1. Introduction

With the rapid development of science and technology, multirobot systems have become the focus of advanced research and applications in the field of robotics. The application fields of multirobot systems continue to expand from industrial manufacturing to intelligent transportation, and then to service robots [

1]. For example, in industrial manufacturing, a specific task requires multiple robots to work together [

2]. In the field of intelligent transportation, multirobot systems can be used in autonomous driving fleets to cooperatively complete vehicle navigation and obstacle avoidance tasks, improving safety and efficiency in road traffic [

3]. In the field of service robots, for example, medical robot teams can cooperate to complete surgical tasks, which improves the accuracy and safety of surgery [

4]. In these application scenarios, the collaboration and cooperation of multirobot systems are critical, and path planning and formation control are key technologies for ensuring their efficient operation. As a key technology in multirobot systems, path planning can be further divided into global path planning and local path planning.

The sampling-based path planning algorithm in global path planning [

5] uses a sampler to sample the unknown space and obtain space information. With increases in the number of sampling points, the unknown space can be described with higher resolution so that feasible paths can quickly be found. The rapid exploration random tree (RRT) algorithm is widely used. The collision checking module can maneuver in complex spaces and is thus suitable for solving high-dimensional or multiconstraint planning problems [

6]. However, due to the random sampling nature of the RRT algorithm, the paths it generates often suffer from poor quality, such as excessive length, too many turning points, and other inefficiencies. Additionally, RRT cannot be guaranteed to find the globally optimal path, especially in complex environments, where its search efficiency is low, and it is prone to falling into local optima. These limitations restrict the application of RRT in practical multi-robot collaborative tasks, necessitating an improved method that can optimize path quality and enhance search efficiency. To address this problem, many scholars have proposed improved methods. To solve the problem of low-quality generated paths, Karaman et al. [

7] proposed the RRT* algorithm, which introduces the ChooseParent and Rewire procedures when new nodes are added to the tree, making the algorithm asymptotically optimal. Bao et al. [

8] proposed a method to optimize the initial path generated by RRT; that is, the tree is merged on the basis of the initial path to form a closed-loop path, and then optimization is carried out to obtain a relatively optimal path. Chen et al. [

9] proposed a bidirectional pruning optimization strategy to prune redundant nodes from the starting point and end point of the path and select the shortest optimized path to effectively improve the quality of the path. However, the RRT* algorithm needs infinite iterations to find the optimal path. Although the pruning optimization improves the quality of the path, there is a gap between it and the optimal path.

As a supplement to global path planning, local path planning focuses on how to avoid obstacles and adjust the path in real time during the robot’s movement. As one of the classical algorithms of local path planning, the artificial potential field method is simple and efficient and is widely used today. However, the original algorithm has problems, such as an unreachable target and local optimality [

10]. In this context, many scholars have made various improvements to the algorithm. Fan et al. [

11] adopted the regular hexagon guidance method to guide the robot along one side of a virtual regular hexagon centered on an obstacle to escape the local minimum. Jia et al. [

12] proposed a new repulsion force algorithm that adds Gaussian functions related to the position of the robot and the target point on the basis of the traditional repulsion force to solve the unreachable problem of the target point near the obstacle. Sun et al. [

13] used the dynamic window method and evaluated the simulation trajectory to predict the local minimum region to prevent the robot from falling into the local minimum point in advance. However, the above improvements do not consider the problem of cooperative obstacle avoidance among multiple robots.

The consistency and stability of multirobot formations are also important problems in multirobot systems. Ge et al. [

14] applied the consistency control law to the formation control problem of multiagent systems and proved that several traditional formation strategies, such as the leader–follower strategy, can be realized by using the consistency theory. Lin et al. [

15], based on the symbolic Laplacian matrix of the multirobot affine formation control method, analyzed the conditions of the affine transformation realization of multirobot systems, providing a new method for multirobot formation control. Zhao et al. [

16] studied the affine formation control method corresponding to the undirected graph stress matrix to provide sufficient and necessary conditions for robot formation to realize affine positioning. Different formation controllers based on affine transformation are designed under different conditions, and the stability and global convergence of the proposed control methods are proven. However, these strategies have their limitations and disadvantages, which limit their wide application in complex scenarios.

