waste can be considered the best of the available technologies because the processing of waste in biogas plants can partially reduce environmental problems and has significant economic benefits in the form of decentralized renewable energy production (Table 4).

Table 4.

Effects from the implementation of biogas projects.

In addition to the environmental and economic effects, the social outcome is considerable, which is the improvement of the health of the population and expansion of the capacity to provide the population of rural areas with appropriate benefits. The social effect and important advantage of biogas power plants is the creation of a large number of new jobs, the training of workers, and the development of local economies as additional sources of revenue for local budgets and to increase household incomes. It is bioenergy that creates the largest number of jobs per 1 MWh of electricity produced from RES (renewable energy sources), including a significant part in related areas such as raw materials and biofuels, mechanical engineering, logistics, and more [3,40].

The relevance of biogas technologies also lies in preventing fires during droughts, as they use as raw materials and fuel, just those forest and agricultural wastes and residues that lead to mass fires. Biogas technologies are likewise one of the most efficient means of processing agricultural waste into organic fertilizers [41].

Moreover, the socio-economic effect of the implementation of biogas projects is that the heating generated by cogeneration plants is directed towards schools and office buildings. Therefore, biogas plants are an effective way to solve the problems of using agricultural waste, including animal by-products. Hence, the introduction of biogas plants operating on household waste and agricultural waste is relevant and economically feasible and contributes to strengthening the country’s overall energy security, as well as regional economic development [38].

Ukraine’s potential in the development of biogas production is huge. Ukraine has a well-developed agricultural sector, the waste from which provides an excellent raw material base. In 2018, the biogas production potential was estimated at 7.8 billion m3 of CH4 per year. This is about 25% of total natural gas consumption. According to the State Agency for Energy Efficiency and Energy Saving, the usage of only 37% of waste from livestock and crop production will produce more than 10 billion cubic meters of bio-gas [3]. Due to the available crop and livestock residues in agriculture, favorable climatic conditions, the accessibility to agricultural land, relatively inexpensive labor, and a large number of landfills, the use of biogas has significant potential for heat and electricity production [42].

The potential for biogas production is 9633.4 million m3/h. However, this potential is rarely used. At the beginning of 2020, only 86.1 MW of biogas power plants were operated in the country. As a result, the “National Renewable Energy Action Plan until 2020” in terms of the introduction of electricity generating capacity on biogas has not been fully implemented. Of the planned 290 MW, only 86 MW was installed, which is 29.7%. The development of biogas facilities for the processing of agricultural, industrial, and municipal waste should be considered as a way to address the issue of waste disposal and environmental pollution. It is also an important component of a circular economy and sustainable development, as well as a powerful factor in reducing greenhouse gas emissions. With a total production of electricity by biogas plants of 247.4 million kWh in 2019, the reduction of greenhouse gas emissions amounted to more than 300,000 tons of CO2 eq./year [16,36].

The energy potential of biogas consists of various potentials. These include:

- -

- potential of areas for growing energy crops;

- -

- theoretically possible potentials of traditional organic fertilizers (purulent liquid, solid manure, chicken manure, etc.);

- -

- potentials of the manufacturing industry (organic waste);

- -

- potential use of municipal waste

- -

- increasing efficiency in growing energy crops per hectare.

The use of the available potential makes possible continuous biogas production. Thus, the average biogas plant, which can be co-located on a livestock complex and process about 37,000 tons/year of manure, after processing can generate approximately 35,000 tons of valuable biofertilizers per year. One ton of such fertilizers contains an average of 3.5 kg of total nitrogen. Implementation of biogas complexes makes it possible not only to process crop and livestock waste but also to eliminate the need to provide conditions for storage of waste [43]. The various potentials for biogas use are important, including clean electricity generation, electricity and heat production (CHP), or transport. It should be noted, however, that the political and legal framework, as well as the existing infrastructure, play a crucial role in the development of biogas production and the efficient use of existing potentials [3].

Studies of the activities of already launched biogas plants have revealed a number of main factors influencing the viability of such projects. The results of the studies revealed what one needs to pay attention to when planning them. The main positive factor is the existence of its own raw material base with the projected cost and quality of raw materials. The second factor determines the need, before the implementation of the biogas project, to predict how the heat produced will be used. In most cases, the “green” electricity tariff does not provide the necessary indicators of project profitability.

In reality, almost no biogas plant in Ukraine has reached the desired efficiency of electricity generation. Therefore, if the business plan is calculated taking into account 100% capacity utilization, and in practice, the output is only 30%, then the payback period is 3 times longer, and the biogas plant will be cost-effective in generating 8200 h of electricity per year. To increase the profitability of biogas plants, it is important to have heat consumers because, in fact, for every MW of electricity, there are MW of heat that can either be sold or wasted, whereupon it pollutes the atmosphere and contributes to global warming. Therefore, when designing biogas plants, it is necessary to consider and include heat consumers in the scheme [3].

