Evaluating Fluid Distribution by Distributed Acoustic Sensing (DAS) with Perforation Erosion Effect

Abstract

1. Introduction

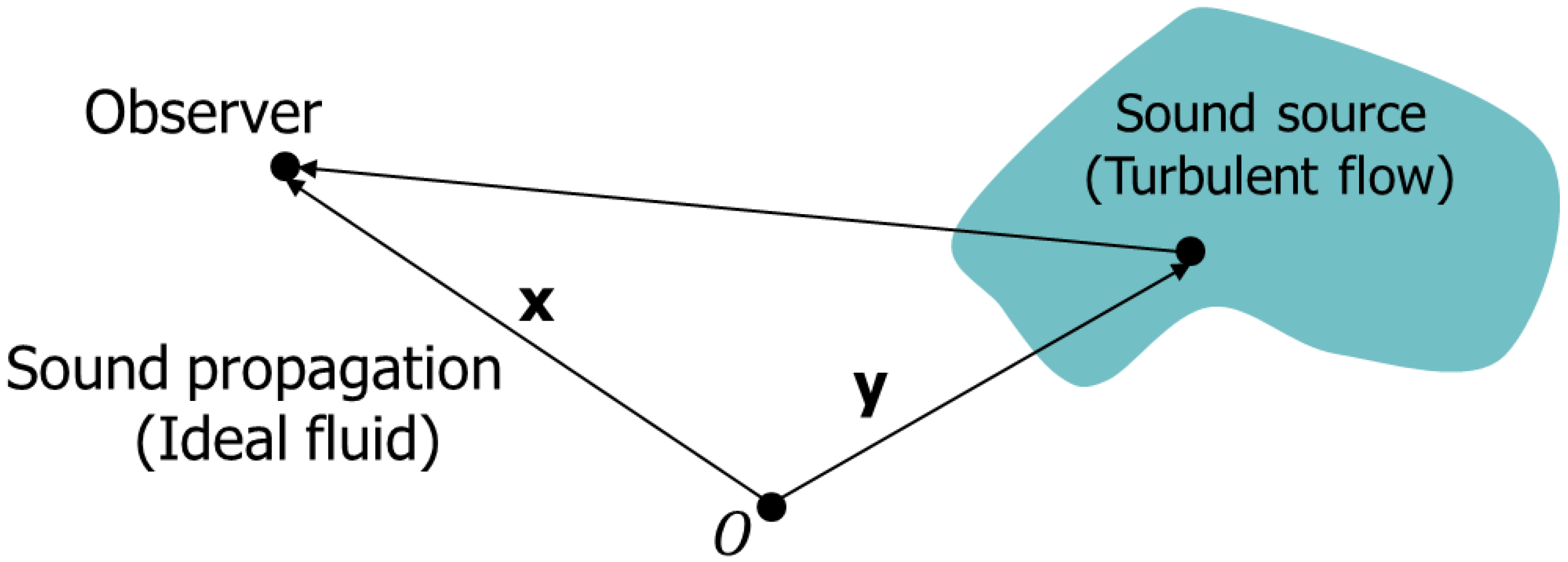

2. Acoustic Theories

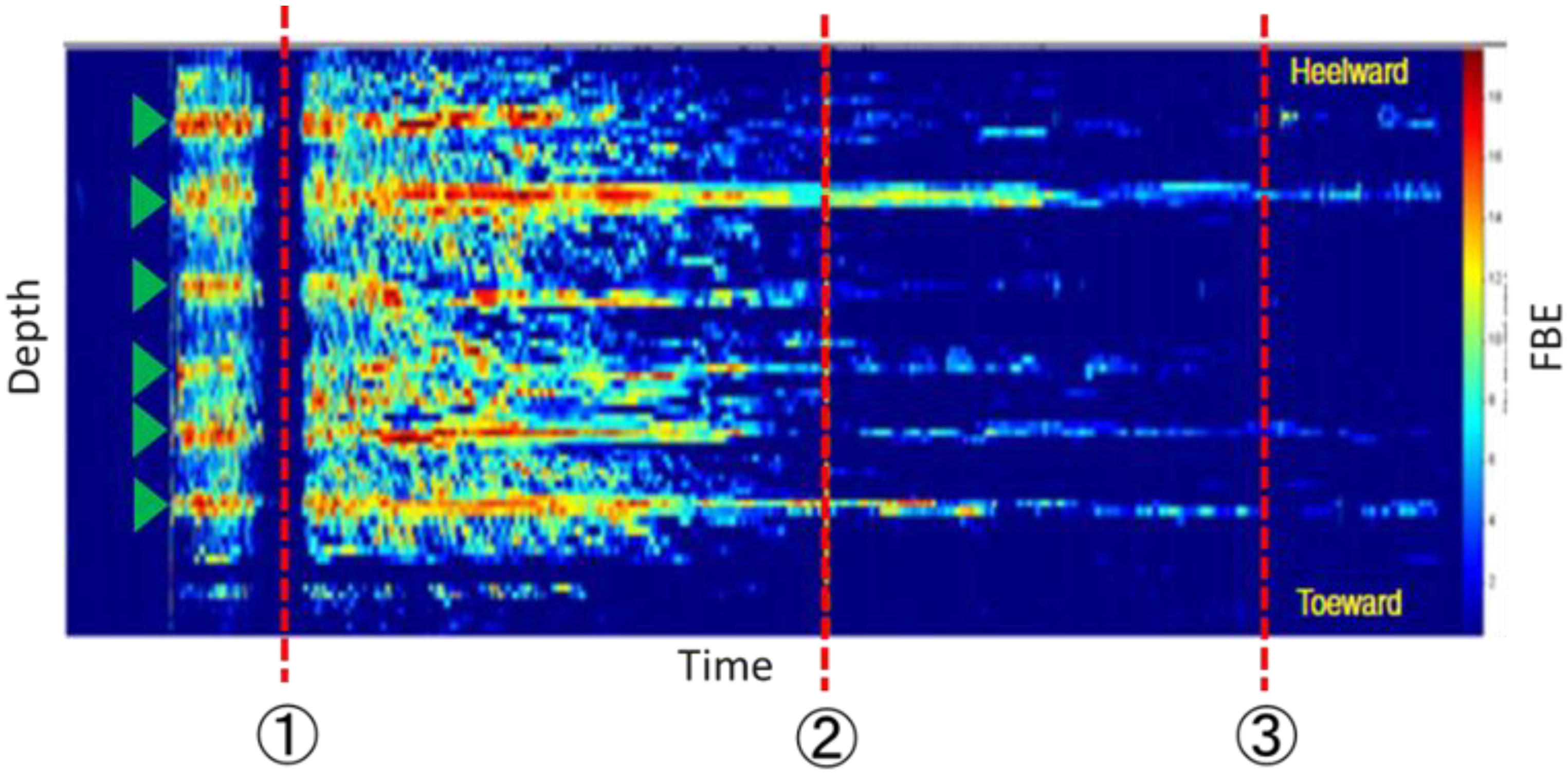

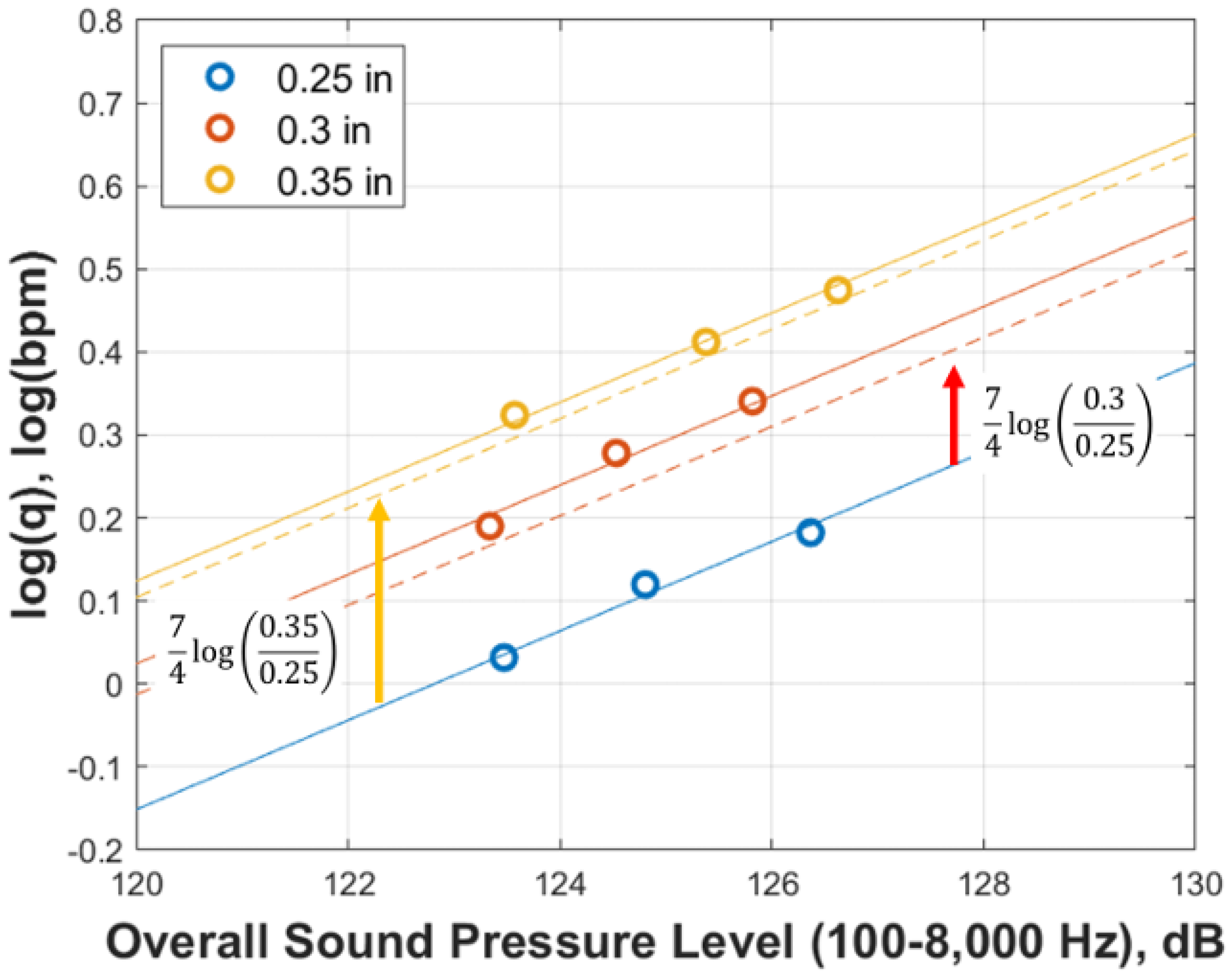

2.1. Empirical Correlation of Acoustics Induced by Perforation Flow

2.2. Perforation Erosion Effect on Acoustic Signal

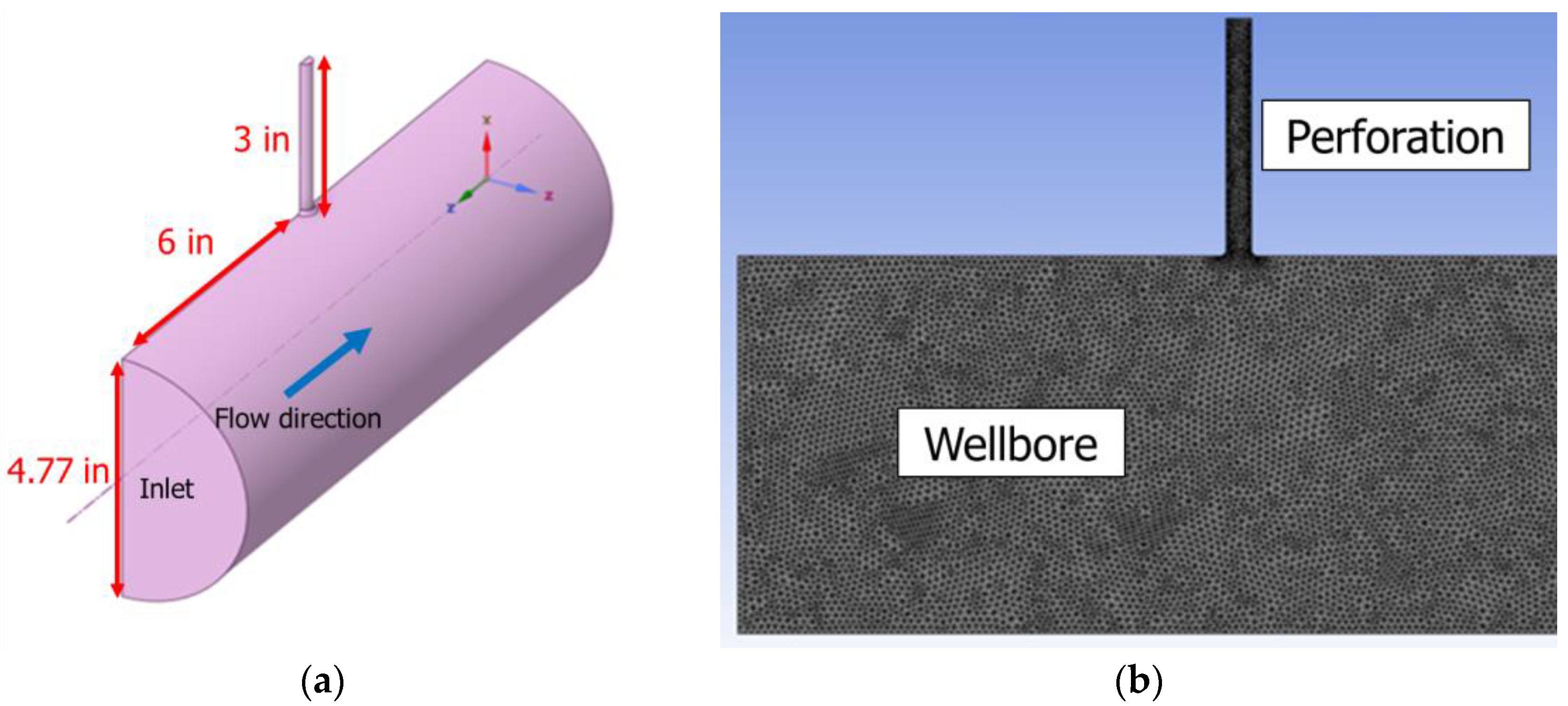

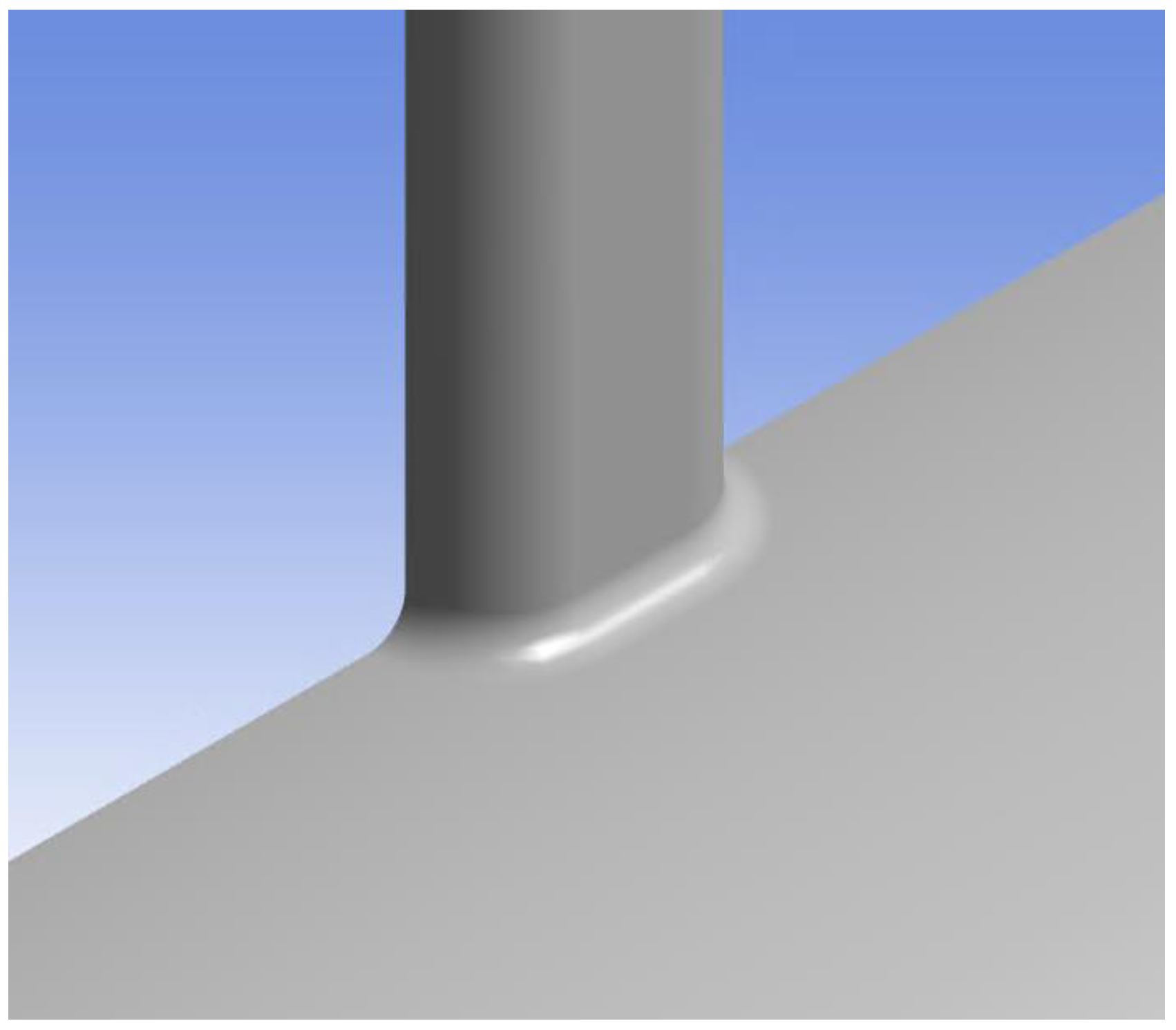

3. CFD Acoustic Simulation

3.1. Work Flow

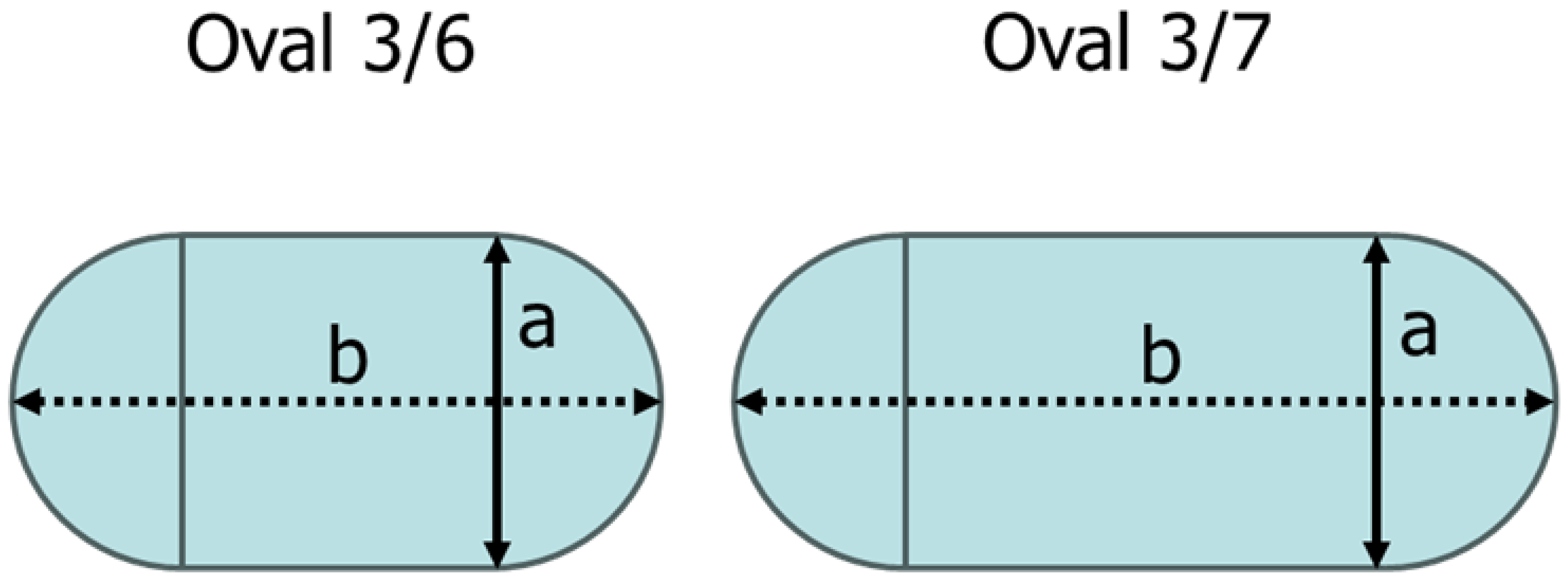

