1. Introduction

The reliability and efficiency of machinery are of paramount importance in modern industry. Maintenance strategies such as condition-based maintenance (CBM) and predictive maintenance (PM) have therefore gained increasing importance, especially with the introduction of Industry 4.0 [

1,

2,

3,

4]. As a result, online condition monitoring and fault diagnosis (FD) of electromechanical systems have become crucial tasks in many industrial applications. Condition monitoring, upon which CBM and PM are based, involves tracking the system state of health to detect fault occurrences [

2,

5,

6]. Indeed, early detection and identification of faults allow minimizing downtime, optimizing maintenance schedules, and preventing costly repairs.

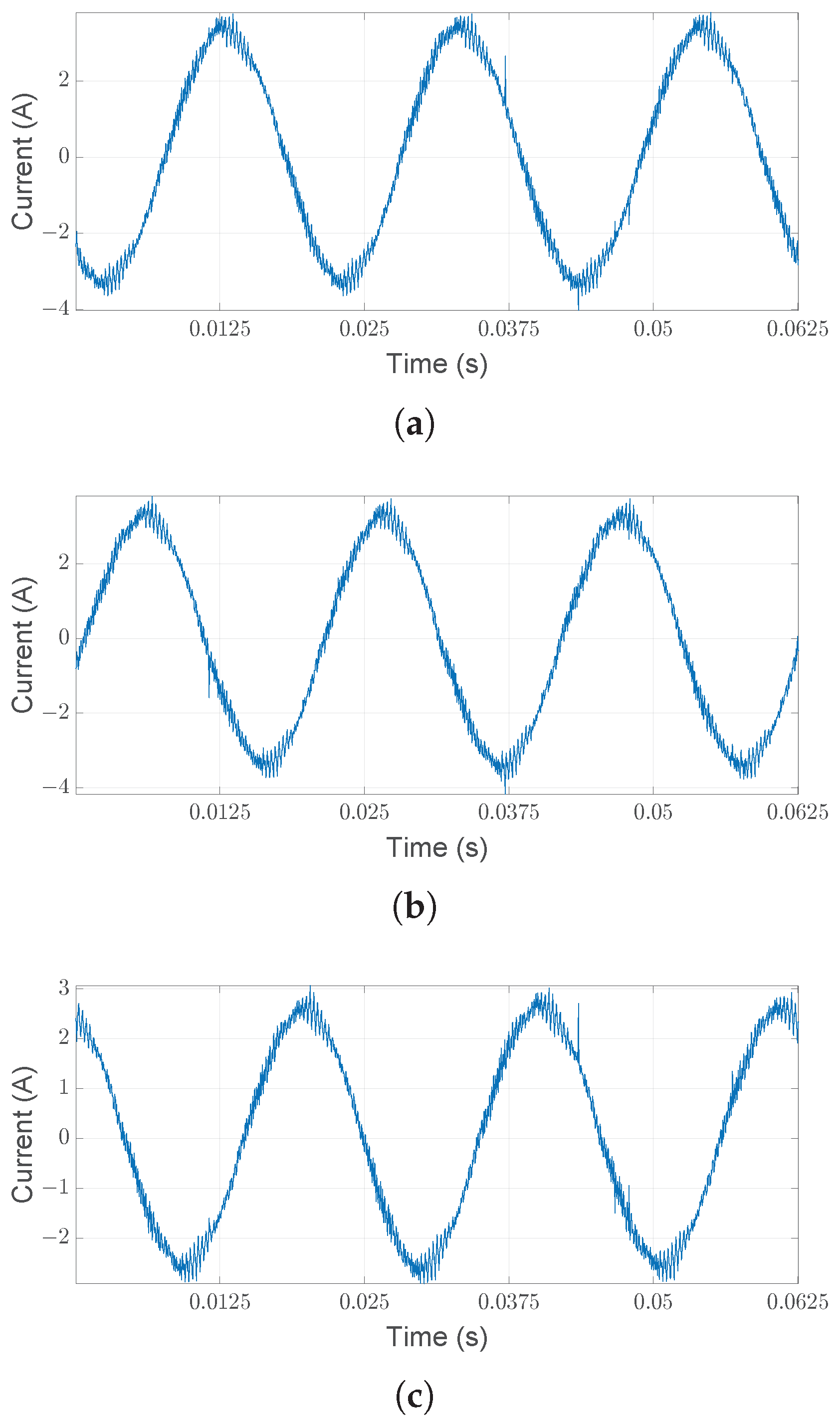

Any condition monitoring (CM) procedure requires sensor measurements and analysis of signals (such as vibration, speed, current, and temperature) that are relevant to the performance state of the system’s components. Although vibration analysis remains the most widely used method [

5,

7,

8], motor current signature analysis (MCSA) has gained increasing attention in recent years [

