Optimal Sensor Placement in Buildings: Stationary Excitation

Abstract

1. Introduction

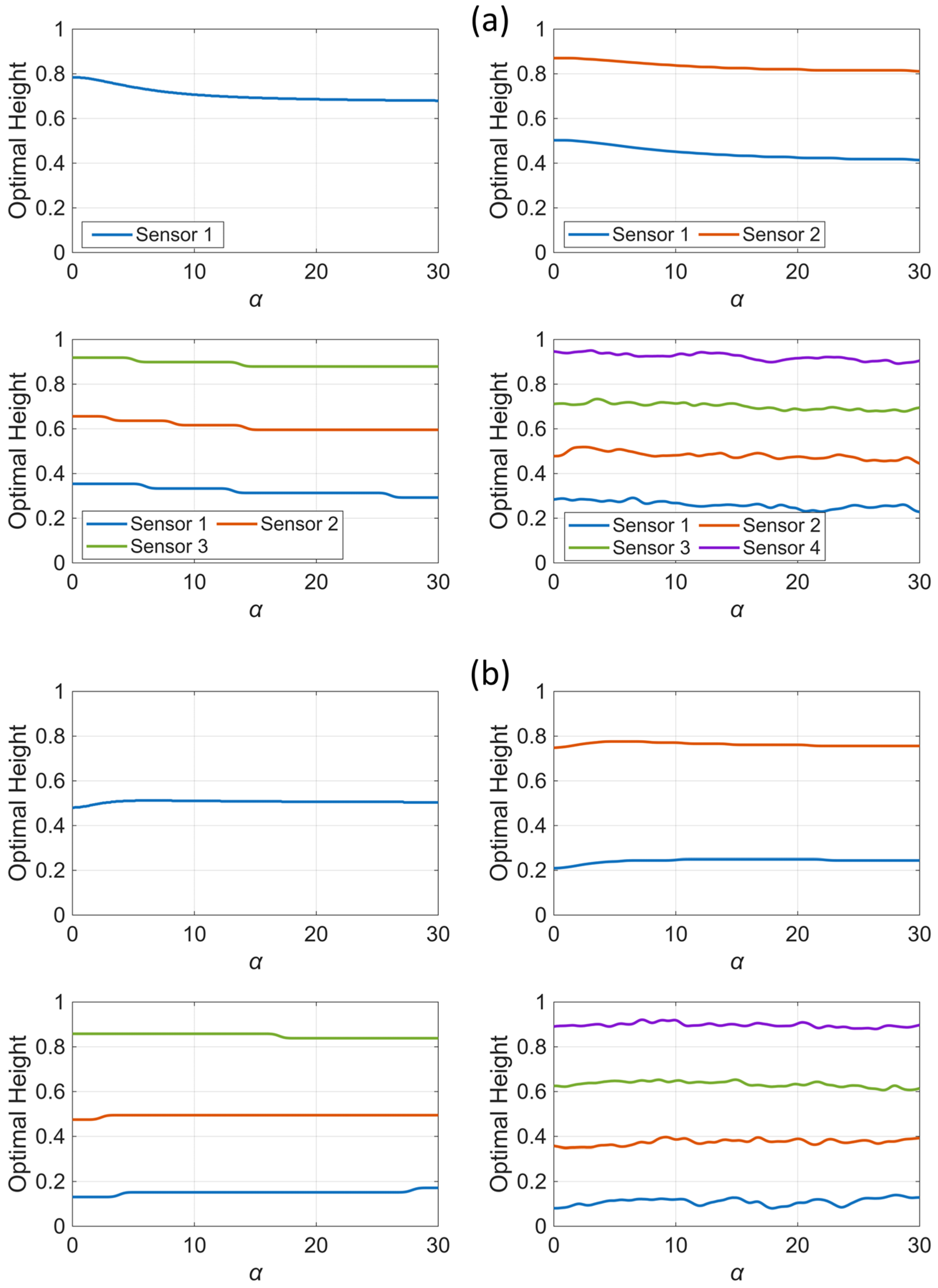

2. The Proposed Approach

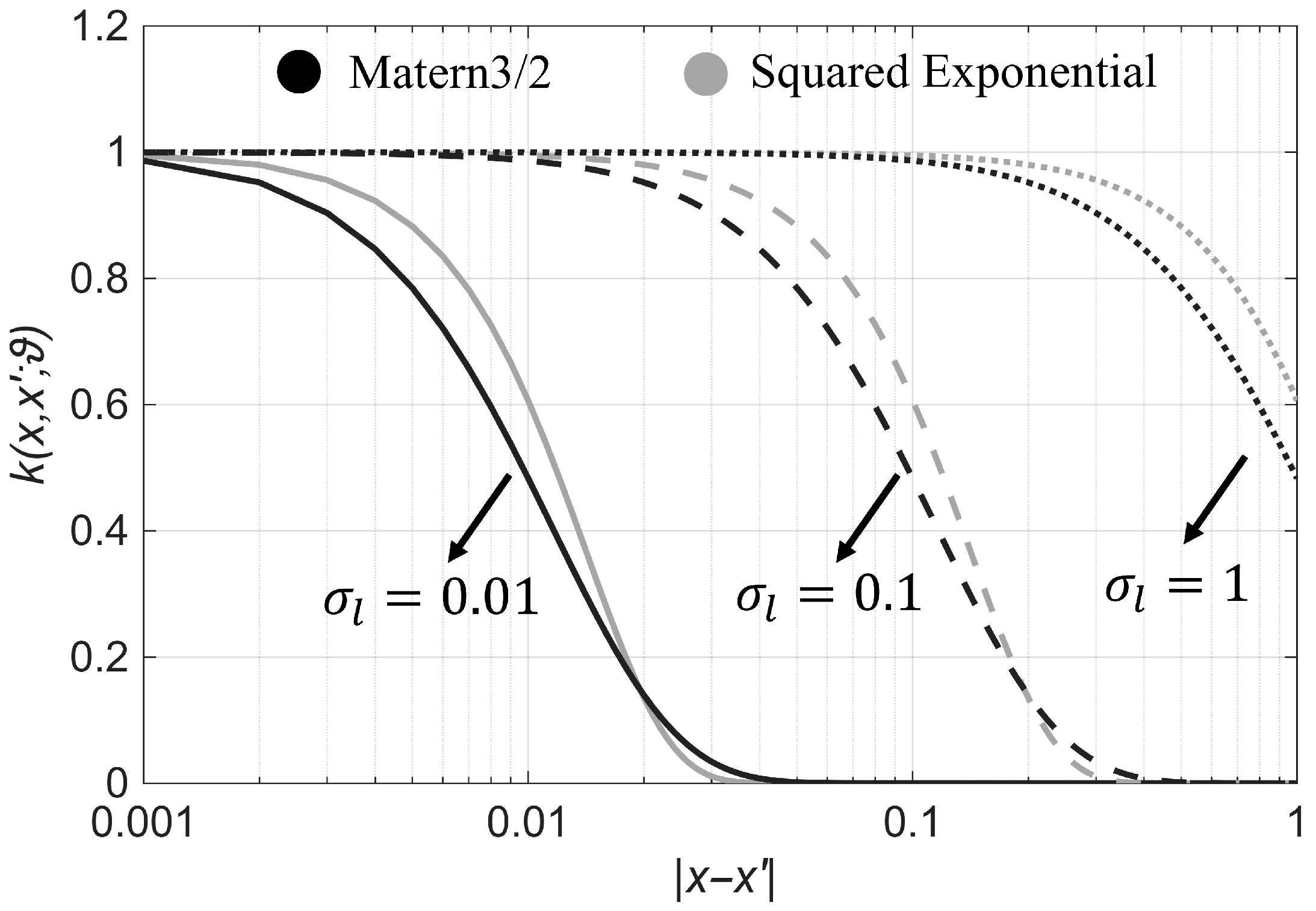

2.1. Gaussian Process Regression

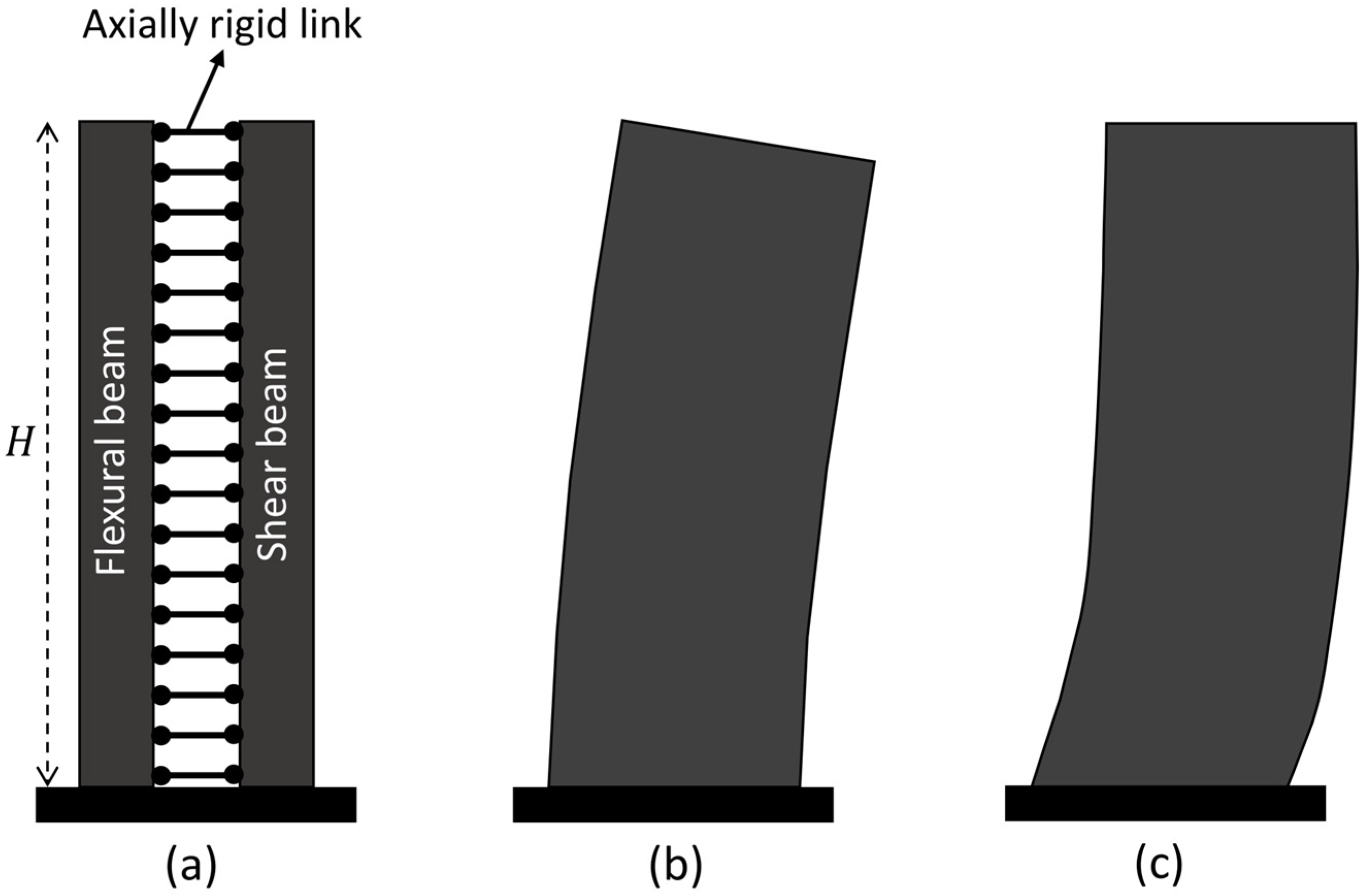

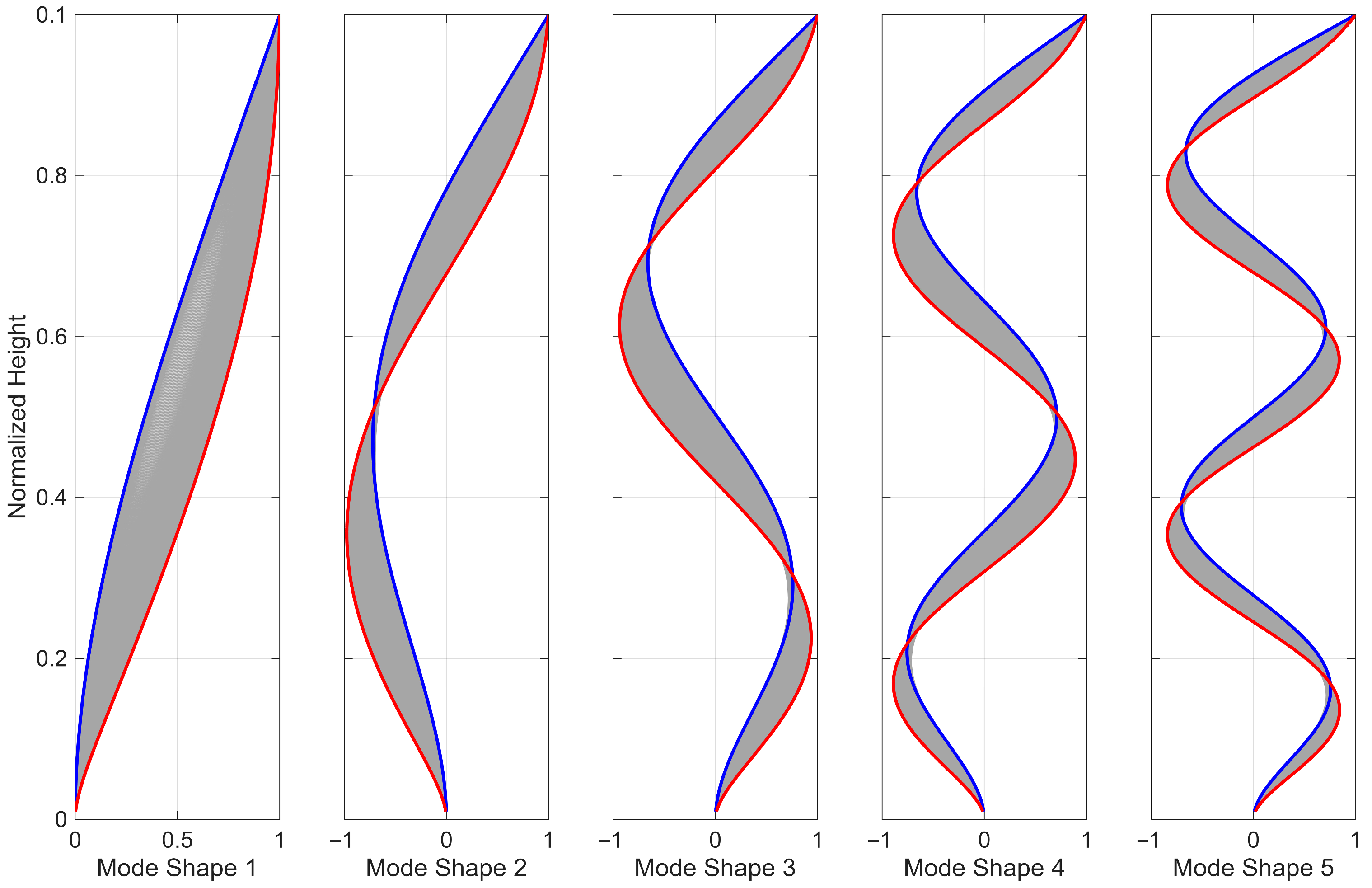

2.2. Analytical Covariance Kernel Using Beam Model

2.3. The Objective Function

- In shear wall and braced frame buildings, typically ranges between 0 and 1.5.

- In dual structural systems—such as a combination of moment-resisting frames with shear walls or braced frames— usually falls between 1.5 and 5.

- In moment-resisting frame buildings, typically ranges from 5 and 20.

