Gaussian Process-Based Multi-Fidelity Bayesian Optimization for Optimal Calibration Point Selection

Abstract

1. Introduction

2. Problem Formulation and Theoretical Foundation

2.1. Calibration Point Selection Problem

2.2. Objective Function Formulation

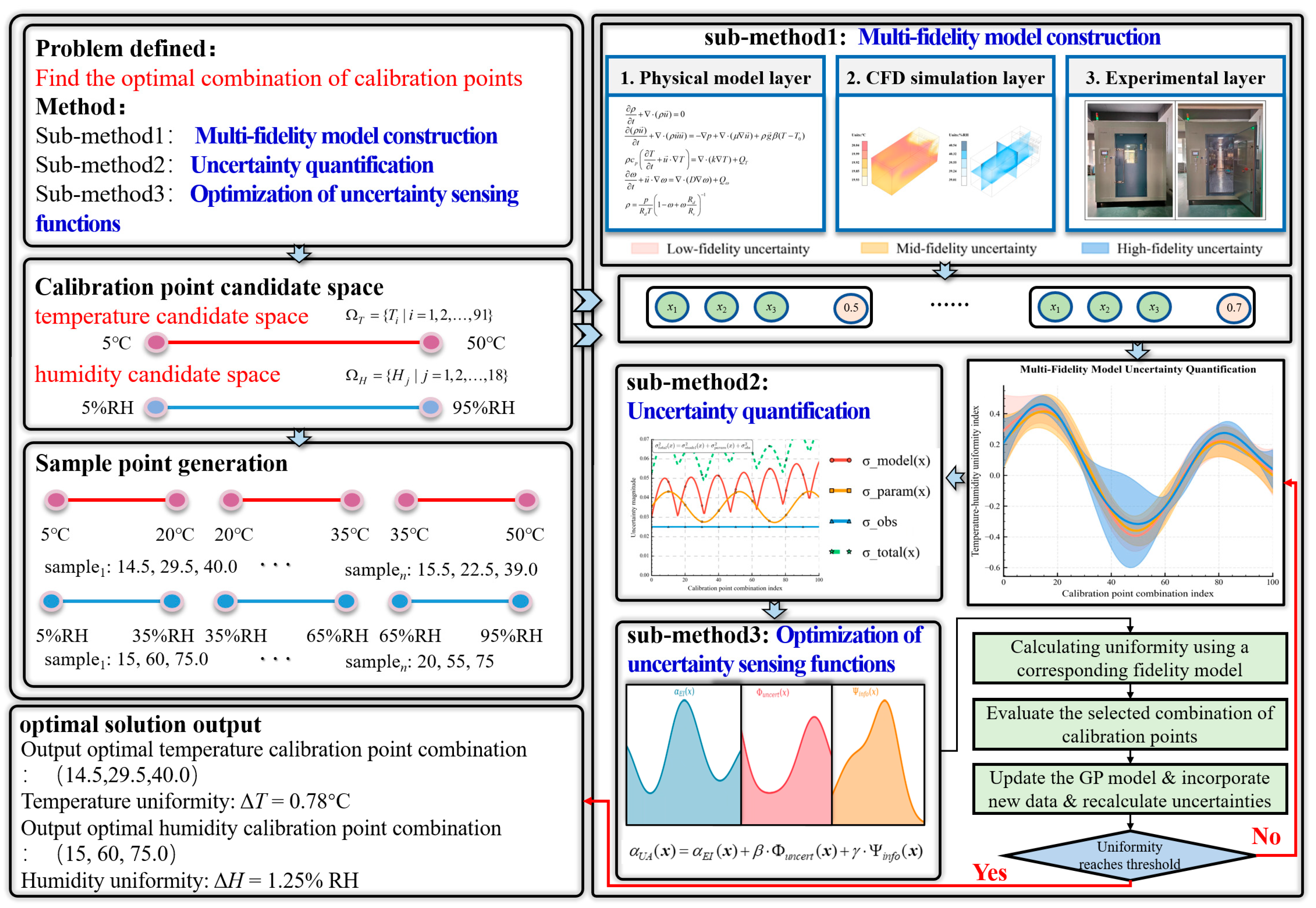

3. Proposed GP-MFBO Framework

3.1. GP-MFBO Framework Design

