Analysis of the Influence of Macro-Bending Loss in Single-Mode Optical Fibers on OFDR Signal Quality

Abstract

1. Introduction

2. Theory of Macro-Bending Loss in Optical Fibers

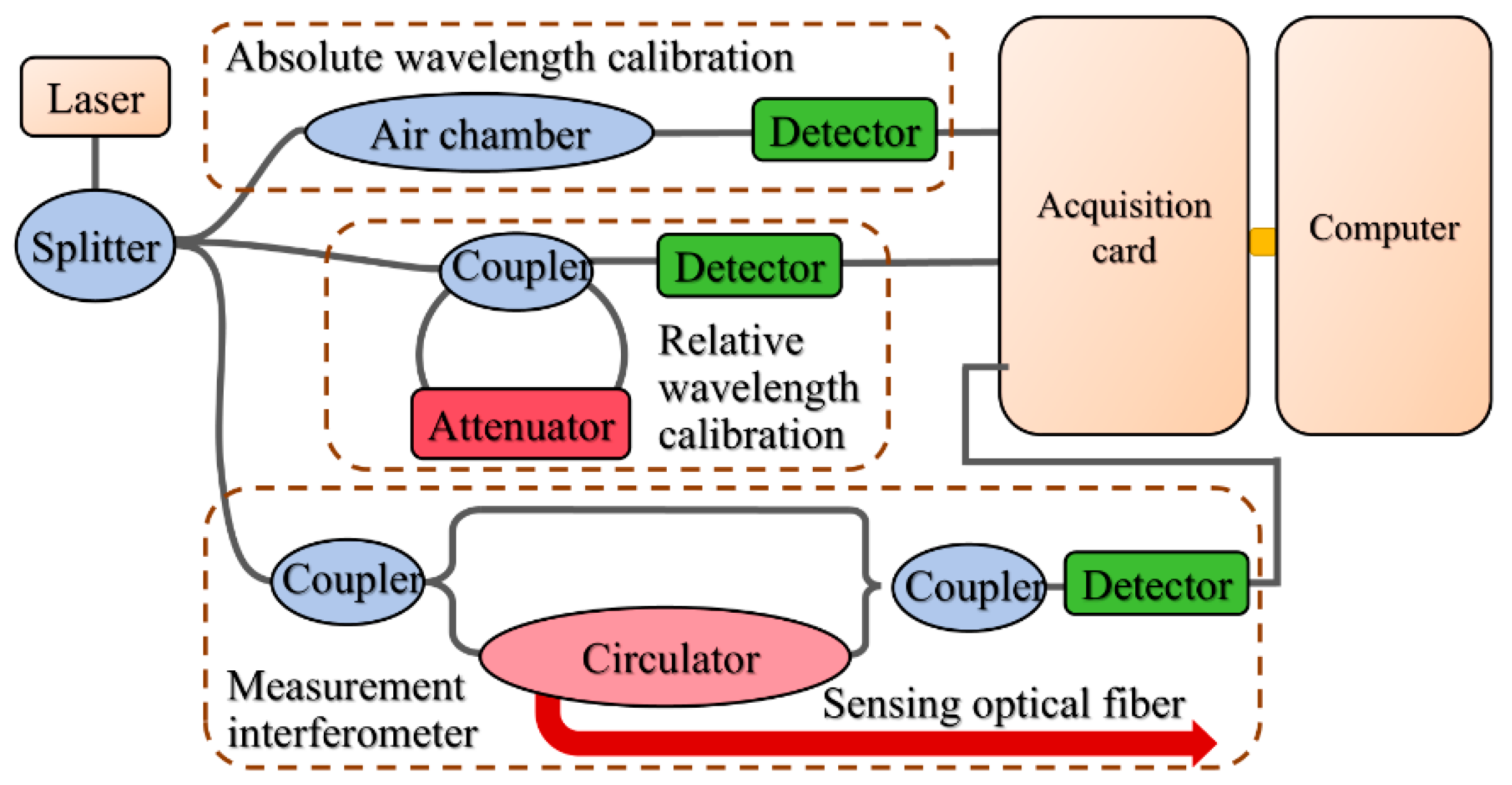

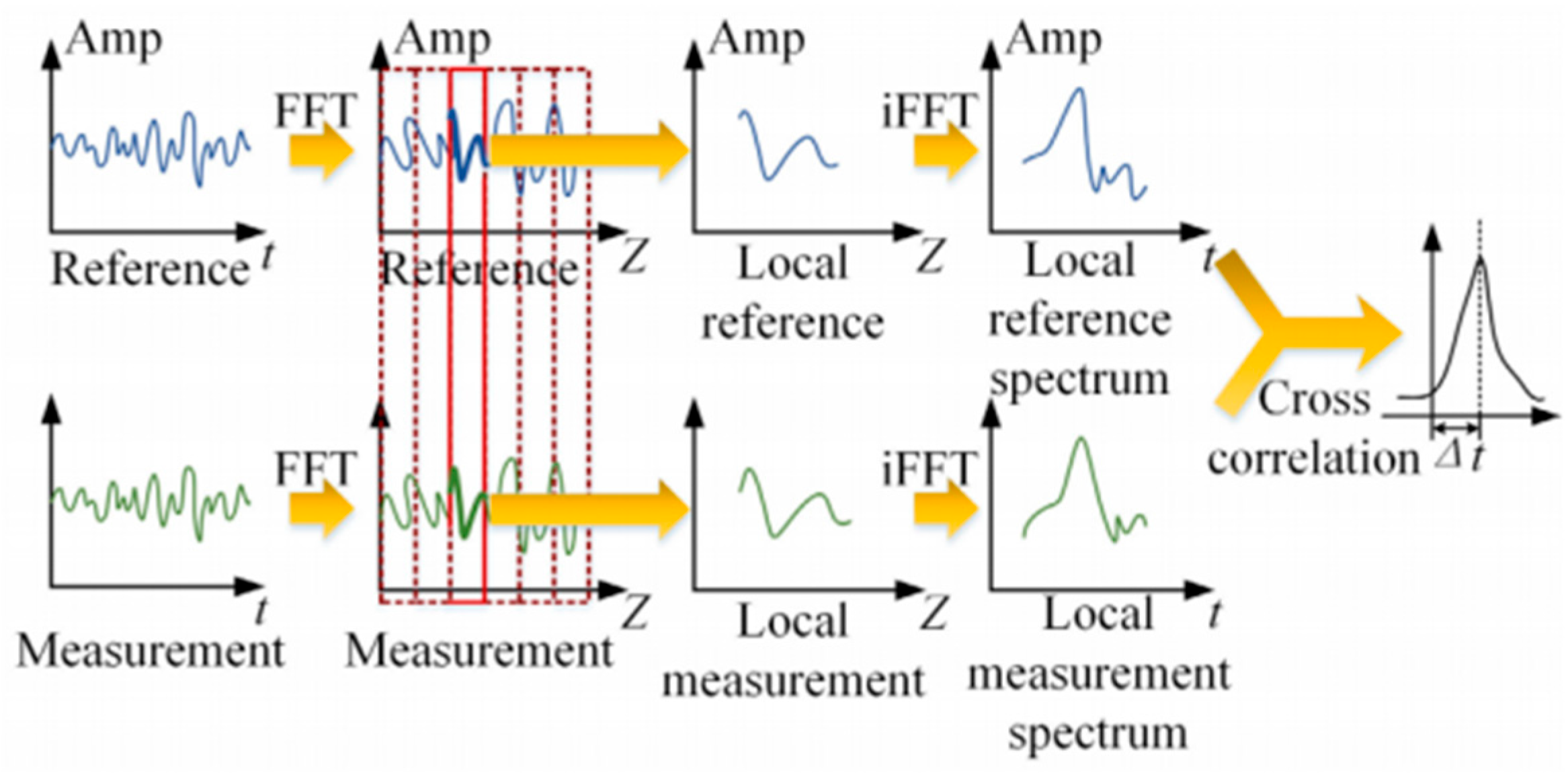