Forecasts of the development of any production and marketing activity of enterprises or industries are scientific explanations of possible quantitative and qualitative changes in the level of development as a whole or within an individual area of activity. In this paper, the forecast of biogas production and conversion is calculated on the basis of statistical data of previous periods using regression analysis and the Excel spreadsheet editor. Here, regression analysis makes it possible to estimate the degree of relationship between variables and predict the value of a particular variable based on known values (Table 5).

Table 5.

Biogas production and conversion and development forecast, (units-GJ).

On the basis of the obtained data of the State Statistics Service of Ukraine (section Fuel and energy resources), the state of biogas production and its conversion at thermal power plants and heating plants was investigated using calculation and tabular methods (Table 5). The resulting model reveals an increase in its production and conversion to thermal power plant inputs by 2024, while the conversion of biogas into heating purposes shows a tendency to a steady decline (Figure 3).

Figure 3.

Trend model of biogas production and conversion. Source: own calculation.

In analyzing the trend model of biogas production and conversion for the period 2015–2024, it should be noted that biogas production in 2015–2019 was constantly growing, and the trend line showed a further tendency to increase its production to 3957 GJ in 2024. Similarly, the graph shows the growth of the conversion of biogas into fueling thermal power plants, which by 2024, will reach the level of 3919 GJ. However, the conversion of biogas into thermal plant operation input in the period 2017–2019 is characterized by a decrease in production, and the trend line shows a tendency to a steady decline to 37.9 GJ by 2024 (Table 5, Figure 3).

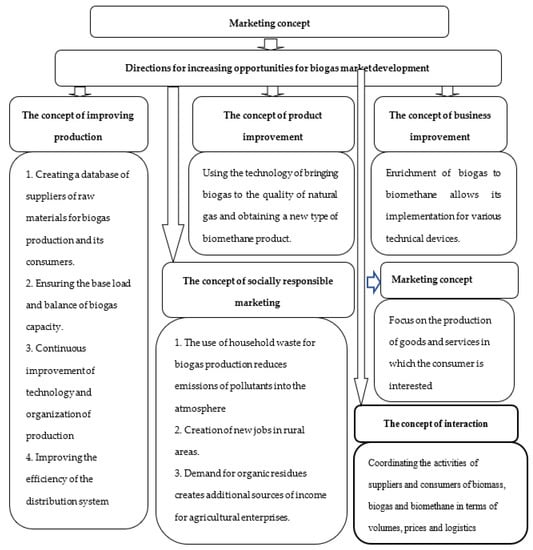

To develop the biogas market, companies need to achieve their goals by meeting the needs and desires of selected target groups of consumers. This can be achieved through a set of activities within the framework of marketing concepts. The concept means a way of presenting the process of organization and implementation of any activity. World science and practice recommend the use of the concept of productivity improvement, the concept of product improvement, the concept of intensification of commercial efforts (sales), the concept of marketing, the concept of socio-ethical (socially responsible) marketing and marketing interaction [44].

When using the concept of improving production, manufacturers need to take into account that buyers will prefer products already on offer due to wide availability, their relatively low prices, and the maturation of the production technique. The main thing when using the production concept is the manufacture and increase in the production of the existing range of goods. Using this concept, one needs to systematically improve the production system and focus on achieving high series production and sales of goods through all possible sales companies [45,46].

In 2018, the State Agency for Energy Efficiency, with the participation of local governments and experts of relevant associations, conducted a study of the prospects of installing biogas facilities at landfills. It was found that it is economically feasible to build biogas facilities on landfills with a total amount of waste of over 1 million tons. As of 1 January 2020, biogas plants have already been installed at almost 90% of Ukraine’s landfills with a total amount of waste of more than 1 million tons. Therefore, the potential of landfill gas is used to the maximum. However, it is estimated that the growth rate of biogas capacity using agricultural waste as input in the next 3–5 years should increase by about +40 MW annually. This is due, in particular, to the adoption in 2019 of the Law of Ukraine, “On Amendments to Some Laws of Ukraine to Ensure Competitive Conditions for Electricity Production from Alternative Energy Sources”, which kept the “green” tariff for biomass and biogas at a stable level (12.39€ cent/kWh) for another 10 years (until 2030) [9]. One of the areas of implementation of the marketing concept of product improvement is the cultivation of energy crops for biomass for biogas production [47,48].

The peculiarity of the concept of product improvement is that the manufacturer directs all their efforts to improve product characteristics and improve product quality and develop a sufficient number of modifications with the best consumer properties. Often the problem of decentralized production of electricity and heat from biogas is the lack of heat dissipation. Enriching biogas to biomethane can solve this problem. With the help of enrichment technology, biogas can be purified and brought to the quality of natural gas. Significant advantages of biomethane, compared to other renewable energy sources, is that it can use the existing natural gas supply infrastructure and that it does not require the creation of new storage systems. Existing natural gas networks with huge capacities offer an efficient and economical solution for the storage and supply of biomethane with low capital costs [49].

