Modeling of Diesel Engine Fuel Systems Reliability When Operating on Biofuels

Abstract

:1. Introduction

- conduct analytical studies by developing a system of equations to determine the degree of influence of biodiesel fuel on the reliability of the diesel engine fuel system;

- determine complex indicators that will allow to assess the reliability of diesel engines running on biodiesel fuel; and

- conduct experimental studies of the effect of biodiesel fuels on the fuel system of diesel engines, according to the developed model.

- The fulfillment of the tasks set will make it possible to develop a methodology to predict the resource of fuel systems of diesel engines when operating on biodiesel fuel.

2. Materials and Methods

3. Results

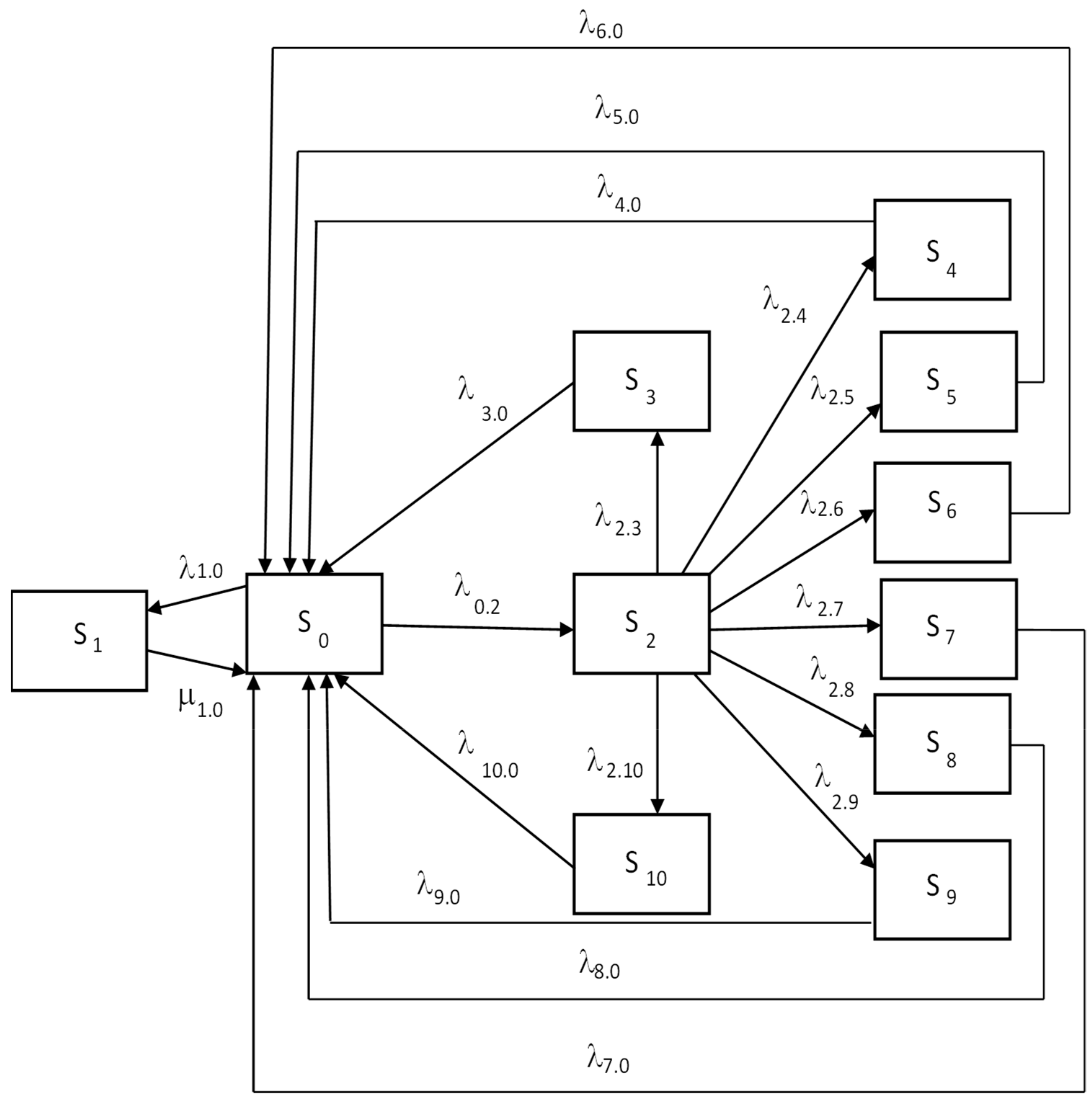

3.1. Results of Analytical Studies on the Development of a Fuel System Reliability Model

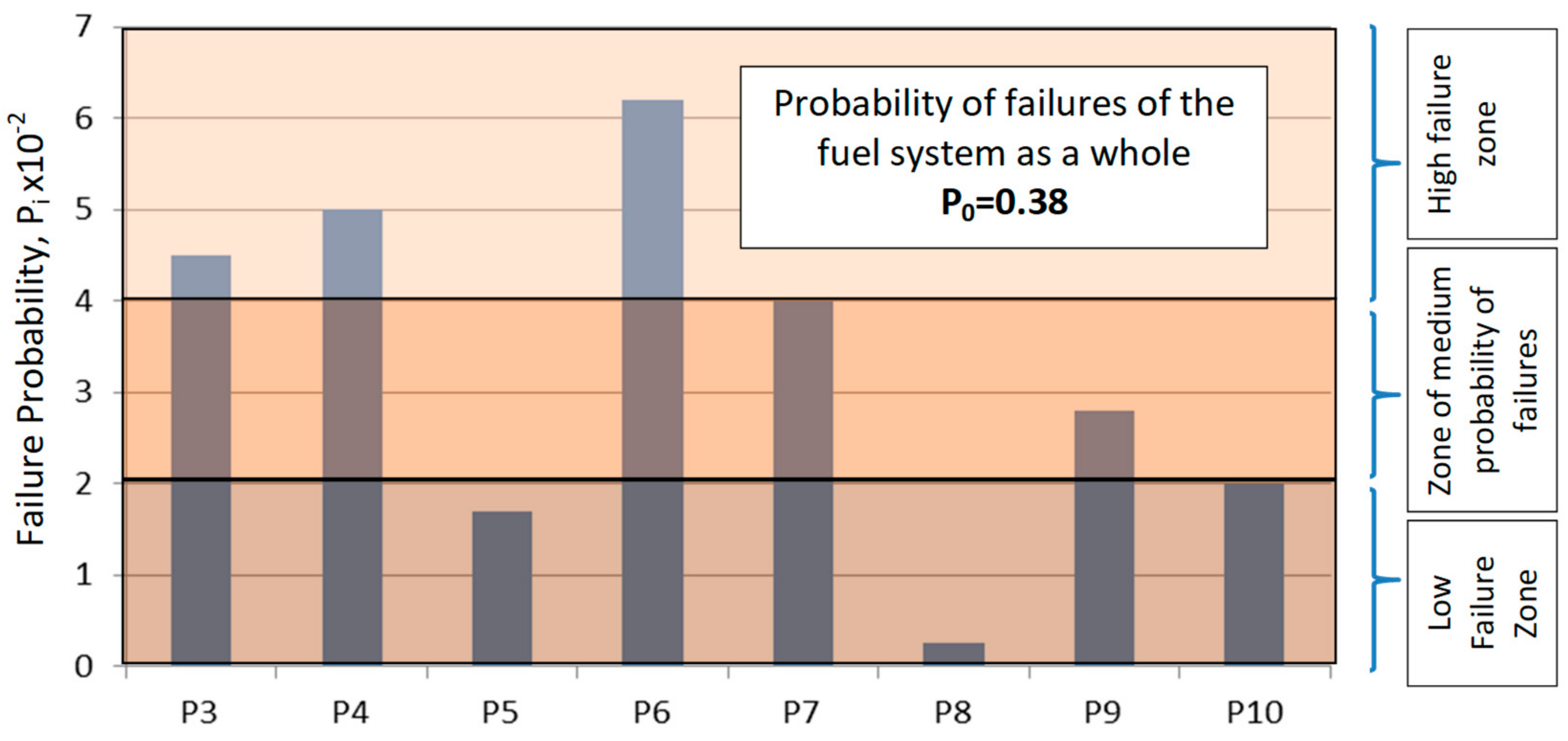

3.2. Results of Experimental Studies

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Čedík, J.; Pexa, M.; Mader, D.; Pražan, R. Combustion characteristics of compression ignition engine operating on rapeseed oil-diesel fuel blends. Agron. Res. 2019, 17, 957–973. [Google Scholar]

