Sensitivity Enhancement of Polymer Optical Fiber Surface Plasmon Resonance Sensor Utilizing ITO Overlayer

Abstract

1. Introduction

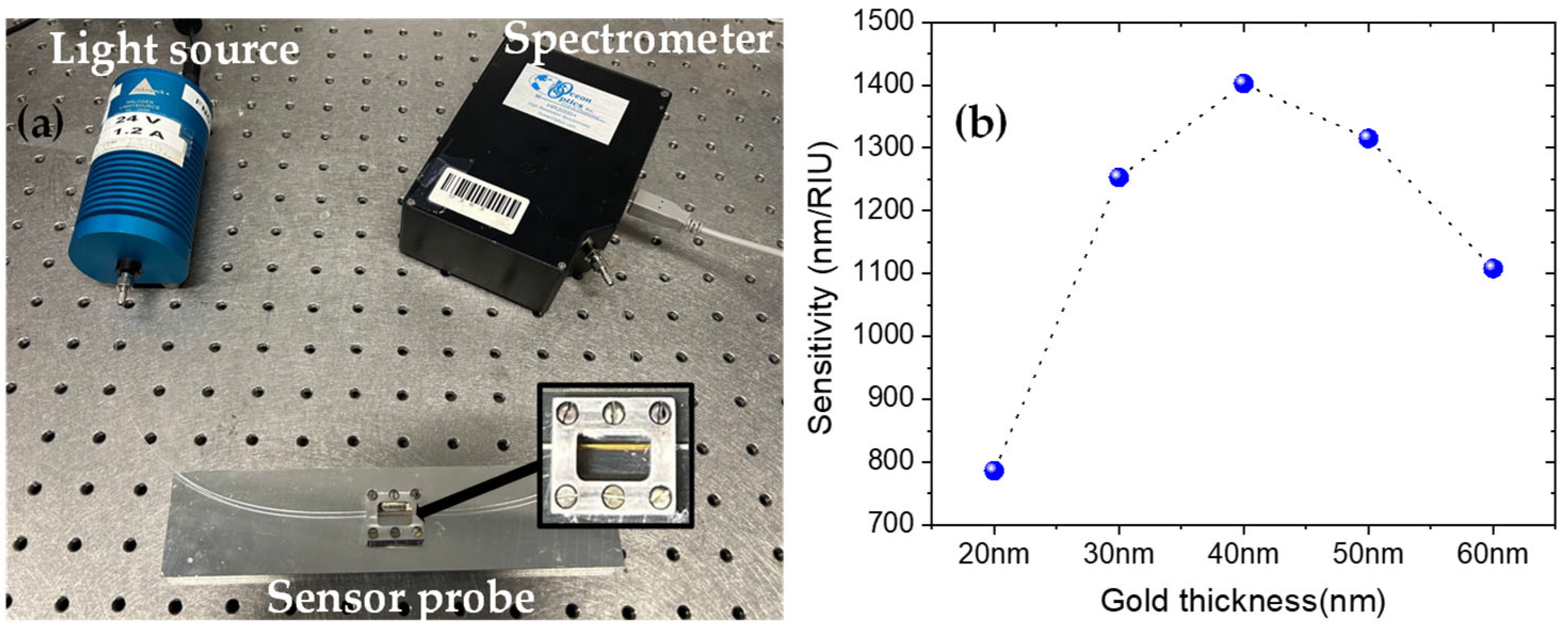

2. Materials and Methods

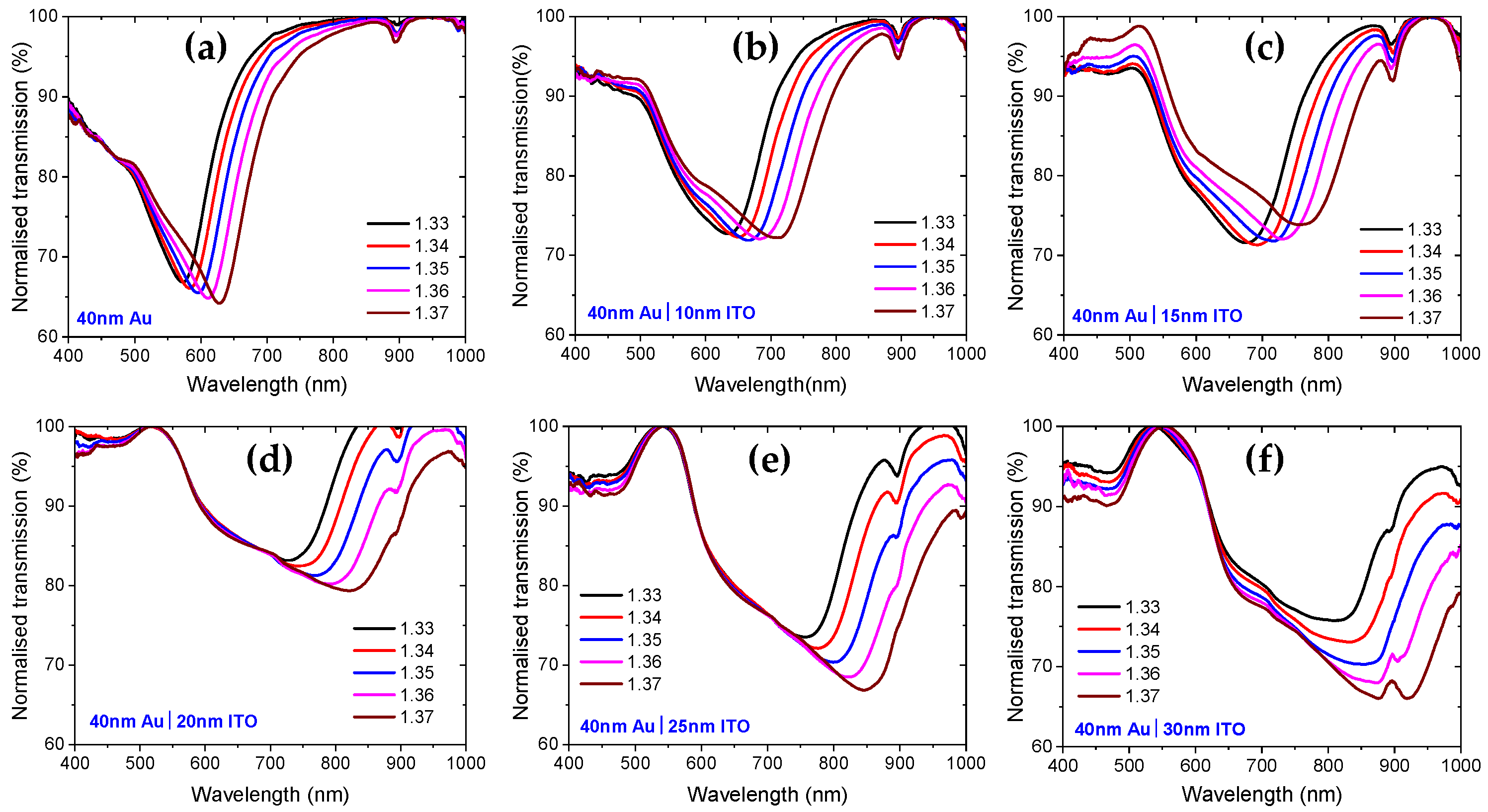

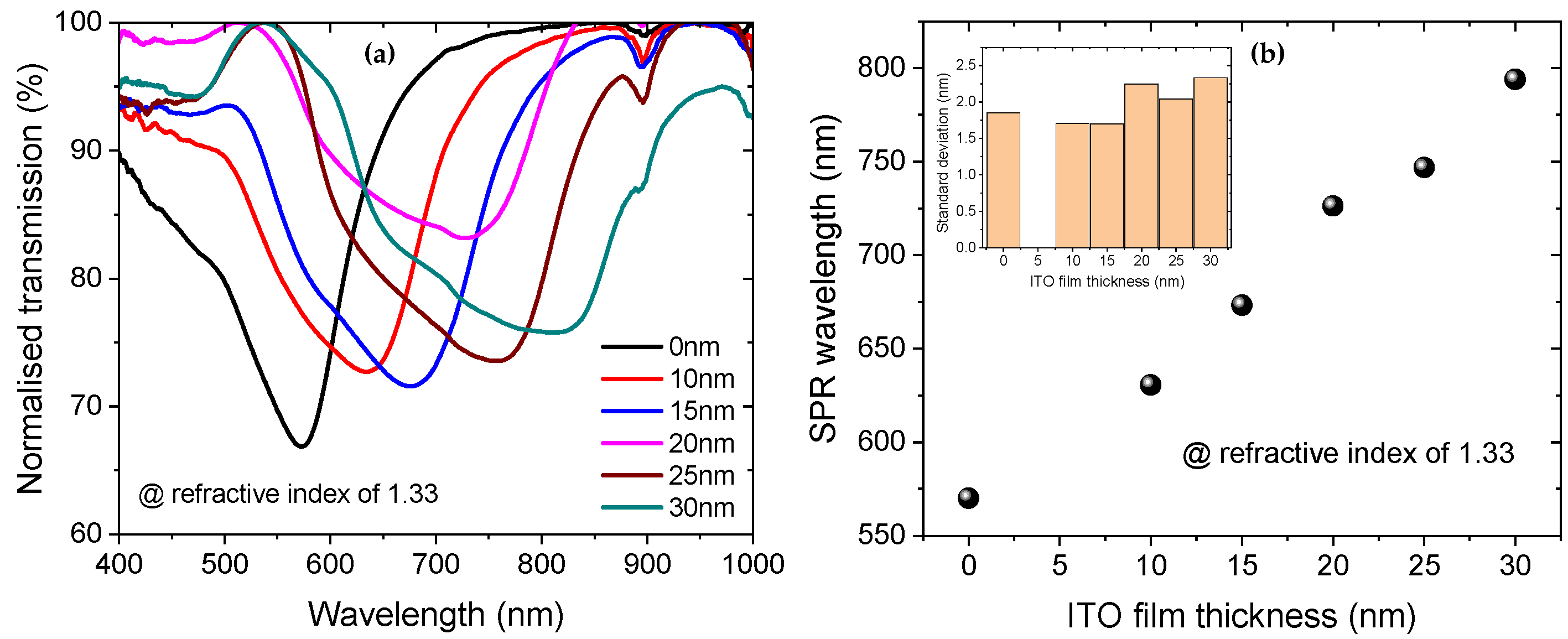

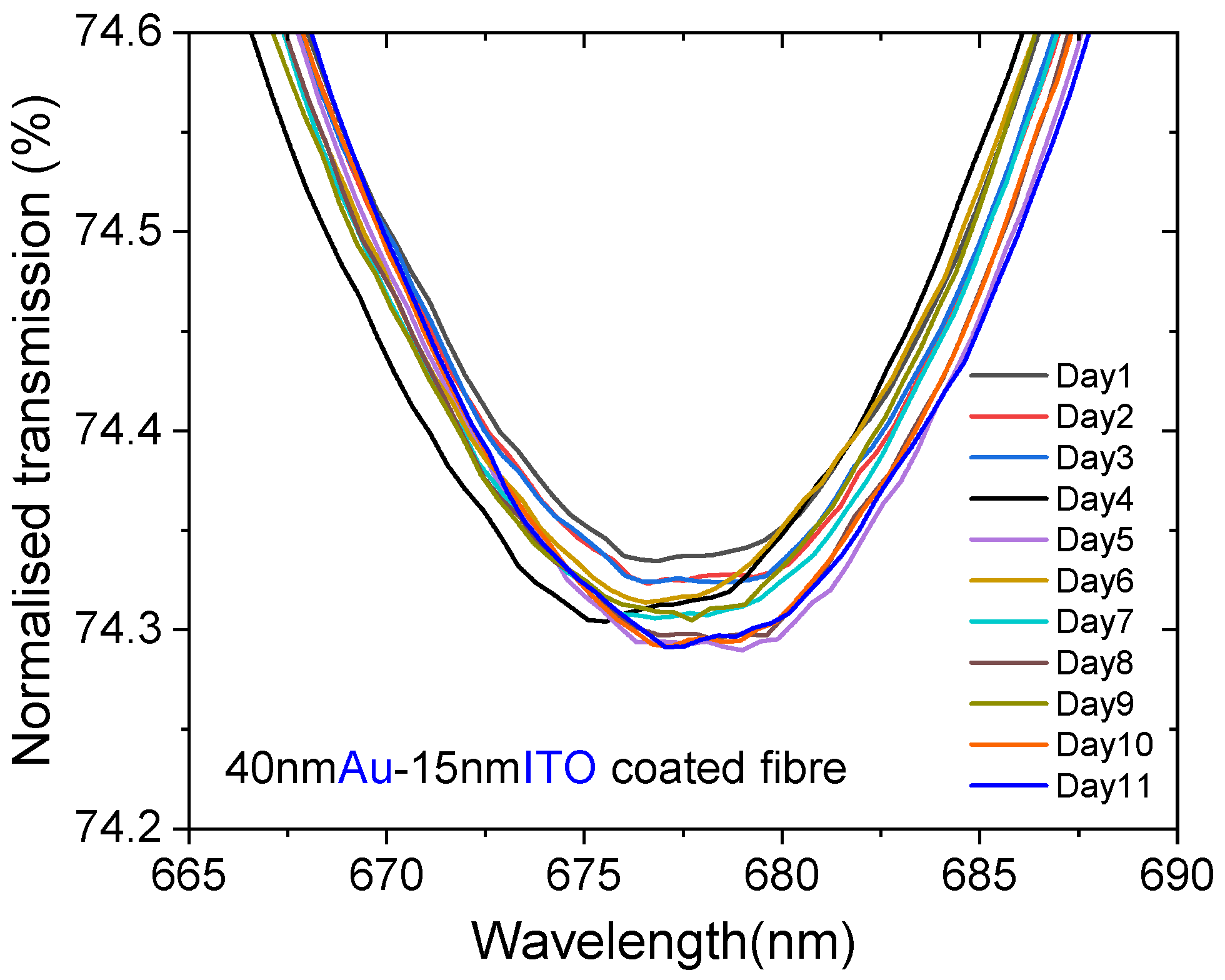

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yesudasu, V.; Pradhan, H.S.; Pandya, R.J. Recent progress in surface plasmon resonance based sensors: A comprehensive review. Heliyon 2021, 7, e06321. [Google Scholar] [CrossRef]

- Chauhan, M.; Singh, V.K. Review on recent experimental SPR/LSPR based fiber optic analyte sensors. Opt. Fiber Technol. 2021, 64, 102580. [Google Scholar] [CrossRef]

- Kretschmann, E.; Raether, H. Radiative decay of non-radiative surface plasmons excited by light. Z. Naturforsch. 1968, 23, 2135–2136. [Google Scholar] [CrossRef]

- Jorgenson, R.C.; Yee, S.S. A fiber-optic chemical sensor based on surface plasmon resonance. Sens. Actuators B Chem. 1993, 12, 213–220. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, W. Fiber-Optic Surface Plasmon Resonance Sensors and Biochemical Applications: A Review. J. Light. Technol. 2021, 39, 3781–3791. [Google Scholar] [CrossRef]

- Sharma, A.K.; Jha, R.; Gupta, B.D. Fiber-optic sensors based on surface plasmon resonance: A comprehensive review. IEEE Sens. J. 2007, 7, 1118–1129. [Google Scholar] [CrossRef]

- Masson, J.-F. Portable and field-deployed surface plasmon resonance and plasmonic sensors. Analyst 2020, 145, 3776–3800. [Google Scholar] [CrossRef]

- Gupta, B.D.; Verma, R.; Srivastava, S.K. Fiber Optic Sensors Based on Plasmonics; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2015. [Google Scholar]

- Cennamo, N.; Massarotti, D.; Conte, L.; Zeni, L. Low cost sensors based on SPR in a plastic optical fiber forbiosensor implementation. Sensors 2011, 11, 11752–11760. [Google Scholar]