3.2. Multi-Fidelity Modeling Theory

3.3. Uncertainty Quantification Framework

3.4. Uncertainty-Aware Acquisition Function

4. Hierarchical Multi-Fidelity Modeling Framework

4.1. Physical Analytical Model Layer

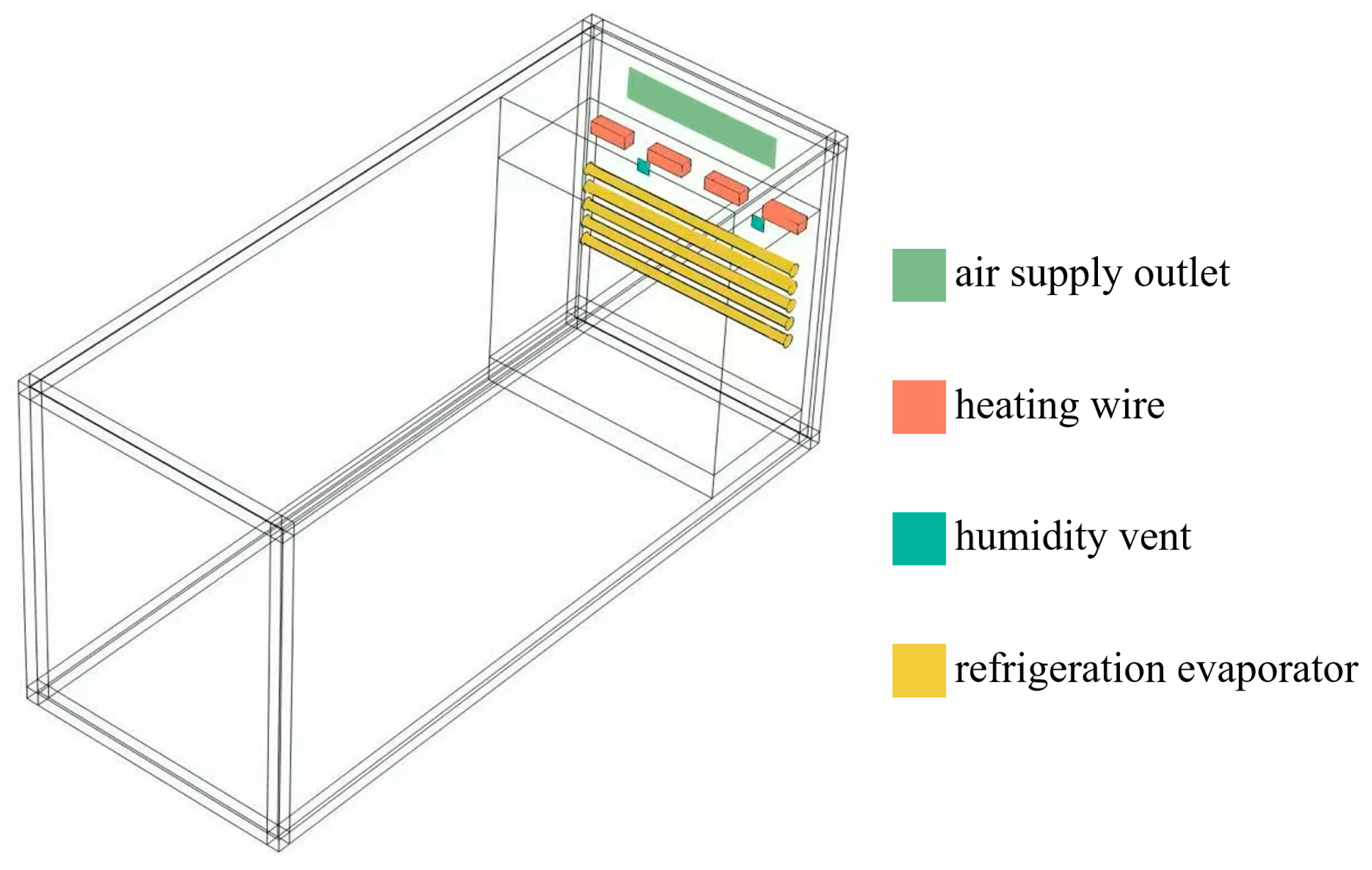

4.2. Finite Element Simulation Model Layer

Validation of FE Model