3.2. Oval-Shaped Perforation Geometry

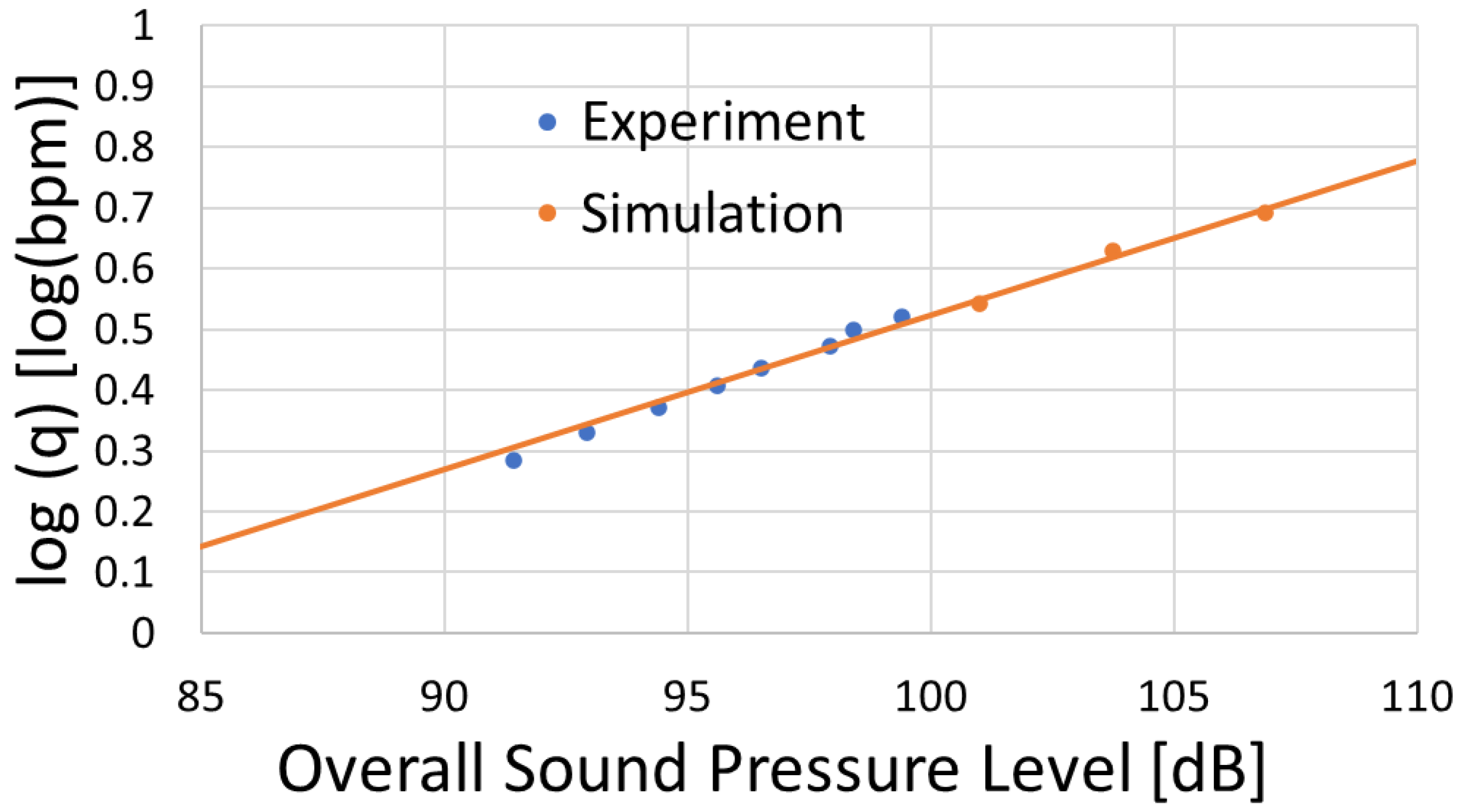

4. Model Validation Using a Circular Perforation

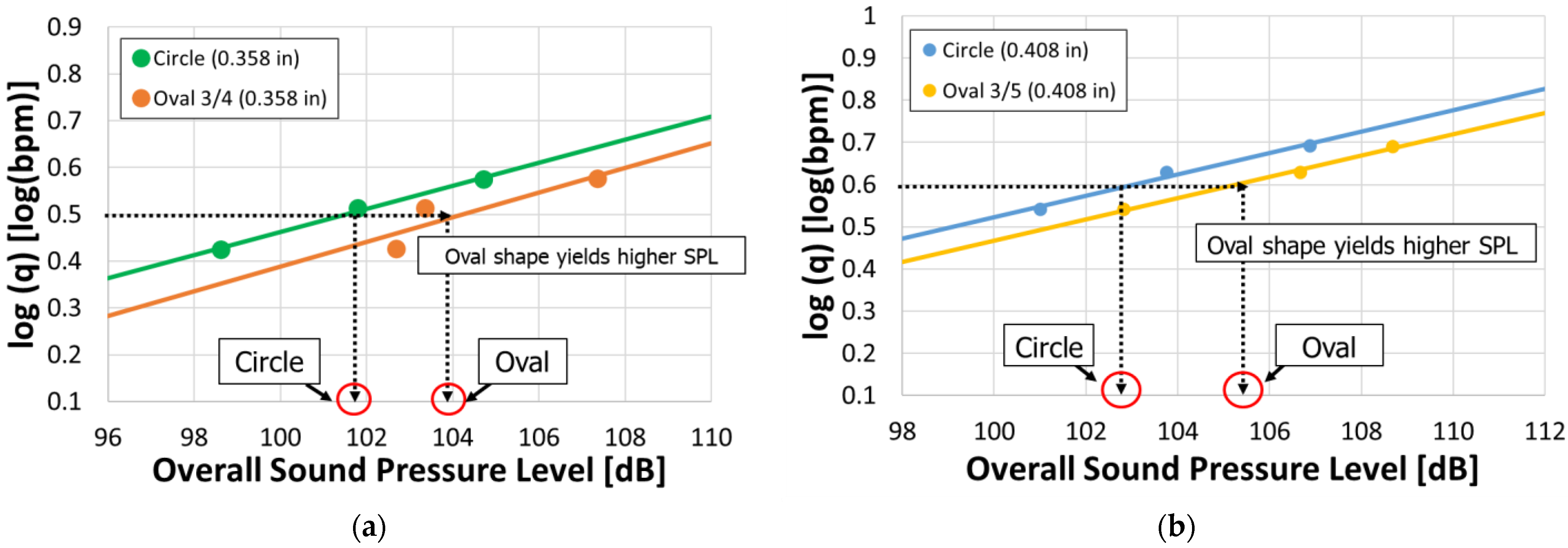

5. Comparison Under Equal Minor Axis

6. Comparison Under Equal Cross-Sectional Area

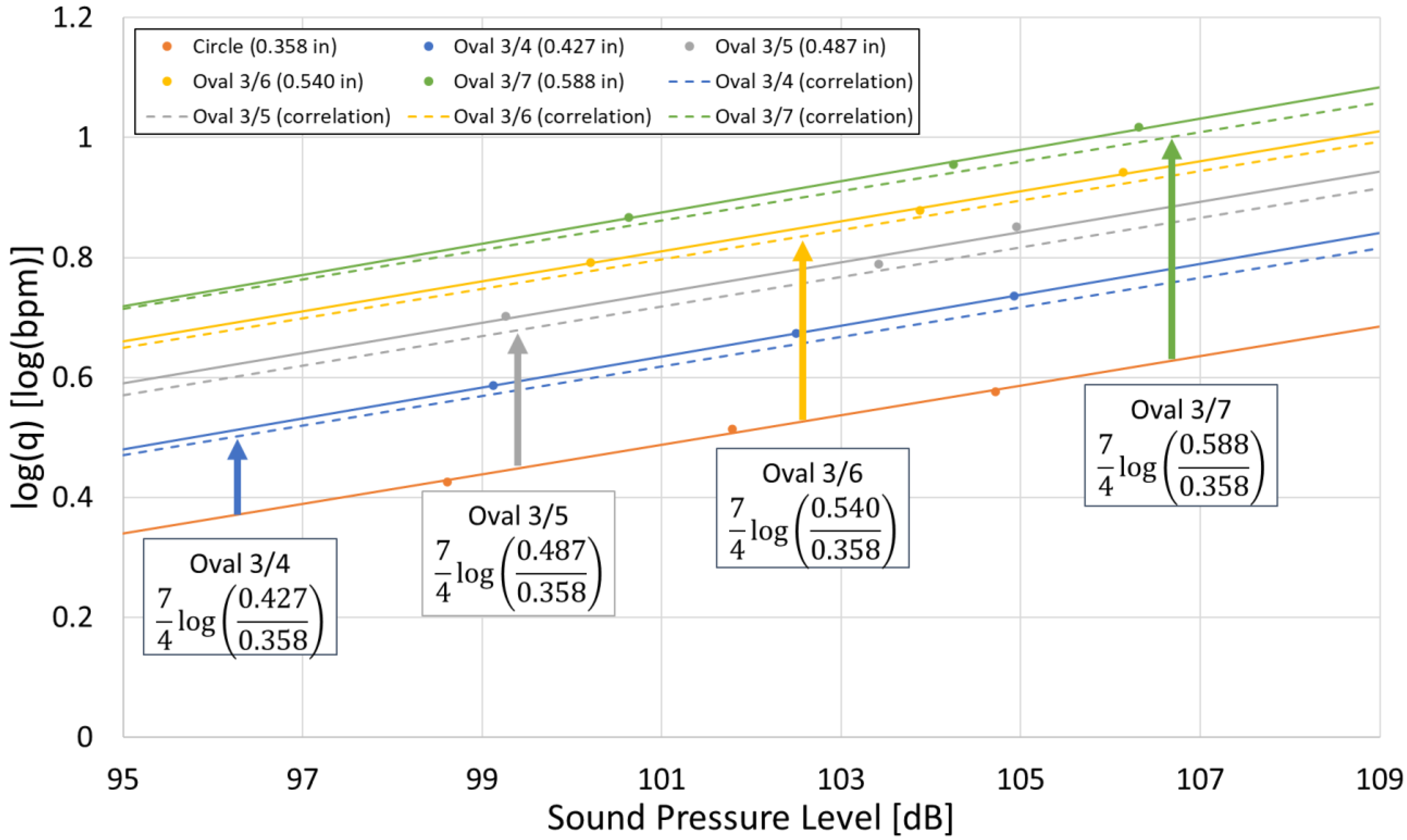

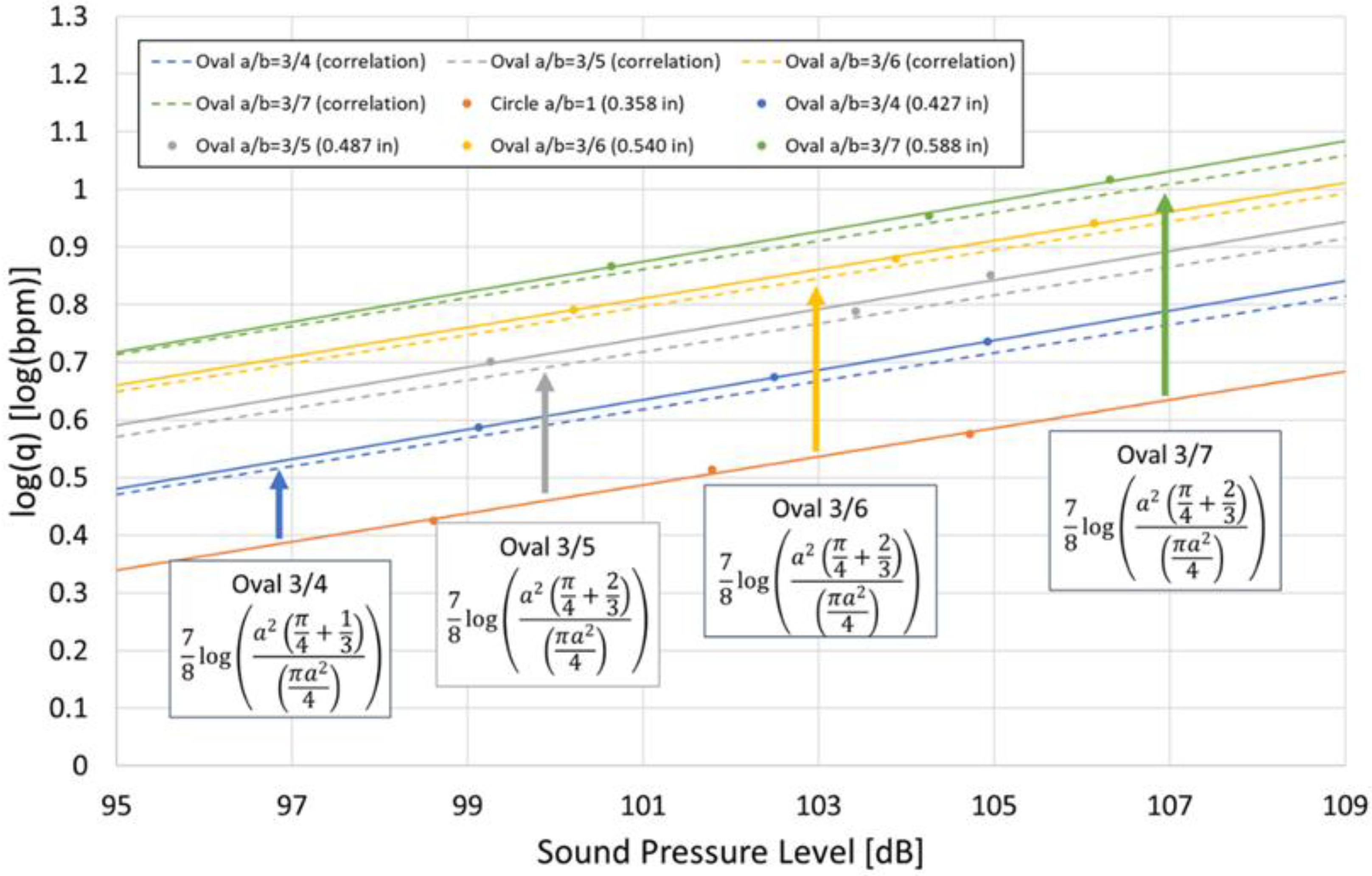

7. Acoustic Correlation

8. Conclusions

- From the results of Case 1 and Case 2, it was confirmed that even when perforations erode in the flow direction and evolve into oval shapes, the relationship between