9,

10,

11,

12,

13,

14,

15,

16,

17]. MCSA is a non-intrusive and cost-effective approach when compared to vibration-based techniques, as it relies only on the motor phase currents, which are already used in motor control. Other advantages over vibration analysis include simpler sensor installation, reduced sensitivity to sensor installation location, and less sensitivity to external factors such as background noise. Initially, this technique was adopted only to monitor electric motor components [

18,

19] (e.g., windings, rotor, bearings, resistance); this allows the tracking of the motor’s internal state of health, but it does not provide insight into the condition of the mechanical systems driven by the motor. In the last years, MCSA has also been applied to fault diagnosis of components in the mechanisms attached to the electric motor, such as gears [

9,

11,

13], bearings [

12,

13], belt conveyor systems [

16], and rotate vector reducers [

15]. In fact, faults in the mechanical load driven by the motor, such as bearing defects, gear misalignments, and unbalanced loads, manifest as changes in the motor’s current behavior [

9,

10,

12].

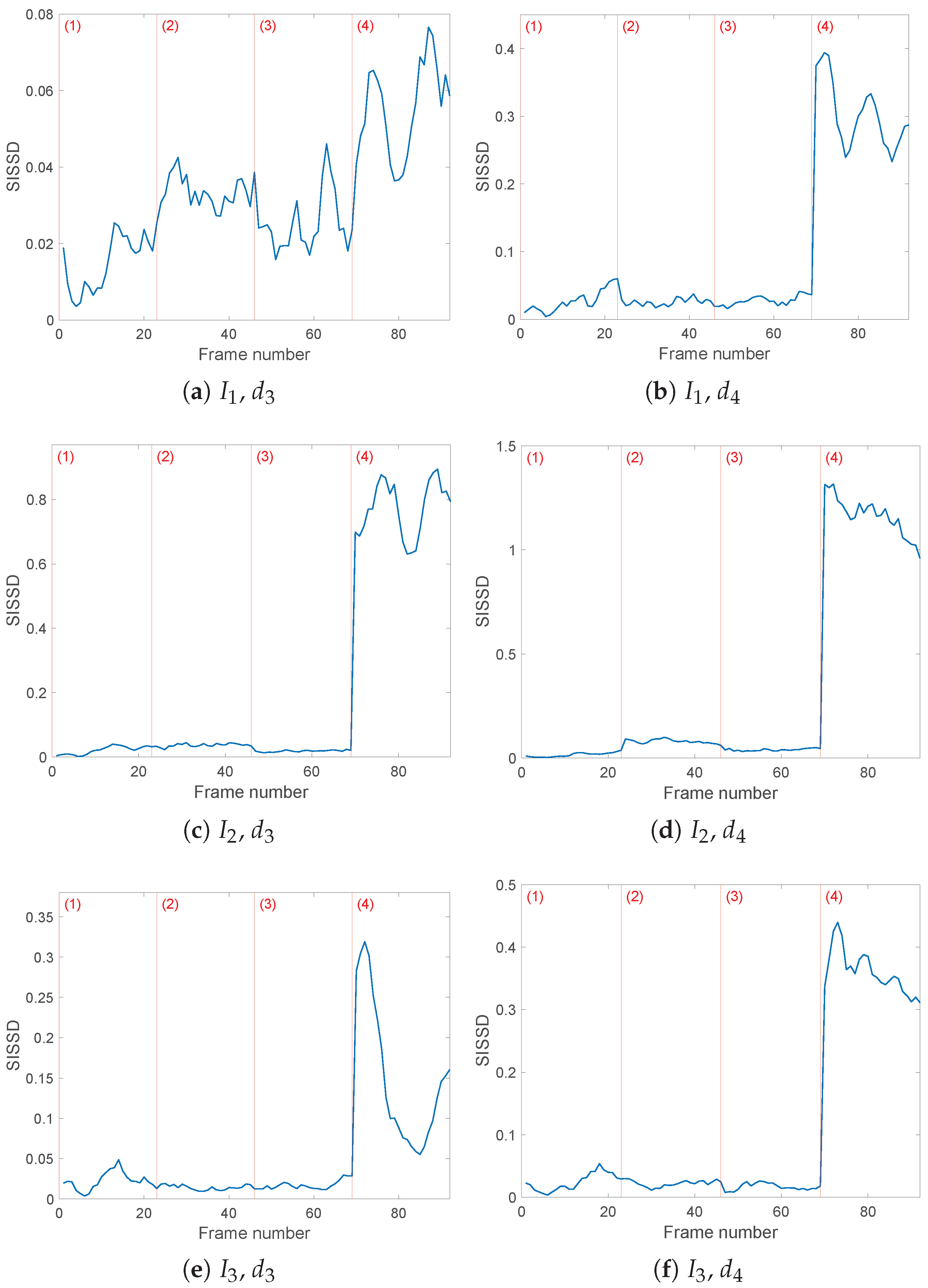

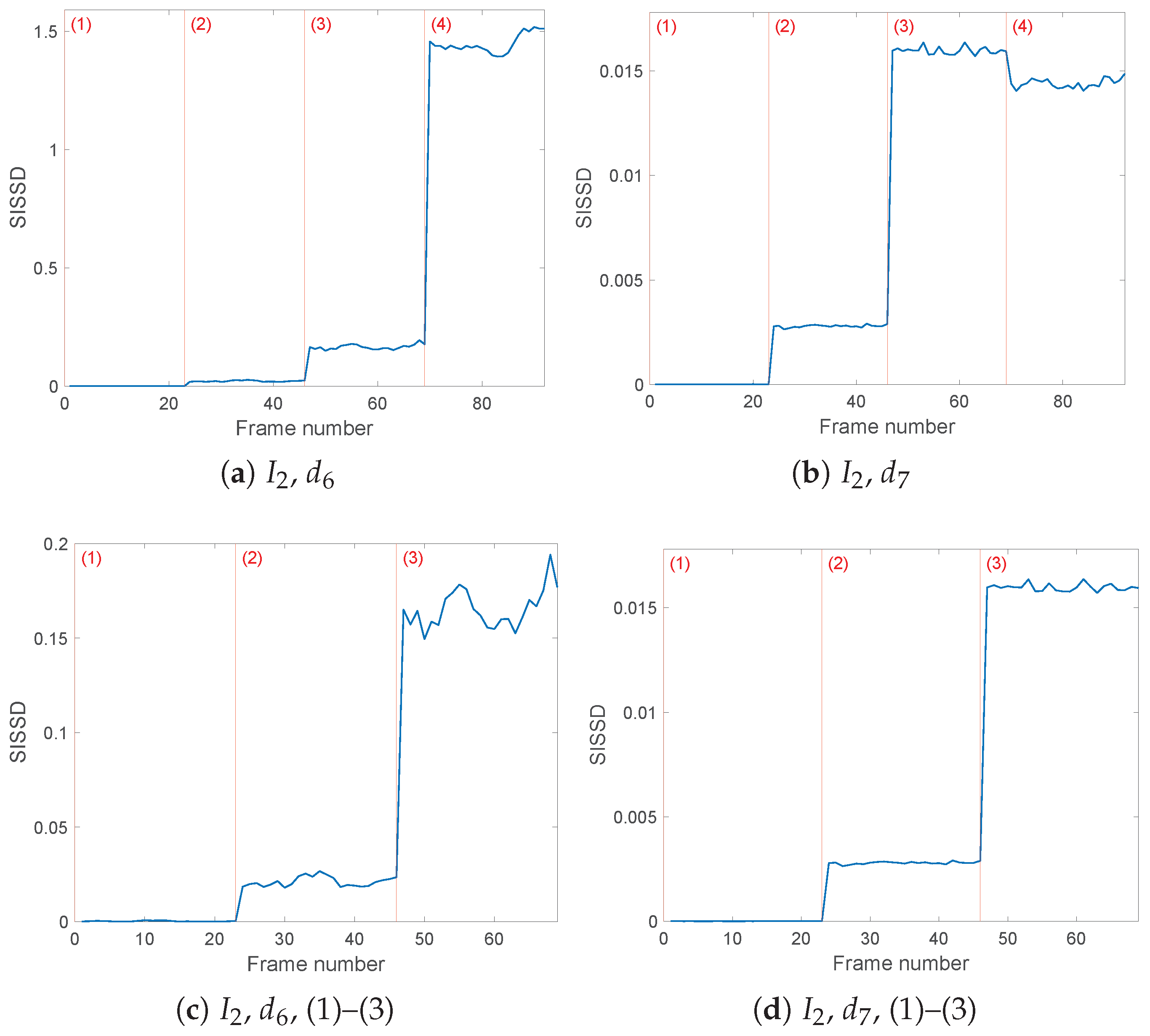

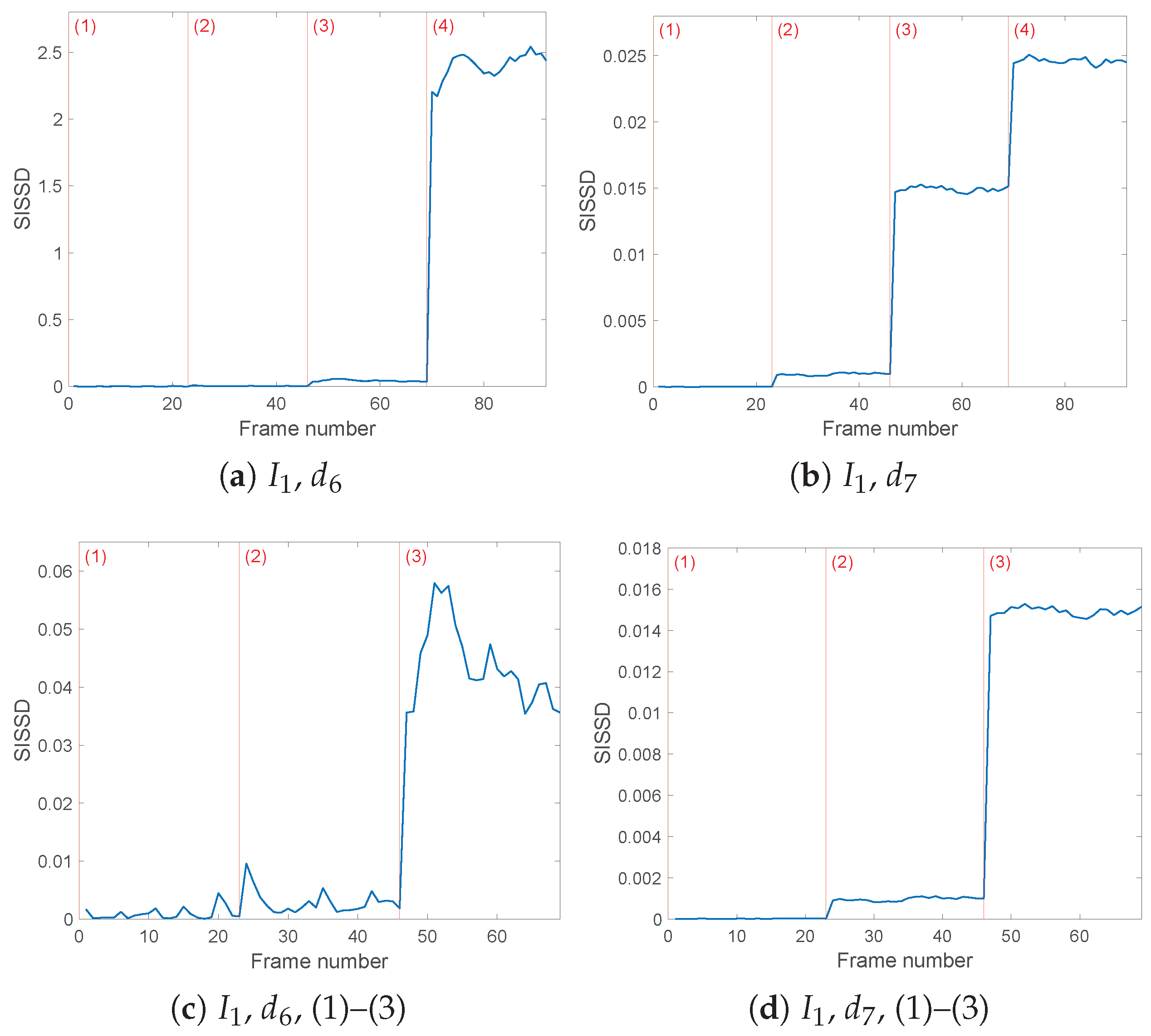

To extract features for FD from the raw current signals frequency domain, time–frequency domain, or combinations of time and frequency domain techniques have been proposed in the literature. In [

9], the discrete wavelet transform (DWT) is combined with fast Fourier transform (FFT) to trace the sidebands of the gear mesh frequencies (GMF). In [

10], amplitude demodulation and frequency demodulation are applied to the current drawn by the induction motor to detect the rotating shaft frequencies and GMFs. Then, DWT is applied for denoising. The effects induced by gear tooth surface damage faults on the torque oscillation profile are investigated in [

11]. In particular, it is shown that such effects produce fault-related frequencies in the stator current spectrum and specific harmonics as integer multiples of the rotation frequency in the stator current space vector instantaneous frequency spectrum. In [

12], an efficient method is presented for extracting defective bearing characteristics from the stator current of a loaded machine using the continuous wavelet transform (CWT) based on Morlet’s complex wavelet. In particular, a feature extraction technique is proposed to cope with the fact that the peaks in the frequency spectrum corresponding to the fault components have very low amplitudes and are usually obscured by noise. For this reason, 2D and 3D scalograms of stator current signatures for both healthy and damaged bearings were used to characterize the defects in the time–frequency domain. A health indicator that exploits both a time domain feature (peak-to-peak values) and a frequency domain feature (maximum value of the FFT) is proposed in [

13]. The obtained indicator is then used to classify gear and bearing faults through an adaptive neuro-fuzzy inference system. In [

14], data acquired from multiple current sensors are fused using a 2D convolutional neural network (CNN), with features extracted from the FFT spectra of the current signals. The CNN is used to classify different types of gear faults.

