Development of a Cost-Effective Multiparametric Probe for Continuous Real-Time Monitoring of Aquatic Environments

Highlights

- We present a low-cost (bill of materials < EUR 1000), open-source, solar-powered multiparameter probe (pH, EC, temperature, water level) with GSM/GPRS telemetry and microSD fallback for long-term unattended monitoring.

- We quantified uncertainty: expanded uncertainty of ±0.4 pH, with ±56.5/±512/±3200 µS/cm at 1413/12,880/80,000 µS/cm, and ±5.2 cm for water level; precision comes from 1000-sample repeats (e.g., pH SD ≈ 0.004).

- We obtain a high-frequency pH/EC/T/level time series with stated expanded uncertainties (k = 2), enabling defensible thresholds and targeted confirmatory sampling.

- We develop an open ESP32-based system with cellular telemetry and microSD, supporting scalable deployments; the next step is a short field co-deployment against certified instruments.

Abstract

1. Introduction

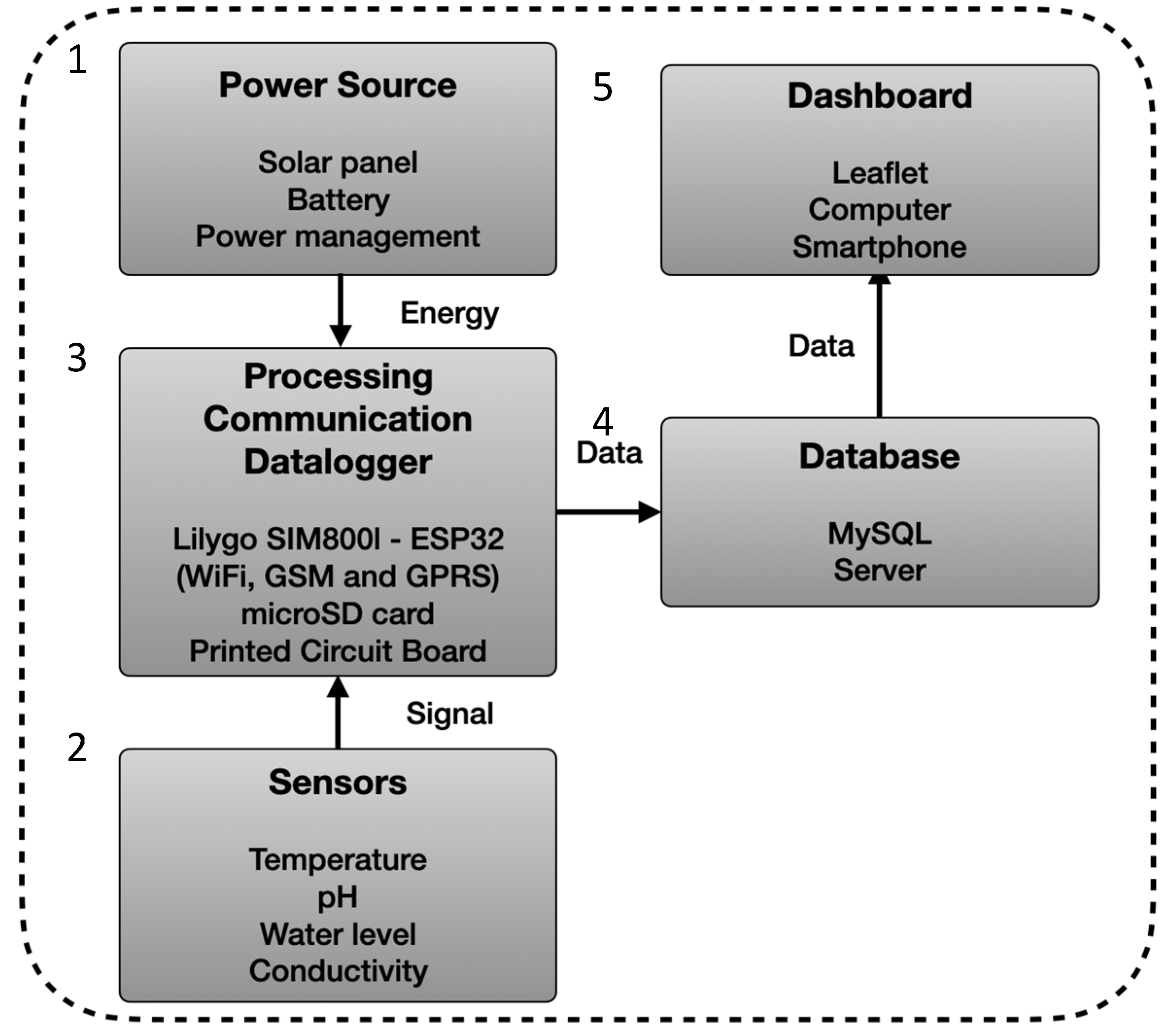

2. Materials and Methods

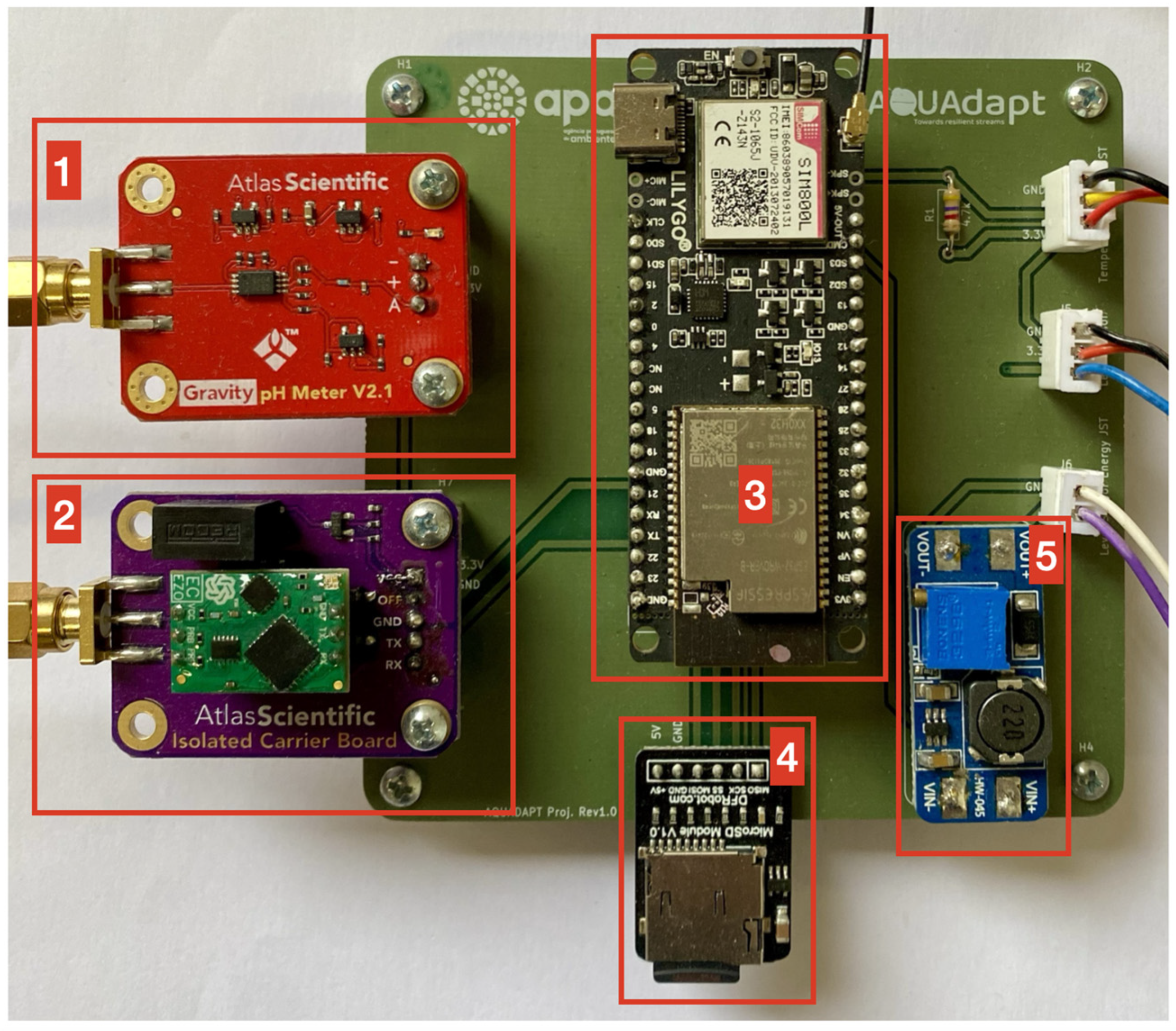

2.1. Sensor Description

2.1.1. pH Sensor

2.1.2. Conductivity Sensor

2.1.3. Temperature Sensor

2.1.4. Water Level Sensor

2.1.5. Maintenance Requirements and Field Durability

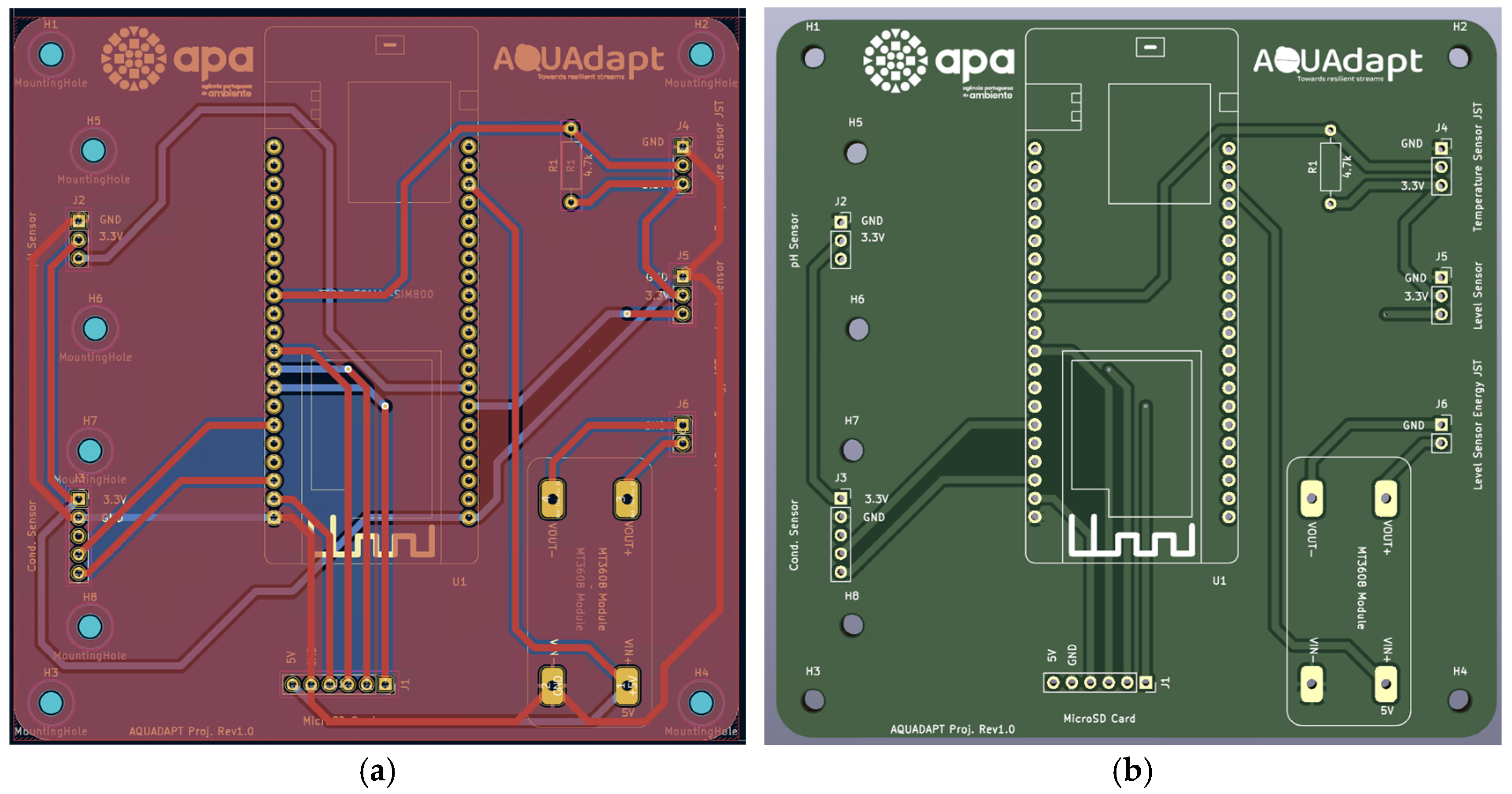

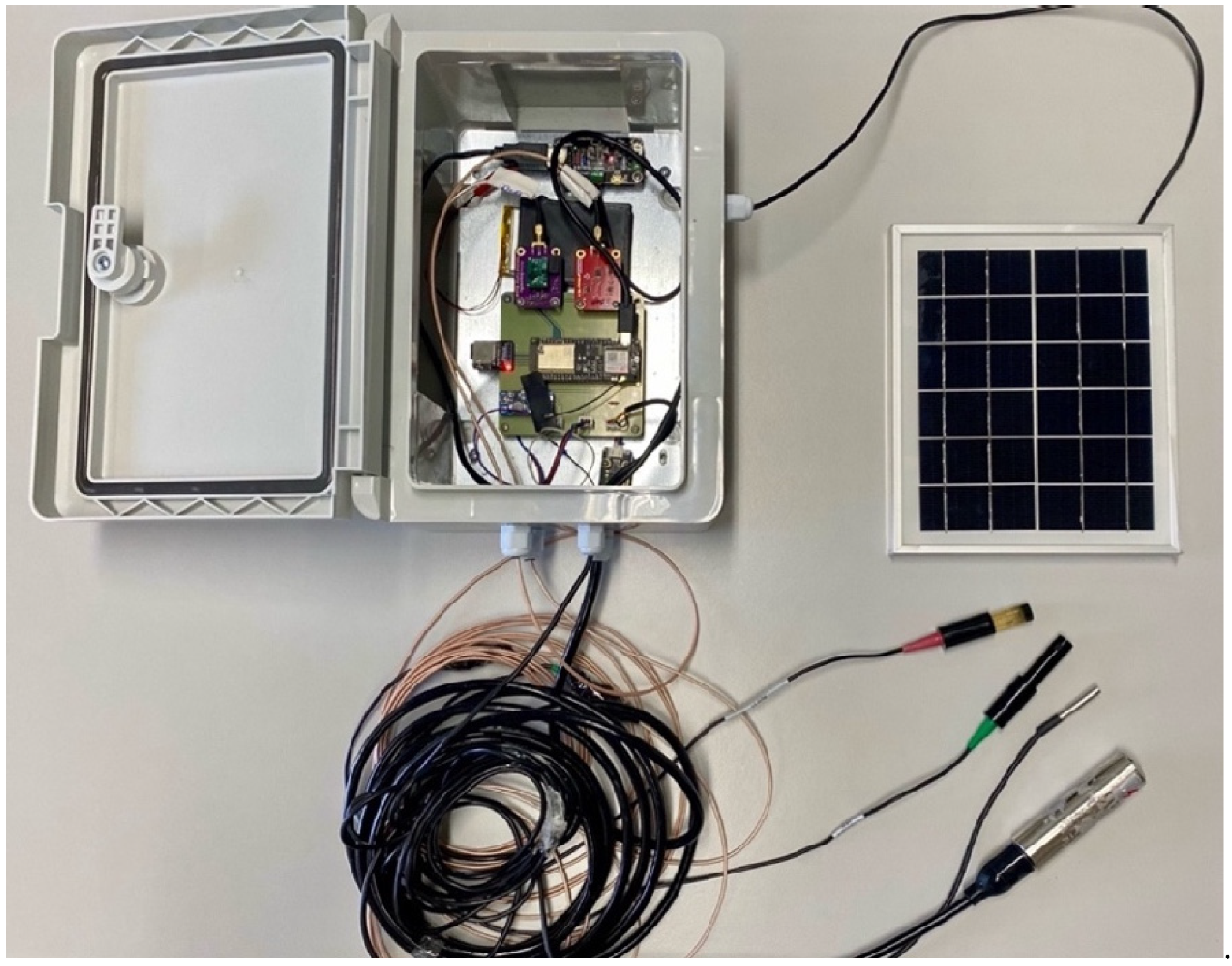

2.2. Printed Circuit Board

2.3. Embedded System and Data Storage

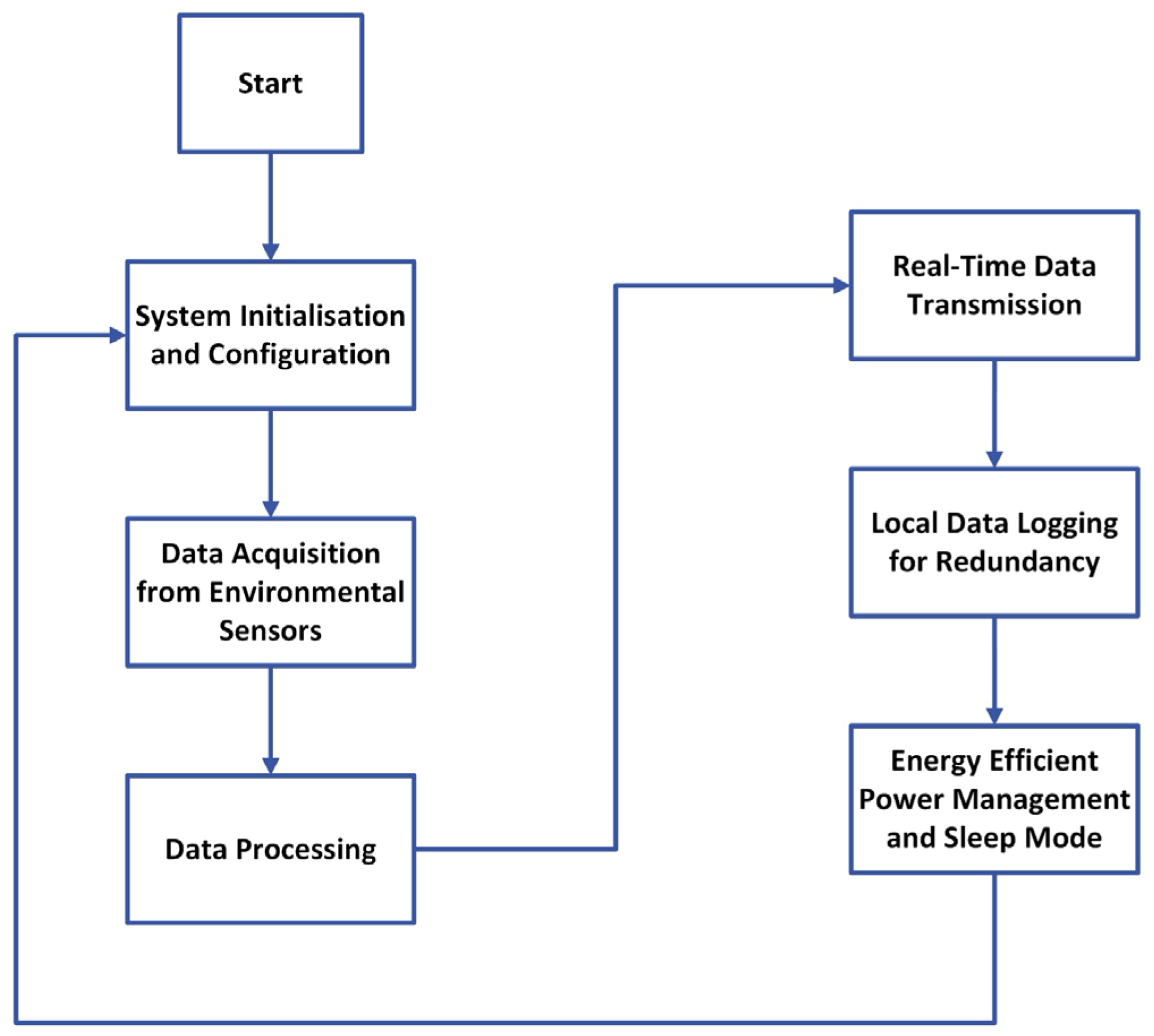

2.4. Measurement System Workflow

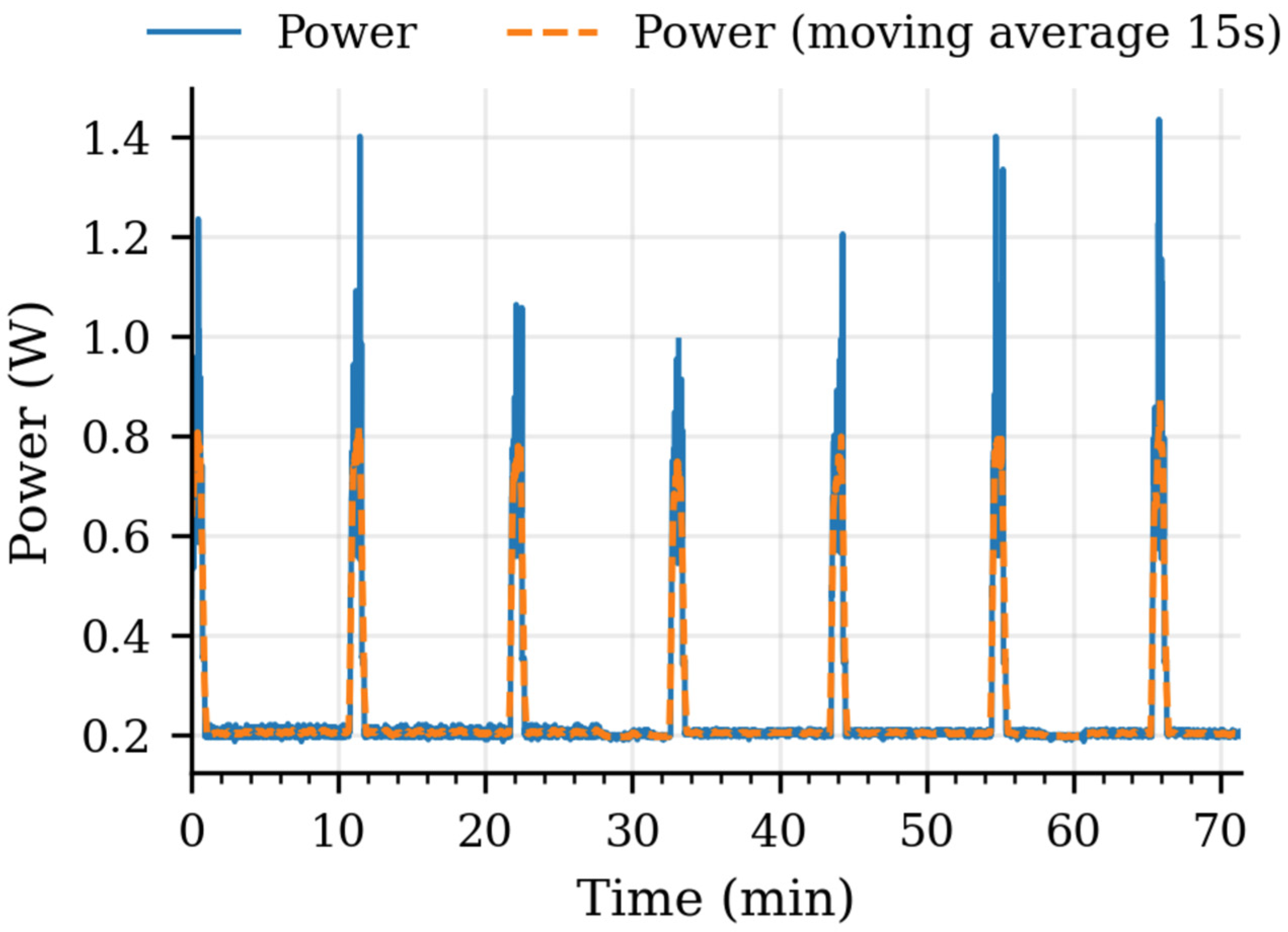

2.5. Power Source and Storage

2.6. Sensitivity Analysis for Combined Uncertainty Evaluation

2.7. Calibration Methods for pH (With Temperature Compensation), Electrical Conductivity, and Water Level