- De, T.; Sikder, J.; Narayanan, C.M. Biodiesel synthesis using immobilised lipase enzyme in semi-fluidised bed bioreactors—Bioreactor design and performance analysis. Environ. Prog. Sustain. Energy 2017, 36, 1537–1545. [Google Scholar] [CrossRef]

- Martin, S.S.; Chebak, A.; El Ouafi, A.; Mabrouki, M. Modeling and Simulation of Hybrid Power System Integrating Wind, Solar, Biodiesel Energies and Storage Battery. In Proceedings of the 2016 International Renewable and Sustainable Energy Conference (IRSEC), Marrakech, Morocco, 14–17 November 2016; pp. 457–463. [Google Scholar] [CrossRef]

- Janardhana, K.; Sridhar, S.; Dixit, C.K.; Deivakani, M.; Tamilselvi, S.; Kaladgi, A.R.; Afzal, A.; Baig, M.A.A. ANFIS modeling of biodiesels’ physical and engine characteristics: A review. Heat Transf. 2021, 50, 8052–8079. [Google Scholar] [CrossRef]

- Oke, E.O.; Adeyi, O.; Okolo, B.I.; Ude, C.J.; Adeyi, J.A.; Salam, K.K.; Nwokie, U.; Nzeribe, I. Heterogeneously catalyzed biodiesel production from Azadiricha Indica oil: Predictive modelling with uncertainty quantification, experimental optimization and techno-economic analysis. Bioresour. Technol. 2021, 332, 125141. [Google Scholar] [CrossRef]

- Georgogianni, K.G.; Kontominas, M.G.; Pomonis, P.J.; Avlonitis, D.; Gergis, V. Conventional and in situ transesterification of sunflower seed oil for the production of biodiesel. Fuel Process. Technol. 2008, 89, 503–509. [Google Scholar] [CrossRef]

