Testing of a Falling-Film Evaporator for Adsorption Chillers

Abstract

:1. Introduction

2. Methodology

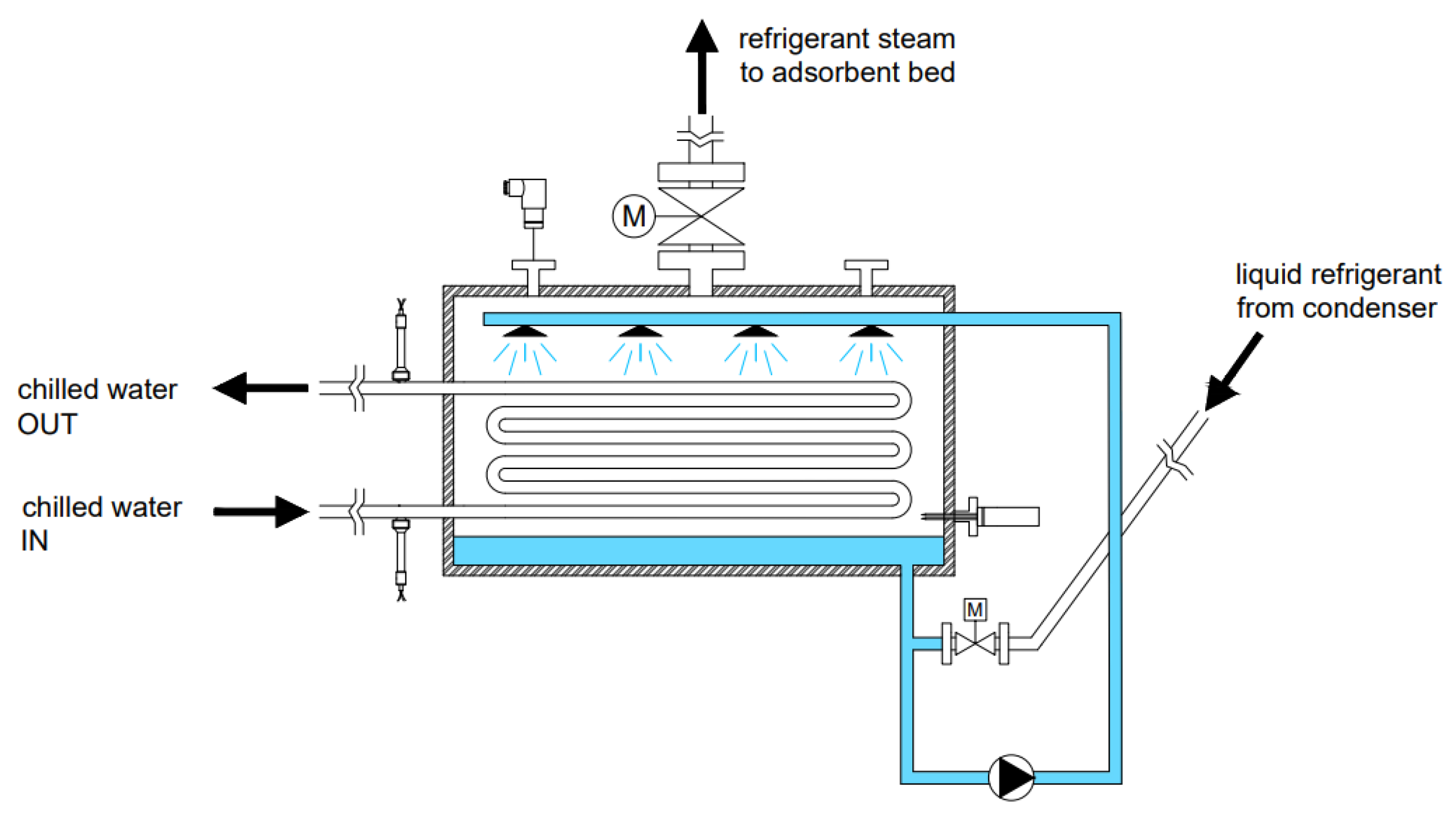

2.1. The Experimental Set-Up

2.2. Test Procedure

- -

- Phase 1: Heating up. Keeping both the valves V1 and V2 closed, the adsorption bed was heated up to 90 °C, while the condenser was maintained at a temperature of 25–30 °C by the medium-temperature circuit. This phase was terminated when the pressure in the bed reached the pressure in the condenser.

