Novel Higher Order Technologies, Based on Spectral Moduli, for Condition Monitoring of Rotating Machinery

Abstract

1. Introduction

- Propose and develop novel fault diagnosis technologies based on moduli of characteristic spectral components.

- Perform a novel comprehensive validation of TOM technology via experimental trials for pristine and faulty motor bearings, using motor current signature analysis.

- Perform a novel comparison of TOM technology with the CB technology via experimental trials for pristine and faulty motor bearings.

2. New Higher Order Spectral Technologies

- Using the same time-frequency transform;

- Exploiting statistical dependencies between characteristic spectral components;

- Using the moduli of characteristic spectral components;

- Time-dependent;

- Dependent on multiple frequencies;

- Using very similar methodologies for diagnostic feature estimation;

- Using the normalized diagnostic features to avoid a misleading interpretation;

- Using diagnostic features, which are in the range [0; 1];

- Allowing an early damage diagnosis.

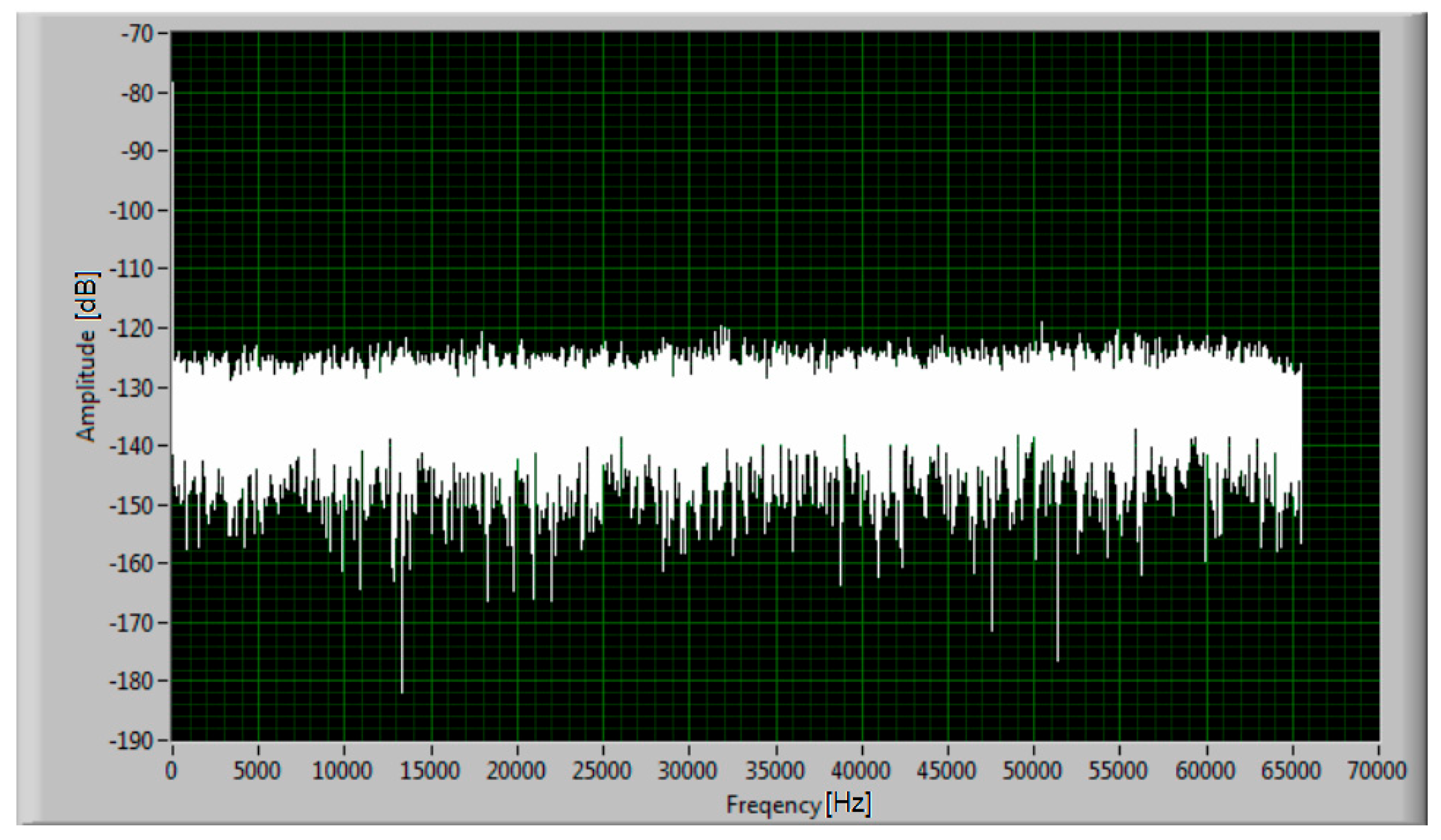

3. Experimental Setup

4. Diagnosis Results and Discussion

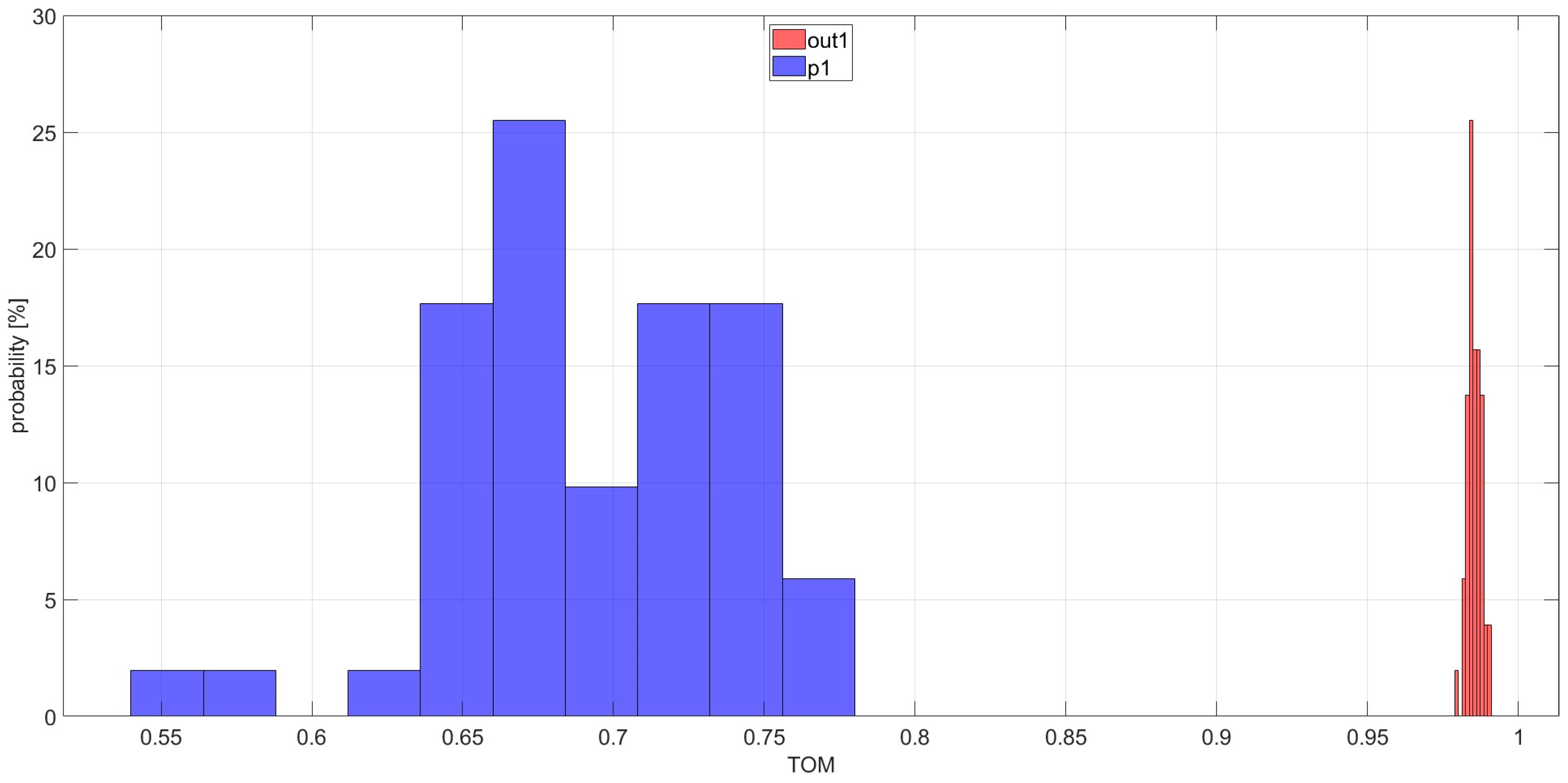

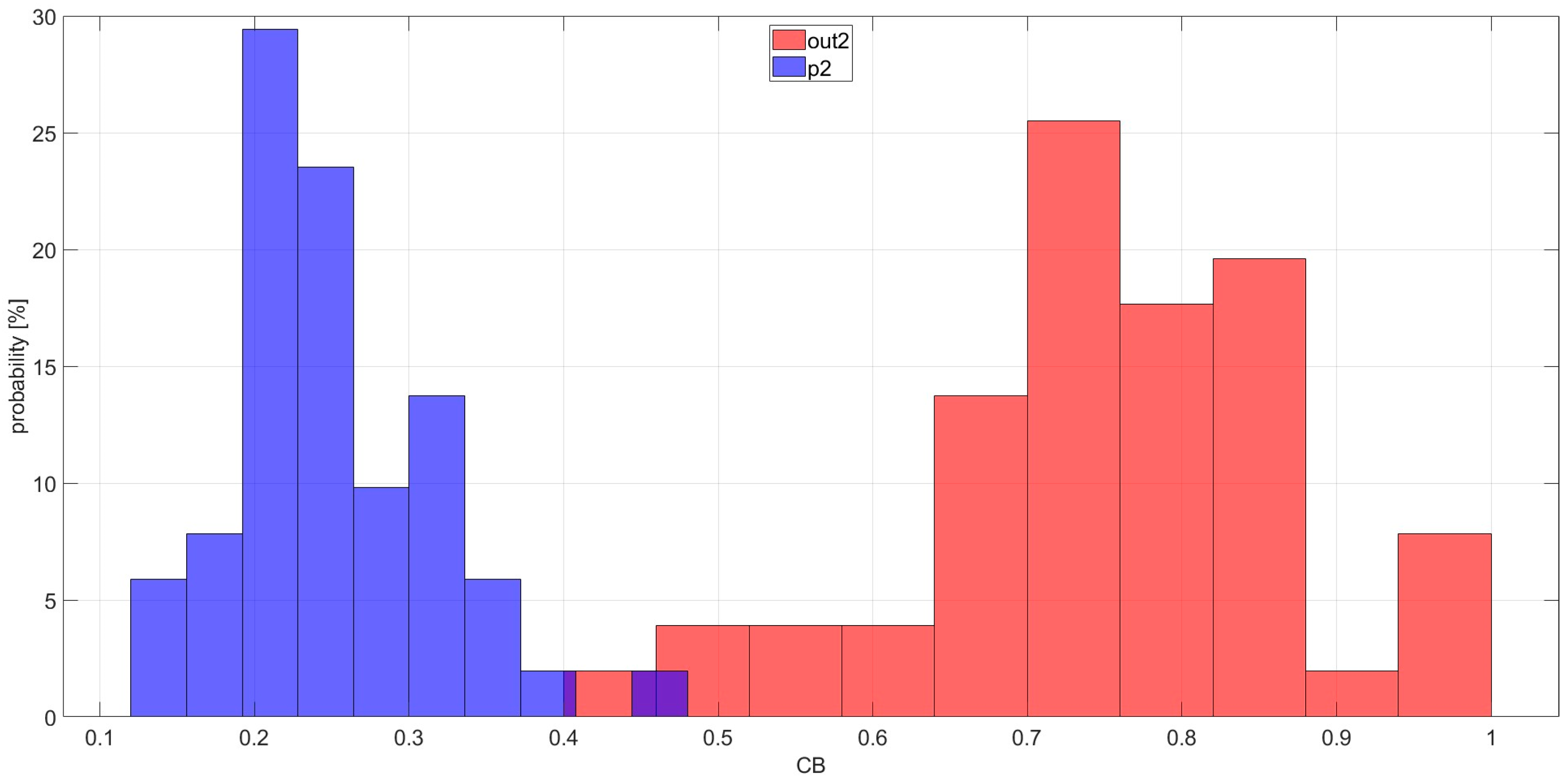

4.1. Outer Race Damage

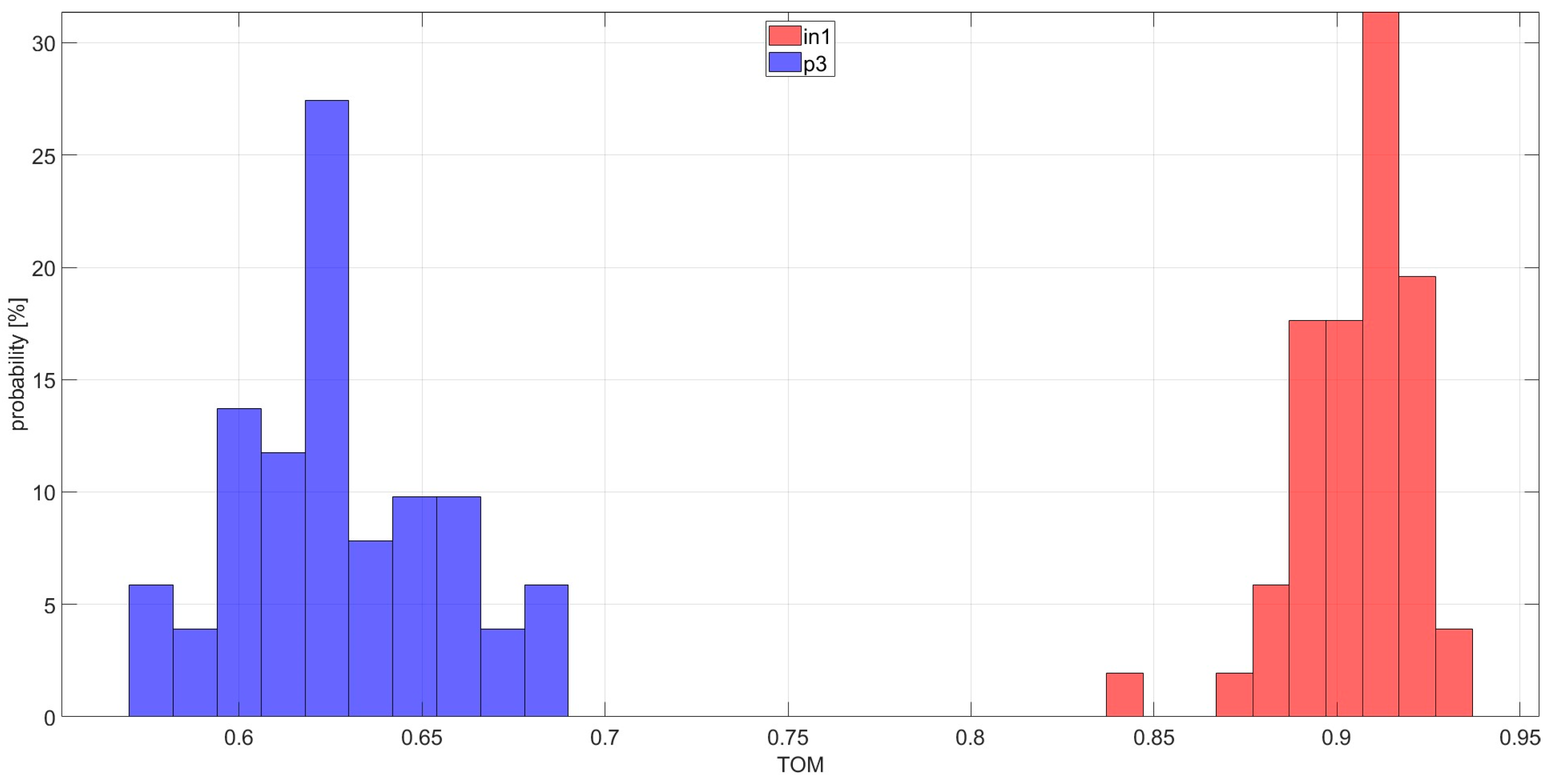

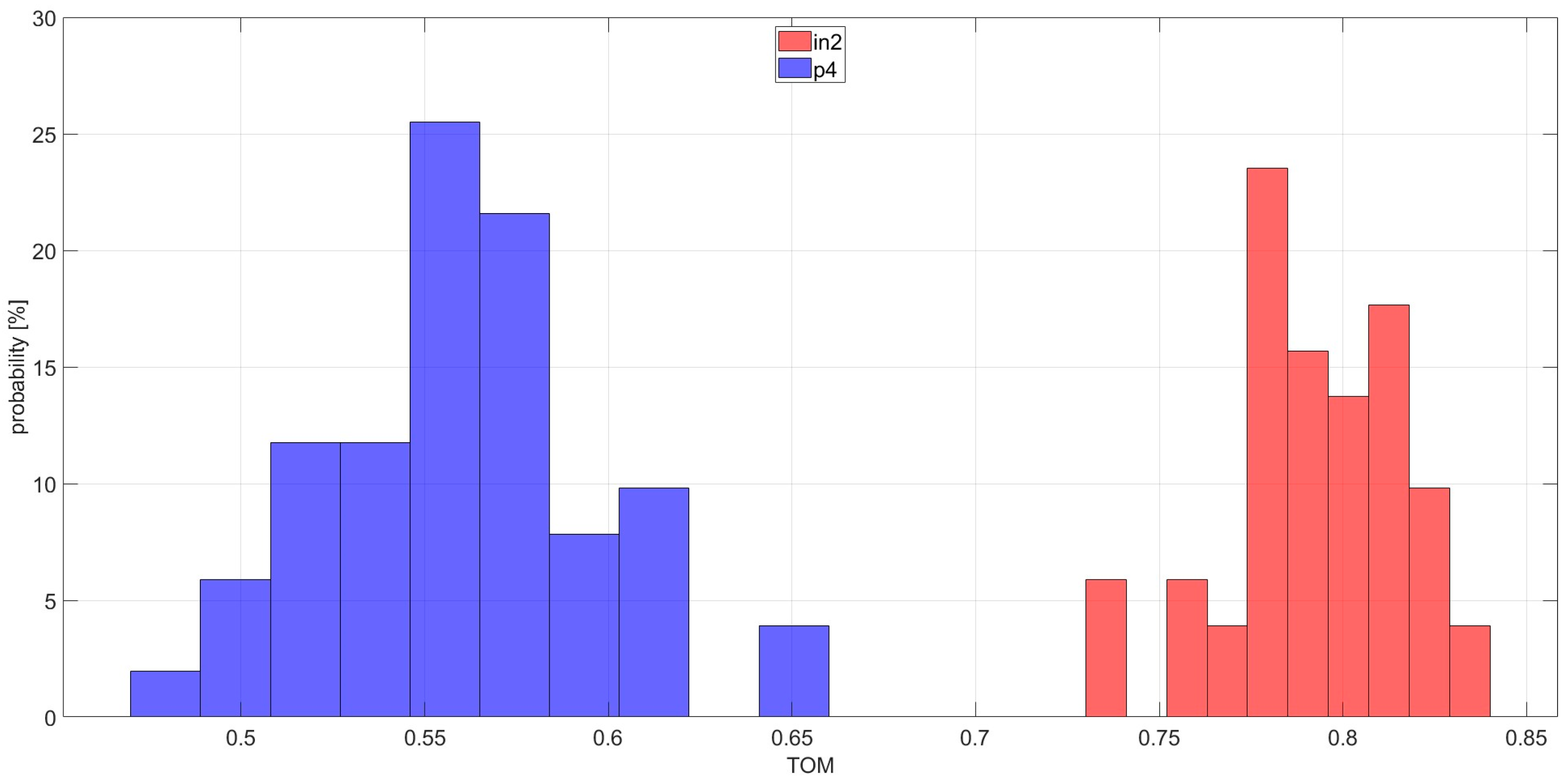

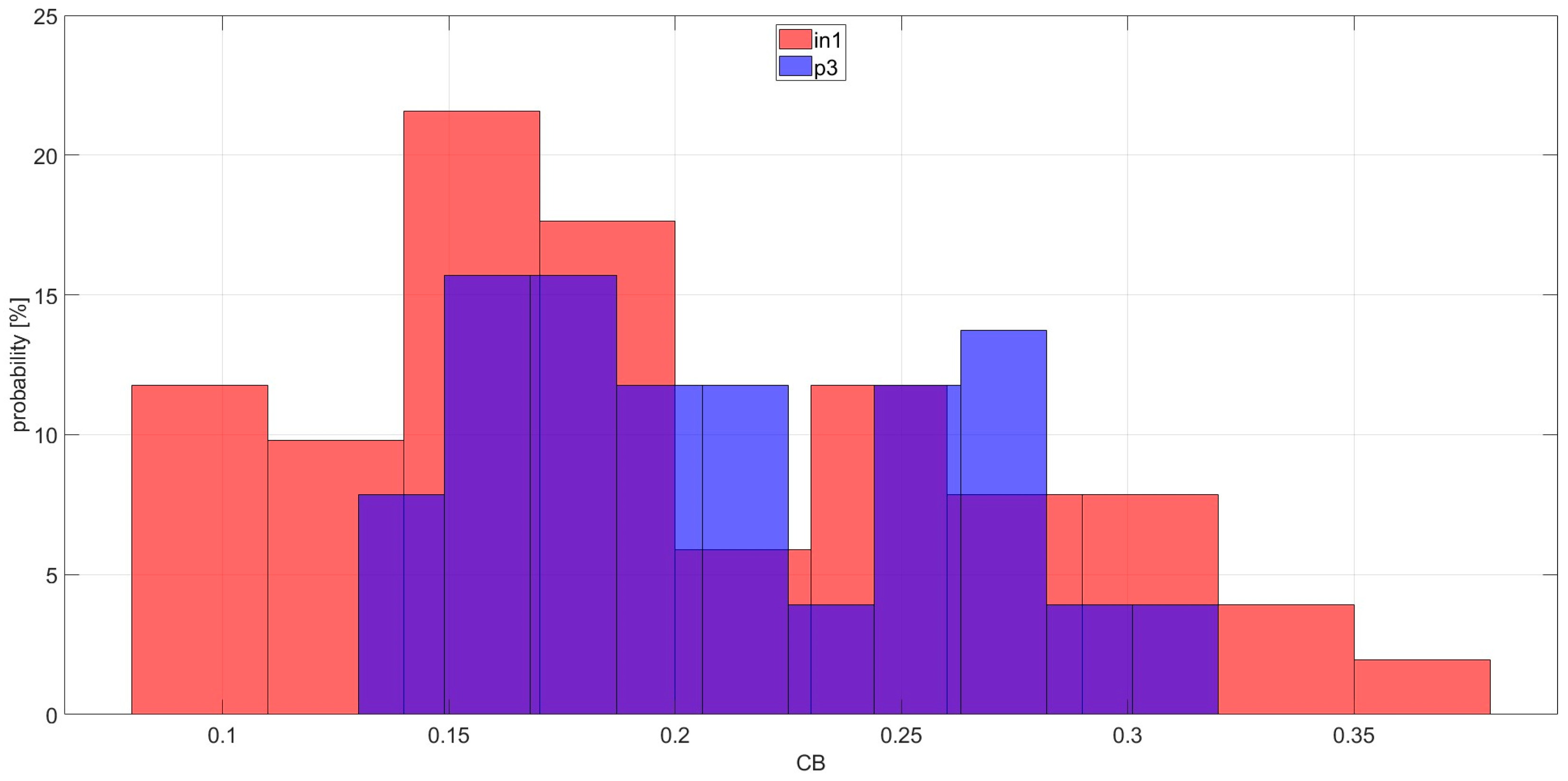

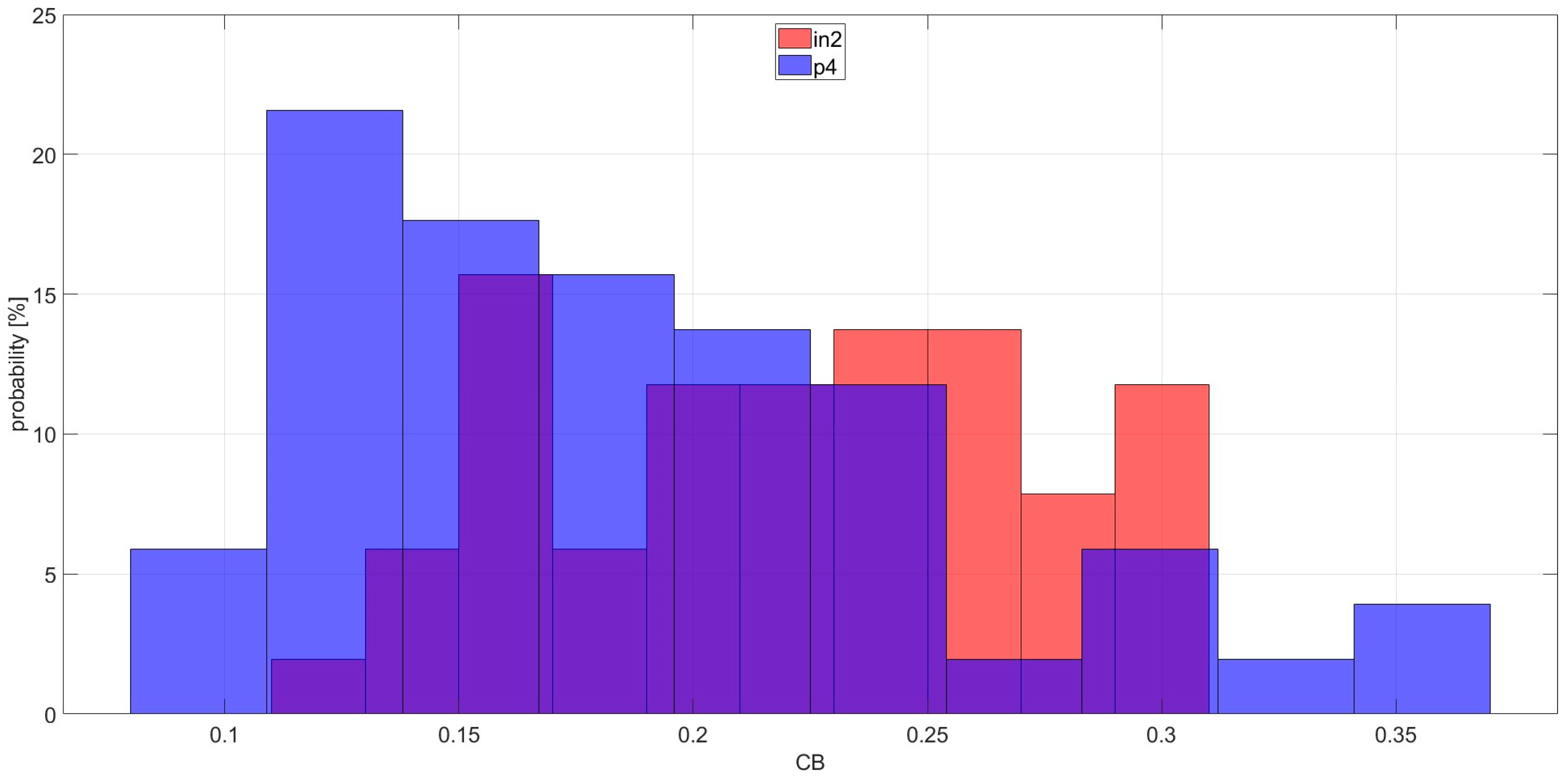

4.2. Inner Race Damage

5. Conclusions

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations List

| TOM | third order modulus |

| IM | induction motor |

| MCSA | motor current signature analysis |

| RSH | rotor slot harmonics |

| DI | diagnostic indicator |

| HOS | higher order spectra |