3. Case Studies

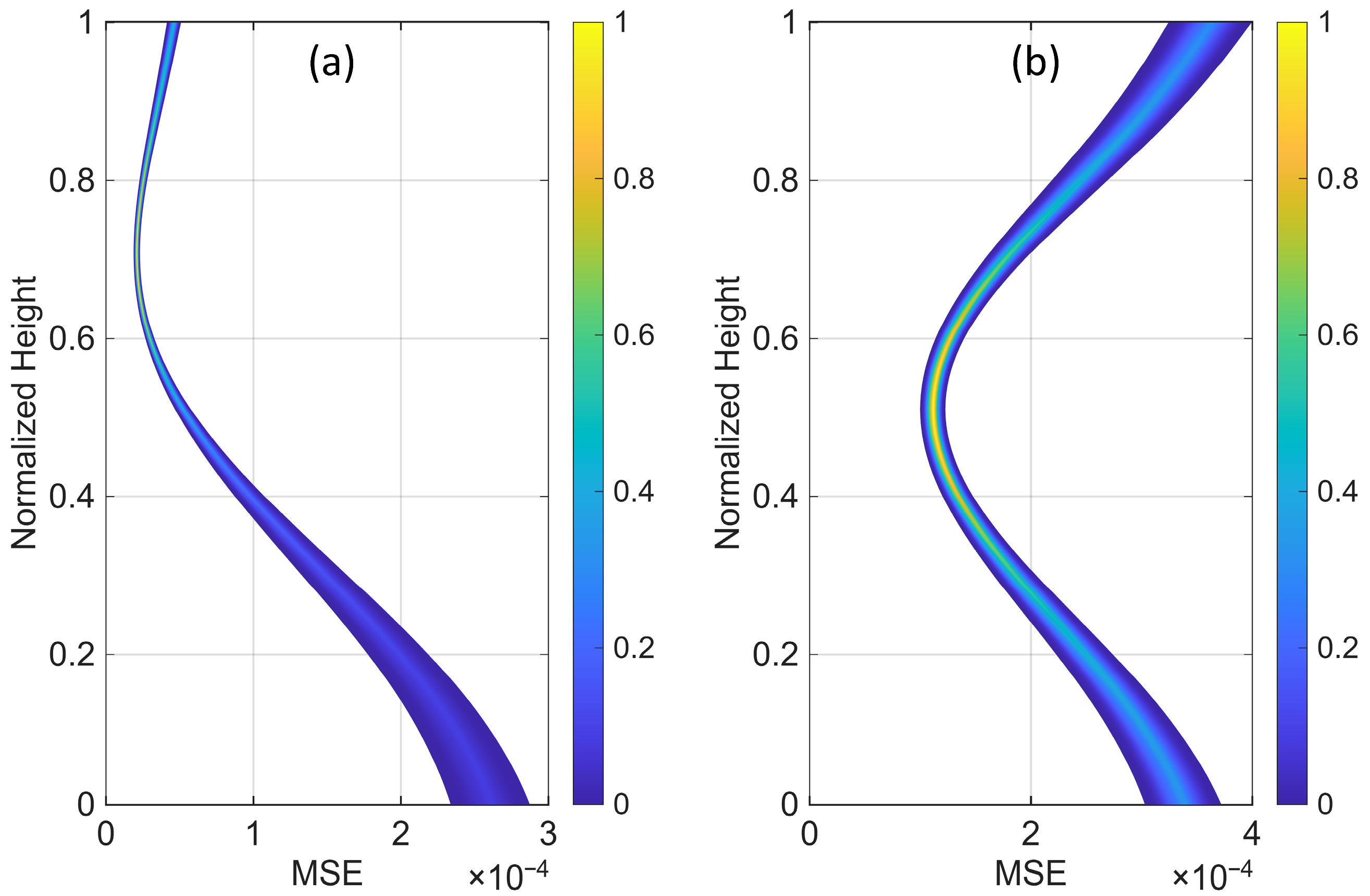

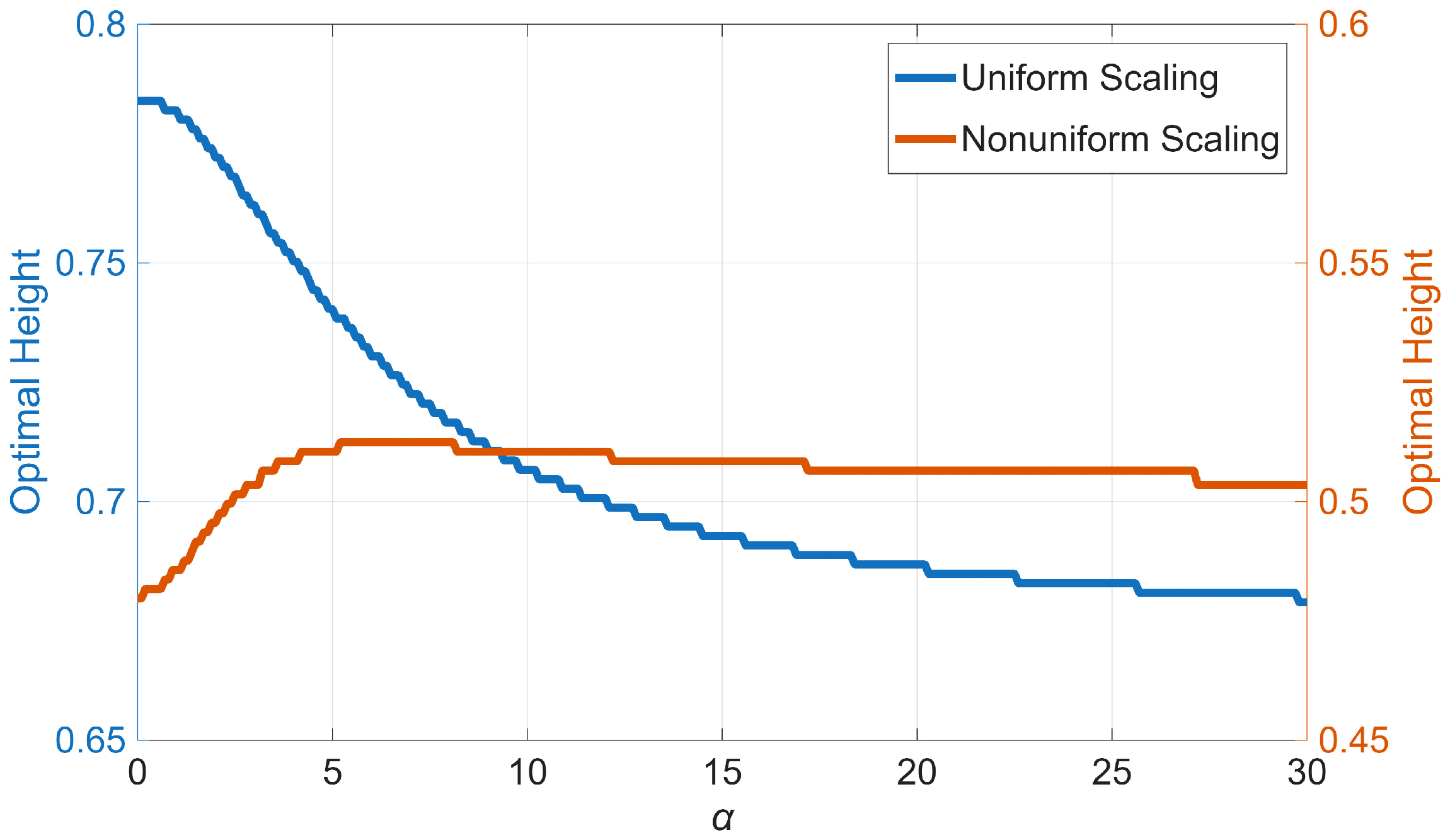

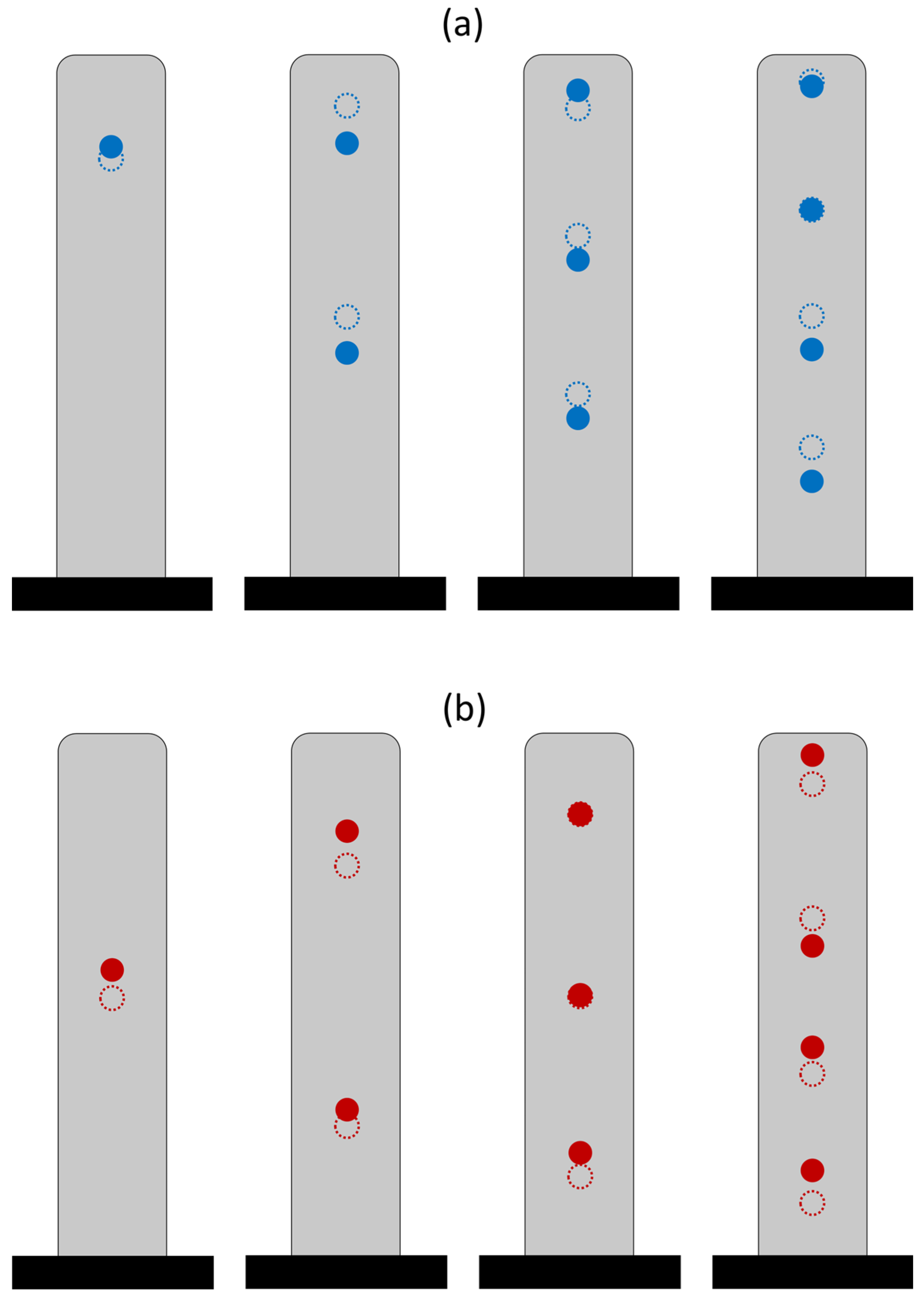

3.1. Single Sensor

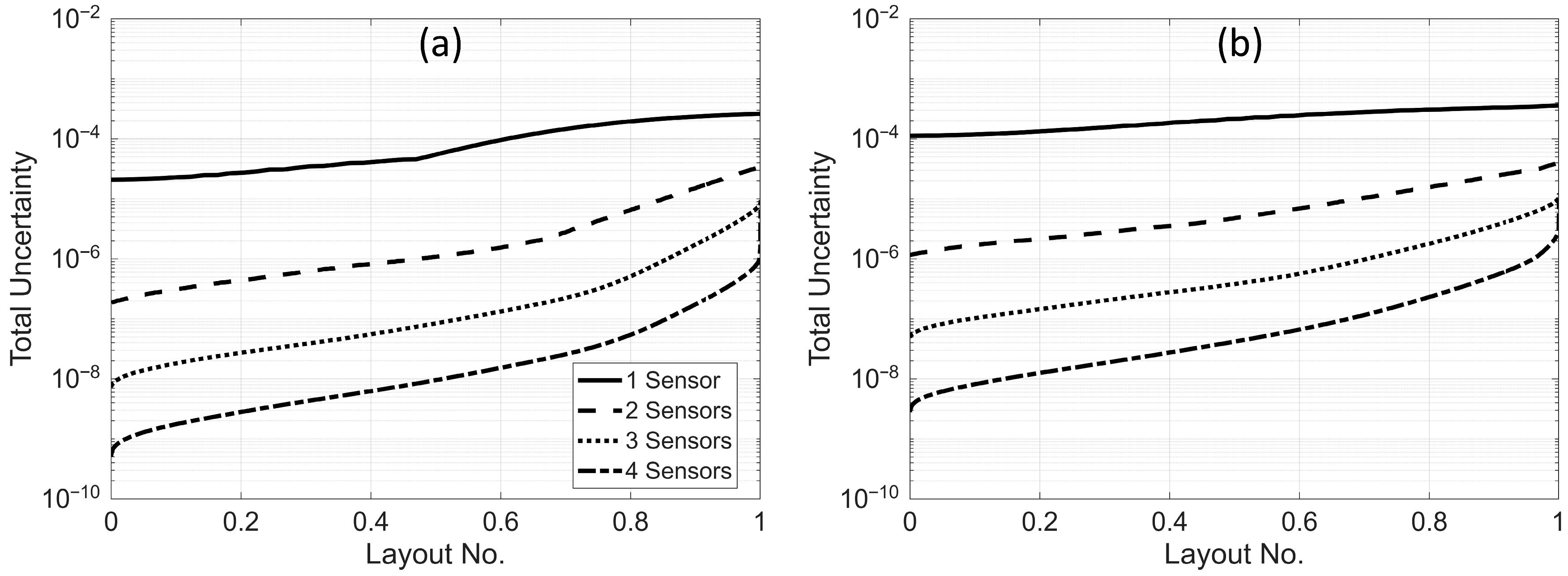

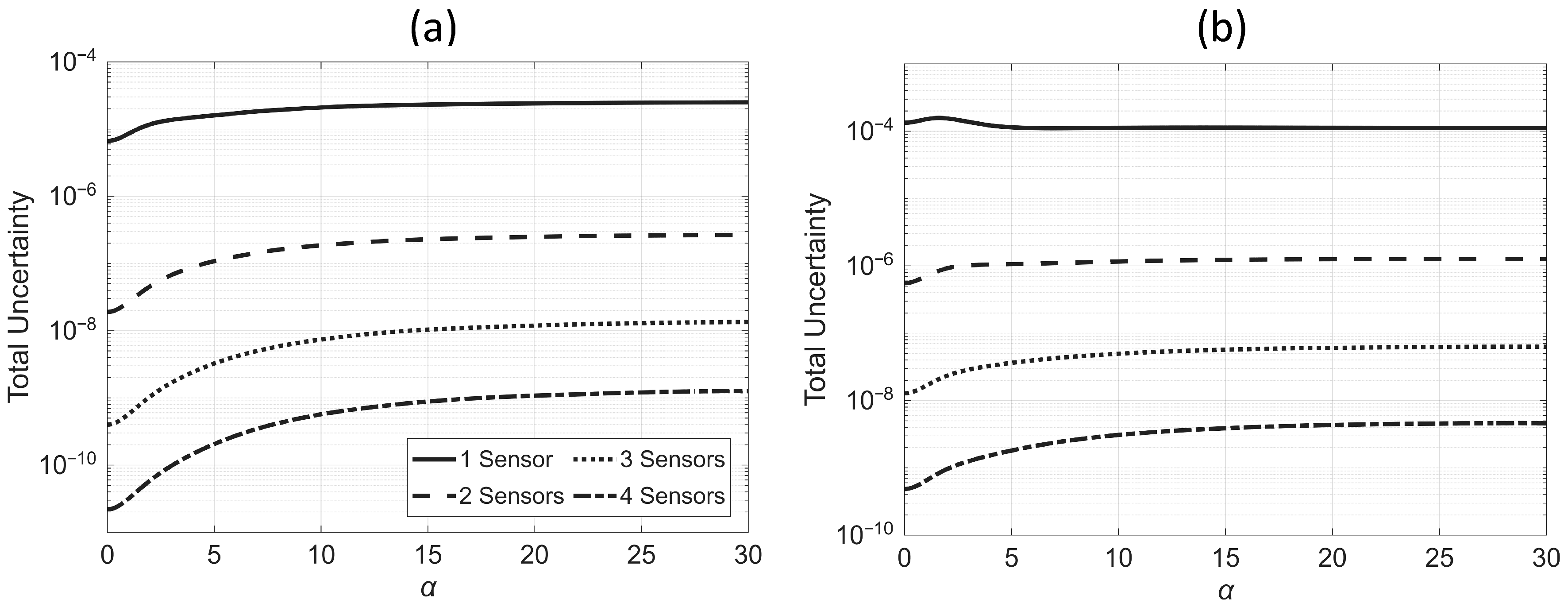

3.2. Multiple Sensors

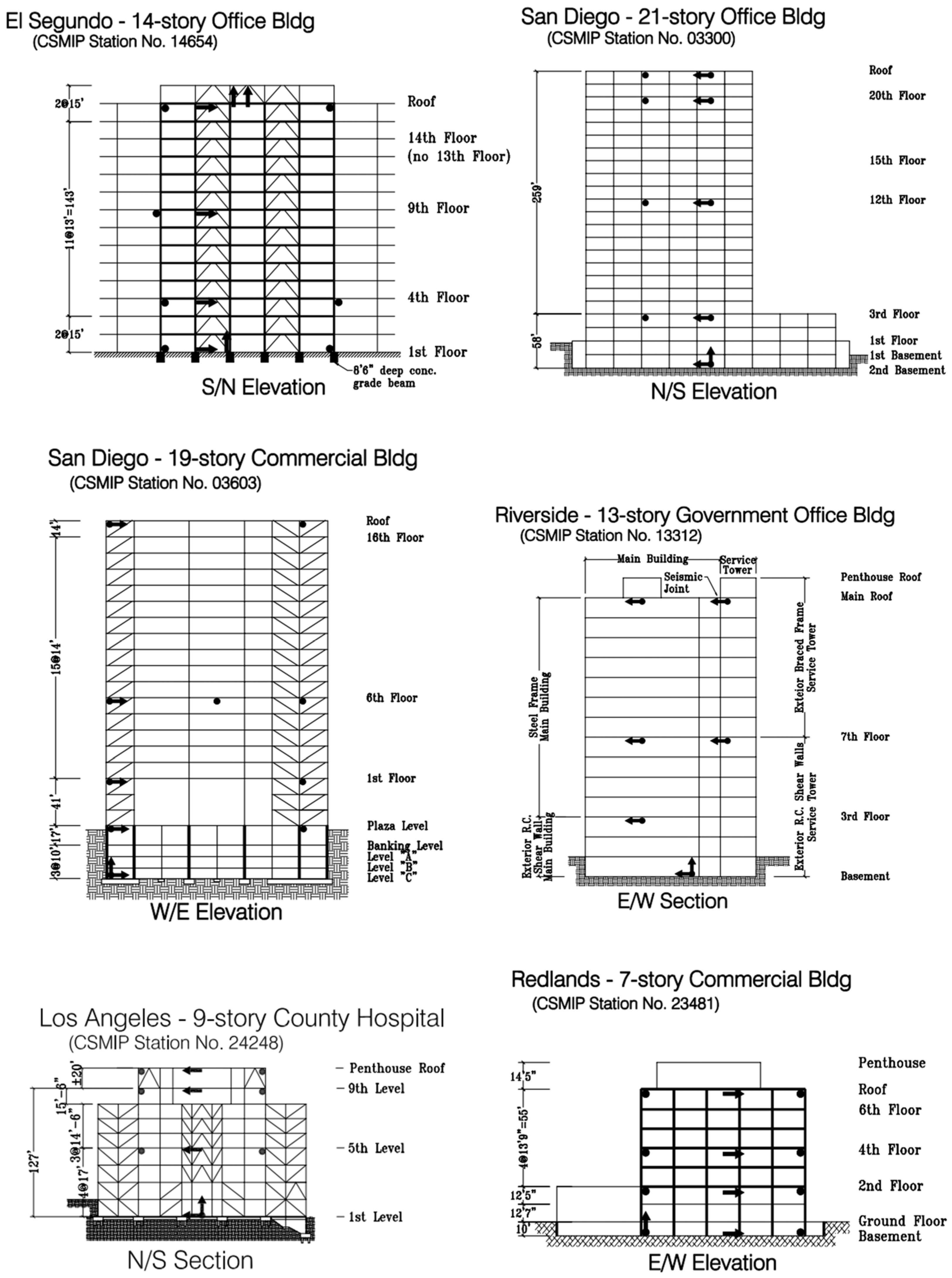

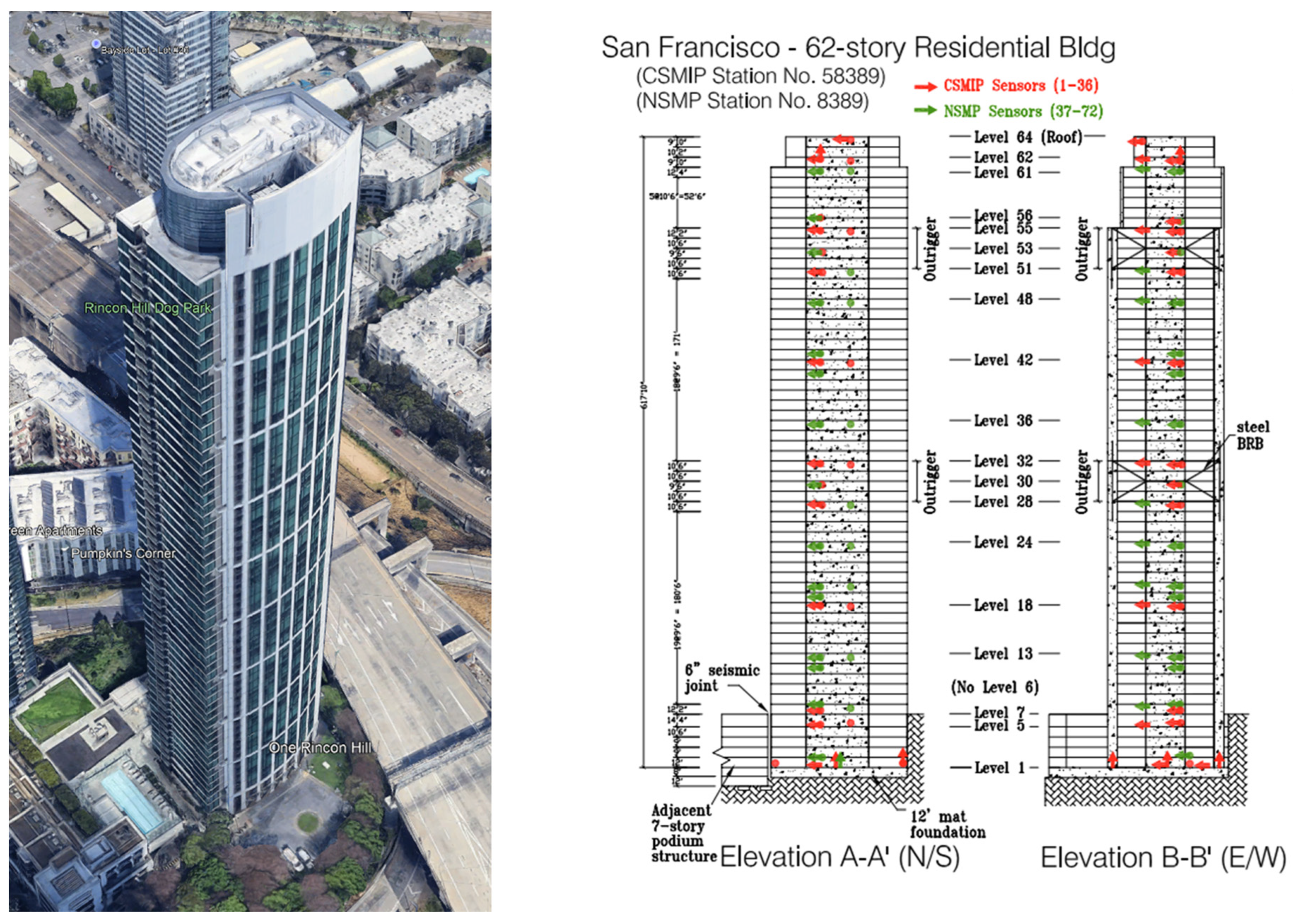

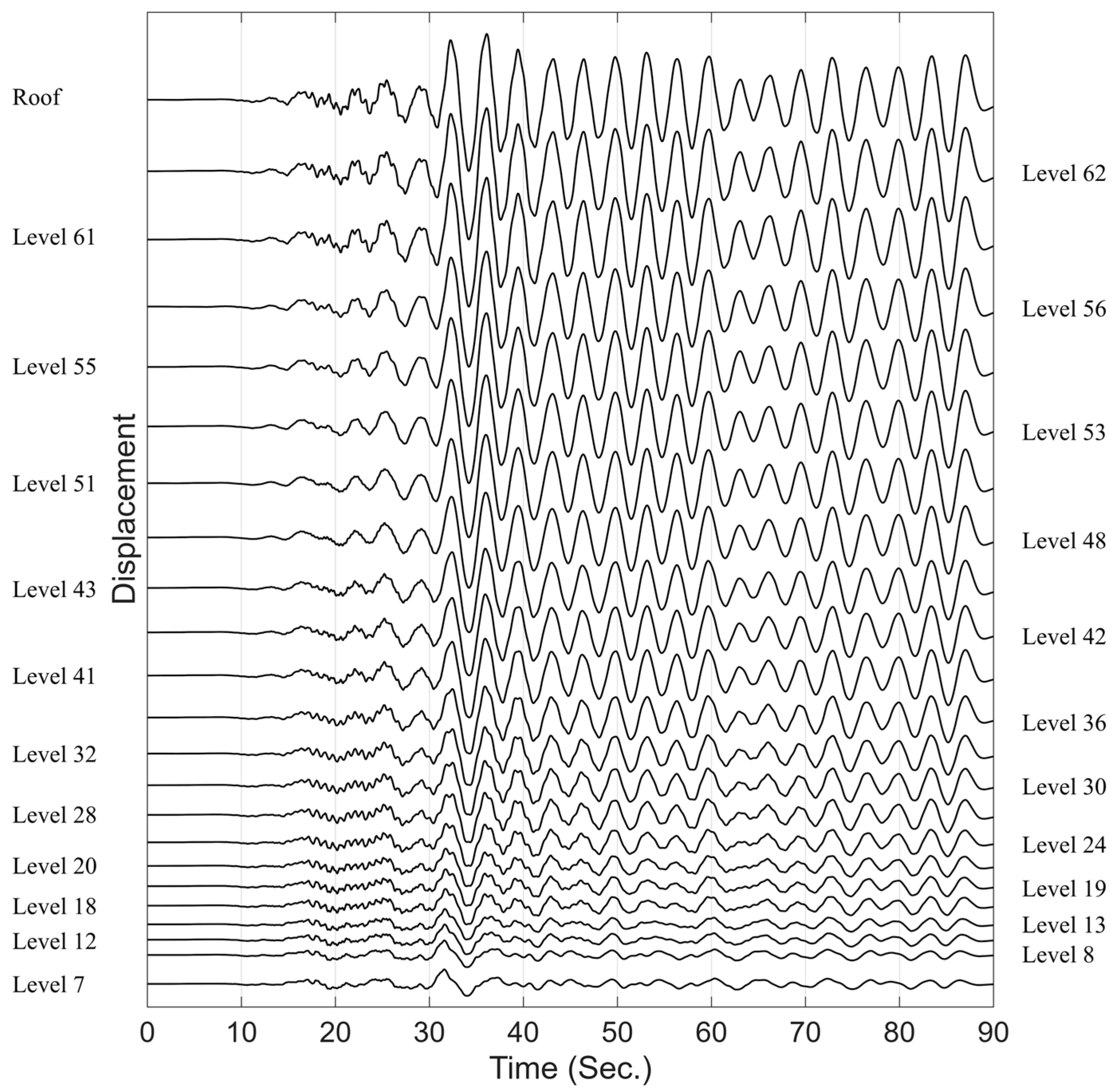

4. Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviation

| Symbol | Description |

| Gaussian Process | |

| Expected value | |

| Kernel function | |

| Covariance matrix | |

| Measurement noise variance | |

| Normal distribution with and variance | |

| Number of data points/instrumented floors | |

| Mass per unit length | |