The concept of intensification of commercial efforts is based on the sales process itself. This concept is used when the buyer is insufficiently aware of the product and its properties. The concept involves the impact on the consumer by various means: product demonstrations, advertising, special discounts [46].

Marketing concepts in the formation of the biomass market in Ukraine include enrichment of biogas to biomethane, as doing so expands sales opportunities. Due to biomethane and natural gas holding the same quality, biomethane can be used in existing technical devices (household, industrial, transport). The enriched biogas can either be used directly on-site or fed into the existing natural gas network [49].

The dominant form of production and marketing activities in market-oriented countries is the concept of marketing. Implementing this concept, companies are constantly conducting market research, identifying the needs and real purchasing power of consumers with a focus on maximizing the adaptation of production to consumer requirements and making a profit from it. This concept is used in areas where there is work with goods in mass demand, which are produced by large enterprises [46].

The concept of socio-ethical marketing has emerged under the influence of external factors such as limited natural resources and environmental degradation. This concept examines the activities of enterprises in close connection with new global problems and the reorientation to combine the interests of producers, consumers, and society. That is, it is socially responsible in that it is an activity that uses ethical ways of achieving goals that do not harm people, nature, and society [46,50].

The socially responsible orientation of biogas production contributes to the improvement of the local economy. This is because the use of household waste for biogas production significantly reduces pollutant emissions, and the produced biogas is converted into electricity and heat at thermal power plants. Due to the production of biogas and biomethane from local resources, new jobs are created in rural areas.

The positive environmental effect of biogas production is that it is climate-neutral, as the biomass used removes carbon dioxide from the atmosphere throughout the growing season, which is then released again during the combustion of biogas or biomethane. The socially responsible direction of biogas production from biomass has been demonstrated by the pilot project on the cultivation of energy willow. The energy that is produced from energy willow is considered carbon-neutral because the amount of carbon released during combustion corresponds to the amount of carbon absorbed by the crop during growth. In addition, fallen leaves and willow roots help enrich the soil with minerals and nutrients, and rooted branches effectively protect the topsoil from erosion and landslides. Energy willow, like other energy crops, can be grown on slopes and degraded lands, hence, preventing further degradation and promoting long-term recovery. Socially responsible marketing is, hence, the highest level of ethical marketing concepts to focus upon [51].

In addition to the classic concept of marketing and its extension to social responsibility, in modern conditions, it is advisable to use the concept whose main task is to form a relationship with the buyer to organize the buying and selling process. The proposed conceptual model (Figure 4) draws attention to the factors that contribute to the development of biogas production. The presence of a large raw material base allows successfully producing biogas throughout Ukraine [46].

Figure 4.

Conceptual model of biogas market development. Source: own elaboration.

The results of the research show that, despite the presence of significant biomass potential in the domestic agricultural sector, biogas production in Ukraine has not received sufficient development. There are a number of factors that hinder the implementation of biogas projects, in particular:

- -

- insufficiently developed infrastructure for transporting raw materials for bioenergy projects

- -

- high interest rates;

- -

- high cost of the initial investments;

- -

- the lack of current assets and investments;

- -

- high inflation rate;

- -

- inappropriate approaches to biomass leftovers;

- -

- poor incentive to use biomass technologies;

- -

- insufficient business awareness of the prospects and benefits of biogas production and usage;

- -

- the existence of a complex procedure for allocating land plots for RES facilities [11].

To stimulate the development of this area, in 2015, Ukraine introduced a “green” tariff for electricity from biogas at the level of 12.39 Eurocents/kWh. In addition, the Law of 25.04.2019 No. 2712-VIII on ensuring competitive conditions for the production of electricity from alternative energy sources implies:

- -

- maintaining the current “green” tariff for electricity from biogas until 2030;

- -

- voluntary participation of developers of such projects in auctions;

- -

- the possibility of selling electricity from biogas at the auction price for 20 years [14,51].

To intensify the processes of biogas production in the agricultural enterprises of Ukraine, it is advisable to develop a government program to promote the introduction of biogas plants, approve a system of benefits, subsidies, and guarantees for investors, and create a regulatory framework for the design and construction of biogas plants and biogas production, etc. at the legislative level.

4. Discussion

The energy needs of the population and the global environmental crisis are forcing the countries of the world to introduce and apply alternative means of energy production. There is a need, therefore, to find innovative energy sources that do not harm the environment and have a significant economic effect. The development of the country’s economy depends on many factors, including the volume of industrial production, agricultural products, and others. However, in modern conditions, an extensive increase in production is not always appropriate and socio-economically justified. Ukrainian publications raise the issue of energy independence as an important issue. Over the last decade, Ukrainian scientists have intensified their efforts to analyze the environmental situation in the country, its regions, and specific localities, and the new task for business units is to minimize the negative impact on the environment. The transition to the use of resource-saving, environmentally friendly, low-waste technologies is a modern challenge for Ukraine’s economy, but this process is complex and capital-intensive. In addition, it involves the abandonment of conventional management methods [1,52].