| CB | classic bicoherence |

| FOM | fourth order modulus |

| AM | amplitude modulation |

| FT | Fourier transform |

| PoCD | probability of correct diagnosis |

| FC | Fisher criterion |

References

- Ciszewski, T.; Gelman, L.; Ball, A. Novel fault identification for electromechanical systems via spectral technique and electrical data processing. Electronics 2020, 9, 1560. [Google Scholar] [CrossRef]

- Gelman, L.; Soliński, K.; Ball, A. Novel higher-order spectral cross-correlation technologies for vibration sensor-based diagnosis of gearboxes. Sensors 2020, 20, 5131. [Google Scholar] [CrossRef]

- Gelman, L.; Petrunin, I.; Komoda, J. The new chirp-Wigner higher order spectra for transient signals with any known nonlinear frequency variation. Mech. Syst. Signal Process. 2010, 24, 567–571. [Google Scholar] [CrossRef]

- Schoen, R.; Habetler, T.G.; Kamran, F.; Bartheld, R.G. Motor bearing damage detection, using stator current monitoring. IEEE Trans. Ind. Appl. 1995, 31, 1274–1279. [Google Scholar] [CrossRef]

- Areias, I.A.d.S.; Borges da Silva, L.E.; Bonaldi, E.L.; de Lacerda de Oliveira, L.E.; Lambert-Torres, G.; Bernardes, V.A. Evaluation of current signature in bearing defects by envelope analysis of the vibration in induction motors. Energies 2019, 12, 4029. [Google Scholar] [CrossRef]

- Gangsar, P.; Tiwari, R. Signal based condition monitoring techniques for fault detection and diagnosis of induction motors: A state-of-the-art review. Mech. Syst. Signal Process. 2020, 144, 106908. [Google Scholar] [CrossRef]

- Sintoni, M.; Macrelli, E.; Bellini, A.; Bianchini, C. Condition monitoring of induction machines: Quantitative analysis and comparison. Sensors 2023, 23, 1046. [Google Scholar] [CrossRef]

- Gelman, L.; Chandra, N.H.; Kurosz, R.; Pellicano, F.; Barbieri, M.; Zippo, A. Novel spectral kurtosis technology for adaptive vibration condition monitoring of multi-stage gearboxes. Insight-Non-Destr. Test. Cond. Monit. 2016, 58, 409–416. [Google Scholar] [CrossRef]

- Combet, F.; Gelman, L.; Anuzis, P.; Slater, R. Vibration detection of local gear damage by advanced demodulation and residual techniques. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2009, 223, 507–514. [Google Scholar] [CrossRef]

- Gryllias, K.C.; Gelman, L.; Shaw, B.; Vaidhianathasamy, M. Local damage diagnosis in gearboxes using novel wavelet technology. Int. J. Insight-Non-Destr. Test. Cond. Monit. 2010, 52, 437–442. [Google Scholar] [CrossRef]

- Gelman, L.; Kripak, D.; Fedorov, V.; Udovenko, L. Condition monitoring diagnosis methods of gearbox units. Mech. Syst. Signal Process. 2000, 14, 613–624. [Google Scholar] [CrossRef]

