A Novel Unsupervised Structural Damage Detection Method Based on TCN-GAT Autoencoder

Abstract

1. Introduction

2. Theoretical Basis

2.1. Temporal Convolutional Network

2.2. Graph Attention Network

2.3. Autoencoder Architecture

3. Methodology

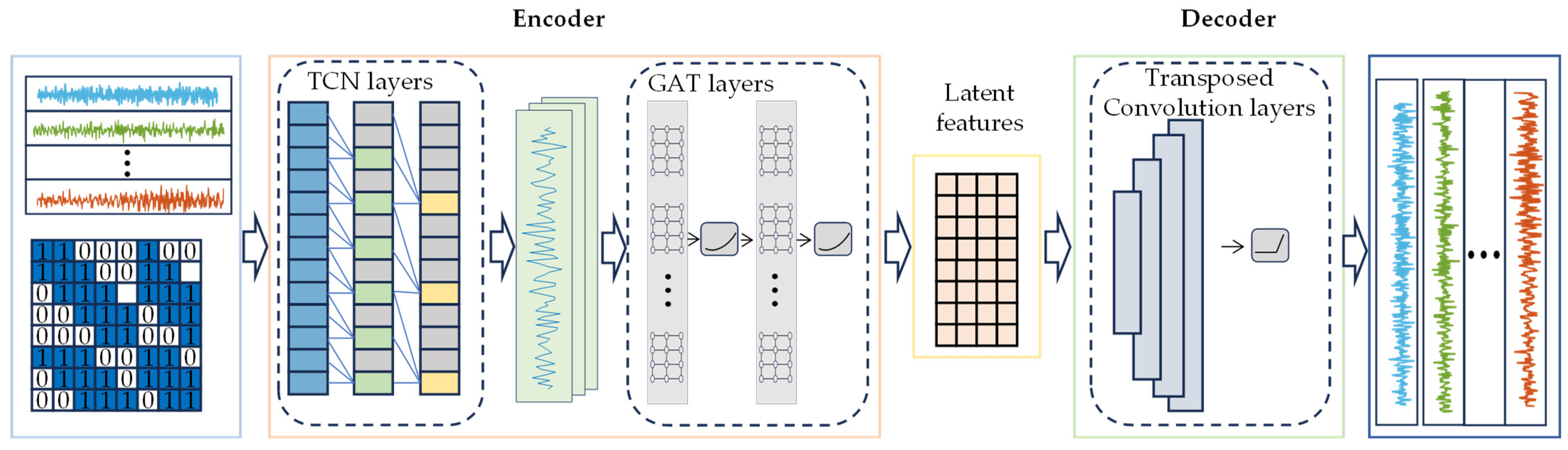

3.1. TCNGAT-AE Architecture

3.1.1. Encoder

3.1.2. Decoder

3.1.3. Loss Function

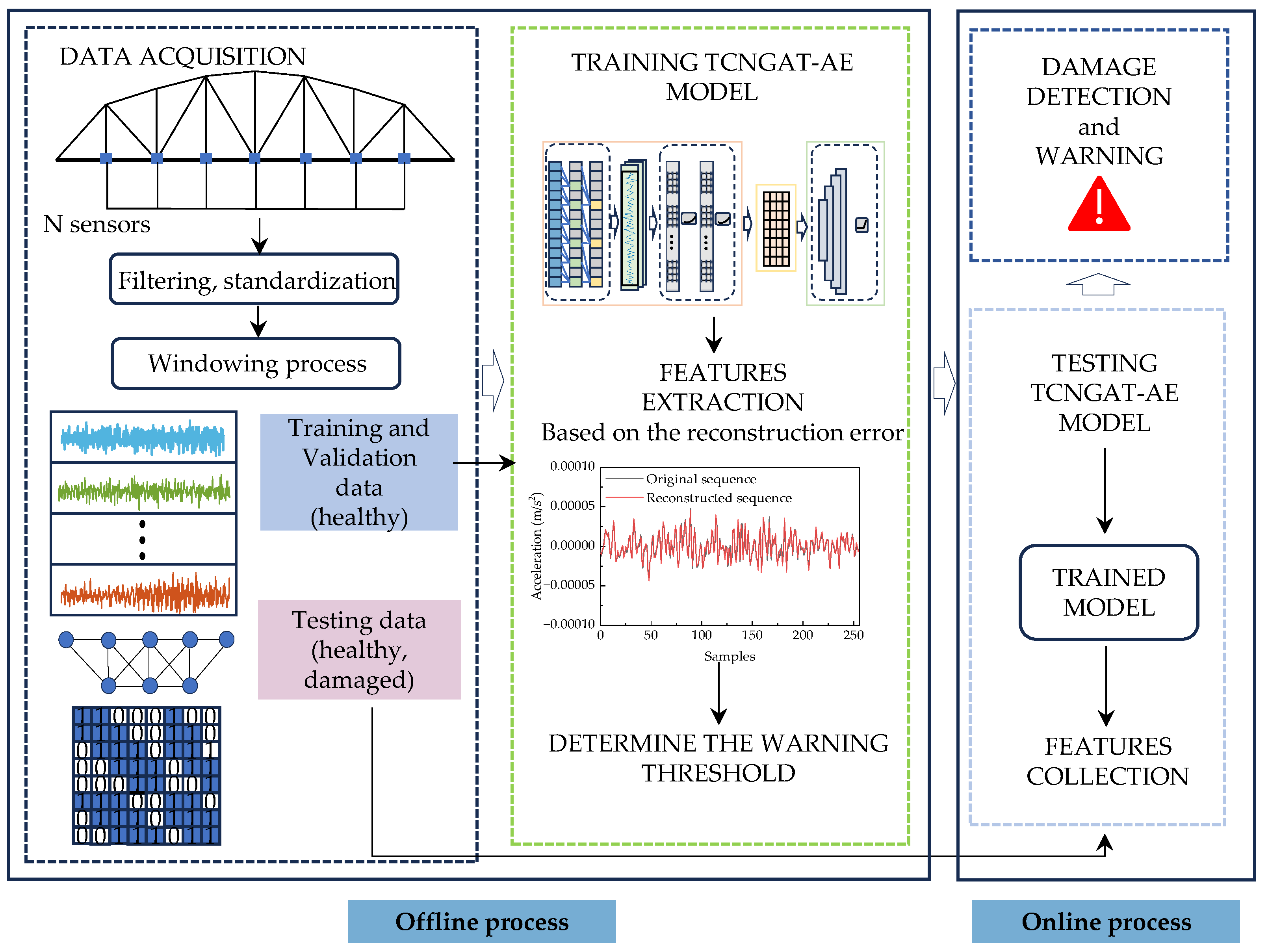

3.2. Damage Detection Process Based on TCNGAT-AE

3.2.1. Offline Process: Data Preparation and Model Training

- 1.