| Shear stiffness | |

| Flexural stiffness | |

| Beam length/building height | |

| j-th mode shape | |

| j-th model coordinate | |

| Dimensionless parameter | |

| Lateral displacement | |

| j-th modal mass | |

| j-th modal stiffness | |

| j-th modal load | |

| j-th undamped natural frequency | |

| j-th modal damping ratio | |

| j-th mass-normalized mode shape | |

| j-th damped natural frequency | |

| Modal coordinates cross-reaction | |

| Modal loads’ cross-correlation | |

| Correlation response | |

| Vector of instrumented locations | |

| Total number of floors | |

| Vector of optimal locations | |

| Load spatial distribution | |

| Load temporal distribution | |

| Load temporal variance | |

| Number of time samples |

References

- Çelebi, M.; Ghahari, S.F.; Haddadi, H.; Taciroglu, E. Response study of the tallest California building inferred from the Mw7.1 Ridgecrest, California earthquake of 5 July 2019 and ambient motions. Earthq. Spectra 2020, 36, 1096–1118. [Google Scholar] [CrossRef]

- Los Angeles Tall Buildings Structural Design Council (LATBSDC). An Alternative Procedure for Seismic Analysis and Design of Tall Buildings Located in the Los Angeles Region; LATBSDC: Los Angeles, CA, USA, 2020. [Google Scholar]

- Limongelli, M.P.; Çelebi, M. Seismic Structural Health Monitoring. From Theory to Successful Applications. In Springer Tracts in Civil Engineering; Springer: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Ghahari, F.; Malekghaini, N.; Ebrahimian, H.; Taciroglu, E. Bridge digital twinning using an output-only Bayesian model updating method and recorded seismic Measurements. Sensors 2022, 22, 1278. [Google Scholar] [CrossRef]

- Rahmani, M.; Todorovska, M.I. Structural health monitoring of a 32-storey steel-frame building using 50 years of seismic monitoring data. Earthq. Eng. Struct. Dyn. 2021, 50, 1777–1800. [Google Scholar] [CrossRef]

- Malekghaini, N.; Ghahari, F.; Ebrahimian, H.; Bowers, M.; Ahlberg, E.; Taciroglu, E. A two-step FE model updating approach for system and damage identification of prestressed bridge girders. Buildings 2023, 13, 420. [Google Scholar] [CrossRef]

