Research on Experimental Validation and Prevention Strategies for Pin Shaft Failure in Concrete Pump Trucks

Abstract

1. Introduction

2. Materials and Methods

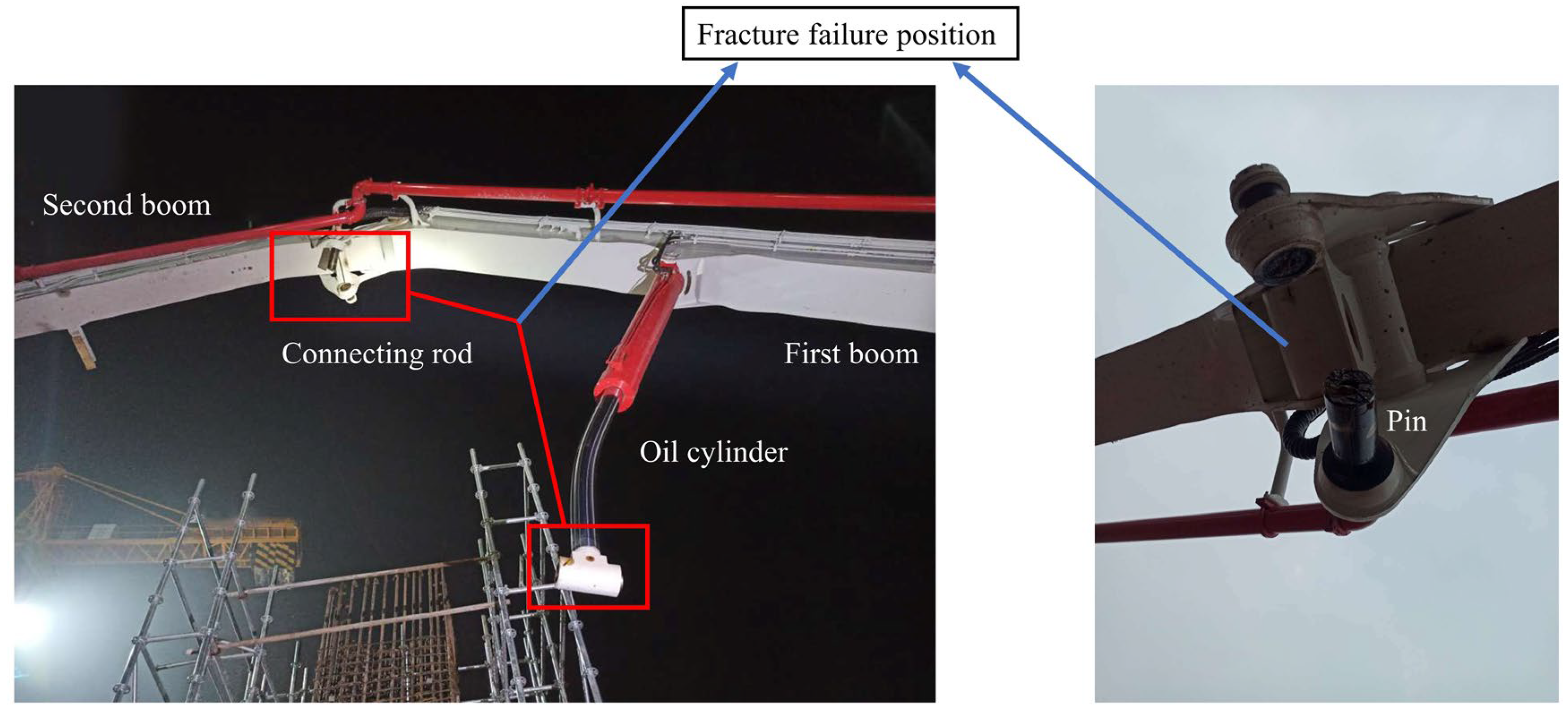

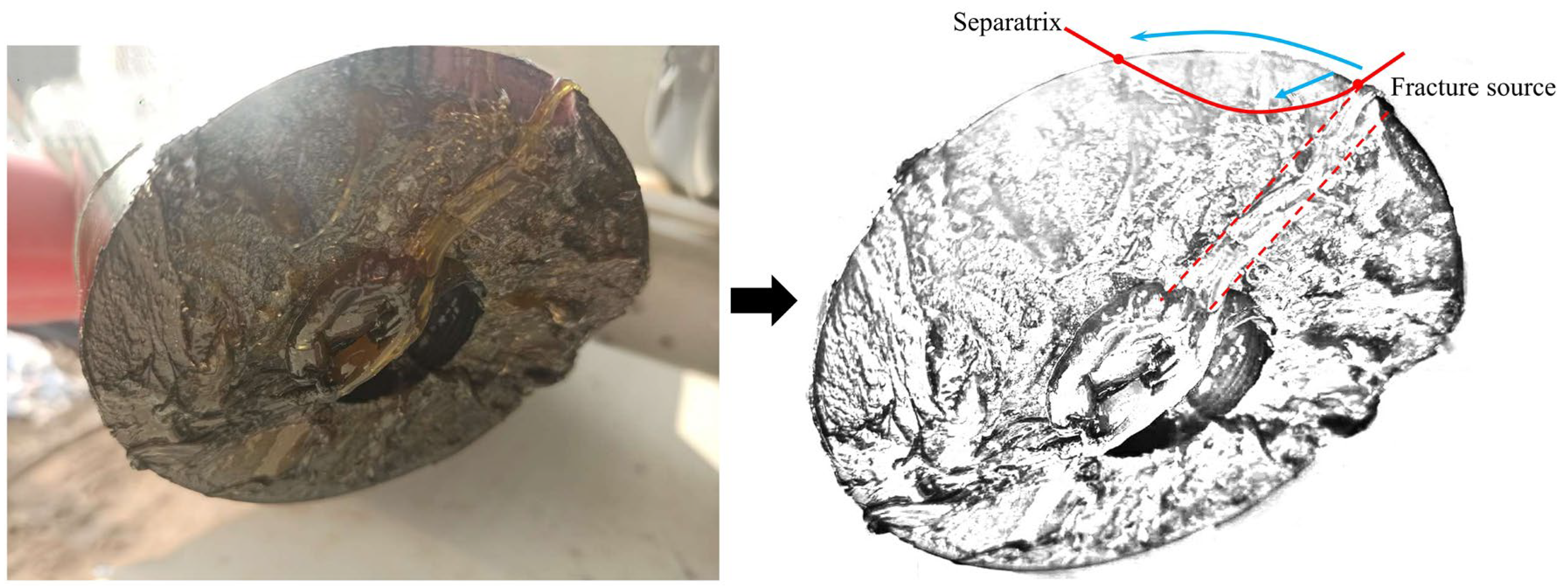

2.1. Problem Formulation

2.2. Principle and Purpose of the Experiment

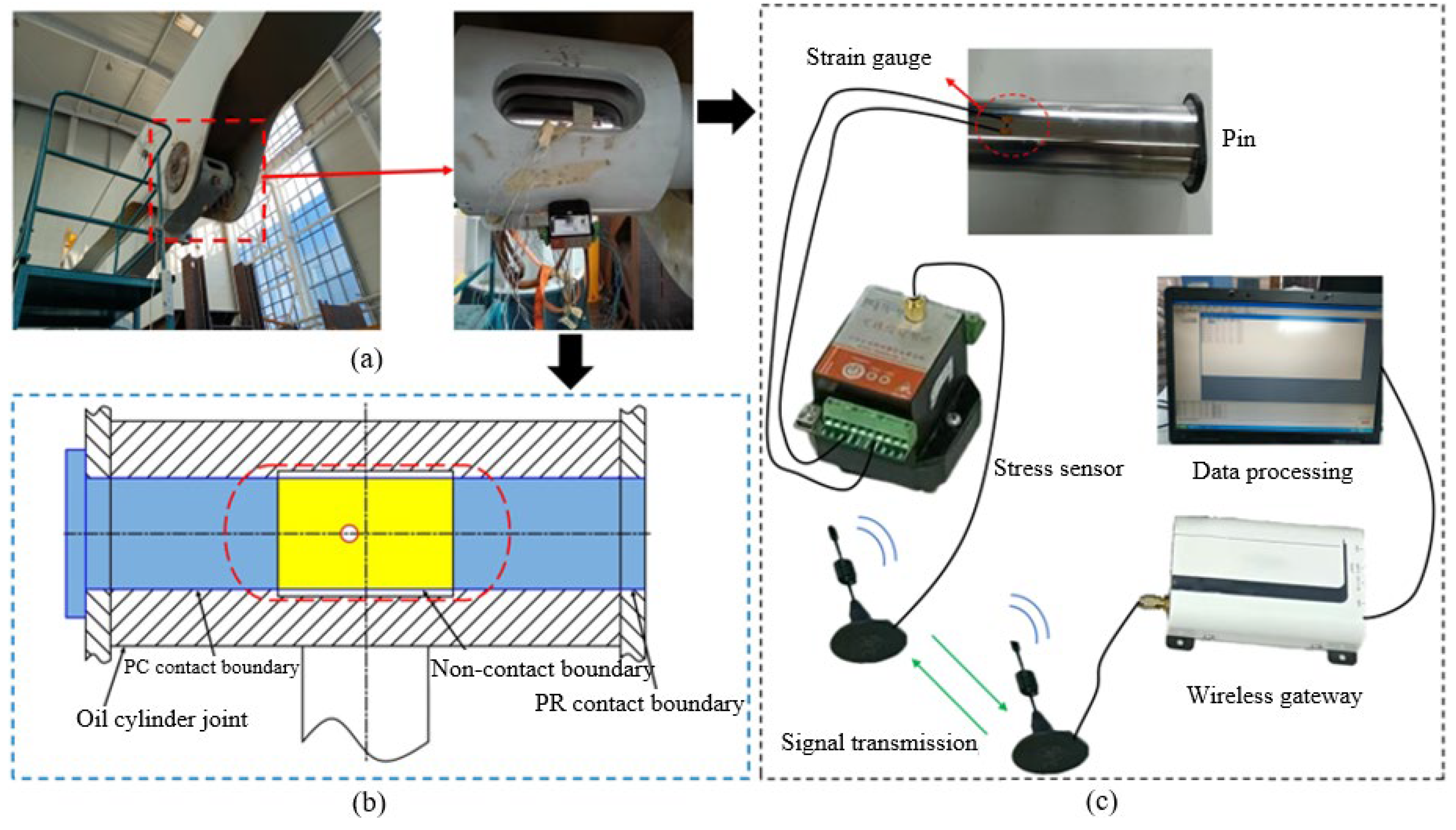

2.3. Test Subjects and Equipment

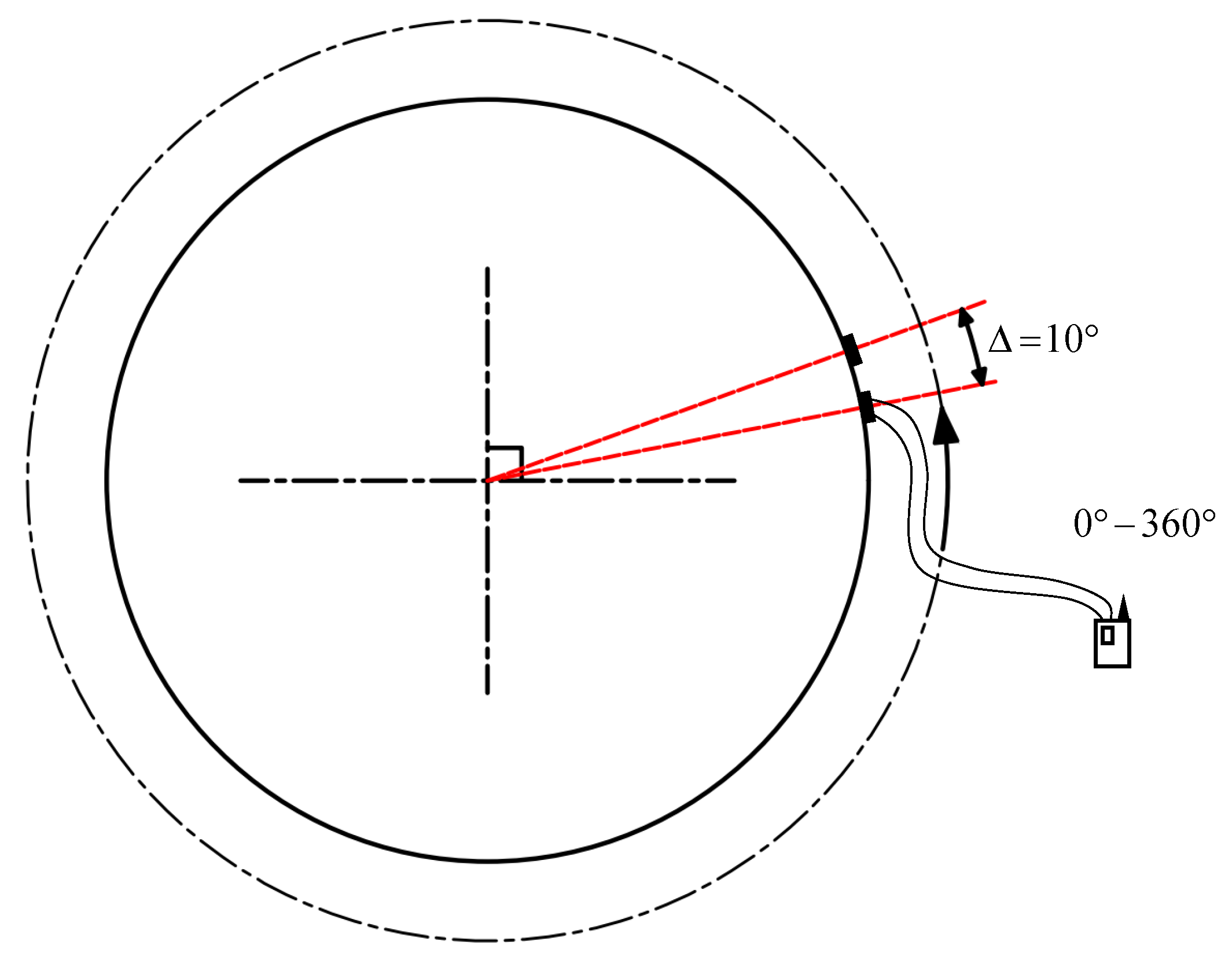

2.4. Test Method

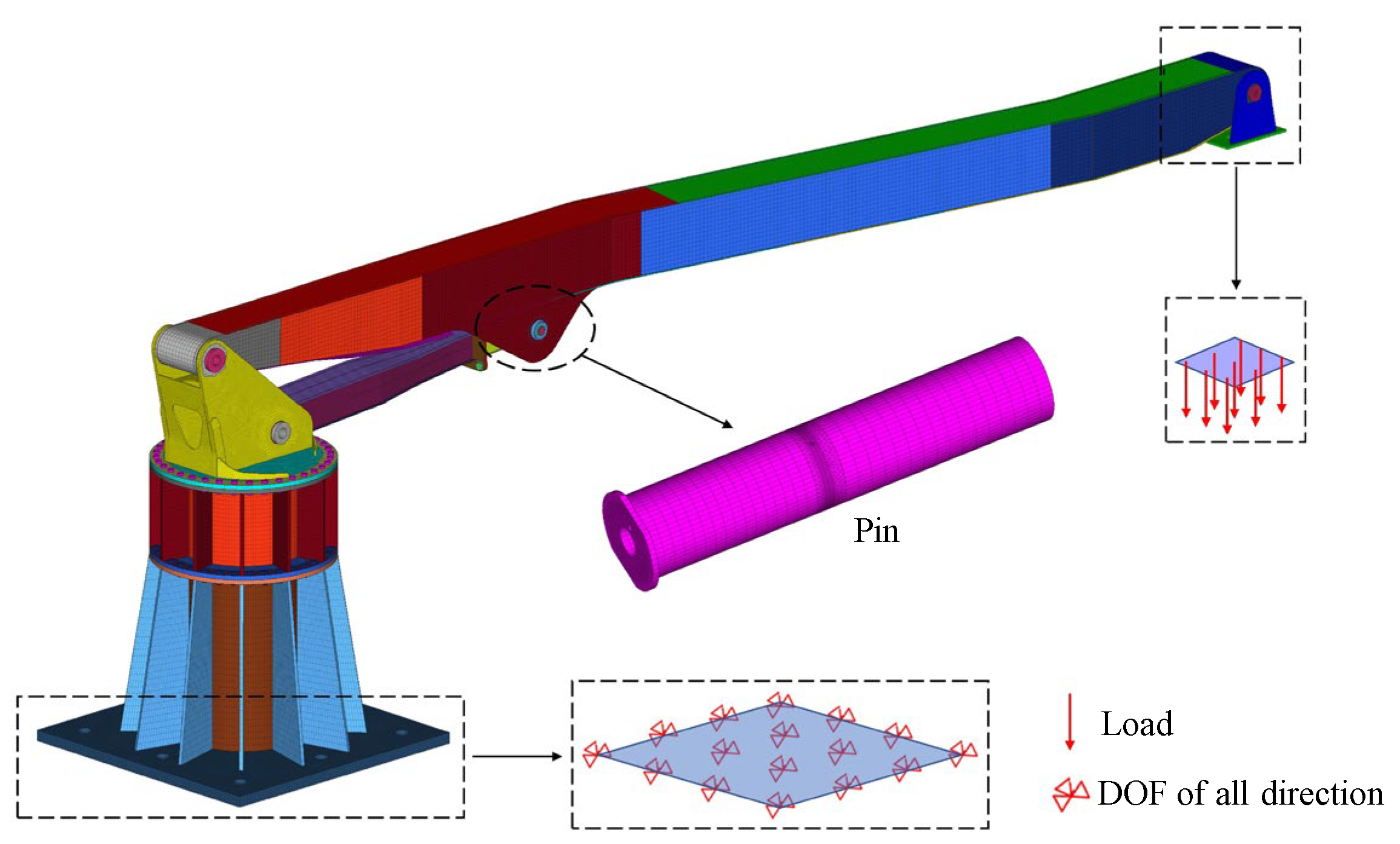

2.5. Simulation Model

| Material Property | 42CrMo |

|---|---|

| Density (Kg/m3) | 7850 |

| Young’s Modulus (GPa) | 212 |

| Poisson’s Ratio | 0.28 |

| Elastic Limit (MPa) | 489 |

| Tensile Yield Stress (MPa) | 650 |

| Ultimate Tensile Stress (MPa) | 1000 |

| Fracture Toughness (MPa·m1/2) | 50–80 |

| Hardness | HB 220–230 |

| Elongation (%) | 12 |

2.6. Material Attribute Type

2.7. Boundary Conditions

3. Results

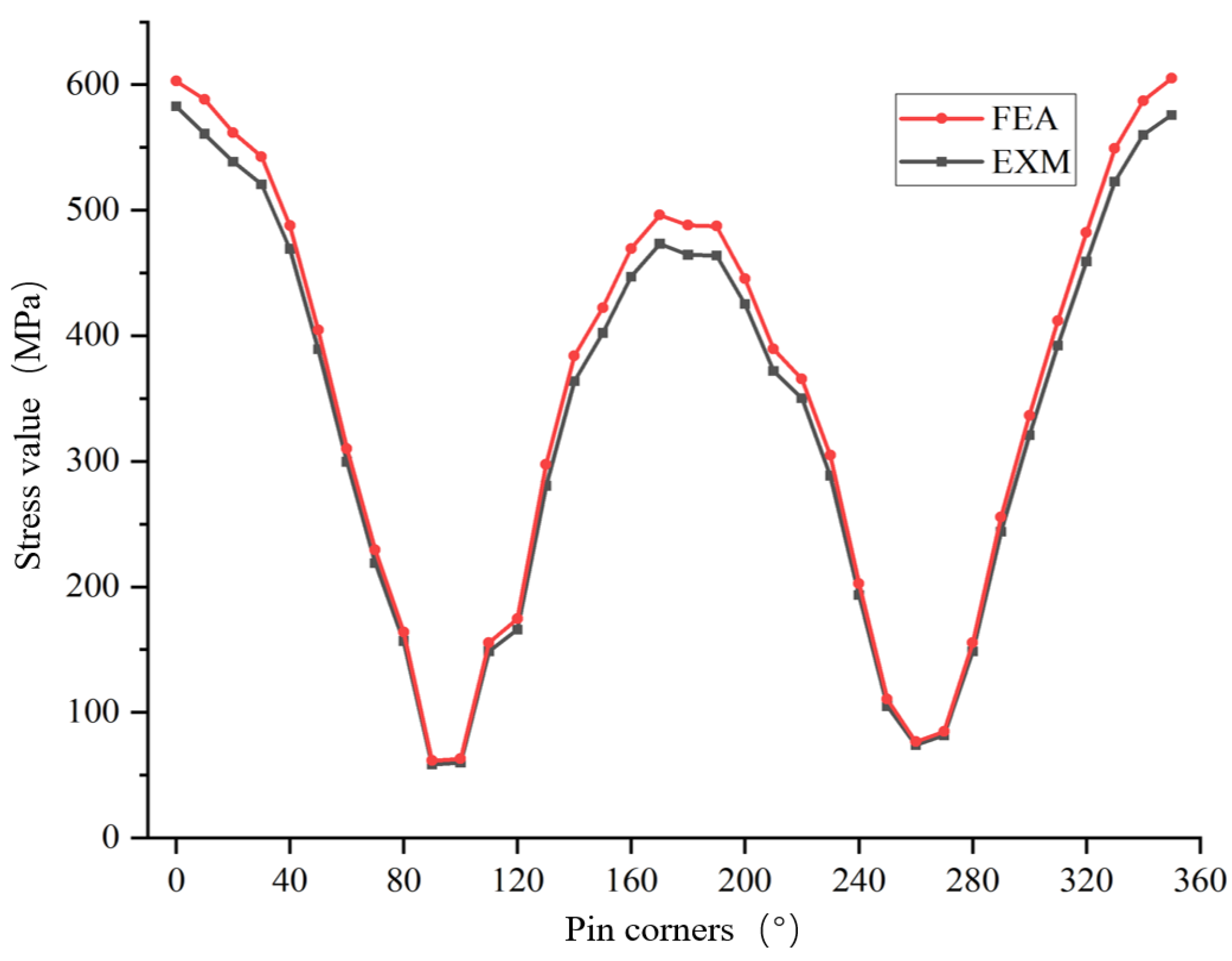

3.1. The Pin Shaft 360° Rotation Test Results

3.2. The Pin Shaft 360° Rotation Calculation Results

- (1)