2.7.1. pH Temperature Compensation and Calibration

2.7.2. Conductivity Sensor Calibration

2.7.3. Water Level Sensor Calibration

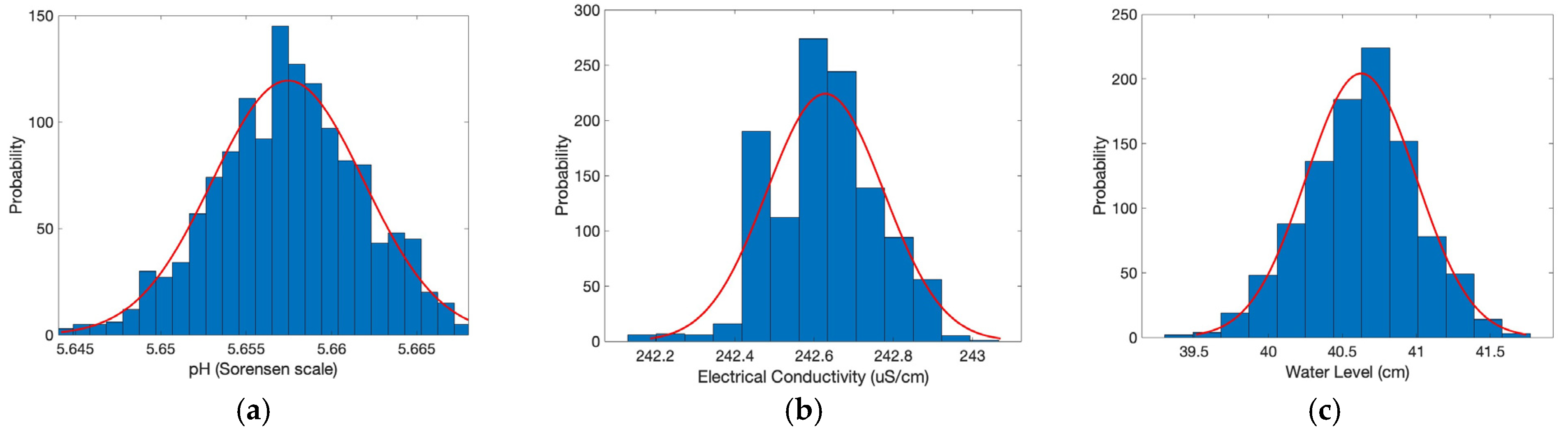

2.8. Measurement Distribution Analysis

2.9. System Integration and Housing

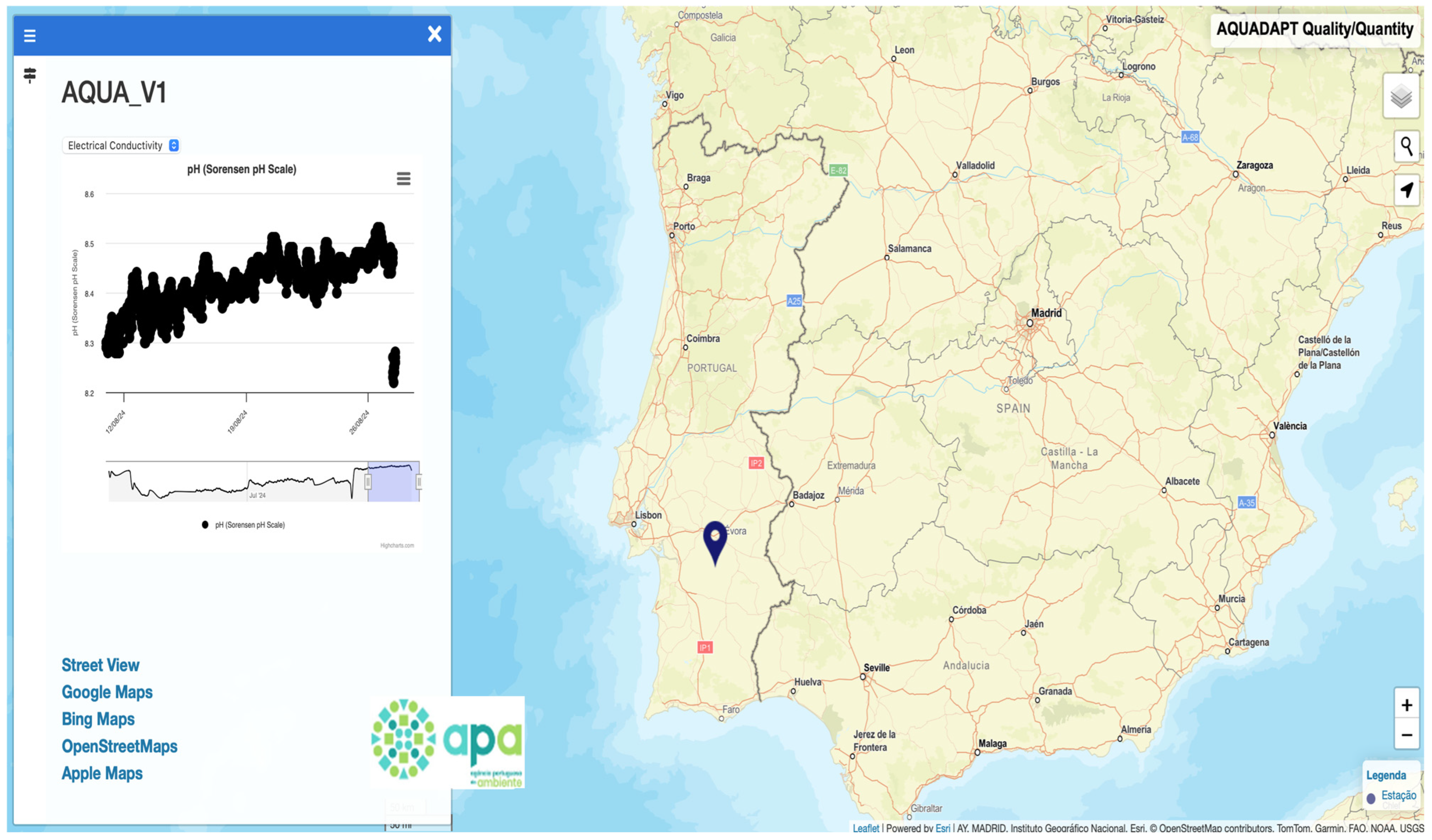

2.10. Dashboard of the Multiparametric Probe System

3. Results and Discussion

3.1. Probability Density Function of Repeated Measurements

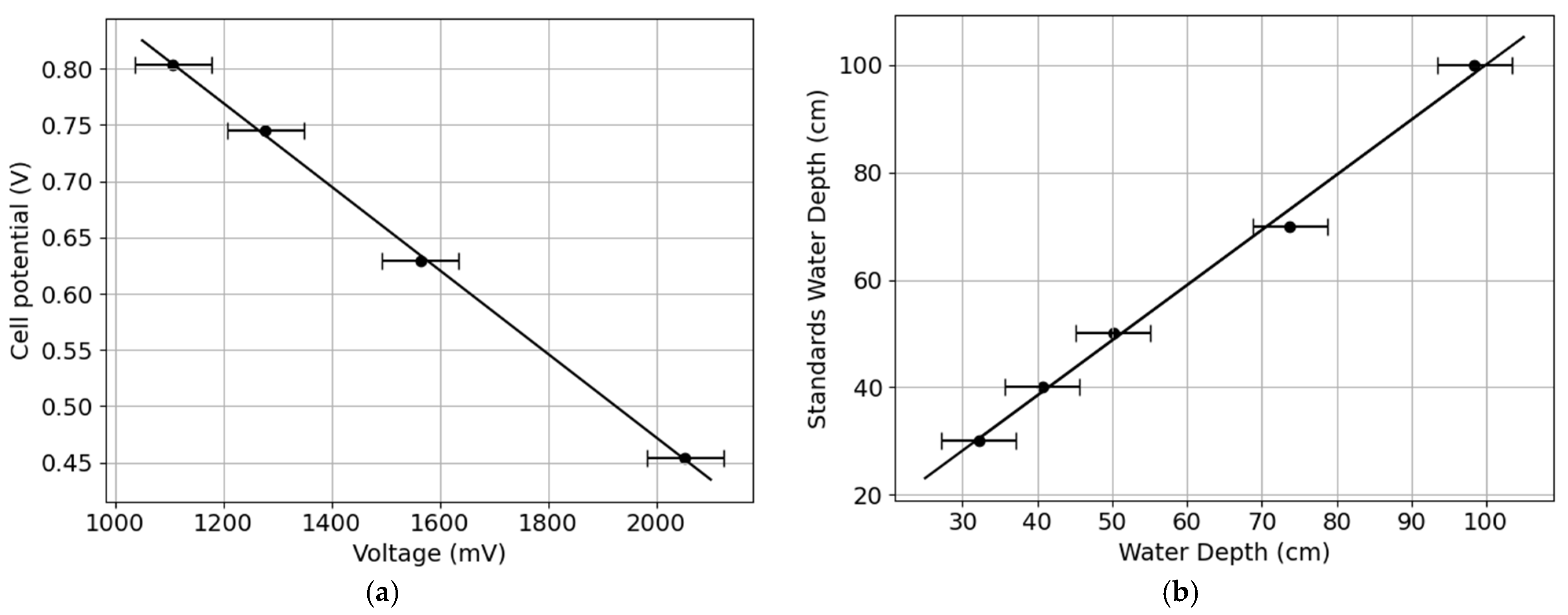

3.2. Calibration Results and Uncertainty for pH (Temperature-Compensated) and Water Level

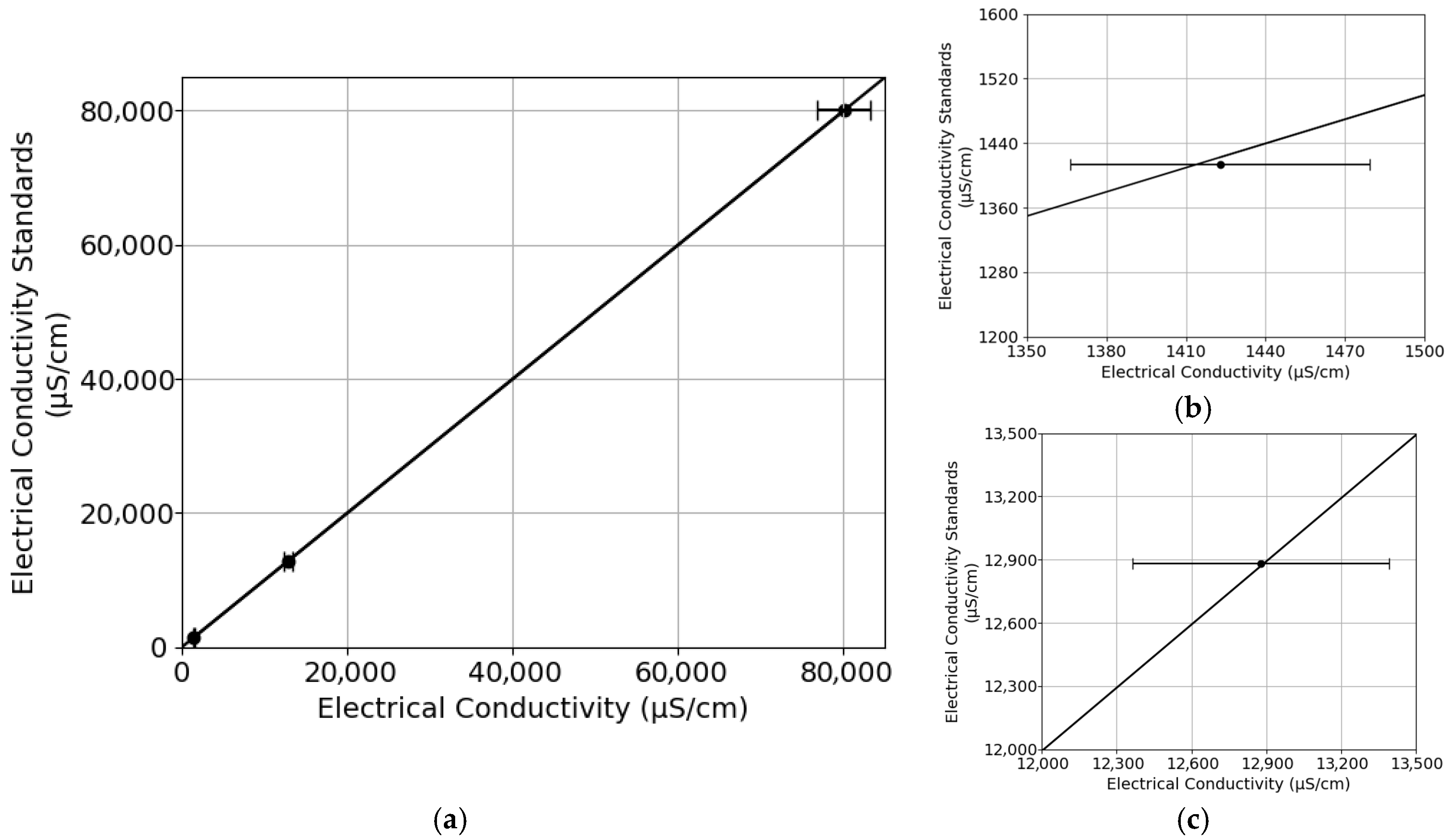

3.3. Conductivity Calibration Results and Uncertainty

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rosa, L.; Chiarelli, D.D.; Rulli, M.C.; Dell’Angelo, J.; D’Odorico, P. Global agricultural economic water scarcity. Sci. Adv. 2020, 6, eaaz6031. [Google Scholar] [CrossRef]

- Dolan, F.; Lamontagne, J.; Link, R.; Hejazi, M.; Reed, P.; Edmonds, J. Evaluating the economic impact of water scarcity in a changing world. Nat. Commun. 2021, 12, 1915. [Google Scholar] [CrossRef]

- Zhang, K.; Li, Y.; Yu, Z.; Yang, T.; Xu, J.; Chao, L.; Ni, J.; Wang, L.; Gao, Y.; Hu, Y.; et al. Xin’anjiang Nested Experimental Watershed (XAJ-NEW) for Understanding Multiscale Water Cycle: Scientific Objectives and Experimental Design. Engineering 2022, 18, 207–217. [Google Scholar] [CrossRef]

- Cheng, P.; Wu, L.; Zhang, H.; Zhou, J. Inclusion of root water absorption and reinforcement in upper bound limit stability analysis of vegetated slopes. Comput. Geotech. 2024, 169, 106227. [Google Scholar] [CrossRef]

