Detection of Sub-pT Field of Magnetic Responses in Metals and Magnetic Materials by Highly Sensitive Magnetoresistive Sensors

Abstract

1. Introduction

2. Magnetic Response to the Applied Magnetic Field

3. Experiments

3.1. Measurement Samples

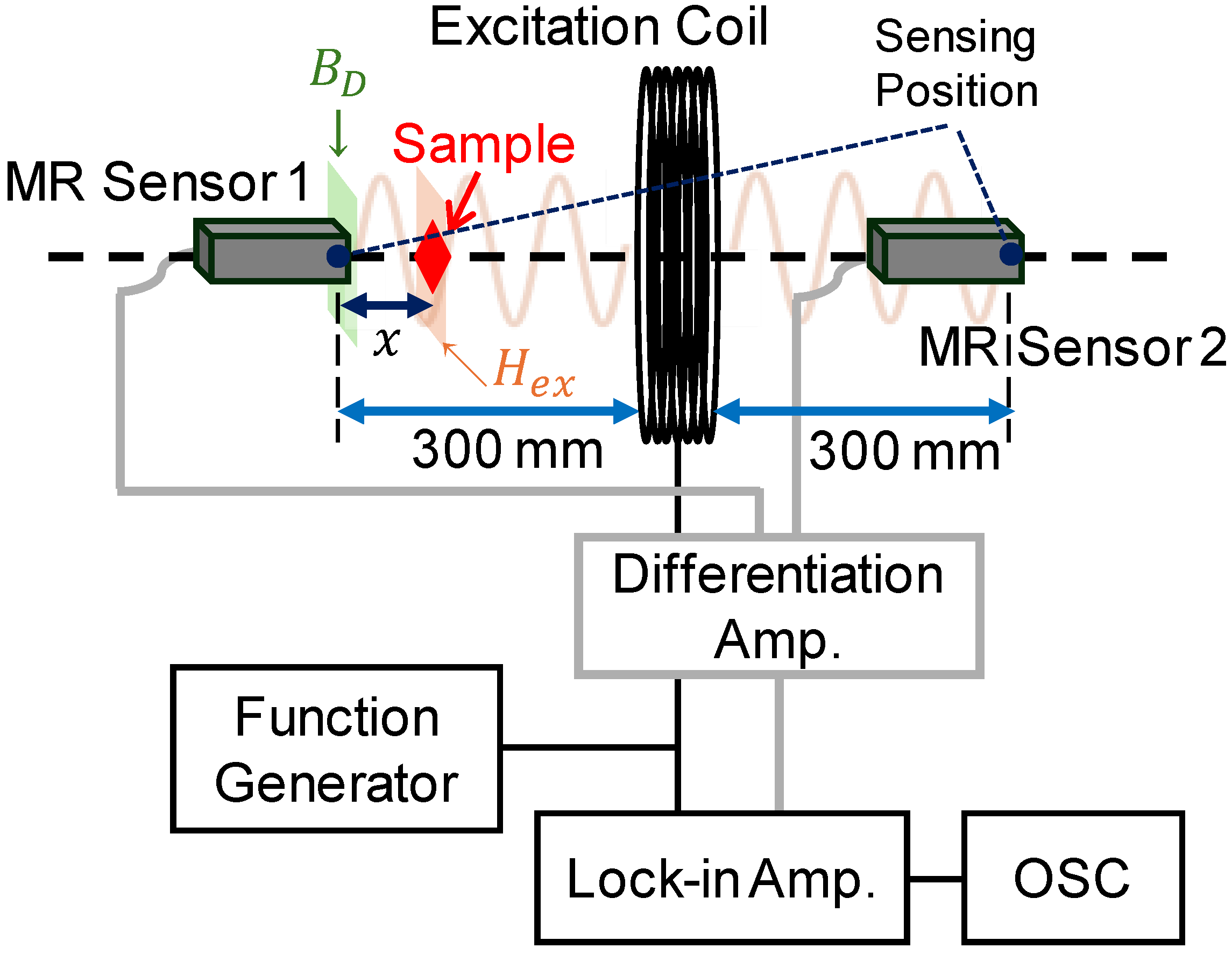

3.2. Measurement Method

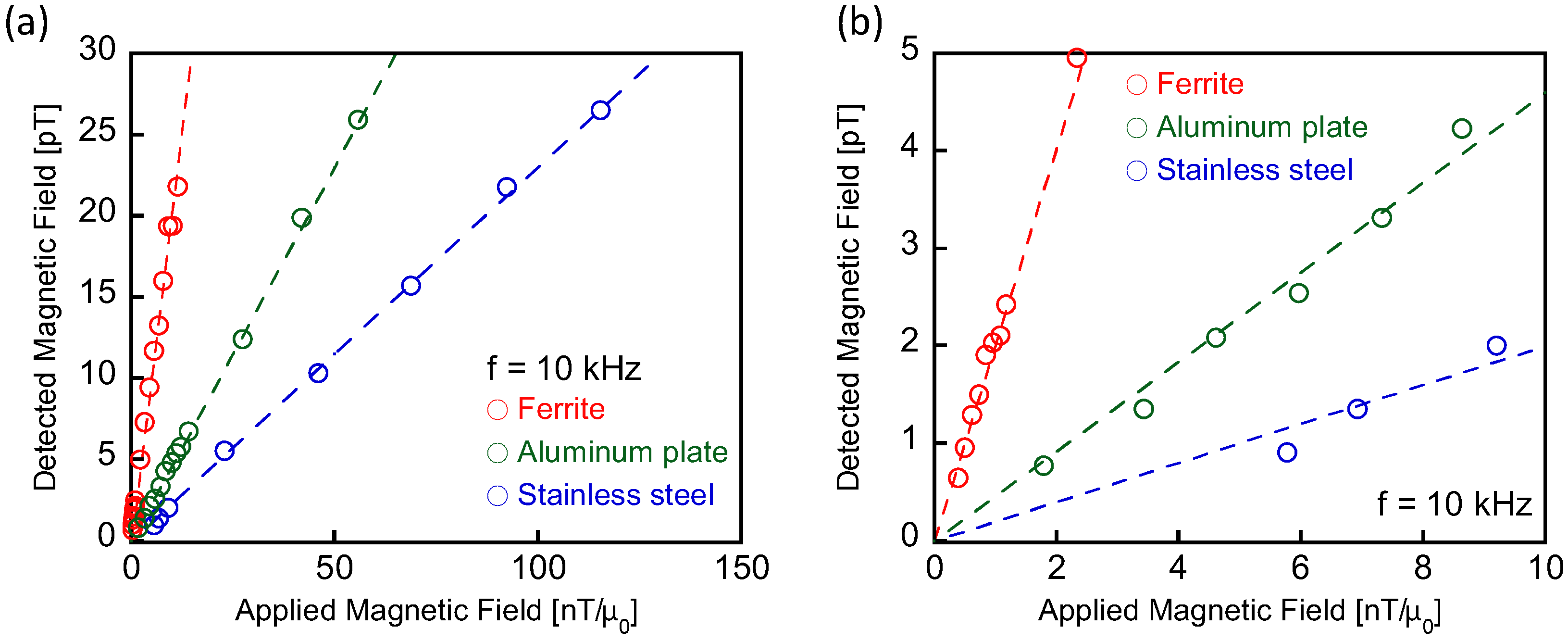

4. Results and Discussion

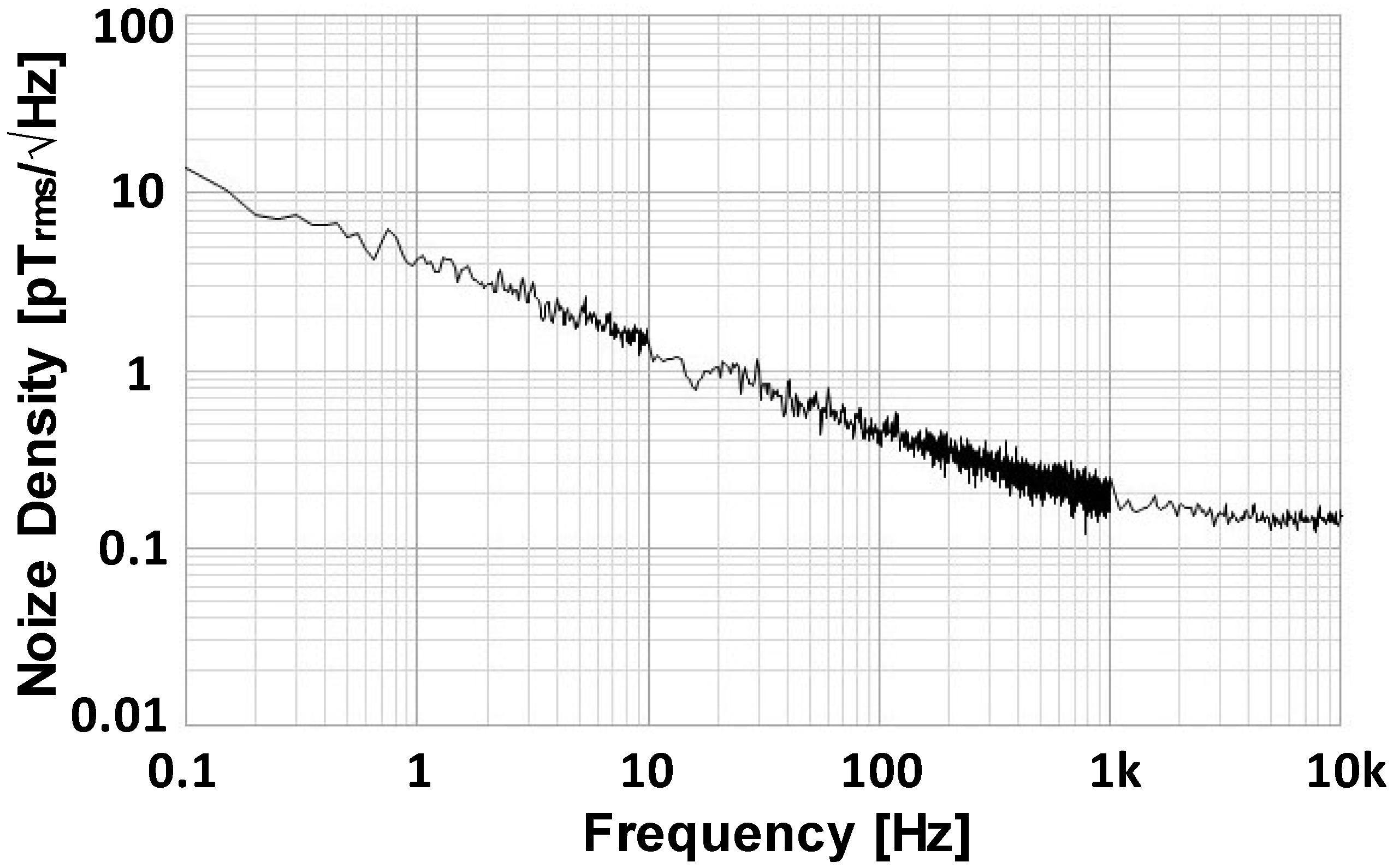

4.1. Sensitivity of MR Sensor

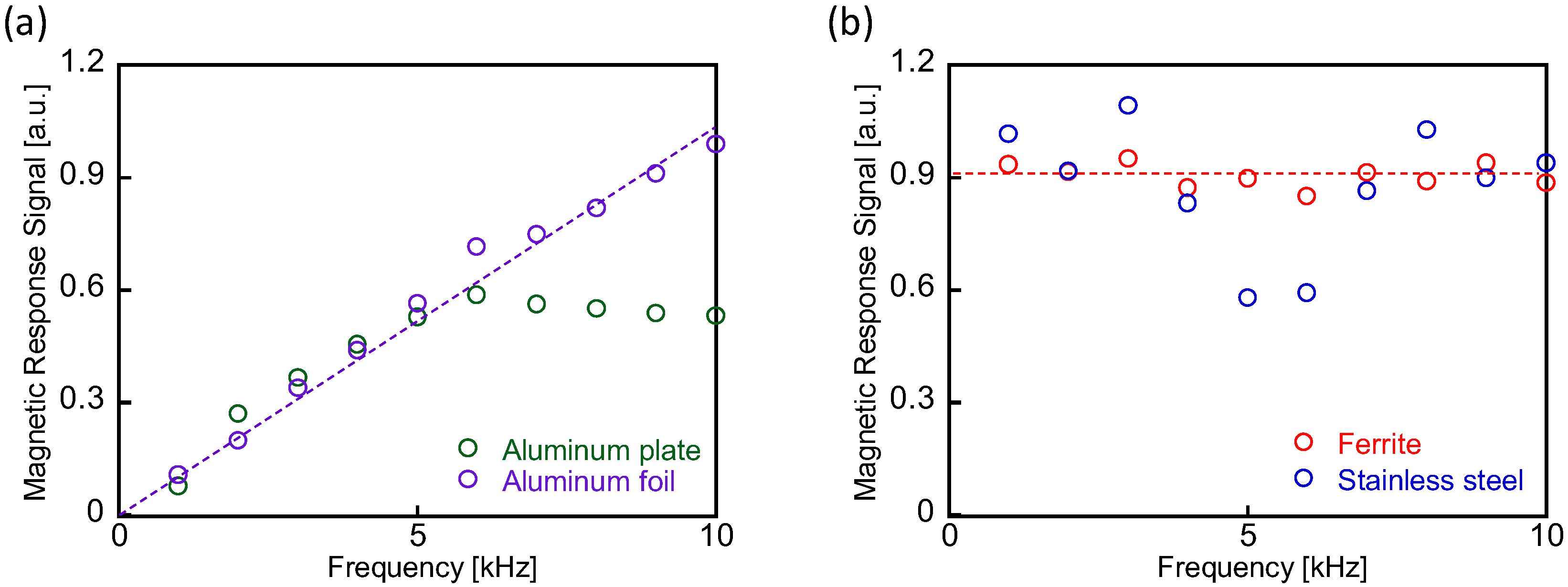