2.1. Principle of Strain Measurement Based on OFDR

2.2. Calculation Formula of Macro-Bending Loss

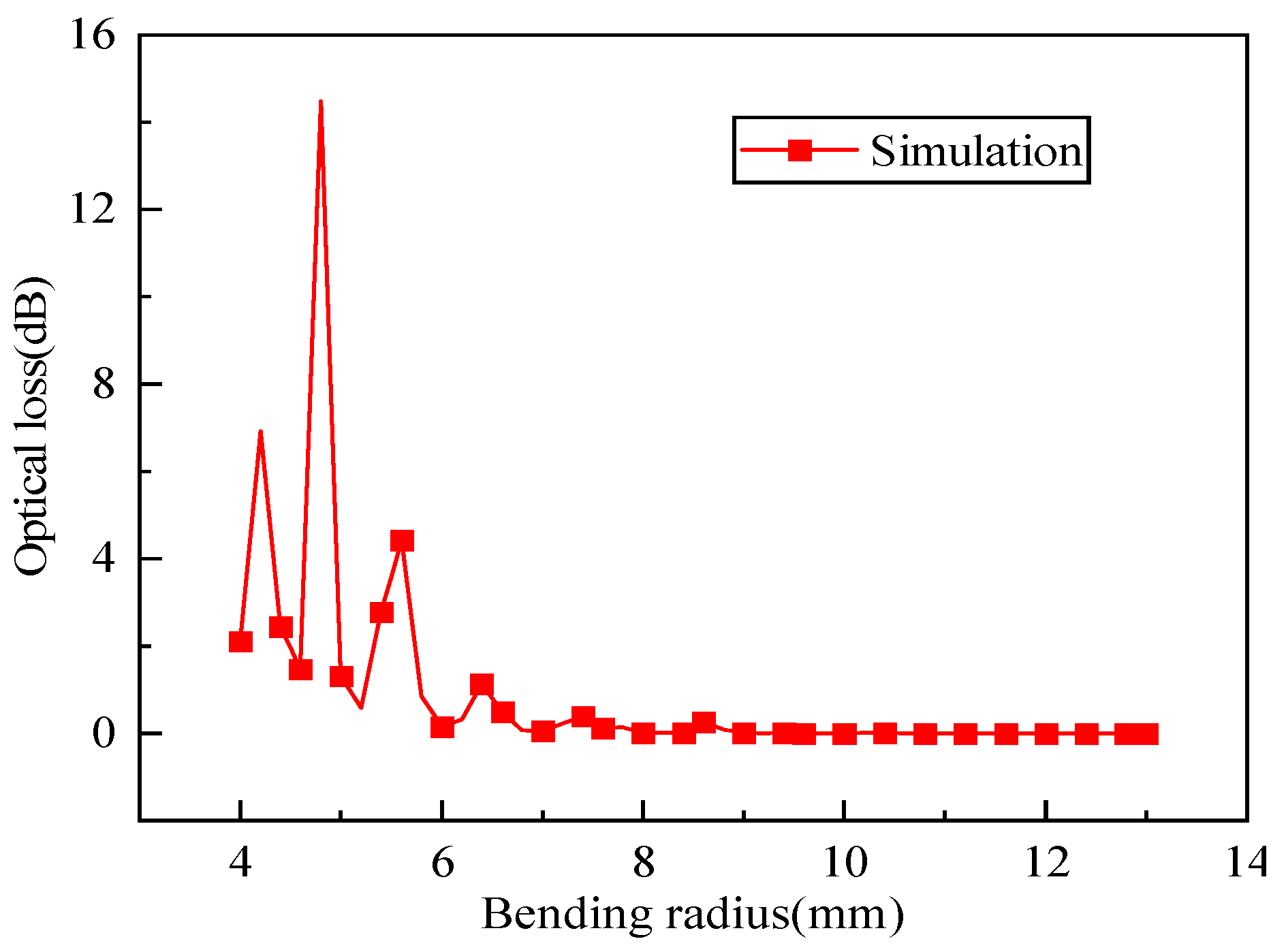

3. Numerical Simulation of Macro-Bending Loss

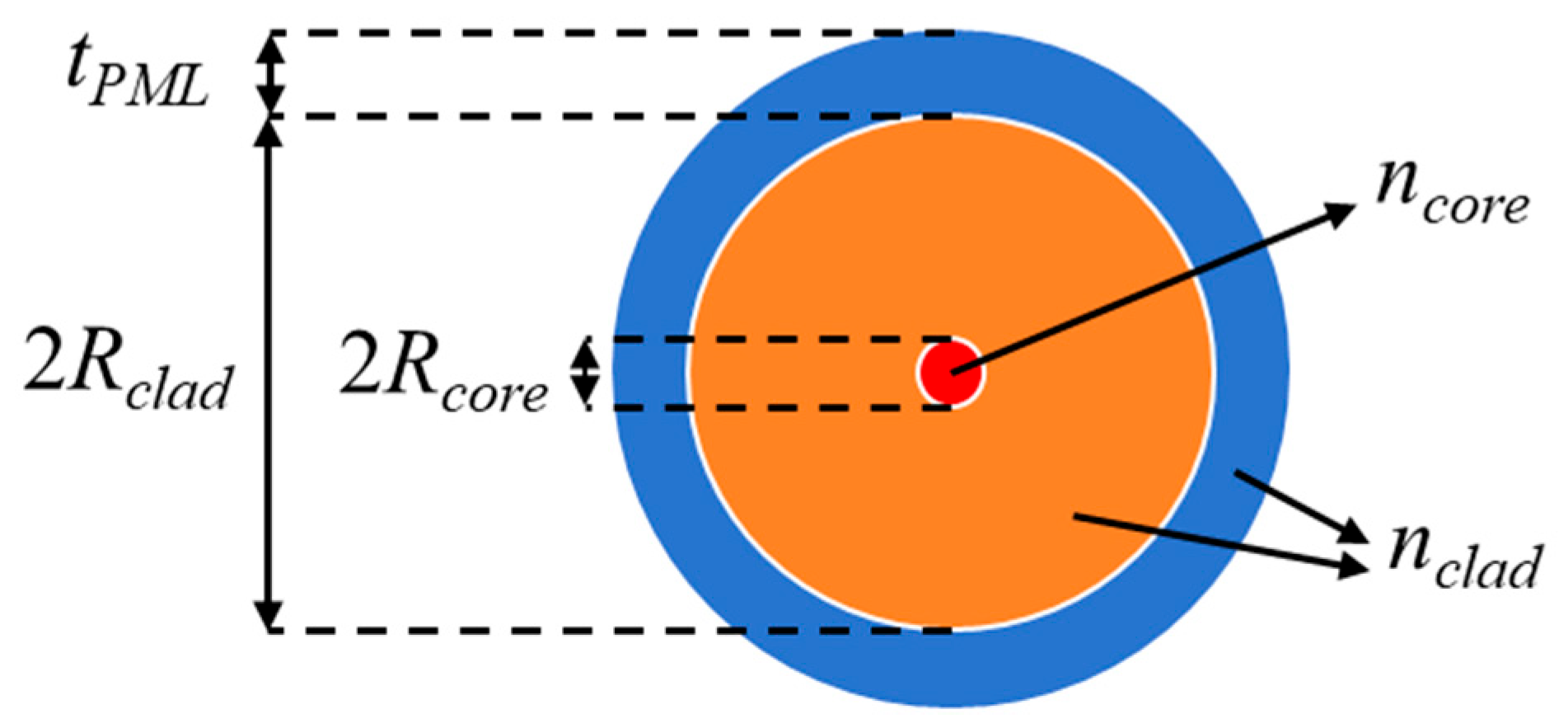

3.1. Finite Element Method

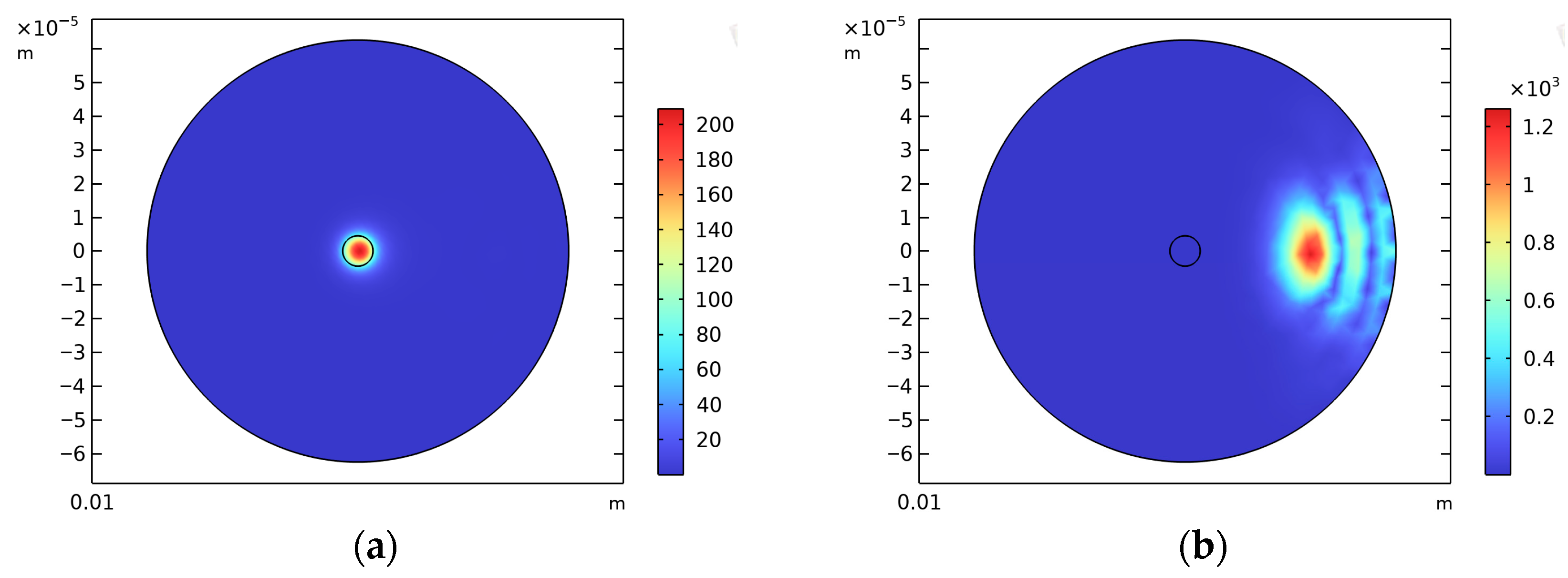