- European Parliament; Council of the European Union. Directive 2000/60/EC of the European Parliament and of the Council of 23 October 2000 Establishing a Framework for Community Action in the Field of Water Policy. Off. J. Eur. Communities 2000, 327, 1–73. [Google Scholar]

- Glassmeyer, S.T.; Furlong, E.T.; Kolpin, D.W.; Batt, A.L.; Benson, R.; Boone, J.S.; Conerly, O.; Donohue, M.J.; King, D.N.; Kostich, M.S.; et al. Nationwide reconnaissance of contaminants of emerging concern in source and treated drinking waters of the United States. Sci. Total. Environ. 2017, 581–582, 909–922. [Google Scholar] [CrossRef]

- Korostynska, O.; Mason, A.; Al-Shamma’a, A.I. Monitoring pollutants in wastewater: Traditional lab based versus modern real-time approaches. In Smart Sensors for Real-Time Water Quality Monitoring; Smart Sensors, Measurement and Instrumentation; Springer: Berlin/Heidelberg, Germany, 2013; Volume 4, pp. 1–24. [Google Scholar] [CrossRef]

- Demeter, K.; Burnet, J.B.; Stadler, P.; Kirschner, A.; Zessner, M.; Farnleitner, A.H. Automated online monitoring of fecal pollution in water by enzymatic methods. Curr. Opin. Environ. Sci. Health 2020, 16, 82–91. [Google Scholar] [CrossRef]

- la Cecilia, D.; Dax, A.; Ehmann, H.; Koster, M.; Singer, H.; Stamm, C. Continuous high-frequency pesticide monitoring to observe the unexpected and the overlooked. Water Res. X 2021, 13, 100125. [Google Scholar] [CrossRef] [PubMed]

- Seifert-Dähnn, I.; Furuseth, I.S.; Vondolia, G.K.; Gal, G.; de Eyto, E.; Jennings, E.; Pierson, D. Costs and benefits of automated high-frequency environmental monitoring—The case of lake water management. J. Environ. Manag. 2021, 285, 112108. [Google Scholar] [CrossRef]

- Yin, L.; Wang, L.; Li, T.; Lu, S.; Tian, J.; Yin, Z.; Li, X.; Zheng, W. U-Net-LSTM: Time Series-Enhanced Lake Boundary Prediction Model. Land 2023, 12, 1859. [Google Scholar] [CrossRef]

