Research and Experimental Testing of a Remotely Controlled Ankle Rehabilitation Exoskeleton Prototype

Abstract

1. Introduction

2. Related Work

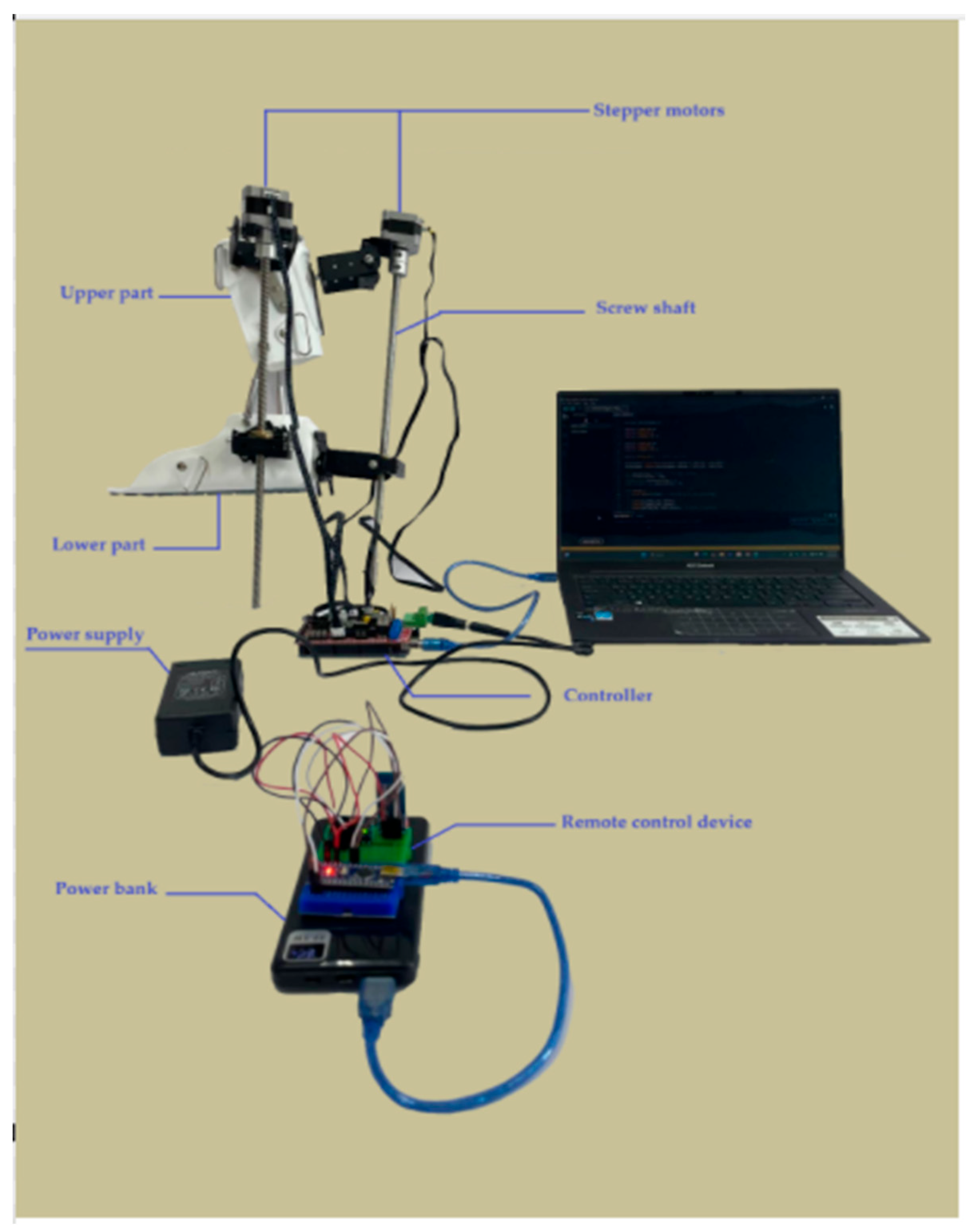

3. Materials and Methods

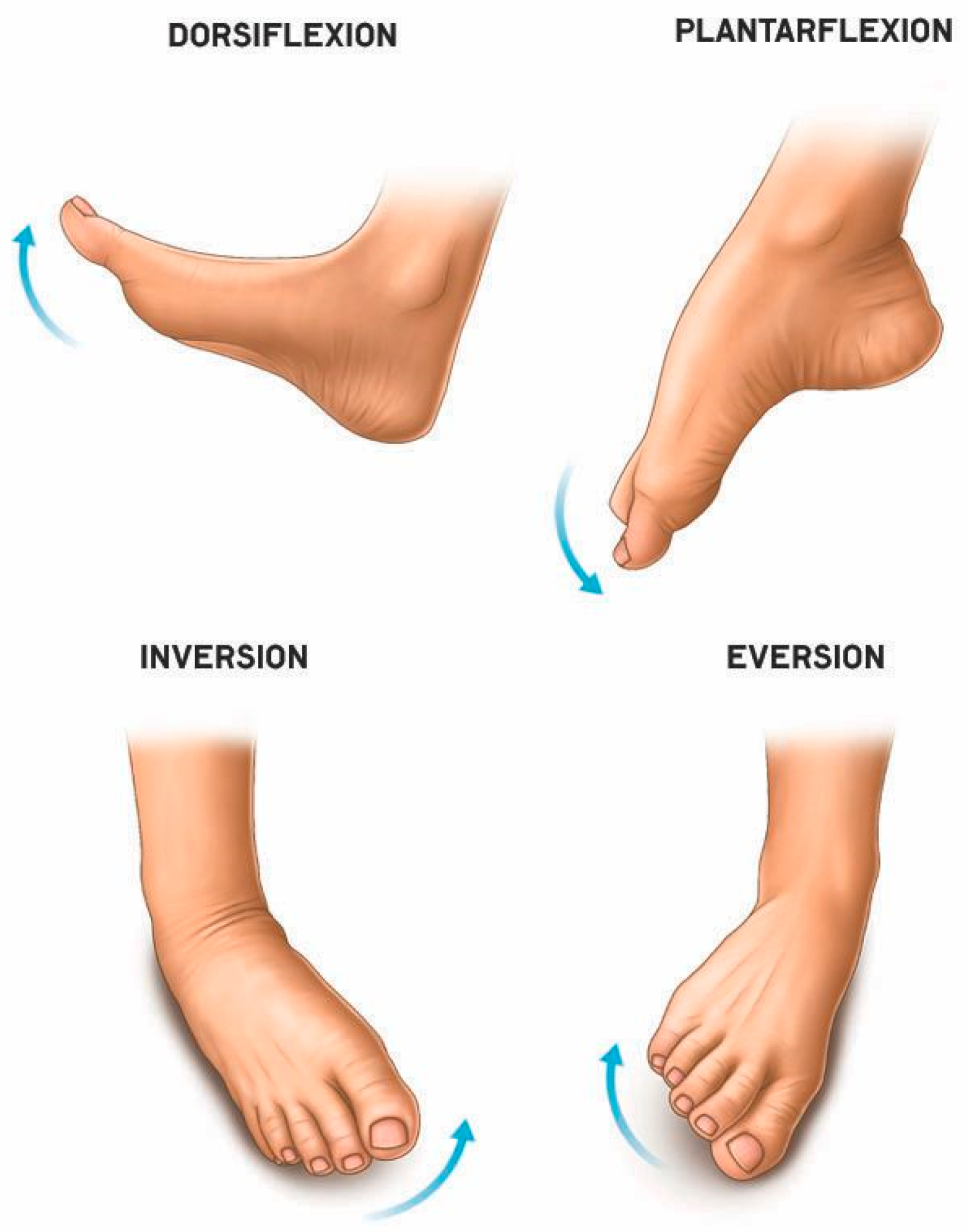

3.1. Determination of Biomechanical Characteristics for the Ankle Joint

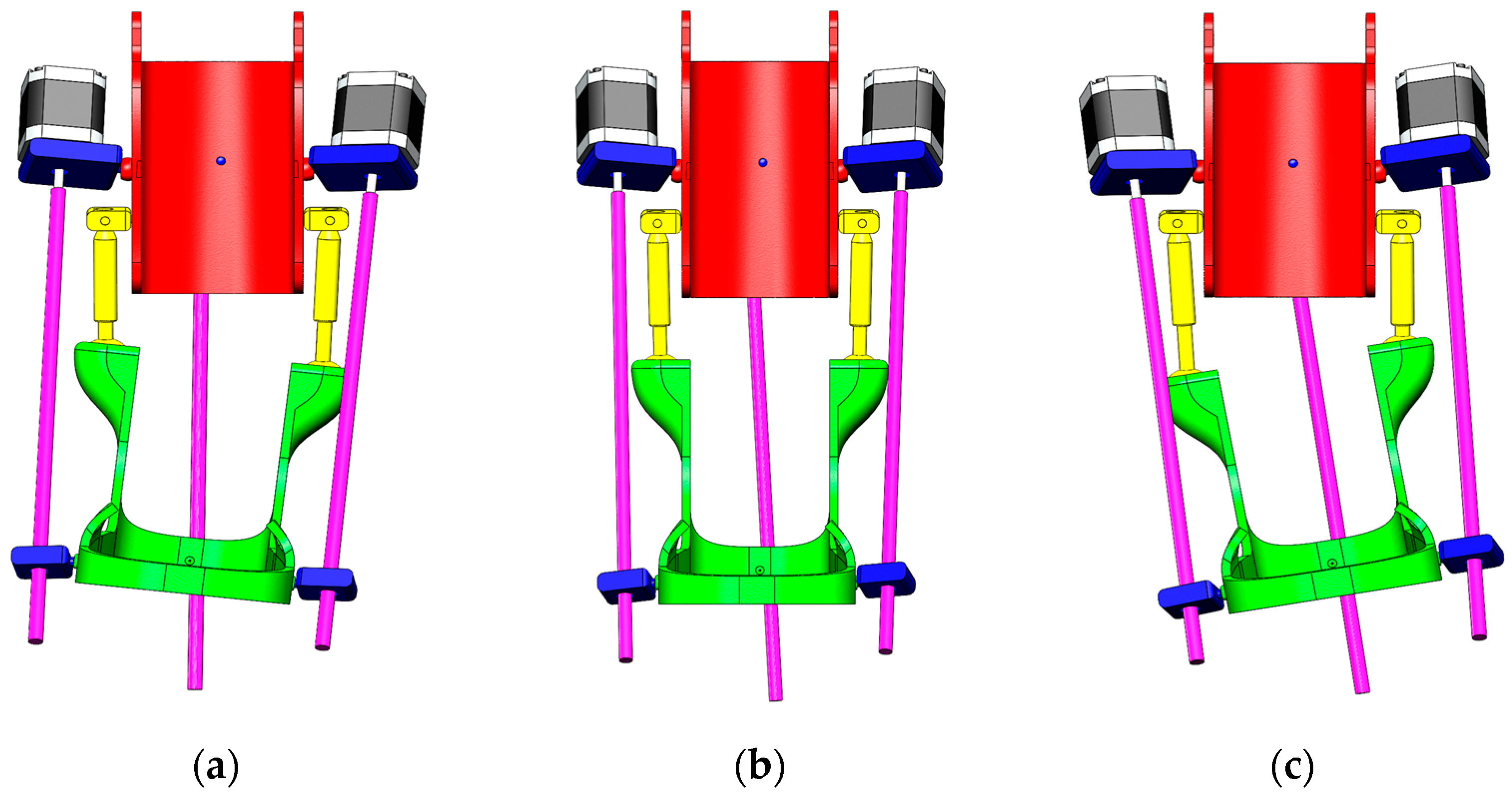

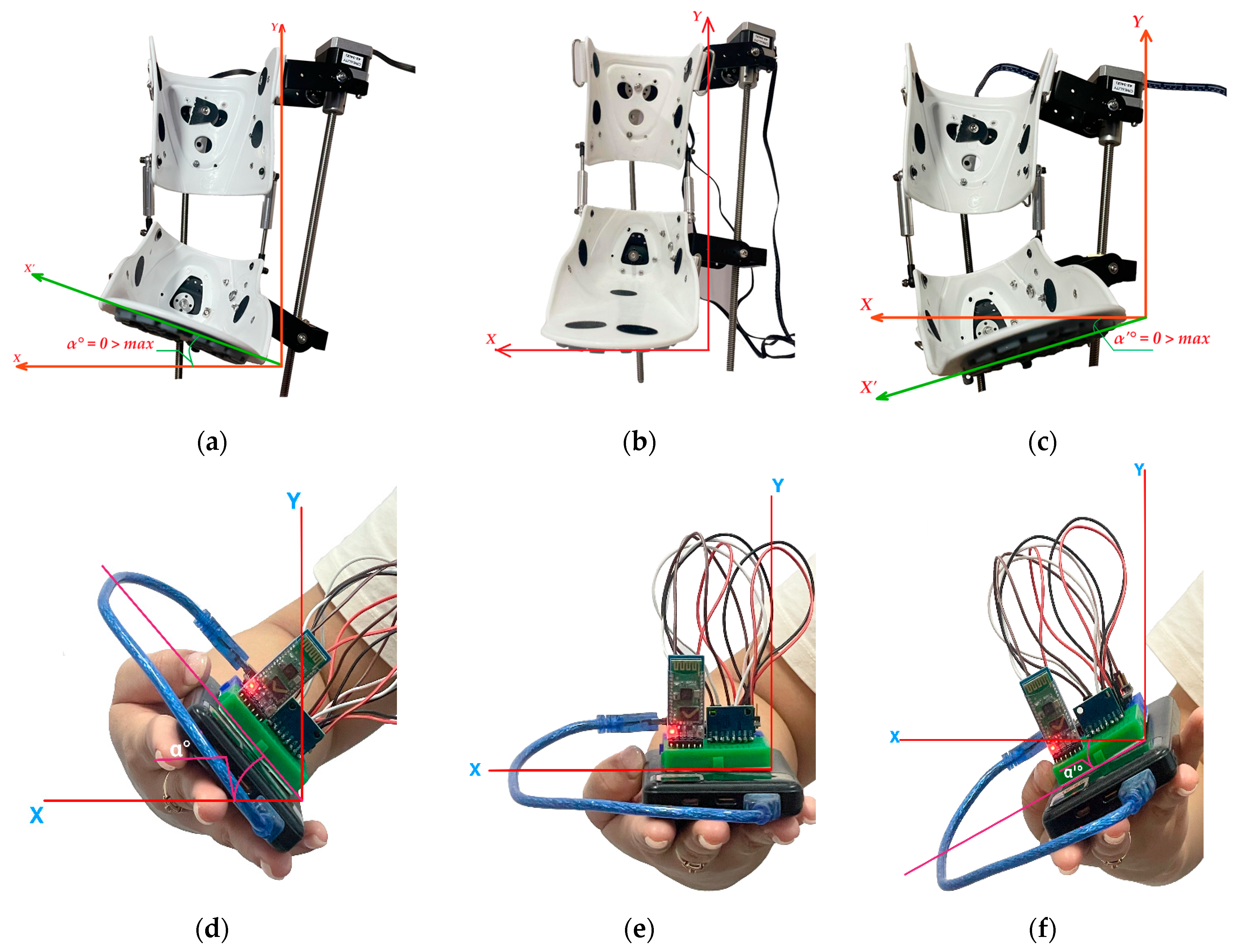

3.2. Designing a Prototype Exoskeleton for Ankle Rehabilitation

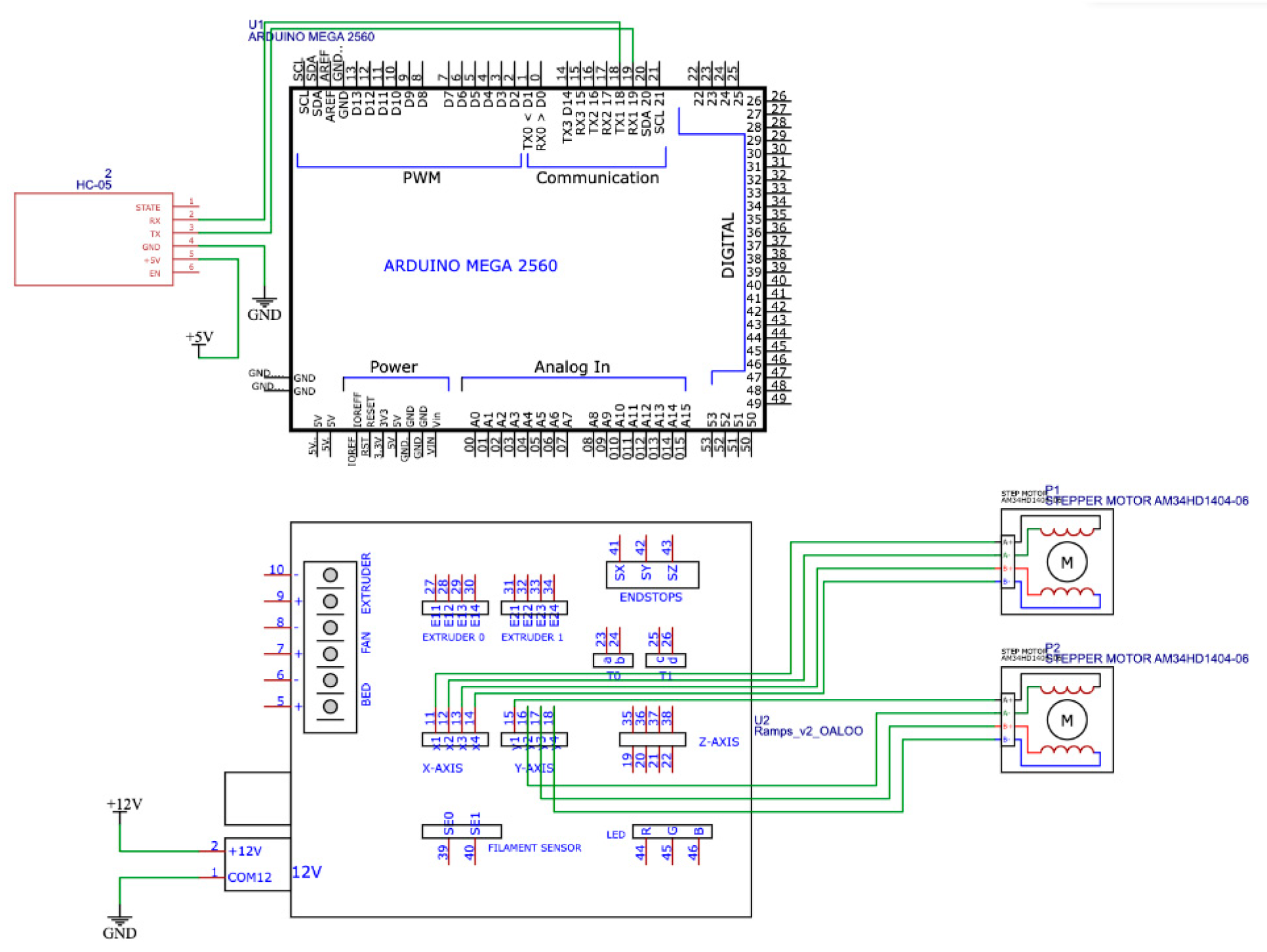

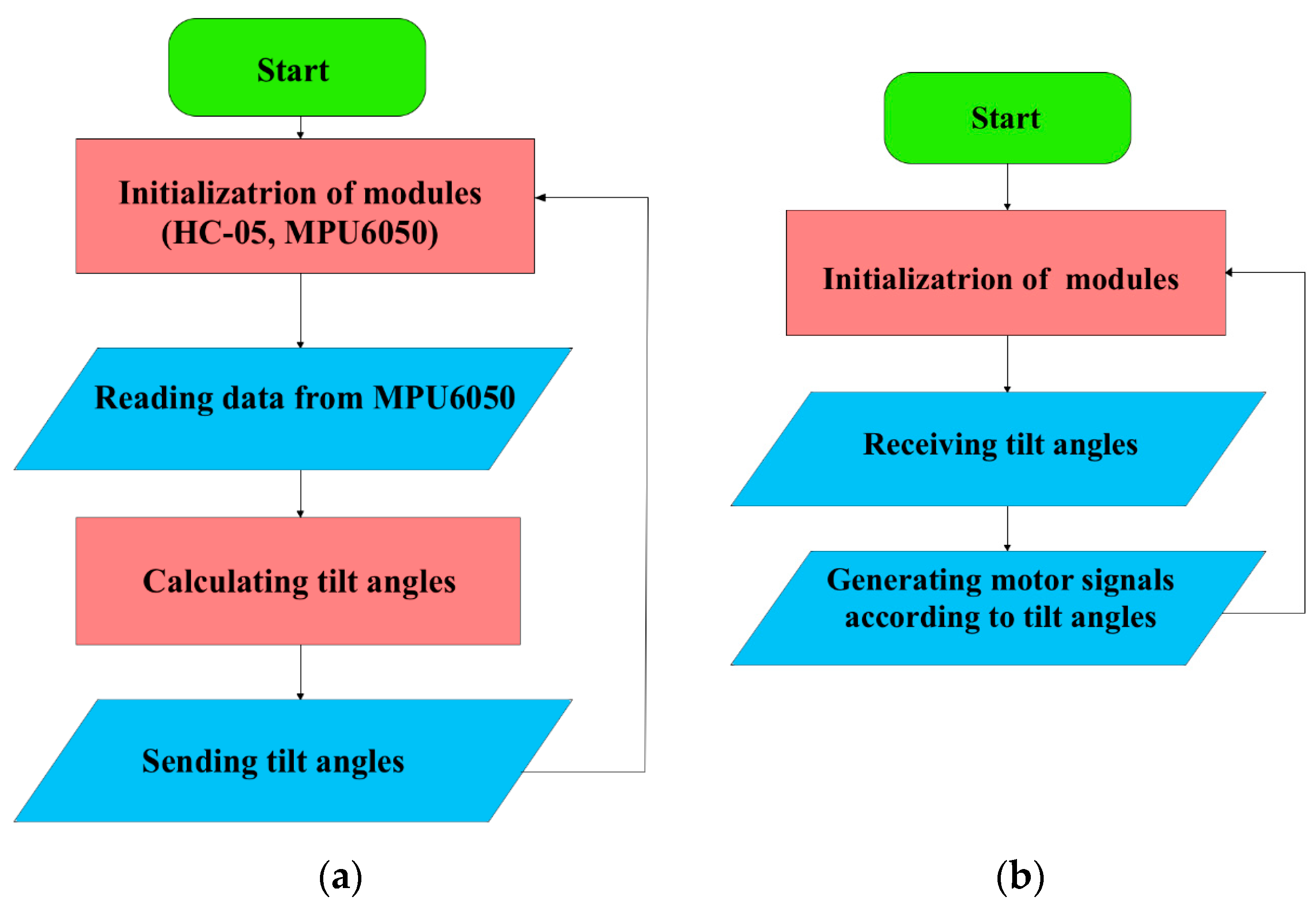

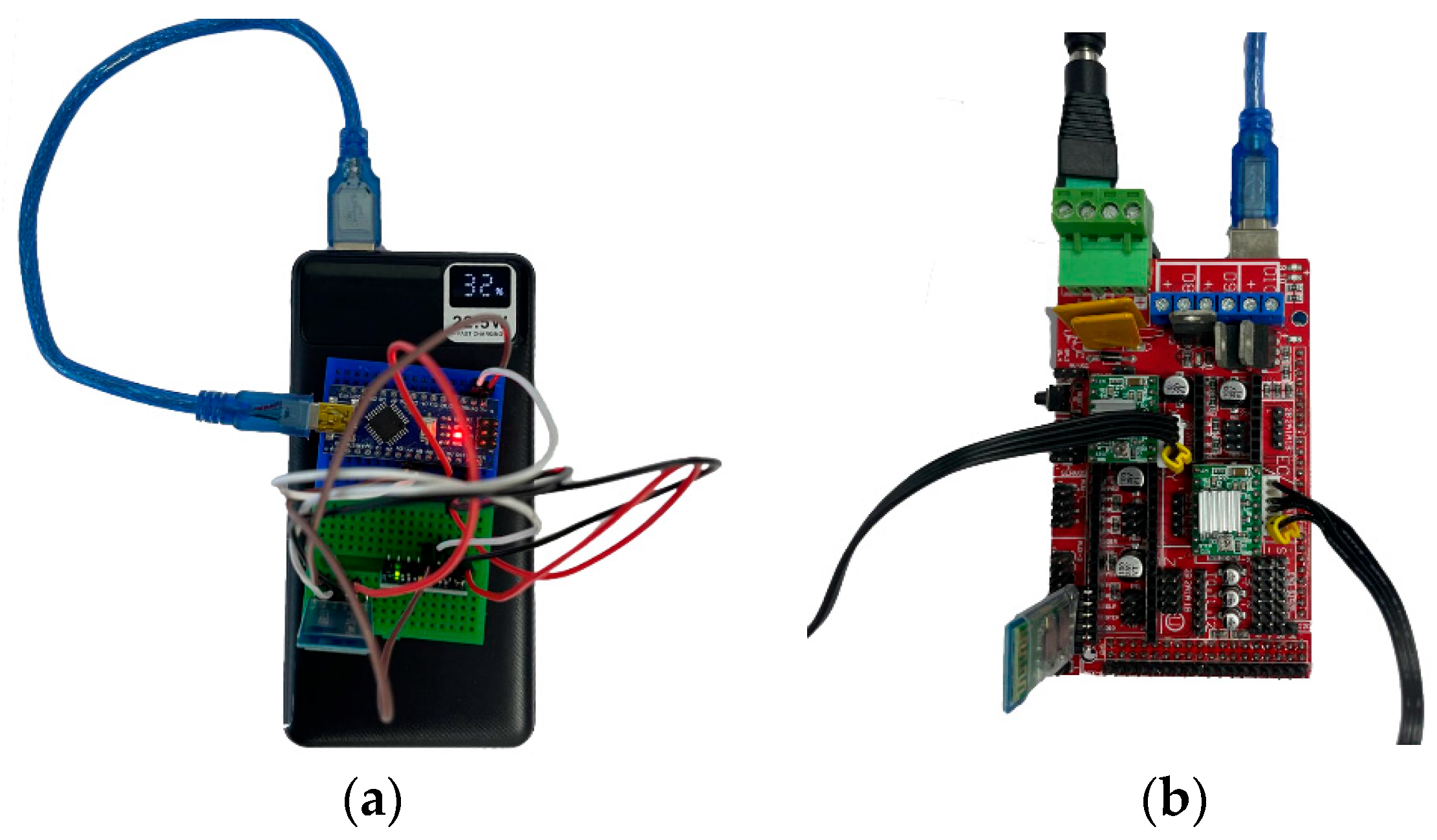

3.3. Developing a Wireless Communication Platform

3.4. Development of a Remote Control System for the Exoskeleton Prototype

3.5. Safety and Fail-Safe Design Considerations

4. Results and Discussion

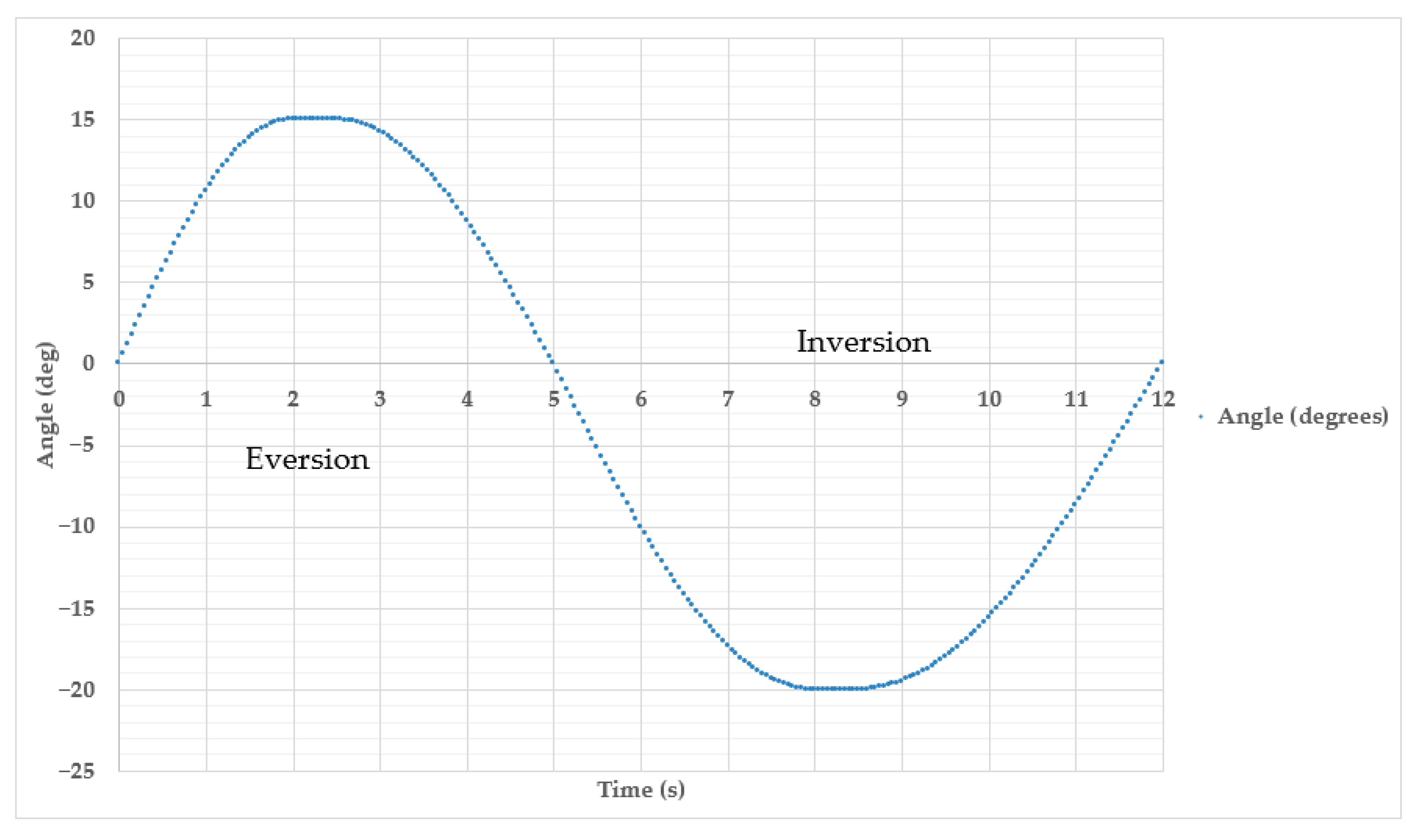