3.2. Results Analysis

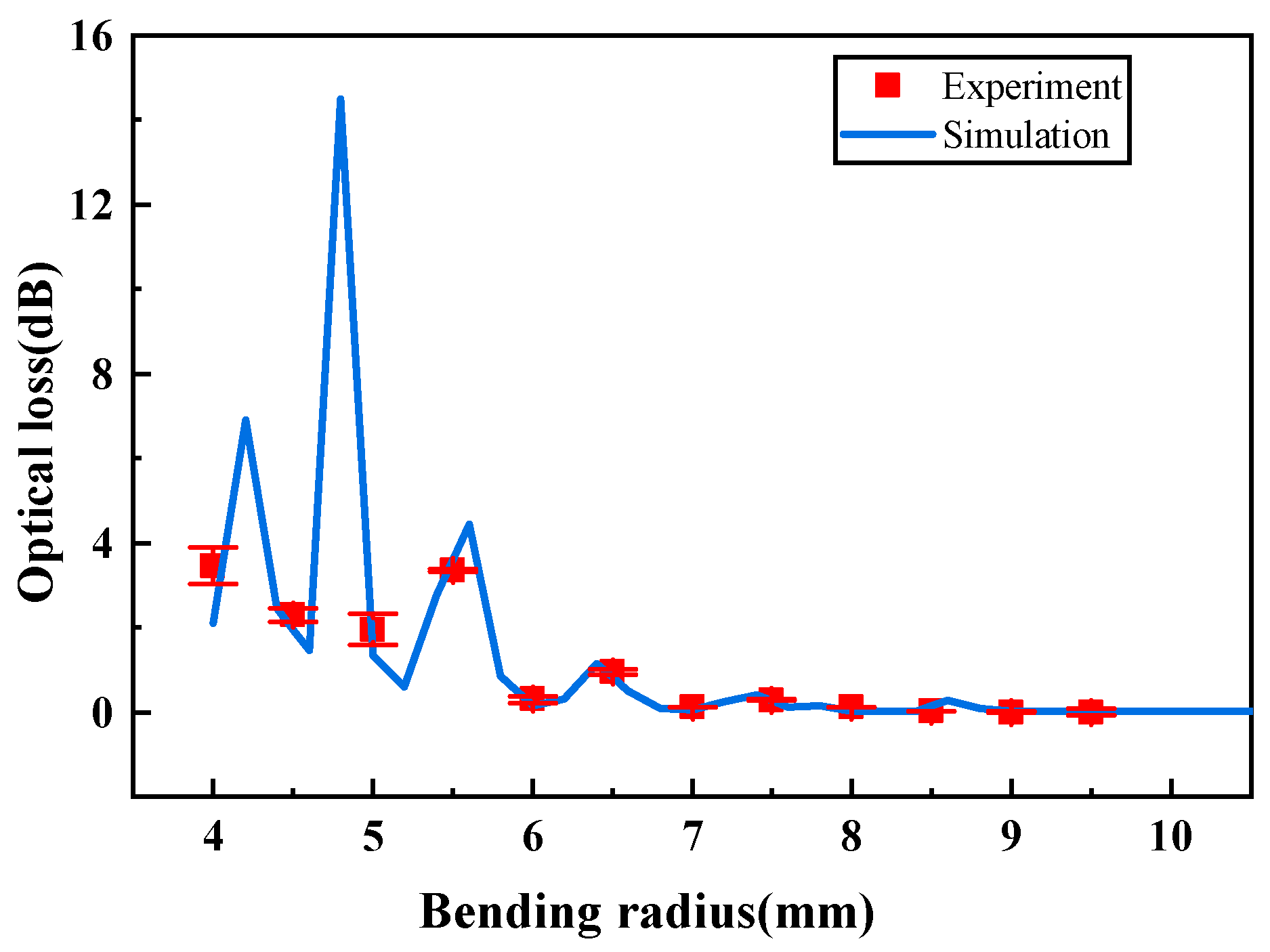

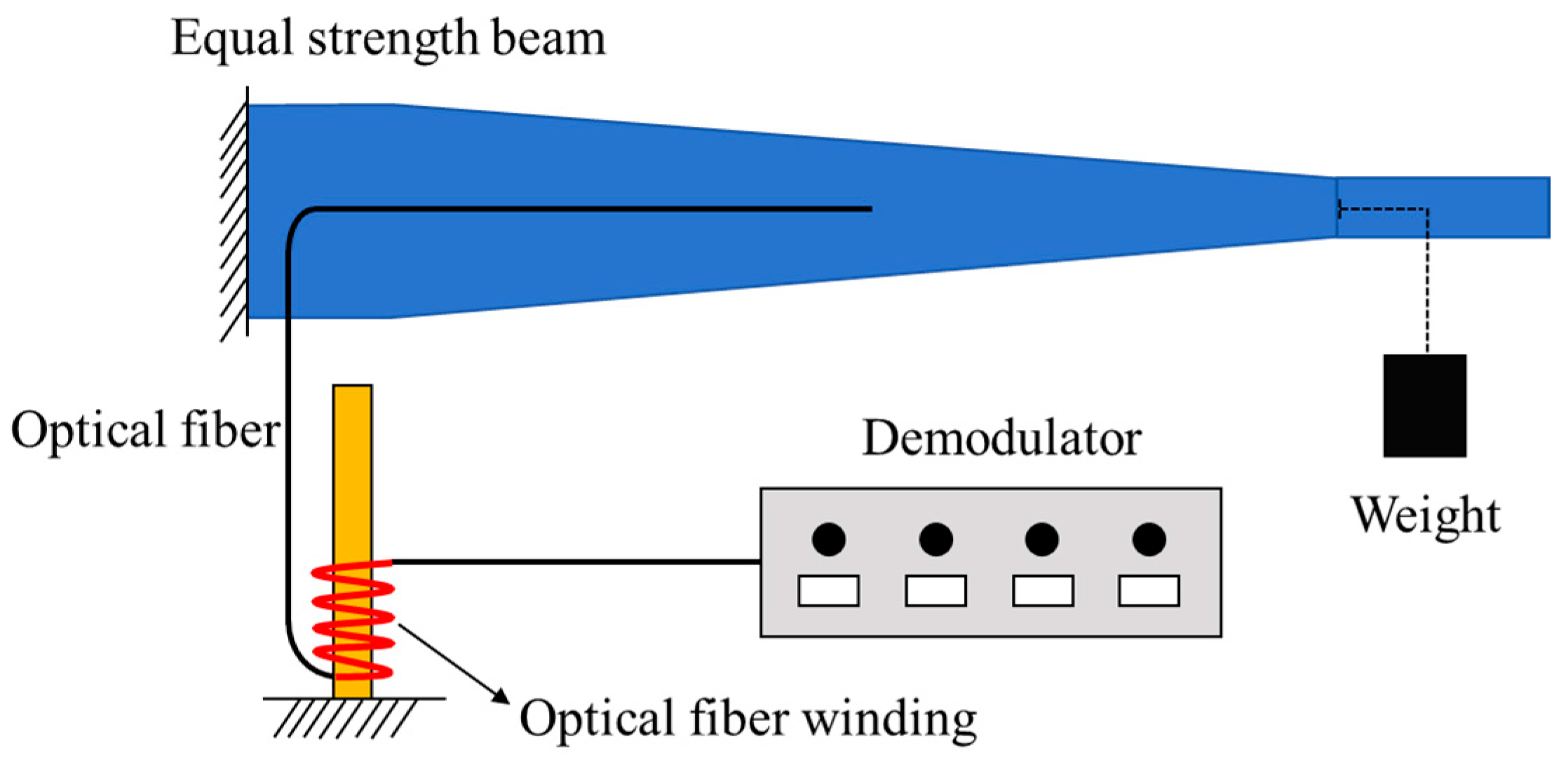

4. Experimental Verification

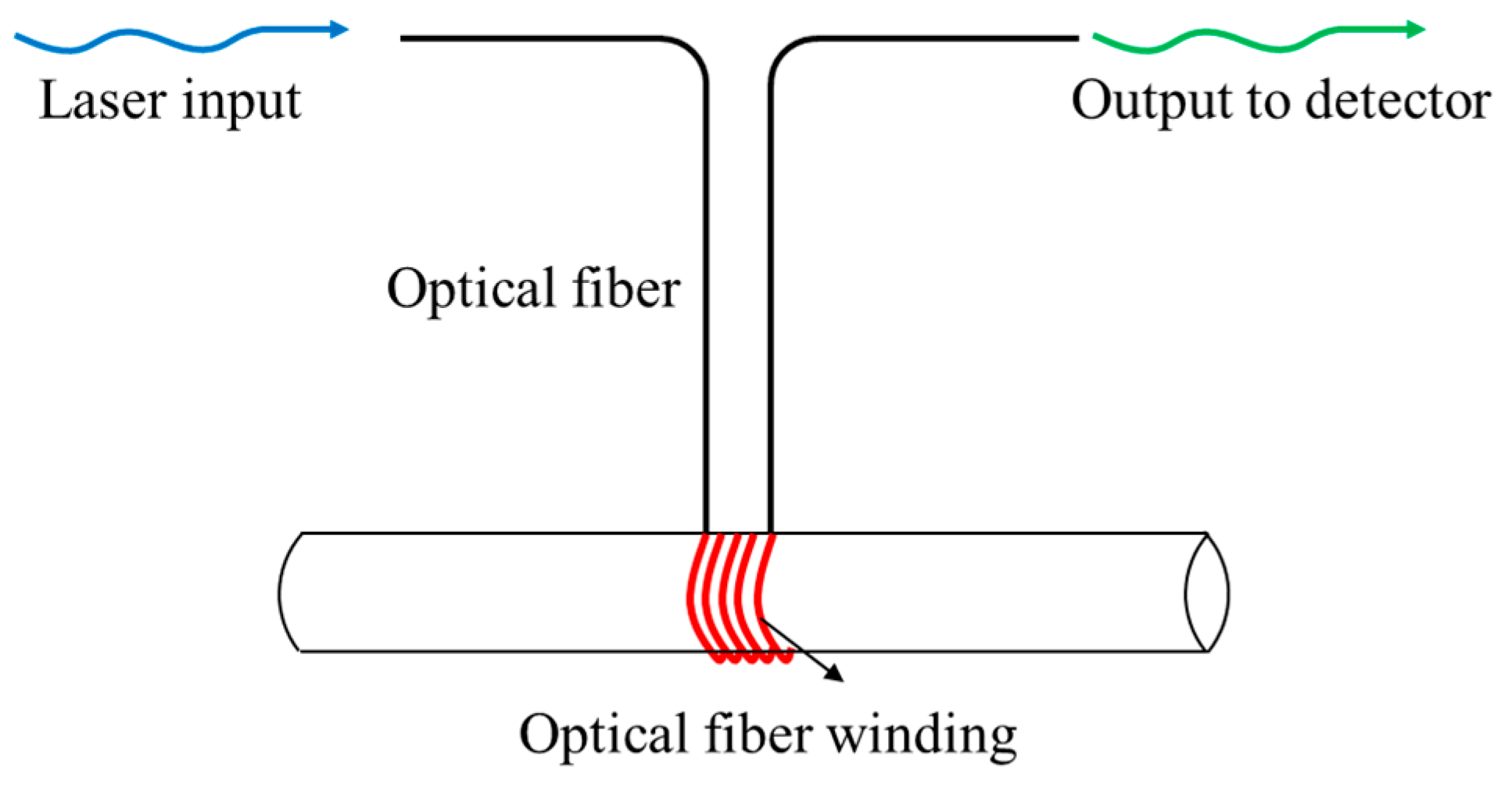

4.1. Optical Loss Test

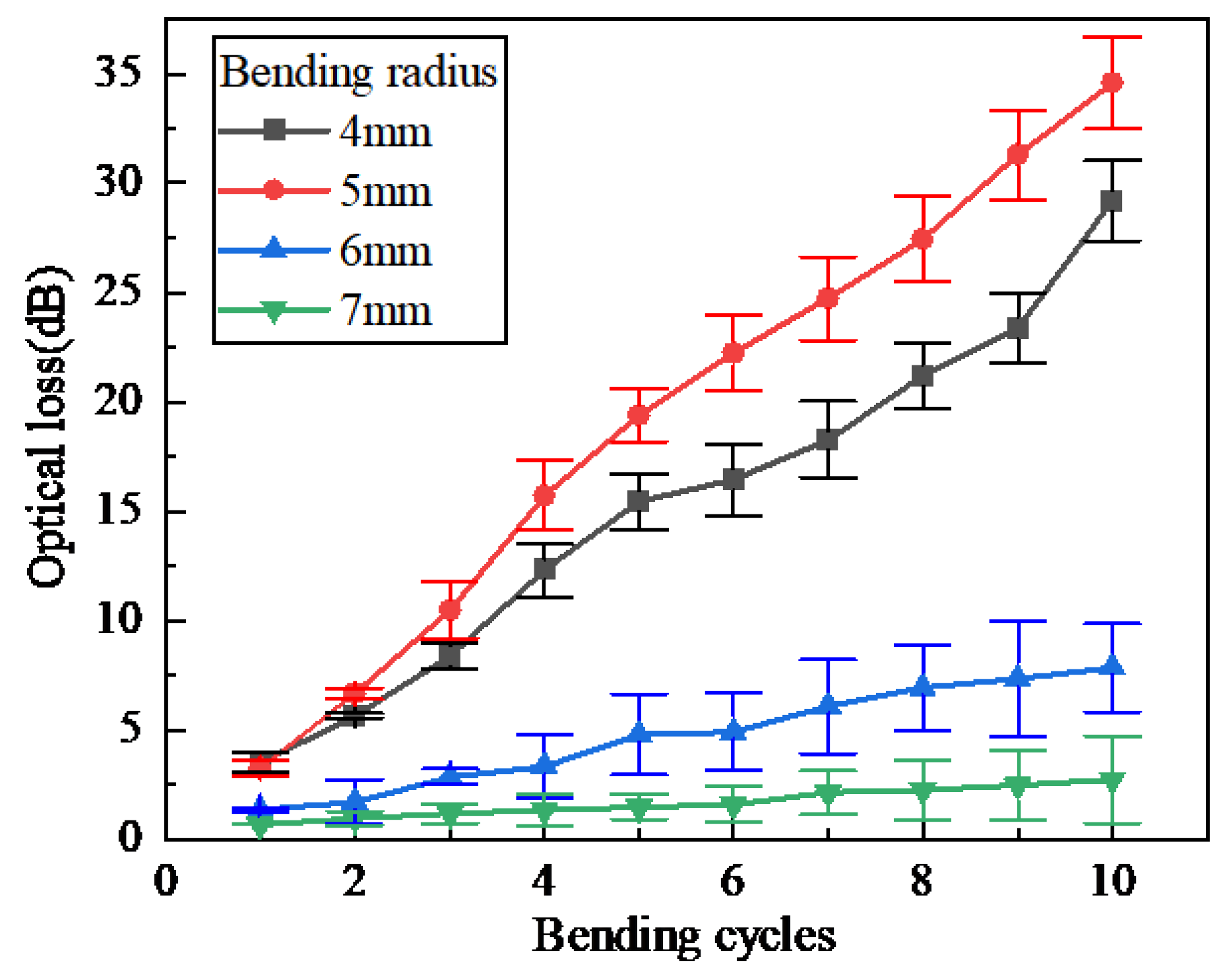

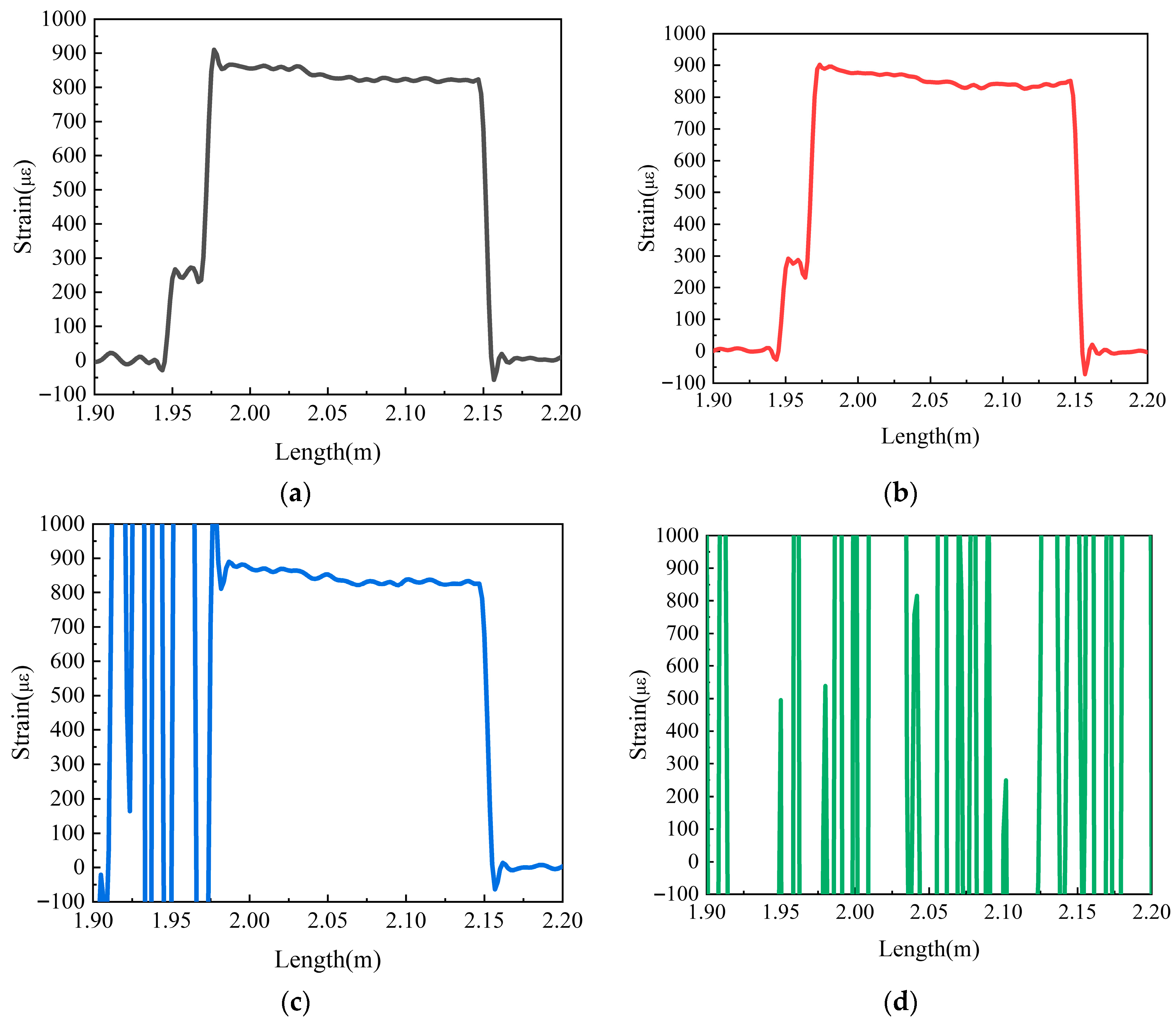