- Kovalenko, N.; Hutsol, T.; Labenko, O.; Glowacki, S.; Sorokin, D. Ecological and Economical Substatiation of Production of Hydrogen. In ENVIRONMENT. TECHNOLOGIES. RESOURCES. Proceedings of the International Scientific and Practical Conference; Rezekne Academy of Technologies: Rēzekne, Latvia, 2021; Volume 1, pp. 127–131. [Google Scholar] [CrossRef]

- Kovalenko, N.; Kovalenko, V.; Hutsol, T.; Ievstafiieva, Y.; Polishchuk, A. Economic Efficiency and Internal Competitive Advantages of Grain Production in The Central Region of Ukraine. Agric. Eng. 2021, 25, 51–62. [Google Scholar] [CrossRef]

- Kukharets, S.; Hutsol, T.; Glowacki, S.; Sukmaniuk, O.; Rozkosz, A.; Tkach, O. Concept of Biohydrogen Production by Agricultural Enterprises. Agric. Eng. 2021, 25, 63–72. [Google Scholar] [CrossRef]

- Mohapatra, A.K.; Senapati, A.K.; Jha, G.; Sharma, K.; Kumar, P. Preheating of sunflower blended biodiesel for the improvement of performance characteristics of a DI diesel engine under various loads. Int. J. Eng. Adv. Technol. 2019, 8, 921–926. [Google Scholar] [CrossRef]

- Singh, P.; Goel, V.; Chauhan, S.R. Effects of dual biofuel approach for total elimination of diesel on injection system by reciprocatory friction monitor. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 1068–1076. [Google Scholar] [CrossRef]

