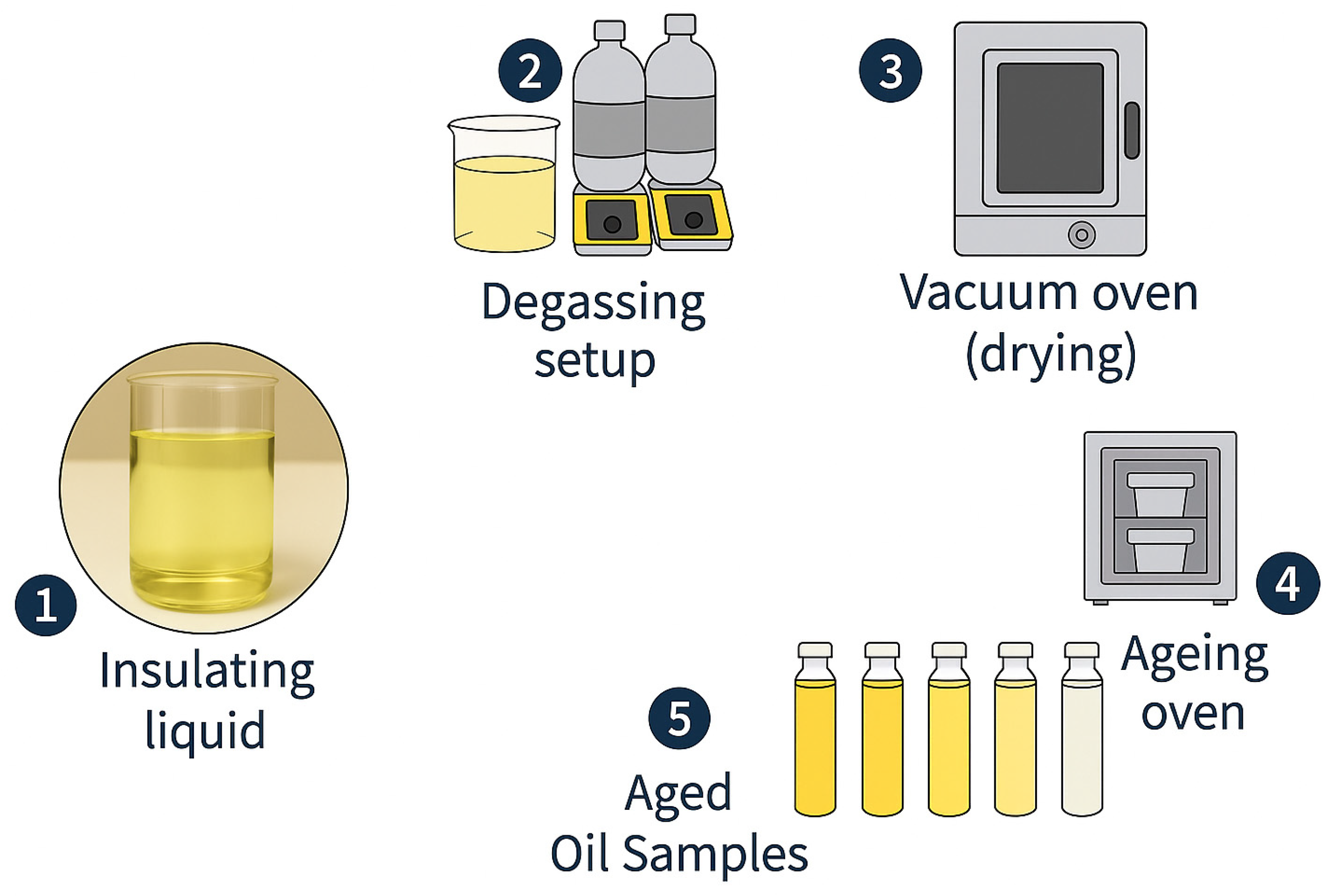

1. Introduction

Previous studies have highlighted in detail the importance of online ageing detection to circumvent the challenges of conventional offline ageing detection strategies, such as possible sample contamination during repeated sampling procedures, economic costs associated with the different diagnostic chains (sampling, transportation, diagnostics, analysis, and reporting), exposure to possible risks for personnel undertaking any element of the five diagnostic chains, person-hour loss, and poor adaptability for predictive maintenance practices [

1,

2,

3,

4].

Out of the various online ageing detection methods for transformer oil, such as cross capacitance sensors exploiting the changes in capacitance that follow dielectric property changes [

5], horn antenna in an anechoic chamber exploiting the reflection coefficient from incident and reflected electromagnetic waves [

6], photoacoustic spectroscopy (PAS) system exploiting the thermodynamic properties of dissolved gases [

7]; optical fibre sensors stand out owing to their electromagnetic interference immunity, compact size, high sensitivity, extreme environment adaptability, and resistance to ionisation [

3,

8,

9,

10]. The key instrumentation variable for fibre-optic sensors is the refractive index, as transformer oil ageing markers such as moisture accumulation, darkening, particle size changes, acidity growth, and polar contaminant accumulation affect it.

Fibre optic sensors (particularly intensity-modulated optical fibre sensors) have reportedly been used for ageing detection studies in transformer oil. Using an optical spectrum analyser (OSA), the authors of [

11] utilised a single-mode-multimode-single-mode (SMS) intensity modulation configuration to detect breakdown (BDV) values in transformer oil. The authors of [

2] utilised a single-mode intensity modulation configuration for BDV marker identification in transformer oil. The authors of [

10,

12] utilised a U-shaped intensity modulation configuration for a sensitivity analysis study on various sucrose and transformer oils. Aside from the intensity modulation configuration, the wavelength modulation configuration has been previously used for ageing marker detection studies in transformer oil. The authors of [

13,

14] utilised the Fibre Bragg Grating (FBG) sensor, taking advantage of its wavelength modulation to track the BDV marker in transformer oil. Phase modulation optical fibre sensors, such as Fabry–Pérot interferometric sensors, are also utilised in transformer oil ageing monitoring, though their applications are less frequently reported than those of intensity-modulated optical fibre sensors. A more detailed literature review of various transformer oil online sensors conducted by the authors is available in [