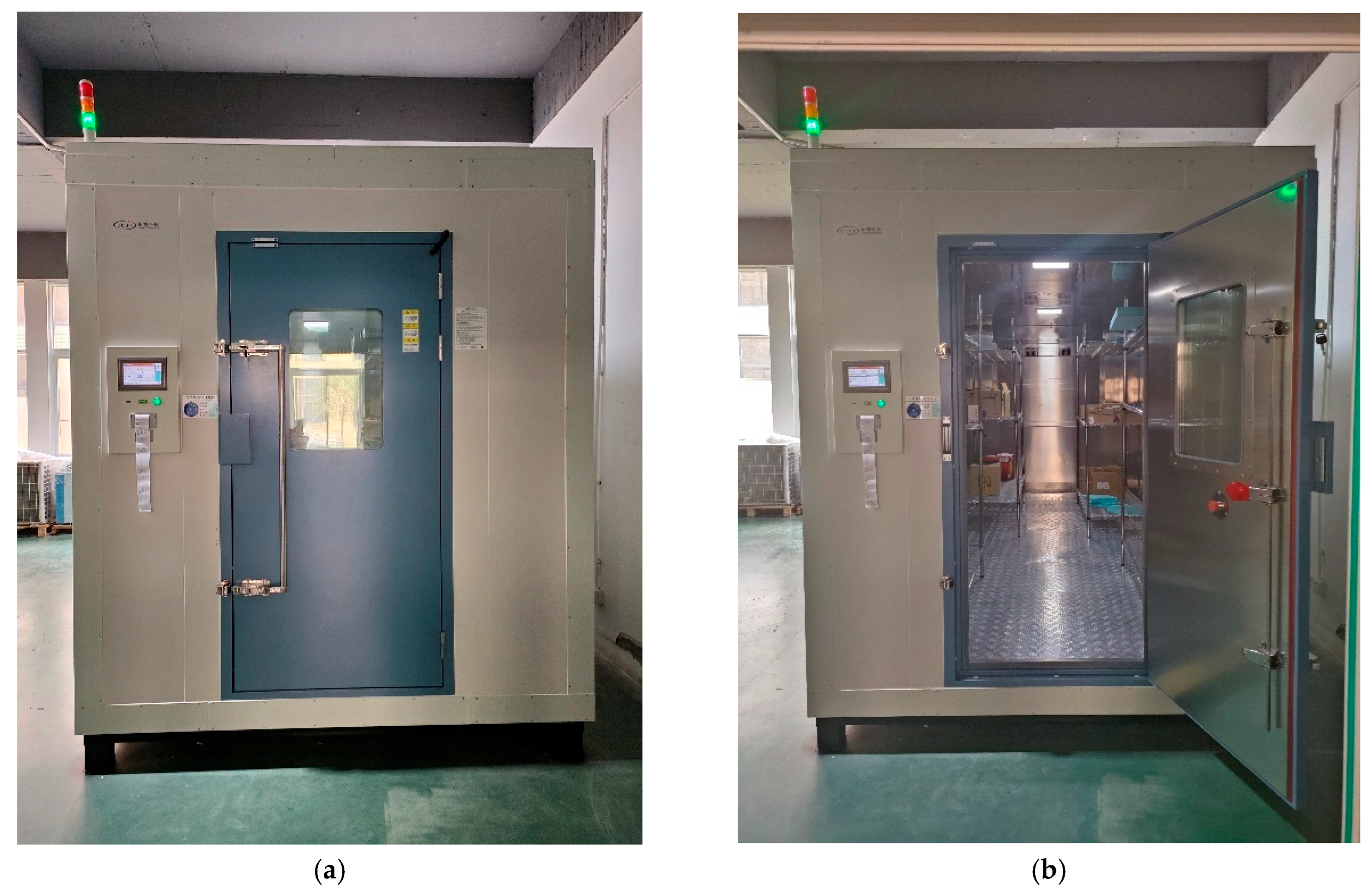

4.3. Experimental Validation Layer

5. Experimental Design and Results

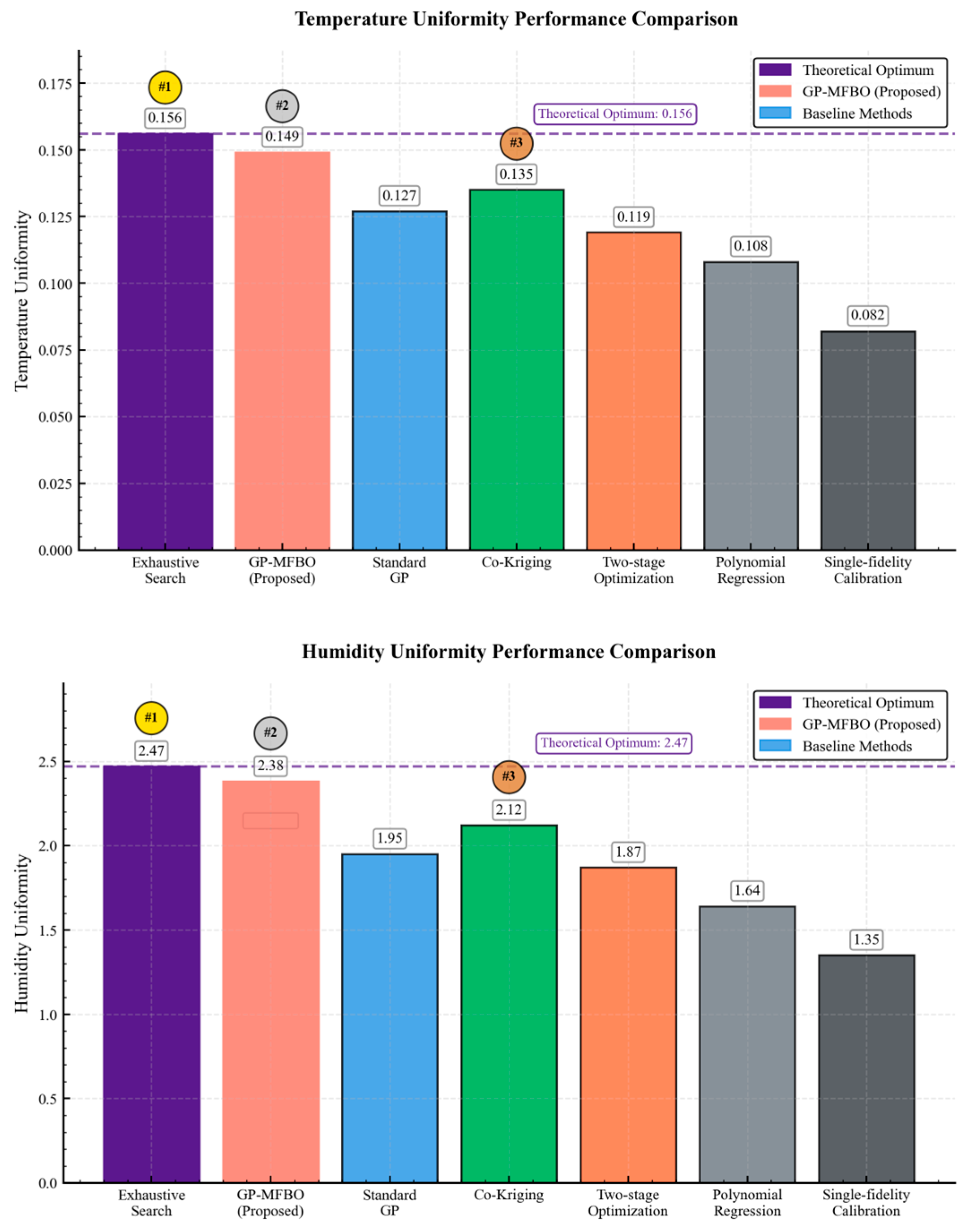

5.1. Benchmark Methods Setup

5.2. Experimental Methodology

5.3. Results and Analysis

5.3.1. Optimal Calibration Point Combinations

5.3.2. Comprehensive Performance Evaluation

6. Conclusions

- (1)

- Established hierarchical multi-fidelity modeling systems through constructing three-layer progressive architectures of physical analytical models (second-level computation), CFD simulation models (hour-level computation), and experimental validation models (day-level validation), achieving an effective balance between computational accuracy and efficiency.