Experimental Study of an Ankle Exoskeleton Prototype with Integrated Wireless Communication Platform

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- UN Sustainable Development Goals. United Nations Department of Economic and Social Affairs. Goal 3: Ensure Healthy Lives and Promote Well-Being for All at All Ages. Available online: https://www.un.org/sustainabledevelopment/health (accessed on 4 August 2025).

- United Nations. The Sustainable Development Goals Report 2023: Special Edition—Towards a Rescue Plan for People and Planet; United Nations: New York, NY, USA, 2023; Available online: https://unstats.un.org/sdgs/report/2023 (accessed on 10 July 2023).

- World Health Organization. A Global Health Strategy for 2025–2028: Advancing Equity and Resilience in a Turbulent World (Fourteenth General Programme of Work); World Health Organization: Geneva, Switzerland, 2025; Available online: https://www.who.int/publications/b/74927 (accessed on 4 August 2025).

- Institute for Health Metrics and Evaluation: GBD Compare. Available online: https://vizhub.healthdata.org/gbd-compare (accessed on 4 August 2025).

- Cardiovascular diseases (CVDs): Key Facts. Available online: https://www.who.int/news-room/fact-sheets/detail/cardiovascular-diseases-(cvds) (accessed on 31 July 2025).

- Gomez-Vargas, D.; Ballen-Moreno, F.; Barria, P.; Aguilar, R.; Azorín, J.M.; Munera, M.; Cifuentes, C.A. The Actuation System of the Ankle Exoskeleton T-FLEX: First Use Experimental Validation in People with Stroke. Brain Sci. 2021, 11, 412. [Google Scholar] [CrossRef]