- Kolbe, S.; Gelman, L.; Ball, A. Novel prediction of diagnosis effectiveness for adaptation of the spectral kurtosis technology to varying operating conditions. Sensors 2021, 21, 6913. [Google Scholar] [CrossRef]

- Gelman, L.; Soliński, K.; Ball, A. Novel instantaneous wavelet bicoherence for vibration fault detection in gear systems. Energies 2021, 14, 6811. [Google Scholar] [CrossRef]

- Gelman, L.; Kolbe, S.; Shaw, B.; Vaidhianathasamy, M. Novel adaptation of the spectral kurtosis for vibration diagnosis of gearboxes in non-stationary conditions. Int. J. Insight-Non-Destr. Test. Cond. Monit. 2017, 59, 434–439. [Google Scholar] [CrossRef]

- Gelman, L.; Solinski, K.; Shaw, B.; Vaidhianathasamy, M. Vibration diagnosis of a gearbox by wavelet bicoherence technology. Int. J. Insight-Non-Destr. Test. Cond. Monit. 2017, 59, 440–444. [Google Scholar] [CrossRef]

- Zhao, D.; Gelman, L.; Chu, F.; Ball, A. Vibration health monitoring of rolling bearings under variable speed conditions by novel demodulation technique. Struct. Control. Health Monit. 2020, 28, e2672. [Google Scholar] [CrossRef]

- Gelman, L.; Patel, T.H.; Persin, G.; Murray, B.; Thomson, A. Novel technology based on the spectral kurtosis and wavelet transform for rolling bearing diagnosis. Int. J. Progn. Health Manag. 2013, 4, 2153–2648. [Google Scholar] [CrossRef]

- Gelman, L.; Murray, B.; Patel, T.; Thomson, A. Vibration diagnostics of rolling bearings by novel nonlinear non-stationary wavelet bicoherence technology. Eng. Struct. 2014, 80, 514–520. [Google Scholar] [CrossRef]

- Gelman, L.; Persin, G. Novel fault diagnosis of bearings and gearboxes based on simultaneous processing of spectral kurtoses. Appl. Sci. 2022, 12, 9970. [Google Scholar] [CrossRef]

- Nikolaou, N.G.; Antoniadis, I.A. Rolling element bearing fault diagnosis using wavelet packets. NDT E Int. 2002, 35, 197–205. [Google Scholar] [CrossRef]

- Lou, X.; Loparo, K. Bearing fault diagnosis based on wavelet transform and fuzzy inference. Mech. Syst. Signal Process. 2004, 18, 1077–1095. [Google Scholar] [CrossRef]

- Yaqub, M.F.; Loparo, K.A. An automated approach for bearing damage detection. J. Vib. Control. 2016, 22, 3253–3266. [Google Scholar] [CrossRef]

- Yiakopoulos, C.; Antoniadis, I. Wavelet based demodulation of vibration signals generated by defects in rolling element bearings. Shock Vib. 2002, 9, 293–306. [Google Scholar] [CrossRef]

- Yang, D.; Karimi, H.R.; Gelman, L. A fuzzy fusion rotating machinery fault diagnosis framework based on the enhancement deep convolutional neural networks. Sensors 2022, 22, 671. [Google Scholar] [CrossRef] [PubMed]

- Farhat, M.H.; Gelman, L.; Conaghan, G.; Kluis, W.; Ball, A. Novel diagnosis technologies for a lack of oil lubrication in gearmotor systems, based on motor current signature analysis. Sensors 2022, 22, 9507. [Google Scholar] [CrossRef] [PubMed]

- Han, Q.; Ding, Z.; Xu, X.; Wang, T.; Chu, F. Stator current model for detecting rolling bearing faults in induction motors using magnetic equivalent circuits. Mech. Syst. Signal Process. 2019, 131, 554–575. [Google Scholar] [CrossRef]

- Acosta, G.G.; Verucchi, C.J.; Gelso, E.R. A current monitoring system for diagnosing electrical failures in induction motors. Mech. Syst. Signal Proc. 2006, 20, 953–965. [Google Scholar] [CrossRef]

- Corne, B.; Vervisch, B.; Derammelaere, S.; Knockaert, J.; Desmet, J. The reflection of evolving bearing faults in the stator current’s extended park vector approach for induction machines. Mech. Syst. Signal Process. 2018, 107, 168–182. [Google Scholar] [CrossRef]

- Silva, J.L.H.; Cardoso, A.J.M. Bearing failures diagnosis in three-phase induction motors by extended Park’s vector approach. In Proceedings of the 31st Annual Conference of IEEE Industrial Electronics Society, IECON 2005, Raleigh, NC, USA, 6–10 November 2005. [Google Scholar]

- Wang, C.; Wang, M.; Yang, B.; Song, K.; Zhang, Y.; Liu, L. A novel methodology for fault size estimation of ball bearings using stator current signal. Measurement 2021, 171, 108723. [Google Scholar] [CrossRef]

- Treetrong, J. Fault detection and diagnosis of induction motors based on higher-order spectrum. In Proceedings of the International Multi Conference of Engineers and Computer Scientists 2010, Hong Kong, China, 17–19 March 2010. [Google Scholar]

- Tulicki, J.; Sułowicz, M.; Pragłowska-Ryłko, N. Application of the bispectral analysis in the diagnosis of cage induction motors. In Proceedings of the 2016 13th Selected Issues of Electrical Engineering and Electronics (wzee), Rzeszow, Poland, 4–8 May 2016. [Google Scholar] [CrossRef]

- Zarei, J.; Poshtan, J. An advanced park’s vectors approach for bearing fault detection. IEEE Int. Conf. Ind. Technol. 2006, 42, 213–219. [Google Scholar] [CrossRef]

- Blödt, M.; Granjon, P.; Raison, B.; Rostaing, G. Models for bearing damage detection in induction motors using stator current monitoring. IEEE Trans. Ind. Electron. 2008, 55, 1813–1822. [Google Scholar] [CrossRef]

- Eren, L.; Karahoca, A.; Devaney, M.J. Neural network based motor bearing fault detection. In Proceedings of the 21st IEEE Instrumentation and Measurement Technology Conferenc, Como, Italy, 18–20 May 2004; Volume 3, pp. 1657–1660. [Google Scholar] [CrossRef]