4.2. Frequency Dependence of Detected Field Intensity

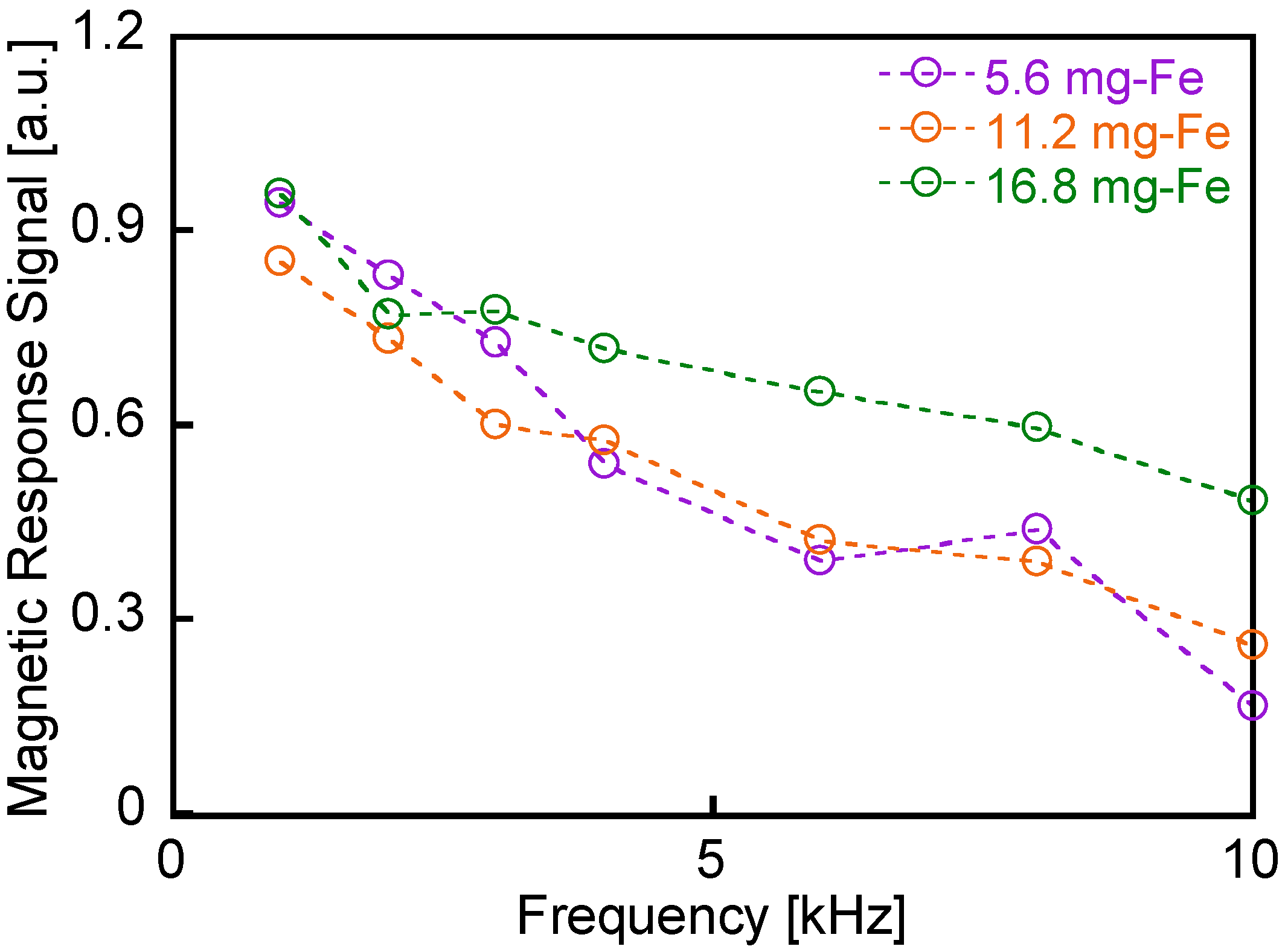

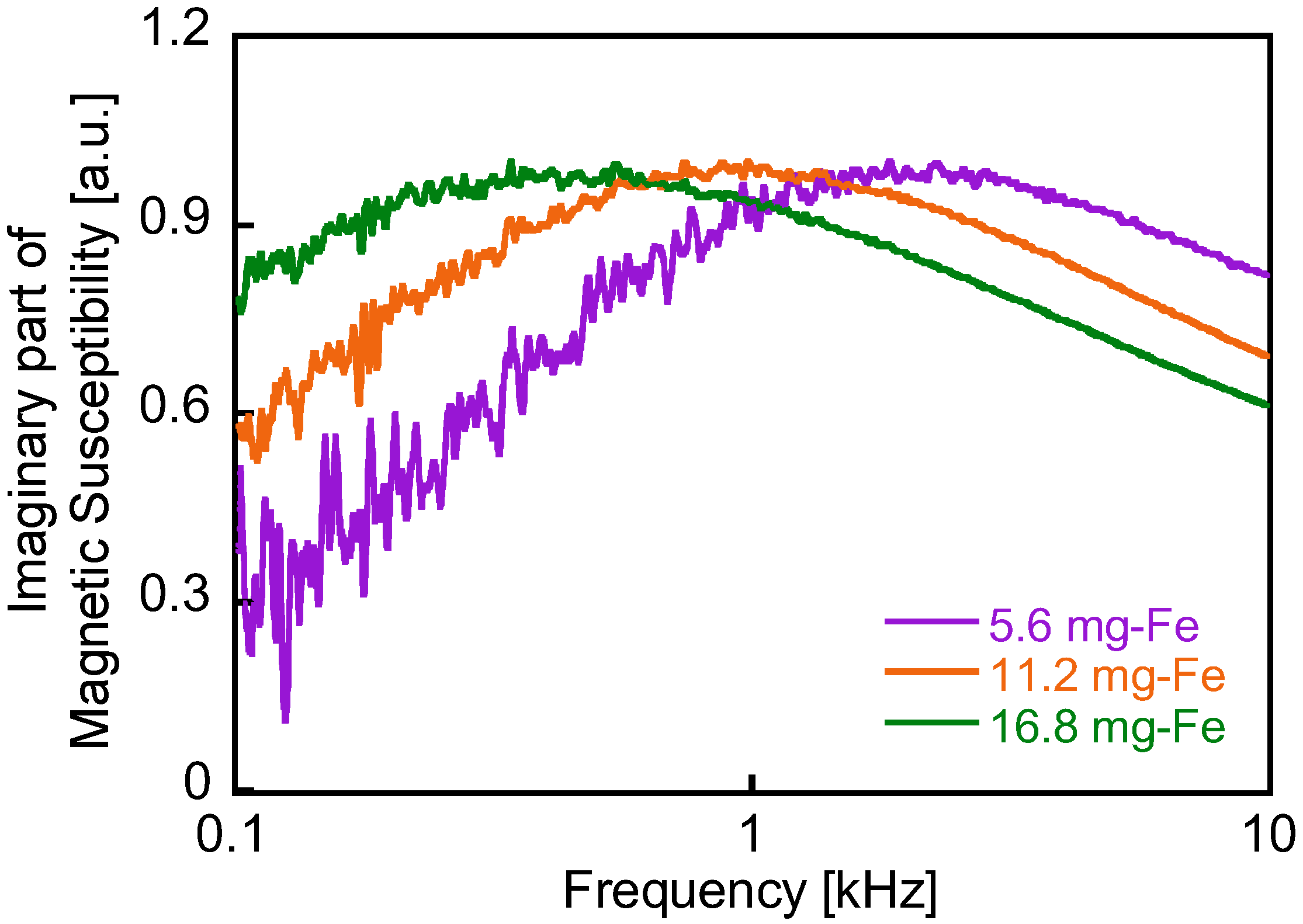

4.3. Measurement of Magnetic Nanoparticles

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zolfaghari, A.; Kolahan, F. Reliability and sensitivity of visible liquid penetrant NDT for inspection of welded components. Mater. Test. 2017, 59, 290–294. [Google Scholar] [CrossRef]