- Singh, P.; Chauhan, S.R. Influence of temperature on tribological performance of dual biofuel. Fuel 2017, 207, 751–762. [Google Scholar] [CrossRef]

- Tziourtzioumis, D.; Demetriades, L.; Zogou, O.; Stamatelos, A.M. Experimental investigation of the effect of a B70 biodiesel blend on a common-rail passenger car diesel engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2009, 223, 685–701. [Google Scholar] [CrossRef]

- Ahmed, S.A.; Zhou, S.; Zhu, Y.; Feng, Y.; Malik, A.; Huang, Y. Numerical and comparative study of butanol and ethanol diesel blends in a turbocharged compression ignition diesel engine 2019. Int. Agric. Eng. J. 2009, 28, 19–32. [Google Scholar]

- Lin, B.-F.; Huang, J.-H.; Huang, D.-Y. Experimental study of the effects of vegetable oil methyl ester on DI diesel engine performance characteristics and pollutant emissions. Fuel 2009, 88, 1779–1785. [Google Scholar] [CrossRef]

- Tryhuba, A.; Hutsol, T.; Tryhuba, I.; Pokotylska, N.; Kovalenko, N.; Tabor, S.; Kwasniewski, D. Risk Assessment of Investments in Projects of Production of Raw Materials for Bioethanol. Processes 2021, 9, 12. [Google Scholar] [CrossRef]

- Yildiz, I.; Caliskan, H.; Mori, K. Energy, exergy and environmental assessments of biodiesel and diesel fuels for an internal combustion engine using silicon carbide particulate filter. J. Therm. Anal. Calorim. 2021, 145, 739–750. [Google Scholar] [CrossRef]

- Tryhuba, A.; Bashynsky, O.; Hutsol, T.; Rozkosz, A.; Prokopova, O. Parameters of the Energy Supply System of Agricultural Enterprises with Using Wind Power Installations. In Proceedings of the 6th International Conference—Renewable Energy Sources (ICoRES 2019), Krynica, Poland, 12–14 June 2019; Volume 154, p. 06001. [Google Scholar] [CrossRef] [Green Version]

- Marczak-Grzesik, M.; Budzyń, S.; Tora, B.; Szufa, S.; Kogut, K.; Burmistrz, P. Low-Cost Organic Adsorbents for Elemental Mercury Removal from Lignite Flue Gas. Energies 2021, 14, 2174. [Google Scholar] [CrossRef]

- Ganesan, R.; Manigandan, S.; Shanmugam, S.; Chandramohan, V.P.; Sindhu, R.; Kim, S.H.; Brindhadevi, K.; Pugazhendhi, A. A detailed scrutinize on panorama of catalysts in biodiesel synthesis. Sci. Total Environ. 2021, 777, 145683. [Google Scholar] [CrossRef]

- De Faria, D.R.G.; de Medeiros, J.L.; Araújo, O.D.Q.F. Screening biorefinery pathways to biodiesel, green-diesel and propylene-glycol: A hierarchical sustainability assessment of process. J. Environ. Manag. 2021, 300, 113772. [Google Scholar] [CrossRef]

- Milojević, S.; Džunić, D.; Marić, D.; Mitrović, S.; Pešić, R. Tribological assessment of aluminum cylinder material for piston compressors in trucks and buses brake systems. Int. J. Engine Res. 2021, 22, 2267–2280. [Google Scholar]

- Senthil Kumar, A.P.; Yuvaraj, S.; Thomas Renald, C.J.; Janaki, S.; Sadesh, K. A review of the performance and emission characteristics of a stationary diesel engine fueled by schleicheraoleosa oil methyl ester (Some), blends of neem biodiesel, Rice bran biodiesel, palm and palm Kernel oil, Jatropha oil. Int. J. Mech. Prod. Eng. Res. Dev. 2019, 9, 857–861. [Google Scholar]