- Prominent Period Closure Characteristics: Both test values and calculated values exhibit periodicity from 0° to 360°, with “corresponding high values at the beginning and end” forming a cycle. The numerical values at the start and end of the cycle are very close—test values at 0° and 350° are 583.09 and 577.81, respectively, with a difference of only 5.28; calculated values at 0° and 350° are 602.82 and 604.89, respectively, with a difference of only 2.07. Both test and calculated values achieve a “high-value start to high-value end” cycle closure, demonstrating their alignment with the angle period.

- (2)

- Consistent Core Low Valley Interval: Both test and calculated values reach their lowest point across the entire cycle at 90°, with a secondary low valley appearing near 260°. Specifically, the test values show a minimum of 62.52 at 90° and a secondary low of 74.31 at approximately 260°, while the calculated values reach 61.59 at 90° and 76.74 at approximately 260°. The angular positions of both the minimum value and the secondary low valley are identical, indicating that both sets of data strongly agree on the weakest mechanical response occurring at 90° and 260° for the pin shaft.

- (3)

- Synchronized Critical Change Phases: Both test and calculated values exhibit three distinct phases across the full cycle: a rapid decline from 0° to 90° (which constitutes the largest drop interval for both, with test values decreasing by 89% and calculated values by 89.8%), followed by a period of oscillatory fluctuations characterized by multiple peaks and valleys from 90° to 260°, and finally a steady rise from 260° to 350°. The overall temporal evolution pattern of these changes demonstrates complete synchronization between the test and calculated data.

- (1)

- Difference in Overall Numerical Levels: The calculated values consistently exceed the test values throughout the entire cycle, with the difference remaining relatively stable. At 0°, the calculated value (602.82) is 19.73 higher than the test value (583.09); at 350°, the calculated value (604.89) is 27.08 higher than the test value (577.81). On average, the calculated values are approximately 20~30 MPa higher than the test values across the full cycle. This discrepancy is likely attributed to errors inherent in numerical simulation versus experimental testing, such as assumptions in material parameters or interference from testing environments.

- (2)

- Differences in Local Fluctuation Magnitude: Within the 150–190° interval, the calculated values exhibit greater fluctuation amplitude compared to the test values. Specifically, the calculated values rise sharply from 322.36 at 150° to 495.97 at 170° (an increase of 53.8%) and then drop to 347.90 at 180° (a decrease of 30%), whereas the test values increase from 404.96 at 150° to 478.15 at 170° (an increase of 18.1%) and then decrease slightly to 465.82 at 180° (a decrease of 2.6%). This suggests that the calculated values display more pronounced “steep rises and steep drops,” while the test values show relatively smoother local changes, which may likely be related to the simplifications in the simulation model versus the smoothing effects inherent in experimental data.

