Nitrogen Dioxide Monitoring by Means of a Low-Cost Autonomous Platform and Sensor Calibration via Machine Learning with Global Data Correlation Enhancement

Abstract

:1. Introduction

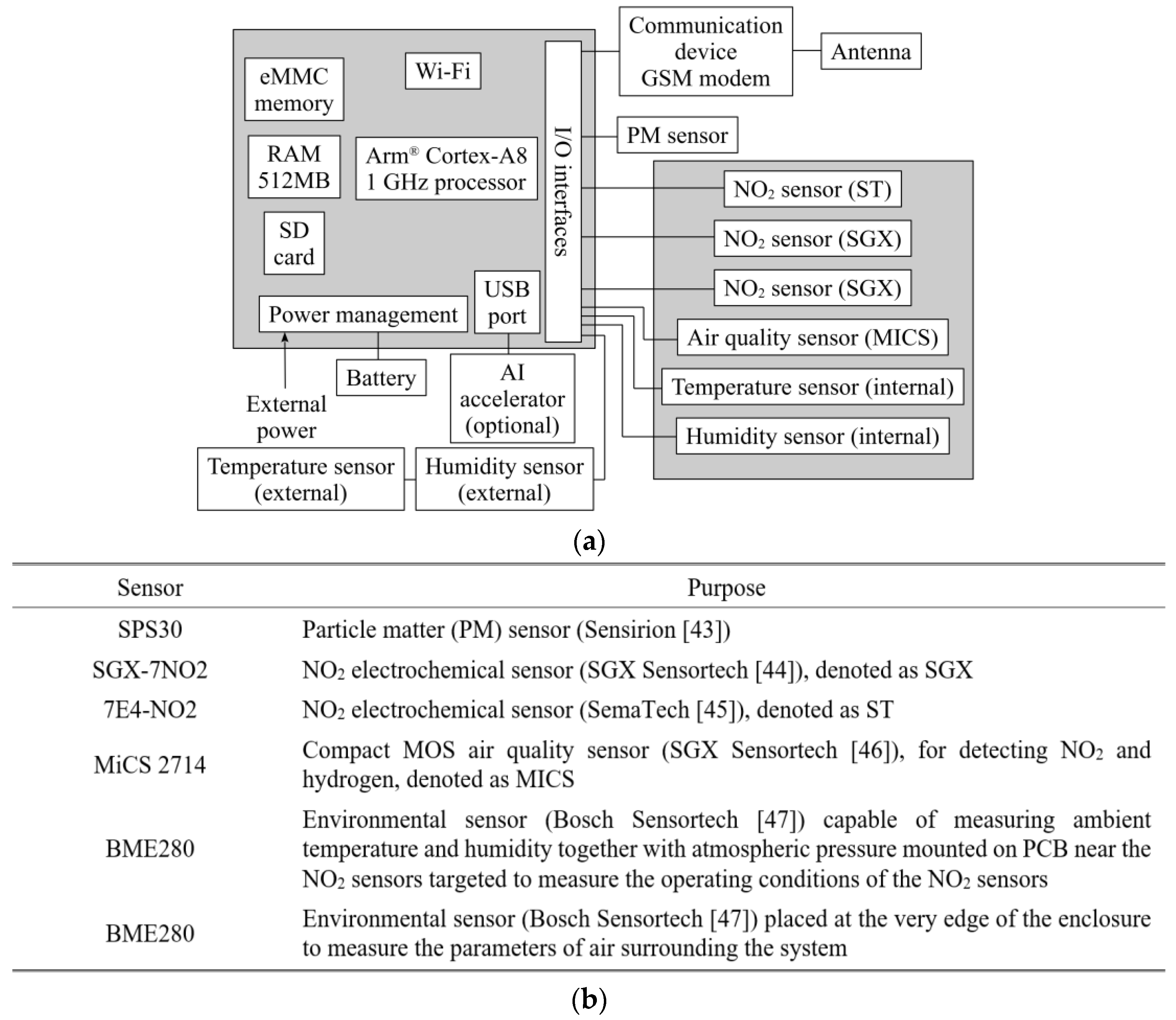

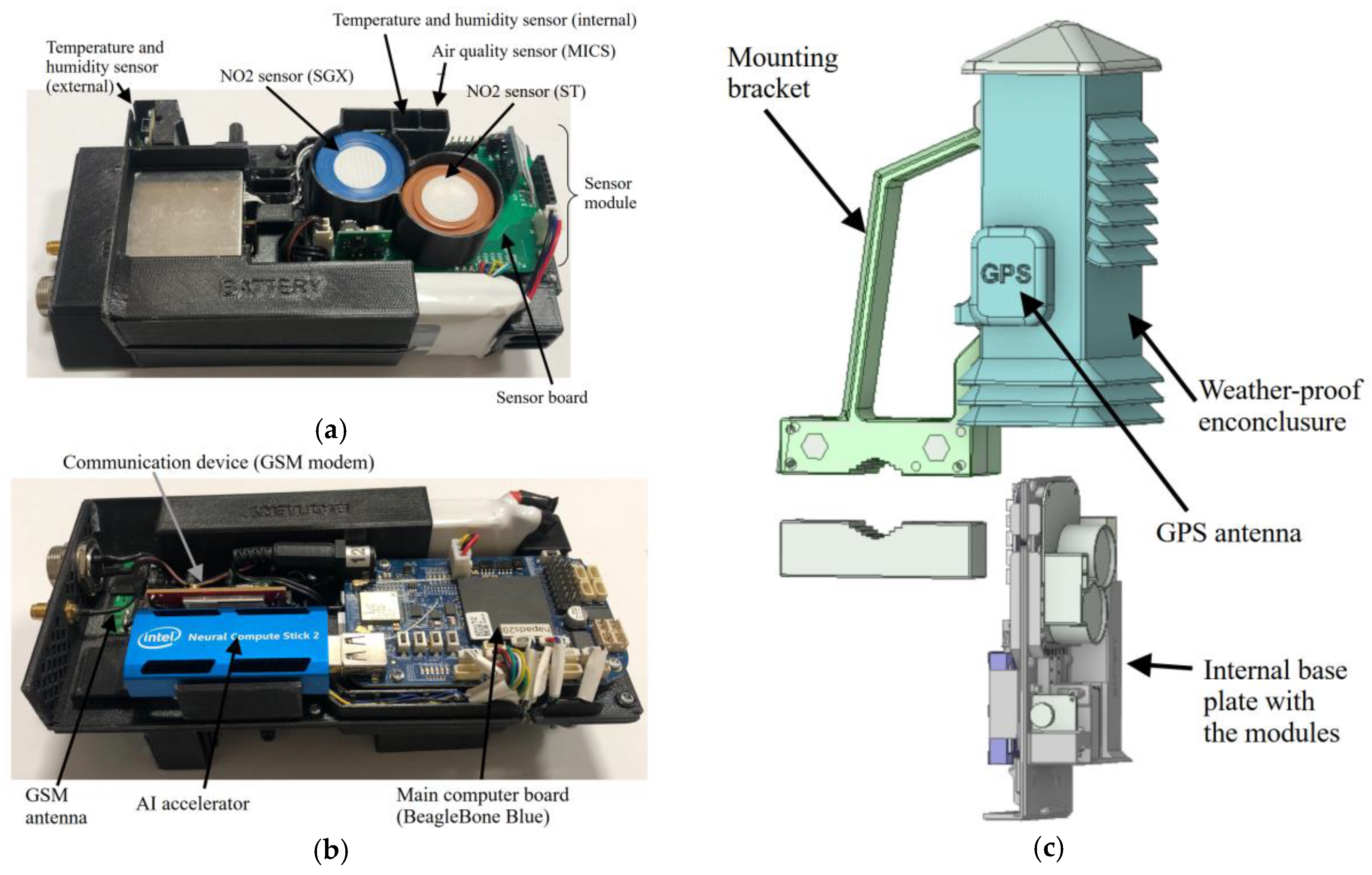

2. Inexpensive NO2 Sensing Units

2.1. Autonomous Monitoring Platform

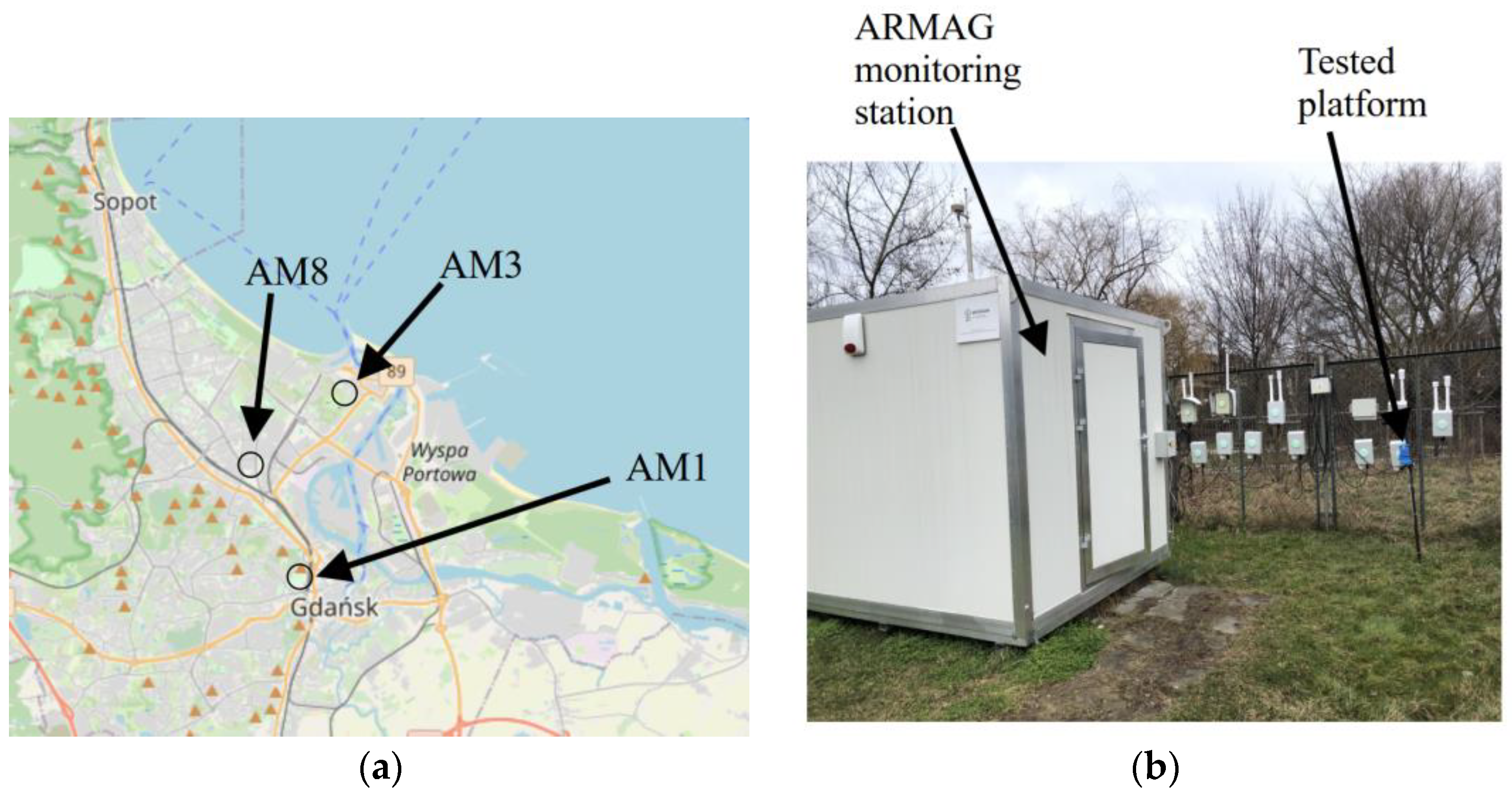

2.2. Reference Data

- Thermo environmental 42C chemiluminescent NOx analyzer (stations 1 and 3);