- Molina, G.J.; Morrison, J.; Carapia, C.; Soloiu, V. A study on viscosity and lubricity effects of n-butanol and its mixtures in oil. In Proceedings of the STLE 2019—74th Annual Meeting and Exhibition of the Society of Tribologists and Lubrication Engineers, Nashville, TN, USA, 19–23 May 2019; pp. 105–109. [Google Scholar]

- Silva, J.R.; Carvalho Filho, M.G.A.; Brasilino, T.C.; Bicudo, I.M.G.; Santos, A.G.; Souza Candeia, R.A. Influence of soybean biodiesel content on basic properties of biodiesel-diesel blends. Fuel 2009, 88, 738–743. [Google Scholar] [CrossRef]

- Janakiraman, S.; Lakshmanan, T.; Chandran, V.; Subramani, L. Comparative behavior of various nano additives in a DIESEL engine powered by novel Garcinia gummi-gutta biodiesel. J. Clean. Prod. 2020, 245, 118940. [Google Scholar] [CrossRef]

- Caligiuri, C.; Renzi, M.; Bietresato, M.; Baratieri, M. Experimental investigation on the effects of bioethanol addition in diesel-biodiesel blends on emissions and performances of a micro-cogeneration system. Energy Convers. Manag. 2019, 185, 55–65. [Google Scholar] [CrossRef]

- Zare, A.; Stevanovic, S.; Jafari, M.; Verma, P.; Babaie, M.; Yang, L.; Brown, R.J.; Bodisco, T.A. Analysis of cold-start NO2 and NOx emissions, and the NO2/NOx ratio in a diesel engine powered with different diesel-biodiesel blends. Environ. Pollut. 2021, 290, 118052. [Google Scholar] [CrossRef] [PubMed]

- Kurczyński, D. Effect of the rme biodiesel on the diesel engine fuel consumption and emission. Commun. Sci. Lett. Univ. Zilina 2021, 23, B308–B316. [Google Scholar] [CrossRef]

- Hönig, V. Specifications of wear of oils in two-fuel systems. Manuf. Technol. 2018, 18, 567–571. [Google Scholar] [CrossRef] [Green Version]

- Mosarof, M.H.; Kalam, M.A.; Masjuki, H.H.; Alabdulkarem, A.; Habibullah, M.; Arslan, A.; Monirul, I.M. Assessment of friction and wear characteristics of Calophyllum inophyllum and palm biodiesel. Ind. Crops Prod. 2016, 83, 470–483. [Google Scholar] [CrossRef]

- Nagy, A.L.; Knaup, J.; Zsoldos, I. A friction and wear study of laboratory aged engine oil in the presence of diesel fuel and oxymethylene ether. Tribol. Mater. Surf. Interfaces 2019, 13, 20–30. [Google Scholar] [CrossRef]

- Peng, D.-X. Room temperature tribological performance of biodiesel (soybean oil). Ind. Lubr. Tribol. 2016, 68, 617–623. [Google Scholar] [CrossRef]

- Reddy, M.S.; Sharma, N.; Agarwal, A.K. Effect of straight vegetable oil blends and biodiesel blends on wear of mechanical fuel injection equipment of a constant speed diesel engine. Renew. Energy 2016, 99, 1008–1018. [Google Scholar] [CrossRef]

- Singh, P.; Goel, V.; Chauhan, S.R. Impact of dual biofuel approach on engine oil dilution in CI engines. Fuel 2017, 207, 680–689. [Google Scholar] [CrossRef]

- Kiktev, N.; Lendiel, T.; Vasilenkov, V.; Kapralуuk, O.; Hutsol, T.; Glowacki, S.; Kuboń, M.; Kowalczyk, Z. Automated Microclimate Regulation in Agricultural Facilities Using the Air Curtain System. Sensors 2021, 21, 8182. [Google Scholar] [CrossRef]

- Dzieniszewski, G.; Kuboń, M.; Pristavka, M.; Findura, P. Operating Parameters and Environmental Indicators of Diesel Engines Fed with Crop-Based Fuels. Agric. Eng. 2021, 25, 13–28. [Google Scholar] [CrossRef]

