Practical Application of Passive Air-Coupled Ultrasonic Acoustic Sensors for Wheel Crack Detection

Abstract

Highlights

- Passive air-coupled ultrasonic acoustic (UA) sensors were tested in both laboratory and track settings, where a reliable acoustic fingerprint for wheel damage was identified. The decay rate emerged as the primary diagnostic feature, achieving near-perfect ROC performance for severely damaged wheels.

- The acoustic fingerprint showed strong sensitivity to frictional and mass-loss defects such as shattered rim cracks and flange damage, but limited response to non-frictional surface conditions like Rolling Contact Fatigue (RCF), spalls, etc.

- This verified signature from UA sensors offers the “ground truth” needed to develop a practical, in-motion, passive acoustic monitoring system for railroad wheels, shifting the challenge from signal discovery to isolating targeted signals.

- The findings support a hybrid engineering approach for wayside deployment, combining physical acoustic focusing (e.g., waveguides) to improve signal-to-noise ratio with multi-feature machine learning models to enhance classification robustness.

Abstract

1. Introduction and Literature Review

1.1. The Critical Need for Railway Wheel Integrity Monitoring

1.2. State-of-the-Art in Wheel Inspection and Its Limitations

1.3. The Proposed Passive Air-Coupled Ultrasonic Approach

1.4. Research Challenges and Study Contributions

- Development of a robust, automated pipeline for analyzing acoustic bursts.

- Discovery and statistical validation of a new “acoustic fingerprint” primarily based on the decay rate feature.

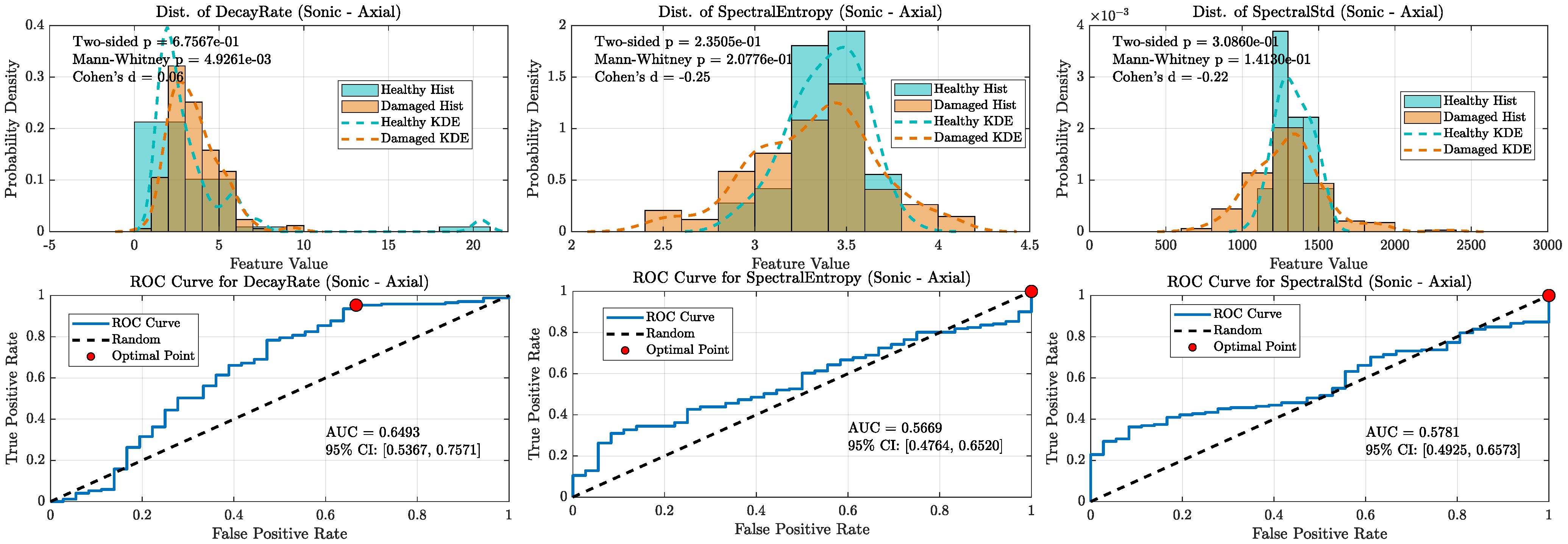

- Comparative analysis of the damage signature in both ultrasonic and sonic frequency bands was conducted to evaluate the feasibility of an alternative low-cost sonic sensor-based system. The results confirmed the hypothesized superiority of ultrasonics for passive wheel crack detection.

- Validation of the acoustic fingerprint on a library of wheels with realistic, service-induced incipient defects.