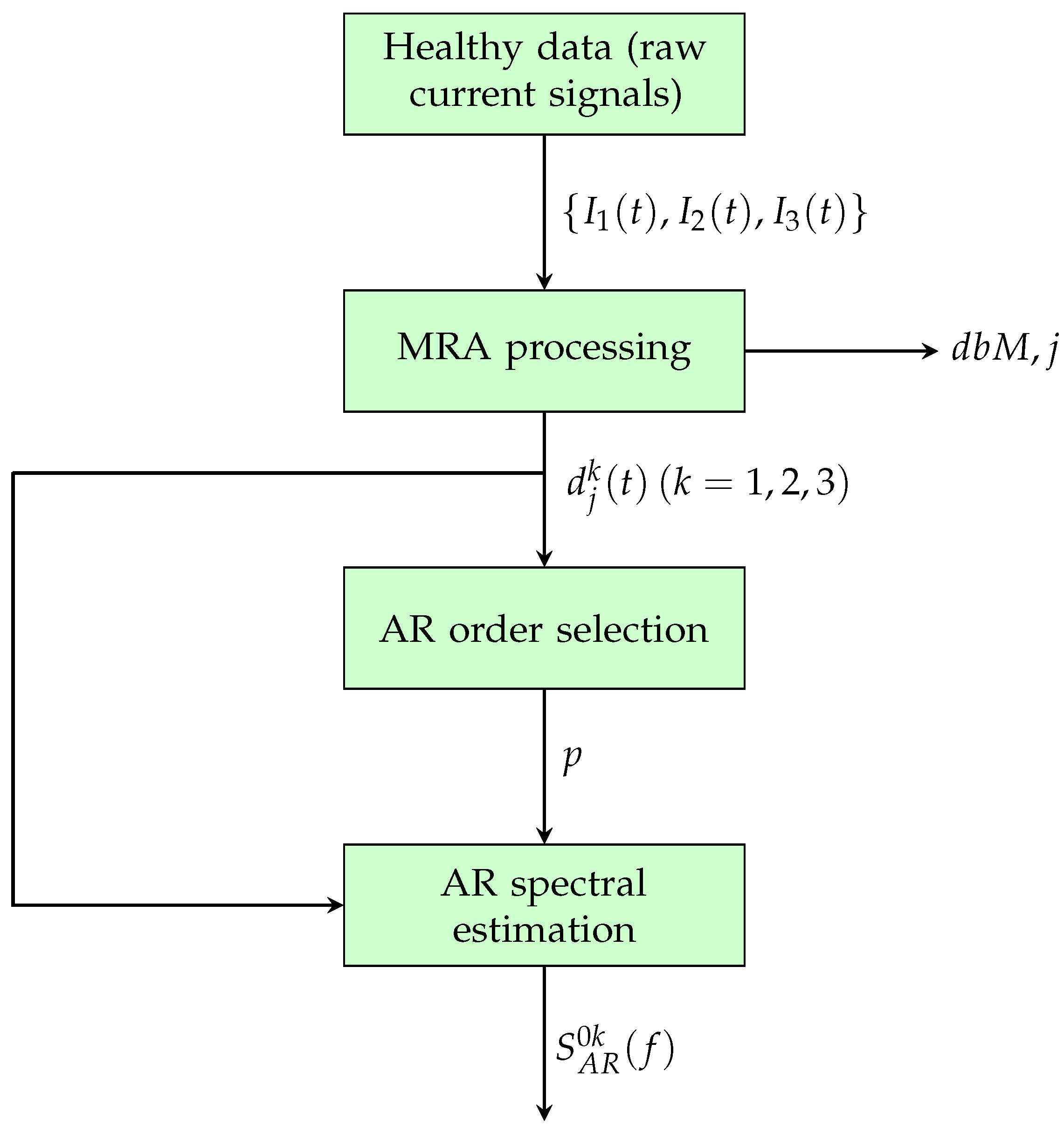

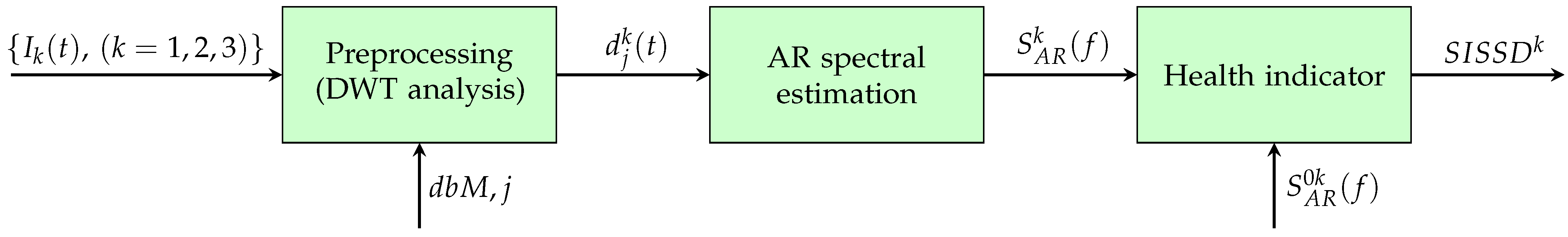

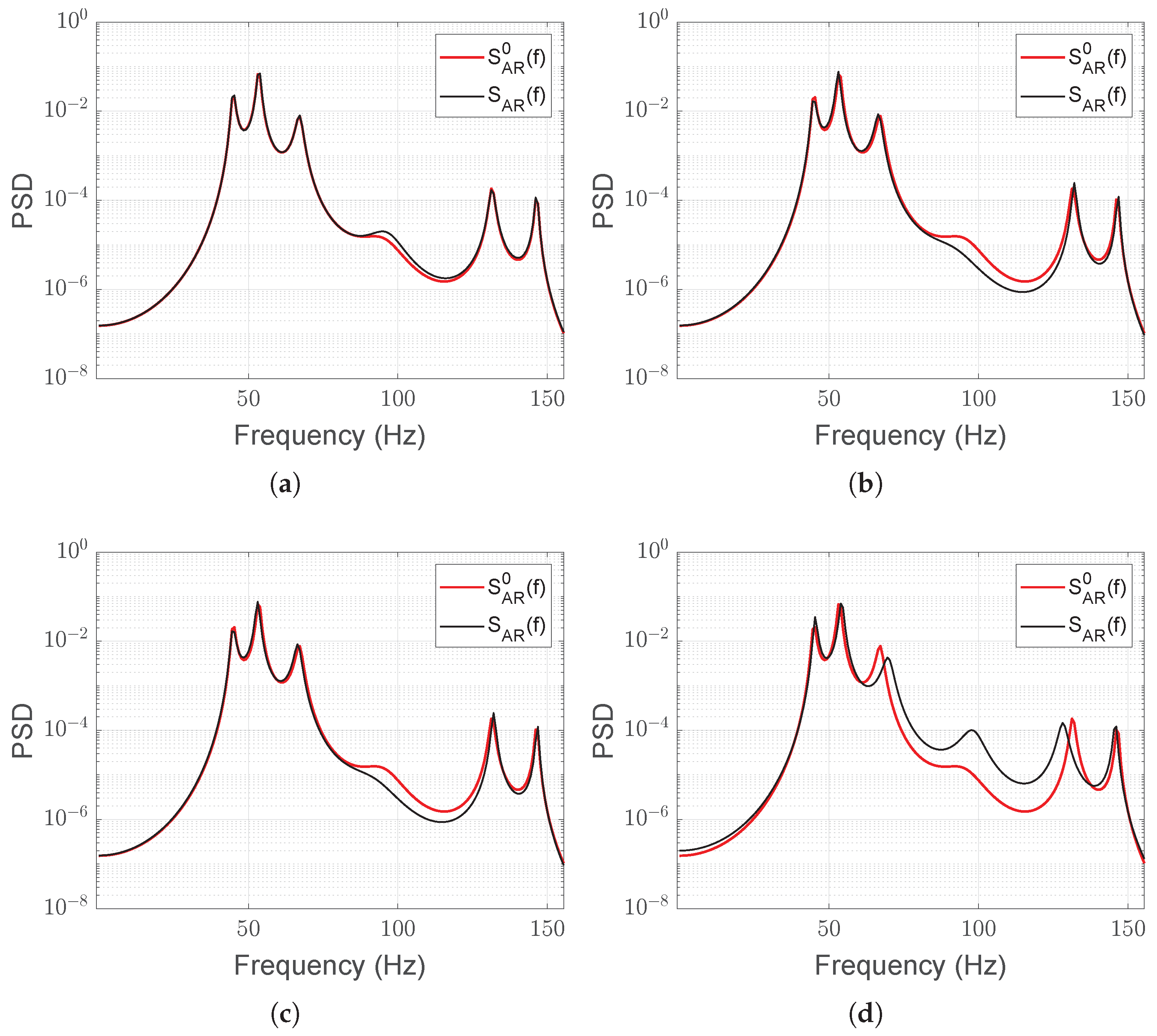

This paper proposes a method based on autoregressive (AR) spectral estimation of wavelet-processed motor currents. Autoregressive modeling is a very popular tool for time series analysis and spectral estimation [

20,

21,

22]. It is well known that AR models provide more accurate spectral estimates with respect to classical Fourier-transform-based methods, like periodograms and the Blackman–Tukey method. This is mainly due to the fact that, unlike FFT-based methods, the estimated AR spectra (power spectral densities) do not have the

transform response characteristic of conventional windowed spectra and therefore, they do not suffer from sidelobe leakage and spectral smearing. Moreover, the AR power spectral density (PSD) has been shown to be highly sensitive to system changes, making it particularly effective for fault diagnosis applications [