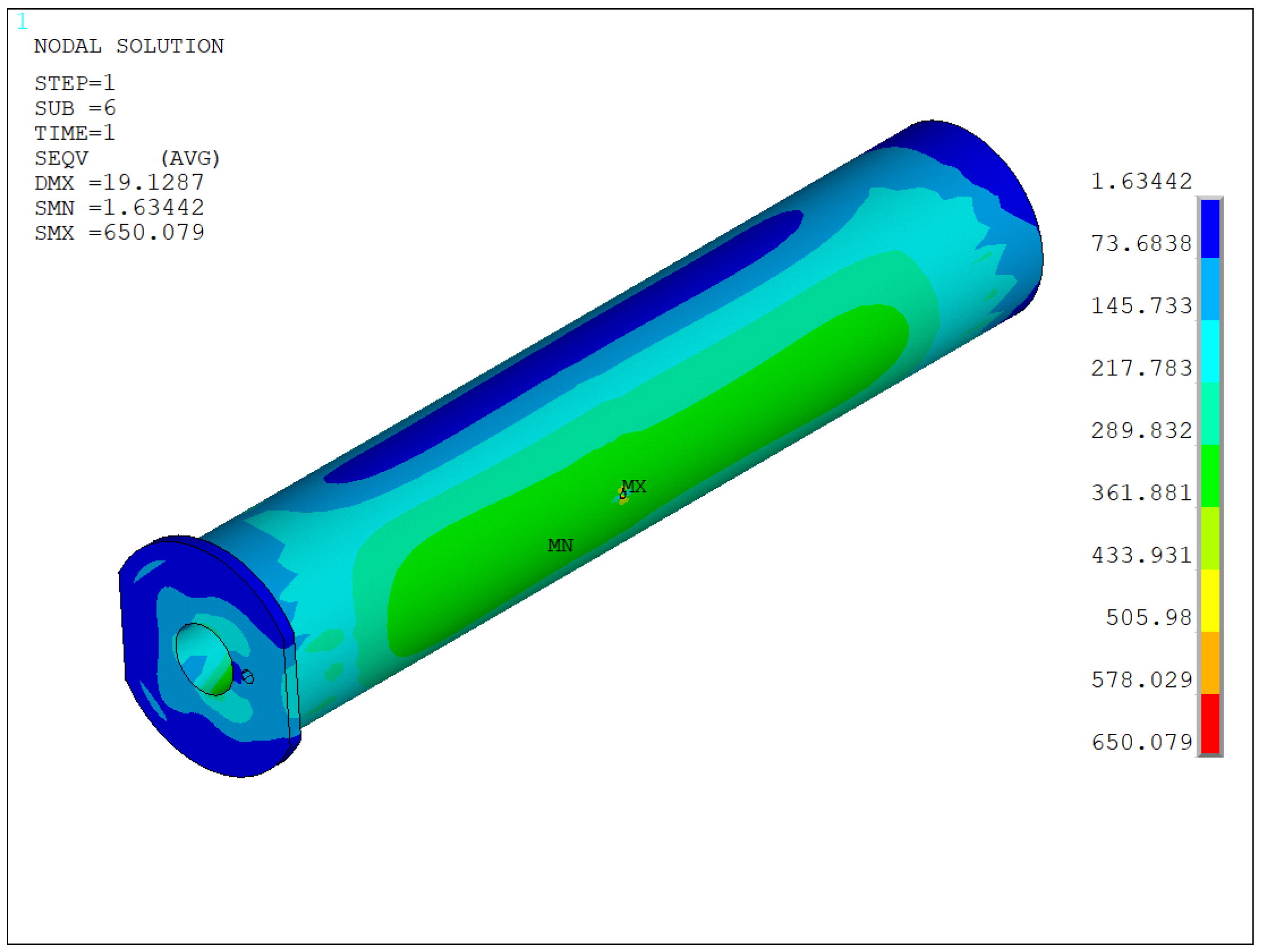

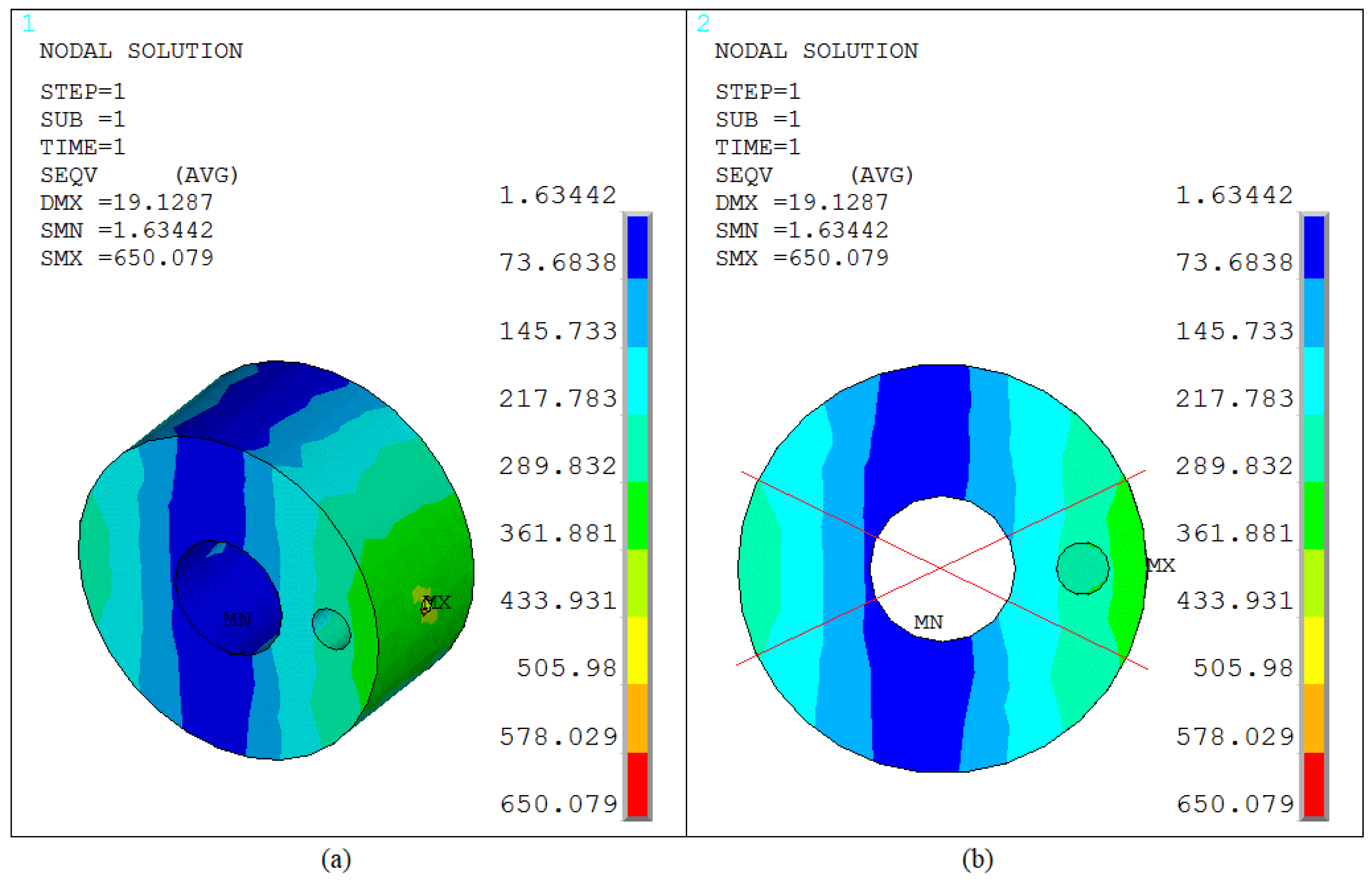

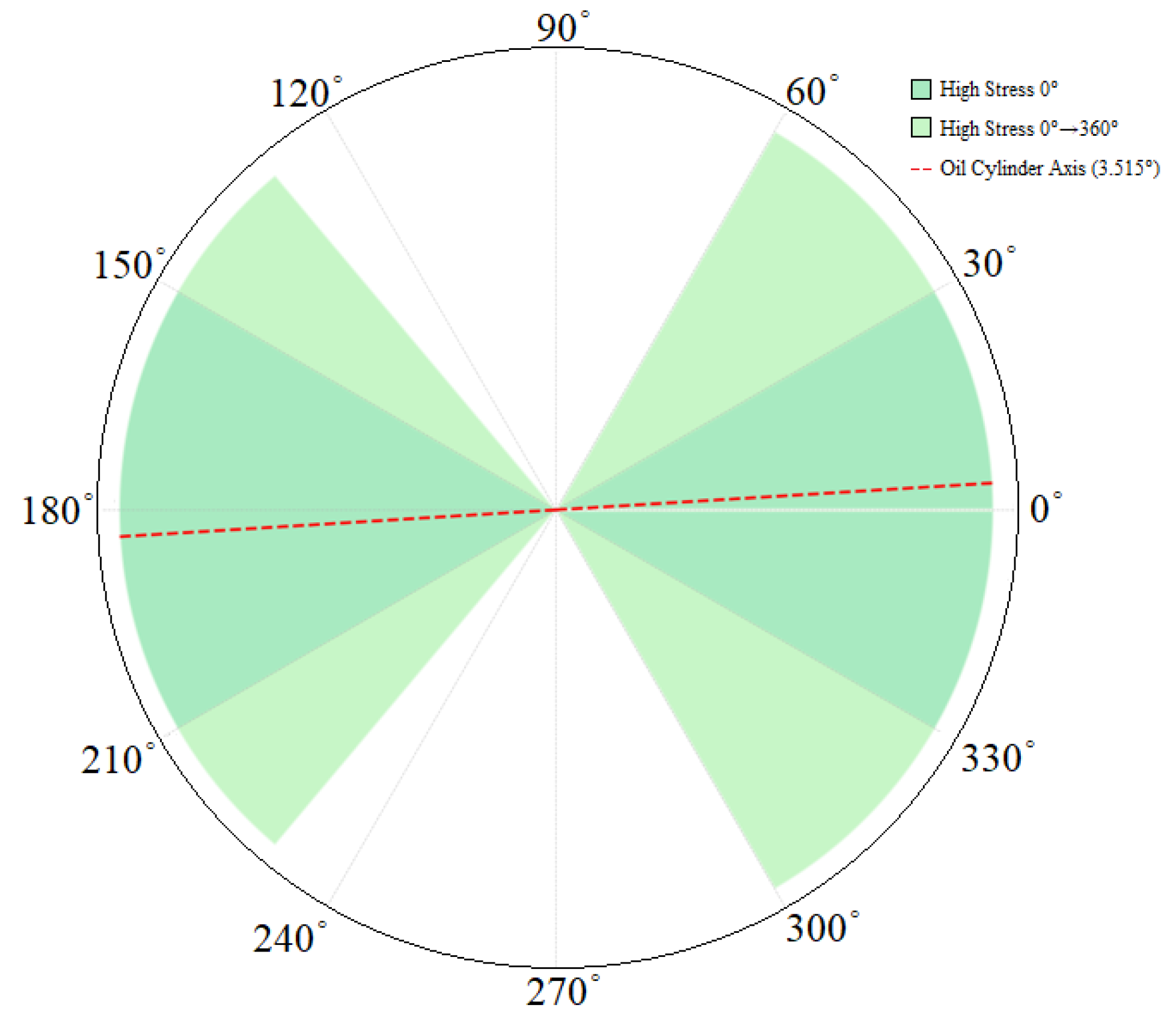

3.3. Calculation Results for the Pin Shaft at 0° Installation Angle

4. Discussion

4.1. Discussion on Results for the Pin Shaft at 0° Installation Angle

4.2. Discussion of the Pin Shaft 360° Rotation Results

5. Conclusions

- (1)

- Breaking through the traditional “load-dominated” framework, a new failure mechanism of “installation angle-axis-line-stress” has been established. Traditional studies often attribute the pin shaft failures to excessive loads and material fatigue, neglecting the influence of installation parameters, making it difficult to explain “failure under low loads.” This study proposes a hypothesis for the first time: improper installation angle (the angle between the oil passage axis and the horizontal plane) may cause the oil hole to fall into the high-stress zone dominated by the cylinder axis. Through experimental and simulation validation, when the oil hole axis is parallel or nearly parallel to the cylinder axis, the stress concentration peak at the oil hole approaches the material’s yield strength, ultimately forming a causal chain: “installation angle deviation → oil hole enters the high-stress zone → stress exceeds limits → fatigue failure.” This fills the research gap on the impact of installation angles on the pin shaft failures.

- (2)

- Constructing a “Dynamic Testing + Safety Factor Reverse Design” collaborative system to enhance the reliability of results. First, an innovative dynamic full-angle testing design is adopted, breaking the limitations of traditional fixed-angle static testing: by applying 360° stepwise loading to the pin shaft, the periodic characteristics of “angle-stress” are accurately captured, improving the engineering adaptability of the test data. Second, finite element safety factor reverse design is implemented: addressing the issue of traditional simulation ideal parameters overestimating strength, the simulation uses parameters without heat treatment under conditions where the tested pin shaft undergoes heat treatment beyond the yield strength. This approach leverages material performance deviations to retain safety factors, balancing analysis safety and model practicality.