2. UAE System Setup and Initial Feasibility Tests

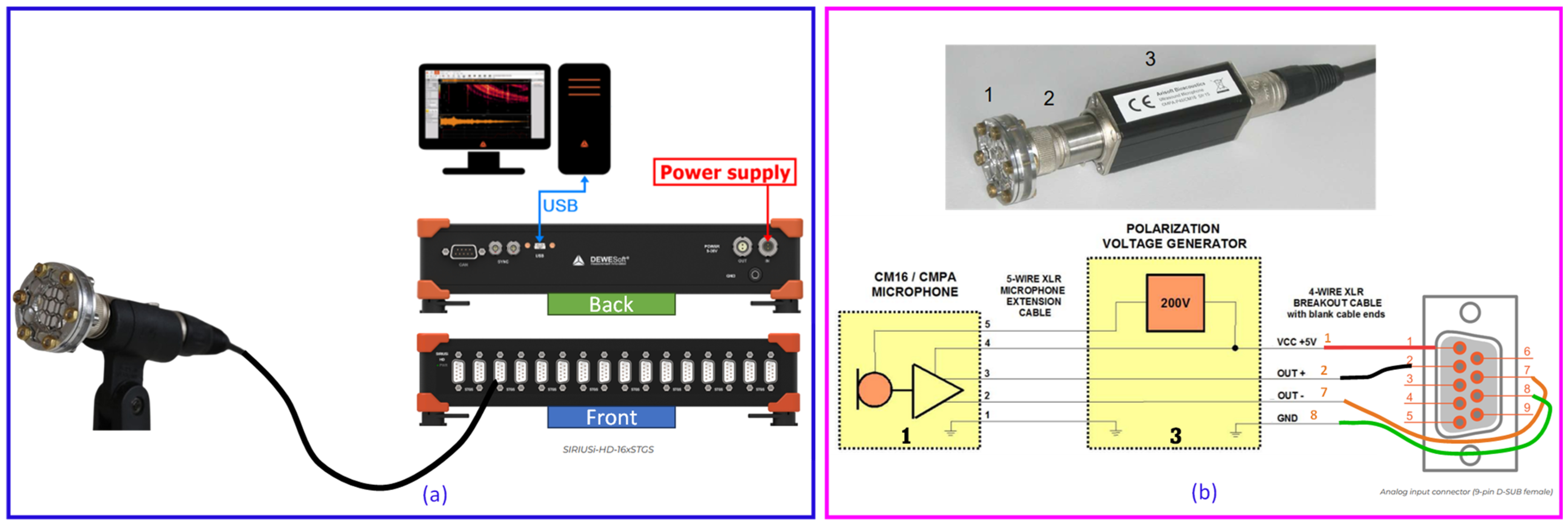

2.1. UAE Data Acquisition System Configuration

2.2. Laboratory Feasibility Validation

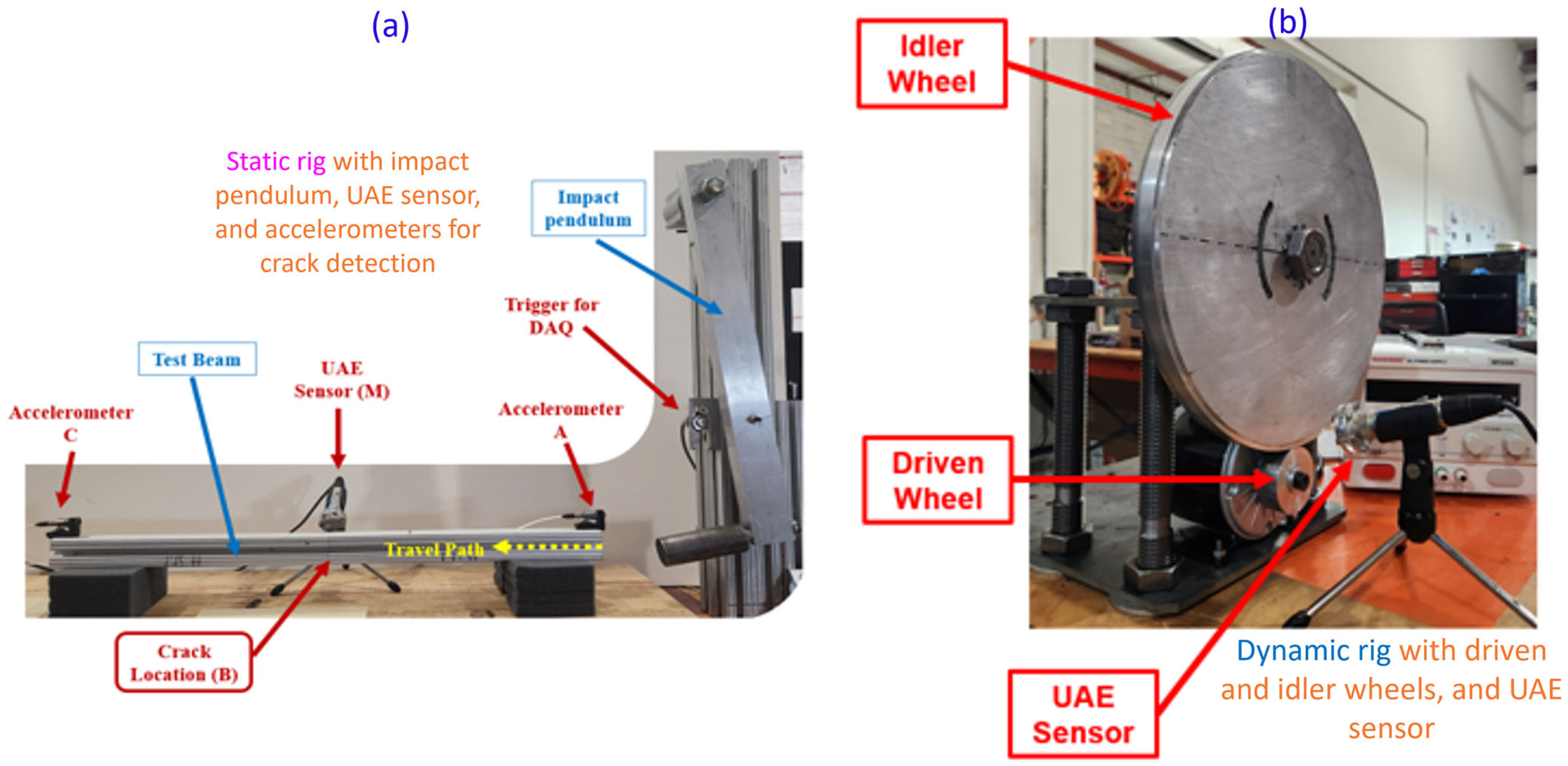

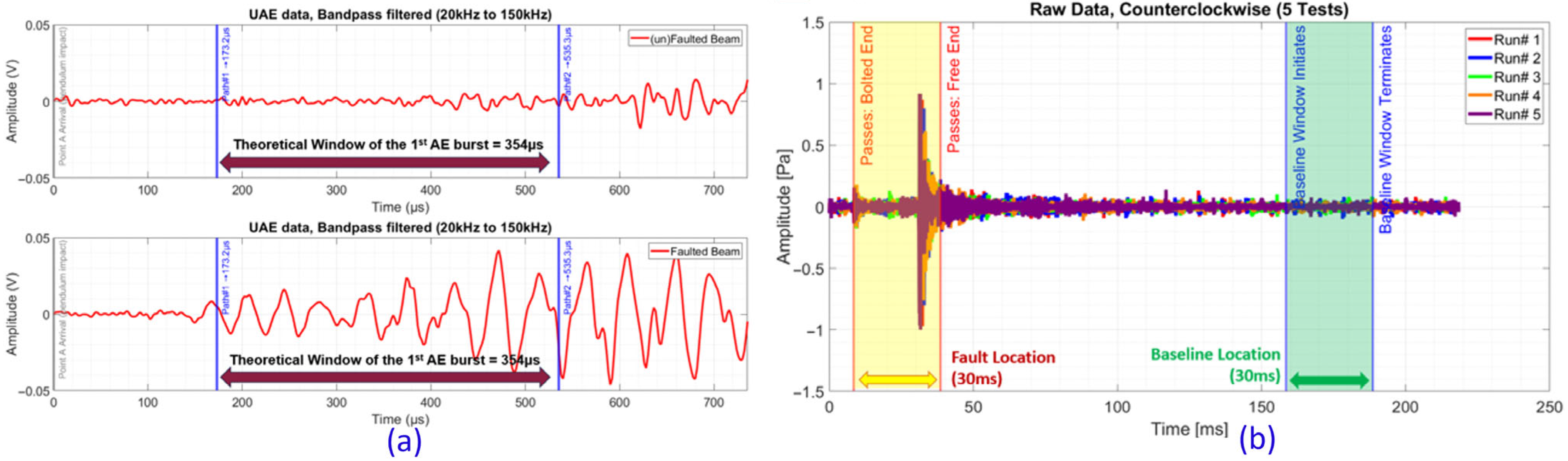

2.2.1. Static Impact and Dynamic Rig Evidence

2.2.2. Key Insight

3. Initial Field Deployment and Wayside Acoustic Challenge

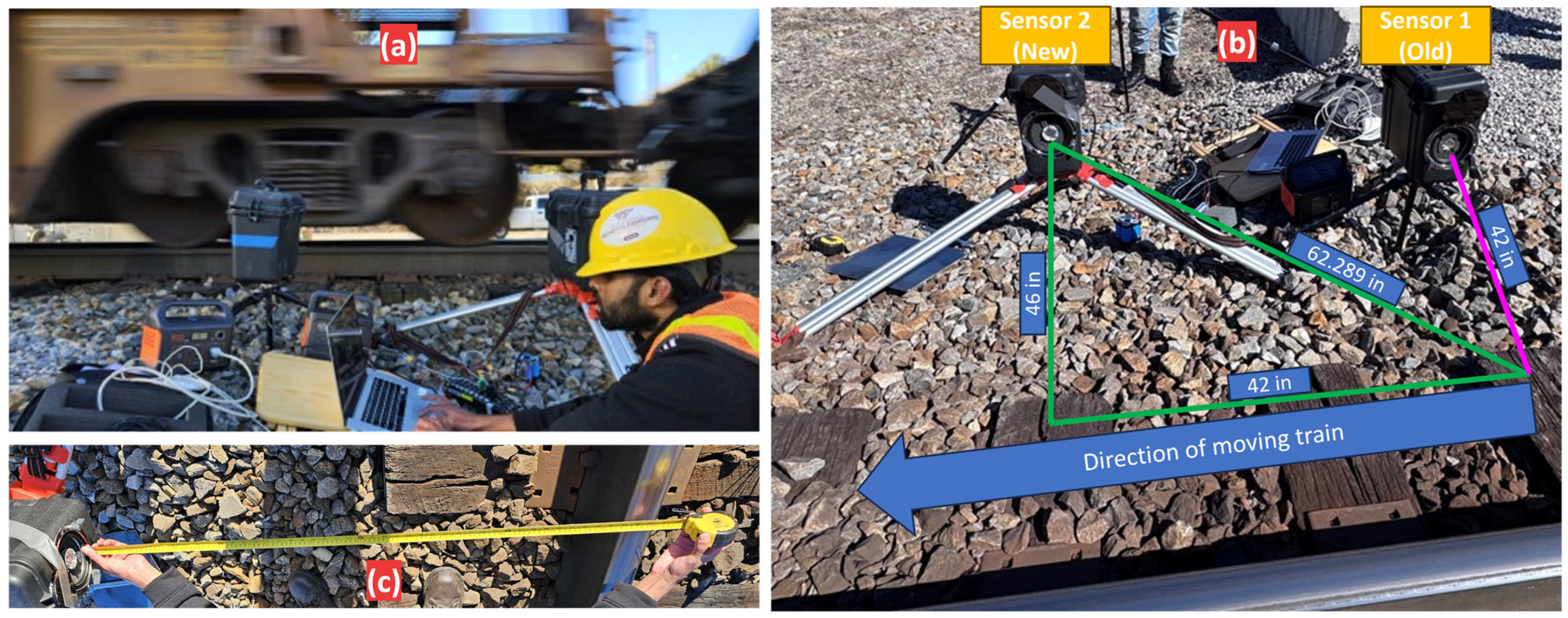

3.1. Trackside Setup