- Saalidong, B.M.; Aram, S.A.; Otu, S.; Lartey, P.O. Examining the dynamics of the relationship between water pH and other water quality parameters in ground and surface water systems. PLoS ONE 2022, 17, e0262117. [Google Scholar] [CrossRef]

- Sun, F.; Mu, Y.; Leung, K.M.Y.; Su, H.; Wu, F.; Chang, H. China is establishing its water quality standards for enhancing protection of aquatic life in freshwater ecosystems. Environ. Sci. Policy 2021, 124, 413–422. [Google Scholar] [CrossRef]

- Zhu, X.; Wang, L.; Zhang, X.; He, M.; Wang, D.; Ren, Y.; Yao, H.; net Victoria Ngegla, J.; Pan, H. Effects of different types of anthropogenic disturbances and natural wetlands on water quality and microbial communities in a typical black-odor river. Ecol. Indic. 2022, 136, 108613. [Google Scholar] [CrossRef]

- Bonacina, L.; Fasano, F.; Mezzanotte, V.; Fornaroli, R. Effects of water temperature on freshwater macroinvertebrates: A systematic review. Biol. Rev. 2023, 98, 191–221. [Google Scholar] [CrossRef]

- Tian, L.; Zhu, X.; Wang, L.; Du, P.; Peng, F.; Pang, Q. Long-term trends in water quality and influence of water recharge and climate on the water quality of brackish-water lakes: A case study of Shahu Lake. J. Environ. Manag. 2020, 276, 111290. [Google Scholar] [CrossRef]

- Suresh, K.; Tang, T.; Van Vliet, M.T.H.; Bierkens, M.F.P.; Strokal, M.; Sorger-Domenigg, F.; Wada, Y. Recent advancement in water quality indicators for eutrophication in global freshwater lakes. Environ. Res. Lett. 2023, 18, 063004. [Google Scholar] [CrossRef]

- Hamid, A.; Bhat, S.U.; Jehangir, A. Local determinants influencing stream water quality. Appl. Water Sci. 2020, 10, 24. [Google Scholar] [CrossRef]