- Disability: Global Report on Health Equity for Persons with Disabilities. Available online: https://www.who.int/publications/i/item/9789240063600 (accessed on 2 December 2022).

- World Health Organization. Cardiovascular Diseases. Available online: https://www.who.int/health-topics/cardiovascular-diseases#tab=tab_1 (accessed on 2 November 2023).

- Cisek, K.; Kelleher, J.D. Current Topics in Technology-Enabled Stroke Rehabilitation and Reintegration: A Scoping Review and Content Analysis. IEEE Trans. Neural Syst. Rehabil. Eng. 2023, 31, 3341–3352. [Google Scholar] [CrossRef] [PubMed]

- Hussain, M.A.; Waris, A.; Gilani, S.O.; Mushtaq, S.; Pujari, A.N.; Khan, N.B.; Jameel, M.; Daminova, G.; Khan, M.I. Virtual Reality as a Non-Conventional Rehabilitation for Stroke: A Comprehensive Review. J. Neurorestoratol. 2024, 12, 100135. [Google Scholar] [CrossRef]

- Nolan, K.J.; Ames, G.R.; Dandola, C.M.; Breighner, J.E.; Franco, S.; Karunakaran, K.K.; Saleh, S. Intensity Modulated Exoskeleton Gait Training Post Stroke. In Proceedings of the 2023 45th Annual International Conference of the IEEE Engineering in Medicine & Biology Society (EMBC), Sydney, Australia, 24–27 July 2023; pp. 1–4. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, H.; Wang, J.; Lu, R.; Tian, J.; Wu, B.; Chu, J.; Li, J. Virtual Reality-Based Robotic Training for Lower Limb Rehabilitation in Stroke Patients with Hemiplegia: A Pilot Study. Aging Health Res. 2025, 5, 100233. [Google Scholar] [CrossRef]

- Spiess, A.A.F.; Skempes, D.; Bickenbach, J.; Stucki, G. Exploration of Current Challenges in Rehabilitation from the Perspective of Healthcare Professionals: Switzerland as a Case in Point. Health Policy 2022, 126, 173–182. [Google Scholar] [CrossRef]