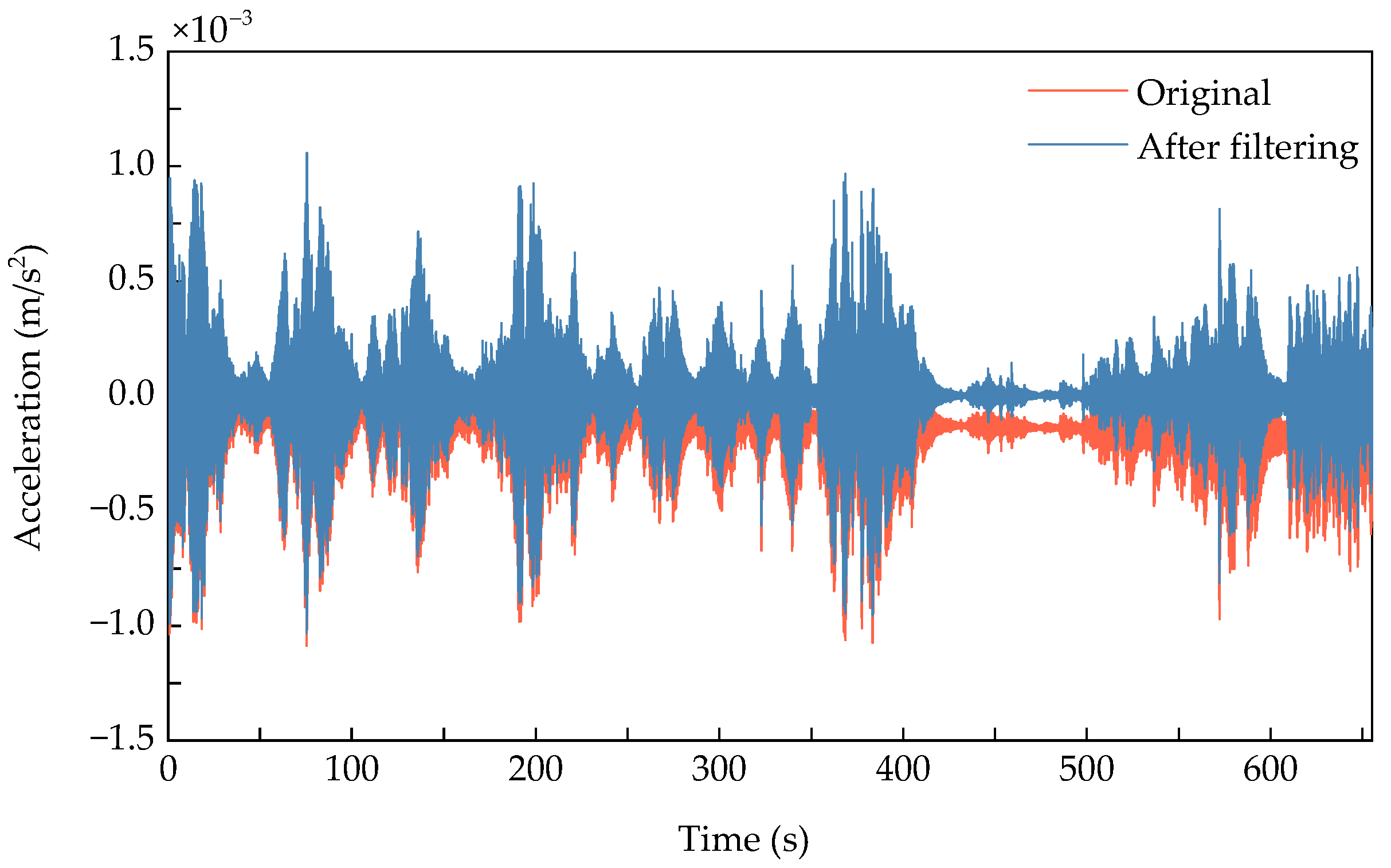

- Data Acquisition and Preprocessing: Vibration response data is collected through the deployed sensor network while the structure remains in its healthy state. Raw signals undergo preprocessing procedures including noise filtering to eliminate environmental interference and high-frequency noise. The processed data is subsequently partitioned into training and validation sets according to a predetermined ratio, designated for model parameter optimization and performance evaluation respectively.

- 2.

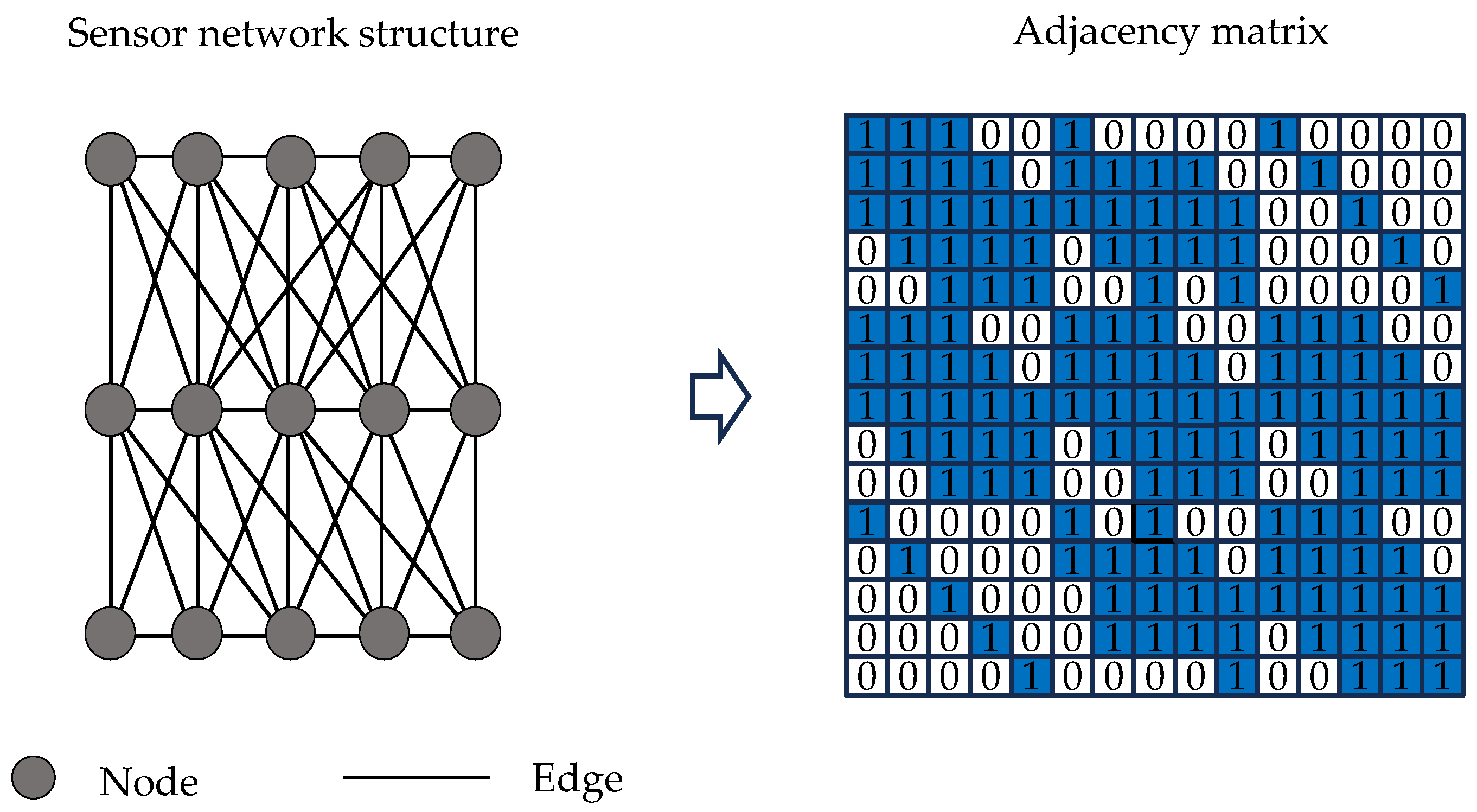

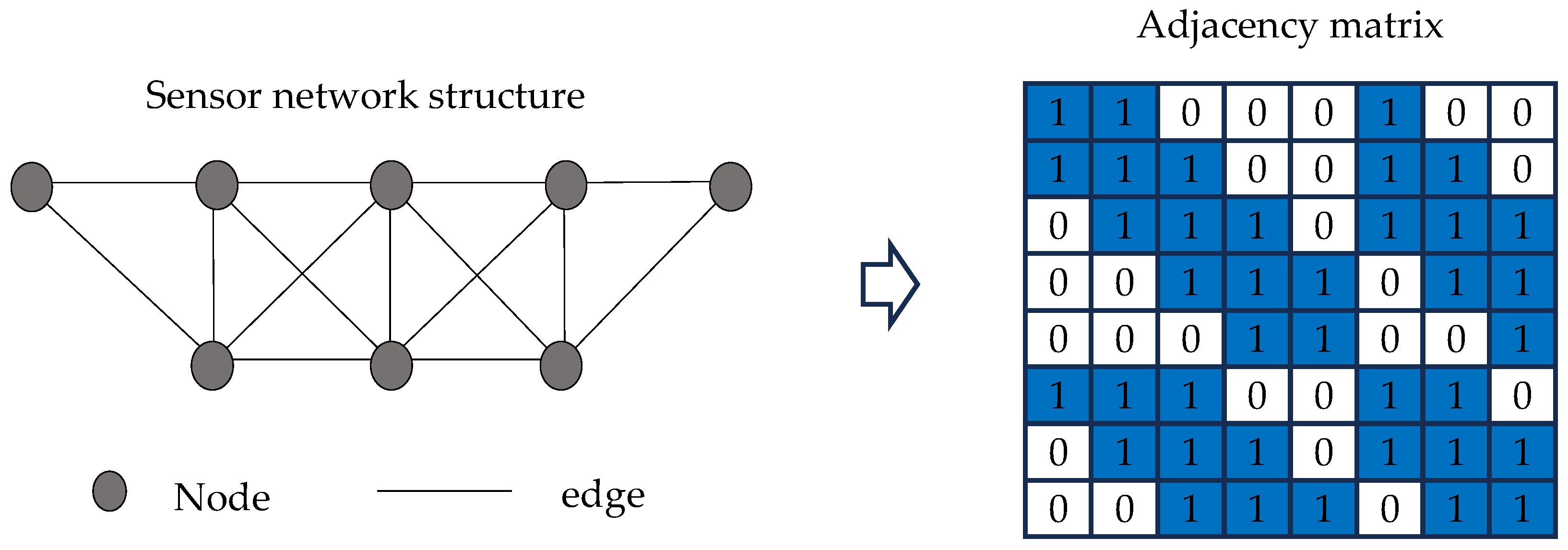

- Input Data Construction: Multi-sensor time-series response data are segmented using a sliding window approach, generating data slices (where represents the number of sensors, the window length, and the segment index). Based on physical sensor coordinates, an adjacency matrix is constructed to represent its spatial topology. The adjacency matrix , representing the spatial topology based on sensor coordinates, is constructed using the Euclidean distance between nodes and . The node relationships are defined as follows:

- 3.