1]. Comparatively, the patented FISO FRI architecture used here combines white-light Fabry–Pérot sensing with Fizeau cross-correlation to return an absolute optical path difference (central correlation peak), thereby eliminating fringe-order ambiguity, preserving a wide RI range (1.000–1.700), and delivering high repeatability with a linear thermal coefficient (~ –0.0004 RIU °C

−1) across four oil chemistries (

Section 4.1,

Section 4.2, and

Section 4.3). This unique configuration directly addresses practical limitations in other configurations: intensity-modulated probes (U-shaped/SMS) are amplitude-based and thus susceptible to turbidity/scattering, alignment and source fluctuations, and surface fouling [

4,

10], whereas the FRI’s phase readout with white-light cross-correlation is less sensitive to absolute intensity and provides a stable central-peak metric even when throughput varies; FBG (wavelength-modulated) schemes require spectral tracking and show cross-sensitivities to temperature/strain, while the FRI yields absolute optical path difference (OPD) with a simple, linear thermal coefficient that facilitates straightforward temperature compensation [

15,

16]; and monochromatic Fabry–Pérot sensors suffer fringe-order ambiguity and restricted dynamic range, which the FRI overcomes via its white-light correlation to provide an unambiguous measurement across a broad RI span [

17]. Additionally, the FRI-NP package offers EMI/RFI immunity, 0–100 °C operation, and a 1000 psi proof rating for in-situ deployment, consistent with the settling, repeatability, and thermal-linearity results reported here (see

Table 1).