- Akhtar, N.; Syakir Ishak, M.I.; Bhawani, S.A.; Umar, K. Various Natural and Anthropogenic Factors Responsible for Water Quality Degradation: A Review. Water 2021, 13, 2660. [Google Scholar] [CrossRef]

- Manoj, M.; Kumar, V.D.; Arif, M.; Bulai, E.R.; Bulai, P.; Geman, O. State of the Art Techniques for Water Quality Monitoring Systems for Fish Ponds Using IoT and Underwater Sensors: A Review. Sensors 2022, 22, 2088. [Google Scholar] [CrossRef] [PubMed]

- Jackson, M.C.; Loewen, C.J.G.; Vinebrooke, R.D.; Chimimba, C.T. Net effects of multiple stressors in freshwater ecosystems: A meta-analysis. Glob. Change Biol. 2016, 22, 180–189. [Google Scholar] [CrossRef]

- Ormerod, S.J.; Dobson, M.; Hildrew, A.G.; Townsend, C.R. Multiple stressors in freshwater ecosystems. Freshw. Biol. 2010, 55, 1–4. [Google Scholar] [CrossRef]

- Simonin, M.; Rocca, J.D.; Gerson, J.R.; Moore, E.; Brooks, A.C.; Czaplicki, L.; Ross, M.R.V.; Fierer, N.; Craine, J.M.; Bernhardt, E.S. Consistent declines in aquatic biodiversity across diverse domains of life in rivers impacted by surface coal mining. Ecol. Appl. 2021, 31, e02389. [Google Scholar] [CrossRef]

- Raven, J.A.; Gobler, C.J.; Hansen, P.J. Dynamic CO2 and pH levels in coastal, estuarine, and inland waters: Theoretical and observed effects on harmful algal blooms. Harmful Algae 2020, 91, 101594. [Google Scholar] [CrossRef] [PubMed]

- Ocheli, A.; Otuya, O.B.; Umayah, S.O. Appraising the risk level of physicochemical and bacteriological twin contaminants of water resources in part of the western Niger Delta region. Environ. Monit. Assess. 2020, 192, 324. [Google Scholar] [CrossRef] [PubMed]