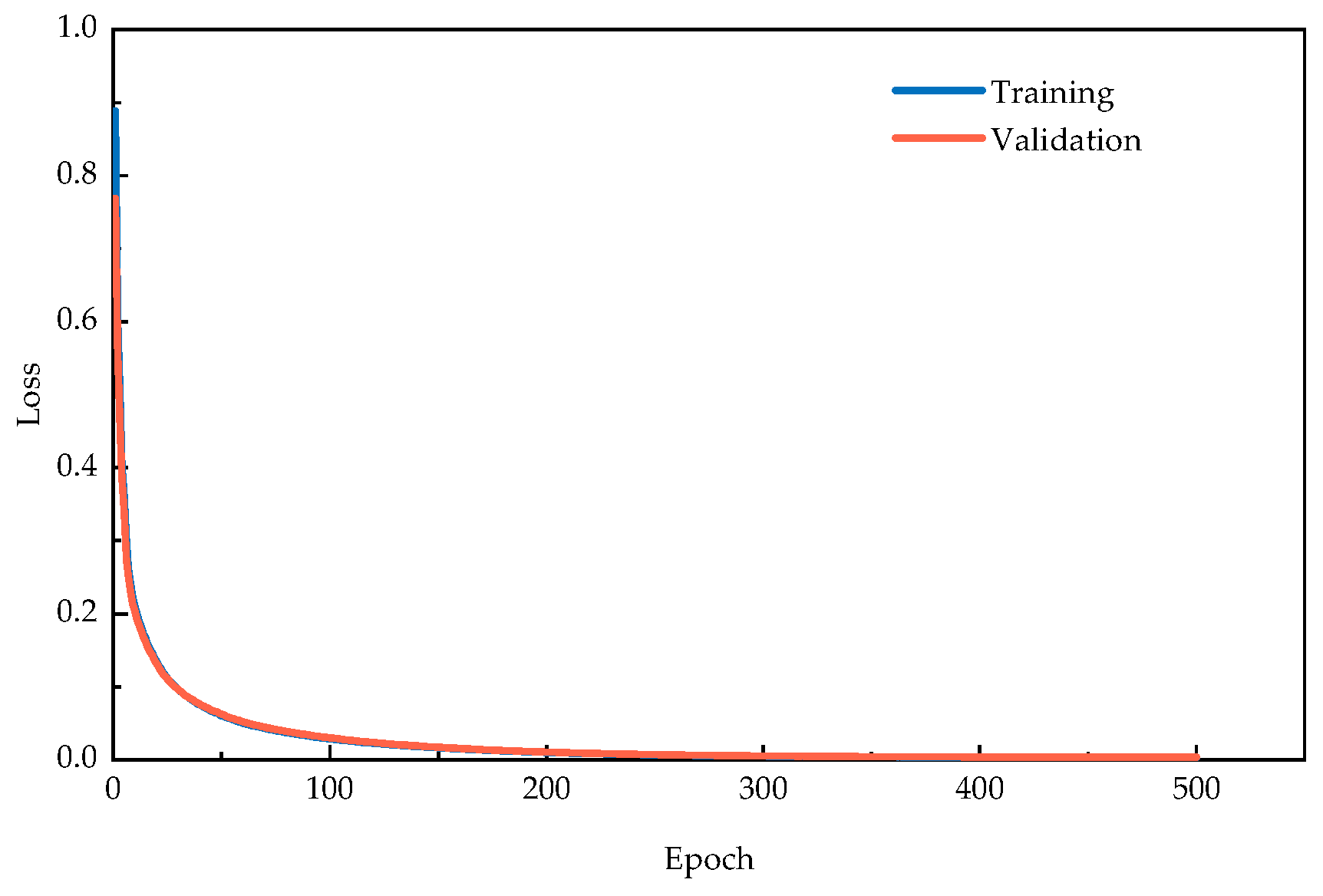

- Model Training and Optimization: The Mean Squared Error (MSE) between input data and reconstructed output serves as the loss function. Parameters of both encoder and decoder are iteratively updated through backpropagation algorithm until the reconstruction error on the validation set demonstrates stable convergence.

- 4.

- Damage Threshold Determination: The reconstruction MSE is employed as the Structural Damage Indicator (SDI). To effectively discriminate between intact and damaged structural states, this paper introduces a threshold determination method based on the “ criterion”—a well-established empirical threshold in engineering applications suitable for Gaussian-distributed data [40]. It should be noted that this criterion inherently assumes approximate normality of the underlying data. As an optional robustness check, distribution-insensitive quantile-based thresholds (e.g., the 95th percentile) can be considered if significant deviation from normality is observed. The threshold is defined as:

3.2.2. Online Process: Near-Real-Time Damage Detection

- Preprocessing real-time sensor response data through filtering and standardization, followed by segmentation using the identical sliding window strategy to obtain .

- Feeding to the model and computing the corresponding SDI values. Structural damage is identified when the calculated SDI exceeds the predetermined threshold.