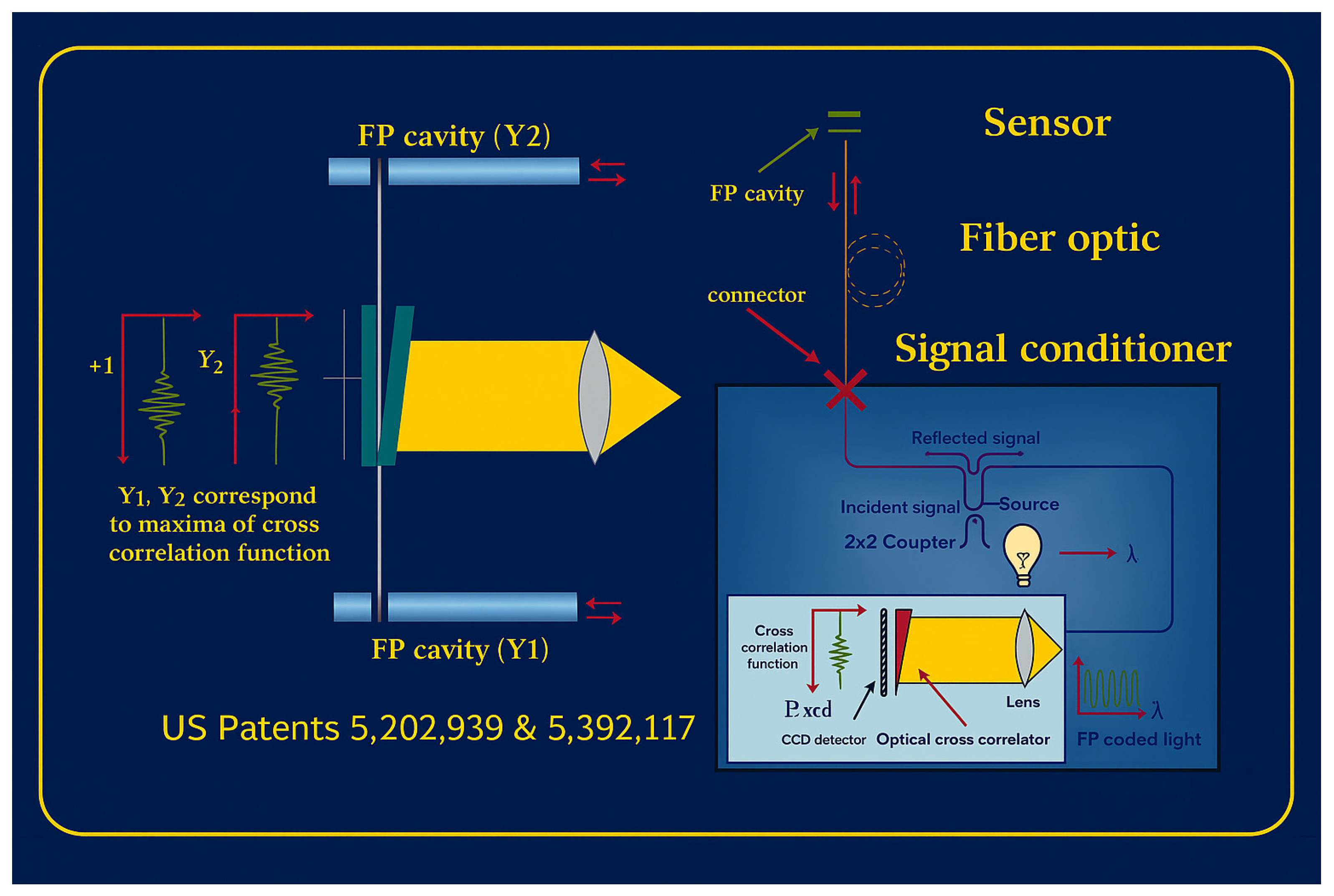

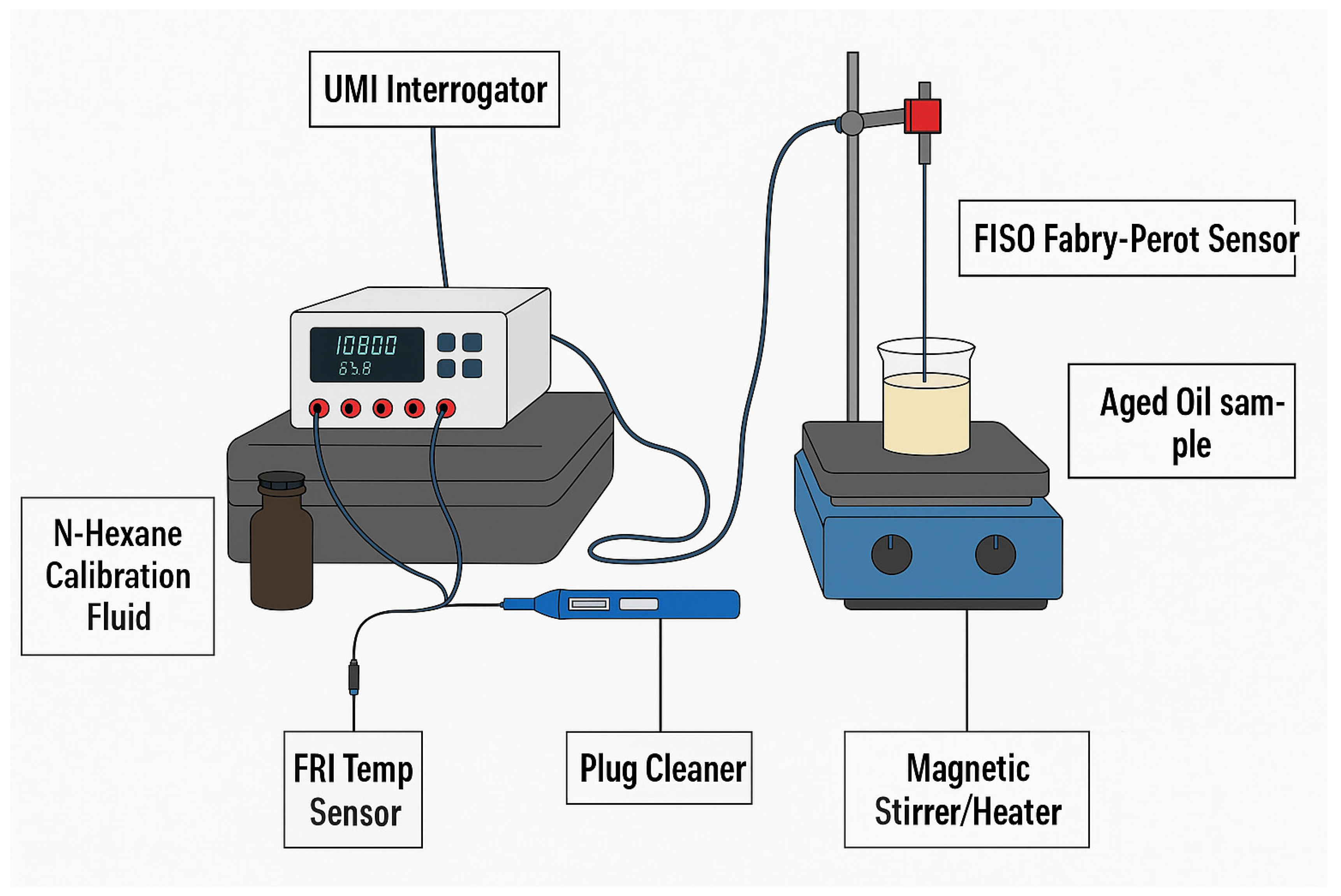

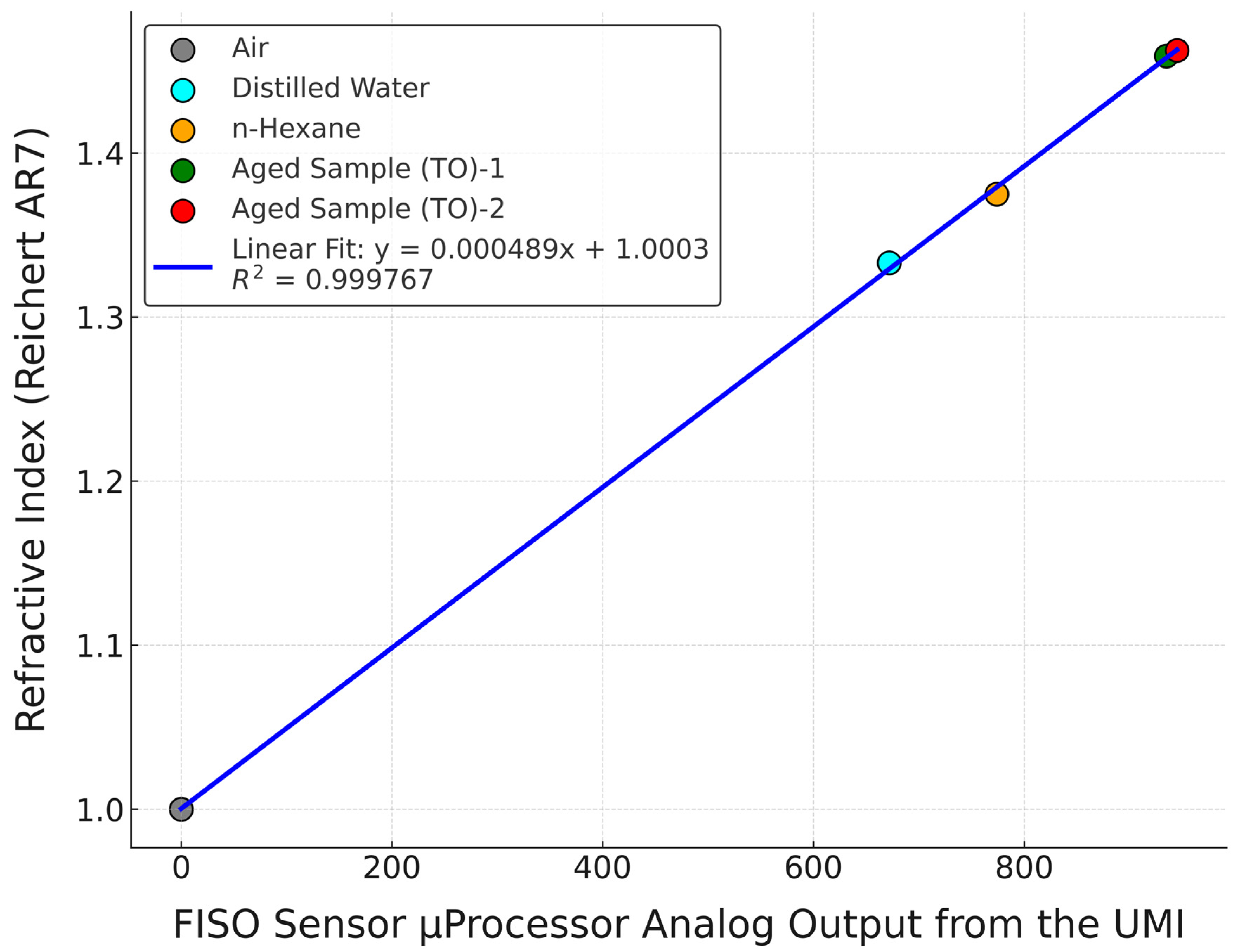

In collaboration with FISO Resonetics, this study investigates the novel, patented FRI refractive index sensor (see