and the overall sound pressure level continues to follow a straight line with a defined intercept and slope, consistent with previous studies.

- From the results of Case 1 and Case 2, it was also shown that even when perforations erode into an oval shape and only the major axis increases, the intercept increases logarithmically with erosion, resulting in a reduction in sound amplitude, while the slope remains constant.

- From the results of Case 3 and Case 4, it was demonstrated that when the cross-sectional area and flow rate are the same, oval-shaped perforations generate a greater overall sound pressure level compared to circular perforations. Based on these results, it is suggested that when estimating flow rate from DAS data, assuming a circular erosion shape could lead to overestimations or inaccuracies.

- By rewriting the correlation derived by Hamanaka [17] in terms of the cross-sectional area, an area-based correlation was developed that incorporates both the minor and major axes of oval-shaped perforations. This area-based correlation enables consideration of the effects of perforation shape differences and helps reduce potential errors in DAS interpretation that may arise from variations in perforation geometry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, D.; Furui, K. Modern Completion Technology for Oil and Gas Wells; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Roberts, G.; Whittaker, J.; McDonald, J.; Paxson, T. Proppant Distribution Observations from 20,000+ Perforation Erosion Measurements. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2020. [Google Scholar] [CrossRef]

- Horton, B. A Shot in the Dark: How Your Post-Fracture Perforation Imaging Can Be Misleading and How to Better Understand Cluster Efficiency and Optimize Limited Entry Perforating. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Virtual, 4–6 May 2021. [Google Scholar] [CrossRef]

- Eckdahl, R.; Vigrass, A.; Singh, A.; Liu, X.; Chrusch, L. Assessment of Limited Entry Cluster Distribution Effectiveness and Impactful Variables Using Perforation Erosion Measurements. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 1–3 February 2022. [Google Scholar] [CrossRef]

- Liu, X.; Wang, J.; Singh, A.; Rijken, M.; Wehunt, D.; Chrusch, L.; Ahmad, F.; Miskimins, J. Achieving Near-Uniform Fluid and Proppant Placement in Multistage Fractured Horizontal Wells: A Computational Fluid Dynamics Modeling Approach. SPE Prod. Oper. 2021, 36, 926–945. [Google Scholar] [CrossRef]

- Snider, P.; Baumgartner, S.; Mayerhofer, M.; Woltz, M. Execution and Learnings from the First Two Surface Tests Replicating Unconventional Fracturing and Proppant Transport. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 1–3 February 2022. [Google Scholar] [CrossRef]