- (2)

- Proposed systematic uncertainty quantification frameworks through explicit modeling of three major uncertainty sources, including model uncertainty, parameter uncertainty, and observation uncertainty, establishing complete uncertainty propagation and quantification theoretical systems.

- (3)

- Designed uncertainty-aware adaptive acquisition functions by introducing uncertainty penalty terms and multi-fidelity information gain terms based on traditional expected improvement criteria, constructing adaptive sampling strategies that comprehensively consider function improvement potential, prediction reliability, and information acquisition value.

- (4)

- Constructed complete experimental validation systems by establishing real temperature and humidity calibration experimental platforms with spatial layout design of 24 high-precision sensors, obtaining high-quality benchmark data for method validation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, M.Y.; Fang, K.L. The temperature and humidity control of artificial climate chamber based on feed-forward compensation decoupling. Adv. Mater. Res. 2013, 816, 343–347. [Google Scholar]

- Ma, J.; Lin, Z.; Bao, C.; Wang, J.; Liu, S. Intelligent control and implementation of a new type constant temperature and humidity box. In Proceedings of the 29th Chinese Control Conference, Beijing, China, 29–31 July 2010; pp. 4263–4266. [Google Scholar]

- Darehshouri, S.; Michelsen, N.; Schüth, C.; Schulz, S. A low-cost environmental chamber to simulate warm climatic conditions. Vadose Zone J. 2020, 19, e20023. [Google Scholar] [CrossRef]

- Pu, L.; Li, Y.; Xiao, F.; Ma, Z.; Qi, D.; Shen, S. Effects of different inlet vent positions on the uniformity of humidity inside a building chamber. Energy Build. 2014, 76, 565–571. [Google Scholar] [CrossRef]

- Qian, W.; Li, C.; Gao, H.; Zhuang, L.; Lu, Y.; Liu, J. Estimating indoor air temperature and humidity distributions by data assimilation with finite observations: Validation using an actual residential room. Build. Environ. 2025, 269, 112495. [Google Scholar] [CrossRef]

- Mao, Q.; Li, H. Simulation of ambient temperature and humidity distribution in eight-span greenhouse under different wind conditions and corn height. Case Stud. Therm. Eng. 2024, 61, 105099. [Google Scholar] [CrossRef]

- Mara, T.A.; Tarantola, S. Application of global sensitivity analysis of model output to building thermal simulations. In Building Simulation; Springer: Berlin/Heidelberg, Germany, 2008; Volume 1, pp. 290–302. [Google Scholar]

- Seeger, M. Gaussian processes for machine learning. Int. J. Neural Syst. 2004, 14, 69–106. [Google Scholar] [CrossRef] [PubMed]

- Forrester, A.I.; Keane, A.J. Recent advances in surrogate-based optimization. Prog. Aerosp. Sci. 2009, 45, 50–79. [Google Scholar] [CrossRef]

- Liu, C.; Zhao, C.; Wang, Y.; Wang, H. Machine-learning-based calibration of temperature sensors. Sensors 2023, 23, 7347. [Google Scholar] [CrossRef]

- Yamamoto, K.; Togami, T.; Yamaguchi, N.; Ninomiya, S. Machine learning-based calibration of low-cost air temperature sensors using environmental data. Sensors 2017, 17, 1290. [Google Scholar] [CrossRef]

- Herbinger, F.; Vandenhof, C.; Kummert, M. Building energy model calibration using a surrogate neural network. Energy Build. 2023, 289, 113057. [Google Scholar] [CrossRef]

- Chen, X.; Gong, Z.; Zhao, X.; Zhou, W.; Yao, W. A machine learning surrogate modeling benchmark for temperature field reconstruction of heat source systems. Sci. China Inf. Sci. 2023, 66, 152203. [Google Scholar] [CrossRef]

- Sisti, E.; Rossetti, A.; Minetto, S.; Marinetti, S.; Tosato, G.; Beghi, A.; Rampazzo, M. Assessment of basic control strategies through dynamic simulations: A CO2-based chiller under extreme off-design conditions. Energy Build. 2023, 289, 113066. [Google Scholar] [CrossRef]