- (3)

- Quantifying the stability and periodic coordination of high-stress zones provides a basis for precise regulation. Traditional studies can only qualitatively determine that oil holes are prone to stress concentration, and fail to clarify their distribution range and variation patterns. Through refined analysis, this study reveals two core laws for the first time: First, the spatial stability law of high-stress zones confirms that the high-stress zones of the pin shaft do not shift with the rotation of the installation angle, always concentrating symmetrically around the cylinder axis (3.515°) in intervals such as [0° to 30°], providing quantitative support for avoiding high-stress zones. Second, the periodic coordination law between angles and stress captures the “dual-peak two-valley” periodic characteristics, with the period coordinating with the force flow path of the cylinder axis, breaking through the traditional understanding of “random stress fluctuations” and identifying low-stress safe intervals.

- (4)

- Expanding the Application Scenarios from “Post-Failure Analysis” to “Full-Cycle Active Prevention”: Traditional studies often stop at failure cause analysis, offering general yet impractical recommendations. This research innovatively establishes a “Full-Cycle Prevention System”: On one hand, based on identified patterns, precise installation guidelines are proposed, adjusting the pin shaft installation angle to a safe zone perpendicular to the hydraulic cylinder axis. This significantly enhances the service life of the pin shaft structure and provides direct on-site guidance, addressing the “vagueness” issue of conventional suggestions. On the other hand, the entire technical chain is extended by integrating angle control with lightweight design, predictive maintenance of oil hole status, and automated sensing monitoring, forming a closed-loop system of “Design–Installation–Maintenance–Monitoring.” This provides a replicable paradigm for the long-term service of key components in similar construction machinery.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Li, W.; Liu, Y. Fatigue life prediction for boom structure of concrete pump truck. Eng. Fail. Anal. 2016, 60, 176–187. [Google Scholar] [CrossRef]

- Ivanović, B.; Saha, A.; Stević, Ž.; Puška, A.; Zavadskas, E.K. Selection of truck mixer concrete pump using novel MEREC DNMARCOS model. Arch. Civ. Mech. Eng. 2022, 22, 173. [Google Scholar] [CrossRef]

- Ren, Y.; Yang, W.; Sun, X.; Zhi, J.; Li, J.; Wang, H. Vibration characteristics of concrete pump trucks with multiple postures and multiple conditions based on the secondary development of HyperWorks. Processes 2023, 11, 1483. [Google Scholar] [CrossRef]

- Papadopoulou, S.; Pressas, I.; Vazdirvanidis, A.; Pantazopoulos, G. Fatigue failure analysis of roll steel pins from a chain assembly: Fracture mechanism and numerical modeling. Eng. Fail. Anal. 2019, 101, 320–328. [Google Scholar] [CrossRef]

- Whitworth, H.A.; Othieno, M.; Barton, O. Failure analysis of composite pin loaded joints. Compos. Struct. 2003, 59, 261–266. [Google Scholar] [CrossRef]

- Toubal, L.; Karama, M.; Lorrain, B. Stress concentration in a circular hole in composite plate. Compos. Struct. 2005, 68, 31–36. [Google Scholar] [CrossRef]

- Arola, D.; Williams, C.L. Estimating the fatigue stress concentration factor of machined surfaces. Int. J. Fatigue 2002, 24, 923–930. [Google Scholar] [CrossRef]

- Totten, G. Fatigue crack propagation. Adv. Mater. Process. 2008, 166, 39–42. [Google Scholar]

- Beden, S.M.; Abdullah, S.; Ariffin, A.K. Review of fatigue crack propagation models for metallic components. Eur. J. Sci. Res. 2009, 28, 364–397. [Google Scholar]

- Toyosada, M.; Gotoh, K.; Niwa, T. Fatigue crack propagation for a through thickness crack: A crack propagation law considering cyclic plasticity near the crack tip. Int. J. Fatigue 2004, 26, 983–992. [Google Scholar] [CrossRef]

- MackAldener, M.; Olsson, M. Tooth interior fatigue fracture—Computational and material aspects. Int. J. Fatigue 2001, 23, 329–340. [Google Scholar] [CrossRef]

- Sakai, T.; Nakagawa, A.; Oguma, N.; Nakamura, Y.; Ueno, A.; Kikuchi, S.; Sakaida, A. A review on fatigue fracture modes of structural metallic materials in very high cycle regime. Int. J. Fatigue 2016, 93, 339–351. [Google Scholar] [CrossRef]

- Smith, J.; Bassim, M.N.; Liu, C.D. Effects of fatigue precracking on stretch zone formation. Eng. Fract. Mech. 1995, 52, 401–408. [Google Scholar] [CrossRef]

- Beaurepaire, P.; Schuëller, G.I. Modeling of the variability of fatigue crack growth using cohesive zone elements. Eng. Fract. Mech. 2011, 78, 2399–2413. [Google Scholar] [CrossRef]

- Veselý, V.; Frantík, P. An application for the fracture characterisation of quasi-brittle materials taking into account fracture process zone influence. Adv. Eng. Softw. 2014, 72, 66–76. [Google Scholar] [CrossRef]

- Lipton, R. Cohesive dynamics and brittle fracture. J. Elast. 2016, 124, 143–191. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-damage model for cyclic loading of concrete structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Momeni, A.; Karakus, M.; Khanlari, G.; Heidari, M. Effects of cyclic loading on the mechanical properties of a granite. Int. J. Rock Mech. Min. Sci. 2015, 77, 89–96. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F. A review of experimental and theoretical research on the deformation and failure behavior of rocks subjected to cyclic loading. J. Rock Mech. Geotech. Eng. 2021, 13, 1203–1230. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, M.; Wang, Y. Experimental and constitutive model study of structural steel under cyclic loading. J. Constr. Steel Res. 2011, 67, 1185–1197. [Google Scholar] [CrossRef]

- Zhou, C.; Feng, G.; Zhao, X. An Efficient Calculation Method for Stress and Strain of Concrete Pump Truck Boom Considering Wind Load Variation. Machines 2023, 11, 161. [Google Scholar] [CrossRef]

- Pratt, D.; Bowker, P.; Wardlaw, D.; McLauchlan, J. Load measurement in orthopaedics using strain gauges. J. Biomed. Eng. 1979, 1, 287–296. [Google Scholar] [CrossRef]