- -

- Phase 2: Desorption–condensation. The temperatures of the high- and medium-temperature circuits were maintained constant and valve V1 was kept closed, while valve V2 was opened to allow the vapor desorbed from the bed to flow toward the condenser, where the condensate water accumulates on the bottom of the condenser.

- -

- Phase 3: Cooling down. Once the desorption was completed, valve V2 was closed and the adsorber was cooled down by the intermediate circuit at temperatures of 25 or 30 °C, based on the required test conditions. At the same time, the water stored at the bottom of the condenser was discharged to the evaporator by gravity and the low-temperature circuit was activated to prepare the evaporator.

- -

- Phase 4: Adsorption–evaporation. At first, the pump circulating the refrigerant in the evaporator was activated. Then, valve V1 was opened to start the adsorption process, which induces evaporation in the evaporator, heated by the low-temperature circuit at temperatures ranging from 7 to 25 °C, based on the required conditions.

2.3. Data Analysis and Uncertainty

- -

- The capacity of the evaporator creates a delay between the evaporation process and the resulting heat transfer at the chilled water. This is more relevant during rapid transient conditions, such as at the beginning of the evaporation process, but does not significantly impact steady-state conditions or slow variations.

- -

- Similar consideration can be performed for the time required by the chilled water to flow across the evaporator pipes and reach the temperature sensor. This causes a delay of up to 8 s between what happens in the evaporator and the moment the sensor measures this.

- -

- Heat losses through the evaporator casing create an imbalance between the actual heat of evaporation and the heat transfer from the chilled water to the refrigerant. The evaporator has been insulated, reducing the losses to a value of about 10 W, estimated based on the surface of the evaporator casing (0.46 m2) and the recirculation circuit, the insultation thickness (2.5 cm) and thermal conductivity (0.04 ).