- Gasior, K.; Martynkien, T.; Napiorkowski, M.; Zolnacz, K.; Mergo, P.; Urbanczyk, W. A surface plasmon resonance sensor based on a single mode D-shape polymer optical fiber. J. Opt. 2017, 19, 1–7. [Google Scholar] [CrossRef]

- Cao, S.; Shao, Y.; Wang, Y.; Wu, T.; Zhang, L.; Huang, Y.; Zhang, F.; Liao, C.; He, J.; Wang, Y. Highly sensitive surface plasmon resonance biosensor based on a low-index polymer optical fiber. Opt. Express 2018, 26, 3988. [Google Scholar] [CrossRef]

- Teng, C.; Wang, Y.; Yuan, L. Polymer optical fibers based surface plasmon resonance sensors and their applications: A review. Opt. Fiber Technol. 2023, 77, 103256. [Google Scholar] [CrossRef]

- Kadhim, R.A.; Abdul, A.K.K.; Yuan, L. Advances in Surface Plasmon Resonance-Based Plastic Optical Fiber Sensors. IETE Tech. Rev. 2022, 39, 442–459. [Google Scholar] [CrossRef]

- Wu, X.; Wang, Y.; Zhang, J.; Zhang, Y.; Rao, X.; Chen, C.; Liu, H.; Deng, Y.; Liao, C.; Smietana, M.J.; et al. A D-Shaped Polymer Optical Fiber Surface Plasmon Resonance Biosensor for Breast Cancer Detection Applications. Biosensors 2023, 14, 15. [Google Scholar] [CrossRef]

- Wang, Y.; Rao, X.; Wu, X.; Chen, G.Y.; Liao, C.; Smietana, M.J.; Wang, Y. Highly-Sensitive Polymer Optical Fiber SPR Sensor for Fast Immunoassay. Photonic Sens. 2024, 14, 1–11. [Google Scholar] [CrossRef]

- Cennamo, N.; Arcadio, F.; Minardo, A.; Montemurro, D.; Zeni, L. Experimental characterization of plasmonic sensors based on lab-built tapered plastic optical fibers. Appl. Sci. 2020, 10, 4389. [Google Scholar] [CrossRef]

- Christopher, C.; Subrahmanyam, A.; Sai, V.V.R. Gold Sputtered U-Bent Plastic Optical Fiber Probes as SPR- and LSPR-Based Compact Plasmonic Sensors. Plasmonics 2018, 13, 493–502. [Google Scholar] [CrossRef]

- Liu, L.; Deng, S.; Zheng, J.; Yuan, L.; Deng, H.; Teng, C. An enhanced plastic optical fiber-based surface plasmon resonance sensor with a double-sided polished structure. Sensors 2021, 21, 1516. [Google Scholar] [CrossRef]

- Dwivedi, Y.S.; Sharma, A.K.; Gupta, B.D. Influence of design parameters on the performance of a surface plasmon sensor based fiber optic sensor. Plasmonics 2008, 3, 79–86. [Google Scholar] [CrossRef]

- Wei, W.; Hong, R.; Jing, M.; Shao, W.; Tao, C.; Zhang, D. Thickness-dependent surface plasmon resonance of ITO nanoparticles for ITO/In-Sn bilayer structure. Nanotechnology 2018, 29, 015705. [Google Scholar] [CrossRef]

- Shalabney, A.; Abdulhalim, I. Electromagnetic fields distribution in multilayer thin film structures and the origin of sensitivity enhancement in surface plasmon resonance sensors. Sens. Actuators A Phys. 2010, 159, 24–32. [Google Scholar] [CrossRef]

- Lahav, A.; Auslender, M.; Abdulhalim, I. Sensitivity enhancement of guided-wave surface-plasmon resonance sensors. Opt. Lett. 2008, 33, 2539. [Google Scholar] [CrossRef]

- Bhatia, P.; Gupta, B.D. Surface-plasmon-resonance-based fiber-optic refractive index sensor: Sensitivity enhancement. Appl. Opt. 2011, 50, 2032–2036. [Google Scholar] [CrossRef]