- API Teledyne 200E chemiluminescent NOx analyzer (station 8).

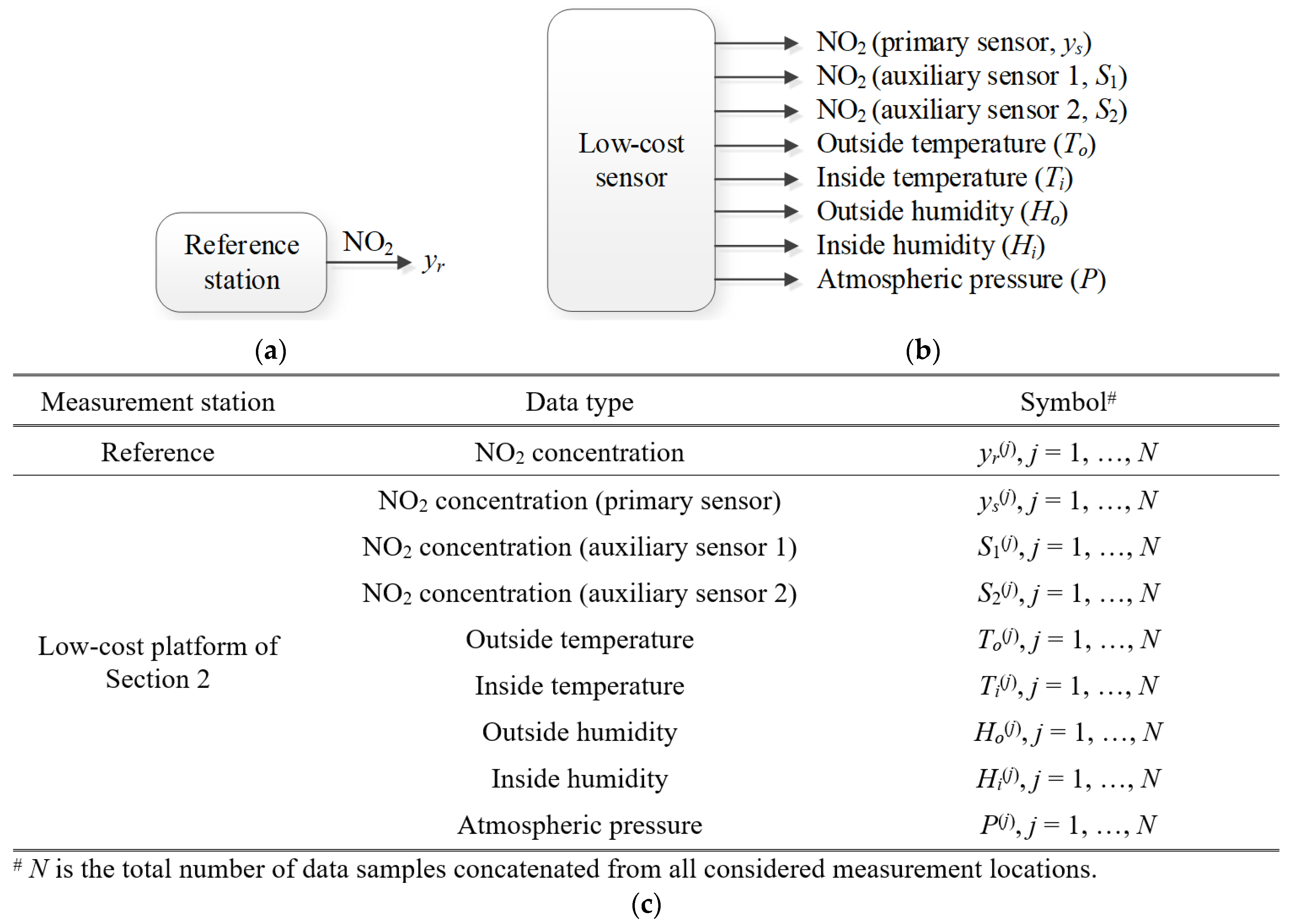

3. Machine-Learning-Based Sensor Calibration

3.1. Problem Statement

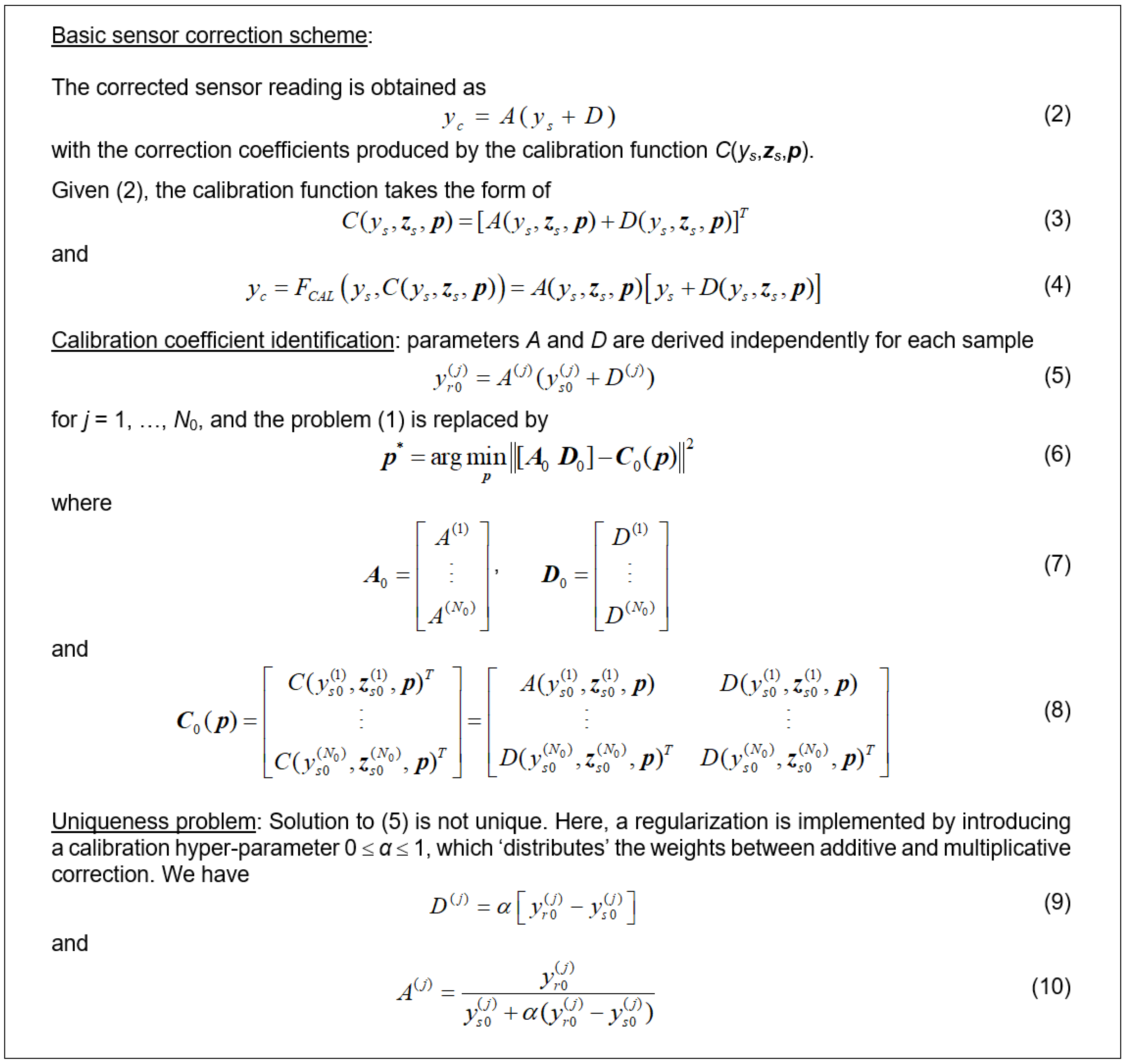

3.2. Basic Correction Scheme. Affine Response Scaling

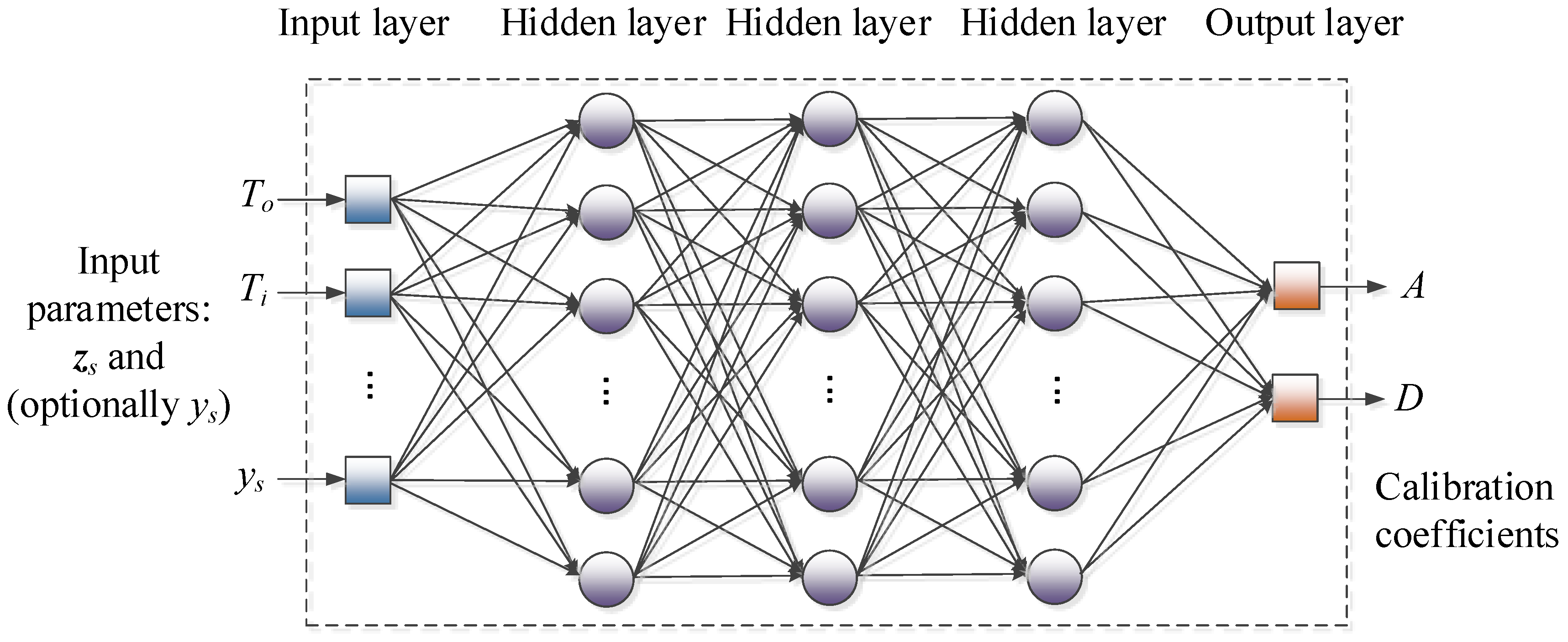

3.3. ML-Based Sensor Calibration

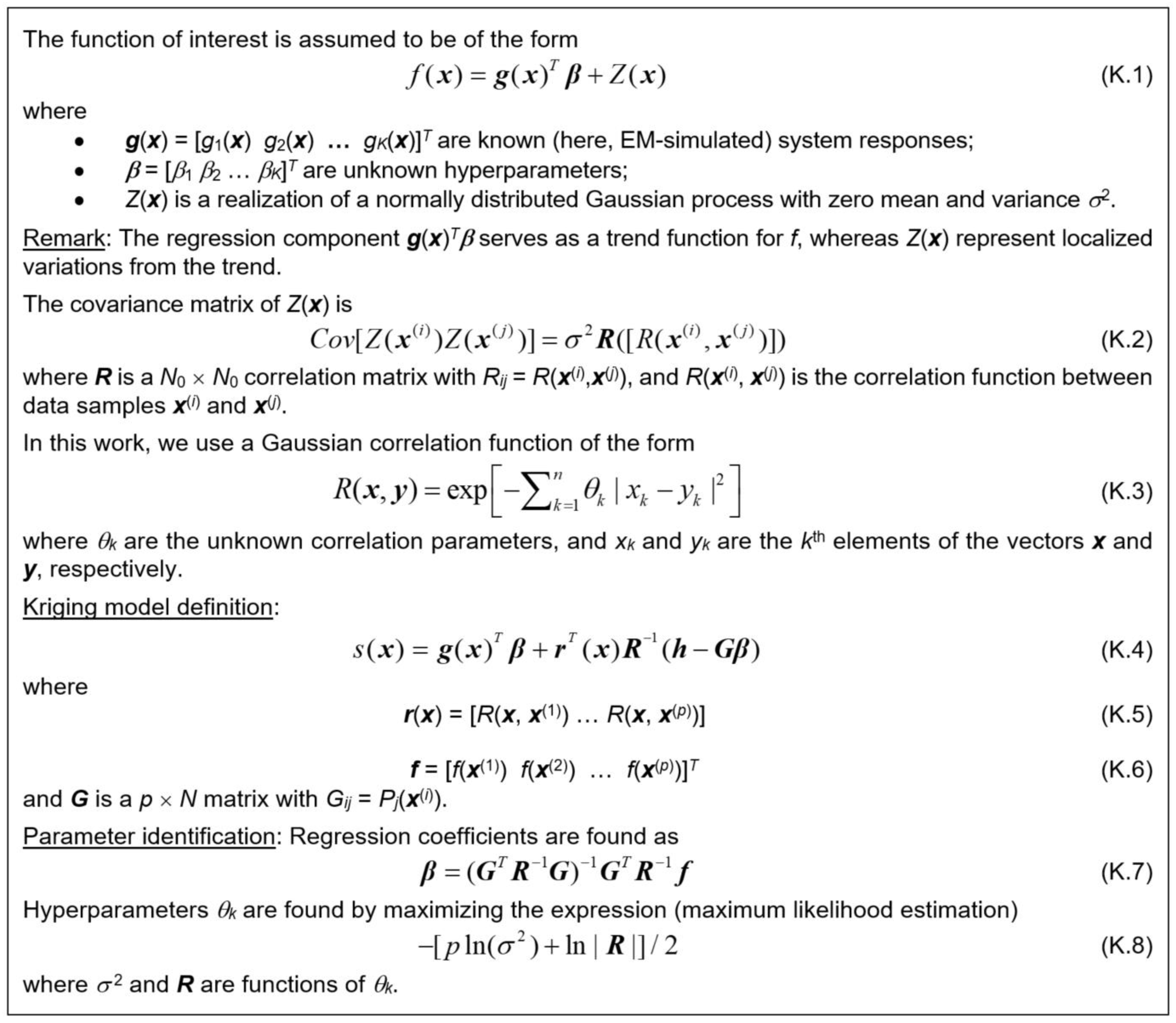

3.4. Auxiliary Correction by Means of Kriging Interpolation

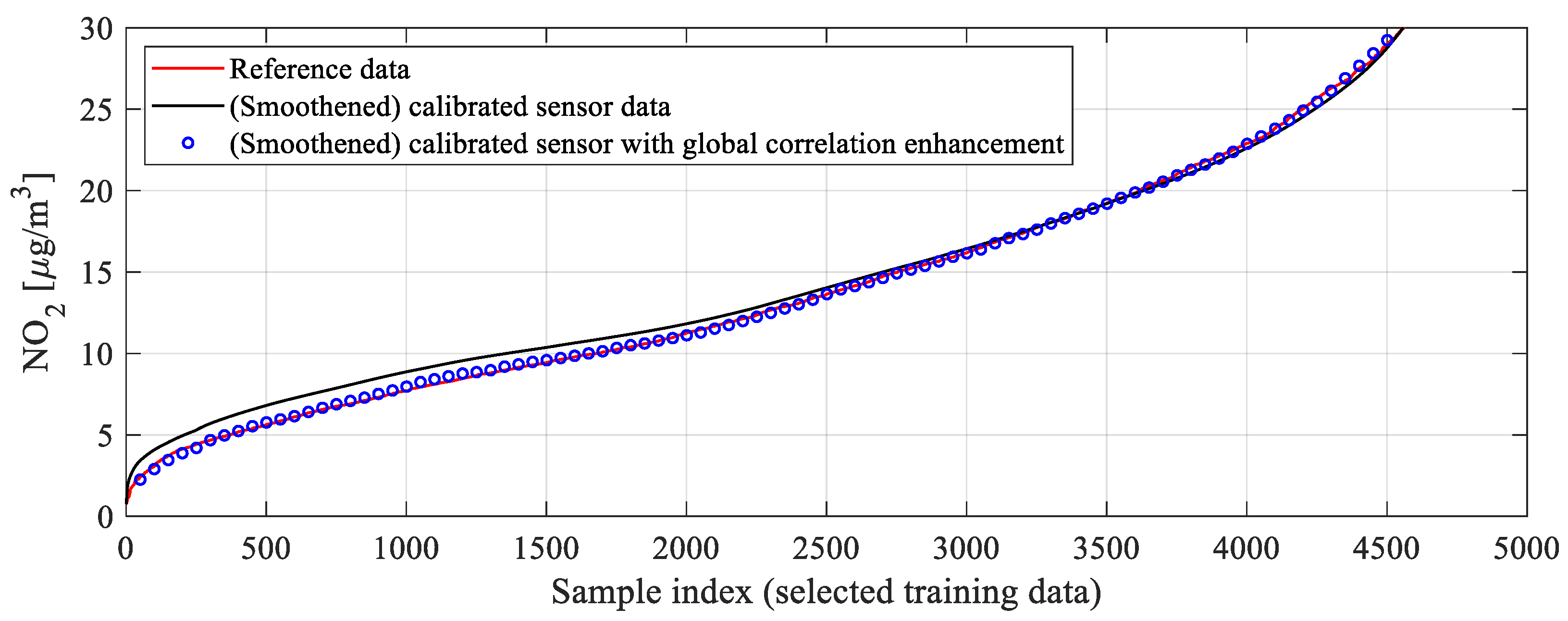

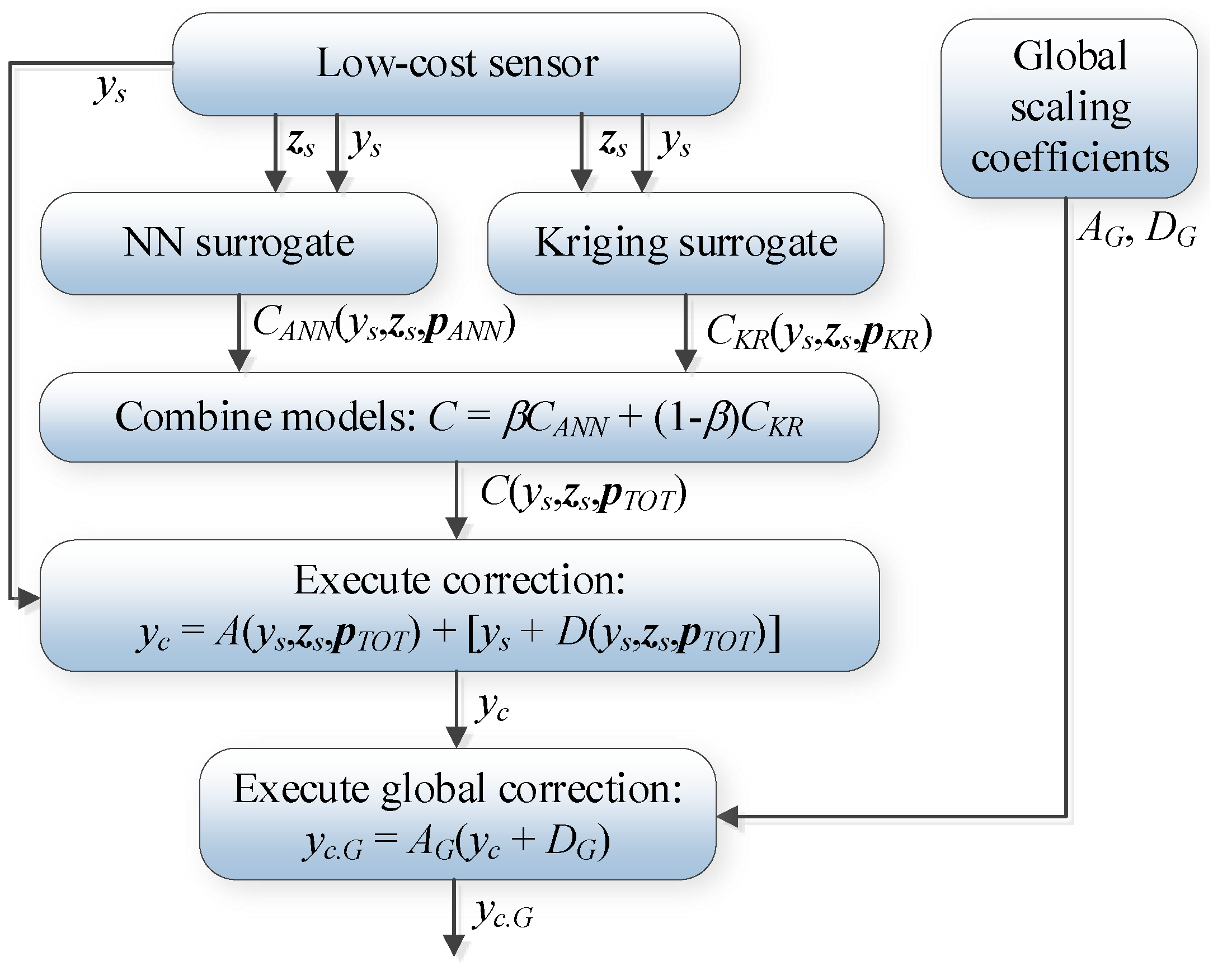

3.5. Global Data Correlation Enhancement