The demand for alternative energy sources in the world is growing every year. The technologies of biogas production deserve special attention. Ukraine has great potential for producing biomass available for energy use. The largest amount of agricultural biomass is formed in the areas located in the central, south-eastern, and southern regions of the country, that is, in places most favorable for growing crops [53].

The attention to the issues of rational waste management in Ukraine by both the authorities and scientific circles has significantly increased in recent years. A solution to the problem is possible through implementing effective measures for rapid, safe recycling of waste and obtaining a positive economic and environmental effect from the disposal and reuse of raw materials. At the same time, biogas of organic biomass, regardless of origin, can be significant competition to traditional fuels due to the low cost of source material [54].

Obtaining biogas from organic residues in the agricultural sector of the economy is considered one of the important vectors for the development of renewable energy. As noted in the introduction, one of the priority areas of Ukraine’s energy policy is to increase the use of biomass for electricity and heat production [3]. It should be noted that in the EU countries, the use of biogas is also mainly aimed at electricity and heat production. In addition, biogas is converted into biomethane, which can be introduced into the natural gas network or used as biofuel in vehicles [55]. It is noteworthy that several countries in the north-central part of the European Union have implemented effective policies to promote the use of biomethane for public and private transport [12].

It is estimated that the prospects for biogas production in Europe indicate a tenfold increase in production by 2030. It is now believed that in biogas production, it is better to focus on less conflicting raw material resources, such as livestock manure, agricultural waste, and residues that do not compete with agricultural land used for food production. This model is advocated by Denmark, which opened its first manure-based biogas plant in 1975. The country began developing biomethane after the adoption of the national “energy agreement” for 2012–2020. As a result, biomethane now accounts for about 10% of what is introduced into the natural gas network. The Danish model has become the gold standard in Europe and has greatly inspired others, such as France and Italy. Ukraine, too, has entered into the global trend of replacing fossil energy sources (natural gas, oil, coal) with renewable ones, including biogas.

Ukraine does not neglect the global challenges of humanity, in particular, the problems of climate change and adaptation to these changes. The country is a party to the Paris Climate Agreement and has already expressed its intention to implement the principles of the European Green Course. The concept of the green energy transition of Ukraine until 2050 has been developed and presented on paper. Energy production is the main source of anthropogenic greenhouse gas emissions in the world, and therefore the introduction of renewable energy sources, enhancing energy efficiency, and practicing energy conservation play key roles. Considering the possibilities of biogas production in Ukraine, it is worth noting the significant potential that exists due to the available biological waste and agricultural raw materials [41].

Biogas production is an attractive alternative in terms of energy production. Given the almost inexhaustible raw material resources, the attention of the state is directed towards attracting more and more opportunities for biogas production [56]. It should be underlined that this type of fuel is multifunctional and can make use of existing transportation infrastructure. The growth of biogas plants in Europe has been driven primarily by government policies to improve environmental protection and combat greenhouse gas emissions due to low recycling of household and industrial waste. Methane (a component of biogas), which is formed during the decomposition of waste, without processing, pollutes the air and thus complicates the environmental situation. Therefore, European countries support and encourage through “green” tariffs and preferential interest rates on loans for such projects, companies that process household and other organic waste and are engaged in the production of biogas with subsequent production of electricity, heat, and bioethanol [7].

In order to achieve the set goals in the development of Ukraine as a viable, independent nation, the choice of marketing concepts to be followed is important. That which needs to be practiced is one in which the enterprise meets the needs of consumers without conflicting with the long-term needs of society [44]. Production of biogas fulfills this obligation.

5. Conclusions

In conditions of unstable fossil fuel prices, given the inevitability of reducing greenhouse gas emissions, the production of renewable energy is becoming more relevant. In order to enhance its energy self-sufficiency, it is extremely important for Ukraine to diversify energy production by increasing the use of renewable energy sources. The Law of Ukraine “On Energy Conservation” defines the legal, economic, social, and environmental bases of energy conservation and green energy production as actions aimed at the rational production of energy and its economical use. One of the most notable directions in the development of renewable energy is the production of biofuels.

An important reason for the increase in the use of renewable energy sources is the uncontrolled growth of household and industrial waste. This adversely affects the natural environment. Moreover, it generates costs in disposal. By waste, we do not mean exclusively household or construction waste, but mainly sewage and wastes from the agricultural and food industries. Obtaining biogas from the organic waste remaining after the production cycles of agricultural enterprises is considered one of the most visible vectors of renewable energy production.