- Singh, S.; Mishra, S.K.; Gupta, B.D. Sensitivity enhancement of a surface plasmon resonance based fibre optic refractive index sensor utilizing an additional layer of oxides. Sens. Actuators A Phys. 2013, 193, 136–140. [Google Scholar] [CrossRef]

- Kashyout, A.E.H.B.; Fathy, M.; Soliman, M.B. Studying the properties of RF-sputtered nanocrystalline tin-doped indium oxide. Int. J. Photoenergy 2011, 2011, 139374. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Dong, J.; Hu, S.; Zhu, W.; Qiu, W.; Lu, H.; Yu, J.; Guan, H.; Gao, S.; et al. Sensitivity-enhanced surface plasmon resonance sensor utilizing a tungsten disulfide (WS2) nanosheets overlayer. Photonics Res. 2018, 6, 485. [Google Scholar] [CrossRef]

- Chen, S.; Liu, C.; Liu, Y.; Liu, Q.; Lu, M.; Bi, S.; Jing, Z.; Yu, Q.; Peng, W. Label-Free Near-Infrared Plasmonic Sensing Technique for DNA Detection at Ultralow Concentrations. Adv. Sci. 2020, 7, 2000763. [Google Scholar] [CrossRef]

- Samad, F.A.; Abdel-wahab, M.S.; Tawfik, W.Z.; Qayyum, H.; Apsari, R.; Mohamed, T. Thickness-dependent nonlinear optical properties of ITO thin films. Opt. Quantum Electron. 2023, 55, 753. [Google Scholar] [CrossRef]

- Homola, J. On the sensitivity of surface plasmon resonance sensors with spectral interrogation. Sens. Actuators B Chem. 1997, 41, 207–211. [Google Scholar] [CrossRef]

- Yin, Z.; Jing, X.; Li, K.; Zhang, Z. Cascaded dual-channel broadband SPR fiber optic sensor based on Ag/ZnO and Ag/TiO2/PDMS films structure. Opt. Laser Technol. 2024, 174, 110579. [Google Scholar] [CrossRef]

- Yin, Z.; Jing, X.; Bai, G.; Wu, B.; Gao, Z.; Liu, C.; Wang, C.; Li, Y. Experimental Study of Dual-Parameter SPR Sensor With Integrated Sensing Channel. IEEE Sens. J. 2023, 23, 8385–8390. [Google Scholar] [CrossRef]

- Yin, Z.; Jing, X.; Li, K.; Zhang, Z.; Li, J. Modulation of the sensing bandwidth of dual-channel SPR sensors by TiO2 film. Opt. Laser Technol. 2024, 169, 110105. [Google Scholar] [CrossRef]

- Cennamo, N.; Massarotti, D.; Galatus, R.; Conte, L.; Zeni, L. Performance comparison of two sensors based on surface plasmon resonance in a plastic optical fiber. Sensors 2013, 13, 721–735. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woyessa, G.; Bang, O. Sensitivity Enhancement of Polymer Optical Fiber Surface Plasmon Resonance Sensor Utilizing ITO Overlayer. Sensors 2025, 25, 1863. https://doi.org/10.3390/s25061863

Woyessa G, Bang O. Sensitivity Enhancement of Polymer Optical Fiber Surface Plasmon Resonance Sensor Utilizing ITO Overlayer. Sensors. 2025; 25(6):1863. https://doi.org/10.3390/s25061863

Chicago/Turabian StyleWoyessa, Getinet, and Ole Bang. 2025. "Sensitivity Enhancement of Polymer Optical Fiber Surface Plasmon Resonance Sensor Utilizing ITO Overlayer" Sensors 25, no. 6: 1863. https://doi.org/10.3390/s25061863

APA StyleWoyessa, G., & Bang, O. (2025). Sensitivity Enhancement of Polymer Optical Fiber Surface Plasmon Resonance Sensor Utilizing ITO Overlayer. Sensors, 25(6), 1863. https://doi.org/10.3390/s25061863