4. Case Study Validation and Discussion

4.1. Introduction

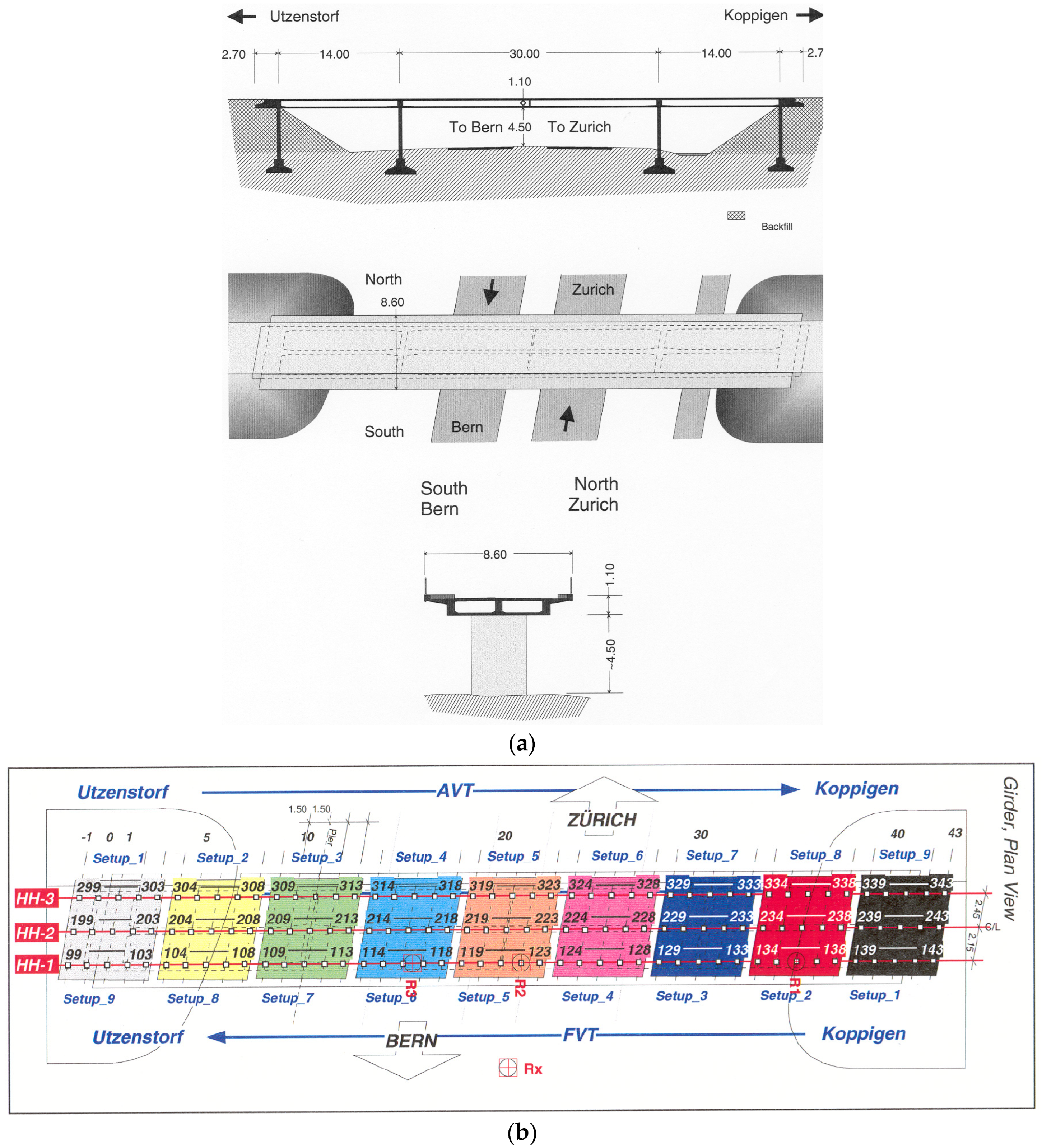

4.2. Z-24 Bridge Verification

4.2.1. Case Description

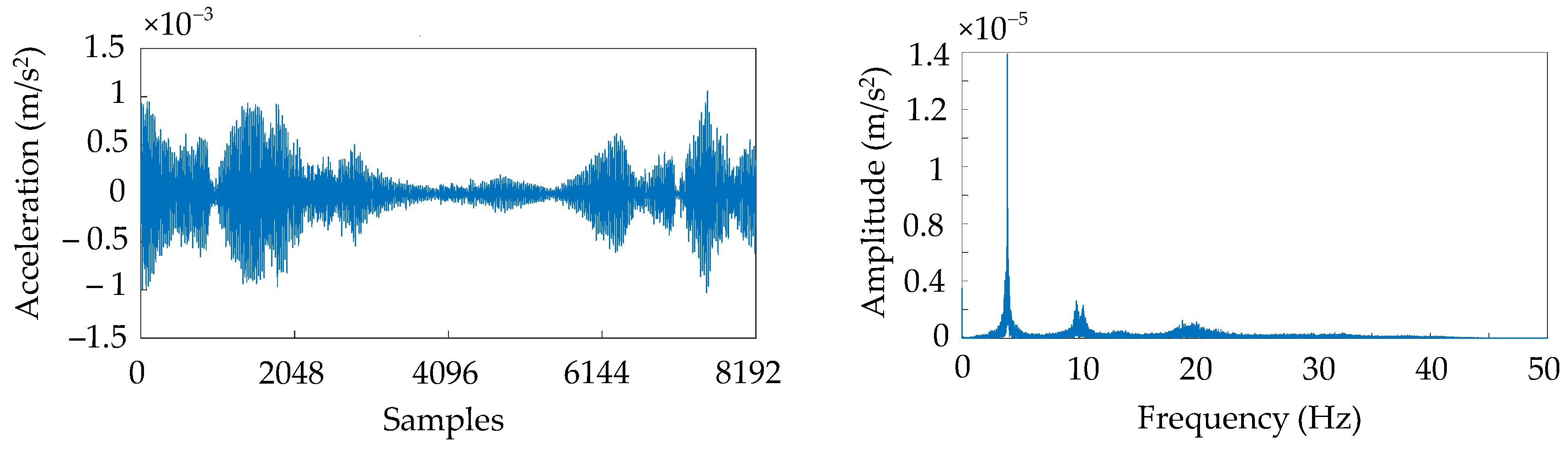

4.2.2. Experimental Configuration

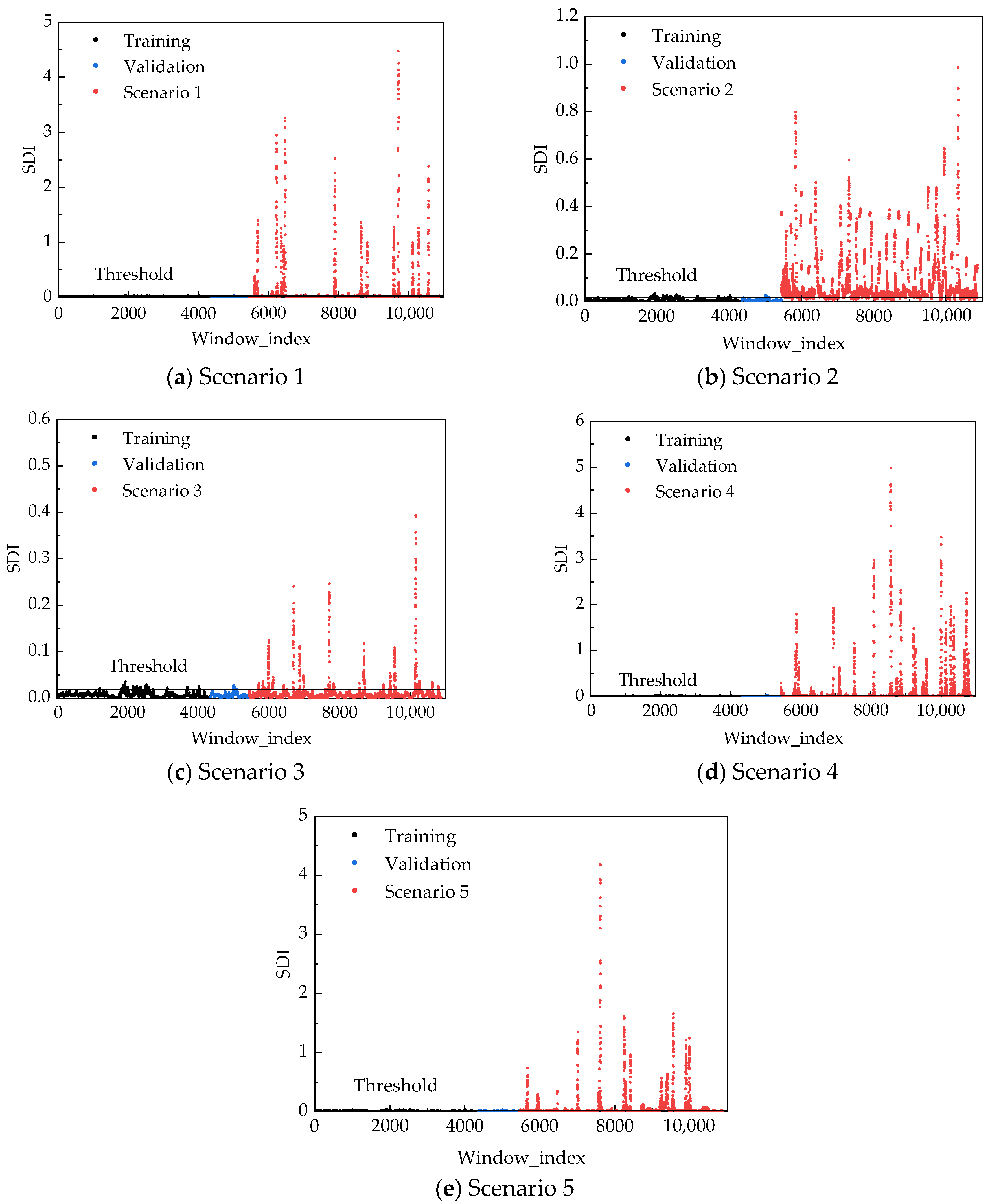

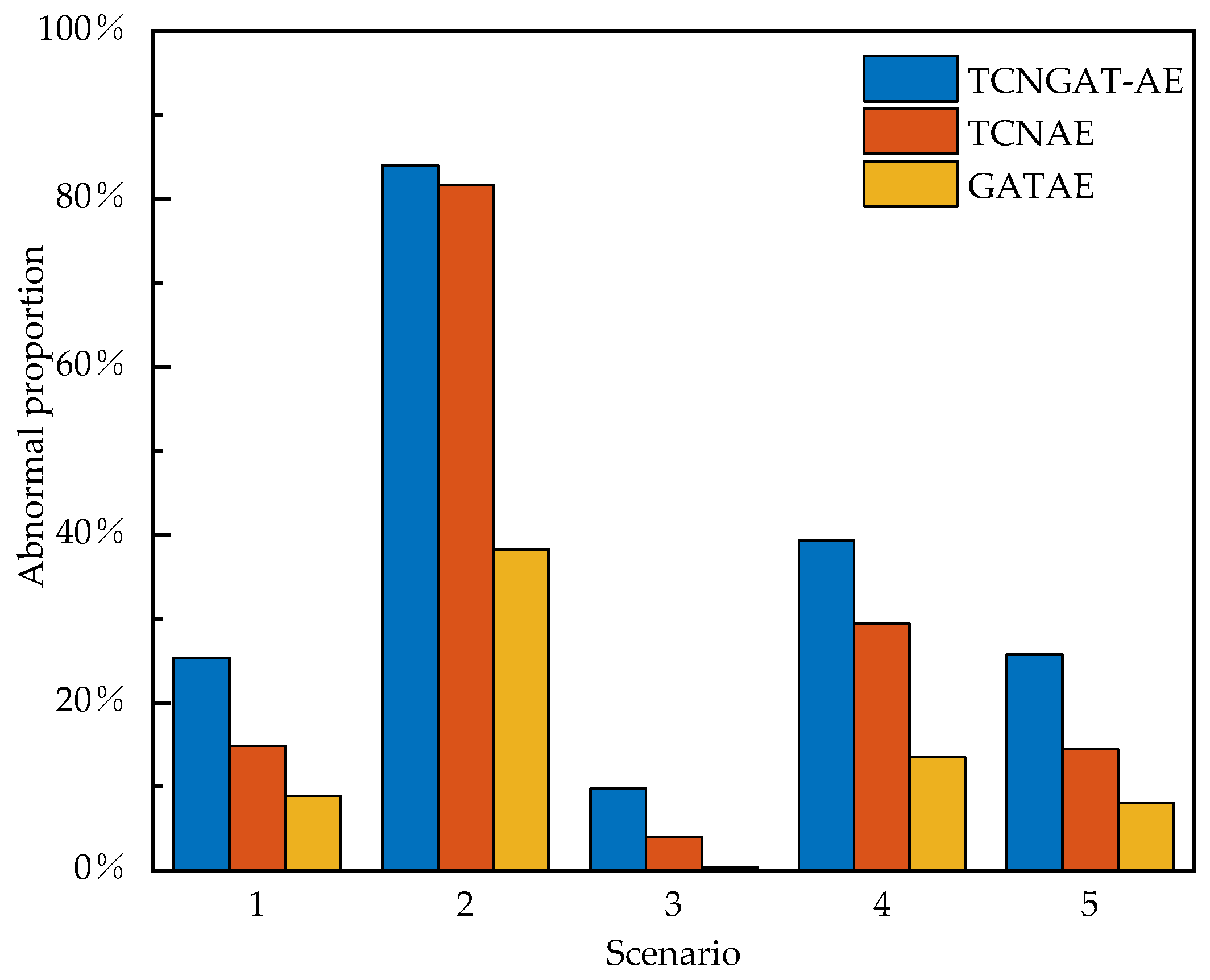

4.2.3. Results and Analysis

4.2.4. Ablation Study

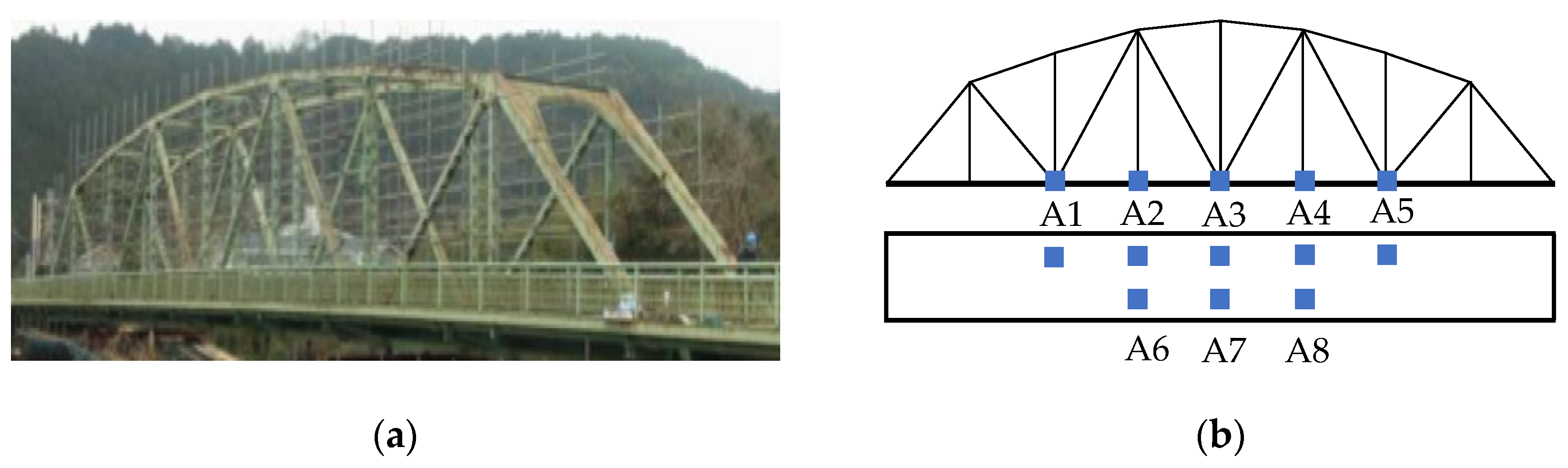

4.3. Old Ada Bridge Verification

4.3.1. Case Description

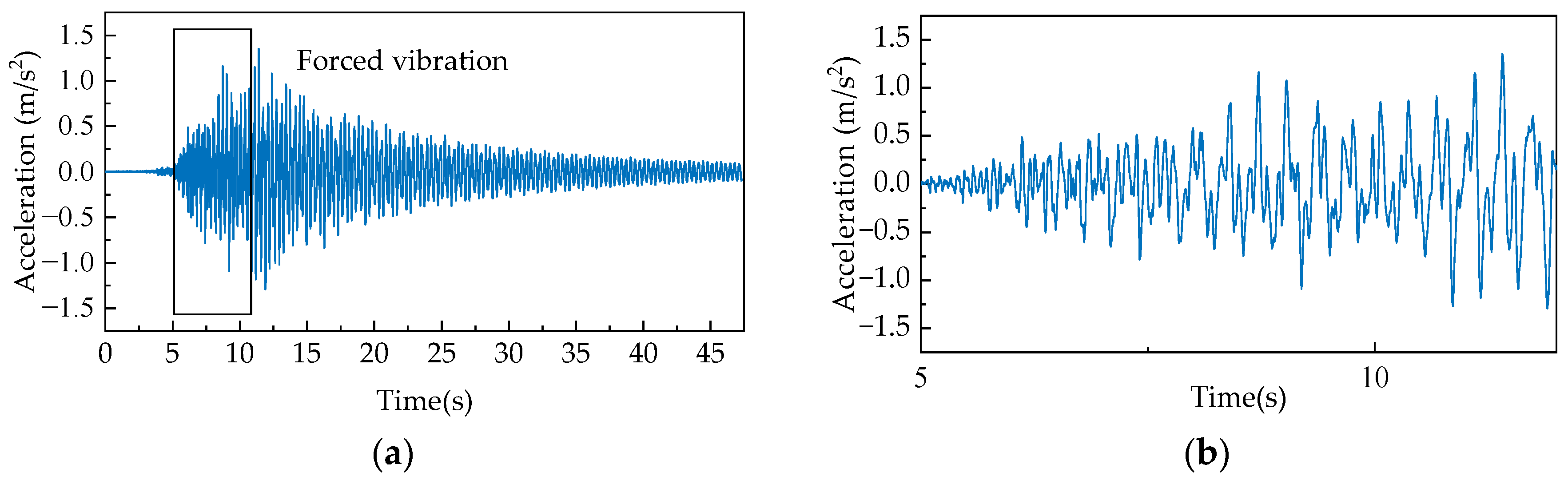

4.3.2. Experimental Configuration

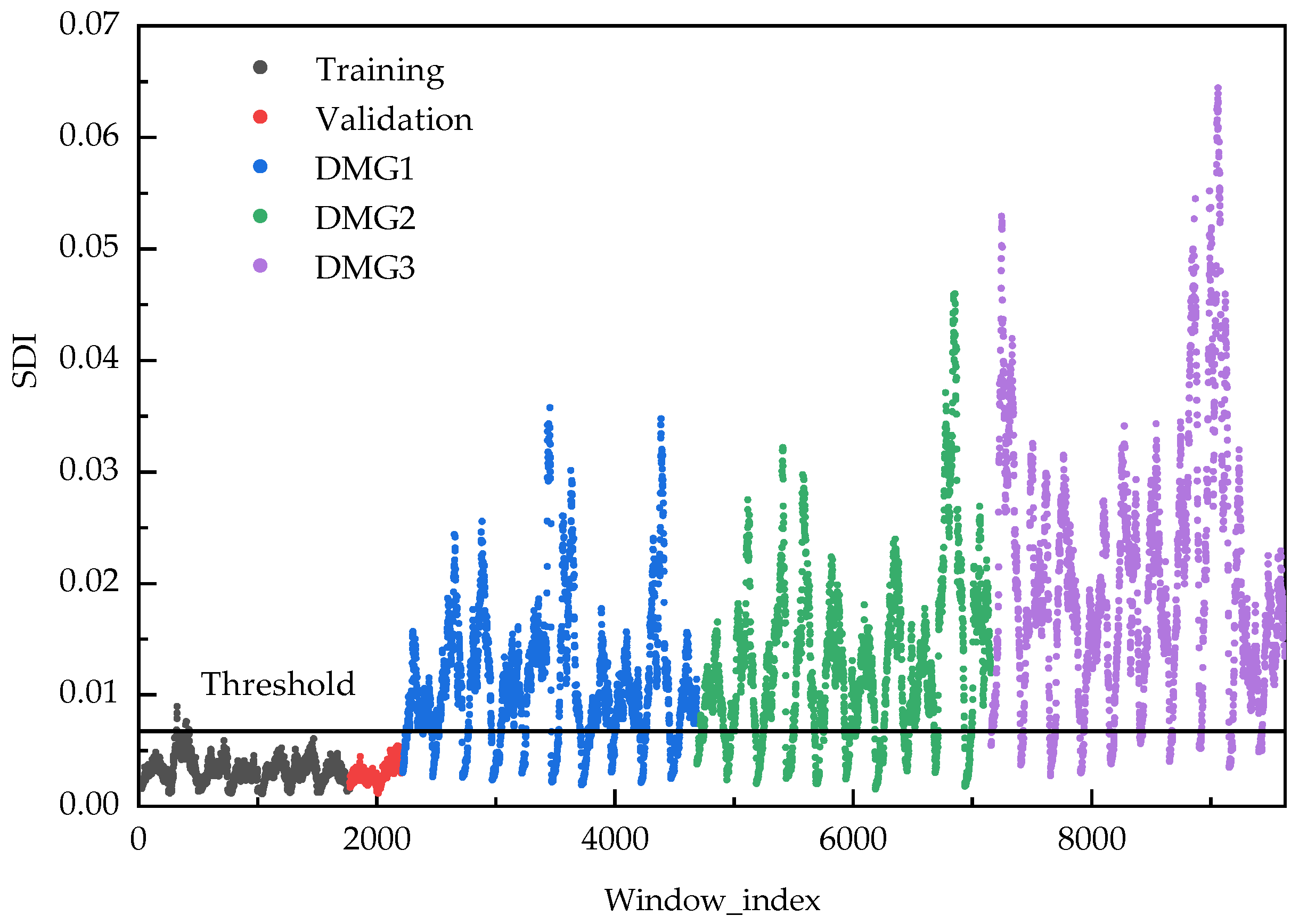

4.3.3. Results and Analysis

4.3.4. Ablation Study

4.4. Comprehensive Analysis and Discussion

5. Conclusions

- Advanced Spatiotemporal Modeling ArchitectureThe hierarchical framework successfully overcomes limitations of conventional methods in capturing spatiotemporal interactions through its unique “temporal-to-spatial” processing paradigm. The TCN module extracts multi-scale temporal patterns while the GAT module captures complex spatial dependencies within the sensor network. Bayesian-optimized hyperparameters enable exceptional signal reconstruction performance, with SDI values of 0.006120 ± 0.004229 and 0.002867 ± 0.000849 for healthy states of Z-24 and Ada bridges respectively. The precise reconstruction at critical waveform characteristics confirms the model’s robust representation capability across varying excitation conditions.

- Substantial Performance Enhancement through Feature FusionAblation studies on the Z-24 Bridge reveal the crucial importance of integrated spatiotemporal modeling. TCNGAT-AE achieves consistent superiority over single-modality benchmarks, particularly in Scenario 3 (minor damage) where it demonstrates a remarkable 9.80% detection rate—representing improvements of 145.61% and 2030.43% over TCN-AE and GAT-AE respectively. These results unequivocally demonstrate that the synergistic combination of temporal and spatial features significantly enhances damage sensitivity and detection reliability.