- Borek, K.; Romaniuk, W.; Roman, K.; Roman, M.; Kuboń, M. The Analysis of a Prototype Installation for Biogas Production from Chosen Agricultural Substrates. Energies 2021, 14, 2132. [Google Scholar] [CrossRef]

- Khokhlov, A.; Golubev, V.; Khokhlov, A.; Marin, D.; Golubev, S. Decreasing the wear of precision pairs of fuel injection equipment in diesel engines. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 403, p. 012101. [Google Scholar]

- Sudan, R.D.M.; Nanthagopal, K. Tribological aspects of biofuels—A review. Fuel 2019, 258, 116066. [Google Scholar] [CrossRef]

- Rocabruno-Valdés, C.I.; González-Rodriguez, J.G.; Díaz-Blanco, Y.; Juantorena, A.U.; Muñoz-Ledo, J.A.; El-Hamzaoui, Y.; Hernández, J.A. Corrosion rate prediction for metals in biodiesel using artificial neural networks. Renew. Energy 2019, 140, 592–601. [Google Scholar] [CrossRef]

- Jain, N.L.; Soni, S.L.; Poonia, M.P.; Sharma, D.; Srivastava, A.K.; Jain, H. A durability study of a compression ignition engine operating with Thumba (Citrullus colocyntis) vegetable oil. Environ. Sci. Pollut. Res. 2019, 26, 8992–9004. [Google Scholar] [CrossRef]

- Xiao, H.; Zou, H.; Liu, S.; Li, C. An investigation of the friction and wear behavior of soybean biodiesel. Tribol. Int. 2019, 131, 377–385. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Wasiak, A.; Świć, A. Thermodynamic fundamentals for fuel production management. Sustainability 2019, 11, 4449. [Google Scholar] [CrossRef] [Green Version]

- Holubek, M.; Pexa, M.; Pavlu, J.; Cedík, J.; Vesela, K.; Kuchar, P. Analysis of the influence of fuel on oil charge and engine wear. Manuf. Technol. 2019, 19, 64–70. [Google Scholar] [CrossRef]

- Dharma, S.; Sebayang, A.H.; Silitonga, A.S.; Sebayang, R.; Sarjianto; Ginting, B.; Damanik, N.; Ramlan, Y.P.; Alif, H.H. Corrosion behaviours of mild steel in biodiesel-diesel fuel blend. In Proceedings of the 2018 International Conference on Applied Science and Technology (iCAST), Manado, Indonesia, 26–27 October 2018; Volume 8751635, pp. 10–15. [Google Scholar]

- Nagy, A.L.; Knaup, J.; Zsoldos, I.A.L.; Knaup, J.; Zsoldos, I.; Knaup, J. A review on the effect of alternative fuels on the friction and wear of internal combustion engines. In Vehicle and Automotive Engineering; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2018; pp. 42–55. [Google Scholar]

- Sinha, S.; Agarwal, A.K. Experimental investigation of the effect of biodiesel utilization on lubricating oil degradation and wear of a transportation cidi engine. J. Eng. Gas Turbines Power 2010, 132, 042801. [Google Scholar] [CrossRef]

- Shamun, S.; Belgiorno, G.; Blasio, G.D. Engine Parameters Assessment for Alcohols Fuels Application in Compression Ignition Engines; Springer: Singapore, 2020; Volume 8, pp. 125–139. [Google Scholar] [CrossRef]

- Niculescu, R.; Clenci, A.; Iorga-Siman, V. Review on the Use of Diesel–Biodiesel–Alcohol Blends in Compression Ignition Engines. Energies 2019, 12, 1194. [Google Scholar] [CrossRef] [Green Version]

| Name of Operations | The Nature of the Use of Fuel Biodiesel Systems | |||

|---|---|---|---|---|

| No Replacement of Materials | With the Replacement of Materials | |||

| Average Operation Time Ti [h] | Intensity Transition from One State to Another λij | Average Operation Time Ti [h] | Intensity Transition from One State to Another λij | |

| 1. Diagnosing malfunction and preparing for the repair of the fuel tank | Т2.3 = 40 | 0.025 | Т2.3 = 30 | 0.033 |