Figure 1) for transformer oil ageing monitoring applications. The patented FISO FRI sensor employs a white-light Fabry–Pérot (F–P) interferometric principle that fundamentally differs from conventional fibre-optic refractive index measurement techniques, including traditional F–P approaches (see

Table 1) [

18,

19]. Unlike typical F–P sensors, which often rely on monochromatic light and relative fringe counting, this sensor uses an incoherent broadband (white-light) source injected into a fibre-based F–P cavity containing the sample [

18,

19]. The emerging interference signal is reinjected into the fibre and processed using a Fizeau wedge cross-correlation scheme (see

Figure 1 and

Figure 2), producing a distinct central correlation peak corresponding to the optical path difference of the cavity. This configuration eliminates the fringe-order ambiguity and the limited dynamic range commonly associated with conventional F–P sensors, enabling highly precise, linear measurements of refractive index across a wide range. By reinjecting the interference signal into the fibre and using a robust cross-correlation readout, the system achieves enhanced stability, reproducibility, and suitability for in-situ applications, attributes not typically attainable with classical F–P or evanescent-field fibre-optic sensors [

18,

19]. This article presents an initial exploration of its use for industrial transformer oil applications, beginning with characterisation studies on four transformer oil samples. These studies focus on evaluating stability, repeatability, and temperature response, providing foundational insight into the sensor’s suitability for monitoring industrial oil systems.

2. Principle of Instrumentation

According to [

19,

20,

21], a Fabry–Pérot cavity is designed by separating two parallel partially reflecting surfaces by a distance

, with a medium between the two surfaces having a refractive index,

n. To enhance the functionality of the instrumentation, a partially reflective surface is employed to enable directed external light to enter the system (via the Universal Multichannel Instrument [UMI] and a multimode fibre) and exit the cavity (through the multimode fibre back to the UMI). This setup generates a spectrally varying transmission or reflection function due to the interference of multiple reflected waves. The integrated white-light source operates over 650–1000 nm with an effective central wavelength near 800 nm (see

Table 2). This NIR window is appropriate for transformer oils, which are essentially transparent in this band, supporting low-loss interferometric measurements. Given the short optical path and low source power, illumination-induced self-heating is negligible. Constructive interference occurs when the reflected waves are in phase, producing a transmission peak, whereas destructive interference arises when the waves are out of phase, leading to diminished transmission [

19,

20].

The transmission function,

, is represented mathematically as [

20,

21]:

where

represents the distance between the reflecting surfaces,

represents the wavelength of the light, n represents the refractive index of the material between the cavity, F represents the finesse (the measure of the sharpness of transmission or reflection), which is a function of the mirror reflectance, R. Mathematically, the finesse is expressed as:

The transmission function, as shown in Equation (1), explains that the Fabry–Pérot sensor can effectively be used for refractive index measurement, n, by keeping

constant [

20,

21].

According to Pinet [

19], the FISO F-P sensor for refractive index (RI) measurement consists of a fixed cavity length (ensuring constant

), and the cavity is opened instead of being sealed, to allow non-viscous fluid passage whose RI value (typically between 1.0000 and 1.7000) is to be inferred. The FSIO Fabry–Pérot sensor specification is summarised in

Table 2 below. The FISO FRI sensor employs a multimode optical fibre with a 50 µm core (125 µm cladding, per the IEC 60793 multimode specification), corresponding to the F1 configuration for the UMI system. The use of this fibre geometry increases broadband coupling efficiency and improves the optical throughput of the interferometric signal. Although multimode propagation can introduce modal dispersion, the very short Fabry–Pérot cavity length and the Fizeau cross-correlation readout scheme effectively suppress these effects, ensuring highly stable and repeatable refractive-index measurements.

Figure 1.

FISO FRI Sensor Diagram [

22].

Figure 1.

FISO FRI Sensor Diagram [

22].