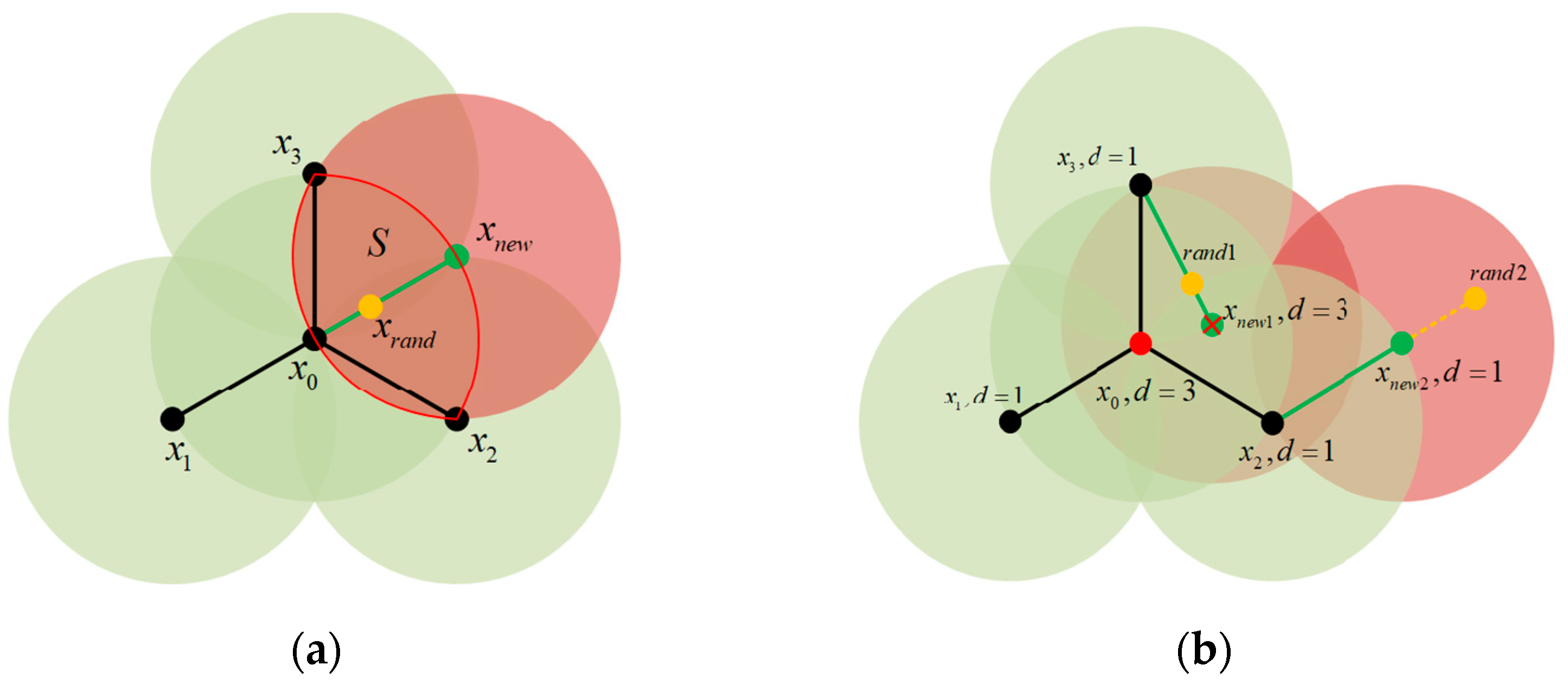

In summary, although many studies have focused on path planning and the formation control of multiple robots, there is a lack of research on their ability to maintain formation stability, and follower loss easily occurs in multiple obstacle regions. Therefore, in this paper, the leader–follower method is used as the premise for formation control, and a global path planning algorithm based on the RRT algorithm, namely, the density detection rapidly exploring random tree (DDRRT) algorithm, is proposed. In this algorithm, a density detection mechanism is added to the RRT algorithm extension, and tree nodes whose density values exceed the threshold are deactivated to avoid invalid expansion and shorten the pathfinding time. Additionally, a rope contraction path optimization method is proposed. The randomly generated path is treated as a rope, with its starting point fixed while the endpoint is adjusted to shorten the overall path, resulting in a path close to the optimal solution and providing a high-quality path for the robot.