- Wu, Q.; Dong, K.; Qin, X.; Hu, Z.; Xiong, X. Magnetic particle inspection: Status, advances, and challenges—Demands for automatic non-destructive testing. NDTE Int. 2024, 143, 103030. [Google Scholar] [CrossRef]

- Gleich, B.; Weizenecker, J. Tomographic imaging using the nonlinear response of magnetic particles. Nature 2005, 435, 1214–1217. [Google Scholar] [CrossRef] [PubMed]

- Preclinical Magnetic Particle Imaging (MPI) Scanner. Available online: https://www.bruker.com/en/products-and-solutions/preclinical-imaging/mpi.html (accessed on 18 November 2024).

- Magnetic Insight’s Momentum CT. Available online: https://magneticinsight.com/hardware/ (accessed on 18 November 2024).

- Graeser, M.; Thieben, F.; Szwargulski, P.; Werner, F.; Gdaniec, N.; Boberg, M.; Griese, F.; Möddel, M.; Ludewig, P.; van de Ven, D.; et al. Human-sized magnetic particle imaging for brain applications. Nat. Commun. 2019, 10, 1936. [Google Scholar] [CrossRef] [PubMed]

- Mattingly, E.; Sliwiak, M.; Chacon-Caldera, J.; Barksdale, A.; Niebel, F.; Mason, E.; Wald, L. A human-scale magnetic particle imaging system for functional neuroimaging. Int. J. Mag. Part Imag. 2024, 10, 2403016. [Google Scholar]

- Nomura, K.; Washino, M.; Matsuda, T.; Seino, S.; Nakagawa, T.; Kiwa, T.; Kanemaru, M. Development of human head size magnetic particle imaging system. Int. J. Mag. Part Imag. 2024, 10, 2403001. [Google Scholar]

- Thieben, F.; Foerger, F.; Mohn, F.; Hackelberg, N.; Boberg, M.; Scheel, J.-P.; Möddel, M.; Graeser, M.; Knopp, T. System characterization of a human-sized 3D real-time magnetic particle imaging scanner for cerebral applications. Commun. Eng. 2024, 3, 47. [Google Scholar] [CrossRef]

- Yoshida, T.; Kamei, Y.; Takemura, Y.; Nagano, T.; Ide, A.; Sasayama, T. Development of magnetic particle imaging modules using high-Tc superconducting coils. Int. J. Mag. Part Imag. 2024, 10, 2403038. [Google Scholar]

- Rosensweig, R.E. Heating magnetic fluid with alternating magnetic field. J. Magn. Magn. Mat. 2002, 252, 370. [Google Scholar] [CrossRef]