- Giraldo, A.; Ruschel, S.; Zhang, X.; Lu, Y.; Liu, Z.; Guterl, J.; Smirnov, R.D.; Snyder, P.; Rusydi, A.F. Correlation between conductivity and total dissolved solid in various type of water: A review. IOP Conf. Ser. Earth Environ. Sci. 2018, 118, 012019. [Google Scholar] [CrossRef]

- Marandi, A.; Polikarpus, M.; Jõeleht, A. A new approach for describing the relationship between electrical conductivity and major anion concentration in natural waters. Appl. Geochem. 2013, 38, 103–109. [Google Scholar] [CrossRef]

- Bhatt, S.; Mishra, A.P.; Chandra, N.; Sahu, H.; Chaurasia, S.K.; Pande, C.B.; Agbasi, J.C.; Khan, M.Y.A.; Abba, S.I.; Egbueri, J.C.; et al. Characterizing seasonal, environmental and human-induced factors influencing the dynamics of Rispana River’s water quality: Implications for sustainable river management. Results Eng. 2024, 22, 102007. [Google Scholar] [CrossRef]

- Belete, M.D.; Diekkrüger, B.; Roehrig, J. Linkage between Water Level Dynamics and Climate Variability: The Case of Lake Hawassa Hydrology and ENSO Phenomena. Climate 2017, 5, 21. [Google Scholar] [CrossRef]

- Cheng, V.Y.S.; Saber, A.; Arnillas, C.A.; Javed, A.; Richards, A.; Arhonditsis, G.B. Effects of hydrological forcing on short- and long-term water level fluctuations in Lake Huron-Michigan: A continuous wavelet analysis. J. Hydrol. 2021, 603, 127164. [Google Scholar] [CrossRef]

- Hayashi, M.; Van Der Kamp, G. Water level changes in ponds and lakes: The hydrological processes. In Plant Disturbance Ecology: The Process and the Response; Elsevier: Amsterdam, The Netherlands, 2021; pp. 321–351. [Google Scholar] [CrossRef]

- Singh, S.; Singh, S.K.; Kanga, S.; Shrivastava, P.K.; Sajan, B.; Meraj, G.; Kumar, P.; Đurin, B.; Kranjčić, N.; Dogančić, D. Analysis of hydrological changes in the Banas River: Analysing Bisalpur Dam impact and trends of the water scarcity. Results Eng. 2024, 22, 101978. [Google Scholar] [CrossRef]

- Mameri, D.; Branco, P.; Ferreira, M.T.; Santos, J.M. Heatwave effects on the swimming behaviour of a Mediterranean freshwater fish, the Iberian barbel Luciobarbus bocagei. Sci. Total. Environ. 2020, 730, 139152. [Google Scholar] [CrossRef]

- Brown, S.J. Future changes in heatwave severity, duration and frequency due to climate change for the most populous cities. Weather. Clim. Extrem. 2020, 30, 100278. [Google Scholar] [CrossRef]

- Graham, D.J.; Bierkens, M.F.P.; van Vliet, M.T.H. Impacts of droughts and heatwaves on river water quality worldwide. J. Hydrol. 2023, 629, 130590. [Google Scholar] [CrossRef]

- Srivastava, S.; Vaddadi, S.; Sadistap, S. Smartphone-based System for water quality analysis. Appl. Water Sci. 2018, 8, 130. [Google Scholar] [CrossRef]

- Reljić, M.; Romić, M.; Romić, D.; Gilja, G.; Mornar, V.; Ondrasek, G.; Kovačić, M.B.; Zovko, M. Advanced Continuous Monitoring System—Tools for Water Resource Management and Decision Support System in Salt Affected Delta. Agriculture 2023, 13, 369. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, X.; Xiang, W.; Wang, T.; Otis, C.; Sarge, L.; Lei, Y.; Li, B. Forward-Looking Roadmaps for Long-Term Continuous Water Quality Monitoring: Bottlenecks, Innovations, and Prospects in a Critical Review. Environ. Sci. Technol. 2022, 56, 5334–5354. [Google Scholar] [CrossRef] [PubMed]

- Essamlali, I.; Nhaila, H.; El Khaili, M. Advances in machine learning and IoT for water quality monitoring: A comprehensive review. Heliyon 2024, 10, e27920. [Google Scholar] [CrossRef]

- Karthikeyan, V.; Visu, Y.P.; Raja, E. Integrated intelligent system for water quality monitoring and theft detection. Water Pr. Technol. 2023, 18, 3035–3047. [Google Scholar] [CrossRef]

- Lu, H.-Y.; Cheng, C.-Y.; Cheng, S.-C.; Cheng, Y.-H.; Lo, W.-C.; Lu, H.-Y.; Cheng, C.-Y.; Cheng, S.-C.; Cheng, Y.-H.; Lo, W.-C.; et al. A Low-Cost AI Buoy System for Monitoring Water Quality at Offshore Aquaculture Cages. Sensors 2022, 22, 4078. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Wang, X.; Funk, T.; Rashid, I.; Herman, B.; Bompoti, N.; Mahmud, M.S.; Chrysochoou, M.; Yang, M.; Vadas, T.M.; et al. A Critical Review for Real-Time Continuous Soil Monitoring: Advantages, Challenges, and Perspectives. Environ. Sci. Technol. 2022, 56, 13546–13564. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, H.; Xu, C.; Zhou, X.; Liu, Z.; Zhao, D.; Lin, J.; Wu, G. A Real-Time Data Acquisition System for Single-Band Bathymetric LiDAR. IEEE Trans. Geosci. Remote. Sens. 2023, 61, 5702721. [Google Scholar] [CrossRef]

- Hao, J.; Chen, P.; Chen, J.; Li, X. Multi-task federated learning-based system anomaly detection and multi-classification for microservices architecture. Futur. Gener. Comput. Syst. 2024, 159, 77–90. [Google Scholar] [CrossRef]

- Westerhoff, R.; McDowell, R.; Brasington, J.; Hamer, M.; Muraoka, K.; Alavi, M.; Muirhead, R.; Lovett, A.; Ruru, I.; Miller, B.; et al. Towards implementation of robust monitoring technologies alongside freshwater improvement policy in Aotearoa New Zealand. Environ. Sci. Policy 2022, 132, 1–12. [Google Scholar] [CrossRef]

- Chander, B.; Pal, S.; De, D.; Buyya, R. Artificial Intelligence-based Internet of Things for Industry 5.0. In Internet of Things; Springer Nature: Berlin/Heidelberg, Germany, 2022; pp. 3–45. [Google Scholar] [CrossRef]

- O’Grady, J.; Zhang, D.; O’Connor, N.; Regan, F. A comprehensive review of catchment water quality monitoring using a tiered framework of integrated sensing technologies. Sci. Total. Environ. 2021, 765, 142766. [Google Scholar] [CrossRef] [PubMed]

- Sudriani, Y.; Sebestyen, V.; Abonyi, J. Surface Water Monitoring Systems—The Importance of Integrating Information Sources for Sustainable Watershed Management. IEEE Access 2023, 11, 36421–36451. [Google Scholar] [CrossRef]

- Thomas, O.; Causse, J. Remote sensing and high-frequency monitoring. In UV-Visible Spectrophotometry of Waters and Soils; Elsevier Science: Amsterdam, The Netherlands, 2022; pp. 297–320. [Google Scholar] [CrossRef]

- Wu, L.; He, B.; Peng, J. Analysis of Rainfall-Caused Seepage into Underlying Bedrock Slope Based on Seepage Deformation Coupling. Int. J. Geéomeéch. 2024, 24, 04024076. [Google Scholar] [CrossRef]

- Carminati, M.; Turolla, A.; Mezzera, L.; Di Mauro, M.; Tizzoni, M.; Pani, G.; Zanetto, F.; Foschi, J.; Antonelli, M. A Self-Powered Wireless Water Quality Sensing Network Enabling Smart Monitoring of Biological and Chemical Stability in Supply Systems. Sensors 2020, 20, 1125. [Google Scholar] [CrossRef]

- Chan, K.; Schillereff, D.N.; Baas, A.C.W.; Chadwick, M.A.; Main, B.; Mulligan, M.; O’Shea, F.T.; Pearce, R.; Smith, T.E.L.; van Soesbergen, A.; et al. Low-cost electronic sensors for environmental research: Pitfalls and opportunities. Prog. Phys. Geogr. Earth Environ. 2021, 45, 305–338. [Google Scholar] [CrossRef]

- Mahbub, M. A smart farming concept based on smart embedded electronics, internet of things and wireless sensor network. Internet Things 2020, 9, 100161. [Google Scholar] [CrossRef]

- Ye, L. Study on embedded system in monitoring of intelligent city pipeline network. Comput. Commun. 2020, 153, 451–458. [Google Scholar] [CrossRef]

- Franklin, R.J. Mohana Industry 4.0: Real time embedded system with integrated data acquisition. In Proceedings of the 3rd International Conference on Smart Systems and Inventive Technology, ICSSIT, Tirunelveli, India, 20–22 August 2020; pp. 637–642. [Google Scholar] [CrossRef]

- Tian, W.; Zhao, Y.; Hou, R.; Dong, M.; Ota, K.; Zeng, D.; Zhang, J. A Centralized Control-Based Clustering Scheme for Energy Efficiency in Underwater Acoustic Sensor Networks. IEEE Trans. Green Commun. Netw. 2023, 7, 668–679. [Google Scholar] [CrossRef]