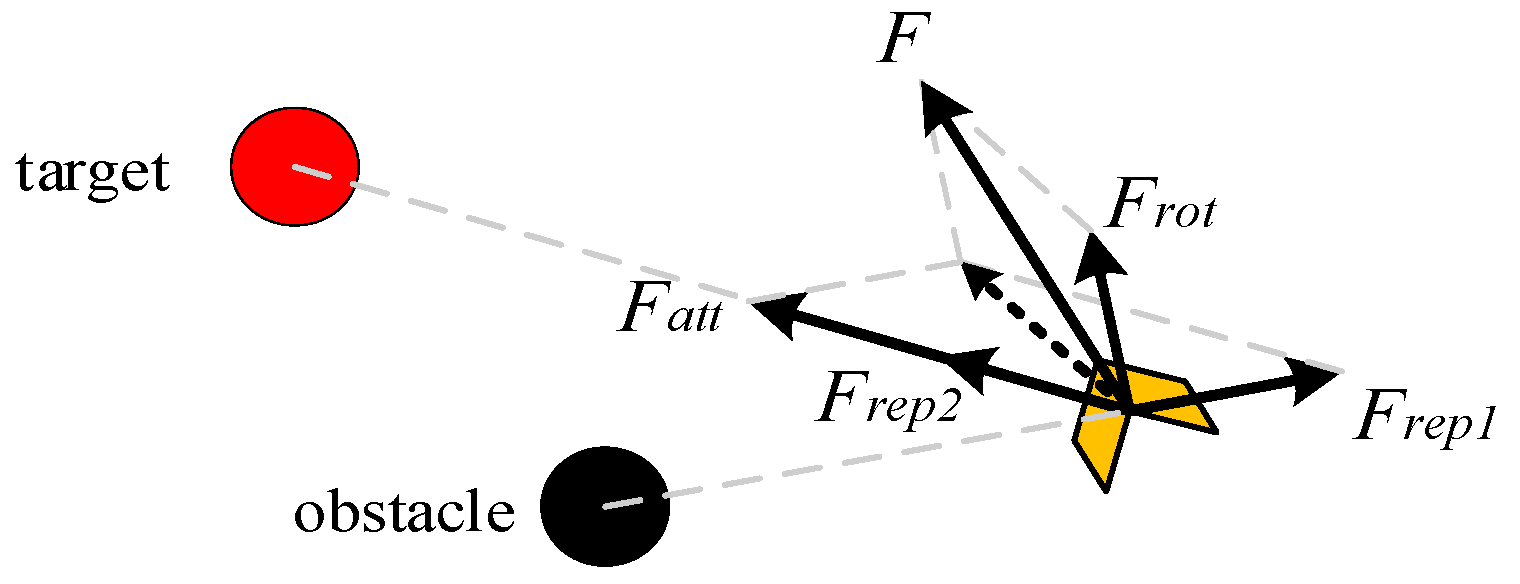

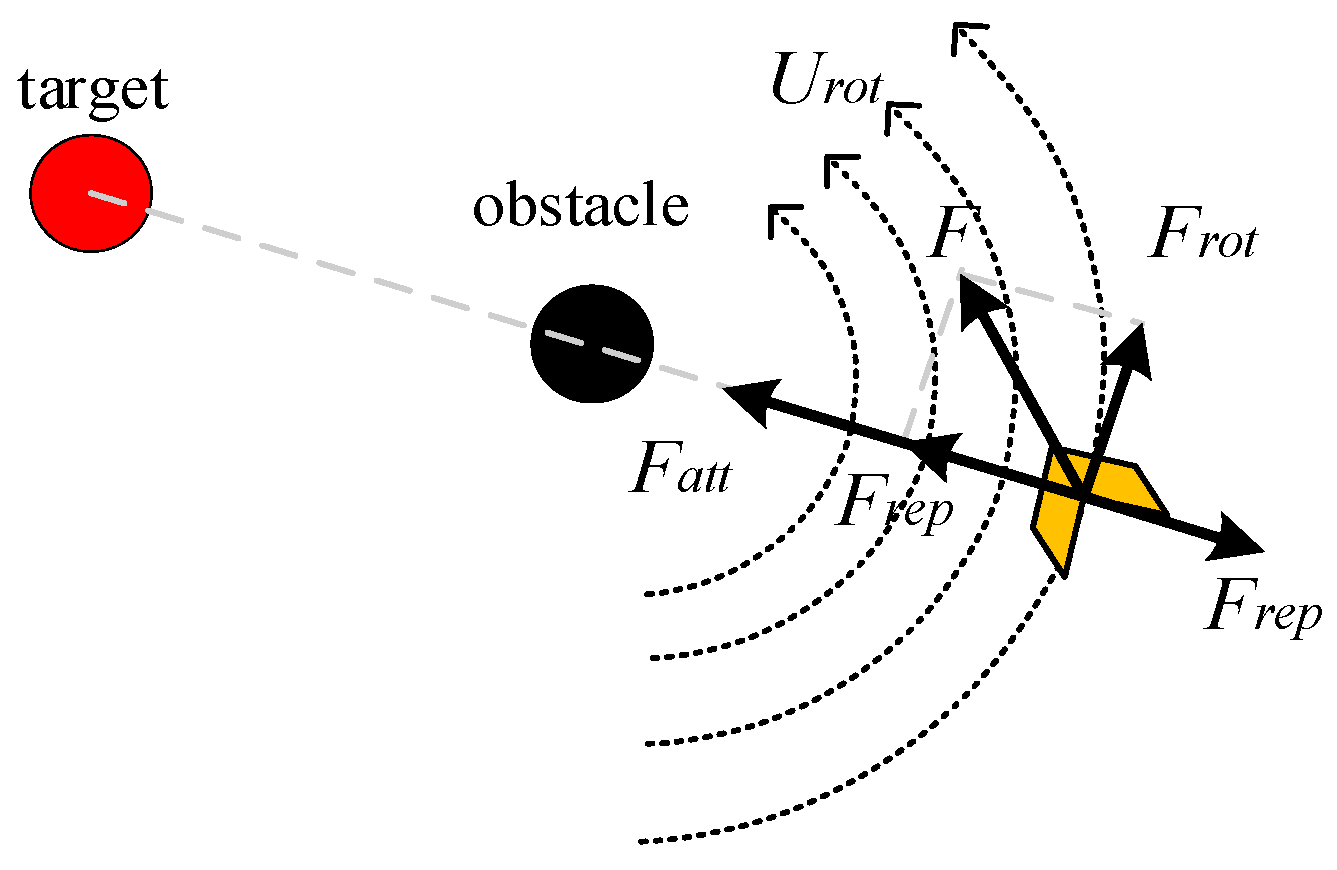

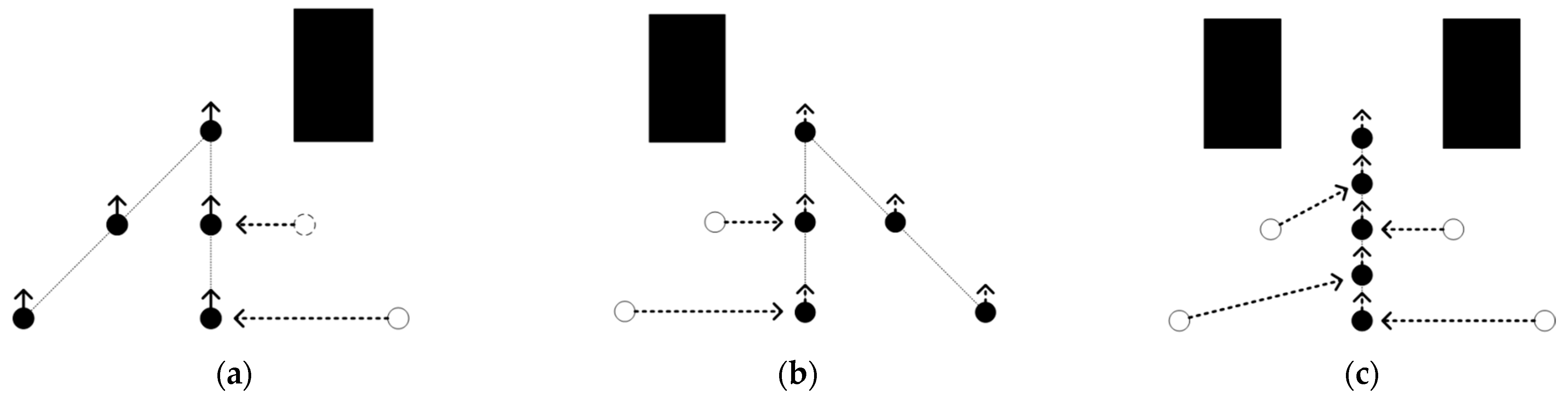

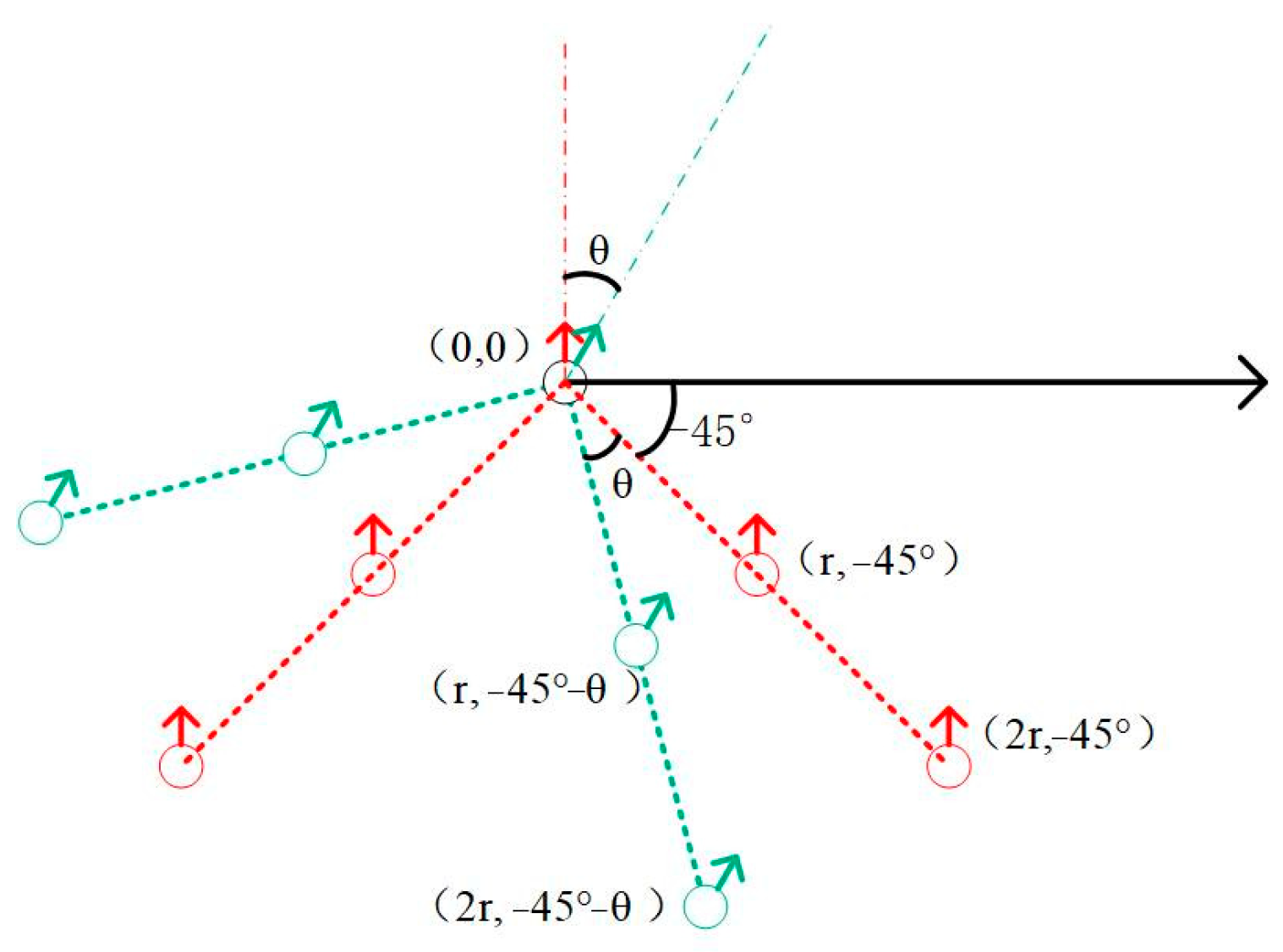

Furthermore, the potential field function of the artificial potential field method is improved. The repulsive force potential field is adjusted to avoid force balance and prevent the robot from falling into local optima. A rotating potential field is added around obstacles to increase the robot’s obstacle avoidance speed and eliminate local oscillation movements. Finally, the consistency algorithm is used to realize multirobot cooperative formation operations, and a formation transformation mechanism based on polar coordinates is proposed to enable formation steering and obstacle avoidance, thereby improving the stability of multirobot formation operations.

5. Simulation and Results

To verify the proposed algorithm, this paper compares and analyzes the rope path optimization algorithm under various maps. The improved artificial potential field methods are compared and analyzed under the multi-obstacle map. Finally, multirobot path planning and collaborative formations are verified and analyzed via a comprehensive map. The size of all the global maps is 100 px × 100 px, and the size of the artificial potential field method experiment scene is 35 px × 35 px. Among them, 1 px represents 1 m in the real world. All the simulations are performed on a computer equipped with an Intel(R) Core(TM) i7-12700H 2.30 GHz CPU and 16 GB of RAM. The simulation platform for all the experiments is MATLAB R2022a.

5.1. Global Path Planning

The global path planning experiment parameters are set as shown in

Table 1. Among them,

dstepsize is the random tree expansion step,

dstep is the movement distance of the path point when the rope contracts,

r is the end point detection radius, and

N is the maximum sampling number.