Summing up the results of the study, it should be noted that Ukraine has favorable climatic conditions, large areas of agricultural land, and a developed agricultural sector. The wastes generated within the agricultural sector can provide an excellent raw material base, along with municipal wastes as disposed of in landfills to create conditions for heat and electricity production from biogas. According to the State Agency for Energy Efficiency and Energy Saving, the use of only 37% of livestock and crop waste will produce more than 10 billion cubic meters of biogas. However, while the potential for biogas production is 9633.4 million m3/h., this potential is not being used. At the beginning of 2020, only 86.1 MW of biogas power plants operated in the country. As a result, The National Renewable Energy Action Plan until 2020 in terms of addressing electricity generation via biogas has not been implemented. Of the planned 290 MW, only 86 MW, or 29.7%, has been installed. It should be noted that increasing the number and capacity of biogas plants for the processing of agricultural, industrial, and municipal waste is a powerful factor in addressing the issue of environmental degradation and its related health factors.

Using the available potential makes continuous biogas production viable. Currently, the average biogas plant that is located in livestock production complexes processes about 37 thousand tons/year of manure, and after biogas production, generates about 35,000 tons of valuable biofertilizers per year. The introduction of biogas complexes on-site allows, not only the processing of crop and livestock waste, but also eliminates the need to provide conditions for waste storage.

Biogasses can be used for many purposes in the substitution of fossil fuels. Among others, these include clean electricity generation, co-electricity and heat production (CHP), and transportation. The existing infrastructure and political and legal framework play important roles in the development of biogas production and efficient use of existing potential.

By solving Ukraine’s energy production problems through stimulating the production of electricity and heat from biogas, the state increases the level of environmental security in Ukraine, as waste from agriculture and utilities, food, and processing industries pose threats to public health, soil, air, and groundwater. Biogas technology is one of the main and most efficient ways of disposing of organic waste. Another factor in favor of biogas is that biogas plants do not depend on weather conditions and can ensure the uninterrupted operation of power plants by way of the stable supply of raw bio-materials.

Research into the already launched biogas plants has revealed a number of key factors influencing the viability of such projects. The results of the present study demonstrate that planning is of utmost importance. The main positive factor in biogas production is the existence and extent of the raw material base. However, there is a need to predict how the generated heat will be used before constructing a biogas plant. In most cases, the “green” electricity tariff does not provide the necessary indicators of project profitability, as almost no biogas plant has achieved the desired efficiency of electricity production. Therefore, if the business plan is calculated taking into account 100% capacity utilization, and in practice, the output is only 30%, the payback period is 3 times longer than planned. The biogas plant will, however, still be cost-effective in the long run providing that it generates more than 8200 h of electricity per year. To increase the profitability of biogas plants, when designing them, it is advisable to take into account and include in the scheme, the heat consumers. To stimulate the development of this sector in Ukraine, the government, in 2015, introduced a “green” tariff for electricity from biogas at 12.39 Eurocents/kWh, which will remain until 2030.

The calculation of the forecast of biogas production and transformation on the basis of statistical data of previous periods using regression analysis showed a further trend of growth of its production in 2024 to 3957 Gigajoules. Also, the growth of biogas conversion to thermal power plants in 2024 will reach 3083 Gigajoules. However, the conversion of biogas to thermal power plant input tends to steadily decrease to 37.9 Gigajoules in 2024 as a result of reduced production in 2017–2019.

To stimulate the biogas technology industry in Ukraine, a special bill was adopted in April 2019—the Law of Ukraine “On Amendments to Certain Laws of Ukraine on Ensuring Competitive Conditions for Electricity Production from Alternative Energy Sources”. It allows voluntary participation in auctions of investment projects in electricity from biomass and provides an appropriate government support mechanism by maintaining the auction price of electricity for 20 years [9]. Given that the country’s economy is largely dependent on fossil sources, the adopted Energy Strategy of Ukraine for the period up to 2035 provides for up to 25% of the energy produced from renewable sources, including biogas. To implement this strategy, “green tariffs” have been approved, which make the production of electricity from biogas profitable.

To achieve the goals of biogas market development, it is necessary to put in place a set of measures within the framework of marketing concepts. The main object of the marketing concept is to establish a comprehensive study of buyers of goods of enterprises with their requests and needs. Manufacturers must build all their activities with the expectation of maximum actor satisfaction instead of making the appropriate profit. Thus, the starting point of the concept is the theory of consumer sovereignty. Taking into account the concept of marketing in the historical context, there are five global, basic concepts that any firm interested in making a profit should use.

Based on the study, it can be argued that the production and use of biogas in Ukraine has great prospects due to favorable climatic conditions and great potential for the development of biogas production. It should be noted that the study reveals the state of development of the biogas market in Ukraine on the basis of available statistical materials. An obstacle to a more detailed analysis of the state of production and use of biogas, the management system for production and sale of finished products, as well as the strength of relationships with raw material suppliers and consumers of biogas, was the limited available statistics covering the production dynamics. However, the mining of the available sources has allowed the researchers of this paper to gain new knowledge about this problem.