4.2. Influence of Optical Loss on Signal Quality

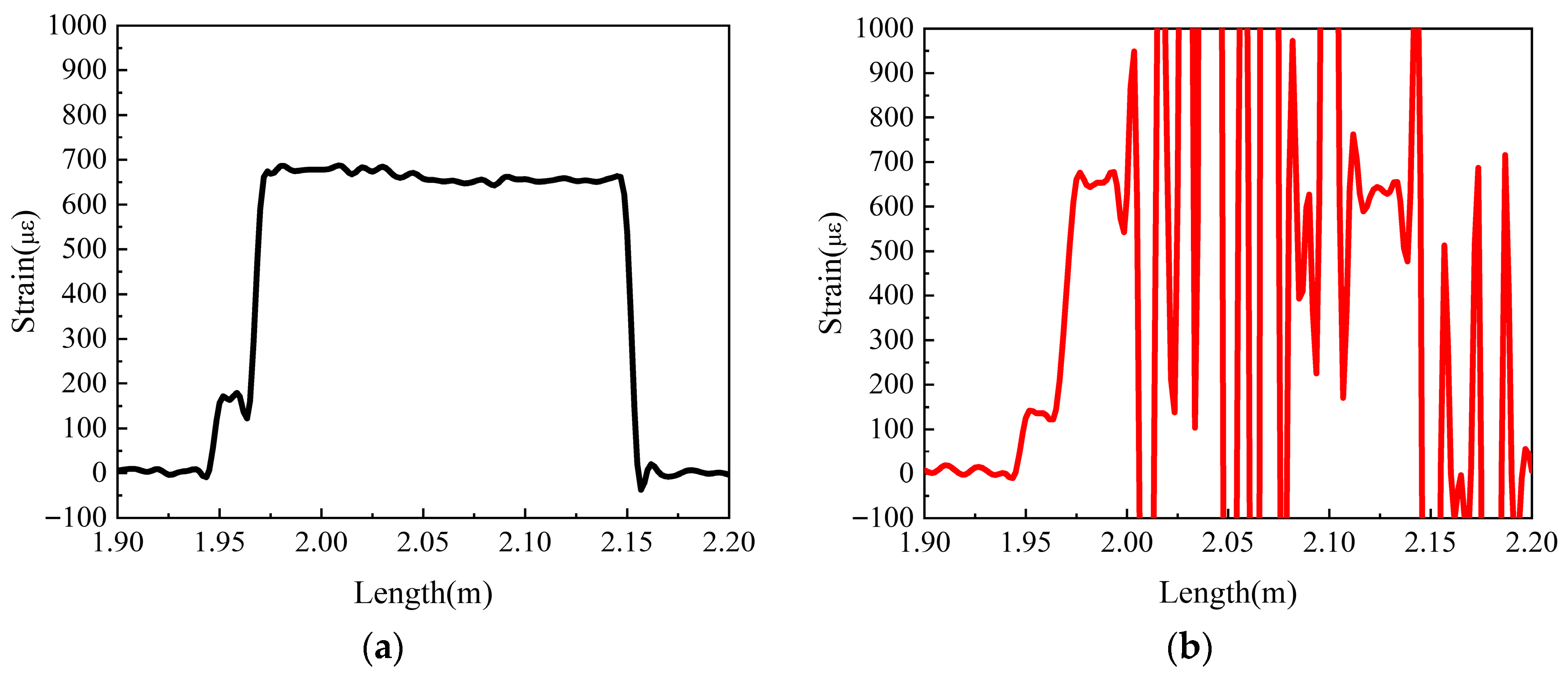

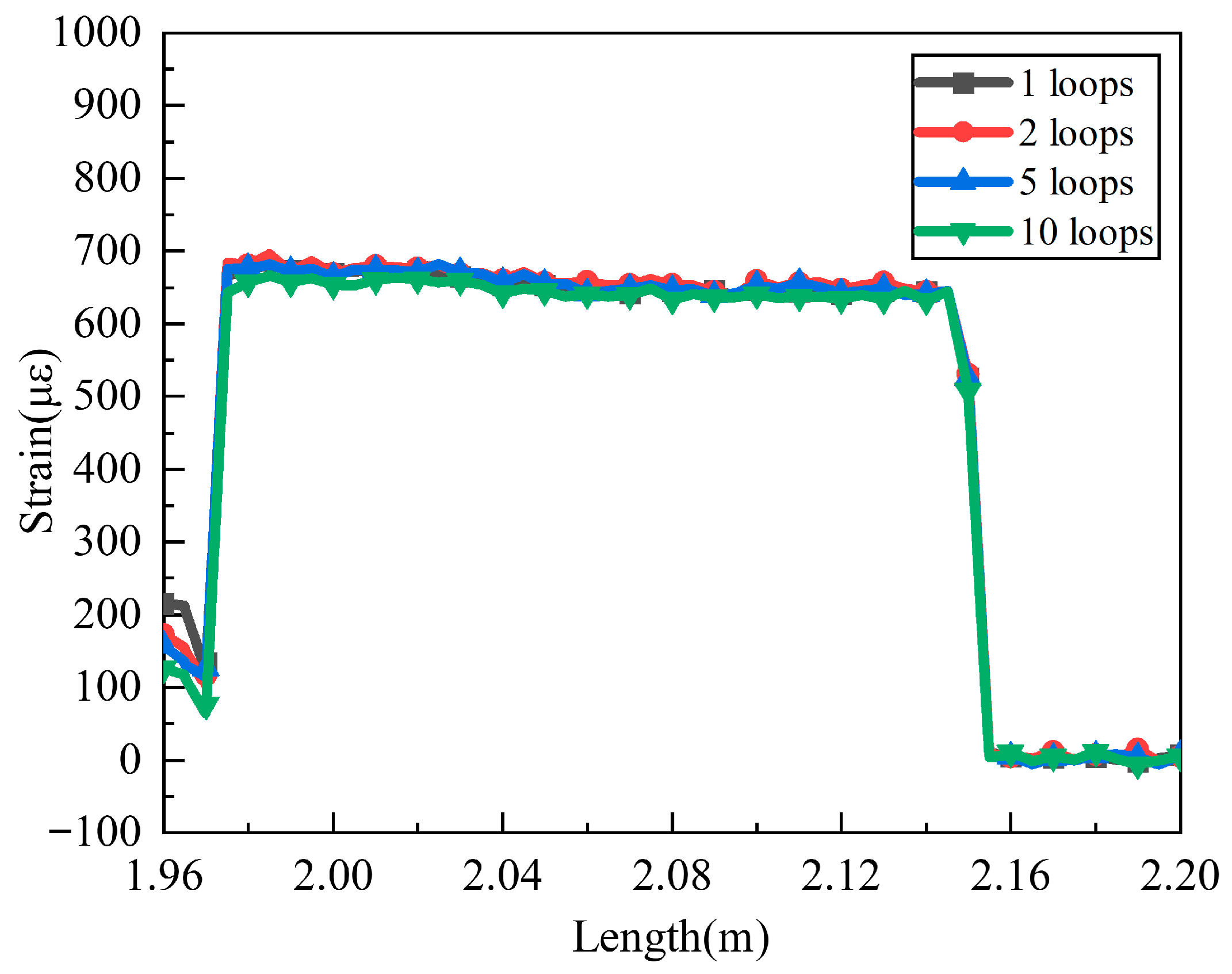

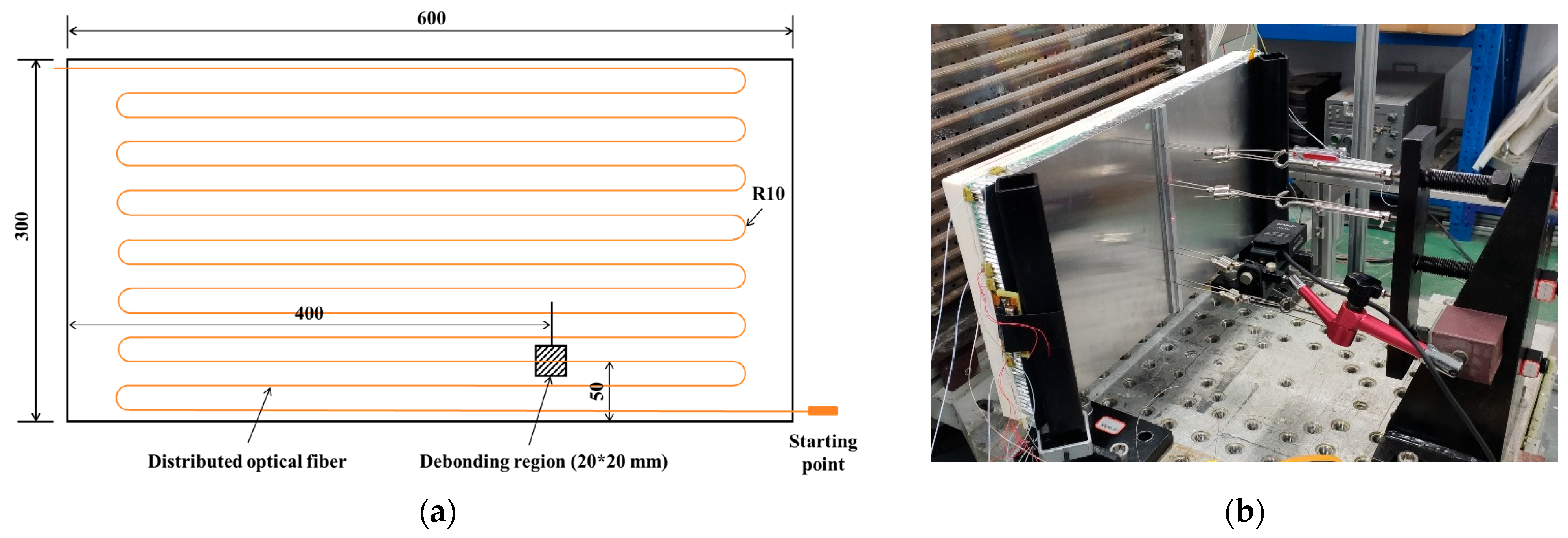

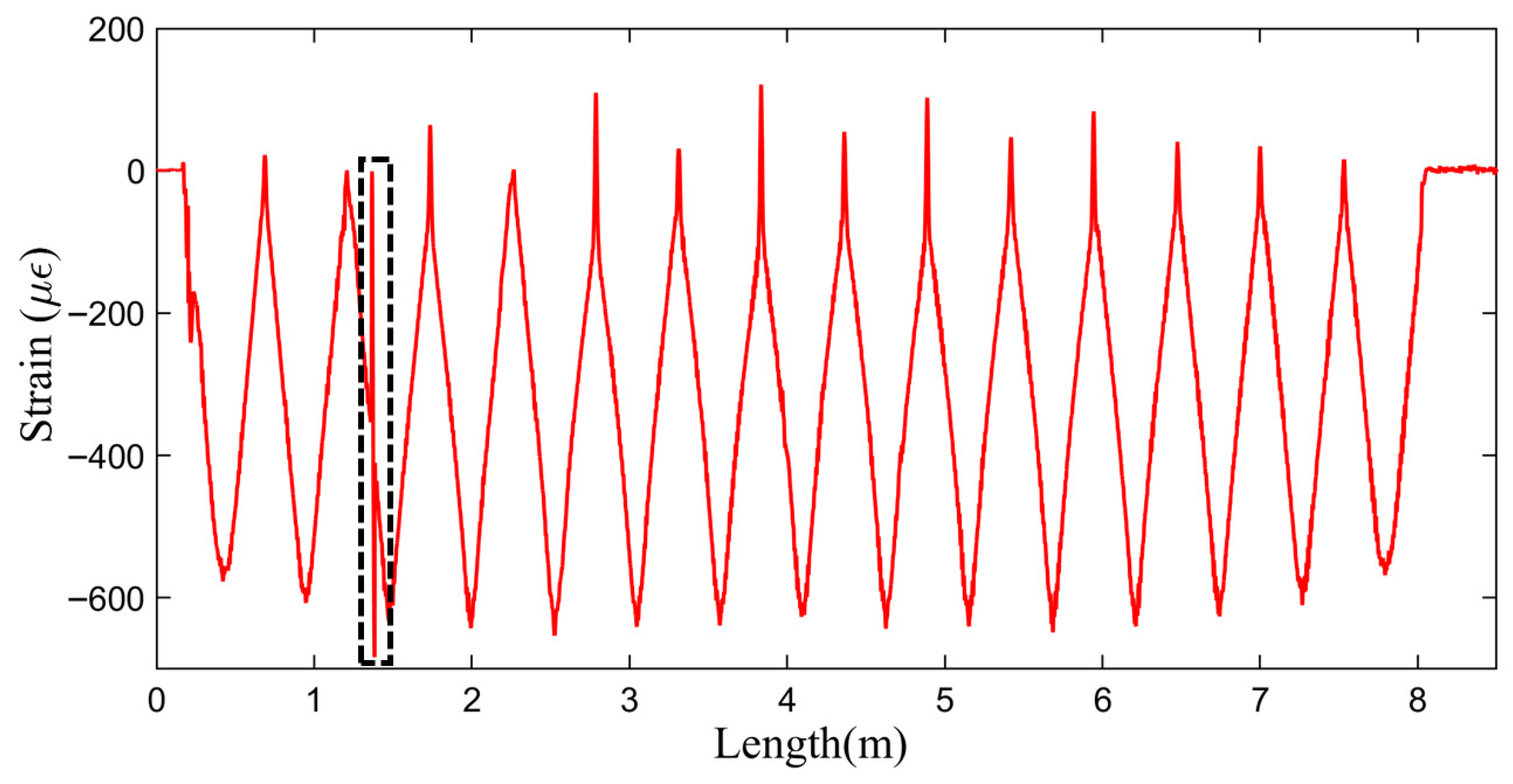

4.3. Application

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Rezapour, S.M.; Jiang, N.; Ozturk, E.; Yetisen, A.K.; Tasoglu, S. Biomedical optical fibers. Lab Chip 2021, 21, 627–640. [Google Scholar] [CrossRef]

- Monsberger, C.M.; Lienhart, W. Distributed fiber optic shape sensing of concrete structures. Sensors 2021, 21, 6098. [Google Scholar] [CrossRef]

- Zhao, S.Y.; Cui, J.W.; Chen, M.M. Review on optical fiber shape sensing technology. Opt. Precis. Eng 2020, 28, 10–29. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Zhang, J.Q.; Gao, D.Y. Advance of aerospace smart material and structure. Aeronaut. Manuf. Technol. 2017, 17, 36–48. [Google Scholar]

- Yang, H.Y.; Zhou, Z.; Ou, J.P. A novel smart steel strand based on optical-electrical co-sensing for full-process and full-scale monitoring of prestressing concrete structures. Int. J. Smart Nano Mater. 2023, 14, 337–368. [Google Scholar] [CrossRef]