- Practical Framework with Demonstrated Generalization CapabilityThe implemented “offline-online” operational framework enables near-real-time damage assessment through sliding window processing and statistical thresholding. This end-to-end pipeline processes raw vibration signals directly, eliminating complex preprocessing requirements. Comprehensive testing across both bridges shows significant SDI elevations in all damage scenarios, with statistical significance (p < 0.001) confirming damage-induced variations rather than random fluctuations. The framework’s robust performance across diverse structural types and loading conditions underscores its practical engineering value.

6. Future Research Directions

- Dynamic Graph Structure OptimizationThe present approach, though incorporating dynamic attention weights, relies on predefined adjacency matrices based on physical sensor locations. Future work should develop adaptive graph generation mechanisms that continuously update topological connections according to real-time structural response characteristics, enabling more accurate tracking of damage-induced spatial correlation changes.

- Physics-Informed Learning IntegrationBased on physical principles, the finite element method (FEM) is a classical approach for structural state assessment. It offers clear interpretability and uses low-dimensional parameters, making it suitable for scenarios with well-defined properties—such as during the design stage—where it achieves high-fidelity response reconstruction. However, its application to in-service structures faces limitations: performance degrades due to model-reality discrepancies (e.g., hidden cracks or material degradation); strong nonlinear responses often require simplifying assumptions, losing damage-related information; and high-fidelity simulations are computationally expensive, limiting real-time use. Data-driven machine learning methods address these shortcomings. They learn directly from monitoring data (e.g., vibration, strain) without relying on explicit physical models, adapt well to uncertainties, and capture complex nonlinear patterns for accurate damage identification. Once trained offline, they enable millisecond-level inference, meeting real-time engineering needs. Notably, both approaches are complementary. Integrating them—e.g., via Physics-Informed Neural Networks (PINNs)—embeds physical constraints such as equilibrium equations into the learning process, often through physics-based penalty terms in the loss function. This preserves data-driven flexibility while ensuring physical consistency, improving both reliability and applicability in practical structural state assessment [49].