- Cheng, S.; Quilodrán-Casas, C.; Ouala, S.; Farchi, A.; Liu, C.; Tandeo, P.; Fablet, R.; Lucor, D.; Iooss, B.; Arcucci, R.; et al. Machine learning with data assimilation and uncertainty quantification for dynamical systems: A review. IEEE/CAA J. Autom. Sin. 2023, 10, 1361–1387. [Google Scholar] [CrossRef]

- Tripathy, R.K.; Bilionis, I. Deep UQ: Learning deep neural network surrogate models for high dimensional uncertainty quantification. J. Comput. Phys. 2018, 375, 565–588. [Google Scholar] [CrossRef]

- Allaire, D.; Willcox, K. Surrogate modeling for uncertainty assessment with application to aviation environmental system models. AIAA J. 2010, 48, 1791–1803. [Google Scholar] [CrossRef]

- Phillips, D.L.; Marks, D.G. Spatial uncertainty analysis: Propagation of interpolation errors in spatially distributed models. Ecol. Model. 1996, 91, 213–229. [Google Scholar] [CrossRef]

- Slot, R.M.; Sørensen, J.D.; Sudret, B.; Svenningsen, L.; Thøgersen, M.L. Surrogate model uncertainty in wind turbine reliability assessment. Renew. Energy 2020, 151, 1150–1162. [Google Scholar] [CrossRef]

- Barry, A.; Bachoc, F.; Bouquet, S.; Zuniga, M.M.M.; Prieur, C. Optimal Design of Physical and Numerical Experiments for Computer Code Calibration. 2024. Available online: https://inria.hal.science/hal-04615127v2/file/DOEpaper.pdf (accessed on 2 July 2025).

- Damblin, G.; Barbillon, P.; Keller, M.; Pasanisi, A.; Parent, É. Adaptive numerical designs for the calibration of computer codes. SIAM/ASA J. Uncertain. Quantif. 2018, 6, 151–179. [Google Scholar] [CrossRef]

- Chevalier, C.; Bect, J.; Ginsbourger, D.; Vazquez, E.; Picheny, V.; Richet, Y. Fast parallel kriging-based stepwise uncertainty reduction with application to the identification of an excursion set. Technometrics 2014, 56, 455–465. [Google Scholar] [CrossRef]

- Kennedy, M.C.; O’Hagan, A. Bayesian calibration of computer models. J. R. Stat. Soc. Ser. B Stat. Methodol. 2001, 63, 425–464. [Google Scholar] [CrossRef]

- Forrester, A.I.; Sóbester, A.; Keane, A.J. Multi-fidelity optimization via surrogate modelling. Proc. R. Soc. Math. Phys. Eng. Sci. 2007, 463, 3251–3269. [Google Scholar] [CrossRef]

- Le Gratiet, L.; Garnier, J. Recursive co-kriging model for design of computer experiments with multiple levels of fidelity. Int. J. Uncertain. Quantif. 2014, 4, 365–386. [Google Scholar] [CrossRef]

- Peherstorfer, B.; Willcox, K.; Gunzburger, M. Survey of multifidelity methods in uncertainty propagation, inference, and optimization. Siam Rev. 2018, 60, 550–591. [Google Scholar] [CrossRef]

- Fernández-Godino, M.G. Review of multi-fidelity models. arXiv 2016, arXiv:1609.07196. [Google Scholar]

- Frazier, P.I. A tutorial on Bayesian optimization. arXiv 2018, arXiv:1807.02811. [Google Scholar] [CrossRef]

- Jones, D.R.; Schonlau, M.; Welch, W.J. Efficient global optimization of expensive black-box functions. J. Glob. Optim. 1998, 13, 455–492. [Google Scholar] [CrossRef]

- Srinivas, N.; Krause, A.; Kakade, S.M.; Seeger, M. Gaussian process optimization in the bandit setting: No regret and experimental design. arXiv 2009, arXiv:0912.3995. [Google Scholar]

- Zhang, Y.; Hoang, T.N.; Low, B.K.H.; Kankanhalli, M. Information-based multi-fidelity Bayesian optimization. J. Mach. Learn. Res. JMLR 2017, 49. [Google Scholar]