- Abazarsa, F.; Ghahari, S.F.; Nateghi, F.; Taciroglu, E. Response-only modal identification of structures using limited sensors. Struct. Control. Heal. Monit. 2013, 20, 987–1006. [Google Scholar] [CrossRef]

- Ghahari, S.F.; Abazarsa, F.; Ghannad, M.A.; Taciroglu, E. Response-only modal identification of structures using strong motion data. Earthq. Eng. Struct. Dyn. 2013, 42, 1221–1242. [Google Scholar] [CrossRef]

- Ghahari, S.F.; Abazarsa, F.; Ghannad, M.A.; Çelebi, M.; Taciroglu, E. Blind modal identification of structures from spatially sparse seismic response signals. Struct. Control. Heal. Monit. 2013, 21, 649–674. [Google Scholar] [CrossRef]

- Friswell, M.I.; Mottershead, J.E. Finite element model updating in structural dynamics. In Solid Mechanics and Its Applications; Springer: New York, NY, USA, 1995; Volume 38, pp. 1–286. [Google Scholar] [CrossRef]

- Mottershead, J.E.; Link, M.; Friswell, M.I. The sensitivity method in finite element model updating: A tutorial. Mech. Syst. Signal Process. 2011, 25, 2275–2296. [Google Scholar] [CrossRef]

- Ebrahimian, H.; Taha, A.; Ghahari, F.; Asimaki, D.; Taciroglu, E. The sensitivity method in finite element model updating: A tutorial. Buildings 2022, 13, 28. [Google Scholar] [CrossRef]

- Ghahari, S.F.; Abazarsa, F.; Avci, O.; Çelebi, M.; Taciroglu, E. Blind identification of the Millikan Library from earthquake data considering soil-structure interaction. Struct. Control. Heal. Monit. 2016, 23, 684–706. [Google Scholar] [CrossRef]

- Roohi, M.; Hernandez, E.M.; Rosowsky, D. Nonlinear seismic response reconstruction and performance assessment of instrumented wood-frame buildings—Validation using NEESWood Capstone full-scale tests. Struct. Control. Heal. Monit. 2019, 26, e2373. [Google Scholar] [CrossRef]

- Song, M.; Astroza, R.; Ebrahimian, H.; Moaveni, B.; Papadimitriou, C. Adaptive Kalman filters for nonlinear finite element model updating. Mech. Syst. Signal Process. 2020, 143, 106837. [Google Scholar] [CrossRef]

- Lynch, J.P. An overview of wireless structural health monitoring for civil structures. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2007, 365, 345–372. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Q.; Fei, Y.; Lu, X.; Liao, W.; Zhang, W.; Chen, P.-Y.; Kurtulus, A.; Ghahari, F.; Vela, V.; Taciroglu, E. Influence of Sensor Density on Seismic Damage Assessment: A Case Study for Istanbul. Bull. Seism. Soc. Am. 2022, 112, 2156–2169. [Google Scholar] [CrossRef]

- Liao, W.; Fei, Y.; Ghahari, F.; Zhang, W.; Chen, P.-Y.; Kurtulus, A.; Yen, C.-H.; Cheng, Q.; Lu, X.; Taciroglu, E. Influence of accelerometer type on uncertainties in recorded ground motions and seismic damage assessment. Bull. Earthq. Eng. 2022, 20, 4419–4439. [Google Scholar] [CrossRef]

- Wahba, G. Spline Models for Observational Data. Math. Comput. 1991, 57, 444. [Google Scholar] [CrossRef]

- Naeim, F.; Lee, H.; Hagie, S.; Bhatia, H.; Alimoradi, A.; Miranda, E. Three-dimensional analysis, real-time visualization, and automated post-earthquake damage assessment of buildings. Struct. Des. Tall Spec. Build. 2006, 15, 105–138. [Google Scholar] [CrossRef]

- Limongelli, M. The interpolation damage detection method for frames under seismic excitation. J. Sound Vib. 2011, 330, 5474–5489. [Google Scholar] [CrossRef]

- Kodera, K.; Nishitani, A.; Okihara, Y. Cubic spline interpolation based estimation of all story seismic responses with acceleration measurement at a limited number of floors. Jpn. Arch. Rev. 2020, 3, 435–444. [Google Scholar] [CrossRef]

- Ghahari, F.; Swensen, D.; Haddadi, H.; Taciroglu, E. A hybrid model-data method for seismic response reconstruction of instrumented buildings. Earthq. Spectra 2024, 40, 1235–1268. [Google Scholar] [CrossRef]

- Miranda, E. Approximate seismic lateral deformation demands in multistory buildings. J. Struct. Eng. 1999, 125, 417–425. [Google Scholar] [CrossRef]

- Miranda, E.; Taghavi, S. Approximate floor acceleration demands in multistory buildings. I: Formulation. J. Struct. Eng. 2005, 131, 203–211. [Google Scholar] [CrossRef]

- Taghavi, S.; Miranda, E. Approximate floor acceleration demands in multistory buildings. II: Applications. J. Struct. Eng. 2005, 131, 212–220. [Google Scholar] [CrossRef]

- Taciroglu, E.; Ghahari, S.; Abazarsa, F. Efficient model updating of a multi-story frame and its foundation stiffness from earthquake records using a Timoshenko beam model. Soil Dyn. Earthq. Eng. 2017, 92, 25–35. [Google Scholar] [CrossRef]

- Krige, D.G. A statistical approach to some basic mine valuation problems on the Witwatersrand. J. South. Afr. Inst. Min. Metall. 1951, 52, 119–139. [Google Scholar]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Tamhidi, A.; Kuehn, N.; Ghahari, S.F.; Rodgers, A.J.; Kohler, M.D.; Taciroglu, E.; Bozorgnia, Y. Conditioned simulation of ground-motion time series at uninstrumented sites using Gaussian process regression. Bull. Seism. Soc. Am. 2022, 112, 331–347. [Google Scholar] [CrossRef]

- FEMA P-58-1; Seismic Performance Assessment of Buildings Volume 1—Methodology. Technical Report FEMA-P58; Applied Technology Council: Redwood City, CA, USA, 2018.

- Cremen, G.; Baker, J.W. Quantifying the benefits of building instruments to FEMA P-58 rapid post-earthquake damage and loss predictions. Eng. Struct. 2018, 176, 243–253. [Google Scholar] [CrossRef]

- Morari, M.; O'Dowd, M.J. Optimal sensor location in the presence of nonstationary noise. Automatica 1980, 16, 463–480. [Google Scholar] [CrossRef]

- Kammer, D.C. Sensor placement for on-orbit modal identification and correlation of large space structures. J. Guid. Control Dyn. 1991, 14, 251–259. [Google Scholar] [CrossRef]

- Lin, F.; Chiu, P. A near-optimal sensor placement algorithm to achieve complete coverage-discrimination in sensor networks. IEEE Commun. Lett. 2005, 9, 43–45. [Google Scholar]

- Zimmerman, D.L. Optimal network design for spatial prediction, covariance parameter estimation, and empirical prediction. Environmetrics 2006, 17, 635–652. [Google Scholar] [CrossRef]

- Ranieri, J.; Chebira, A.; Vetterli, M. Near-optimal sensor placement for linear inverse problems. IEEE Trans. Signal Process. 2014, 62, 1135–1146. [Google Scholar] [CrossRef]

- Li, R.; Mehr, N.; Horowitz, R. Submodularity of optimal sensor placement for traffic networks. Transp. Res. Part B Methodol. 2023, 171, 29–43. [Google Scholar] [CrossRef]

- Udwadia, F.E. Methodology for Optimum Sensor Locations for Parameter Identification in Dynamic Systems. J. Eng. Mech. 1994, 120, 368–390. [Google Scholar] [CrossRef]

- Kirkegaard, P.; Brincker, R. On the optimal location of sensors for parametric identification of linear structural systems. Mech. Syst. Signal Process. 1994, 8, 639–647. [Google Scholar] [CrossRef]

- Papadimitriou, C.; Beck, J.L.; Au, S.-K. Entropy-based optimal sensor location for structural model updating. J. Vib. Control. 2000, 6, 781–800. [Google Scholar] [CrossRef]