- Application to Building StructuresThe TCNGAT-AE framework demonstrates strong potential for application in building structural health monitoring (SHM). In future work, the framework will be extended to monitor building systems equipped with sensor networks, leveraging the monitoring data characteristics of building structures described in the existing literature [50,51,52,53]. This extension will include evaluating the framework’s performance across diverse structural configurations and validating its generalization capability in spatiotemporal response analysis of multi-sensor systems. By capitalizing on its inherent ability to model spatiotemporal dependencies, the adapted framework will effectively capture the unique dynamic behaviors of building environments, thereby reinforcing its cross-domain applicability and increasing its practical value in real-world structural monitoring.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Deng, Y.; Zhao, Y.; Ju, H.; Yi, T.H.; Li, A. Abnormal Data Detection for Structural Health Monitoring: State-of-the-Art Review. Dev. Built Environ. 2024, 17, 100337. [Google Scholar] [CrossRef]

- Mishra, M.; Loureno, P.B.; Ramana, G.V. Structural Health Monitoring of Civil Engineering Structures by Using the Internet of Things: A Review. J. Build. Eng. 2022, 48, 103954. [Google Scholar] [CrossRef]

- Eltouny, K.; Gomaa, M.; Liang, X. Unsupervised Learning Methods for Data-Driven Vibration-Based Structural Health Monitoring: A Review. Sensors 2023, 23, 3290. [Google Scholar] [CrossRef]

- Lydakis, E.; Koss, H.; Brincker, R.; Amador, S.D. Data-Driven Sensor Fault Diagnosis for Vibration-Based Structural Health Monitoring Under Ambient Excitation. Measurement 2024, 237, 115232. [Google Scholar] [CrossRef]

- Moravvej, M.; El-Badry, M. Reference-Free Vibration-Based Damage Identification Techniques for Bridge Structural Health Monitoring—A Critical Review and Perspective. Sensors 2024, 24, 876. [Google Scholar] [CrossRef]

- Fan, Y.; Zhang, X.; Cheng, E.; Qin, C.; Qin, N.; Wu, J.; Guo, T. 1D In-Situ Convolution System Based on Vibration Signal for Real-Time Structural Health Monitoring. Nano Energy 2024, 127, 109694. [Google Scholar] [CrossRef]

- Lin, Y.Z.; Nie, Z.H.; Ma, H.W. Structural Damage Detection with Automatic Feature-Extraction Through Deep Learning. Comput. Aided Civ. Infrastruct. Eng. 2017, 32, 1025–1046. [Google Scholar] [CrossRef]