| 2. Diagnosing malfunction and preparation for repair of the booster pump | Т2.4 = 50 | 0.02 | Т2.4 = 40 | 0.025 |

| 3. Diagnosing fault and preparation for filter repair | Т2.5 = 20 | 0.05 | Т2.5 = 15 | 0.067 |

| 4. Diagnosing malfunction and preparation for repair of the high pressure fuel pump | Т2.6 = 80 | 0.0125 | Т2.6 = 65 | 0.0153 |

| 5. Diagnosing fault and preparation for repair of injectors | Т2.7 = 70 | 0.0143 | Т2.7 = 50 | 0.02 |

| 6. Diagnosing fault and preparation for pipeline repair | Т2.8 = 16 | 0.063 | Т2.8 = 10 | 0.1 |

| 7. Diagnosing fault and preparation for valve repair | Т2.9 = 20 | 0.05 | Т2.9 = 18 | 0.056 |

| 8. Diagnosing fault and preparation for repair of seals | Т2.1 = 55 | 0.018 | Т2.1 = 65 | 0.015 |

| Name of Operations | The Nature of the Use of Fuel Biodiesel Systems | |||

|---|---|---|---|---|

| Without Replacement of Materials | With the Replacement of Materials | |||

| Average Operation Time Ti [h] | Intensity Transition from One State to Another λij | Average Operation Time Ti [h] | Intensity Transition from One State to Another λij | |

| 1. Fuel tank repair | Т30 = 80 | 0.0125 | Т30 = 80 | 0.0125 |

| 2. Booster pump repair | Т40 = 120 | 0.0084 | Т40 = 120 | 0.0084 |

| 3. Filter repair | Т50 = 15 | 0.067 | Т50 = 15 | 0.067 |

| 4. HPFP repair | Т60 = 240 | 0.0042 | Т60 = 240 | 0.0042 |

| 5. Injector repair | Т70 = 120 | 0.0084 | Т70 = 120 | 0.0084 |

| 6. Pipeline repair | Т80 = 5 | 0.2 | Т80 = 5 | 0.2 |

| 7. Valve repair | Т90 = 30 | 0.034 | Т90 = 30 | 0.034 |

| 8. Seals repair | Т100 = 120 | 0.0084 | Т100 = 1 | 0.0084 |

| 9. Preparation for the diagnosis of repair work | Т02 = 100 | 0.01 | Т02 = 90 | 0.011 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuravel, D.; Samoichuk, K.; Petrychenko, S.; Bondar, A.; Hutsol, T.; Kuboń, M.; Niemiec, M.; Mykhailova, L.; Gródek-Szostak, Z.; Sorokin, D. Modeling of Diesel Engine Fuel Systems Reliability When Operating on Biofuels. Energies 2022, 15, 1795. https://doi.org/10.3390/en15051795

Zhuravel D, Samoichuk K, Petrychenko S, Bondar A, Hutsol T, Kuboń M, Niemiec M, Mykhailova L, Gródek-Szostak Z, Sorokin D. Modeling of Diesel Engine Fuel Systems Reliability When Operating on Biofuels. Energies. 2022; 15(5):1795. https://doi.org/10.3390/en15051795

Chicago/Turabian StyleZhuravel, Dmytro, Kyrylo Samoichuk, Serhii Petrychenko, Andrii Bondar, Taras Hutsol, Maciej Kuboń, Marcin Niemiec, Lyudmyla Mykhailova, Zofia Gródek-Szostak, and Dmytro Sorokin. 2022. "Modeling of Diesel Engine Fuel Systems Reliability When Operating on Biofuels" Energies 15, no. 5: 1795. https://doi.org/10.3390/en15051795

APA StyleZhuravel, D., Samoichuk, K., Petrychenko, S., Bondar, A., Hutsol, T., Kuboń, M., Niemiec, M., Mykhailova, L., Gródek-Szostak, Z., & Sorokin, D. (2022). Modeling of Diesel Engine Fuel Systems Reliability When Operating on Biofuels. Energies, 15(5), 1795. https://doi.org/10.3390/en15051795