- Morrow, C.M.; Johnson, E.; Simpson, K.N.; Seo, N.J. Determining Factors that Influence Adoption of New Post-Stroke Sensorimotor Rehabilitation Devices in the USA. IEEE Trans. Neural Syst. Rehabil. Eng. 2021, 29, 1213–1222. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Yu, L. AI and stroke rehabilitation: The past, present and future. Regenesis Repair Rehabil. 2025, 1, 6–11. [Google Scholar] [CrossRef]

- Moscatelli, N.; Brambilla, C.; Lanzani, V.; Tosatti, L.M.; Scano, A. Assessing Transparency of Robots, Exoskeletons, and Assistive Devices: A Systematic Review. Sensors 2025, 25, 4444. [Google Scholar] [CrossRef]

- Andersson, R.; Bermejo-García, J.; Chilo, J. Exploring the Influence of a Passive Exoskeleton on Range of Motion and Step Length During Walking. In Proceedings of the 2024 IEEE 19th Conference on Industrial Electronics and Applications (ICIEA), Kristiansand, Norway, 23–26 June 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Cabrera-Brito, M.E.; Carcelén-Fraile, M.d.C.; Aibar-Almazán, A.; Hita-Contreras, F.; Vico-Rodríguez, P.; Cano-Orihuela, M.; Castellote-Caballero, Y. Effect of Lokomat® Robotic Rehabilitation on Balance, Postural Control, and Functional Independence in Subacute and Chronic Stroke Patients: A Quasi-Experimental Study. Med. Sci. 2025, 13, 157. [Google Scholar] [CrossRef]

- Potašová, M.; Mačej, P.; Moraučíková, E.; Baňárová, P.S.; Kutiš, P. Lokomat vs. Conventional Therapy—Impact on Gait Symmetry in Hemiparetic Patients: Preliminary Clinical Study. Healthcare 2025, 13, 929. [Google Scholar] [CrossRef]

- Lee, S.H.; Kim, J.; Lee, H.J.; Kim, Y.-H. A wearable ankle-assisted robot for improving gait function and pattern in stroke patients. J. Neuroeng. Rehabil. 2025, 22, 89. [Google Scholar] [CrossRef] [PubMed]

- Arias Guadalupe, J.; Pereira-Cabral Perez, A.; Blanco Rojas, D.; Copaci, D. A Lightweight Soft Exosuit for Elbow Rehabilitation Powered by a Multi-Bundle SMA Actuator. Actuators 2025, 14, 337. [Google Scholar] [CrossRef]

- Liu, J.; Fang, H.; Xu, J. Online Adaptive PID Control for a Multi-Joint Lower Extremity Exoskeleton System Using Improved Particle Swarm Optimization. Machines 2022, 10, 21. [Google Scholar] [CrossRef]

- Su, Z.; Gao, W.; Gao, Y. Research and Design of a Lower Limb Rehabilitation Exoskeleton Robot Driven by Cables. In Proceedings of the 2024 IEEE International Conference on Signal, Information and Data Processing (ICSIDP), Zhuhai, China, 22–24 November 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Andersson, R.; Cronhjort, M.; Chilo, J. Wireless PID-Based Control for a Single-Legged Rehabilitation Exoskeleton. Machines 2024, 12, 745. [Google Scholar] [CrossRef]

- Shafi, F.; Aftab, Z.; Hanif, M.A.; Ali, Z. A Lower-Body Exoskeleton Platform with Remote Actuation. In Proceedings of the 2021 6th IEEE International Conference on Advanced Robotics and Mechatronics (ICARM), Chongqing, China, 3–5 July 2021; pp. 68–74. [Google Scholar] [CrossRef]

- Kagirov, I.; Kapustin, A.; Kipyatkova, I.; Klyuzhev, K.; Kudryavcev, A.; Kudryavcev, I.; Loskutov, Y.; Ryumin, D.; Karpov, A. Medical Exoskeleton “Remotion” with an Intelligent Control System: Modeling, Implementation, and Testing. Simul. Model. Pract. Theory 2021, 107, 102200. [Google Scholar] [CrossRef]

- Aktan, M.E.; Falkowski, P.; Zawalski, K.; Jeznach, K.; Ömürlü, V.E.; Akdoğan, E. Design and PID Control of a Lower Limb Exoskeleton for Virtual Reality-Based Telerehabilitation. In Proceedings of the 2025 11th International Conference on Mechatronics and Robotics Engineering (ICMRE), Lille, France, 24–26 February 2025; pp. 272–277. [Google Scholar] [CrossRef]

- Ghezal, M.; Guiatni, M.; Boussioud, I.; Renane, C.S. Design and Robust Control of a 2 DOFs Lower Limb Exoskeleton. In Proceedings of the 2018 International Conference on Communications and Electrical Engineering (ICCEE), El Oued, Algeria, 17–18 December 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Belov, M.P.; Dang Truong, D.; Khoa, T.D. Self-Tuning Subordinate Control System Based on Neural Network for Nonlinear Electric Drivers of Lower Limbs of Exoskeleton. In Proceedings of the 2022 Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), Saint Petersburg, Russia, 25–28 January 2022; pp. 549–553. [Google Scholar] [CrossRef]

- Tangmanee, N.; Muengtaweepongsa, S.; Limtrakarn, W. Development of a DIY Rehabilitation Device for Lower Limb Weakness in Acute to Subacute Ischemic Stroke. MethodsX 2022, 9, 101582. [Google Scholar] [CrossRef]

- Leerskov, K.S.; Rikhof, C.J.H.; Spaich, E.G.; Dosen, S.; Prange-Lasonder, G.B.; Prinsen, E.C.; Rietman, J.S.; Struijk, L.N.S.A. A Robot-Based Hybrid Lower Limb System for Assist-As-Needed Rehabilitation of Stroke Patients: Technical Evaluation and Clinical Feasibility. Comput. Biol. Med. 2024, 179, 108839. [Google Scholar] [CrossRef]

- Majeed, A.P.P.A.; Taha, Z.; Abidin, A.F.Z.; Zakaria, M.A.; Khairuddin, I.M.; Razman, M.A.M.; Mohamed, Z. The Control of a Lower Limb Exoskeleton for Gait Rehabilitation: A Hybrid Active Force Control Approach. Procedia Comput. Sci. 2017, 105, 183–190. [Google Scholar] [CrossRef]

- Flor-Unda, O.; Arcos-Reina, R.; Toapanta, C.; Villao, F.; Bustos-Estrella, A.; Suntaxi, C.; Palacios-Cabrera, H. Challenges in the Development of Exoskeletons for People with Disabilities. Technologies 2025, 13, 291. [Google Scholar] [CrossRef]

- Falkowski, P.; Osiak, T.; Wilk, J.; Prokopiuk, N.; Leczkowski, B.; Pilat, Z.; Rzymkowski, C. Study on the Applicability of Digital Twins for Home Remote Motor Rehabilitation. Sensors 2023, 23, 911. [Google Scholar] [CrossRef] [PubMed]