3. Results and Discussion

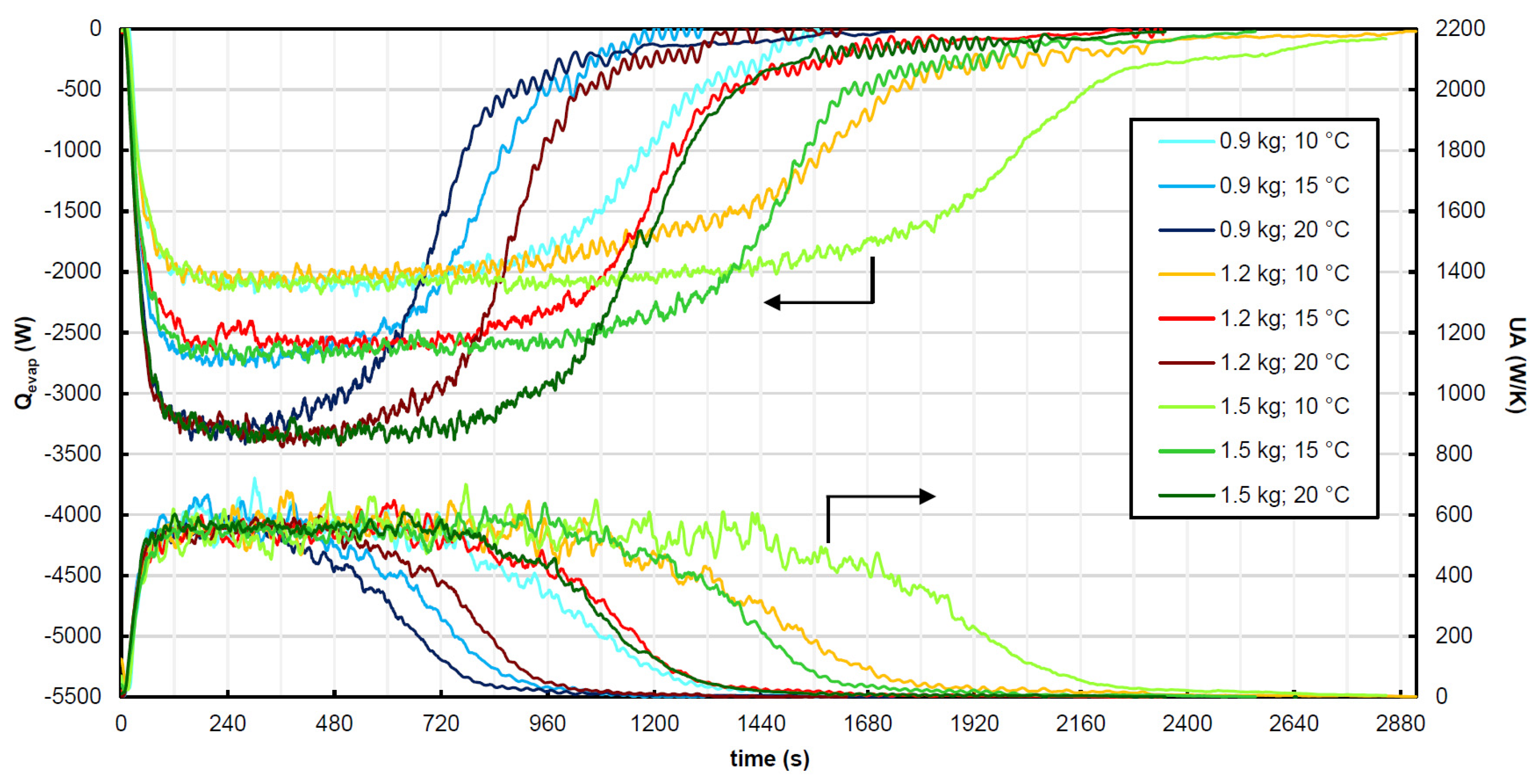

3.1. Impact of the Initial Water Content Inside the Evaporator

3.2. Impact of the Chilled Water Flow Rate

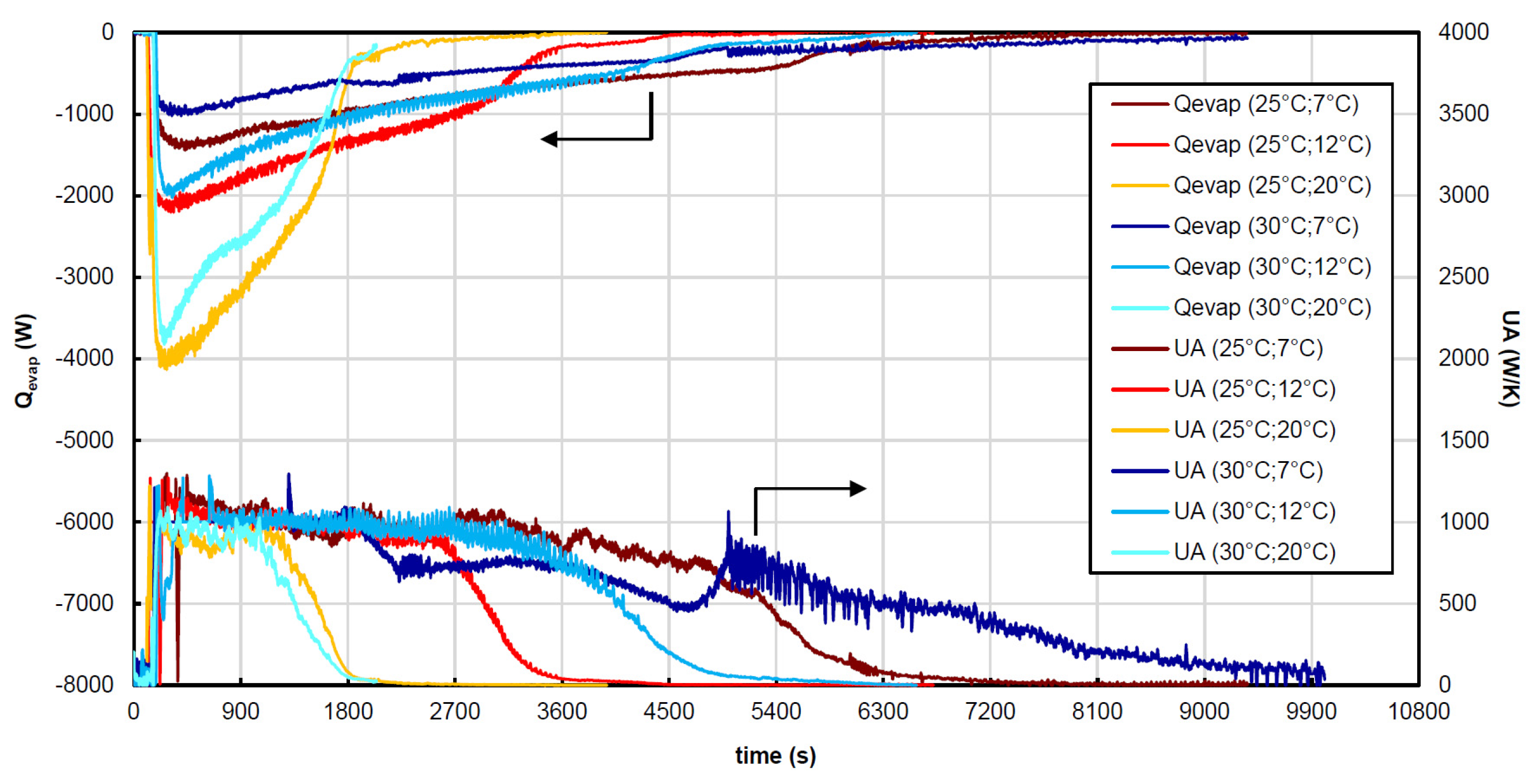

3.3. Impact of the Cooling Water Temperature

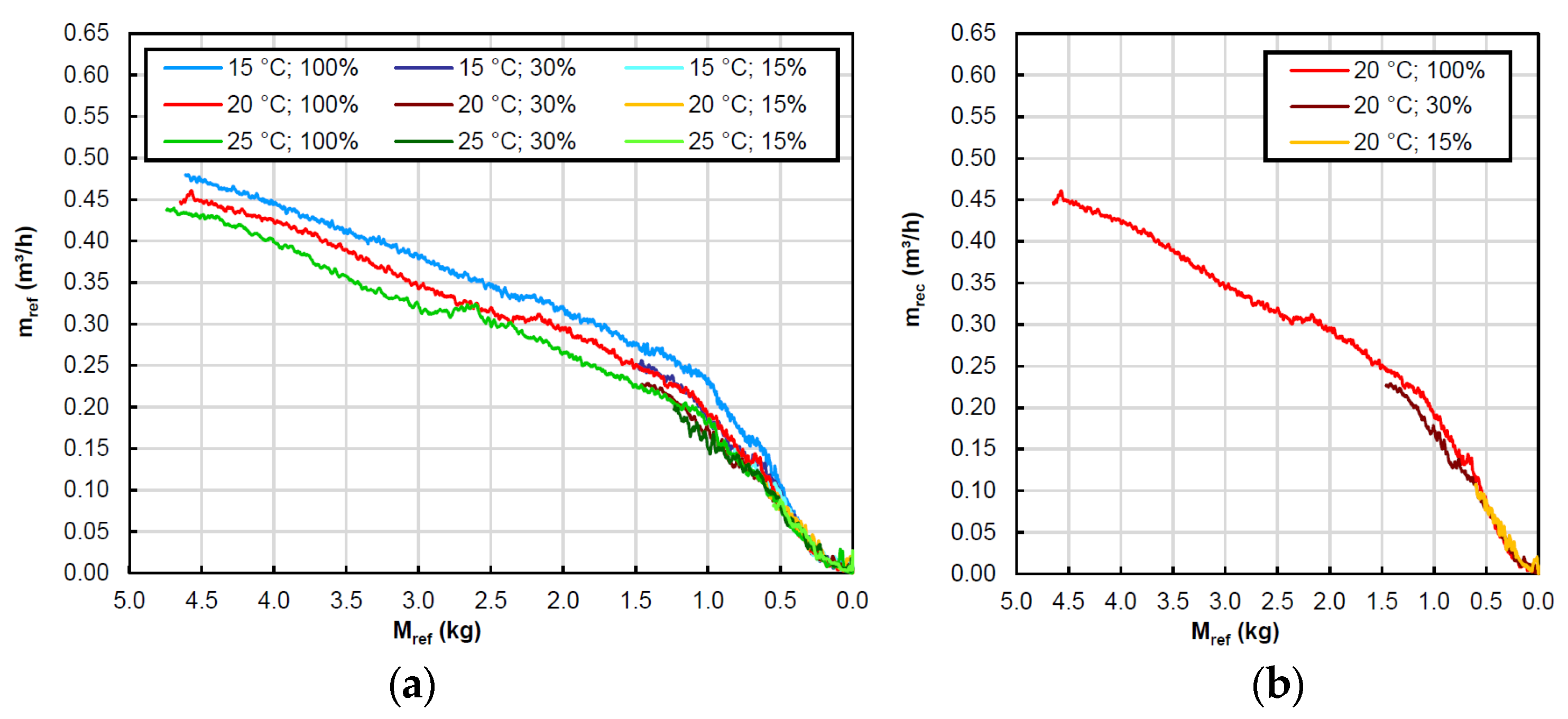

3.4. Impact of the Recirculated Water Mass Flow Rate

4. Conclusions

- -

- Given the transient nature of the adsorption process, the heat transfer rate was not constant during the evaporation, but after an initial phase it reached a plateau before declining towards the end of the process. A similar trend was found for the overall heat transfer conductance.