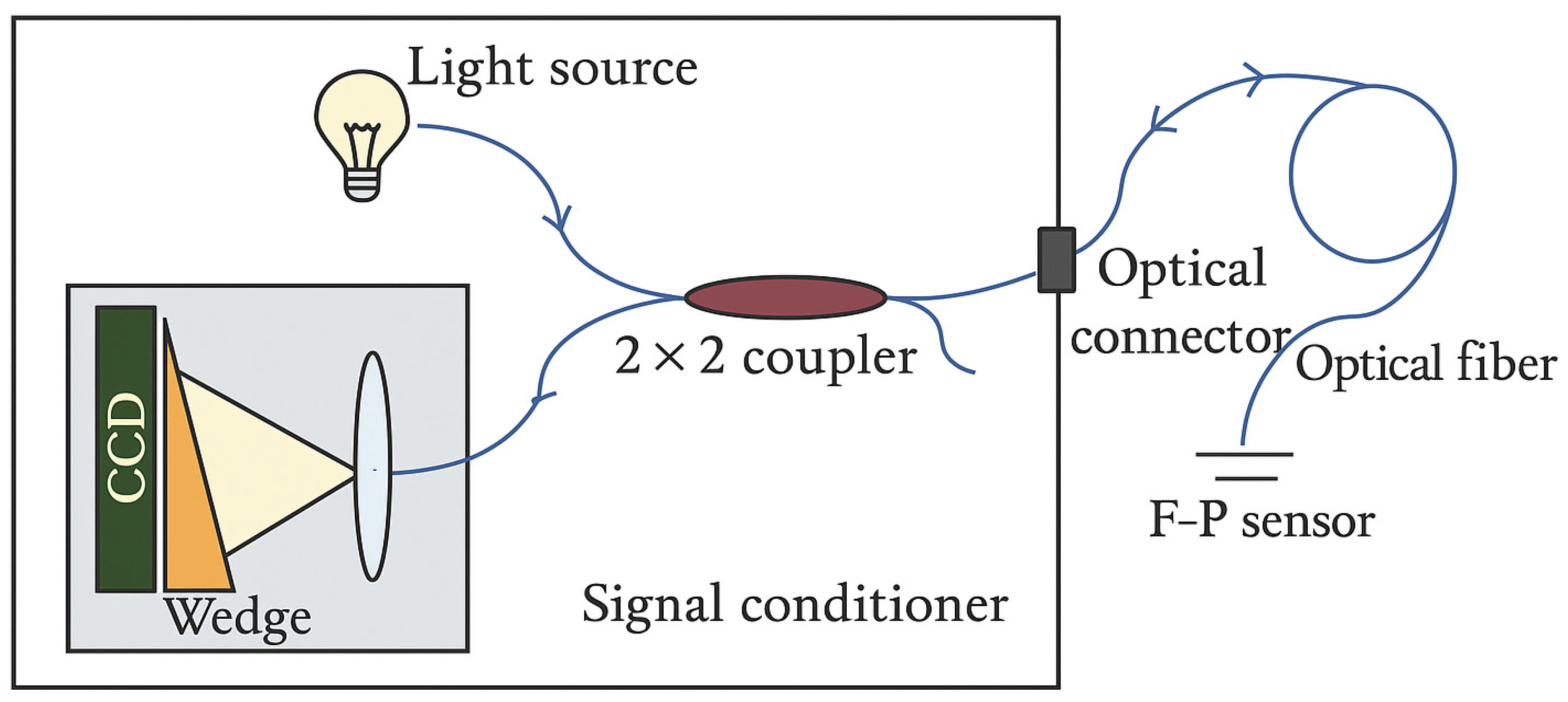

Figure 2.

FISO FRI UMI Schematic Diagram [

18].

Figure 2.

FISO FRI UMI Schematic Diagram [

18].

5. Discussion, Conclusions, and Future Works

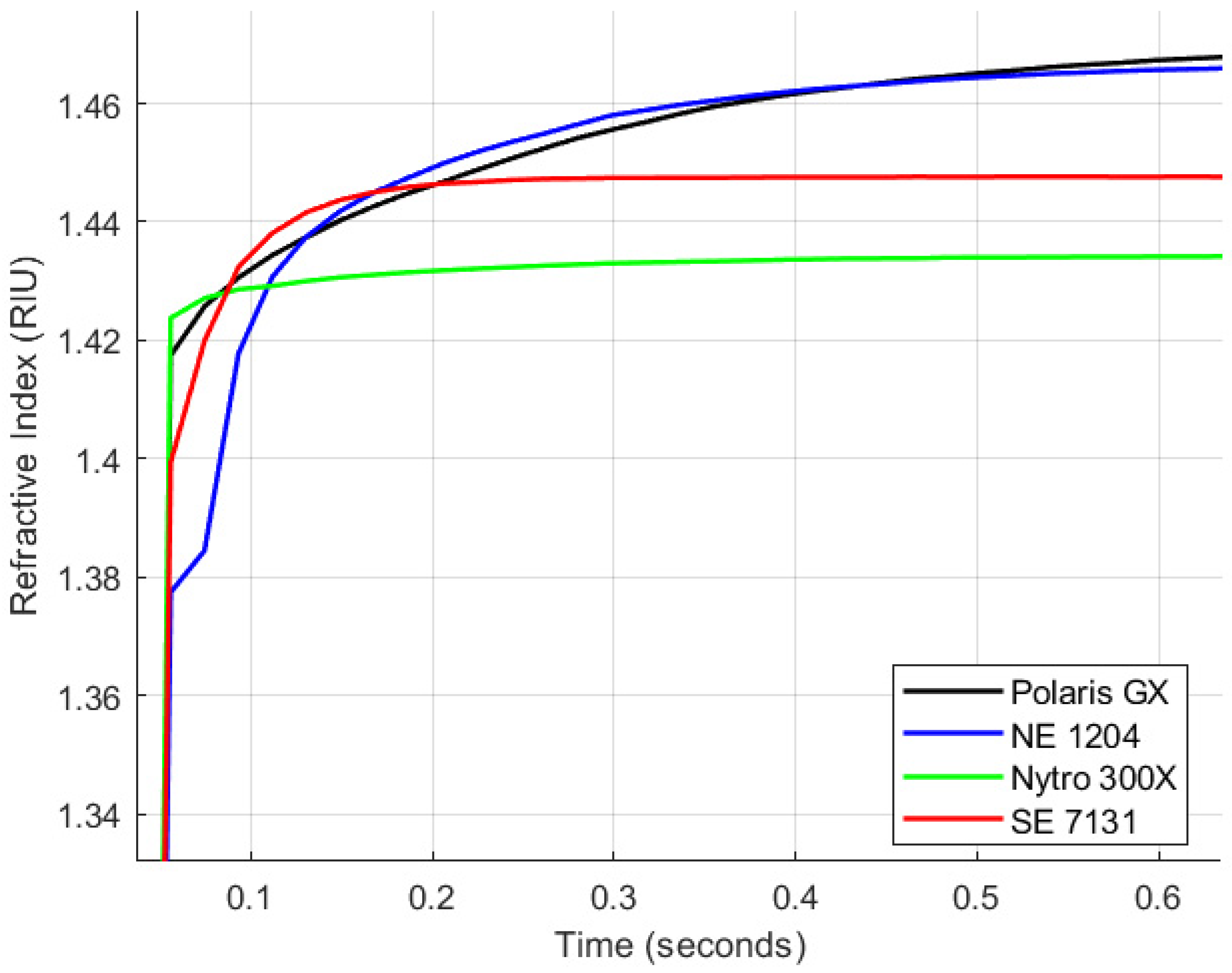

Refractometric fibre-optic sensors play a pivotal role in online detection of ageing in transformer oils by leveraging refractive index (RI) variations that occur as the oil degrades over time. This experimental study demonstrates that the patented FISO Fabry–Pérot phase-modulated fibre-optic sensor has strong potential for monitoring transformer oil ageing, owing to its precision, fast settling time, and resilience under varying operating conditions.