- Qu, X.X.; Zhao, S.Y.; Ma, F.Q.; Li, J.; Li, H.; Yang, Z.; Xu, H.; Yang, L.; Wu, Z. Strain monitoring and installation adjustment of satellite–rocket connection device based on distributed optical fibers. Photonics 2024, 11, 335. [Google Scholar] [CrossRef]

- Qu, X.X.; Li, J.L.; Shan, Y.N.; Yang, Z.; Yang, L.; Xu, H.; Liu, M.; Wu, Z.; Zhao, S. Various static loading condition monitoring of carbon fiber composite cylinder with integrated optical fiber sensors. Opt. Fiber Technol. 2024, 83, 103685. [Google Scholar] [CrossRef]

- Yang, L.; Wang, J.F.; Wang, Q.; Xiao, P.; Gao, J.; Wu, Z. Preparation and performance characterization of intelligent woven composites embedded with distributed fiber optic sensors. Compos. Commun. 2025, 58, 102527. [Google Scholar] [CrossRef]

- Li, J.L.; Wang, D.L.; Zhu, M.R.; Li, J.; Xu, H.; Yang, L.; Wu, Z. Strain monitoring of reusable launch vehicle four-legged landing system using fiber Bragg grating sensors. J. Spacecr. Rocket. 2025. [Google Scholar] [CrossRef]

- Chen, C. The Sensing Technology and Application of Broad Dynamic Range Distributed Optical Fiber Sensor. Ph.D. Thesis, Wuhan University, Wuhan, China, 2013. [Google Scholar]

- She, Y.L.; Zhou, D.J.; Chen, X.Y.; An-Si, X. Study on ultralow bending loss of bend-insensitive single mode optical fiber. Opt. Fiber Technol. 2019, 50, 225–232. [Google Scholar] [CrossRef]

- Silveira, M.; Frizera, A.; Leal-Junior, A.; Ribeiro, D.; Marques, C.; Blanc, W.; Díaz, C.A.R. Transmission–reflection analysis in high scattering optical fibers: A comparison with single-mode optical fiber. Opt. Fiber Technol. 2020, 58, 102303. [Google Scholar] [CrossRef]

- Bado, M.F.; Casas, J.R.; Gómez, J. Post-processing algorithms for distributed optical fiber sensing in structural health monitoring applications. Struct. Health Monit. 2020, 20, 661–680. [Google Scholar] [CrossRef]

- Suo, L.J. Study on Strain Demodulation Methods of Distributed Optical Fiber Based on OFDR. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2019. [Google Scholar]

- Tanaka, T.; Kawakami, W.; Kuwabara, S.; Kobayashi, S.; Hirano, A. Intelligent monitoring of optical fiber bend using artificial neural networks trained with constellation data. IEEE Netw. Lett. 2019, 1, 60–62. [Google Scholar] [CrossRef]

- Peng, X.L.; Zhang, H.; Li, Y.L. Simulation study on influencing factors of macrobending loss of optical fiber. Laser Infrared 2014, 44, 1132–1136. [Google Scholar]

- Schulze, C.; Lorenz, A.; Flamm, D.; Hartung, A.; Schröter, S.; Bartelt, H.; Duparré, M. Mode resolved bend loss in few-mode optical fibers. Opt. Express 2013, 21, 3170–3181. [Google Scholar] [CrossRef] [PubMed]

- Zendehnam, A.; Mirzaei, M.; Farashiani, A.; Farahani, L.H. Investigation of bending loss in a single-mode optical fibre. Pramana 2010, 74, 591–603. [Google Scholar] [CrossRef]

- Peng, F.; Wang, Q.; Farrell, G.; Rajan, G.; Freir, T.; Cassidy, J. Investigation of macrobending losses of standard single mode fiber with small bend radius. Microw. Opt. Technol. Lett. 2007, 49, 2133–2138. [Google Scholar]

- You, S.H.; Hao, S.J.; Yin, Z.M.; Fan, X.B. Analysis and test of bend loss in single-mode fiber. Acta Photonica Sin. 2003, 4, 409–412. [Google Scholar]

- Zheng, X.J.; Ren, G.B.; Huang, L.; Zheng, H.L. Study on bending losses of few-mode optical fibers. Acta Phys. Sin. 2016, 65, 166–173. [Google Scholar] [CrossRef]

- Cherpak, P.; Khramov, I.; Shaidullin, R.; Ryabushkin, O. Optical radiation losses of metal-coated optical fibers at different wavelengths. Appl. Phys. B Laser Opt. 2021, 127, 155. [Google Scholar] [CrossRef]

- Bulatov, M.I.; Grigoriev, N.S.; Kosolapov, A.F.; Semjonov, S.L. Optical loss in copper-coated multimode optical fibers of different diameters. Phys. Wave Phenom. 2022, 30, 397–400. [Google Scholar] [CrossRef]

- Vandenberge, P.; Gopalakrishnan, J.; Grosek, J. Sensitivity of confinement losses in optical fibers to modeling approach. Opt. Express 2023, 31, 26735–26756. [Google Scholar] [CrossRef]

- Meng, L.; Wang, L.; Xiong, H.; Wang, H.; Guo, X. An investigation in the influence of helical structure on bend loss of pavement optical fiber sensor. Optik 2019, 183, 189–199. [Google Scholar] [CrossRef]

- Jin, X.; Payne, F.P. Numerical investigation of microbending loss in optical fibres. J. Light. Technol. 2016, 34, 1247–1253. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, J.; Zheng, S.; Zhao, S. Noise-limited sensitivity analysis model for optical frequency domain reflectometry. Opt. Laser Technol. 2025, 192, 113424. [Google Scholar] [CrossRef]

- Marcuse, D. Curvature loss formula for optical fibers. J. Opt. Soc. Am. 1976, 66, 216–220. [Google Scholar] [CrossRef]

- Velamuri, A.V.; Patel, K.; Sharma, I.; Gupta, S.S.; Gaikwad, S.; Krishnamurthy, P.K. Investigation of planar and helical bend losses in single- and few-mode optical fibers. J. Light. Technol. 2019, 37, 3544–3556. [Google Scholar] [CrossRef]

- Luna Technologies. LUNA OBR 4600 Optical Backscatter Reflectometer™ Data Sheet. Available online: https://lunainc.com/product/obr-4600 (accessed on 1 January 2025).

| Rcore/μm | Rclad/μm | tPML/μm | ncore | nclad | λ/μm |

|---|---|---|---|---|---|

| 4.15 | 62.5 | 15.5 | 1.4507 | 1.4440 | 1.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, X.; Ma, F.; Zhao, S.; Yang, L.; Wu, Z.; Chen, B. Analysis of the Influence of Macro-Bending Loss in Single-Mode Optical Fibers on OFDR Signal Quality. Sensors 2025, 25, 6983. https://doi.org/10.3390/s25226983

Qu X, Ma F, Zhao S, Yang L, Wu Z, Chen B. Analysis of the Influence of Macro-Bending Loss in Single-Mode Optical Fibers on OFDR Signal Quality. Sensors. 2025; 25(22):6983. https://doi.org/10.3390/s25226983

Chicago/Turabian StyleQu, Xiaoxi, Fuqiang Ma, Shiyuan Zhao, Lei Yang, Zhanjun Wu, and Bingzhi Chen. 2025. "Analysis of the Influence of Macro-Bending Loss in Single-Mode Optical Fibers on OFDR Signal Quality" Sensors 25, no. 22: 6983. https://doi.org/10.3390/s25226983

APA StyleQu, X., Ma, F., Zhao, S., Yang, L., Wu, Z., & Chen, B. (2025). Analysis of the Influence of Macro-Bending Loss in Single-Mode Optical Fibers on OFDR Signal Quality. Sensors, 25(22), 6983. https://doi.org/10.3390/s25226983