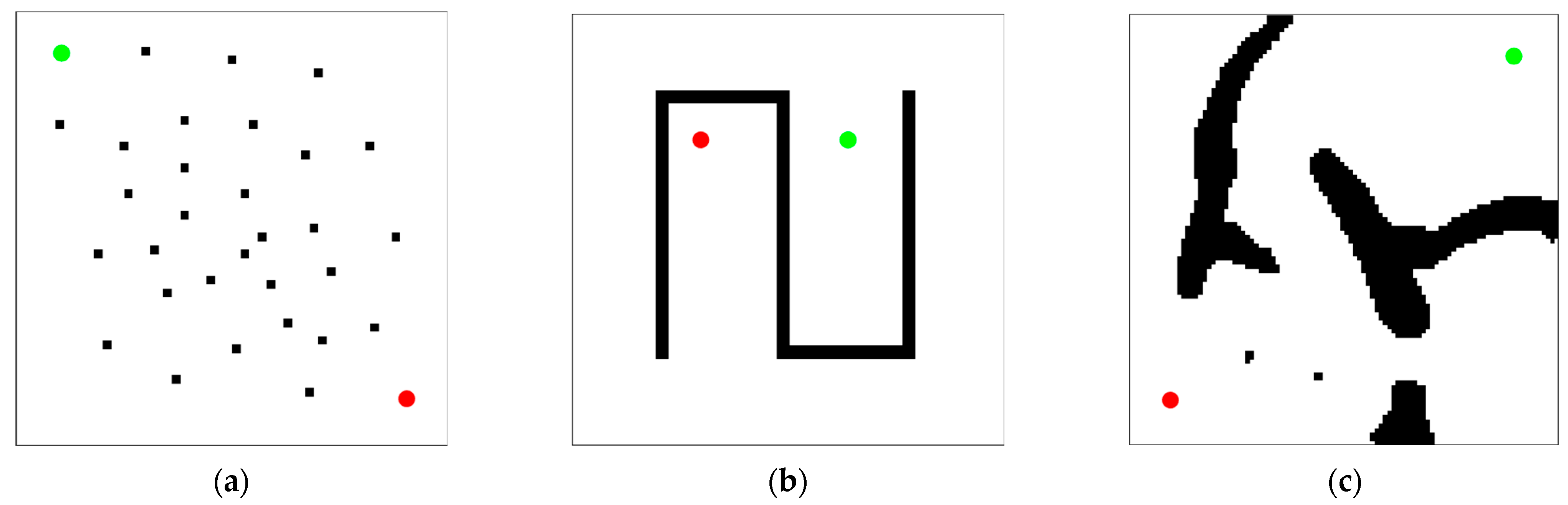

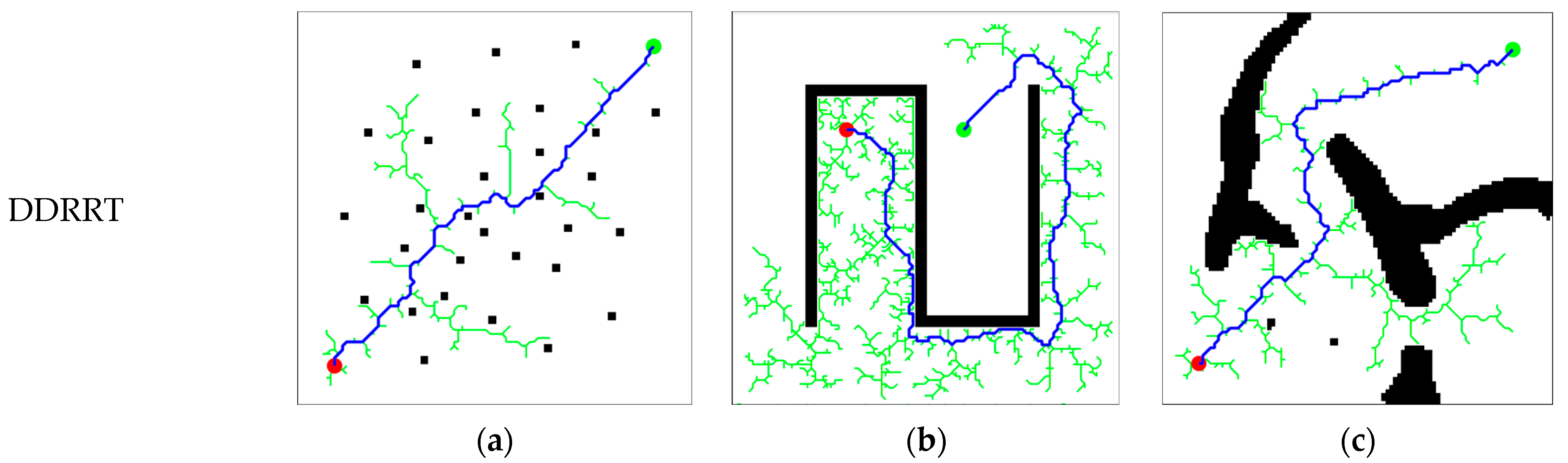

This paper tests the performance of the DDRRT algorithm in three two-dimensional environments. The simple environment shown in

Figure 11a is used to test whether the performance of the new algorithm is significantly reduced due to additional calculations. The U-shaped maze environment shown in

Figure 11b is used to test the performance of the algorithm in a complex environment. The simulation environment shown in

Figure 11c is used to evaluate the actual performance of the algorithm. In the map, the red dots are the starting points, and the green dots are the target points. The entire exploration process is represented by green lines, and the generated path is represented by blue lines. Each experiment is repeated 100 times, and algorithm performance is evaluated based on the average algorithm running time, minimum time, maximum time, number of tree nodes, and time standard deviation.

Figure 12 illustrates the operations of DDRRT, RRT, and RRV [

17] (rapidly exploring random vines) in three different map environments. Regardless of the environment, DDRRT generates significantly fewer tree nodes than both RRT and RRV. The randomly generated tree is more concise than those of RRT and RRV, intuitively demonstrating that DDRRT has a higher utilization rate of tree nodes.

Table 2 presents the operational data of the algorithms in the three map environments. The planning time of DDRRT in different environments is less than that of both the RRT and RRV algorithms, indicating that DDRRT has higher planning efficiency. The time standard deviation of DDRRT is smaller than that of RRT and RRV, suggesting that DDRRT is more stable in the algorithm dataset. Additionally, the average number of tree nodes in DDRRT is significantly smaller than that of the original RRT and RRV algorithms, further indicating its higher node utilization rate.

Based on the above analysis, in different environments, the DDRRT algorithm outperforms both the original RRT and RRV algorithms. The reason lies in DDRRT’s addition of a target-oriented expansion mechanism and continuous detection of vertex density to avoid redundant exploration. This improves vertex utilization and enhances the overall performance of the algorithm.