- Kolle, J.; Mueller, A.; Baumgartner, S.; Cuthill, D. Modeling Proppant Transport in Casing and Perforations Based on Proppant Transport Surface Tests. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 1–3 February 2022. [Google Scholar] [CrossRef]

- Snyder, J.; Cramer, D.; White, M. Improved Treatment Distribution through Oriented Perforating. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Virtual, 4–6 May 2021. [Google Scholar] [CrossRef]

- Shoaibi, S.; Farsi, S.; Suchta, B.; Persac, S.; Wakwak, A.; Gorgi, S. Fluid and Proppant Distribution and Fracture Geometry Calibration Using Permanent Fiber-Optic Sensing DAS/DTS–Oman Case Study. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 10–12 October 2023. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Z.; Wang, M.; Li, S.; Li, J.; Xu, J.; Cai, B.; Weng, D. A Hybrid Workflow for Fracture Geometry Characterization: Forward Propagation Modeling Integrated with In-Well DAS Data Interpretation. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 20–22 October 2025. [Google Scholar] [CrossRef]

- Cramer, D.D.; Zhang, J. Pressure-Based Diagnostics for Evaluating Treatment Confinement. SPE Prod. Oper. 2021, 36, 530–552. [Google Scholar] [CrossRef]

- Cramer, D.; Friehauf, K.; Roberts, G.; Whittaker, J. Integrating Distributed Acoustic Sensing, Treatment-Pressure Analysis, and Video-Based Perforation Imaging to Evaluate Limited-Entry-Treatment Effectiveness. SPE Prod. Oper. 2020, 35, 0730–0755. [Google Scholar] [CrossRef]

- Chen, K. Acoustic Behavior of Flow from Fracture to Wellbore. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2015. [Google Scholar]

- Pakhotina, I. Using Distributed Acoustic Sensing for Multiple-Stage Fractured Well Diagnosis. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2020. [Google Scholar]

- Pakhotina, J.; Zhu, D.; Hill, A.D.; Santos, R. Characterization of Production through a Fracture Cell Using Acoustic Data. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 9–11 October 2017. [Google Scholar] [CrossRef]

- Sakaida, S.; Hamanaka, Y.; Zhu, D.; Hill, A.D. Development of Fracture Diagnostic Methods for Fluid Distribution Based on Quantitative Interpretation of Distributed Acoustic Sensing and Distributed Temperature Sensing. Interpretation 2023, 11, T757–T767. [Google Scholar] [CrossRef]

- Hamanaka, Y. Investigation of the Influence of Perforation Erosion on High-Frequency Distributed Acoustic Sensing. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2024. [Google Scholar]

- Hamanaka, Y.; Zhu, D.; Hill, A.D.; Kerr, E. Evaluation of Perforation Erosion and Fluid Allocation with Distributed Acoustic Sensing in Multi-Stage Fracture Stimulation. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 4–6 February 2025. [Google Scholar] [CrossRef]

- ANSYS Inc. ANSYS Fluent User’s Guide, Release 2024 R2. Available online: https://ansyshelp.ansys.com (accessed on 5 November 2025).

- Chen, J. Analysis of Acoustic Signals Generated by Proppant Slurry Flow Through Perforations. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2024. [Google Scholar]

- Lighthill, M.J. On Sound Generated Aerodynamically I: General Theory. Proc. R. Soc. Lond. A 1952, 211, 564–587. [Google Scholar] [CrossRef]

- Ffowcs Williams, J.E.; Hawkings, D.L. Sound Generation by Turbulence and Surfaces in Arbitrary Motion. Philos. Trans. R. Soc. Lond. Ser. A Math. Phys. Sci. 1969, 264, 321–342. [Google Scholar] [CrossRef]

- Harris, F.J. On the Use of Windows for Harmonic Analysis with the Discrete Fourier Transform. Proc. IEEE 1978, 66, 51–83. [Google Scholar] [CrossRef]

- Abdelrahman, A.M.; Abdelal, M.A.; Mobasher, A.M. Investigating the Effect of Orifice Area on the Discharge Coefficient for Different Orifice Shapes. Civ. Eng. Res. Mag. 2020, 42, 28–37. [Google Scholar]

| Cases | Perforation Shapes | Overall Sound Pressure Level (dB) at Log(q) = 0.5 | Flow Rate (BPM) at Overall Sound Pressure Level = 100 (dB) |

|---|---|---|---|

| Case 3 *1 | Circle | 101.6 | 2.88 |

| Oval 3/4 | 104.1 | 2.46 | |

| Case 4 *2 | Circle | 99.0 | 3.35 |

| Oval 3/5 | 101.2 | 2.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oshikata, D.; Zhu, D.; Hill, A.D. Evaluating Fluid Distribution by Distributed Acoustic Sensing (DAS) with Perforation Erosion Effect. Sensors 2025, 25, 7037. https://doi.org/10.3390/s25227037

Oshikata D, Zhu D, Hill AD. Evaluating Fluid Distribution by Distributed Acoustic Sensing (DAS) with Perforation Erosion Effect. Sensors. 2025; 25(22):7037. https://doi.org/10.3390/s25227037

Chicago/Turabian StyleOshikata, Daichi, Ding Zhu, and A. D. Hill. 2025. "Evaluating Fluid Distribution by Distributed Acoustic Sensing (DAS) with Perforation Erosion Effect" Sensors 25, no. 22: 7037. https://doi.org/10.3390/s25227037

APA StyleOshikata, D., Zhu, D., & Hill, A. D. (2025). Evaluating Fluid Distribution by Distributed Acoustic Sensing (DAS) with Perforation Erosion Effect. Sensors, 25(22), 7037. https://doi.org/10.3390/s25227037