- Abdeljaber, O.; Avci, O.; Kiranyaz, M.S.; Boashash, B.; Sodano, H.; Inman, D.J. 1-D CNNs for Structural Damage Detection: Verification on a Structural Health Monitoring Benchmark Data. Neurocomputing 2018, 275, 1308–1317. [Google Scholar] [CrossRef]

- Dang, H.V.; Raza, M.; Tran-Ngoc, H.; Bui-Tien, T.; Nguyen, H.X. Connection Stiffness Reduction Analysis in Steel Bridge via Deep CNN and Modal Experimental Data. Struct. Eng. Mech. 2021, 77, 495–508. [Google Scholar]

- Zhang, Y.; Miyamori, Y.; Mikami, S.; Saito, T. Vibration-Based Structural State Identification by a 1-Dimensional Convolutional Neural Network. Comput. Aided Civ. Infrastruct. Eng. 2019, 34, 822–839. [Google Scholar] [CrossRef]

- Shang, Z.Q.; Sun, L.M.; Xia, Y.; Zhang, W. Vibration-Based Damage Detection for Bridges by Deep Convolutional Denoising Auto-Encoder. Struct. Health Monit. 2021, 20, 1880–1903. [Google Scholar] [CrossRef]

- Hou, G.; Li, L.; Xu, Z.; Chen, Q.; Liu, Y.; Qiu, B. A BIM-Based Visual Warning Management System for Structural Health Monitoring Integrated with LSTM Network. KSCE J. Civ. Eng. 2021, 25, 2779–2793. [Google Scholar] [CrossRef]

- Wei, Y.; Li, Q.; Hu, Y.; Wang, Y.; Zhu, X.; Tan, Y.; Liu, C.; Pei, L. Deformation Prediction Model Based on an Improved CNN + LSTM Model for the First Impoundment of Super-High Arch Dams. J. Civ. Struct. Health Monit. 2023, 13, 431–442. [Google Scholar]

- Chen, X.; Jia, J.; Yang, J.; Bai, Y.; Du, X. A Vibration-Based 1DCNN-BiLSTM Model for Structural State Recognition of RC Beams. Mech. Syst. Signal Process. 2023, 203, 110715. [Google Scholar] [CrossRef]

- Sony, S.; Gamage, S.; Sadhu, A.; Samarabandu, J. Vibration-Based Multiclass Damage Detection and Localization Using Long Short-Term Memory Networks. Structures 2022, 35, 436–451. [Google Scholar] [CrossRef]

- Yessoufou, F.; Yang, Y.; Zhu, J. Composite encoder–decoder network for rapid bridge damage assessment using long-term monitoring acceleration data. Struct. Health Monit. 2024, 23, 3387–3415. [Google Scholar] [CrossRef]

- Ghazimoghadam, S.; Hosseinzadeh, S.A.A. A Novel Unsupervised Deep Learning Approach for Vibration-Based Damage Diagnosis Using a Multi-Head Self-Attention LSTM Autoencoder. Measurement 2024, 229, 114410. [Google Scholar] [CrossRef]

- Hasani, H.; Freddi, F.; Piazza, R. AI-driven automated and integrated structural health monitoring under environmental and operational variations. Autom. Constr. 2025, 176, 106222. [Google Scholar] [CrossRef]

- Li, Y.J.; Yang, Z.Y.; Zhang, S.; Mao, R.Z.; Ye, L.C.; Liu, Y. TCN-MBMAResNet: A novel fault diagnosis method for small marine rolling bearings based on time convolutional neural network in tandem with multi-branch residual network. Meas. Sci. Technol. 2025, 36, 026212. [Google Scholar] [CrossRef]

- Gu, R.; Zhang, S.; Zhu, J.; Zhu, H.; Li, Y. Damage-Related Imbalance Identification for UAV Composite Propeller Blades Based on Bidirectional Temporal Convolutional Network and a Flexible Sensing System. Meas. Sci. Technol. 2024, 35, 115001. [Google Scholar] [CrossRef]

- Wettewa, S.; Hou, L.; Zhang, G. Graph Neural Networks for Building and Civil Infrastructure Operation and Maintenance Enhancement. Adv. Eng. Inf. 2024, 62, 102868. [Google Scholar] [CrossRef]

- Chencho; Li, J.; Hao, H. Structural Damage Quantification Using Long Short-Term Memory (LSTM) Auto-Encoder and Impulse Response Functions. J. Infrastruct. Intell. Resil. 2024, 3, 100086. [Google Scholar]

- Dang, V.H.; Vu, T.C.; Nguyen, B.D.; Nguyen, Q.H.; Nguyen, T.D. Structural Damage Detection Framework Based on Graph Convolutional Network Directly Using Vibration Data. Structures 2022, 38, 40–51. [Google Scholar] [CrossRef]

- Dang, V.H.; Pham, H.A. Vibration-Based Building Health Monitoring Using Spatio-Temporal Learning Model. Eng. Appl. Artif. Intell. 2023, 126, 106858. [Google Scholar] [CrossRef]

- Dang, V.H.; Le-Nguyen, K.; Nguyen, T.T. Semi-Supervised Vibration-Based Structural Health Monitoring via Deep Graph Learning and Contrastive Learning. Structures 2023, 51, 158–170. [Google Scholar] [CrossRef]

- Kim, M.; Song, J. Seismic Damage Identification by Graph Convolutional Autoencoder Using Adjacency Matrix Based on Structural Modes. Earthq. Eng. Struct. Dyn. 2024, 53, 815–837. [Google Scholar] [CrossRef]

- Kim, M.; Song, J.; Kim, C.W. Near-Real-Time Damage Identification Under Vehicle Loads Using Dynamic Graph Neural Network Based on Proper Orthogonal Decomposition. Mech. Syst. Signal Process. 2025, 224, 112175. [Google Scholar] [CrossRef]

- Miele, E.S.; Bonacina, F.; Corsini, A. Deep Anomaly Detection in Horizontal Axis Wind Turbines Using Graph Convolutional Autoencoders for Multivariate Time Series. Energy AI 2022, 8, 100145. [Google Scholar] [CrossRef]

- Kuo, P.C.; Chou, Y.T.; Li, K.Y.; Chang, W.T.; Huang, Y.N.; Chen, C.S. GNN-LSTM-Based Fusion Model for Structural Dynamic Responses Prediction. Eng. Struct. 2024, 306, 117733. [Google Scholar] [CrossRef]

- Zhao, Z.M.; Chen, N.Z. An Exponential Smoothing Multi-Head Graph Attention Network (ESMGAT) Method for Damage Zone Localization on Wind Turbine Blades. Compos. Struct. 2024, 342, 116450. [Google Scholar] [CrossRef]

- Meng, Z.; Zhu, J.; Cao, S.; Li, P.; Xu, C. Bearing Fault Diagnosis Under Multisensor Fusion Based on Modal Analysis and Graph Attention Network. IEEE Trans. Instrum. Meas. 2023, 72, 3526510. [Google Scholar] [CrossRef]

- Wang, C.G.; Tian, X.Y.; Zhou, F.N.; Wang, R.; Wang, L.; Tang, X. Current signal analysis using SW-GAT networks for fault diagnosis of electromechanical drive systems under extreme data imbalance. Meas. Sci. Technol. 2025, 36, 016140. [Google Scholar] [CrossRef]

- Bai, S.; Kolter, J.Z.; Koltun, V. An Empirical Evaluation of Generic Convolutional and Recurrent Networks for Sequence Modeling. arXiv 2018, arXiv:1803.01271. [Google Scholar] [CrossRef]

- Veličković, P.; Cucurull, G.; Casanova, A.; Romero, A.; Lio, P.; Bengio, Y. Graph Attention Networks. arXiv 2017, arXiv:1710.10903. [Google Scholar]

- Deng, A.; Hooi, B. Graph Neural Network-Based Anomaly Detection in Multivariate Time Series. In Proceedings of the AAAI Conference on Artificial Intelligence, Virtual Event USA, 19–21 May 2021; Volume 35, pp. 4027–4035. [Google Scholar]

- Michelucci, U. An Introduction to Autoencoders. arXiv 2022, arXiv:2201.03898. [Google Scholar] [CrossRef]

- Qian, J.; Song, Z.; Yao, Y.; Zhu, Z.; Zhang, X. A Review on Autoencoder Based Representation Learning for Fault Detection and Diagnosis in Industrial Processes. Chemom. Intell. Lab. Syst. 2022, 231, 104711. [Google Scholar] [CrossRef]