- Campbell, S.M.; Diduch, C.P.; Sensinger, J.W. Autonomous Assistance-as-Needed Control of a Lower Limb Exoskeleton with Guaranteed Stability. IEEE Access 2020, 8, 51168–51178. [Google Scholar] [CrossRef]

- Agrawal, A.; Harib, O.; Hereid, A.; Finet, S.; Masselin, M.; Praly, L.; Ames, A.D.; Sreenath, K.; Grizzle, J.W. First Steps Towards Translating HZD Control of Bipedal Robots to Decentralized Control of Exoskeletons. IEEE Access 2017, 5, 9919–9934. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Q.; Cai, K.; Wang, Z.; Wang, W.; Liu, J. A Wearable Soft Knee Exoskeleton Using Vacuum-Actuated Rotary Actuator. IEEE Access 2020, 8, 61311–61326. [Google Scholar] [CrossRef]

- Yin, K.; Xiang, K.; Pang, M.; Chen, J.; Anderson, P.; Yang, L. Personalised Control of Robotic Ankle Exoskeleton Through Experience-Based Adaptive Fuzzy Inference. IEEE Access 2019, 7, 72221–72233. [Google Scholar] [CrossRef]

- Sun, L.; Jing, J.; Li, C.; Lu, R. Multi-Terrains Assistive Force Parameter Optimization Method for Soft Exoskeleton. IEEE Trans. Neural Syst. Rehabil. Eng. 2023, 31, 2028–2036. [Google Scholar] [CrossRef] [PubMed]

- Aliman, N.; Ramli, R.; Haris, S.M.; Amiri, M.S.; Van, M. A Robust Adaptive-Fuzzy-Proportional-Derivative Controller for a Rehabilitation Lower Limb Exoskeleton. Eng. Sci. Technol. Int. J. 2022, 35, 101097. [Google Scholar] [CrossRef]

- Mihradi, S.; Sutawika, E.B.; Virdyawan, V.; Goesasi, R.Z.; Todoh, M. Rehab-Bot: A Home-Based Lower-Extremity Rehabilitation Robot for Muscle Recovery. Cogn. Robot. 2025, 5, 114–125. [Google Scholar] [CrossRef]

- Han, D. Application Effect of Rehabilitation Robots in Rehabilitation of Limb Movement Disorders Based on Neural Network Algorithms. SLAS Technol. 2025, 32, 100277. [Google Scholar] [CrossRef]

- Yang, Z.; Yu, S.; Meng, W.; Ma, X.; Yang, L. The Effect of Tele-Rehabilitation Under a Comprehensive Exercise Program on the Function of Patients with Chronic Ankle Instability: A Randomized Controlled Trial. Musculoskelet. Sci. Pract. 2025, 78, 103327. [Google Scholar] [CrossRef]

- Boltaboyeva, A.; Baigarayeva, Z.; Imanbek, B.; Ozhikenov, K.; Getahun, A.J.; Aidarova, T.; Karymsakova, N. A Review of Innovative Medical Rehabilitation Systems with Scalable AI-Assisted Platforms for Sensor-Based Recovery Monitoring. Appl. Sci. 2025, 15, 6840. [Google Scholar] [CrossRef]

- Li, J.; Jiang, H.; Gao, M.; Li, S.; Wang, Z.; Pang, Z.; Zhang, Y.; Jiao, Y. Research on Iterative Learning Method for Lower Limb Exoskeleton Rehabilitation Robot Based on RBF Neural Network. Appl. Sci. 2025, 15, 6053. [Google Scholar] [CrossRef]

- Chen, L.; Huang, J.; Wang, Y.; Guo, S.; Wang, M.; Guo, X. Adaptive Patient-Cooperative Compliant Control of Lower Limb Rehabilitation Robot. Biomim. Intell. Robot. 2024, 4, 100155. [Google Scholar] [CrossRef]

- Chen, C.; Lv, J.; Xu, Z. A Multi-Indicator Evaluation Method for Human-Machine Effectiveness of Lower Limb Wearable Exoskeleton. Biomed. Signal Process. Control 2024, 91, 105976. [Google Scholar] [CrossRef]

- Miner, T.M.; Anderson, M.B.; Van Andel, D.C.; Neher, R.E.; Redfern, R.E.; Duwelius, P.J. Evaluating Self-Directed Rehabilitation for Knee and Hip Arthroplasty During the COVID-19 Pandemic: A Multicenter Study. Med. Sci. 2024, 12, 69. [Google Scholar] [CrossRef]

- Popa, M.V.; Gurzu, I.L.; Handra, C.M.; Gurzu, B.; Pleșea Condratovici, A.; Duceac, M.; Elkan, E.M.; Mîndru, D.E.; Dabija, V.A.; Duceac, L.D. Impact of the COVID-19 Pandemic on Musculoskeletal Disorder-Related Absenteeism Among Pediatric Healthcare Workers. Healthcare 2025, 13, 1116. [Google Scholar] [CrossRef] [PubMed]

- Shakeriaski, F.; Mohammadian, M. Enhancing Upper Limb Exoskeletons Using Sensor-Based Deep Learning Torque Prediction and PID Control. Sensors 2025, 25, 3528. [Google Scholar] [CrossRef]

- Hasan, S.; Alam, N. Comprehensive Comparative Analysis of Lower Limb Exoskeleton Research: Control, Design, and Application. Actuators 2025, 14, 342. [Google Scholar] [CrossRef]

- Zhetenbayev, N.; Balbayev, G.; Zhauyt, A.; Shingissov, B. Design and Performance of the New Ankle Joint Exoskeleton. Int. J. Mech. Eng. Robot. Res. 2023, 12, 151–158. [Google Scholar] [CrossRef]

- Zhetenbayev, N.; Sergazin, G.; Tursunbayeva, G.; Uzbekbayev, A.; Kyrykbayev, B. Development of a Control Algorithm for an Ankle Joint Rehabilitation Device. In Artificial Intelligence in Healthcare; Lecture Notes in Computer Science; Xie, X., Styles, I., Powathil, G., Ceccarelli, M., Eds.; Springer: Cham, Switzerland, 2024; Volume 14975. [Google Scholar] [CrossRef]

- Sergazin, G.; Zhetenbayev, N.; Tursunbayeva, G.; Uzbekbayev, A.; Sarina, A.; Nurgizat, Y.; Nussibaliyeva, A. Design, Simulation and Functional Testing of a Novel Ankle Exoskeleton with 3DOFs. Sensors 2024, 24, 6160. [Google Scholar] [CrossRef]

- Sergazin, G.; Ozhiken, A.; Zhetenbayev, N.; Ozhikenov, K.; Tursunbayeva, G.; Nurgizat, Y.; Uzbekbayev, A.; Ayazbay, A.-A. Development of an Ankle Exoskeleton: Design, Modeling, and Testing. Sensors 2025, 25, 2020. [Google Scholar] [CrossRef]

- Rose, M.J.; Flanagan, W.; Peterson, B.T.; Steffler, P.K.; Tran, B.T.; Su, L.; Humann, R.G.; Clites, T.R. The Impact of Ankle Range of Motion on Lower-Limb Gait Biomechanics. J. Biomech. 2025, 189, 112811. [Google Scholar] [CrossRef] [PubMed]

- Silva, M.R.; Marques, F.; Silva, M.T.; Flores, P. A Methodology to Restrict the Range of Motion of Joints: Application to the Ankle Joint Complex. Mech. Mach. Theory 2024, 198, 105654. [Google Scholar] [CrossRef]

- ISO 13482:2014; Robots and Robotic Devices—Safety Requirements for Personal Care Robots. ISO: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/53820.html (accessed on 15 October 2025).