3.6. Complete Operating Flow of Calibration Procedure

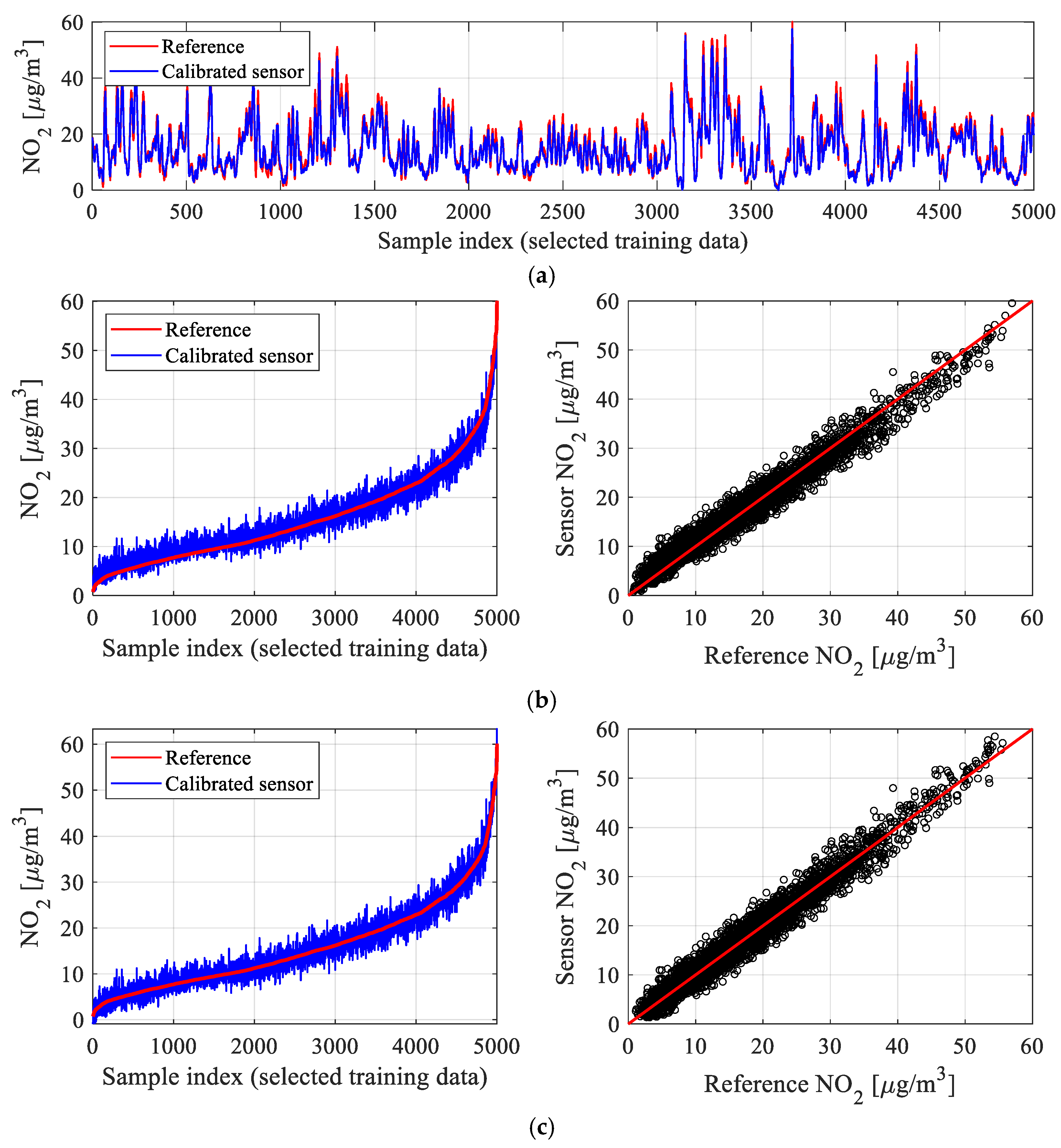

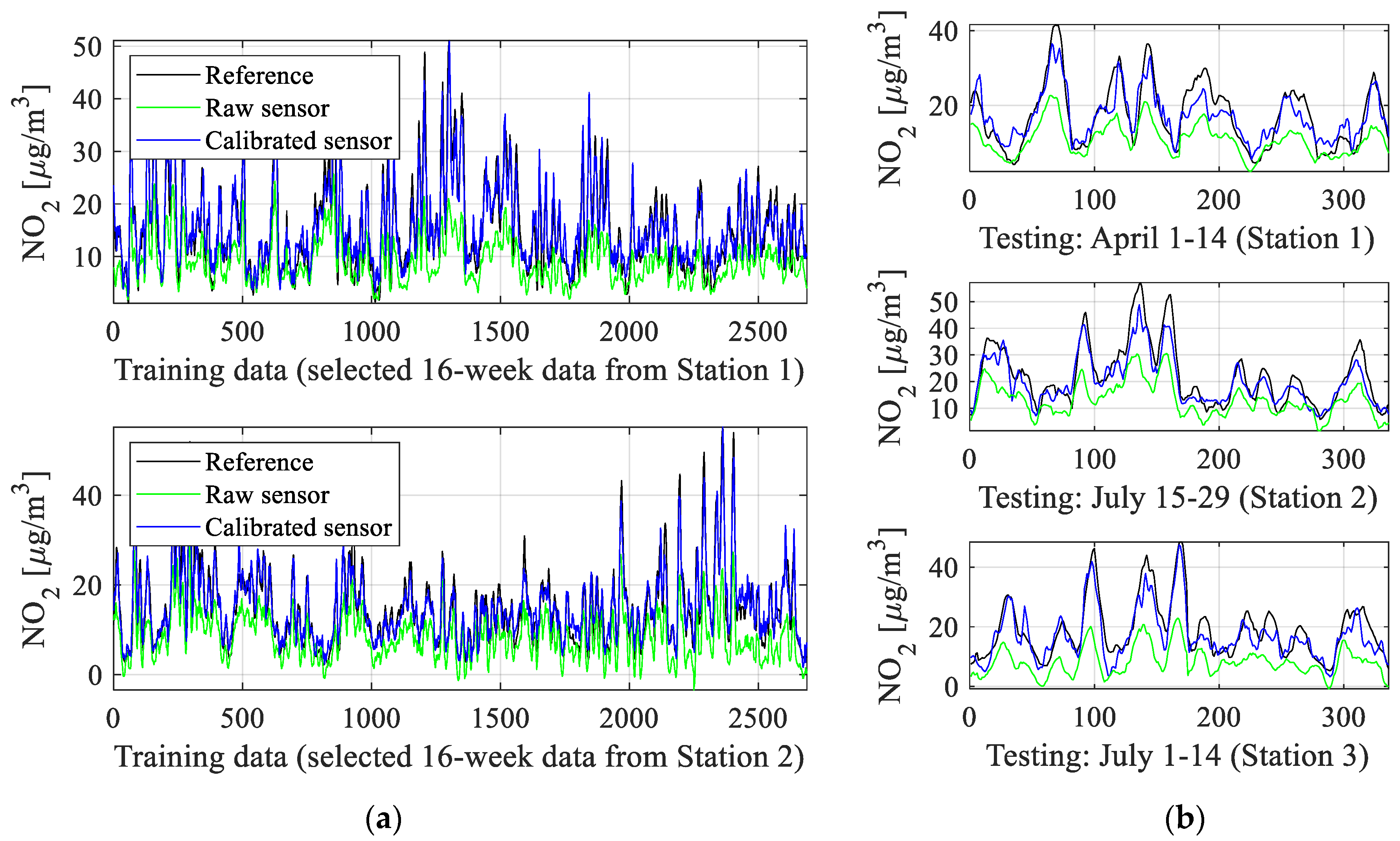

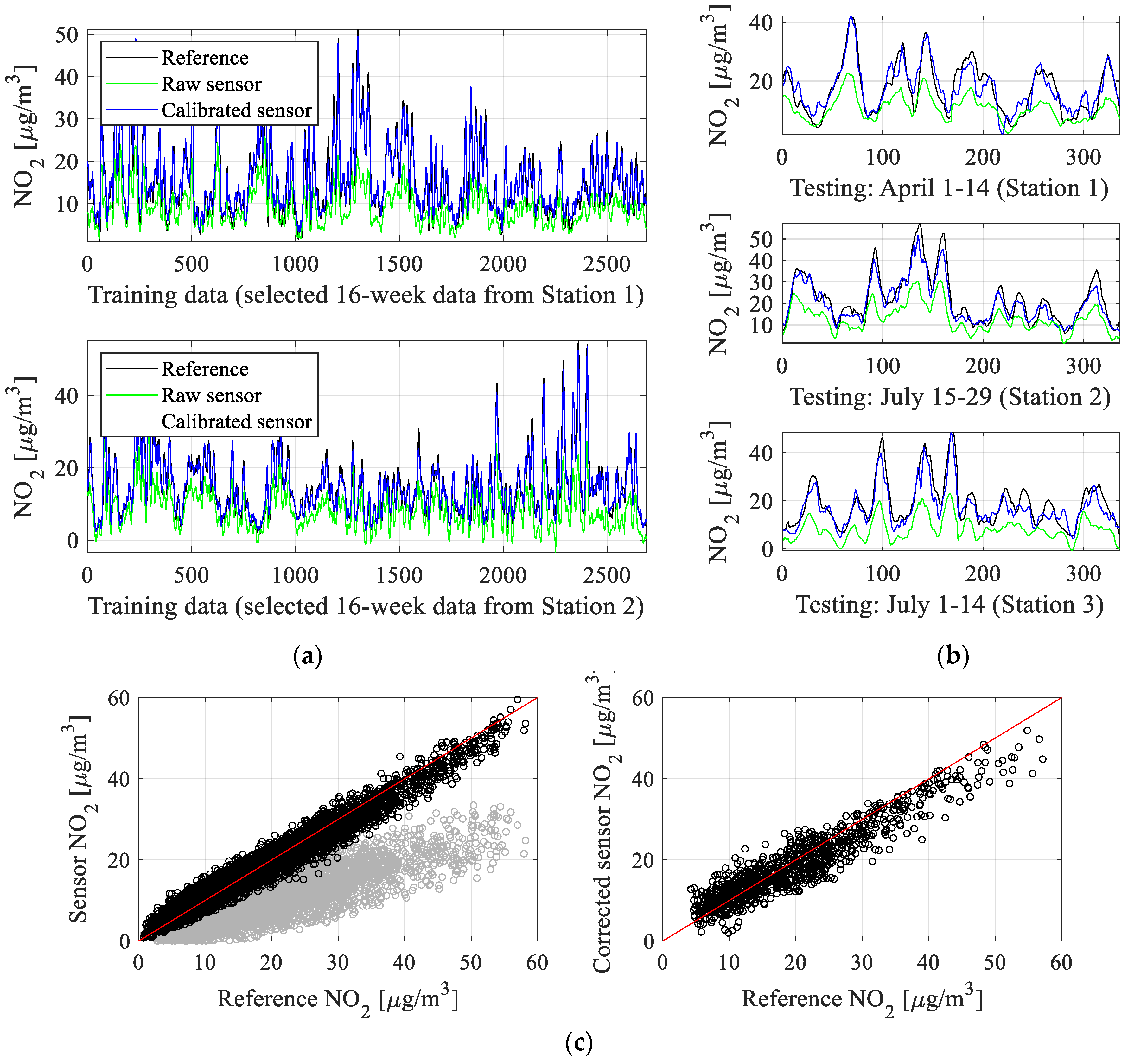

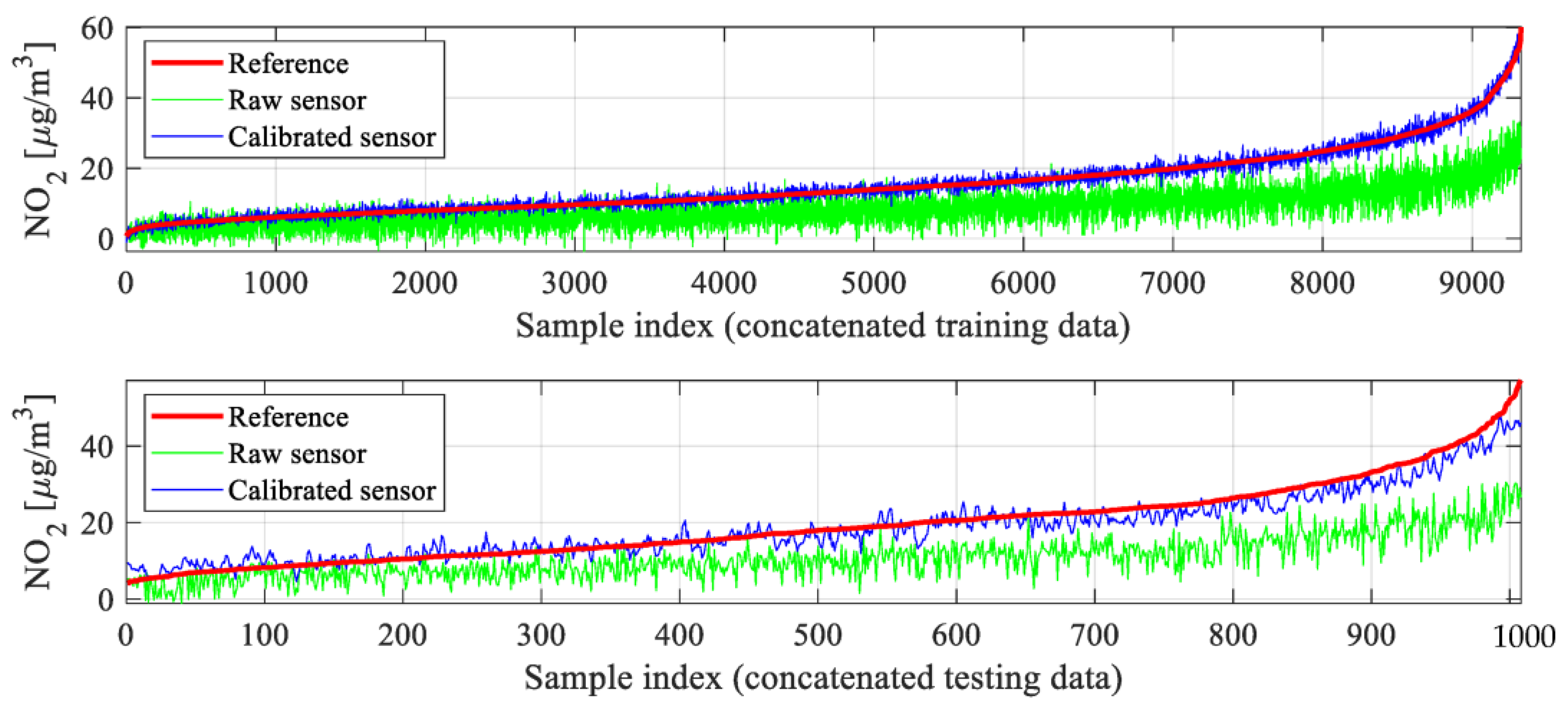

4. Results and Discussion

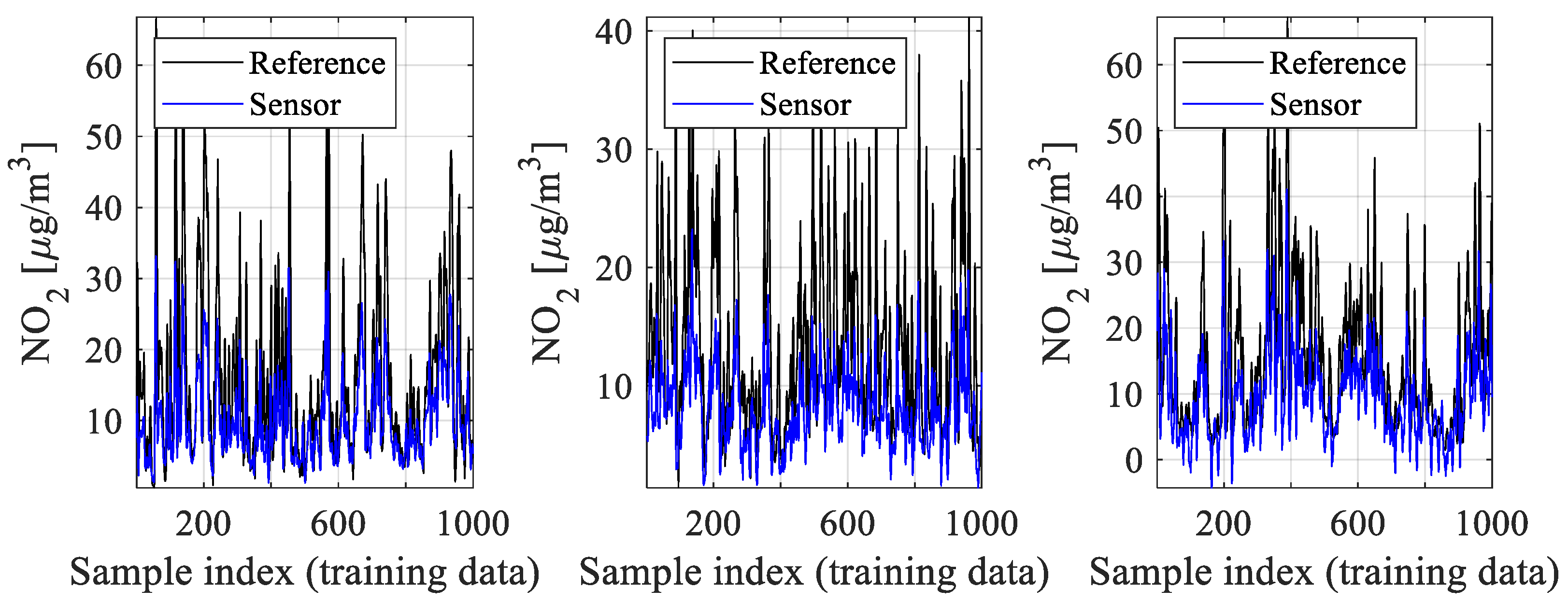

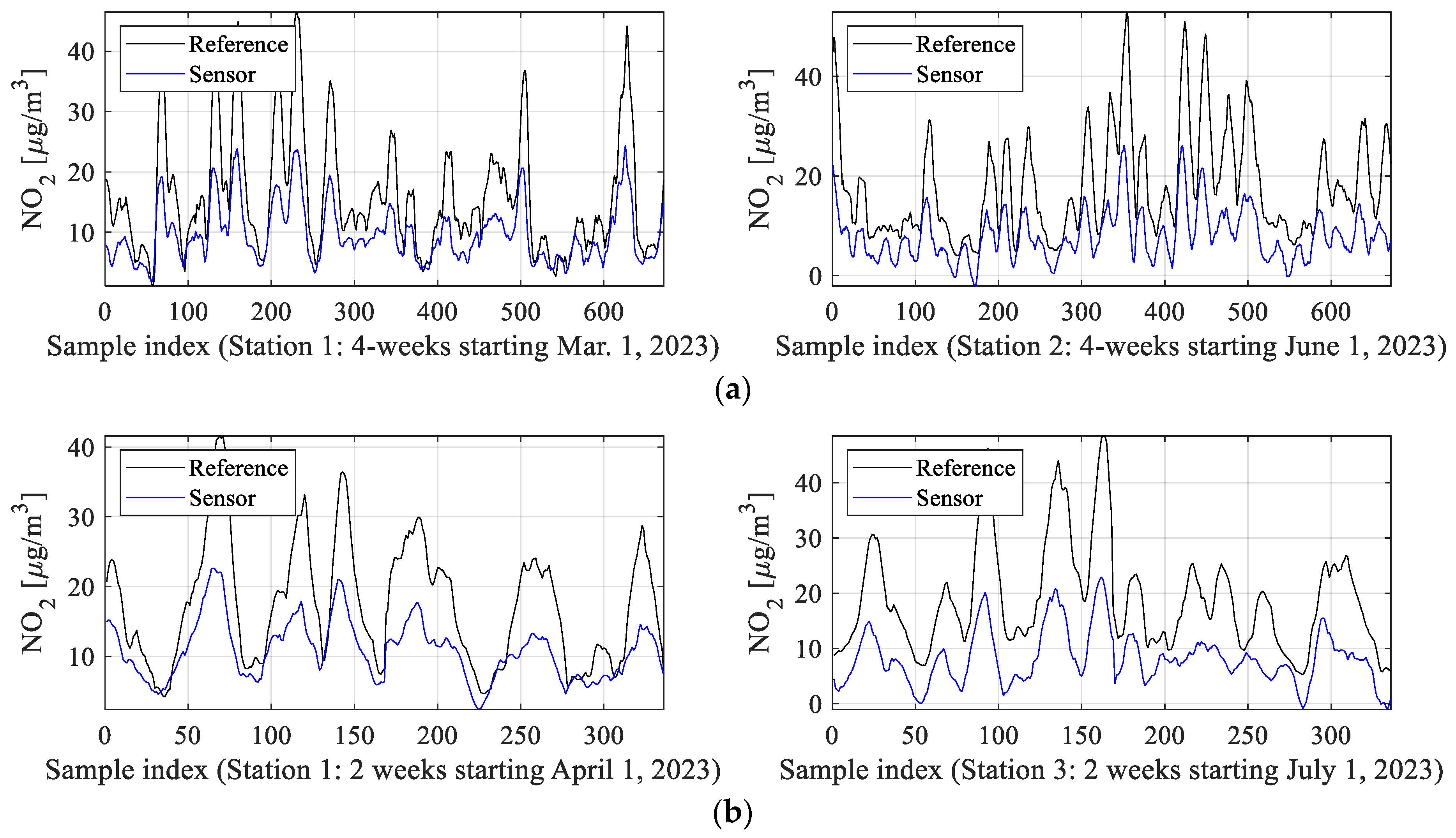

4.1. Data Description

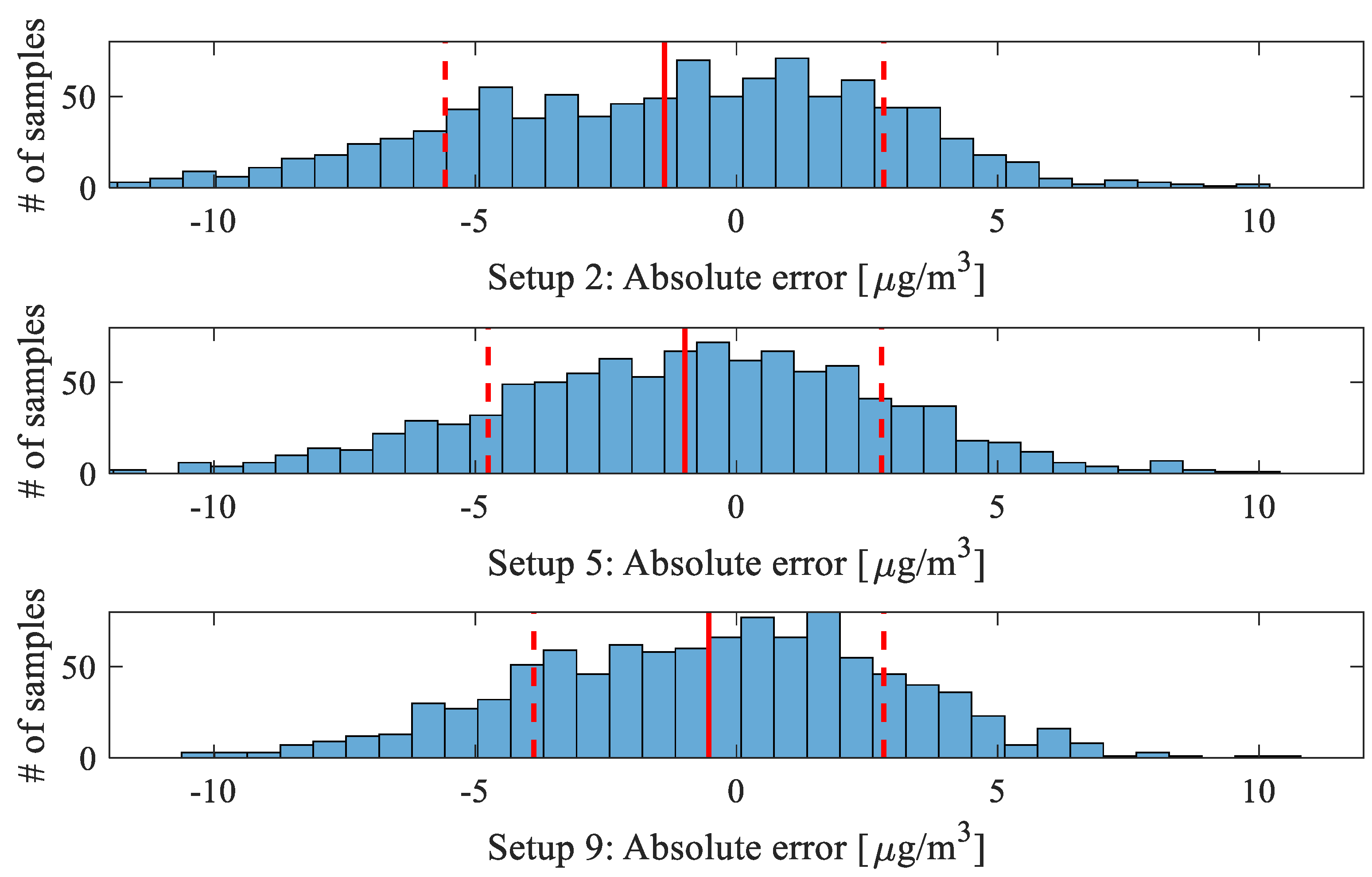

4.2. Numerical Results

4.3. Economic Analysis

4.4. Deployment

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, T.-M.; Kuschner, W.G.; Gokhale, J.; Shofer, S. Outdoor air pollution: Nitrogen dioxide, sulfur