5.2. Global Path Optimization

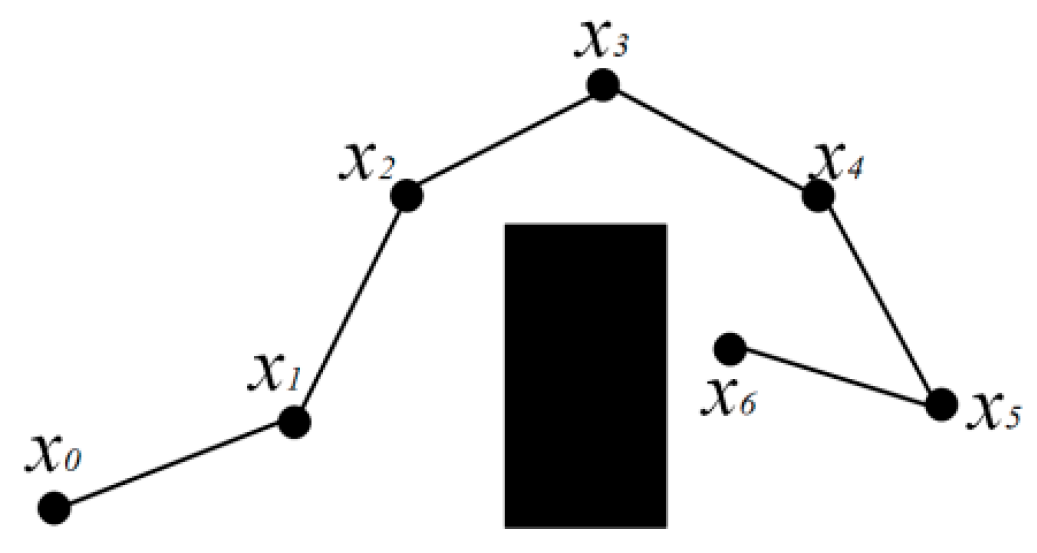

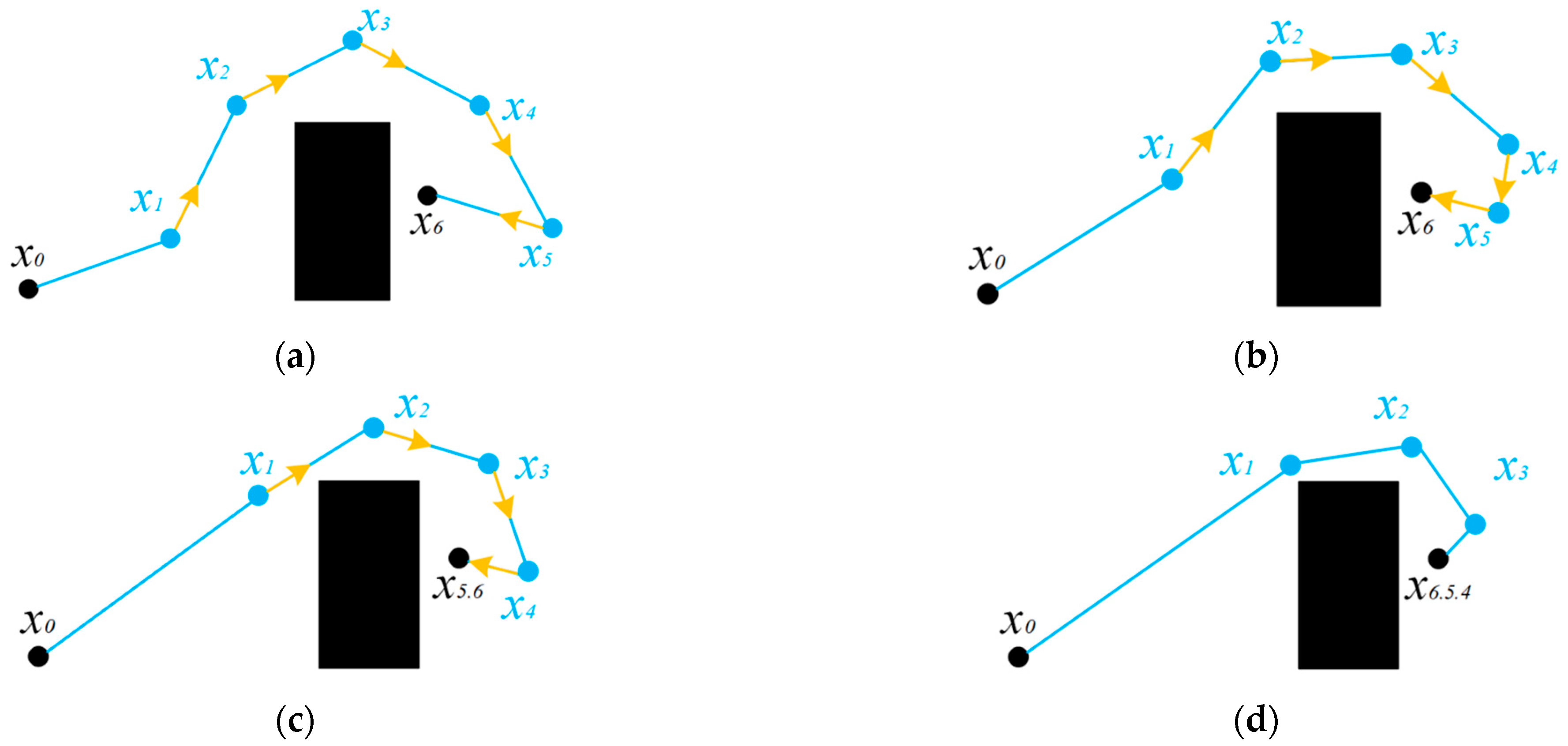

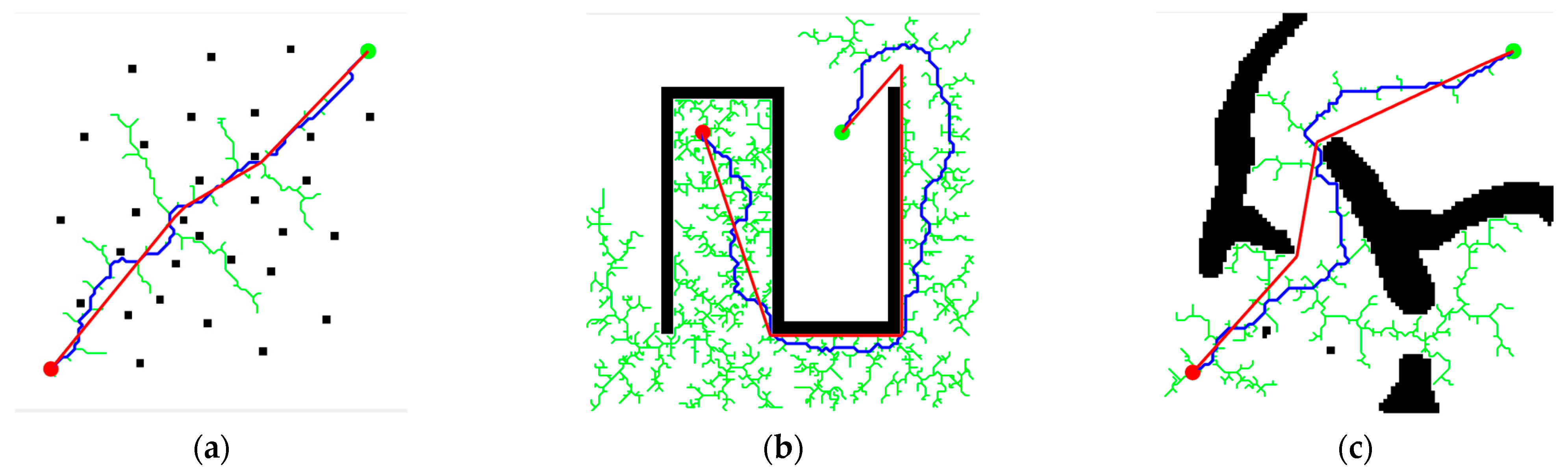

Although DDRRT has great advantages in terms of planning speed and environmental adaptability, there is still room for improvement in the quality of the planned path. Therefore, to solve this problem, this paper proposes a rope path optimization strategy to optimize the path. This paper uses three different maps to verify the feasibility of the rope path optimization method and ensure that it can provide high-quality paths for leaders in different terrains. Each experiment is repeated 100 times, and the quality of the path is evaluated based on path length and smoothness.

Figure 13 shows the simulation results on three maps. The blue line represents the initial path obtained by the RRT based on its own expansion tree, and the red line represents the path optimized by the rope path.

Obviously, the blue paths under the three maps are too tortuous and contain many redundant path points, making it difficult to provide an effective global path for the leader. The red path has almost no redundant path points, and each point can be used as a local destination to provide better guidance for the leader.

Table 3 compares and analyzes the quality of the paths generated in the experiment. On the three different maps, the optimized path has significant improvements in path length and smoothness, and is close to the optimal path. This finding shows that rope path optimization can effectively improve the RRT initial path quality.