Author Contributions

Conceptualization, O.K. and T.H.; methodology, S.G. and A.D.; software, A.M.; validation, A.S.-S. and A.S.; formal analysis, I.A.; project administration, T.H.; funding acquisition, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

Own Scientific Foundation University of Agriculture in Krakow.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Romanchuk, S. The Essence of the Environmental and Economic Efficiency of Recycling: Economic Aspect. Invest. Pract. Exp. 2014, 20, 83–89. Available online: http://nbuv.gov.ua/UJRN/ipd_2014_20_20 (accessed on 28 September 2014).

- Kucher, O.; Prokopchuk, L. The Development of the Market of the Renewable Energy in Ukraine. In Renewable Energy Sources: Engineering, Technology, Innovation; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 71–81, ISSN 2352-2542 (electronic), ISSN 2352-2534; Available online: https://link.springer.com/chapter/10.1007/978-3-319-72371-6_8 (accessed on 26 January 2021).

- Biogas Rat. Production and Use of Biogas in Ukraine. Available online: http://svb.ua/sites/default/files/biogas_ukr.pdf (accessed on 16 May 2012).

- Was, A.; Sulewski, P.; Krupin, V.; Popadynets, N.; Malak-Rawlikowska, A.; Szymanska, M.; Skorokhod, I.; Wysokinski, M. The Potential of Agricultural Biogas Production in Ukraine—Impact on GHG Emissions and Energy Production. Energies 2020, 13, 5755. [Google Scholar] [CrossRef]

- Kucher, O.; Prokopchuk, L. Economic Aspects of Biomass Market Development in Ukraine. In Proceedings of the 6th International Conference—Renewable Energy Sources (ICoRES 2019), Krynica, Poland, 12–14 June 2019. [Google Scholar] [CrossRef]

- Palamarenko, Y. The Current Situation and Prospects of Development of the Biogase Industry of Ukraine. Investytsiyi Prakt. Dosvid. 2019, 21, 54–62. [Google Scholar] [CrossRef]

- Sakun, L.; Riznichenko, L.; Vielkin, B. Prospects of Biogas Market Development in Ukraine and Abroad. Econ. Organ. Manag. 2020, 1, 160–170. [Google Scholar] [CrossRef]

- Misiuk, M.; Kucher, O.; Zakhodym, M.; Ievstafieva, Y. Marketing concepts in the formation of the biomass market in Ukraine. In Renewable Energy Sources: Engineering, Technology, Innovation ICORES 2018; Springer: Cham, Switzerland, 2019; pp. 209–216. [Google Scholar] [CrossRef]

- Biogas in Ukraine: Great Prospects and Reality. 2020. Available online: https://energytransition.in.ua/sfera-biohazu-v-ukraini-velyki-perspektyvy-ta-real-nist/ (accessed on 9 April 2020).

- Okhota, Y.; Kozak, K. The Main Trends of Efficient Use of Biogas in Ukraine. Effic. Econ. 2018, 4. Available online: http://www.economy.nayka.com.ua/pdf/4_2018/162.pdf (accessed on 20 April 2018).

- Trypolska, G.; Diachuk, O.; Podolets, R.; Chepeliev, M. Biogas Projects in Ukraine: Prospects, Consequences and Regulatory Policy. Econ. Forecast. 2018, 2, 111–134. [Google Scholar] [CrossRef]

- Raboni, M.; Urbini, G. Production and use of biogas in Europe: A survey of current status and perspectives. Rev. Ambiente Agua 2014, 9, 191–202. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IRENA). Bioenergy Data. 2021. Available online: https://www.irena.org/bioenergy (accessed on 12 January 2021).

- State Agency for Energy Efficiency and Energy Saving of Ukraine. There Are 70 MW of Biogas Plants in Ukraine. 2019. Available online: https://saee.gov.ua/uk/news/3206 (accessed on 4 November 2019).

- Landlord. Biogas in Agriculture: Cost and Efficiency. 2019. Available online: https://bit.ly/3zXane5 (accessed on 10 January 2019).

- Golub, G.; Skydan, O.; Kukharets, V.; Yarosh, Y.; Kukharets, S. The estimation of energetically self sufficient agroecosystem’s model. J. Cent. Eur. Agric. 2020, 21, 168–175. [Google Scholar] [CrossRef]

- Eenergy.ua. Biogas: Raw Materials and Production Features. 2017. Available online: https://eenergy.com.ua/terminology/biogaz/ (accessed on 26 December 2017).

- Kovalenko, N.; Hutsol, T.; Labenko, O.; Glowacki, S.; Sorokin, D. Ecological and Economical Substatiation of Production of Hydrogen. In Proceedings of the Environment. Technologies. Resources, International Scientific and Practical Conference, Rezekne, Latvia, 17–18 June 2021; Volume 1, pp. 127–131. [Google Scholar] [CrossRef]

- Simon, F. The Future of Biogas in Europe: It’s a Local Affair. Biomethane in the EU. Available online: https://www.euractiv.com/section/energy/news/the-future-of-biogas-in-europe-its-a-local-affair/ (accessed on 1 October 2019).