- Yang, Z.; Xu, B.; Luo, W.; Chen, F. Autoencoder-Based Representation Learning and Its Application in Intelligent Fault Diagnosis: A Review. Measurement 2022, 189, 110460. [Google Scholar] [CrossRef]

- Yang, B.; Xu, W.; Bi, F.; Zhang, Y.; Kang, L.; Yi, L. Multi-scale neighborhood query graph convolutional network for multi-defect location in cfrp laminates. Comput. Ind. 2023, 153, 104015. [Google Scholar] [CrossRef]

- Mcconaghy, T.; Breen, K.; Dyck, J.; Gupta, A. 3-Sigma Verification and Design; Springer: New York, NY, USA, 2013; pp. 65–114. [Google Scholar]

- Krämmer, C.; de Smet, C.; De Roeck, G. Z24 bridge damage detection tests. In Proceedings of the IMAC 17, the International Modal Analysis Conference, Kissimmee, FL, USA, 8–11 February 1999; Society of Photo-optical Instrumentation Engineers: Bellingham, WA, USA, 1999; pp. 1023–1029. [Google Scholar]

- De Roeck, G. The State-of-the-Art of Damage Detection by Vibration Monitoring: The SIMCES Experience. J. Struct. Control 2003, 10, 127–134. [Google Scholar] [CrossRef]

- Reynders, E.; De Roeck, G. Vibration-Based Damage Identification: The Z24 Benchmark. LIRIAS Repository. Available online: https://lirias.kuleuven.be/1725994?limo (accessed on 30 October 2025).

- Abdeljaber, O.; Avci, O.; Kiranyaz, S.; Gabbouj, M.; Inman, D.J. Real-Time Vibration-Based Structural Damage Detection Using One-Dimensional Convolutional Neural Networks. J. Sound Vib. 2017, 388, 154–170. [Google Scholar] [CrossRef]

- James, G.; Witten, D.; Hastie, T.; Tibshirani, R. An introduction to Statistical Learning: With Applications in R; Springer: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Kim, C.W.; Chang, K.C.; Kitauchi, S.; McGetrick, P.J.; Hashimoto, K.; Sugiura, K. Changes in Modal Parameters of a Steel Truss Bridge Due to Artificial Damage. In Proceedings of the 11th International Conference on Structural Safety and Reliability, New York, NY, USA, 16–20 June 2014; pp. 3725–3732. [Google Scholar]

- Kim, C.W.; Zhang, F.L.; Chang, K.C.; McGetrick, P.J.; Goi, Y. Ambient and Vehicle-Induced Vibration Data of a Steel Truss Bridge Subject to Artificial Damage. J. Bridge Eng. 2021, 26, 04721002. [Google Scholar] [CrossRef]

- Kim, C.W.; Zhang, F.L.; Chang, K.C.; McGetrick, P.J.; Goi, Y. Old_ADA_Bridge-Damage_Vibration_Data. Mendeley Data 2020, V2. [Google Scholar] [CrossRef]

- Lei, Y.; Li, J.; Hao, H. Physics-guided deep learning based on modal sensitivity for structural damage identification with unseen damage patterns. Eng. Struct. 2024, 316, 118510. [Google Scholar] [CrossRef]

- Shan, J.Z.; Zhuang, C.H.; Loong, C.N. Parametric identification of Timoshenko-beam model for shear-wall structures using monitoring data. Mech. Syst. Signal Process. 2023, 189, 110100. [Google Scholar] [CrossRef]

- Alcantara, E.A.M.; Saito, T. Machine Learning-Based Rapid Post-Earthquake Damage Detection of RC Resisting-Moment Frame Buildings. Sensors 2023, 23, 4694. [Google Scholar] [CrossRef]

- Li, C.Q.; Li, S.; Zhang, L.Y.; Zar, A.; Zhai, C.H. Reconstructing the full-profile seismic time-history response of buildings based on deep learning and sparse sensor monitoring data. Eng. Struct. 2025, 345, 121454. [Google Scholar] [CrossRef]

- Hu, J.; Zou, C.; Liu, Q.; Li, X.; Tao, Z. Floor vibration predictions based on train-track-building coupling model. Build. Eng. 2024, 89, 109340. [Google Scholar] [CrossRef]

| Case | Scenario Name | Reversible Damage |

|---|---|---|

| Healthy | 0 | Baseline structure |

| Damage | 1 | Support Settlement: 20 mm |

| 2 | Support Settlement: 40 mm | |

| 3 | Support Settlement: 80 mm | |

| 4 | Support Settlement: 95 mm | |

| 5 | Inclination of foundation |

| Parameter Name | Value |

|---|---|

| TCN_layers | 3 |

| TCN_kernel | 32 |

| TCN_channel | 32 |

| GAT_layers | 2 |

| Attention_heads | 4 |

| GAT_hidden_dim1 | 32 |

| GAT_hidden_dim2 | 16 |

| GAT_dropout | 0.4 |

| Batch_sizes | 128 |

| Init_lr | 4.27 × 10−3 |

| Name of Part | Layer | Activation | Input Size | Output Size |

|---|---|---|---|---|

| Input | Input Layer | - | [128, 15, 256] | [1920, 1, 256] |

| Encoder Module | TCNBlock1 | ReLU | [1920, 1, 256] | [1920, 32, 256] |

| TCNBlock2 | ReLU | [1920, 32, 256] | [1920, 32, 256] | |

| TCNBlock3 | ReLU | [1920, 32, 256] | [1920, 32, 256] | |

| Flatten | - | [1920, 32, 256] | [1920, 8192] | |

| Dense | - | [1920, 8192] | [1920, 128] | |

| Reshape | - | [1920, 128] | [128, 15, 128] | |

| GAT Layer1 | LeakyReLU + ELU | [128, 15, 128] | [128, 15, 128] | |

| GAT Layer2 | LeakyReLU + ELU | [128, 15, 128] | [128, 15, 64] | |

| Bottleneck Module | Flatten | - | [128, 15, 64] | [128, 960] |

| Dense | ReLU | [128, 960] | [128, 64] | |

| Reshape | - | [128, 64] | [128, 960] | |

| Decoder Module | Conv1D Transpose | ReLU | [128, 15, 64] | [128, 15, 128] |

| Conv1D Transpose | - | [128, 15, 128] | [128, 15, 256] |

| Scenario Name | Mean | Standard Deviation | Abnormal Proportion |

|---|---|---|---|

| 0 | 0.006120 | 0.004229 | - |

| 1 | 0.095805 | 0.367091 | 25.37% |

| 2 | 0.085315 | 0.113103 | 84.03% |

| 3 | 0.010968 | 0.025168 | 9.80% |

| 4 | 0.136457 | 0.426527 | 39.36% |

| 5 | 0.062490 | 0.237510 | 25.79% |

| Case | Description | Vehicle Speed (km/h) | Number of Tests |

|---|---|---|---|

| INT | Intact bridge | 30 | 11 |

| 40 | 10 | ||

| 50 | 5 | ||

| DMG1 | Half-cut in vertical member at midspan | 40 | 12 |

| DMG2 | Full-cut in vertical member at midspan | 40 | 10 |

| DMG3 | Full-cut in vertical member at 5/8th span | 40 | 10 |

| Parameter Name | Value |

|---|---|

| TCN_layers | 3 |

| TCN_kernel | 32 |

| TCN_channels | 64 |

| GAT_layers | 2 |

| Attention_heads | 4 |

| GAT_hidden_dim1 | 64 |

| GAT_hidden_dim2 | 8 |

| GAT_dropout | 0.3 |

| Batch_sizes | 32 |

| Init_lr | 5.68 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Y.; Jin, Q.; Hu, R. A Novel Unsupervised Structural Damage Detection Method Based on TCN-GAT Autoencoder. Sensors 2025, 25, 6724. https://doi.org/10.3390/s25216724

Ni Y, Jin Q, Hu R. A Novel Unsupervised Structural Damage Detection Method Based on TCN-GAT Autoencoder. Sensors. 2025; 25(21):6724. https://doi.org/10.3390/s25216724

Chicago/Turabian StyleNi, Yanchun, Qiyuan Jin, and Rui Hu. 2025. "A Novel Unsupervised Structural Damage Detection Method Based on TCN-GAT Autoencoder" Sensors 25, no. 21: 6724. https://doi.org/10.3390/s25216724

APA StyleNi, Y., Jin, Q., & Hu, R. (2025). A Novel Unsupervised Structural Damage Detection Method Based on TCN-GAT Autoencoder. Sensors, 25(21), 6724. https://doi.org/10.3390/s25216724