- Song, F.; Liu, Y.; Shen, D.; Li, L.; Tan, J. Learning Control for Motion Coordination in Wafer Scanners: Toward Gain Adaptation. IEEE Trans. Ind. Electron. 2022, 69, 13428–13438. [Google Scholar] [CrossRef]

- Rajalashmi, K.; Sathiyaseelan, M.; Subarathan, S.; Karthi, C.; Vignesh, S. Investigation of Al & Cu for control, operation and maintenance of starter. Mater. Today Proc. 2022, 66, 1284–1288. [Google Scholar] [CrossRef]

- Ahammed, M.T.; Khan, I. Ensuring power quality and demand-side management through IoT-based smart meters in a developing country. Energy 2022, 250, 123747. [Google Scholar] [CrossRef]

- Mohammed, K.; Abdelhafid, M.; Kamal, K.; Ismail, N.; Ilias, A. Intelligent driver monitoring system: An Internet of Things-based system for tracking and identifying the driving behavior. Comput. Stand. Interfaces 2023, 84, 103704. [Google Scholar] [CrossRef]

- Mateos Matilla, D.; Lozano Murciego, Á.; Jiménez-Bravo, D.M.; Sales Mendes, A.; Leithardt, V.R. Low-cost Edge Computing devices and novel user interfaces for monitoring pivot irrigation systems based on Internet of Things and LoRaWAN technologies. Biosyst. Eng. 2022, 223, 14–29. [Google Scholar] [CrossRef]

- Anshori, I.; Mufiddin, G.F.; Ramadhan, I.F.; Ariasena, E.; Harimurti, S.; Yunkins, H.; Kurniawan, C. Design of smartphone-controlled low-cost potentiostat for cyclic voltammetry analysis based on ESP32 microcontroller. Sens. Bio-Sens. Res. 2022, 36, 100490. [Google Scholar] [CrossRef]

- Sneineh, A.A.; Shabaneh, A.A.A. Design of a smart hydroponics monitoring system using an ESP32 microcontroller and the Internet of Things. MethodsX 2023, 11, 102401. [Google Scholar] [CrossRef]

- Kareem, H.; Dunaev, D. The Working Principles of ESP32 and Analytical Comparison of using Low-Cost Microcontroller Modules in Embedded Systems Design. In Proceedings of the 2021 4th International Conference on Circuits, Systems and Simulation, ICCSS, Kuala Lumpur, Malaysia, 26–28 May 2021; pp. 130–135. [Google Scholar] [CrossRef]

- Munoz, O.; Ruelas, A.; Rosales-Escobedo, P.F.; Acuña, A.; Suastegui, A.; Lara, F.; Reyes-Zamora, R.A.; Rocha, A. Development of an IoT smart energy meter with power quality features for a smart grid architecture. Sustain. Comput. Inform. Syst. 2024, 43, 100990. [Google Scholar] [CrossRef]

- Zidar, J.; Aleksi, I.; Matic, T. Analysis of energy consumption for SPI and I2C communications in ultra-low power embedded systems. In Proceedings of the 2023 46th ICT and Electronics Convention, MIPRO 2023—Proceedings, Opatija, Croatia, 22–26 May 2023; pp. 213–217. [Google Scholar] [CrossRef]

- Jabbar, W.A.; Ting, T.M.; Hamidun, M.F.I.; Kamarudin, A.H.C.; Wu, W.; Sultan, J.; Alsewari, A.R.A.; Ali, M.A.H. Development of LoRaWAN-based IoT system for water quality monitoring in rural areas. Expert Syst. Appl. 2024, 242, 122862. [Google Scholar] [CrossRef]

- Rico, A.; Larson, K.; Gamboa, M. Sensor platform for assessment of water usage patterns in informal settlements. Sci. Rep. 2023, 13, 18958. [Google Scholar] [CrossRef]

- Romero, E.; Le Gendre, R.; Garnier, J.; Billen, G.; Fisson, C.; Silvestre, M.; Riou, P. Long-term water quality in the lower Seine: Lessons learned over 4 decades of monitoring. Environ. Sci. Policy 2016, 58, 141–154. [Google Scholar] [CrossRef]

- Zhou, G.; Lin, G.; Liu, Z.; Zhou, X.; Li, W.; Li, X.; Deng, R. An optical system for suppression of laser echo energy from the water surface on single-band bathymetric LiDAR. Opt. Lasers Eng. 2023, 163, 107468. [Google Scholar] [CrossRef]

- Janani, J.; Sanjeevi Gandhi, A.; Aishwarya, S.; Porselvi, T. Smart Water Monitoring with GSM Alerts: An IoT Approach. In Proceedings of the 2024 IEEE International Students’ Conference on Electrical, Electronics and Computer Science, SCEECS, Bhopal, India, 24–25 February 2024. [Google Scholar] [CrossRef]

- Singh, M.; Ahmed, S. IoT based smart water management systems: A systematic review. Mater. Today Proc. 2021, 46, 5211–5218. [Google Scholar] [CrossRef]

- Smol, M.; Adam, C.; Preisner, M. Circular economy model framework in the European water and wastewater sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef]

- Akhmouch, A.; Clavreul, D.; Hendry, S.; Megdal, S.B.; Nickum, J.E.; Nunes-Correia, F.; Ross, A. Introduction: Introducing the OECD Principles on Water Governance. In OECD Principles on Water Governance; Taylor & Francis Group: London, UK, 2020; pp. 5–12. [Google Scholar] [CrossRef]

- Notti, D.; Cina, A.; Manzino, A.; Colombo, A.; Bendea, I.H.; Mollo, P.; Giordan, D. Low-Cost GNSS Solution for Continuous Monitoring of Slope Instabilities Applied to Madonna Del Sasso Sanctuary (NW Italy). Sensors 2020, 20, 289. [Google Scholar] [CrossRef] [PubMed]

- Song, F.; Liu, Y.; Dong, Y.; Chen, X.; Tan, J. Motion Control of Wafer Scanners in Lithography Systems: From Setpoint Generation to Multi-Stage Coordination. IEEE Trans. Instrum. Meas. 2024, 73, 1–40. [Google Scholar] [CrossRef]

- Wang, G.P.; Yang, J.X. SKICA: A feature extraction algorithm based on supervised ICA with kernel for anomaly detection. J. Intell. Fuzzy Syst. 2018, 36, 761–773. [Google Scholar] [CrossRef]

- de Camargo, E.T.; Spanhol, F.A.; Slongo, J.S.; da Silva, M.V.R.; Pazinato, J.; de Lima Lobo, A.V.; Coutinho, F.R.; Pfrimer, F.W.D.; Lindino, C.A.; Oyamada, M.S.; et al. Low-Cost Water Quality Sensors for IoT: A Systematic Review. Sensors 2023, 23, 4424. [Google Scholar] [CrossRef]

- Alam, A.U.; Clyne, D.; Deen, M.J. A Low-Cost Multi-Parameter Water Quality Monitoring System. Sensors 2021, 21, 3775. [Google Scholar] [CrossRef]

- Georgantas, I.; Mitropoulos, S.; Katsoulis, S.; Chronis, I.; Christakis, I. Integrated Low-Cost Water Quality Monitoring System Based on LoRa Network. Electronics 2025, 14, 857. [Google Scholar] [CrossRef]

- Lal, K.; Menon, S.; Noble, F.; Arif, K.M. Low-cost IoT based system for lake water quality monitoring. PLoS ONE 2024, 19, e0299089. [Google Scholar] [CrossRef]

- Hong, W.J.; Shamsuddin, N.; Abas, E.; Apong, R.A.; Masri, Z.; Suhaimi, H.; Gödeke, S.H.; Noh, M.N.A. Water Quality Monitoring with Arduino Based Sensors. Environments 2021, 8, 6. [Google Scholar] [CrossRef]

- Koestoer, R.A.; Saleh, Y.A.; Roihan, I.; Harinaldi. A simple method for calibration of temperature sensor DS18B20 waterproof in oil bath based on Arduino data acquisition system. AIP Conf. Proc. 2019, 2062, 020006. [Google Scholar] [CrossRef]

- Zhou, R.; Xu, H.; Ren, G. Design of temperature measurement system consisted of FPGA and DS18B20. In Proceedings of the 2011 International Symposium on Computer Science and Society, ISCCS, Kota Kinabalu, Malaysia, 16–17 July 2011; pp. 90–93. [Google Scholar] [CrossRef]

- Septiana, R.; Roihan, I.; Karnadi dan Raldi Koestoer, J.A. Calibration of K-Type Thermocouple and MAX6675 Module with Reference DS18B20 Thermistor Based on Arduino DAQ. Pros. SNTTM XVIII 2019, 1–6. [Google Scholar]

- Bokingkito, P.B.; Llantos, O.E. Design and Implementation of Real-Time Mobile-based Water Temperature Monitoring System. Procedia Comput. Sci. 2017, 124, 698–705. [Google Scholar] [CrossRef]

- Kerdkaew, C.; Kaewpho, S.; Chomkokard, S.; Yaemglin, T.; Cheowanish, I.; Jinuntuya, N.; Wongkokua, W. A calibration method of CMOS-based autocollimator using reflected diffraction pattern of strip reflector. Precis. Eng. 2023, 85, 191–196. [Google Scholar] [CrossRef]

- Gaga, A.; Diouri, O.; Ouazzani Jamil, M. Design and realization of nano satellite cube for high precision atmosphere measurement. Results Eng. 2022, 14, 100406. [Google Scholar] [CrossRef]

- DFRobot Gravity. Gravity: Industrial Stainless Steel Submersible Pressure Level Sensor (0~5 m). 2024. Available online: https://wiki.dfrobot.com/Throw-in_Type_Liquid_Level_Transmitter_SKU_KIT0139 (accessed on 11 September 2024).