3.2. The Wayside “Wall of Sound” and a New Problem Statement

4. Experimental Framework for Acoustic Signature Characterization

4.1. Experimental Wheelset Libraries and Test Conditions

4.2. Instrumentation and Test Protocol

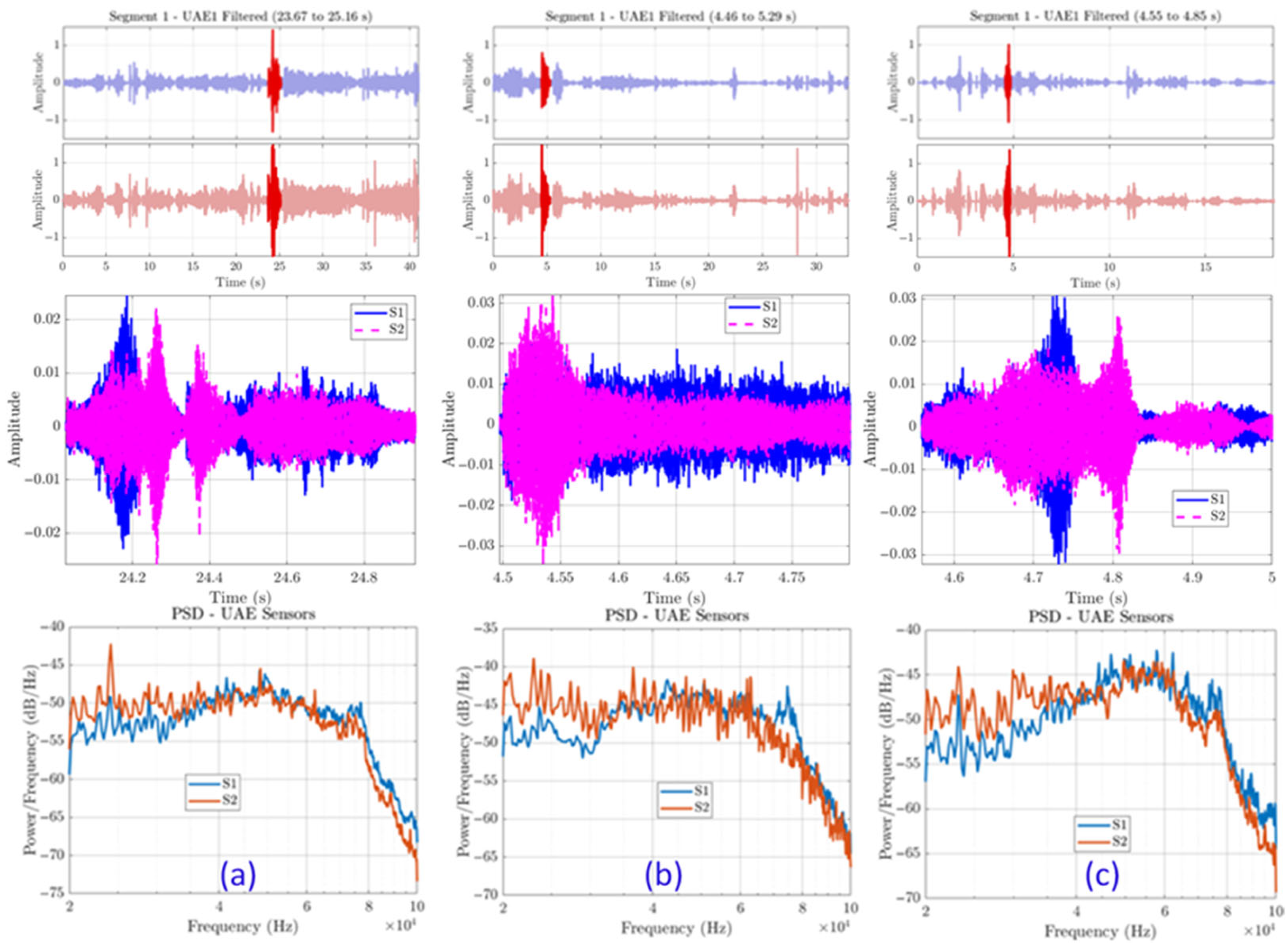

4.3. Automated Signal Processing and Feature Extraction Pipeline

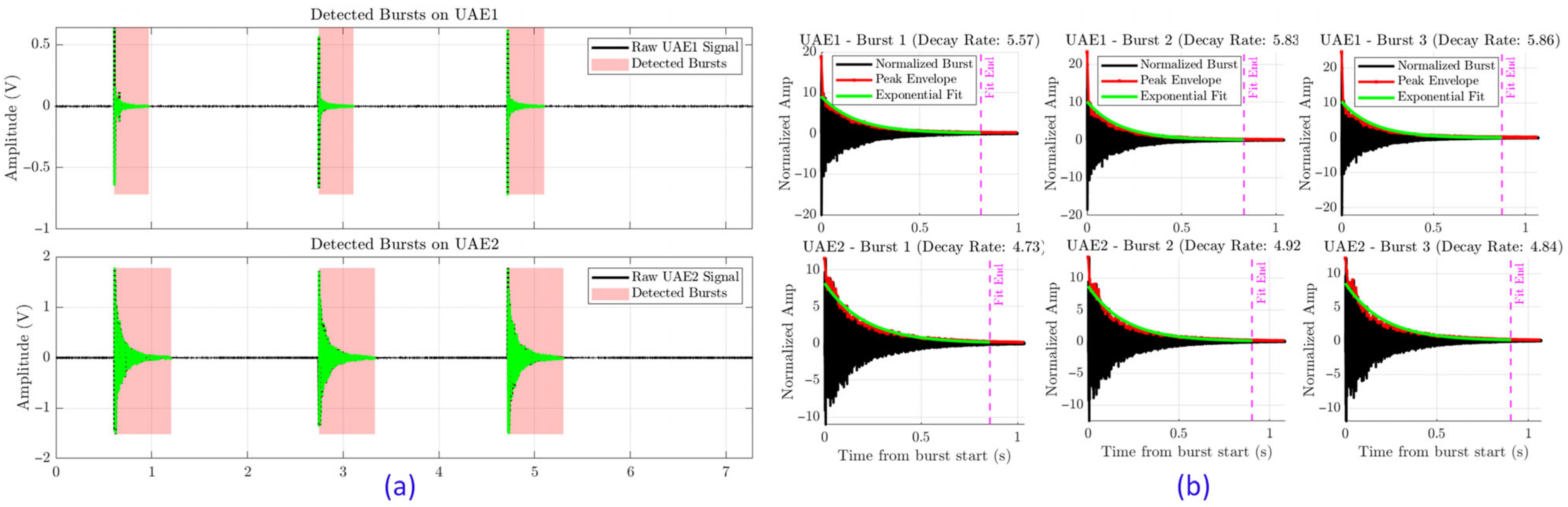

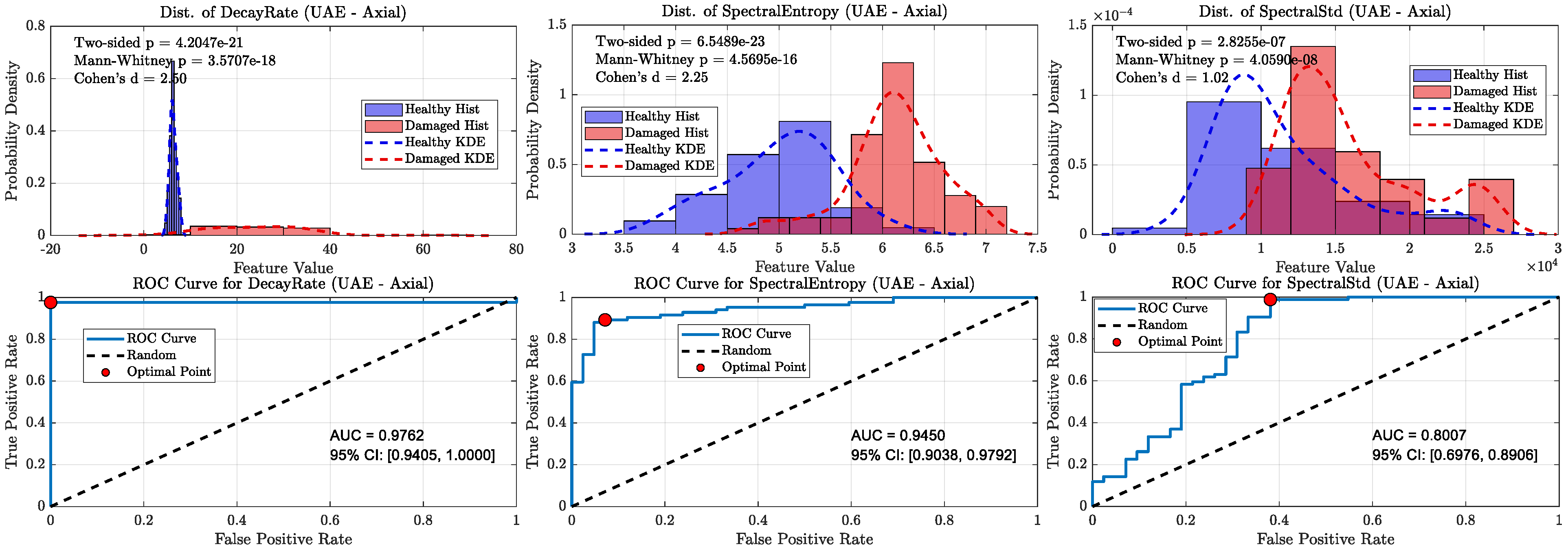

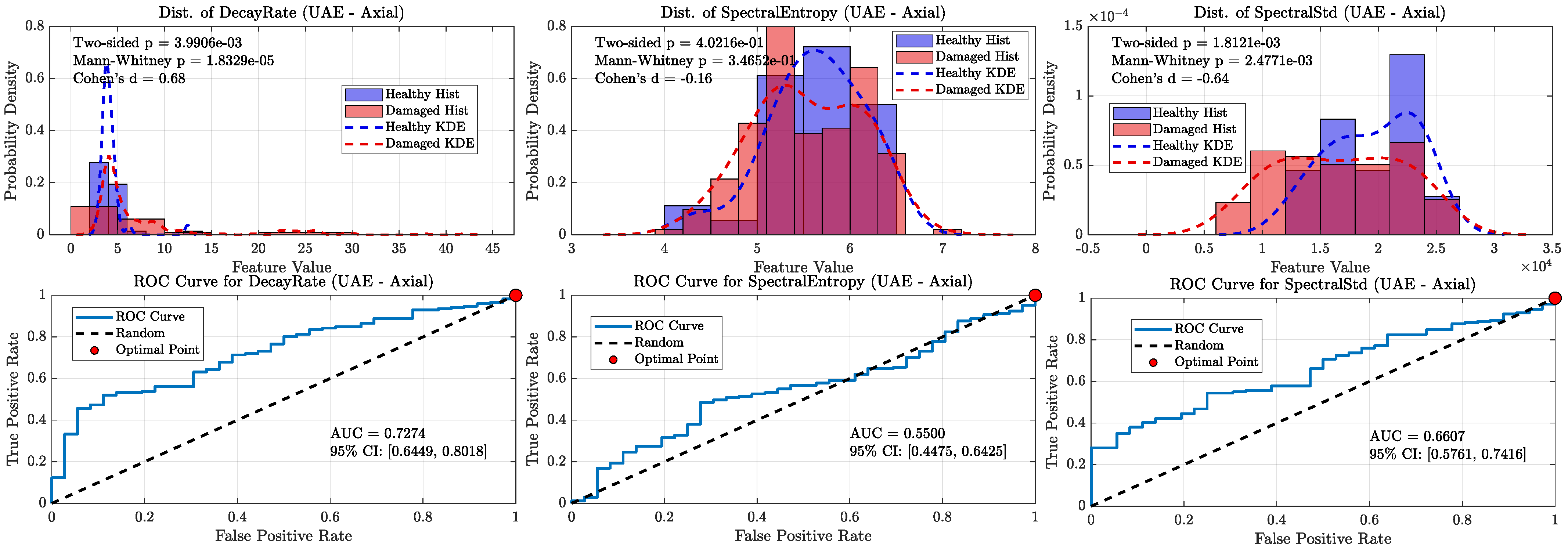