- Papadimitriou, C. Optimal sensor placement methodology for parametric identification of structural systems. J. Sound Vib. 2004, 278, 923–947. [Google Scholar] [CrossRef]

- Papadimitriou, C.; Haralampidis, Y.; Sobczyk, K. Optimal experimental design in stochastic structural dynamics. Probabilistic Eng. Mech. 2005, 20, 67–78. [Google Scholar] [CrossRef]

- Argyris, C.; Papadimitriou, C.; Panetsos, P. Bayesian optimal sensor placement for modal identification of civil infrastructures. J. Smart Cities 2019, 2, 69–86. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Beck, J. Exploiting convexification for Bayesian optimal sensor placement by maximization of mutual information. Struct. Control. Heal. Monit. 2020, 27, e2605. [Google Scholar] [CrossRef]

- Argyris, C.; Papadimitriou, C.; Samaey, G.; Lombaert, G. A unified sampling-based framework for optimal sensor placement considering parameter and prediction inference. Mech. Syst. Signal Process. 2021, 161, 107950. [Google Scholar] [CrossRef]

- Limongelli, M.P. Optimal location of sensors for reconstruction of seismic responses through spline function interpolation. Earthq. Eng. Struct. Dyn. 2003, 32, 1055–1074. [Google Scholar] [CrossRef]

- Bertola, N.J.; Papadopoulou, M.; Vernay, D.; Smith, I.F. Optimal multi-type sensor placement for structural identification by static-load testing. Sensors 2017, 17, 2904. [Google Scholar] [CrossRef]

- Malings, C.; Pozzi, M. Value of information for spatially distributed systems: Application to sensor placement. Reliab. Eng. Syst. Saf. 2017, 154, 219–233. [Google Scholar] [CrossRef]

- Caglar, N.M.; Limongelli, M.P. Optimal Location of Strong Ground Motion Sensors for Seismic Emergency Management. In Experimental Vibration Analysis for Civil Engineering Structures; Springer Nature: Cham, Switzerland, 2023; pp. 582–591. [Google Scholar]

- Argyris, C.; Chowdhury, S.; Zabel, V.; Papadimitriou, C. Bayesian optimal sensor placement for crack identification in structures using strain measurements. Struct. Control. Heal. Monit. 2018, 25, e2137. [Google Scholar] [CrossRef]

- Capellari, G.; Chatzi, E.; Mariani, S. Cost–benefit optimization of structural health monitoring sensor net-works. Sensors 2018, 18, 2174. [Google Scholar] [CrossRef] [PubMed]

- Gorodetsky, A.; Marzouk, Y. Mercer kernels and integrated variance experimental design: Connections between Gaussian process regression and polynomial approximation. SIAM/ASA J. Uncertain. Quantif. 2016, 4, 796–828. [Google Scholar] [CrossRef]

- Tan, Y.; Zhang, L. Computational methodologies for optimal sensor placement in structural health monitoring: A review. Structural Health Monitoring. Struct. Heal. Monit. 2020, 19, 1287–1308. [Google Scholar] [CrossRef]

- Sun, H.; Büyüköztürk, O. Optimal sensor placement in structural health monitoring using discrete optimization. Smart Mater. Struct. 2015, 24, 125034. [Google Scholar] [CrossRef]

- Ditommaso, R.; Ponzo, F.C. Identifying damage in structures: Definition of thresholds to minimize false alarms in SHM systems. Buildings 2024, 14, 821. [Google Scholar] [CrossRef]

- An, H.; Youn, B.D.; Kim, H.S. Optimal sensor placement considering both sensor faults under uncertainty and sensor clustering for vibration-based damage detection. Struct. Multidiscip. Optim. 2022, 65, 1–32. [Google Scholar] [CrossRef]

- Schulz, E.; Speekenbrink, M.; Krause, A. A tutorial on Gaussian process regression: Modelling, exploring, and exploiting functions. J. Math. Psychol. 2018, 85, 1–16. [Google Scholar] [CrossRef]

- Stein, M.L. Interpolation of Spatial Data: Some Theory for Kriging; Springer Science & Business Media: Berlin, Germany, 1999. [Google Scholar]

- Ghahari, S.F.; Sargsyan, K.; Çelebi, M.; Taciroglu, E. Quantifying modeling uncertainty in simplified beam models for building response prediction. Struct. Control. Heal. Monit. 2022, 29, e3078. [Google Scholar] [CrossRef]

- Paultre, P. Dynamics of Structures; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- MATLAB. MATLAB, version 24.1.0 (R2024a); The MathWorks Inc.: Natick, MA, USA, 2024. [Google Scholar]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence properties of the Nelder--Mead simplex method in low dimensions. SIAM J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef]

- Park, S.K. A Transformation Method for Constrained-Function Minimization (No. L-10178). 1975. Available online: https://ntrs.nasa.gov/api/citations/19760004646/downloads/19760004646.pdf (accessed on 7 July 2025).

- Kinemetrics, Inc. EpiSensor ES-U2 Accelerometer. Pasadena, CA, USA. 2023. Available online: https://kinemetrics.com (accessed on 7 July 2025).

- Skolnik, D.A.; Nigbor, R.L.; Wallace, J.W. A quantitative basis for building instrumentation specifications. Earthq. Spectra 2011, 27, 133–152. [Google Scholar] [CrossRef]

| Initialization |

| Set and to arbitrary values |

| Set and based on engineering experience |

| Set based on the lateral system of the building |

| Beam model |

| : numerically find the roots of the characteristic equation corresponding to Equation (17) |

| : Equation (47) |

| : Equation (22) |

| Parameters needed for the optimization |

| : Equation (33) |

| : Equation (28) |

| : Equation (42) |

| : Equation (43) |

| : normalized height of all floors |

| : normalized height of candidate instrumented floors |

| Optimization loop until does not change |

| : Equation (9) |

| : Equation (5) |

| : Equation (6) |

| : Equation (44) |

| Scaling: |

| : Uniform scaling scenario |

| : Nonuniform scaling scenario |

| Objective Function (OF): Equation (46) |

| Update |

| Shear Wall/Braced Frame | Dual System | Moment Frame | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Sensors | Number of Sensors | Number of Sensors | ||||||||||

| Sensor Number | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 4 |

| 1 | 0.80 (0.50) | 0.50 (0.25) | 0.35 (0.15) | 0.30 (0.1) | 0.75 (0.50) | 0.50 (0.25) | 0.35 (0.15) | 0.30 (0.1) | 0.70 (0.5) | 0.45 (0.25) | 0.30 (0.15) | 0.25 (0.1) |

| 2 | 0.9 (0.75) | 0.65 (0.50) | 0.50 (0.35) | 0.85 (0.75) | 0.65 (0.50) | 0.50 (0.35) | 0.85 (0.75) | 0.60 (0.50) | 0.50 (0.35) | |||

| 3 | 0.90 (0.85) | 0.70 (0.65) | 0.90 (0.85) | 0.70 (0.65) | 0.90 (0.85) | 0.70 (0.65) | ||||||

| 4 | 0.95 (0.90) | 0.95 (0.90) | 0.95 (0.90) | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghahari, F.; Swensen, D.; Haddadi, H. Optimal Sensor Placement in Buildings: Stationary Excitation. Sensors 2025, 25, 7470. https://doi.org/10.3390/s25247470

Ghahari F, Swensen D, Haddadi H. Optimal Sensor Placement in Buildings: Stationary Excitation. Sensors. 2025; 25(24):7470. https://doi.org/10.3390/s25247470

Chicago/Turabian StyleGhahari, Farid, Daniel Swensen, and Hamid Haddadi. 2025. "Optimal Sensor Placement in Buildings: Stationary Excitation" Sensors 25, no. 24: 7470. https://doi.org/10.3390/s25247470

APA StyleGhahari, F., Swensen, D., & Haddadi, H. (2025). Optimal Sensor Placement in Buildings: Stationary Excitation. Sensors, 25(24), 7470. https://doi.org/10.3390/s25247470