- SurveyorTM Analog pH Sensor/Meter|Atlas Scientific. Available online: https://atlas-scientific.com/embedded-solutions/surveryor-analog-ph-sensor-meter/ (accessed on 11 September 2024).

- JCGM. Guide to the Expression of Uncertainty in Measurement—Part 6: Developing and Using Measurement Models. 2020. Available online: https://www.bipm.org/documents/20126/50065290/JCGM_GUM_6_2020.pdf/d4e77d99-3870-0908-ff37-c1b6a230a337 (accessed on 16 November 2025).

- Bard, A.J.; Faulkner, L.R.; White, H.S. Electrochemical Methods: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2022. [Google Scholar]

- Hausmann, J.N.; Traynor, B.; Myers, R.J.; Driess, M.; Menezes, P.W. The pH of Aqueous NaOH/KOH Solutions: A Critical and Non-trivial Parameter for Electrocatalysis. ACS Energy Lett. 2021, 6, 3567–3571. [Google Scholar] [CrossRef]

- Manjakkal, L.; Dervin, S.; Dahiya, R. Flexible potentiometric pH sensors for wearable systems. RSC Adv. 2020, 10, 8594–8617. [Google Scholar] [CrossRef] [PubMed]

- Jerkiewicz, G. Standard and Reversible Hydrogen Electrodes: Theory, Design, Operation, and Applications. ACS Catal. 2020, 10, 8409–8417. [Google Scholar] [CrossRef]

- Allan, J.D.; Castillo, M.M. Stream Ecology: Structure and Function of Running Waters; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Schmidt, W.; Raymond, D.; Parish, D.; Ashton, I.G.C.; Miller, P.I.; Campos, C.J.A.; Shutler, J.D. Design and operation of a low-cost and compact autonomous buoy system for use in coastal aquaculture and water quality monitoring. Aquac. Eng. 2018, 80, 28–36. [Google Scholar] [CrossRef] [PubMed]

- Pinto, D.D.R.; Taborda, J.A.P.; Rodriguez, C.G.F.; Martinez, R.G.; Bernal, A.G.A. Water quality probe co-design for water monitoring in rural communities in Colombia. In Proceedings of the 2022 IEEE International Humanitarian Technology Conference, IHTC, Ottawa, ON, Canada, 2–4 December 2022; pp. 124–128. [Google Scholar] [CrossRef]

| Sensor | Cleaning Frequency | Verification/Calibration | Field Durability (Corrosion/Physical) |

|---|---|---|---|

| E.C. Conductivity | Rinse after retrieval. Quarterly chemical clean (EC-safe cleaner); every 2–4 weeks in high fouling. | Annual verification against standards; recalibrate only if verification fails after cleaning. Always apply temperature compensation. | Electrodes robust; housings/cables are usual failure points. Avoid galvanic pairs; isolate from copper. Protect cable with strain relief. |

| pH | Rinse after use; store wet. Quarterly chemical clean (or on drift); monthly in high-fouling/harsh chemistry. | Monthly verification; annual calibration in benign media, up to monthly in harsh acids/bases. Temperature compensation recommended. | Glass bulb/junction fragile; protect from impact/abrasion and thermal shock. |

| Temperature | Minimal; if submerged, quarterly wipe to remove films; monthly if heavy fouling. | Annual verification (ice bath or calibrated meter); recalibration rarely required; prefer 3-/4-wire. | Element is robust; cable/connector ingress and flex fatigue are main risks. Good corrosion resistance. |

| Water Level | At six months, gentle rinse of diaphragm with low-pressure water/air; every 2–4 weeks in high-fouling waters. Never scrape piezoelectric sensor. | Semiannual verification (static head or reference gauge); increase to quarterly in harsh service; zero-check after cleaning. | Use IP68 for continuous submersion. Protect piezoelectric sensor from impact/abrasion with a cage. |

| Water Quality Measurement System | AQUA V1 | [97] | [67] | [98] | HACH SC1000 Multi-Parameter | HANNA Multiparameter HI98194 | Aqua TROLL 800 |

|---|---|---|---|---|---|---|---|

| Cost | <USD 1000 | <GBP 5000 | USD 240 | USD 10,000 to USD 15,000 | USD 2003 to USD 2645 | USD 7000 to USD 8000 | |

| Measurement Principle: pH | Potentiometry | Potentiometry | Potentiometry | Potentiometry | Potentiometry by differential electrode | Potentiometry | Potentiometry |

| Measurement Principle: Conductivity | Electrical conductance | Electrical conductance | Electrical conductance | Inductive (Toroidal) | Electrical conductance | Electrical conductance | |

| Measurement Principle: Water Level | Piezoresistive | Pressure transducer with stainless steel diaphragm | Piezoresistive; Ceramic | ||||

| Response Time: pH | 95% in 1 s | <1 min | T63 < 3 s, T90 < 15 s, 95 < 30 s | ||||

| Response Time: Conductivity | 90% in 1 s | T63 < 1 s, T90 < 3 s, T95 < 5 s | |||||

| Response Time: Water Level | T63 < 1 s, T90 < 1 s, T95 < 1 s | ||||||

| Range: pH | 0–14 pH | 0–14 pH | 0–14 pH | 0–14 pH | −2.0 to 14.0 pH | 0.00 to 14.00 pH | 0 to 14 pH units |

| Range; Conductivity | 5 to 200,000 μS/cm | 1000 to 55,000 μS cm−1 | 0 to 20,000 μS/cm | 200 to 2,000,000 μS/cm | 0 to 200,000 µS/cm. | 0 to 350,000 μS/cm | |

| Range: Water Level | 0 to 5 m | 9.14 m | 0 to 30 m | 0 to 9 m up to 0–250 m | |||

| Expanded Uncertainty: pH | ±0.4 pH | ||||||

| Expanded Uncertainty: Conductivity | ±57.20 μS/cm at 1413 μS/cm; ±515.20 μS/cm at 12,880 μS/cm; ±3200.00 μS/cm at 80.000 μS/cm | ||||||

| Expanded Uncertainty: Water Level | ±5.50 cm | ||||||

| Accuracy: pH | 0.002 pH | 0.15 pH | 0.1 pH | 0.02 pH | 0.02 pH | 0.1 pH | |

| Accuracy: Conductivity | 2.0% | 5% of reading, in waters within a range of 3000 μS cm−1, waters with greater variation can have greater error. | 5.0% | 0.01% of reading | 1% of reading or 1 µS/cm, whichever is greater | 0.5% of reading plus 1 μS/cm from 0 to 100,000 μS/cm; 1.0% of reading from 100,000 to 200,000 μS/cm; 2.0% of reading from 200,000 to 350,000μS/cm | |

| Accuracy: Water Level | 0.5% | 0.003 | 0.16% full scale, 1.5% of reading at constant temp (±2.5 °C); 0.20% full scale, 1.75% of reading from 0 to 30 °C; 0.25% full scale, 2.1% of reading from 0 to 70 °C | 0.1% FS from −5 to 50 °C | |||

| Power Source | Battery/External (DC) | Battery | Battery | External DC supply | External AC supply | Battery | Battery |

| Solar-Powered | ✓ | ✗ | ✓ | ✗ | ✗ | ✗ | ✗ |

| GSM/GPRS | ✓ | ✗ | ✗ | ✗ | ✓ | ✗ | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fernandes, S.; Fialho, A.; Santos, J.M.; Ferreira, T.; Filipe, A.F. Development of a Cost-Effective Multiparametric Probe for Continuous Real-Time Monitoring of Aquatic Environments. Sensors 2025, 25, 7110. https://doi.org/10.3390/s25237110

Fernandes S, Fialho A, Santos JM, Ferreira T, Filipe AF. Development of a Cost-Effective Multiparametric Probe for Continuous Real-Time Monitoring of Aquatic Environments. Sensors. 2025; 25(23):7110. https://doi.org/10.3390/s25237110

Chicago/Turabian StyleFernandes, Samuel, Alice Fialho, José Maria Santos, Teresa Ferreira, and Ana Filipa Filipe. 2025. "Development of a Cost-Effective Multiparametric Probe for Continuous Real-Time Monitoring of Aquatic Environments" Sensors 25, no. 23: 7110. https://doi.org/10.3390/s25237110

APA StyleFernandes, S., Fialho, A., Santos, J. M., Ferreira, T., & Filipe, A. F. (2025). Development of a Cost-Effective Multiparametric Probe for Continuous Real-Time Monitoring of Aquatic Environments. Sensors, 25(23), 7110. https://doi.org/10.3390/s25237110