- Suhling, J.C.; Jaeger, R.C. Silicon piezoresistive stress sensors and their application in electronic packaging. IEEE Sens. J. 2001, 1, 14–30. [Google Scholar] [CrossRef]

- Esfeh, H.K.; Azarafza, A.; Hamid, M.K.A. On the computational fluid dynamics of PEM fuel cells (PEMFCs): An investigation on mesh independence analysis. RSC Adv. 2017, 7, 32893–32902. [Google Scholar] [CrossRef]

- Zadeh, P.G.; Chung, J.D. Efficiency and performance evaluation of a novel EV Air-conditioning and battery cooling system with desiccant-coated heat pump. Appl. Therm. Eng. 2025, 264, 125429. [Google Scholar] [CrossRef]

- Mane, R.; Pandey, P.; Prasad, R.K.; Bansal, A. Ankit Bansal. Computational study of hydrogen-fueled scramjet combustors with forward-slide cavity designs. Appl. Therm. Eng. 2025, 80, 128319. [Google Scholar] [CrossRef]

- Zakeri, J.A.; Tajalli, M.R. Comparison of linear and nonlinear behavior of track elements in contact-impact models. Period. Polytech. Civ. Eng. 2018, 62, 963–970. [Google Scholar] [CrossRef]

- Huang, Y.C.; Lin, Y.C.; Deng, J.; Liu, G.; Chen, M.S. Hot tensile deformation behaviors and constitutive model of 42CrMo steel. Mater. Des. 2014, 53, 349–356. [Google Scholar] [CrossRef]

- Livingston, E.H. The mean and standard deviation: What does it all mean? J. Surg. Res. 2004, 119, 117–123. [Google Scholar] [CrossRef]

| H (m) | ω1 (°) | ω2 (°) | ω3 (°) | ωoc (°) |

|---|---|---|---|---|

| 12.2 | 60 | 47.13 | 120 | 60 |

| r1 (m) | r2 (m) | R3 (m) | L1 (m) | L2 (m) |

|---|---|---|---|---|

| 0.055 | 0.02 | 0.004 | 0.254 | 0.025 |

| Pin Axis Angle (°) | Test Mean Value (MPa) | Pin Axis Angle (°) | Test Mean Value (MPa) |

|---|---|---|---|

| 0 | 583.09 | 180 | 465.82 |

| 10 | 561.04 | 190 | 465.19 |

| 20 | 537.51 | 200 | 427.12 |

| 30 | 523.09 | 210 | 374.57 |

| 40 | 472.26 | 220 | 352.01 |

| 50 | 390.25 | 230 | 288.47 |

| 60 | 299.38 | 240 | 196.71 |

| 70 | 223.63 | 250 | 107.93 |

| 80 | 160.45 | 260 | 74.31 |

| 90 | 62.52 | 270 | 81.59 |

| 100 | 63.19 | 280 | 154.46 |

| 110 | 151.48 | 290 | 247.10 |

| 120 | 167.19 | 300 | 323.37 |

| 130 | 283.35 | 310 | 395.10 |

| 140 | 365.44 | 320 | 458.76 |

| 150 | 404.96 | 330 | 526.76 |

| 160 | 446.75 | 340 | 560.47 |

| 170 | 478.15 | 350 | 577.81 |

| Pin Axis Angle (°) | Calculated Value (MPa) | Pin Axis Angle (°) | Calculated Value (MPa) |

|---|---|---|---|

| 0 | 602.82 | 180 | 347.9 |

| 10 | 588.17 | 190 | 487.28 |

| 20 | 561.65 | 200 | 445.56 |

| 30 | 542.6 | 210 | 359 |

| 40 | 487.58 | 220 | 365.49 |

| 50 | 404.51 | 230 | 304.85 |

| 60 | 310.04 | 240 | 202.6 |

| 70 | 229.4 | 250 | 110.61 |

| 80 | 164.06 | 260 | 76.74 |

| 90 | 61.59 | 270 | 84.84 |

| 100 | 63.07 | 280 | 155.45 |

| 110 | 155.53 | 290 | 255.67 |

| 120 | 174.56 | 300 | 336.65 |

| 130 | 297.42 | 310 | 411.79 |

| 140 | 384.02 | 320 | 482.25 |

| 150 | 322.36 | 330 | 549.1 |

| 160 | 469.44 | 340 | 587.15 |

| 170 | 495.97 | 350 | 604.89 |

| Pin Axis Angle (°) | Deviation | Pin Axis Angle (°) | Deviation |

|---|---|---|---|

| 0 | 3.46% | 180 | 5.04% |

| 10 | 4.89% | 190 | 5.04% |

| 20 | 4.29% | 200 | 4.77% |

| 30 | 4.25% | 210 | 4.70% |

| 40 | 3.92% | 220 | 4.36% |

| 50 | 3.91% | 230 | 5.63% |

| 60 | 3.51% | 240 | 4.72% |

| 70 | 4.78% | 250 | 5.27% |

| 80 | 4.60% | 260 | 3.81% |

| 90 | 5.26% | 270 | 3.98% |

| 100 | 5.27% | 280 | 4.56% |

| 110 | 4.56% | 290 | 4.83% |

| 120 | 5.26% | 300 | 4.94% |

| 130 | 6.02% | 310 | 4.99% |

| 140 | 5.56% | 320 | 5.04% |

| 150 | 5.00% | 330 | 5.06% |

| 160 | 5.03% | 340 | 4.89% |

| 170 | 4.82% | 350 | 5.08% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Cheng, K.; Guan, B.; Wu, B.; Zhao, E. Research on Experimental Validation and Prevention Strategies for Pin Shaft Failure in Concrete Pump Trucks. Sensors 2025, 25, 6518. https://doi.org/10.3390/s25216518

Sun W, Cheng K, Guan B, Wu B, Zhao E. Research on Experimental Validation and Prevention Strategies for Pin Shaft Failure in Concrete Pump Trucks. Sensors. 2025; 25(21):6518. https://doi.org/10.3390/s25216518

Chicago/Turabian StyleSun, Wuhe, Kai Cheng, Bowen Guan, Bin Wu, and Erfei Zhao. 2025. "Research on Experimental Validation and Prevention Strategies for Pin Shaft Failure in Concrete Pump Trucks" Sensors 25, no. 21: 6518. https://doi.org/10.3390/s25216518

APA StyleSun, W., Cheng, K., Guan, B., Wu, B., & Zhao, E. (2025). Research on Experimental Validation and Prevention Strategies for Pin Shaft Failure in Concrete Pump Trucks. Sensors, 25(21), 6518. https://doi.org/10.3390/s25216518