- Sabanza-Gil, V.; Barbano, R.; Pacheco Gutiérrez, D.; Luterbacher, J.S.; Hernández-Lobato, J.M.; Schwaller, P.; Roch, L. Best practices for multi-fidelity Bayesian optimization in materials and molecular research. Nat. Comput. Sci. 2025, 5, 1–10. [Google Scholar] [CrossRef]

- Charayron, R.; Lefebvre, T.; Bartoli, N.; Morlier, J. Pareto optimal fidelity level selection for multi-fidelity Bayesian optimization applied to drone design. In Proceedings of the 12th EASN International Conference on “Innovation in Aviation Space for Opening New Horizons”; MDPI: Basel, Switzerland, 2022. [Google Scholar]

- Cordelier, O.; Diouane, Y.; Bartoli, N.; Laurendeau, E. Multi-fidelity constrained Bayesian optimization with application to aircraft wing design. In Proceedings of the AIAA Aviation Forum and Ascend 2025, Las Vegas, NV, USA, 21–25 July 2025; p. 3474. [Google Scholar]

- Wilson, J.; Hutter, F.; Deisenroth, M. Maximizing acquisition functions for Bayesian optimization. Adv. Neural Inf. Process. Syst. 2018, 31. [Google Scholar]

- Lyu, W.; Yang, F.; Yan, C.; Zhou, D.; Zeng, X. Batch Bayesian optimization via multi-objective acquisition ensemble for automated analog circuit design. In Proceedings of the International Conference on Machine Learning, Stockholm, Sweden, 10–15 July 2018; pp. 3306–3314. [Google Scholar]

- Bussemaker, J.H.; Saves, P.; Bartoli, N.; Lefebvre, T.; Lafage, R. System architecture optimization strategies: Dealing with expensive hierarchical problems. J. Glob. Optim. 2025, 91, 851–895. [Google Scholar] [CrossRef]

- Sun, G.; Li, G.; Stone, M.; Li, Q. A two-stage multi-fidelity optimization procedure for honeycomb-type cellular materials. Comput. Mater. Sci. 2010, 49, 500–511. [Google Scholar] [CrossRef]

- Sun, G.; Li, G.; Zhou, S.; Xu, W.; Yang, X.; Li, Q. Multi-fidelity optimization for sheet metal forming process. Struct. Multidiscip. Optim. 2011, 44, 111–124. [Google Scholar] [CrossRef]

- Zhang, X.; Xie, F.; Ji, T.; Zhu, Z.; Zheng, Y. Multi-fidelity deep neural network surrogate model for aerodynamic shape optimization. Comput. Methods Appl. Mech. Eng. 2021, 373, 113485. [Google Scholar] [CrossRef]

- David, Y. Bi-Level Architectures and Multi-Fidelity Algorithms for Multidisciplinary Optimization in High Dimensions. Ph.D. Thesis, Université de Toulouse, Toulouse, France, 2024. [Google Scholar]

- Alarie, S.; Audet, C.; Diago, M.; Digabel, S.L.; Lebeuf, X. Fidelity and interruption control for expensive constrained multi-fidelity blackbox optimization. arXiv 2023, arXiv:2312.13128. [Google Scholar]

- Kaiser, E.; Kutz, J.N.; Brunton, S.L. Sparse identification of nonlinear dynamics for model predictive control in the low-data limit. Proc. R. Soc. A 2018, 474, 20180335. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Tian, S.; Xue, D.; Zhang, T.; Chen, Y.; Zhang, S. A review of industrial MIMO decoupling control. Int. J. Control Autom. Syst. 2019, 17, 1246–1254. [Google Scholar] [CrossRef]

- Gutierrez, J.S.M.; Peña, I.A.F.; Santa, F.M. Design, construction and implementation of relative humidity and temperature climatic chamber for metrology laboratory. J. Phys. Conf. Ser. 2021, 2135, 012003. [Google Scholar] [CrossRef]

- Salthammer, T. Environmental test chambers and cells. In Organic Indoor Air Pollutants: Occurrence, Measurement, Evaluation; Wiley-VCH: Weinheim, Germany, 2009; pp. 101–115. [Google Scholar]

- Clay Goodman, C.; Vahedifard, F. A Fully-Automated Environmental Chamber to Study the Interplay between Soil Desiccation Cracking, Temperature, and CO2 Concentration. Geotech. Test. J. 2025, 48, 285–301. [Google Scholar] [CrossRef]