- Eren, L.; Teotrakool, K.; Devaney, M.J. Bearing fault detection via wavelet packet decomposition with spectral post processing. In Proceedings of the 2007 IEEE Instrumentation & Measurement Technology Conference IMTC 2007, Warsaw, Poland, 1–3 May 2007; pp. 1–4. [Google Scholar] [CrossRef]

- Gelman, L.; Patel, T.-H. Novel intelligent data processing technology, based on nonstationary nonlinear wavelet bispectrum, for vibration fault diagnosis. IAENG Int. J. Comput. Sci. 2023, 50, 1–6. [Google Scholar]

- Song, X.; Hu, J.; Zhu, H.; Zhang, J. A bearing outer raceway fault detection method in induction motors based on instantaneous frequency of the stator current. IEEE J. Trans. Electr. Electron. Eng. 2018, 13, 510–516. [Google Scholar] [CrossRef]

- Dahiya, N.M.R. Detection of bearing faults of induction motor using park’s vector approach. Int. J. Eng. 2010, 1, 263–266. [Google Scholar]

- Saeidi, M.; Zarei, J.; Hassani, H.; Zamani, A.; Majid, S. Bearing fault detection via park’s vector approach based on anfis. In Proceedings of the 2014 International Conference on Mechatronics and Control (ICMC), Jinzhou, China, 3–5 July 2014. [Google Scholar] [CrossRef]

- Irfan, M.; Saad, N.; Ibrahim, R.; Asirvadam, V.S.; Alwadie, A. Analysis of distributed faults in inner and outer race of bearing via Park vector analysis method. Neural Comput. Appl. 2019, 31, 683–691. [Google Scholar] [CrossRef]

- Koteleva, N.; Korolev, N.; Zhukovskiy, Y.; Baranov, G. A soft sensor for measuring the wear of an induction motor bearing by the park’s vector components of current and voltage. Sensors 2021, 21, 7900. [Google Scholar] [CrossRef] [PubMed]

- Zarei, J.; Poshtan, J. An advanced Park’s vectors approach for bearing fault detection. Tribol. Int. 2009, 42, 213–219. [Google Scholar] [CrossRef]

- Gyftakis, K.N.; Marques Cardoso, A.J.; Antonino-Daviu, J.A. introducing the filtered park’s and filtered extended park’s vector approach to detect broken rotor bars in induction motors independently from the rotor slots number. Mech. Syst. Signal Process. 2017, 93, 30–50. [Google Scholar] [CrossRef]

- Messaoudi, M.; Flah, A.; Alotaibi, A.A.; Althobaiti, A.; Sbita, L.; Ziad El-Bayeh, C. Diagnosis and fault detection of rotor bars in squirrel cage induction motors using combined park’s vector and extended park’s vector approaches. Electronics 2022, 11, 380. [Google Scholar] [CrossRef]

- Bouslimani, S.; Drid, S.; Chrifi-Alaoui, L.; Bussy, P.; Ouriagli, M.; Delahoche, L. An extended Park’s vector approach to detect broken bars faults in induction motor. In Proceedings of the 15th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA), Hammamet, Tunisia, 21–23 December 2014. [Google Scholar]

- Zhang, Q.X.; Li, J.; Bin Li, H.; Liu, C. Motor broken-bar fault diagnosis based on park vector and wavelet neural network. In Advanced Materials Research; Trans Tech Publications, Ltd.: Wollerau, Switzerland, 2011; Volume 382, pp. 163–166. [Google Scholar]

- Zarei, J.; Hassani, H.; Wei, Z.; Karimi, H.R. Broken rotor bars detection via Park’s vector approach based on ANFIS. In Proceedings of the IEEE 23rd International Symposium on Industrial Electronics (ISIE), Istanbul, Turkey, 1–4 June 2014. [Google Scholar]

- Guo, Q.; Li, X.; Yu, H.; Hu, W.; Hu, J. Broken rotor bars fault detection in induction motors using park’s vector modulus and FWNN Approach. In International Symposium on Neural Networks; Advances in Neural Networks—ISNN; Springer: Berlin/Heidelberg, Germany, 2008; pp. 809–821. [Google Scholar]

- Estima, J.O.; Freire, N.M.; Cardoso, A.M. Recent advances in fault diagnosis by Park’s vector approach. In Proceedings of the 2013 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Paris, France, 11–12 March 2013. [Google Scholar]

- Cruz, S.M.; Cardoso, A.M. Stator winding fault diagnosis in three-phase synchronous and asynchronous motors, by the extended Park’s vector approach. IEEE Trans. Ind. Appl. 2001, 37, 1227–1233. [Google Scholar] [CrossRef]

- Nejjari, H.; Benbouzid, M.E.H. Monitoring and diagnosis of induction motors electrical faults using a current Park’s vector pattern learning approach. IEEE Trans. Ind. Appl. 2000, 36, 730–735. [Google Scholar] [CrossRef]

- Wei, S.; Zhang, X.; Xu, Y.; Fu, Y.; Ren, Z.; Li, F. Extended Park’s vector method in early inter-turn short circuit fault detection for the stator windings of offshore wind doubly-fed induction generators. IET Gener. Transm. Distrib. 2020, 14, 3905–3912. [Google Scholar] [CrossRef]

- Sharma, A.; Chatterji, S.; Mathew, L. A novel Park’s vector approach for investigation of incipient stator fault using MCSA in three-phase induction motors. In Proceedings of the International Conference on Innovations in Control, Communication and Information Systems (ICICCI), Greater Noida, India, 12–13 August 2017. [Google Scholar]

- Gelman, L.; Petrunin, I. The new multidimensional time/multi-frequency transform for higher order spectral analysis. Multidimens. Syst. Signal Process. 2007, 18, 317–325. [Google Scholar] [CrossRef]

- Gelman, L.M.; Ottley, M. New processing techniques for transient signals with non-linear variation of the instantaneous frequency in time. Mech. Syst. Signal Process. 2006, 20, 1254–1262. [Google Scholar] [CrossRef]

- Gelman, L. Adaptive time–frequency transform for non-stationary signals with nonlinear polynomial frequency variation. Mech. Syst. Signal Process. 2007, 21, 2684–2687. [Google Scholar] [CrossRef]

- Gelman, L.; Gould, J.D. Time–frequency chirp-Wigner transform for signals with any nonlinear polynomial time varying instantaneous frequency. Mech. Syst. Signal Process. 2007, 21, 2980–3002. [Google Scholar] [CrossRef]