5.3. Local Obstacle Avoidance Optimization Strategy

To verify the superiority of the improved new artificial potential field (NAPF) in the field of local path planning, this paper compares NAPF with the traditional artificial potential field method in rectangular obstacle channels. The map size is 35 px × 35 px. The experimental parameter settings are shown in

Table 4. Among them,

kg is the attraction gain coefficient,

kr is the repulsion gain coefficient,

ke is the rotating force gain coefficient,

ρ is the radius of the obstacle repulsion field, and

vmax is the maximum driving speed.

Figure 14 shows the obstacle avoidance paths planned by two artificial potential field algorithms in a channel environment with rectangular obstacles. Among them, the starting point and ending point remain unchanged.

Figure 14a shows that the two obstacle avoidance algorithms have similar path trajectories in this scenario, and both can avoid obstacles and reach the destination.

Figure 14b is an enlarged image of the green rectangle in

Figure 14a. When the traditional artificial potential field method encounters rectangular obstacles, the path is tortuous because the repulsion force and the attraction force are difficult to balance. The path of the new artificial potential field method is smoother. The reason is that the repulsion field has been improved to greatly increase the attraction force, allowing for obstacles to quickly be avoided when encountered.

Table 5 further shows the operating data of the two algorithms. The data show that using the new artificial potential field method reduces the driving time by 23%, reduces the path length by 2%, and improves path smoothness by 81%. These data further prove that the new artificial potential field method has obvious advantages in performance.

5.4. Robot Cooperative Formation

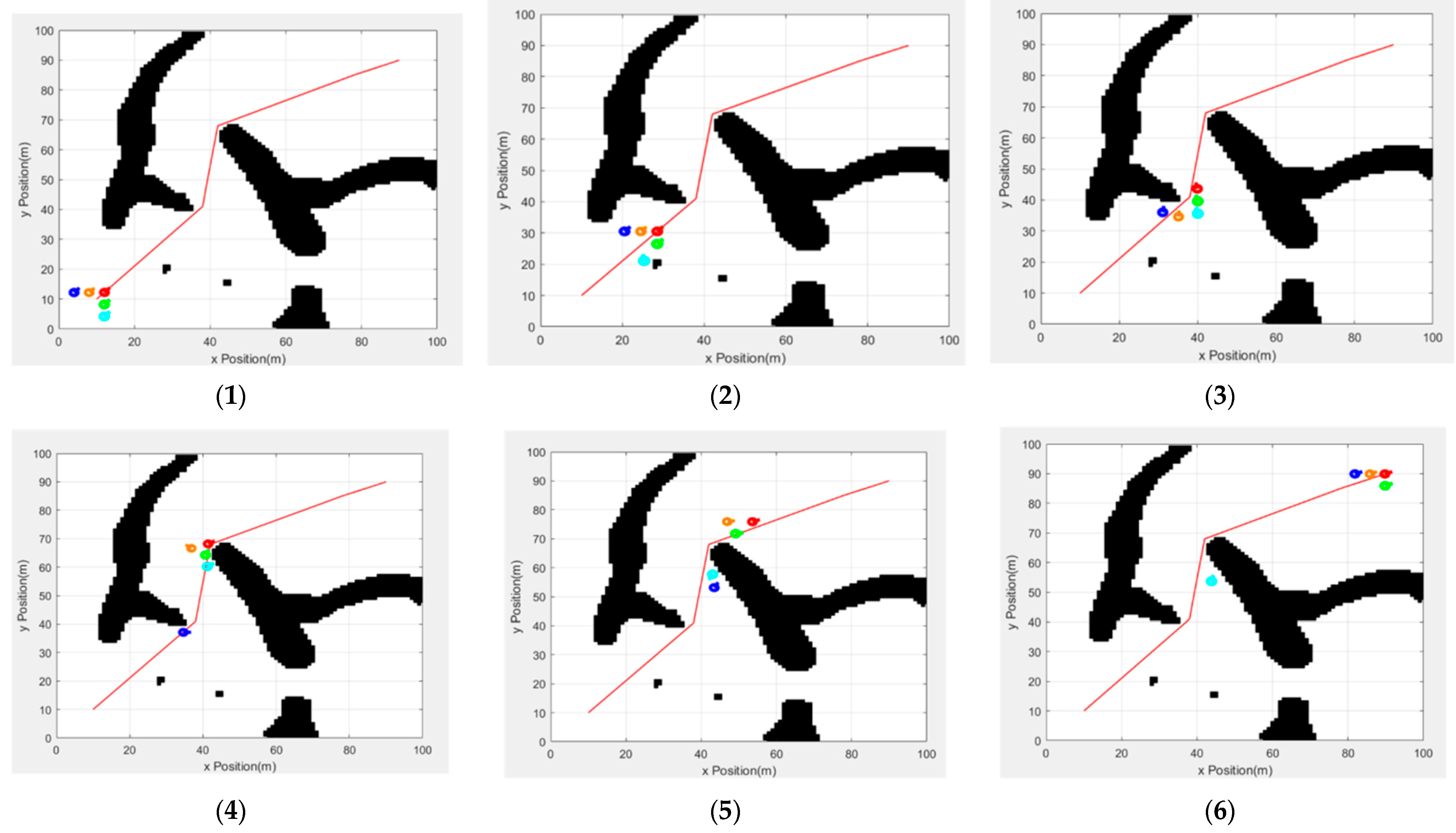

Based on the global path obtained by the leader, this paper combines the consistent control algorithm and the artificial potential field method to realize multirobot formation driving. To ensure that the robot team can avoid obstacles while maintaining formation stability when encountering obstacles, this paper proposes a formation conversion mechanism based on polar coordinate conversion and combines it with a new artificial potential field method to realize multirobot formation driving. To verify the effectiveness of the proposed strategy, it is compared with the traditional strategy without a formation conversion mechanism.

Figure 15 shows the formation driving process of the traditional artificial potential field method without a formation conversion mechanism.

Figure 15(1) shows the beginning of the experiment. The team’s formation is based on the wild goose formation, and the leader runs in turn with the path point of the global path as the stage target.

Figure 15(2) shows the autonomous obstacle avoidance process of the light blue follower robot when the team encounters obstacles for the first time.

Figure 15(3) shows the process of the leader turning and changing the target when reaching the stage target point. At this time, owing to the lack of a formation conversion mechanism, the formation has gradually collapsed.