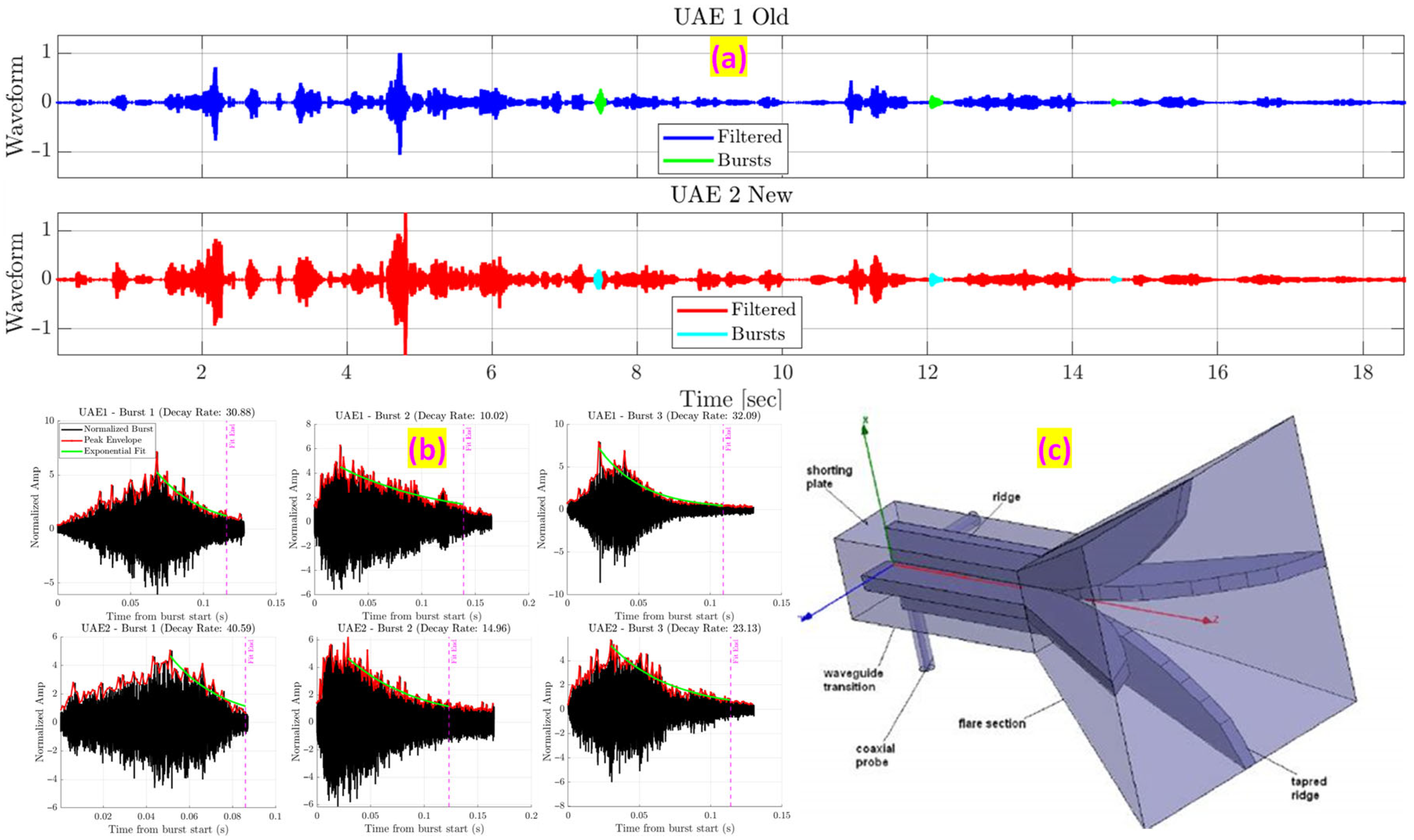

- Decay rate: This feature measures how quickly acoustic energy diminishes. It was determined by first extracting the signal envelope of the burst and then fitting an exponential curve to its decay portion [24] (Figure 11b). The main hypothesis is that internal friction and micro-slip at crack interfaces act as damping mechanisms, resulting in faster dissipation of acoustic energy and a significantly higher decay rate compared to a healthy, resonant wheel.

- RMS Energy: The root-mean-square energy of the burst (in the ultrasonic band 20 to 80 kHz) was calculated to quantify its overall ultrasonic range intensity.

- Spectral Centroid: Calculated as the “center of mass” of the power spectrum, this feature indicates where most of the spectral energy is concentrated [25]. The hypothesis is that damage may change the wheel’s resonant modes, resulting in a shift in the centroid.

- Spectral Entropy: This feature measures the flatness or complexity of the spectrum [26]. A pure tone has low entropy, while white noise has high entropy. It is hypothesized that frictional rubbing at crack faces introduces broadband components, thus altering the spectral entropy.

- Spectral Standard Deviation (Std): Measures the spread of the spectrum around its centroid.

- Band Power Ratio (BPR): The ratio of energy in different frequency bands, specifically .