dioxide, and carbon monoxide health effects. Am. J. Med. Sci. 2007, 333, 249–256. [Google Scholar] [PubMed]

- Schwela, D. Air pollution and health in urban areas. Rev. Environ. Health 2000, 15, 13–42. [Google Scholar] [PubMed]

- Zhao, S.; Liu, S.; Sun, Y.; Liu, Y.; Beazley, R.; Hou, X. Assessing NO2-related health effects by non-linear and linear methods on a national level. Sci. Total Environ. 2020, 744, 140909. [Google Scholar] [PubMed]

- Agras, J.; Chapman, D. The Kyoto protocol, cafe standards, and gasoline taxes. Contemp. Econ. Policy 1999, 17, 296–308. [Google Scholar] [CrossRef]

- WHO. Air Quality Guidelines: Global Update 2005: Particulate Matter, Ozone, Nitrogen Dioxide, and Sulfur Dioxide; World Health Organization: Geneva, Switzerland, 2006. [Google Scholar]

- Mauzerall, D.L.; Sultan, B.; Kim, N.; Bradford, D.F. NOx emissions from large point sources: Variability in ozone production, resulting health damages and economic costs. Atmos. Environ. 2005, 39, 2851–2866. [Google Scholar] [CrossRef]

- Bradshaw, J.; Davis, D.; Crawford, J.; Chen, G.; Shetter, R.E.; Müller, M.; Gregory, G.; Sachse, G.; Blake, D.; Heikes, B.; et al. Photofragmentation—laser induced fluorescence detection of NO2 and NO: Comparison of measurements with model results based on airborne observations during PEM-Tropics A. Geophys. Res. Lett. 1999, 26, 471–474. [Google Scholar] [CrossRef]

- Platt, U. Air monitoring by differential optical absorption spectroscopy. In Encyclopedia of Analytical Chemistry; John and Wiley and Sons: New York, NY, USA, 2017. [Google Scholar]

- Matsumoto, J.; Hirokawa, J.; Akimoto, H.; Kajii, Y. Direct measurement of NO2 in the marine atmosphere by laser-induced fluorescence technique. Atmos. Environ. 2001, 35, 2803–2814. [Google Scholar] [CrossRef]