- Polishchuk, V.M.; Shvorov, S.A.; Krusir, G.V.; Davidenko, T.S. Increased Biogas Output during Fermentation of Manure of Cow with Winemaking Waste in Biogas Plants. Probl. Energeticii Reg. 2020, 2, 123–134. [Google Scholar] [CrossRef]

- Kovalenko, V.; Kovalenko, N. Planning of enterprise fodder base. Sci. J. Plant Soil Sci. 2019, 286, 35–42. [Google Scholar]

- Korys, K.; Latawiec, A.; Grotkiewicz, K.; Kubon, M. The Review of Biomass Potential for Agricultural Biogas Production in Poland. Sustainability 2019, 11, 6515. [Google Scholar] [CrossRef]

- Jewiarz, M.; Wróbel, M.; Mudryk, K.; Szufa, S. Impact of the Drying Temperature and Grinding Technique on Biomass Grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Lijo, L.; Gonzalez-Garcia, S.; Bacenetti, J.; Moreira, M. The environmental effect of substituting energy crops for food waste as feedstock for biogas production. Energy 2017, 137, 1130–1143. [Google Scholar] [CrossRef]

- Bilandzija, N.; Voca, N.; Kricka, T.; Jurisic, V.; Matin, A. Biogas production on dairy farms: A Croatia case study. Mljekarstvo 2013, 63, 22–29. [Google Scholar]

- GalInfo. Biogas Capacity in Ukraine Has Increased by a Third. 2019. Available online: https://bit.ly/3dgcvnt (accessed on 8 January 2019).

- Tryhuba, A.; Hutsol, T.; Glowacki, S.; Tryhuba, I.; Tabor, S.; Kwasniewski, D.; Sorokin, D.; Yermakov, S. Forecasting Quantitative Risk Indicators of Investors in Projects of Biohydrogen Production from Agricultural Raw Materials. Processes 2021, 9, 258. [Google Scholar] [CrossRef]

- Tryhuba, A.; Hutsol, T.; Tryhuba, I.; Pokotylska, N.; Kovalenko, N.; Tabor, S.; Kwasniewski, D. Risk Assessment of Investments in Projects of Production of Raw Materials for Bioethanol. Processes 2021, 9, 12. [Google Scholar] [CrossRef]

- European Biogas Association Statistical Report 2020. Sustainable Agribusiness Forum. Available online: https://saf.org.ua/library/989/ (accessed on 25 March 2020).

- Kukharets, S.; Hutsol, T.; Glowacki, S.; Sukmaniuk, O.; Rozkosz, A.; Tkach, O. Concept of Biohydrogen Production by Agricultural Enterprises. Agric. Eng. 2021, 25, 63–72. [Google Scholar] [CrossRef]

- Statista. Primary Energy Production from Biogas in the European Union (EU) from 2013 to 2018 (in Metric Kilotons of Oil Equivalent). 2019. Available online: https://bit.ly/3dhgWOX (accessed on 27 January 2021).

- State Statistics Service of Ukraine. Available online: http://www.ukrstat.gov.ua/druk/publicat/Arhiv_u/5a/Arch_per_bl.htm (accessed on 26 May 2016).

- State Statistics Service of Ukraine. Fuel and Energy Resources of Ukraine. Statistical Publication. Kyiv 2018. Available online: https://bit.ly/3vWyl67 (accessed on 15 November 2018).

- State Statistics Service of Ukraine. Fuel and Energy Resources of Ukraine. Statistical Publication. Kyiv 2019. Available online: http://www.ukrstat.gov.ua/druk/publicat/kat_u/2019/zb/12/zb_per2018.pdf (accessed on 15 November 2019).

- State Statistics Service of Ukraine. Fuel and Energy Resources of Ukraine. Statistical Publication. Kyiv 2020. Available online: https://bit.ly/3zWk906 (accessed on 15 November 2020).

- Marczak-Grzesik, M.; Budzyń, S.; Tora, B.; Szufa, S.; Kogut, K.; Burmistrz, P. Low-Cost Organic Adsorbents for Elemental Mercury Removal from Lignite Flue Gas. Energies 2021, 14, 2174. [Google Scholar] [CrossRef]

- Romaniuk, W.; Mazur, K.; Borek, K.; Borusiewicz, A.; Wardal, W.; Tabor, S.; Kuboń, M. Biomass Energy Technologies from Innovative Dairy Farming Systems. Processes 2021, 9, 335. [Google Scholar] [CrossRef]

- Ecobusiness. 6 Environmental Effects of Biogas Projects. Ecology of the Enterprise. 2020. Available online: https://ecolog-ua.com/news/6-ekologichnyh-efektiv-realizaciyi-biogazovyh-proyektiv (accessed on 28 April 2020).