Figure 15(4) shows the situation in which the leader reaches the next target point. At this time, the dark blue follower separates from the team due to obstacles;

Figure 15(5) shows the leader’s driving process toward the end point. The dark blue and light blue followers separate from the team again due to obstacles; the formation has completely collapsed.

Figure 15(6) shows that the leader has reached the end point. However, the light blue follower has not yet returned to the team, resulting in mission failure.

Figure 16 shows the formation driving process combined with the formation conversion mechanism and the new artificial potential field method. In

Figure 16(1), at the beginning of the experiment, the team is based on the wild goose formation, and the leader runs in turn with the path point of the global path as the stage target. In

Figure 16(2), the team encounters obstacles for the first time. The right-side followers find the obstacle and change formation to move closer to the middle. In

Figure 16(3), when the stage target point is reached, the leader switches the target. At this time, the left-side followers detect that the obstacle is moving closer to the middle, and the right-side followers spread out. In

Figure 16(4), the leader reaches the next target point and is ready to turn. At this time, the followers on the right side detect that the obstacle is moving closer to the middle, and the formation follows the leader to turn. In

Figure 16(5), the leader is driving toward the end point, and the formation follows the leader to complete the turn. Finally, in

Figure 16(6), the leader reaches the end point. All the robots successfully reach the end point, maintain a certain formation during driving, and successfully complete the task.

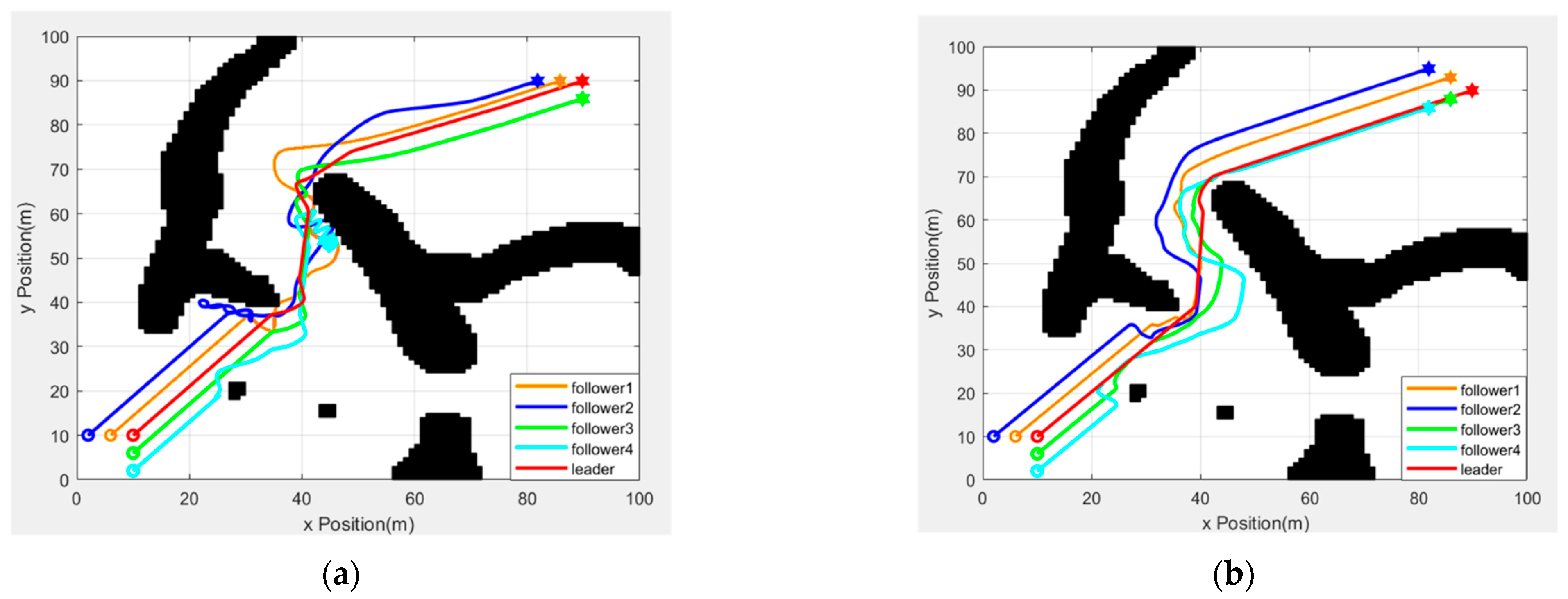

Figure 17 shows the formation trajectory diagram of the robots in the two experiments. In

Figure 17a, the trajectory without the formation conversion mechanism is shown.

Figure 17b shows the trajectory after the formation conversion mechanism is introduced. After introducing the formation conversion mechanism, the robot team can avoid obstacles via conversion when encountering obstacles and avoid the loss of followers. In contrast, the trajectory without the formation conversion mechanism is more chaotic. This means that the overall formation is not working well, and that some followers go missing. This further proves the importance of the formation conversion mechanism.

6. Summary

With respect to the leader–follower formation control method, this paper proposes a sample-based global path planning algorithm, DDRRT, to provide high-quality global paths for the leader. The algorithm restricts the selection and expansion of tree vertices through density detection to improve the utilization rate of each vertex as much as possible. To address the low quality of the path generated by the sampling algorithm, a rope contraction path optimization strategy is proposed. The initial path is simulated as a rope and stretches at both ends to reduce the path length and improve the path quality. This paper improves the potential field function of the artificial potential field method and introduces a rotating potential field to solve the local obstacle avoidance problem of multiple mobile robots. Finally, to solve the problems of slow obstacle avoidance and inability to turn into the consistency control algorithm, an obstacle avoidance mechanism based on formation conversion and a formation turning strategy based on polar coordinate conversion are proposed. Experimental simulations show that the proposed algorithm runs stably and can realize multirobot cooperative formation operations. Although DDRRT performs well in simulation experiments, it still has some limitations in practical applications. First, DDRRT’s computational complexity is relatively high, especially in high-dimensional state spaces or large-scale robot formations, which may limit its real-time performance. Second, DDRRT is primarily designed for static environments, and in dynamic environments (e.g., with moving obstacles or uncertain conditions), it needs to be combined with prediction models or methods such as the Dynamic Window Approach (DWA) to improve adaptability. Additionally, DDRRT relies heavily on sensor accuracy and environmental modeling, and its performance may degrade in real-world applications due to sensor noise or environmental modeling errors. Future research will focus on reducing DDRRT’s computational complexity, enhancing its real-time performance in dynamic environments, and exploring its potential in more complex scenarios.