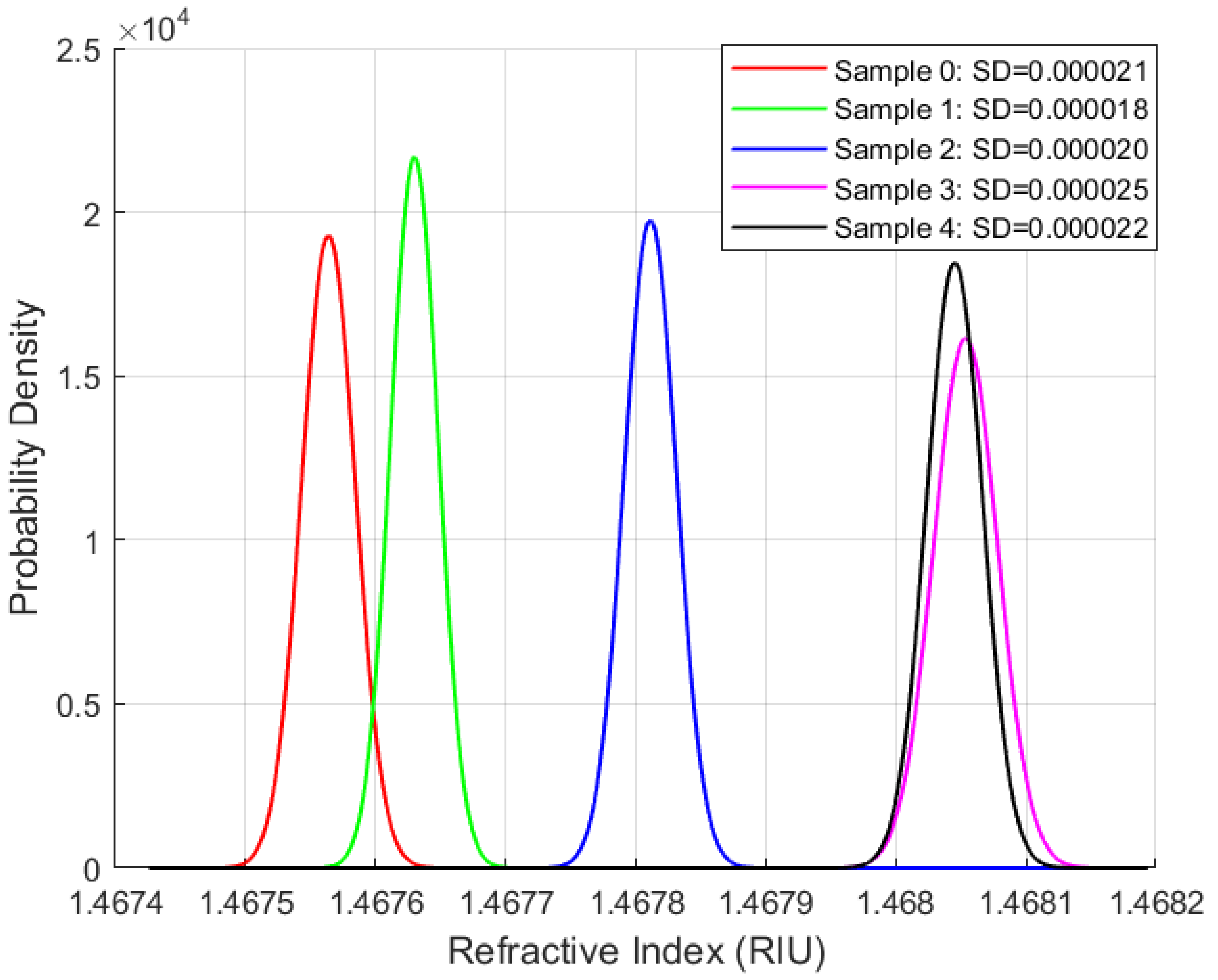

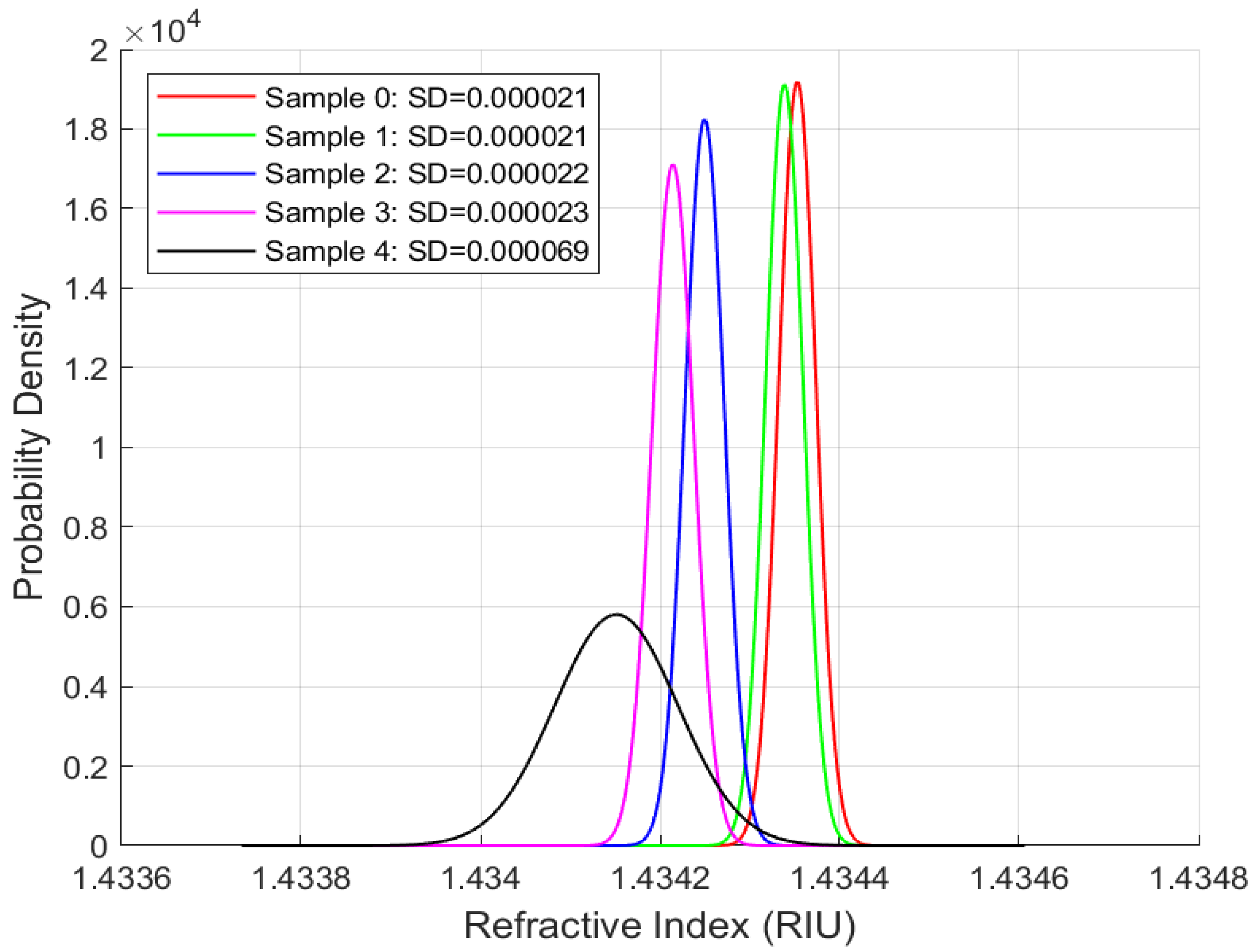

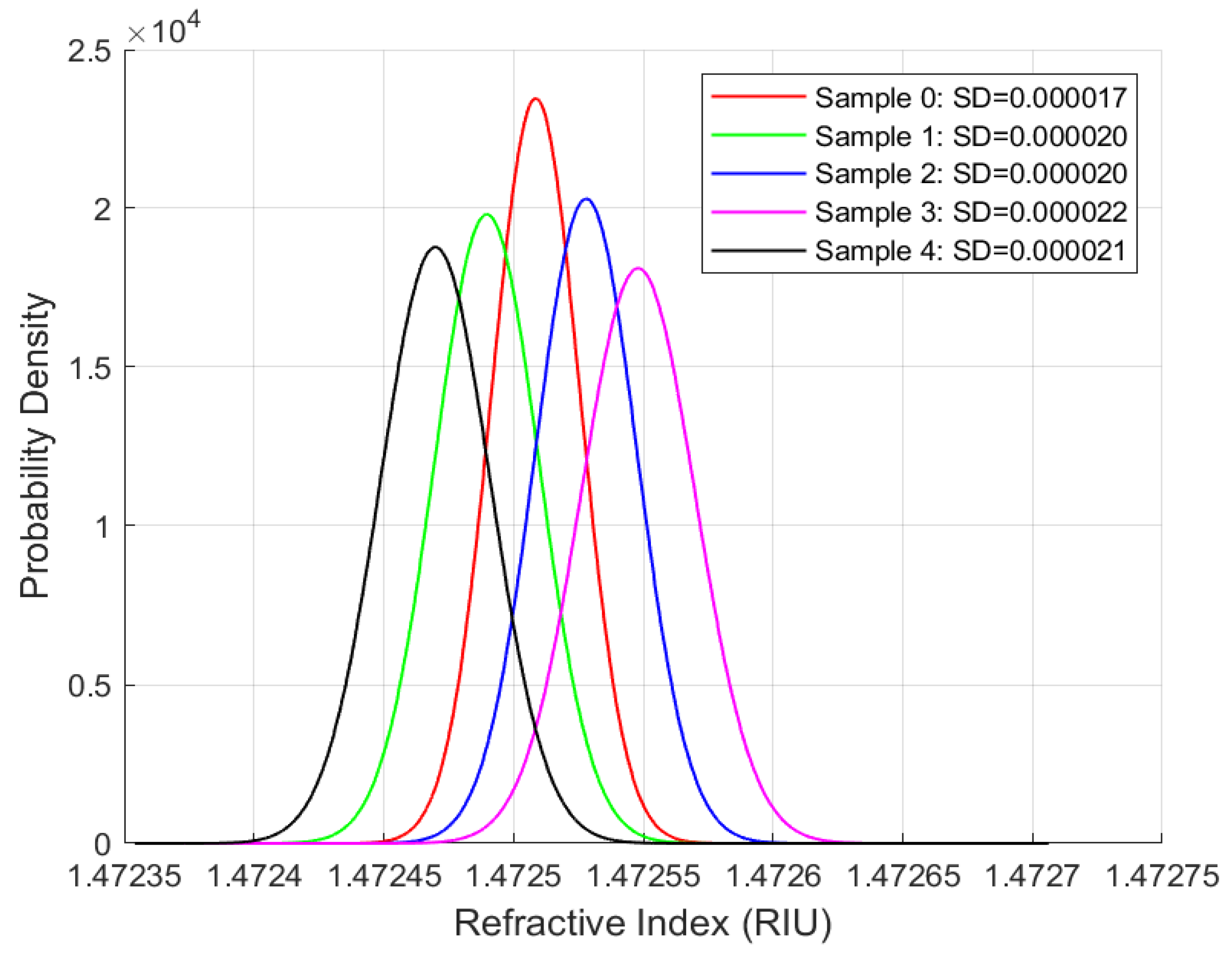

In terms of key instrumentation performance metrics—particularly repeatability—the Fabry–Pérot interferometric refractometric fibre-optic (FRI) sensor consistently delivered low standard deviations and repeatability coefficient across different transformer oil types and stages of thermal ageing. In addition, one-way ANOVA tests indicated statistically significant differences among ageing states for all oils (p < 0.001), demonstrating that the observed variations are not due to random measurement noise. This high repeatability, combined with the sensor’s inherent immunity to external disturbances such as mechanical twisting, positions it as a robust and reliable alternative to conventional intensity-modulated fibre optic sensors for continuous, real-time ageing diagnostics.