- Gao, Z.; Turner, L.; Colby, R.S.; Leprettre, B. Frequency demodulation approach to induction motor speed detection. IEEE Trans. Ind. Appl. 2011, 47, 730–738. [Google Scholar] [CrossRef]

- Thomson, J.; Stewart, H.H. Nonlinear Dynamics and Chaos; John Willey: Hoboken, NJ, USA, 1986. [Google Scholar]

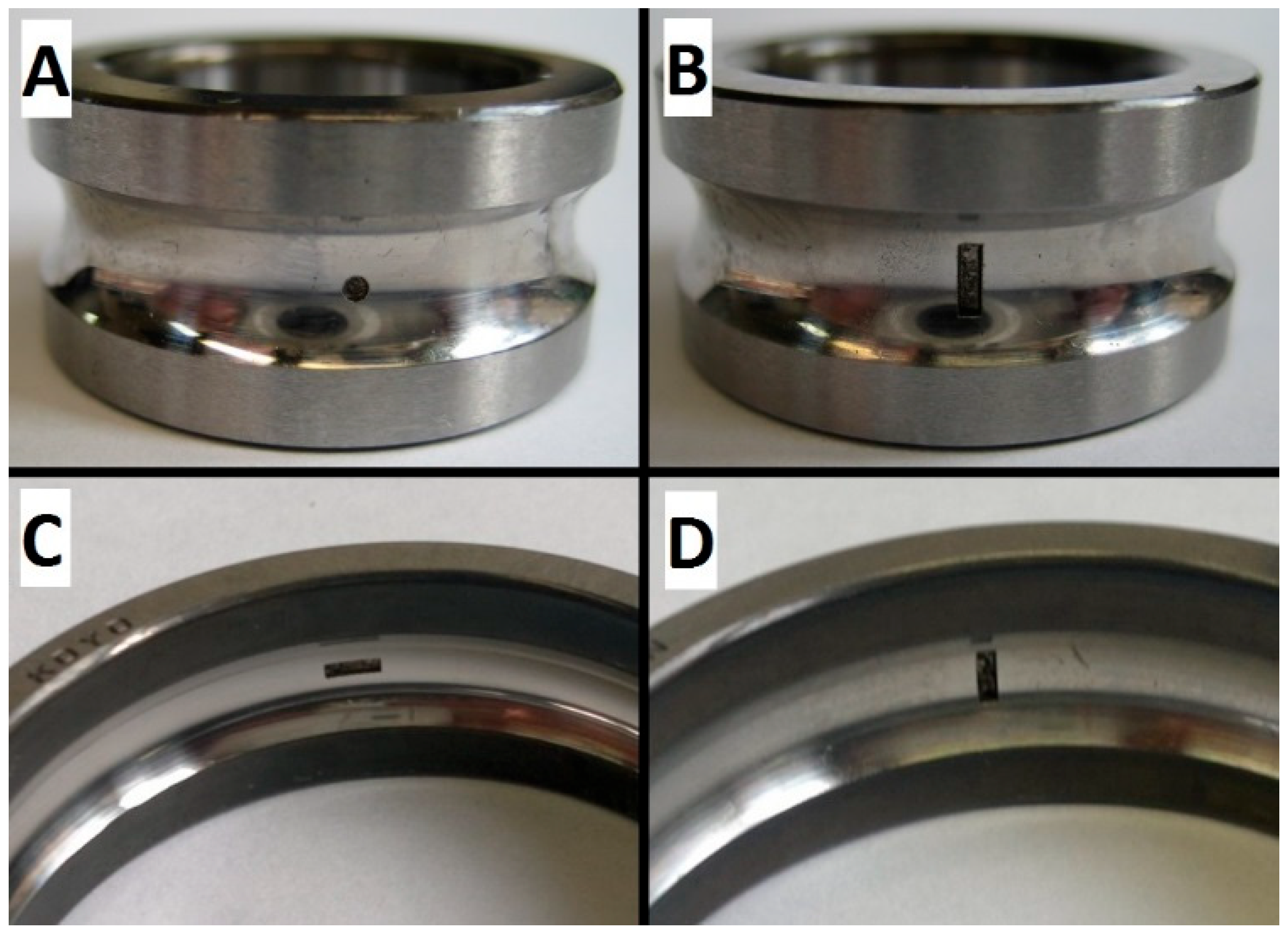

| Bearing | Introduced Damage | Figure |

|---|---|---|

| in1 | inner race pit damage with diameter of 1 mm and depth of 0.5 mm | Figure 3A |

| in2 | inner race scratch damage across the bearing rolling direction with length of 3 mm, width of 1 mm, and depth of 0.7 mm | Figure 3B |

| out1 | outer race scratch damage along the bearing rolling direction with length of 3 mm, width of 1 mm, and depth of 0.5 mm | Figure 3C |

| out2 | outer race scratch damage across the bearing rolling direction with length of 3 mm, width of 1 mm, and depth of 0.5 mm | Figure 3D |

| The FC | The PoCD | |||||

|---|---|---|---|---|---|---|

| The CB | The TOM | FCg | The CB | The TOM | PoCDg | |

| Outer race experiments | 6.90 | 55.49 | 8 | 91% | 100% | 9% |

| Inner race experiments | 0.10 | 52.10 | 521 | 55% | 100% | 45% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ciszewski, T.; Gelman, L.; Ball, A. Novel Higher Order Technologies, Based on Spectral Moduli, for Condition Monitoring of Rotating Machinery. Sensors 2025, 25, 6290. https://doi.org/10.3390/s25206290

Ciszewski T, Gelman L, Ball A. Novel Higher Order Technologies, Based on Spectral Moduli, for Condition Monitoring of Rotating Machinery. Sensors. 2025; 25(20):6290. https://doi.org/10.3390/s25206290

Chicago/Turabian StyleCiszewski, Tomasz, Len Gelman, and Andrew Ball. 2025. "Novel Higher Order Technologies, Based on Spectral Moduli, for Condition Monitoring of Rotating Machinery" Sensors 25, no. 20: 6290. https://doi.org/10.3390/s25206290

APA StyleCiszewski, T., Gelman, L., & Ball, A. (2025). Novel Higher Order Technologies, Based on Spectral Moduli, for Condition Monitoring of Rotating Machinery. Sensors, 25(20), 6290. https://doi.org/10.3390/s25206290