- Enpuku, K.; Yamamura, S.; Yoshida, T. Quantitative explanation of the difference in AC magnetization curves between suspended and immobilized magnetic nanoparticles for biomedical application. J. Magn. Magn. Mat. 2022, 564, 170089. [Google Scholar] [CrossRef]

- Ota, S.; Takemura, Y. Characterization of Neel and Brownian relaxations isolated from complex dynamics influenced by dipole interactions in magnetic nanoparticles. J. Phys. Chem. C 2019, 123, 28859–28866. [Google Scholar] [CrossRef]

- Debye, P.J.W. Polar Molecules; Chemical Catalog: New York, NY, USA, 1929. [Google Scholar]

- Yoshida, T.; Othman, N.B.; Enpuku, K. Characterization of magnetically fractionated magnetic nanoparticles for magnetic particle imaging. J. Appl. Phys. 2013, 114, 173908. [Google Scholar] [CrossRef]

- Yoshida, T.; Tsujimura, N.; Tanabe, K.; Sasayama, T.; Enpuku, K. Evaluation of complex harmonic signals from magnetic nanoparticles for magnetic particle imaging. IEEE Trans. Magn. 2015, 51, 5101704. [Google Scholar] [CrossRef]

- Technologies T.D.D. Nivio xMR Sensor. Available online: https://product.tdk.com/en/techlibrary/developing/bio-sensor/nivio-xmr-sensor.html (accessed on 18 November 2024).

- Adachi, Y.; Oyama, D.; Terazono, Y.; Hayashi, T.; Shibuya, T.; Kawabata, S. Calibration of room temperature magnetic sensor array for biomagnetic measurement. IEEE Trans. Magn. 2019, 55, 5000506. [Google Scholar] [CrossRef]

- Trisnanto, S.B.; Kasajima, T.; Akushichi, J.; Takemura, Y. Sub-pT oscillatory magnetometric system using magnetoresistive sensor array for a low-field magnetic particle imaging. AIP Adv. 2023, 13, 025113. [Google Scholar] [CrossRef]

- Li, M.; Trisnanto, S.B.; Endo, Y.; Ota, S.; Sasayama, T.; Yoshida, T.; Takemura, Y. Microwave susceptibility analysis of ultrafast moment dynamics in multicore magnetic nanoparticle system. Phys. Rev. B 2024, 110, 064421. [Google Scholar] [CrossRef]

- Ota, S.; Yamada, T.; Takemura, Y. Dipole-dipole interaction and its concentration dependence of magnetic fluid evaluated by alternating current hysteresis measurement. J. Appl. Phys. 2015, 117, 17D713. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahn, H.; Tanaka, A.; Kono, Y.; Trisnanto, S.B.; Kasajima, T.; Shibuya, T.; Takemura, Y. Detection of Sub-pT Field of Magnetic Responses in Metals and Magnetic Materials by Highly Sensitive Magnetoresistive Sensors. Sensors 2025, 25, 776. https://doi.org/10.3390/s25030776

Ahn H, Tanaka A, Kono Y, Trisnanto SB, Kasajima T, Shibuya T, Takemura Y. Detection of Sub-pT Field of Magnetic Responses in Metals and Magnetic Materials by Highly Sensitive Magnetoresistive Sensors. Sensors. 2025; 25(3):776. https://doi.org/10.3390/s25030776

Chicago/Turabian StyleAhn, Hyuna, Ayana Tanaka, Yuta Kono, Suko Bagus Trisnanto, Tamon Kasajima, Tomohiko Shibuya, and Yasushi Takemura. 2025. "Detection of Sub-pT Field of Magnetic Responses in Metals and Magnetic Materials by Highly Sensitive Magnetoresistive Sensors" Sensors 25, no. 3: 776. https://doi.org/10.3390/s25030776

APA StyleAhn, H., Tanaka, A., Kono, Y., Trisnanto, S. B., Kasajima, T., Shibuya, T., & Takemura, Y. (2025). Detection of Sub-pT Field of Magnetic Responses in Metals and Magnetic Materials by Highly Sensitive Magnetoresistive Sensors. Sensors, 25(3), 776. https://doi.org/10.3390/s25030776