- -

- The heat transfer rate ranged from about 1000 to 4000 W, while the overall heat transfer conductance ranged from 400 to 1000 W/K.

- -

- The initial heat amount of refrigerant affected neither the maximum heat transfer rate achieved during the evaporation process nor the overall heat transfer conductance. However, it had an impact on the duration of the evaporation process.

- -

- The chilled water inlet temperature and the cooling water inlet temperature at the adsorber impacted the maximum heat transfer, while they did not have any impact on the overall heat transfer conductance. In particular, the heat transfer rate increased when the chilled water temperature increased and when the cooling water temperature was reduced.

- -

- The overall heat transfer conductance depends on the chilled water flow rate, which impacts the Reynolds number inside the tubes and, consequently, the heat transfer coefficient.

- -

- The reduction of the overall heat transfer conductance in the last phase of the evaporation process was due to a reduction of the film mass flow rate, i.e., the flow rate recirculated by the refrigerant pump. In fact, the recirculated flow rate decreased throughout the process due to a reduction of the refrigerant content in the evaporator, which in turn led to a lower hydrostatic pressure at the pump inlet and to a higher cavitation. This suggests that to ensure proper operation of the evaporator in a real application, the evaporation amount of refrigerant in the evaporator has to be maintained above a certain limit.

- -

- The experimental data resulting from this work will be used to develop and calibrate a numerical model able to predict the evaporator performance given the operating conditions and the recirculated mass flow rate.

Author Contributions

Funding

Informed Consent Statement

Conflicts of Interest

Nomenclature

| Area, m2 | |

| D | Diameter, m |

| L | Length, m |

| Cp | Specific heat, J/(kg K) |

| Mass flow rate, kg/s | |

| Heat transfer rate, W | |

| T | Temperature, °C |

| ∆T | Temperature difference, °C |

| Overall heat transfer coefficient, W/(m2 K) | |

| UA | Overall evaporator heat transfer conductance, W/K |

| Heat transfer coefficient, W/(m2 K) | |

| Heat transfer conductance, W/K | |

| k | Thermal conductivity, W/(m K) |

| f | Friction factor |

| Re | Reynolds number |

| Nu | Nusselt number |

| Subscripts | |

| inlet | |

| outlet | |

| internal | |

| external | |

| steel | steel |

| chilled water | |

| saturation | |

References

- San, J.Y.; Tsai, F.K. Testing of a lab-scale four-bed adsorption heat pump. Appl. Therm. Eng. 2014, 70, 274–281. [Google Scholar] [CrossRef]

- Lanzerath, F.; Bau, U.; Seiler, J.; Bardow, A. Optimal design of adsorption chillers based on a validated dynamic object-oriented model. Sci. Technol. Built Environ. 2015, 21, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Kazemi, M.A.; Nobes, D.S.; Elliott, J.A. Experimental and numerical study of the evaporation of water at low pressures. Langmuir 2017, 33, 4578–4591. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, R.F.; Zhang, L.; Mo, D.M.; Wu, C.M.; Li, Y.R. Study on Evaporation Characteristics of Water in Annular Liquid Pool at Low Pressures. ACS Omega 2021, 6, 5933–5944. [Google Scholar] [CrossRef] [PubMed]

- Eames, I.W.; Marr, N.J.; Sabir, H. The evaporation coefficient of water: A review. Int. J. Heat Mass Transf. 1997, 40, 2963–2973. [Google Scholar] [CrossRef]

- Giraud, F.; Rullière, R.; Toublanc, C.; Clausse, M.; Bonjour, J. Experimental evidence of a new regime for boiling of water at subatmospheric pressure. Experimetal Fluid Sci. 2015, 60, 45–53. [Google Scholar] [CrossRef]

- Lee, W.S.; Park, M.Y.; Duong, X.Q.; Cao, N.V.; Chung, J.D. Effects of Evaporator and Condenser in the Analysis of Adsorption Chillers. Energies 2020, 13, 1901. [Google Scholar] [CrossRef] [Green Version]