23,

24,

25,

26,

27,

28,

29,

30]. The AR PSD procedure to perform online condition monitoring requires first estimating a nominal AR model from data gathered under healthy conditions and its PSD. Afterwards, online condition monitoring is achieved by continuously or periodically estimating the AR model from the online data, as well as its PSD, and eventual departures from the nominal AR PSD are detected through several possible methods, in our case the symmetric Itakura–Saito distance, also referred to as COSH distance. An alternative procedure to quantify the dissimilarity between the current and nominal behavior could involve the Fourier spectra of the motor currents; however, this diagnostic process presents more difficulties compared to AR-based methods [

23,

24,

26,

27]. In cases where Fourier-based methods offered fault detection, the robustness of the detection thresholds was more critical than in the AR case, since the spectral distances were smaller [

26,

27].

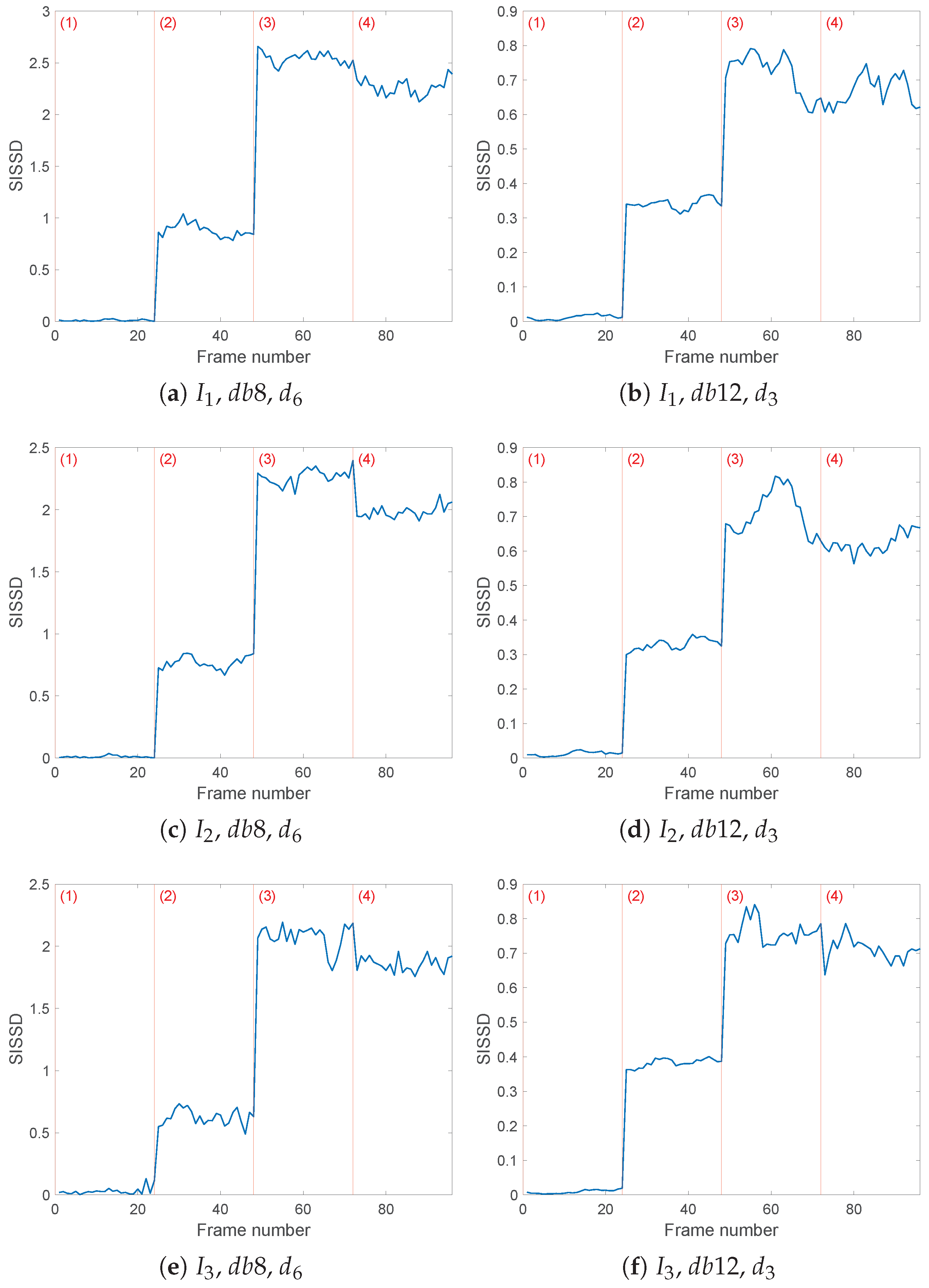

As mentioned above, AR modeling is not applied directly to the raw current signals. Instead, a multiresolution analysis (MRA) of the motor currents is first performed using the discrete wavelet transform with Daubechies filters [