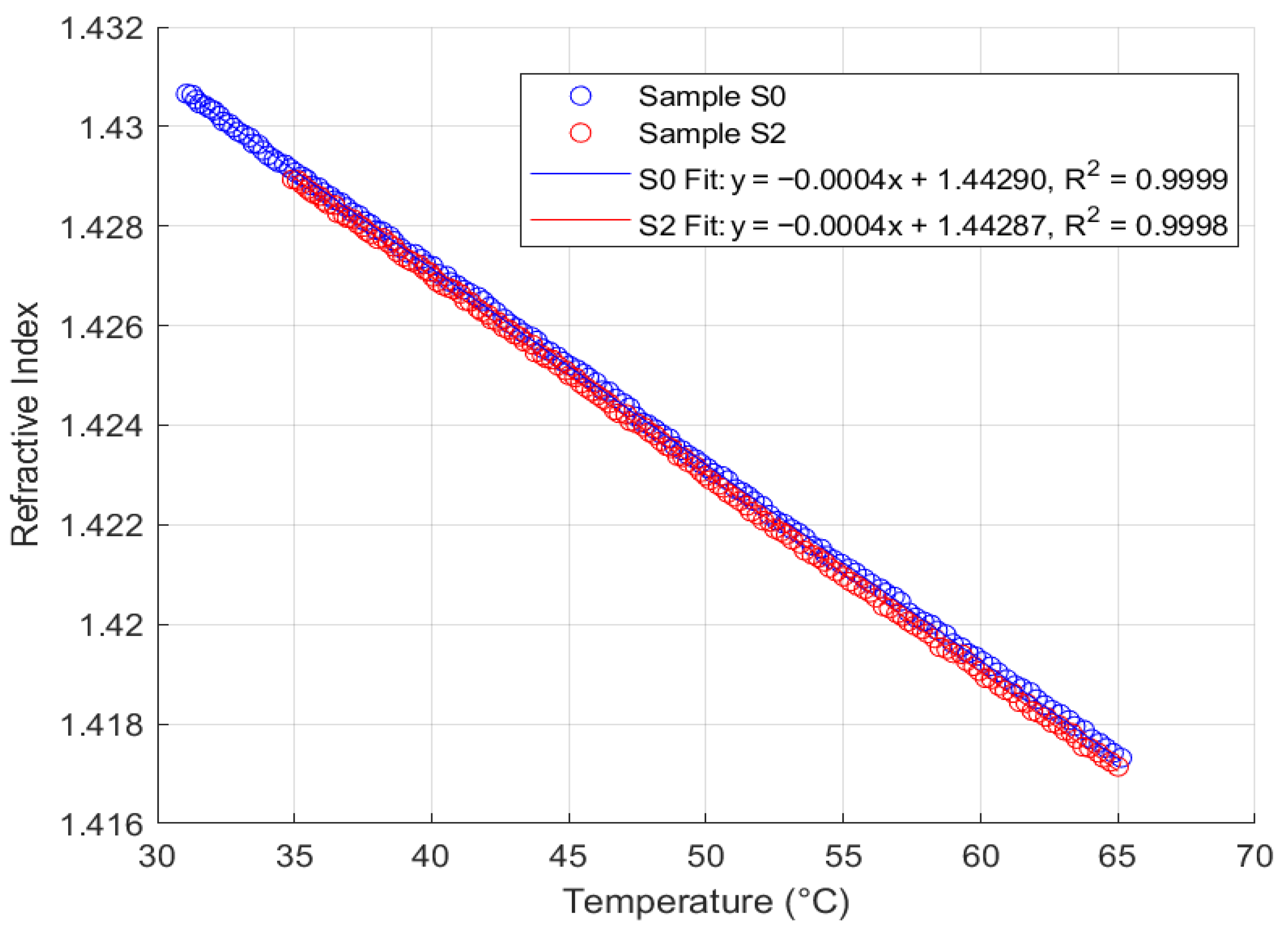

The study further revealed that, based on repeatability and thermal response analyses, natural ester oil and Nytro Bio 300X (a vegetable-based oil) yielded superior performance outcomes compared to synthetic ester oil and Polaris GX mineral oil. Specifically, the Fabry–Pérot sensor maintained a consistent thermal coefficient of approximately 0.0004 RIU/°C, with fitted linear plots exhibiting coefficients of determination exceeding 99% across all oil types. In contrast, the synthetic ester and mineral oils demonstrated greater sensitivity to temperature-induced RI changes, leading to increased measurement variability and lower consistency in thermal analysis plots.

Additionally, the Fabry–Pérot FRI sensor exhibited fast settling times for both fresh and aged samples across all four oil types, highlighting its ability to provide consistent and timely responses under various ageing conditions. These findings reinforce the sensor’s effectiveness and reliability as a precision diagnostic tool for transformer oil ageing monitoring applications.

The FISO FRI refractive index sensor used in this work is a patented commercial device, and as such, some internal calibration and signal-processing parameters are not disclosed by the manufacturer (FISO–Resonetics) to end users. These include, for example, the detailed internal correlation algorithm used in the Fizeau wedge signal-processing module and specific optical cavity parameters embedded in the proprietary firmware of the Universal Multichannel Instrument (UMI). While these parameters are inaccessible, the authors have ensured that all experimentally measurable quantities, such as the refractive index range, resolution, operating wavelength, and temperature range, are reported (

Table 2 of the manuscript). In addition, the authors have provided a comprehensive operational description of the measurement principle and calibration procedure in

Section 3.2 to ensure experimental transparency and reproducibility.

Compared with intensity-based probes, which are affected by turbidity and alignment, and wavelength-based systems, which require spectral tracking and temperature or strain correction, the white-light, phase-based FRI sensor provides a direct, unambiguous measurement of optical path difference. It can measure refractive indices from 1.000 to 1.700, achieves over 99% stability in less than half a minute under the reported test conditions, and uses fibre-optic, EMI-resistant, pressure-rated hardware suitable for in-situ applications.

Despite high short-term repeatability and linear thermal behaviour reported, several practical limits remain. (1) The readout is temperature-dependent; field use therefore requires temperature control or linear compensation. (2) Optical throughput may decline in harsh service due to microfouling/varnish or increased scattering; this mainly lowers fringe contrast rather than biasing phase, but can reduce margin in heavily degraded oils and thus warrants periodic probe cleaning/inspection. (3) A multi-month drift study was not performed; long-term stability will depend on source stability, connector integrity, and fouling rates, and is the subject of planned field trials. (4) Certain internal parameters of the commercial interrogator are proprietary; to support reproducibility, all measurable, user-level specifications (operating band 650–1000 nm, RI range 1.000–1.700, operating temperature 0–100 °C, 1000 psi proof pressure for FRI-NP) and the procedures used here are reported.

Future research would explore advanced temperature-compensation models tailored to the linear temperature response of this sensor, optimised for different oil types and operational temperature ranges. This would enhance the reliability of ageing diagnostics by minimising the impact of temperature-induced RI fluctuations. Furthermore, the potential benefits of sample dilution in improving sensor accuracy and stability merit further investigation, particularly for highly viscous or degraded oil samples. Additional comparative studies between the FISO FRI sensor and other commercial sensors can also be conducted, especially in precision, stability, and thermal-response tests.