- Ribatski, G.; Jacobib, A.M. Falling-film evaporation on horizontal tubes—Accritical review. Int. J. Refrig. 2005, 28, 635–653. [Google Scholar] [CrossRef]

- Seiler, J.; Lanzerath, F.; Jansen, C.; Bardow, A. Only a wet tube is a good tube: Understanding capillary-assisted thin-film evaporation of water for adsorption chillers. Appl. Therm. Eng. 2019, 147, 571–578. [Google Scholar] [CrossRef]

- Xia, Z.Z.; Yang, G.Z.; Wang, R.Z. Experimental investigation of capillary-assisted evaporation on the outside surface of horizontal tubes. Int. J. Heat Mass Transf. 2008, 51, 4047–4054. [Google Scholar] [CrossRef]

- Freni, A.; Bonaccorsi, L.; Proverbio, E.; Maggio, G.; Restuccia, G. Zeolite synthesised on copper foam for adsorption chillers: A mathematical model. Microporous Mesoporous Mater. 2009, 120, 402–409. [Google Scholar] [CrossRef]

- Mahdavikhah, M.; Niazmand, H. Effects of plate finned heat exchanger parameters on the adsorption chiller performance. Appl. Therm. Eng. 2013, 50, 939–949. [Google Scholar] [CrossRef]

- Giraud, F.; Toublanc, C.; Rullière, R.; Bonjour, J.; Clausse, M. Experimental study of water vaporisation occurring inside a channel of a smooth plate-type heat exchanger at subatmospheric pressure. Appl. Therm. Eng. 2016, 106, 180–191. [Google Scholar] [CrossRef]

- Thimmaiah, P.C.; Sharafian, A.; Rouhani, M.; Huttema, W.; Bahrami, M. Evaluation of low-pressure flooded evaporator performance for adsorption chillers. Energy 2017, 122, 144–158. [Google Scholar] [CrossRef]

- Lanzerath, F.; Seiler, J.; Erdogan, H.; Schreiber, M.; Steinhilber, A. Bardow The impact of filling level resolved: Capillary-assisted evaporation of water for adsorption heat pumps. Appl. Therm. Eng. 2016, 102, 513–519. [Google Scholar] [CrossRef] [Green Version]

- Schnabel, L.; Witte, K.; Kowol, J.; Schossig, P. Evaluation of different evaporator concepts for thermally driven sorption heat pumps and chiller. In Proceedings of the Sorption Heat Pump Conference, Padova, Italy, 6–8 April 2011; pp. 525–543. [Google Scholar]

- Cheppudira, T.P.; Sharafian, A.; Huttema, W.; Bahrami, M. Effects of capillary-assisted tubes with different fin geometries on the performance of a low-operating pressure evaporator for adsorption cooling systems. Appl. Energy 2016, 171, 256–265. [Google Scholar] [CrossRef]

- Yu, L.H.; Xu, S.X.; Ma, G.Y.; Wang, J. Experimental Research on Water Boiling Heat Transfer on Horizontal Copper Rod Surface at Sub-Atmospheric Pressure. Energies 2015, 8, 10141–10152. [Google Scholar] [CrossRef] [Green Version]

- Palomba, V.; Frazzica, A. Experimental study of a fin-and-tube heat exchanger working as evaporator in subatmospheric conditions. Appl. Therm. Eng. 2020, 175, 115336. [Google Scholar] [CrossRef]

- Volmer, R.; Eckert, J.; Füldner, G.; Schnabel, L. Evaporator development for adsorption heat transformation devices–Influencing factors on non-stationary evaporation with tube-fin heat exchangers at sub-atmospheric pressure. Renew. Energy 2017, 110, 141–153. [Google Scholar] [CrossRef]

- Giraud, F.; Toublanc, C.; Rullière, R.; Bonjour, J.; Clausse, M. Experimental study of water vaporisation occurring inside the channel of a smooth-plate type heat exchanger connected to an adsorber and comparison with trends observed in absorption configuration. Int. J. Refrig. 2017, 77, 60–74. [Google Scholar] [CrossRef]