- ISO 14971:2019; Medical Devices—Application of Risk Management to Medical Devices. ISO: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/72704.html (accessed on 15 October 2025).

- IEC 80601-2-78:2019; Medical Electrical Equipment—Part 2–78: Particular Requirements for Basic Safety and Essential Performance of Medical Robots for Rehabilitation, Assessment, Compensation or Alleviation. IEC: Geneva, Switzerland, 2019. Available online: https://www.iso.org/standard/68474.html (accessed on 15 October 2025).

- IEC 60601-1:2020; Medical Electrical Equipment—Part 1: General Requirements for Basic Safety and Essential Performance. IEC: Geneva, Switzerland, 2020. Available online: https://webstore.iec.ch/en/publication/67497 (accessed on 15 October 2025).

- ISO 10993-1:2018; Biological Evaluation of Medical Devices—Part 1: Evaluation and Testing Within a Risk Management Process. International Organization for Standardization: Geneva, Switzerland, 2018. Available online: https://www.iso.org/standard/68936.html (accessed on 2 November 2025).

- ISO 17664:2017; Processing of Health Care Products—Information to Be Provided by the Medical Device Manufacturer for the Processing of Medical Devices. International Organization for Standardization: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/66364.html (accessed on 2 November 2025).

| Device | Weight (kg) | Actuation Type | DoF | Max. Torque (N·m) | Range of Motion (°) | Control Method | Application | Features | Limitations |

|---|---|---|---|---|---|---|---|---|---|

| Lokomat (Hocoma, Switzerland) [18] | ≈1000 | Electric actuators, cable belt, treadmill | 4 (hip, knee) | 0–45° (hip), 0–60° (knee) | Gait imitation, position control | Clinical rehabilitation and gait restoration for patients with spinal cord injury, stroke, traumatic brain injury, and neurological disorders | High efficiency in clinical use | Bulky, expensive | |

| AnkleBot (MIT, USA) [20] | 3.5–4 | Electric actuators | 2 | ≈12 | ±25° PF/DF, ±15° INV/EV | PID/impedance control | Local ankle joint therapy, motor learning, neuroplasticity enhancement | Based on motor learning principles and repetitive motion exercises for restoring motor control | Stationary, not portable |

| ReWalk (ReWalk Robotics) [21] | 20–25 | Electric actuators | 4 | 40–60 H·м | 0–120° hip, 0–90° knee | Inertial sensors, manual input | Home and ambulatory rehabilitation | Enables upright mobility and walking with crutches, reducing risks of sedentary lifestyle complications | Requires crutches, high cost |

| Single-Legged Rehabilitation Exoskeleton [24] | ≈6–7 | Electric (BLDC) actuators | 2 (hip, knee) | 18.1 H·м, 2.6 H·м | 45° hip, 60° knee | Wireless PID, Bluetooth/IMU | Tele-rehabilitation, outpatient gait recovery | Used for gait evaluation and motion training via IMU and Bluetooth | Requires clinical validation |

| A Lower-Body Exoskeleton Platform [25] | ≈10 | Cable drive (Bowden), AC motors (400 W) | 4 (hip, knee) | Up to anatomical limit | CANopen, distributed control | Experimental gait restoration testing | Simulates gait motion for post-injury rehabilitation | Cable losses, not suitable for home rehabilitation | |

| Medical Exoskeleton “Remotion” [26] | ≈15 | Electric (BLDC) actuators | 4 | Wi-Fi remote control, EMG/FES | Stationary clinical rehabilitation, motor re-learning | Functional electrical stimulation and gait recovery under remote supervision | Heavy, complex gait dynamics |

| № | X and Y Movements | RoM |

|---|---|---|

| 1 | Plantar flexion | 40° |

| 2 | Dorsiflexion | 25° |

| 3 | Inversion (inward rotation) | 20° |

| 4 | Eversion (outward rotation) | 15° |

| Parameter | Value | Description |

|---|---|---|

| RMSE dorsiflexion/plantar flexion | 23.9° | Root mean square tracking error of the joint angle |

| RMSE inversion/eversion | 12.8° | Root mean square error along the frontal axis |

| Amplitude dorsiflexion/plantar flexion | 65.0° | Motion range in the sagittal plane |

| Amplitude inversion/eversion | 35.0° | Motion range in the frontal plane |

| Repeatability dorsiflexion/plantar flexion | 63.3% | Stability of motion across cycles |

| Repeatability inversion/eversion | 63.5% | Consistency of movements between cycles |

| Average communication latency | 100 мc | Typical delay for the Bluetooth HC-05 module |

| Average power consumption | 5.2 Bт | Power during active operation of stepper motors |

| Bluetooth packet loss | 0.6% | Reliability of the wireless communication link |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ozhiken, A.; Sergazin, G.; Ozhikenov, K.; Wang, H.; Zhetenbayev, N.; Tursunbayeva, G.; Nurmangaliyev, A.; Uzbekbayev, A. Research and Experimental Testing of a Remotely Controlled Ankle Rehabilitation Exoskeleton Prototype. Sensors 2025, 25, 6784. https://doi.org/10.3390/s25216784

Ozhiken A, Sergazin G, Ozhikenov K, Wang H, Zhetenbayev N, Tursunbayeva G, Nurmangaliyev A, Uzbekbayev A. Research and Experimental Testing of a Remotely Controlled Ankle Rehabilitation Exoskeleton Prototype. Sensors. 2025; 25(21):6784. https://doi.org/10.3390/s25216784

Chicago/Turabian StyleOzhiken, Assylbek, Gani Sergazin, Kassymbek Ozhikenov, Haohan Wang, Nursultan Zhetenbayev, Gulzhamal Tursunbayeva, Asset Nurmangaliyev, and Arman Uzbekbayev. 2025. "Research and Experimental Testing of a Remotely Controlled Ankle Rehabilitation Exoskeleton Prototype" Sensors 25, no. 21: 6784. https://doi.org/10.3390/s25216784

APA StyleOzhiken, A., Sergazin, G., Ozhikenov, K., Wang, H., Zhetenbayev, N., Tursunbayeva, G., Nurmangaliyev, A., & Uzbekbayev, A. (2025). Research and Experimental Testing of a Remotely Controlled Ankle Rehabilitation Exoskeleton Prototype. Sensors, 25(21), 6784. https://doi.org/10.3390/s25216784