- Romaniuk, W.; Polishchuk, V.; Marczuk, A.; Titova, L.; Rogovskii, I.; Borek, K. Impact of Sediment Formed in Biogas Production on Productivity of Crops and Ecologic Character of Production of Onion for Chives. Agric. Eng. 2018, 22, 105–125. [Google Scholar] [CrossRef][Green Version]

- Pryshliak, N.; Tokarchuk, D.; Palamarenko, Y. Recommendations for Selecting the Optimal Feedstock for Biogas Production on the Basis of Experimental Data on the Energy Value of Waste. Derzhavne Upr. Udoskon. Rozvyt. 2020, 24, 58–66. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Sielski, J.; Grzesik, M.; Romanowska-Duda, Z.; Piotrowski, K.; Lewandowska, W. Acquisition of Torrefied Biomass from Jerusalem Artichoke Grown in a Closed Circular System Using Biogas Plant Waste. Molecules 2020, 25, 3862. [Google Scholar] [CrossRef] [PubMed]

- Kucher, O.; Hutsol, T.; Zavalniuk, K. Marketing Strategies and Prognoses of Development of the Renewable Energy Market in Ukraine. Polish—Ukrainian Cooperation Scientific Monograph Vol. II. 2017. Available online: http://188.190.33.55:7980/jspui/handle/123456789/905 (accessed on 28 March 2017).

- International Renewable Energy Agency (IRENA). Renewable Capacity Highlights. 2019. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2019/Mar/RE_capacity_highlights_2019.pdf?la=en&hash=BA9D38354390B001DC0CC9BE03EEE559C280013F (accessed on 31 March 2019).

- Kotler, P. Basics of marketing. Short course. Translation from English. Available online: http://htbiblio.yolasite.com/resources/12.11.15/Kotler_kratkiy_2007.pdf (accessed on 26 January 2021).

- Kotler, P.; Kartajaya, H.; Setiawan, I. Marketing 5.0: Technology for Humanity. Available online: https://media.wiley.com/product_data/excerpt/14/11196685/1119668514-29.pdf (accessed on 1 October 2019).

- Misiuk, M.; Kucher, O.; Zakhodym, M. Marketing Concepts in the Formation of the Biomass Market in Ukraine—Renewable Energy Sources: Engineering, Technology, Innovation. 2020. Available online: https://link.springer.com/chapter/10.1007/978-3-030-13888-2_20 (accessed on 17 July 2019).

- Yermakov, S.; Hutsol, T.; Glowacki, S.; Hulevskyi, V.; Pylypenko, V. Primary Assessment of the Degree of Torrefaction of Biomass Agricultural Crops. In Environment. Technology. Resources, Proceedings of the International Scientific and Practical Conference, Rezekne Academy of Technologies, Rezekne, Latvia, 17–18 June 2021. 2021, Volume 1, pp. 264–267. Available online: http://elar.tsatu.edu.ua/handle/123456789/14974 (accessed on 15 November 2021).

- Energy Agriculture in Ukraine: An Alternative Way to Alternative Energy. Available online: https://undpukraine.exposure.co/post-245557 (accessed on 17 August 2017).

- Production and Use of Biogas in Ukraine. 2012. Available online: https://uabio.org/wp-content/uploads/2012/11/biogas-arzinger-handbook.pdf (accessed on 16 May 2012).

- Bilan, O. The Role of Corporate Social Responsibility in the Formation of the Positive Image and Business Reputation of the Enterprise. Available online: http://pev.kpu.zp.ua/journals/2018/4_09_uk/7.pdf (accessed on 4 September 2018).

- Golub, G.; Kukharets, S.; Yarosh, Y.; Zavadska, O. Diversified production and bioenergy conversion for rural development. In Proceedings of the 8th International Scientific Conference Rural Development 2017, Akademija, Lithuania, 23–24 November 2017; pp. 333–337. [Google Scholar] [CrossRef]

- European Biogas Association (EBA). 2021. Available online: https://www.europeanbiogas.eu/ (accessed on 26 January 2021).

- Resuleva, N.S. Perspectives of using plant waste for generating bioenergy in Ukraine. Econ. Time Realities. 2015, 4. Available online: https://economics.net.ua/files/archive/2015/No4/179-185.pdf (accessed on 28 May 2015).

- Tokarchuk, D.; Prishlyak, N.; Palamarenko, Y. Prospects for use of Crop Waste for Biogas Production in Ukraine. Agrosvit 2020, 22, 51–57. [Google Scholar] [CrossRef]

- D’Adamo, I.; Falcone, P.M.; Gastaldi, M.; Morone, P. Corrigendum to “RES-T trajectories and an integrated SWOT-AHP analysis for biomethane. Policy implications to support a green revolution in European transport”. Energy Policy 2020, 140, 111380. [Google Scholar] [CrossRef]