4.4. Statistical Validation Framework

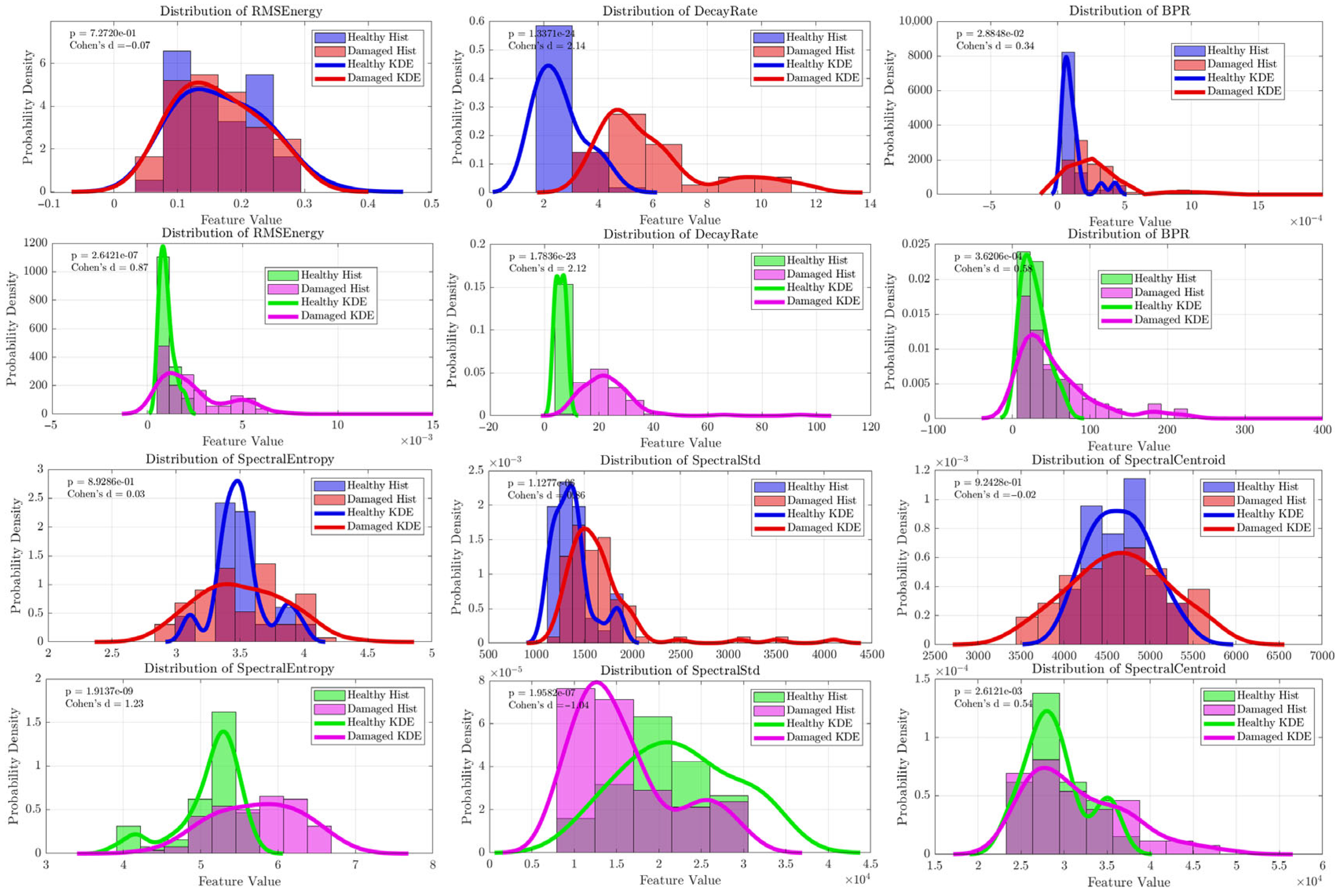

- First, two-sample t-tests were used to assess mean differences, with Levene’s test [27] applied to determine equality of variances. A significance threshold of p < 0.05 was adopted, and Bonferroni correction was applied to account for multiple comparisons. For features exhibiting non-normal distributions, Mann–Whitney U tests [28] were conducted to provide non-parametric confirmation of group differences.

- Beyond significance testing, effect sizes were calculated using Cohen’s d [29], offering a measure of the magnitude of separation. Following established guidelines, d values greater than 0.8 were interpreted as large effects, indicating features with practical diagnostic significance.