- Li, W.; Wu, X.Y.; Luo, Z.; Webb, R.L. Falling water film evaporation on newly-designed enhanced tube bundles. Int. J. Heat Mass Transf. 2011, 54, 2990–2997. [Google Scholar] [CrossRef]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Fundamentals of Heat and Mass Transfer; John Wiley and Sons: New York, NY, USA, 2011. [Google Scholar]

| Parameter | Value | Description |

|---|---|---|

| a (m) | 0.503 | evaporator casing width |

| b (m) | 0.113 | evaporator casing depth |

| c (m) | 0.283 | evaporator casing height |

| Lpipe (m) | 5.4191 | total length of the evaporator internal pipe |

| N°C (-) | 2 | number of coils |

| N°L (-) | 6 | number of levels for each coil |

| dext,pipe (m) | 0.016 | external base pipe diameter |

| dint,pipe (m) | 0.015 | internal base pipe diameter |

| h (m) | 0.003 | fin height |

| p (m) | 0.004 | space between consecutive fins |

| Ksteel | 17 | Thermal conductivity of the corrugated pipe |

| Aext (m²) | 0.7619 | external exchange surface of the evaporator internal pipe |

| Aint (m²) | 0.6124 | internal exchange surface of the evaporator internal pipe |

| Vref (m³) | 0.0136 | internal volume of the exchanger occupied by the liquid refrigerant |

| Test Bench Sensors | Measured Parameter | Range | Accuracy |

|---|---|---|---|

| Resistance temperature detector (Pt 100 1/10 DIN class) | water temperature at inlet/outlet of the component | −10–100 °C | ±0.03 °C at 0 °C |

| Pressure transmitter | pressure inside the component | 0–20 kPa | 0.25% of reading |

| Magnetic flow meter | water flow rate through the component | 200–1000 L/h | <0.5% of reading |

| Ultrasonic flow meter | recirculated water flow rate in the evaporator | 0–600 L/h | ±3% of reading |

| 200 | 1000 | |||

| 7 | 20 | 7 | 20 | |

| 2.55% | 2.54% | 12.80% | 1.06% | |

| 6.40% | 4.18% | 16.13% | 2.85% | |

| Water Content (kg) | Time Range (s) | (W) | (W/K) | |

|---|---|---|---|---|

| Tchw,in = 20°C | 0.9 | 180–280 | −3296 | 561 |

| 1.2 | 180–280 | −3267 | 547 | |

| 1.5 | 180–280 | −3292 | 561 | |

| Tchw,in = 15°C | 0.9 | 180–480 | −2688 | 573 |

| 1.2 | 180–480 | −2549 | 544 | |

| 1.5 | 180–480 | −2656 | 545 | |

| Tchw,in = 10°C | 0.9 | 180–780 | −2070 | 562 |

| 1.2 | 180–780 | −2026 | 573 | |

| 1.5 | 180–780 | −2081 | 551 |

| (°C) | 7 | 12 | 20 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (L/h) | 200 | 400 | 1000 | 200 | 400 | 1000 | 200 | 400 | 1000 |

| (W/K) | 420 | 638 | 940 | 438 | 631 | 948 | 476 | 653 | 945 |

| (-) | 3356 | 6509 | 16,849 | 3794 | 7638 | 20,006 | 4877 | 10,307 | 26,595 |

| (W/K) | 696 | 1477 | 3623 | 776 | 1651 | 3989 | 957 | 1996 | 4641 |

| (W/K) | 1223 | 1294 | 1492 | 1148 | 1160 | 1454 | 1144 | 1094 | 1375 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Toppi, T.; Villa, T.; Vasta, S.; Mittelbach, W.; Freni, A. Testing of a Falling-Film Evaporator for Adsorption Chillers. Energies 2022, 15, 1709. https://doi.org/10.3390/en15051709

Toppi T, Villa T, Vasta S, Mittelbach W, Freni A. Testing of a Falling-Film Evaporator for Adsorption Chillers. Energies. 2022; 15(5):1709. https://doi.org/10.3390/en15051709

Chicago/Turabian StyleToppi, Tommaso, Tommaso Villa, Salvatore Vasta, Walter Mittelbach, and Angelo Freni. 2022. "Testing of a Falling-Film Evaporator for Adsorption Chillers" Energies 15, no. 5: 1709. https://doi.org/10.3390/en15051709

APA StyleToppi, T., Villa, T., Vasta, S., Mittelbach, W., & Freni, A. (2022). Testing of a Falling-Film Evaporator for Adsorption Chillers. Energies, 15(5), 1709. https://doi.org/10.3390/en15051709