- Ma, H.; Zhou, L.; Liu, Z.; Chen, M.; Xia, X.; Zhao, Y. A review of recent development for the CFD-DEM investigations of non-spherical particles. Powder Technol. 2022, 412, 117972. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. Phase change material thermal energy storage systems for cooling applications in buildings: A review. Renew. Sustain. Energy Rev. 2020, 119, 109579. [Google Scholar] [CrossRef]

- Said, Z.; Sundar, L.S.; Tiwari, A.K.; Ali, H.M.; Sheikholeslami, M.; Bellos, E.; Babar, H. Recent advances on the fundamental physical phenomena behind stability, dynamic motion, thermophysical properties, heat transport, applications, and challenges of nanofluids. Phys. Rep. 2022, 946, 1–94. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. The numerical computation of turbulent flows. In Numerical Prediction of Flow, Heat Transfer, Turbulence and Combustion; Pergamon Press: South Croydon, UK, 1983; pp. 96–116. [Google Scholar]

- Liu, M.B.; Liu, G. Smoothed particle hydrodynamics (SPH): An overview and recent developments. Arch. Comput. Methods Eng. 2010, 17, 25–76. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. Standard for Verification and Validation in Computational Fluid Dynamics and Heat Transfer: An American National Standard; American Society of Mechanical Engineers: Little Falls, NJ, USA, 2009. [Google Scholar]

| Element Sizes (mm) | Number of Elements | Temperature (°C) | %RH |

|---|---|---|---|

| 25.0 | 237,573 | 40.82 | 1.13 |

| 20.0 | 413,177 | 40.56 | 1.12 |

| 17.0 | 559,989 | 40.38 | 1.18 |

| 15.0 | 720,479 | 40.21 | 0.98 |

| 12.0 | 884,854 | 40.09 | 0.99 |

| 10.0 | 1,127,909 | 40.10 | 0.98 |

| Method | Temperature Calibration Point | Humidity Calibration Point | Temperature Uniformity | Humidity Uniformity | Confidence Interval Coverage Rate |

|---|---|---|---|---|---|

| Exhaustive experimental method | [8, 25, 42] | [15, 50, 85] | 0.156 | 2.47 | - |

| GP-MFBO | [9, 26, 41] | [16, 51, 83] | 0.149 | 2.38 | 94.2 |

| Standard Gaussian process | [11, 24, 44] | [18, 48, 82] | 0.127 | 1.95 | 86.8 |

| Co-Kriging | [10, 28, 40] | [20, 52, 80] | 0.135 | 2.12 | 89.3 |

| Two-stage optimization | [12, 27, 43] | [17, 49, 84] | 0.119 | 1.87 | 82.5 |

| Polynomial regression | [13, 30, 39] | [22, 47, 78] | 0.108 | 1.64 | 75.1 |

| Single-fidelity calibration | [10, 30, 45] | [20, 50, 80] | 0.082 | 1.35 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuo, H.; Ma, J.; Yang, M.; Zhao, Y.; Yao, L.; Xu, Y.; Yang, K. Gaussian Process-Based Multi-Fidelity Bayesian Optimization for Optimal Calibration Point Selection. Sensors 2025, 25, 7030. https://doi.org/10.3390/s25227030

Zhuo H, Ma J, Yang M, Zhao Y, Yao L, Xu Y, Yang K. Gaussian Process-Based Multi-Fidelity Bayesian Optimization for Optimal Calibration Point Selection. Sensors. 2025; 25(22):7030. https://doi.org/10.3390/s25227030

Chicago/Turabian StyleZhuo, Hua, Jungang Ma, Mei Yang, Yikun Zhao, Lifang Yao, Yan Xu, and Kun Yang. 2025. "Gaussian Process-Based Multi-Fidelity Bayesian Optimization for Optimal Calibration Point Selection" Sensors 25, no. 22: 7030. https://doi.org/10.3390/s25227030

APA StyleZhuo, H., Ma, J., Yang, M., Zhao, Y., Yao, L., Xu, Y., & Yang, K. (2025). Gaussian Process-Based Multi-Fidelity Bayesian Optimization for Optimal Calibration Point Selection. Sensors, 25(22), 7030. https://doi.org/10.3390/s25227030