31,

32]. Each current is decomposed into approximation and detail components. In particular, suitable levels are selected based on the approximate entropy criterion, and the associated detail components are the signals to which AR spectral estimation is applied. The MRA preprocessing phase enables the separation of noise, disturbances, and variable torque effects from the current signals. Consequently, the effects of faults are amplified, and more robust detection thresholds can be defined. In summary, the entire procedure combines the useful properties of the discrete wavelet transform (DWT) with the aforementioned advantages of AR spectral estimation. It is worth highlighting that the proposed method belongs to the so-called data-driven fault diagnosis approaches [

4,

5,

33,

34], as it does not rely on any physical knowledge of the electromechanical systems to be monitored. This also provides great versatility with regard to the type of components to be diagnosed (e.g., bearings, gears, shafts).

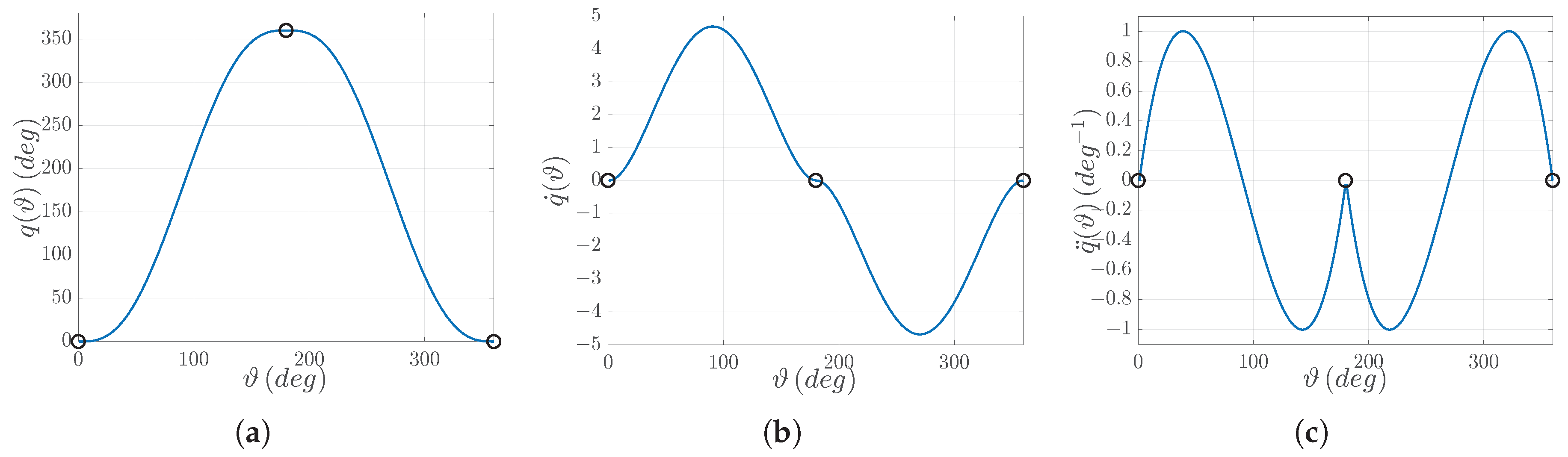

The proposed method has been validated by considering the effects of two very different situations on motor currents: unbalanced load and bearing failure. For the first case, real data were collected while performing electric cam movement tasks in a laboratory experiment. This is a very common situation, as many industrial machines rely on electric cams to perform complex tasks that require synchronization between the various mechanisms involved [

35]. In the second case, data were obtained from a public domain database [

36]. The findings obtained from both scenarios substantiate the efficacy of the method in detecting and isolating faults. It is worth highlighting that the proposed approach differs from those previously described as it does not reference a specific machine component or fault type. Moreover, the parameters required to determine the reference model are computed by using only data collected under healthy conditions. This is a very interesting aspect when fault diagnosis procedures are performed in real industrial contexts, where a large amount of data are collected during normal operating conditions, but very few data related to specific faulty conditions are available.

The remainder of the paper is structured as follows. The proposed fault diagnosis procedure is described in

Section 2. In particular, the whole procedure is first outlined. The multiresolution analysis of the raw current signals performed using a discrete wavelet transform is then described in

Section 2.1 and

Section 2.2 shows how to determine a health indicator by applying AR spectral estimation to the selected wavelet details.

Section 3 describes the testbeds on which the proposed approach was tested and discusses the obtained results.

Section 4 concludes the paper.

The nomenclature for the relevant variables used in the paper is provided in

Table 1.