- Berden, G.; Peeters, R.; Meijer, G. Cavity ring-down spectroscopy: Experimental schemes and applications. Int. Rev. Phys. Chem. 2010, 19, 565–607. [Google Scholar]

- Yu, H.; Li, Q.; Wang, R.; Chen, Z.; Zhang, Y.; Geng, Y.; Zhang, L.; Cui, H.; Zhang, K. A deep calibration method for low-cost air monitoring sensors with multilevel sequence modeling. IEEE Trans. Instrum. Meas. 2020, 69, 7167–7179. [Google Scholar]

- Bi, J.; Wildani, A.; Chang, H.H.; Liu, Y. Incorporating low-cost sensor measurements into high-resolution PM2.5 modeling at a large spatial scale. Environ. Sci. Technol. 2020, 54, 2152–2162. [Google Scholar] [CrossRef]

- Castell, N.; Dauge, F.R.; Schneider, P.; Vogt, M.; Lerner, U.; Fishbain, B.; Broday, D.; Bartonova, A. Can commercial low-cost sensor platforms contribute to air quality monitoring and exposure estimates. Environ. Int. 2017, 99, 293–302. [Google Scholar] [PubMed]

- Laref, R.; Losson, E.; Sava, A.; Siadat, M. Empiric unsupervised drifts correction method of electrochemical sensors for in field nitrogen dioxide monitoring. Sensors 2021, 21, 3581. [Google Scholar] [CrossRef]

- Fonollosa, J.; Fernández, L.; Gutièrrez-Gálvez, A.; Huerta, R.; Marco, S. Calibration transfer and drift counteraction in chemical sensor arrays using direct standardization. Sens. Actuators B Chem. 2016, 236, 1044–1053. [Google Scholar]

- Rai, A.C.; Kumar, P.; Pilla, F.; Skouloudis, A.N.; Sabatino, S.D.; Ratti, C.; Yasar, A.; Rickerby, D. End-user perspective of low-cost sensors for outdoor air pollution monitoring. Sci. Total Environ. 2017, 607, 691–705. [Google Scholar]

- Kim, H.; Müller, M.; Henne, S.; Hüglin, C. Long-term behavior and stability of calibration models for NO and NO2 low-cost sensors. Atmos. Meas. Tech. 2022, 15, 2979–2992. [Google Scholar]

- Poupry, S.; Medjaher, K.; Béler, C. Data reliability and fault diagnostic for air quality monitoring station based on low cost sensors and active redundancy. Measurement 2023, 223, 113800. [Google Scholar]

- Carotta, M.C.; Martinelli, G.; Crema, L.; Malagù, C.; Merli, M.; Ghiotti, G.; Traversa, E. Nanostructured thick-film gas sensors for atmospheric pollutant monitoring: Quantitative analysis on field tests. Sens. Actuators B Chem. 2001, 76, 336–342. [Google Scholar] [CrossRef]

- Wang, Z.; Li, Y.; He, X.; Yan, R.; Li, Z.; Jiang, Y.; Li, X. Improved deep bidirectional recurrent neural network for learning the cross-sensitivity rules of gas sensor array. Sens. Actuators B Chem. 2024, 401, 134996. [Google Scholar]

- Zimmerman, N.; Presto, A.A.; Kumar, S.P.N.; Gu, J.; Hauryliuk, A.; Robinson, E.S.; Robinson, A.L.; Subramanian, R. A machine learning calibration model using random forests to improve sensor performance for lower-cost air quality monitoring. Atmos. Meas. Tech. 2018, 11, 291–313. [Google Scholar]

- Gorshkova, A.; Gorshkov, M.; Tripathi, N.; Tukmakov, K.; Podlipnov, V.; Artemyev, D.; Mishra, P.; Pavelyev, V.; Platonov, V.; Djuzhev, N.A. Enhancement in NO2 sensing properties of SWNTs: A detailed analysis on functionalization of SWNTs with Z-Gly-OH. J. Mater. Sci. Mater. Electron. 2023, 34, 102. [Google Scholar]

- Jiao, W.; Hagler, G.; Williams, R.; Sharpe, R.; Brown, R.; Garver, D.; Judge, R.; Caudill, M.; Rickard, J.; Davis, M.; et al. Community Air Sensor Network (CAIRSENSE) project: Evaluation of low-cost sensor performance in a suburban environment in the southeastern United States. Atmos. Meas. Tech. 2016, 9, 5281–5292. [Google Scholar] [CrossRef]

- Lewis, A.C.; Lee, J.D.; Edwards, P.M.; Shaw, M.D.; Evans, M.J.; Moller, S.J.; Smith, K.R.; Buckley, J.W.; Ellis, M.; Gillot, S.R.; et al. Evaluating the performance of low cost chemical sensors for air pollution research. Faraday Discuss. 2016, 189, 85–103. [Google Scholar] [CrossRef] [PubMed]

- Spinelle, L.; Gerboles, M.; Villani, M.G.; Aleixandre, M.; Bonavitacola, F. Field calibration of a cluster of low-cost commercially available sensors for air quality monitoring. Part B: NO, CO and CO2. Sensor. Actuators B Chem. 2017, 238, 706–715. [Google Scholar] [CrossRef]

- Han, P.; Mei, H.; Liu, D.; Zeng, N.; Tang, X.; Wang, Y.; Pan, Y. Calibrations of low-cost air pollution monitoring sensors for CO, NO2, O3, and SO2. Sensors 2021, 21, 256. [Google Scholar] [CrossRef] [PubMed]

- Müller, M.; Graf, P.; Meyer, J.; Pentina, A.; Brunner, D.; Perez-Cruz, F.; Hüglin, C.; Emmenegge, L. Integration and calibration of non-dispersive infrared (NDIR) CO2 low-cost sensors and their operation in a sensor network covering Switzerland. Atmos. Meas. Tech. 2020, 13, 3815–3834. [Google Scholar] [CrossRef]

- Shusterman, A.A.; Teige, V.E.; Turner, A.J.; Newman, C.; Kim, J.; Cohen, R.C. The BErkeley Atmospheric CO2 Observation Network: Initial evaluation. Atmos. Chem. Phys. Discuss. 2016, 16, 13449–13463. [Google Scholar] [CrossRef]

- Andersen, T.; Scheeren, B.; Peters, W.; Chen, H. A UAV-based active AirCore system for measurements of greenhouse gases. Atmos. Meas. Tech. 2018, 11, 2683–2699. [Google Scholar] [CrossRef]

- Kunz, M.; Lavric, J.; Gasche, R.; Gerbig, C.; Grant, R.H.; Koch, F.-T.; Schumacher, M.; Wolf, B.; Zeeman, M. Surface flux estimates derived from UAS-based mole fraction measurements by means of a nocturnal boundary layer budget approach. Atmos. Meas. Tech. 2020, 13, 1671–1692. [Google Scholar] [CrossRef]

- Miech, J.A.; Stanton, L.; Gao, M.; Micalizzi, P.; Uebelherr, J.; Herckes, P.; Fraser, M.P. Calibration of low-cost NO2 sensors through environmental factor correction. Toxics 2021, 9, 281. [Google Scholar] [CrossRef]

- Nowack, P.; Konstantinovskiy, L.; Gardiner, H.; Cant, J. Machine learning calibration of low-cost NO2 and PM10 sensors: Non-linear algorithms and their impact on site transferability. Atmosph. Meas. Tech. 2021, 14, 5637–5655. [Google Scholar] [CrossRef]

- D’Elia, G.; Ferro, M.; Sommella, P.; De Vito, S.; Ferlito, S.; D’Auria, P.; di Francia, G. Influence of concept drift on metrological performance of low-cost NO2 sensors. IEEE Trans. Instrum. Meas. 2022, 71, 1–11. [Google Scholar] [CrossRef]

- Jain, S.; Presto, A.A.; Zimmerman, N. Spatial modeling of daily PM2.5, NO2, and CO concentrations measured by a low-cost sensor network: Comparison of linear, machine learning, and hybrid land use models. Environ. Sci. Technol. 2021, 55, 8631–8641. [Google Scholar] [CrossRef] [PubMed]

- Ionascu, M.-E.; Castell, N.; Boncalo, O.; Schneider, P.; Darie, M.; Marcu, M. Calibration of CO, NO2, and O3 using Airify: A low-cost sensor cluster for air quality monitoring. Sensors 2021, 21, 7977. [Google Scholar] [CrossRef]

- Bi, J.; Stowell, J.; Seto, E.Y.W.; English, P.B.; Al-Hamdan, M.Z.; Kinney, P.L.; Freedman, F.R.; Liu, Y. Contribution of low-cost sensor measurements to the prediction of PM2.5 levels: A case study in Imperial County, CA, USA. Environ. Res. 2020, 180, 108810. [Google Scholar] [CrossRef] [PubMed]

- van Zoest, V.; Osei, F.B.; Stein, A.; Hoek, G. Calibration of low-cost NO2 sensors in an urban air quality network. Atmos. Environ. 2019, 210, 66–75. [Google Scholar] [CrossRef]

- De Vito, S.; Delli Veneri, P.; Esposito, E.; Salvato, M.; Bright, V.; Jones, R.L.; Popoola, O. Dynamic multivariate regression for on-field calibration of high speed air quality chemical multi-sensor systems. In Proceedings of the XVIII AISEM Annual Conference, Trento, Italy, 3–5 February 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–3. [Google Scholar]

- Masson, N.; Piedrahita, R.; Hannigan, M. Quantification method for electrolytic sensors in long-term monitoring of ambient air quality. Sensors 2015, 15, 27283–27302. [Google Scholar] [CrossRef] [PubMed]

- Esposito, E.; De Vito, S.; Salvato, M.; Bright, V.; Jones, R.L.; Popoola, O. Dynamic neural network architectures for on field stochastic calibration of indicative low cost air quality sensing systems. Sens. Actuators B Chem. 2016, 231, 701–713. [Google Scholar]

- Wang, Z.; Xie, C.; Liu, B.; Jiang, Y.; Li, Z.; Tai, H.; Li, X. Self-adaptive temperature and humidity compensation based on improved deep BP neural network for NO2 detection in complex environment. Sens. Actuators B Chem. 2022, 362, 131812. [Google Scholar] [CrossRef]

- BeagleBone® Blue, BeagleBoard. Available online: https://www.beagleboard.org/boards/beaglebone-blue (accessed on 19 February 2025).

- Datasheet SPS30, Particulate Matter Sensor for Air Quality Monitoring and Control, Sensirion. Available online: https://sensirion.com/products/catalog/SPS30 (accessed on 7 April 2025).

- SGX-7NO2 Datasheet, Industrial Nitrogen Dioxide (NO2) Sensor’, SGX Sensortech. Available online: https://www.sgxsensortech.com/content/uploads/2021/10/DS-0338-SGX-7NO2-datasheet.pdf (accessed on 19 February 2025).

- Four Electrode NO2 Sensor, SemaTech (7E4-NO2-5) (PN: 057-0400-200), SemeaTech Inc. Available online: https://www.semeatech.com/uploads/datasheet/7series/057-0400-200_EN.pdf (accessed on 19 February 2025).

- Datasheet MiCS-2714 1107 rev 6, SGX Sensortech. Available online: https://www.sgxsensortech.com/content/uploads/2014/08/1107_Datasheet-MiCS-2714.pdf (accessed on 19 February 2025).

- Humidity Sensor BME280, Bosch Sensortec. Available online: https://www.bosch-sensortec.com/products/environmental-sensors/humidity-sensors-bme280/ (accessed on 19 February 2025).

- ARMAG Foundation: Home. Available online: https://armaag.gda.pl/en/index.htm (accessed on 19 February 2025).

- Map Data from OpenStreetMap. Available online: https://openstreetmap.org/copyright (accessed on 19 February 2025).

- Vang-Mata, R. (Ed.) Multilayer Perceptrons; Nova Science Pub. Inc.: New York, NY, USA, 2020. [Google Scholar]

- Dlugosz, S. Multi-Layer Perceptron Networks for Ordinal Data Analysis; Logos Verlag: Berlin, Germany, 2008. [Google Scholar]

- Hagan, M.T.; Menhaj, M. Training feed-forward networks with the Marquardt algorithm. IEEE Trans. Neural Netw. 1994, 5, 989–993. [Google Scholar] [PubMed]

- Bingler, A.; Bilicz, S.; Csörnyei, M. Global sensitivity analysis using a kriging metamodel for EM design problems with functional outputs. IEEE Trans. Magn. 2022, 58, 1–4. [Google Scholar] [CrossRef]

- Diago-Mosquera, M.; Aragón-Zavala, A.; Azpilicueta, L.; Shubair, R.; Falcone, F. A 3-D indoor analysis of path loss modeling using kriging techniques. IEEE Antennas Wirel. Propag. Lett. 2022, 21, 1218–1222. [Google Scholar]

- Zhan, D.; Xing, H. A fast kriging-assisted evolutionary algorithm based on incremental learning. IEEE Trans. Evol. Comp. 2021, 25, 941–955. [Google Scholar]

- Yu, S.; Li, Y. Active learning kriging model with adaptive uniform design for time-dependent reliability analysis. IEEE Access 2021, 9, 91625–91634. [Google Scholar]

- Sinha, A.; Shaikh, V. Solving bilevel optimization problems using kriging approximations. IEEE Trans. Cybern. 2022, 52, 10639–10654. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Wang, H.; He, C.; Jin, Y. A kriging-assisted two-archive evolutionary algorithm for expensive many-objective optimization. IEEE Trans. Evol. Comp. 2021, 25, 1013–1027. [Google Scholar]

- Karagulian, F.; Barbiere, M.; Kotsev, A.; Spinelle, L.; Gerboles, M.; Lagler, F.; Redon, N.; Crunaire, S.; Borowiak, A. Review of the performance of low-cost sensors for air quality monitoring. Atmosphere 2019, 10, 506. [Google Scholar] [CrossRef]

- Cordero, J.-M.; Borge, R.; Narros, A. Using statistical methods to carry out in field calibrations of low cost air quality sensors. Sens. Actuators B Chem. 2018, 267, 245–254. [Google Scholar]

- Bigi, A.; Mueller, M.; Grange, S.K.; Ghermandi, G.; Hueglin, C. Performance of NO, NO2 low cost sensors and three calibration approaches within a real world application. Atmos. Meas. Tech. 2018, 11, 3717–3735. [Google Scholar]

- Spinelle, L.; Gerboles, M.; Villani, M.G.; Aleixandre, M.; Bonavitacola, F. Field calibration of a cluster of low-cost available sensors for air quality monitoring. Part A: Ozone and nitrogen dioxide. Sens. Actuators B Chem. 2015, 215, 249–257. [Google Scholar]

| Calibration Setup | Calibration Model | Input Variables | Global Data Correlation Enhancement | |

|---|---|---|---|---|

| Supplementary Data | NO2 Measurements from Main Sensor (ys) | |||

| 1 | NN | Restricted (only To, Ti, Ho, and Hi) | NO | NO |

| 2 | NN | Restricted (zs without pressure P) | NO | NO |

| 3 | NN + kriging 1 | Restricted (zs without pressure P) | NO | NO |

| 4 | NN | Restricted (zs without pressure P) | YES | NO |

| 5 | NN + kriging 1 | Restricted (zs without pressure P) | YES | NO |

| 6 | NN | Complete zs | YES | NO |

| 7 | NN + kriging 1 | Complete zs | YES | NO |

| 8 | NN | Complete zs | YES | YES |

| 9 | NN + kriging 1 | Complete zs | YES | YES |

| Calibration Setup | Training Data | Testing Data | ||

|---|---|---|---|---|

| Correlation Coefficient r | RMSE [μg/m3] | Correlation Coefficient r | RMSE [μg/m3] | |

| 1 | 0.82 | 4.0 | 0.70 | 5.6 |

| 2 | 0.89 | 3.0 | 0.81 | 14.3 |

| 3 | 0.95 | 2.2 | 0.82 | 4.4 |

| 4 | 0.91 | 2.8 | 0.84 | 4.0 |

| 5 | 0.95 | 2.0 | 0.85 | 3.9 |

| 6 | 0.93 | 2.5 | 0.86 | 3.9 |

| 7 | 0.96 | 1.8 | 0.86 | 3.8 |

| 8 | 0.94 | 2.4 | 0.878 | 3.6 |

| 9 | 0.96 | 1.7 | 0.883 | 3.5 |

| Calibration Method | Training Data | Testing Data | ||

|---|---|---|---|---|

| Correlation Coefficient r2 | RMSE [μg/m3] | Correlation Coefficient r2 | RMSE [μg/m3] | |

| Linear regression S(zs) | 0.28 | 7.8 | 0.07 | 9.9 |

| Linear regression Sy(zs, ys) | 0.66 | 5.4 | 0.56 | 6.8 |

| Direct ANN #-based prediction (zs) | 0.77 | 4.4 | 0.26 | 8.8 |

| Direct ANN #-based prediction (zs and ys) | 0.83 | 3.8 | 0.61 | 6.4 |

| Direct CNN USD-based prediction (zs and ys) (convolution layers: 32, 16, 8) | 0.50 | 6.5 | 0.29 | 8.6 |

| Direct CNN USD-based prediction (zs and ys) (convolution layers: 64, 32, 16) | 0.72 | 4.8 | 0.45 | 7.6 |

| Direct CNN USD-based prediction (zs and ys) (convolution layers: 128, 64, 32) | 0.77 | 4.5 | 0.42 | 7.7 |

| No. | Name of the Component/Module | Approximate Cost at Unit Production | Lifetime |

|---|---|---|---|

| 1. | SPS30 particulate matter (PM) sensor (Sensirion [43]) | USD 60 | >10 years |

| 2. | SGX-7NO2⟶NO2 electrochemical sensor (SGX Sensortech [44]) | USD 80 | >24 months |

| 3. | 7E4-NO2⟶NO2 electrochemical sensor (SemaTech [45]) | USD 140 | 3 years |

| 4. | MiCS 2714⟶Compact MOS ambient quality sensor (SGX Sensortech [46]) for NO2 and hydrogen detection) | USD 16 | not applicable |

| 5. | BME280⟶Environmental sensor (Bosch Sensortech [47]) capable of detecting air temperature and humidity together with atmospheric pressure (2 pieces) | USD 14 | 10 years |

| 6. | BeagleBone Blue microcomputer board | USD 140 | n/a |

| 7. | Minor passive components, supplementary modules and accessories | USD 300 | n/a |

| Total cost of hardware | USD 750 | ||

| Electricity (per year) | USD 25 | ||

| GSM transmission costs for IoT GSM rate for 1nce operator (per year) (www.1nce.com, accessed on 19 February 2025) | USD 11 |

| No. | Name | Approximate Cost | Remarks |

|---|---|---|---|

| 1. | Air-conditioned container, without the measurement equipment (similar to the one shown in Figure 3b) | USD 25,000 | purchase cost |

| 2. | NO-NO2-NOx Analyzer i.e., API T200 | USD 25,000 | purchase cost |

| 3. | PM analyzer PM10, PM2.5, PM1 i.e., GRiMM EDM 280 | USD 37,000 | purchase cost |

| 4. | Service and maintenance of the analyzers | USD 500 | cost per year |

| 5. | Electricity (measurement equipment, air-conditioning, heating) | USD 2800 | cost per year |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koziel, S.; Pietrenko-Dabrowska, A.; Wójcikowski, M.; Pankiewicz, B. Nitrogen Dioxide Monitoring by Means of a Low-Cost Autonomous Platform and Sensor Calibration via Machine Learning with Global Data Correlation Enhancement. Sensors 2025, 25, 2352. https://doi.org/10.3390/s25082352

Koziel S, Pietrenko-Dabrowska A, Wójcikowski M, Pankiewicz B. Nitrogen Dioxide Monitoring by Means of a Low-Cost Autonomous Platform and Sensor Calibration via Machine Learning with Global Data Correlation Enhancement. Sensors. 2025; 25(8):2352. https://doi.org/10.3390/s25082352

Chicago/Turabian StyleKoziel, Slawomir, Anna Pietrenko-Dabrowska, Marek Wójcikowski, and Bogdan Pankiewicz. 2025. "Nitrogen Dioxide Monitoring by Means of a Low-Cost Autonomous Platform and Sensor Calibration via Machine Learning with Global Data Correlation Enhancement" Sensors 25, no. 8: 2352. https://doi.org/10.3390/s25082352

APA StyleKoziel, S., Pietrenko-Dabrowska, A., Wójcikowski, M., & Pankiewicz, B. (2025). Nitrogen Dioxide Monitoring by Means of a Low-Cost Autonomous Platform and Sensor Calibration via Machine Learning with Global Data Correlation Enhancement. Sensors, 25(8), 2352. https://doi.org/10.3390/s25082352