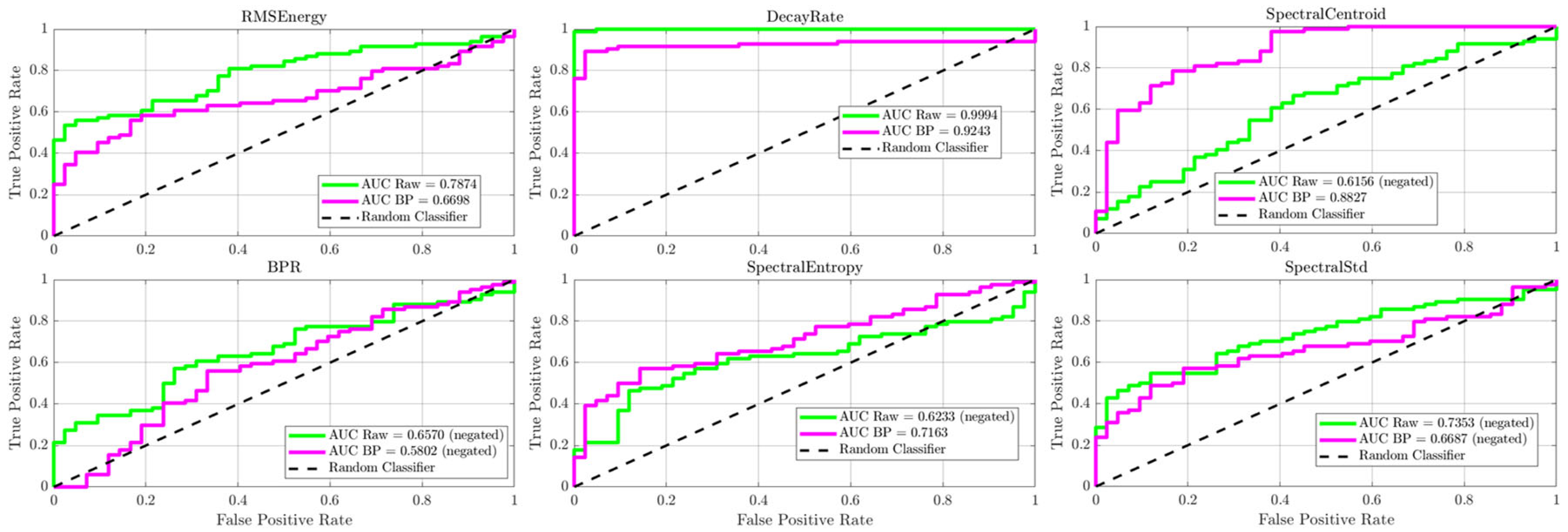

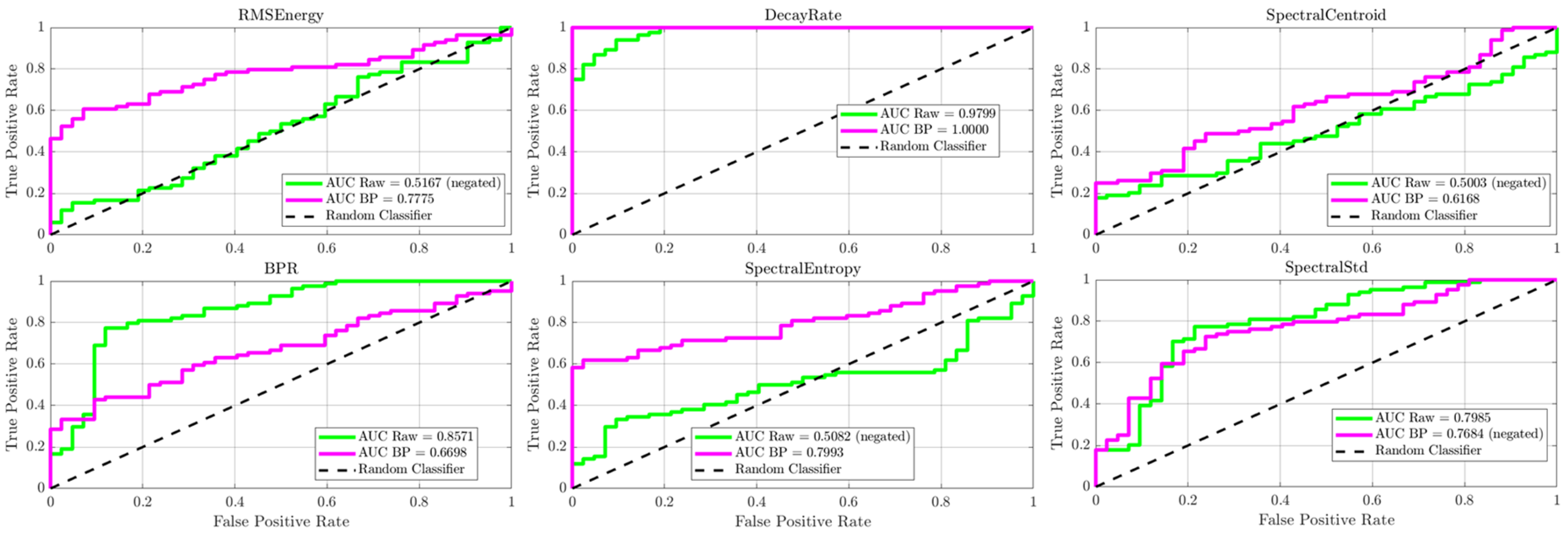

- Finally, Receiver Operating Characteristic (ROC) [30] analysis was employed to evaluate classification performance. The Area Under the Curve (AUC) served as a robust single metric of discriminative ability, where AUC = 1.0 indicates perfect classification and AUC = 0.5 corresponds to random guessing.

- For AUC, 95% confidence intervals were estimated with a class-stratified bootstrap (2000 resamples). First, the score direction was fixed: AUC was computed once with the raw feature and once with its negative; the larger value set the direction and was used for all resamples. In each resample, healthy and damaged cases were drawn within their own groups (with replacement) to keep the class balance, and a new AUC was computed. The 2.5th and 97.5th percentiles of these 2000 AUC values formed the 95% CI. A fixed random seed makes the result repeatable. CIs are omitted if either class has fewer than two samples.

5. Results: Characterization and Validation of a Damage-Induced Acoustic Fingerprint

5.1. Discovery of a Robust Damage Fingerprint with UAE Sensors

5.2. Comparative Analysis of Ultrasonic and Sonic Signatures

5.3. Performance Validation on Service-Induced Incipient Defects

- Rolling Contact Fatigue (RCF)

- Shattered Rims (SRC)

- Spalls (SP)

- Blind Holes (BH)

- Notches (NT)

- Flange Damage (FL)

- High Sensitivity and Clear Separation for Frictional/Geometric Defects: The box plots for wheels with defects known to involve internal frictional interfaces, such as Shattered Rim Crack (SRC, seen in Wheels 4 and 5), or significant geometric changes and mass loss, like Flange Damage (FL, Wheel 9), show a clear and statistically significant shift to higher Decay Rate values. Notably, the interquartile ranges (the boxes) for these defect types show minimal to no overlap with the distributions of the healthy wheels (H), indicating a robust separation (especially for the axial sensor orientation). With the severity-ordered display, the median Decay Rate increases with apparent damage severity, reinforcing the expected damping trend, particularly in the axial sensor. The higher median values and wider data spread for these wheels strongly corroborate the hypothesis that the method is highly sensitive to conditions that either increase frictional damping or fundamentally alter the wheel’s natural modes of vibration.

- Overlapping Distributions for Non-Frictional Defects: Conversely, the box plots for wheels with surface or near-surface defects that do not inherently create frictional interfaces, such as Rolling Contact Fatigue (RCF) and spalls (SP), show distributions that are largely indistinguishable from those of the healthy wheels (Figure 24b). Their median Decay Rates are similar, and their interquartile ranges exhibit significant overlap. This key finding, clearly visualized by the box plots, reveals the current limitations of relying on a single feature for classification. It highlights that under this controlled hammer-impact test configuration, these types of defects do not produce a unique damping signature and will likely require more advanced, multi-feature classification models for reliable detection.

6. Paths Forward: From Fingerprint to In-Motion Deployment

6.1. Considerations for Robustness in Wayside Deployment

6.2. The Remaining Challenge: Isolating Wheel-Specific Signals

6.3. Proposed Solution: Physical Acoustic Focusing with Waveguides and Development of an Automated Diagnostic Model

7. Conclusions and Future Work

7.1. Conclusions

- A robust and statistically validated “acoustic fingerprint” for railroad wheel damage can be identified and confirmed. The most effective and dependable feature within this fingerprint is the acoustic decay rate, which assesses how quickly the signal diminishes. This feature achieved near-perfect classification (AUC > 0.95) between healthy wheels and those with obvious structural damage.

- The diagnostic signature is directly connected to the fundamental physics of the defect. The method’s high sensitivity to defects that involve internal frictional interfaces (for example, shattered rim cracks) and major geometric changes (such as flange damage) supports the core physical hypothesis of the passive UAE method: that frictional cracks and large geometric changes speed up energy dissipation and can be detected through broadband ultrasonic emissions.

- The ultrasonic frequency band (20–80 kHz) provides the highest-quality diagnostic information. Although the main decay rate signature is a broadband phenomenon detectable by sonic sensors, the ultrasonic band offers superior classification confidence and contains richer spectral data needed for a more comprehensive, multi-feature analysis.

7.2. Future Work

- 1.

- Laboratory Validation and Hardware Refinement

- 2.

- Advanced Classification Models

- 3.

- Integrated Field Demonstration

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AAR | Association of American Railroads |

| AE | Acoustic Emission |

| AUC | Area Under the (ROC) Curve |

| BH | Blind Hole(s) (defect label) |

| BPR | Band Power Ratio |

| DAQ | Data Acquisition system |

| EMAT | Electromagnetic Acoustic Transducer |

| EEG | Electroencephalography |

| FL | Flange Damage (defect label) |

| FRA | Federal Railroad Administration |

| H | Healthy (class label) |

| ICP® | Integrated Circuit Piezoelectric (constant-current sensor interface) |

| KDE | Kernel Density Estimation |

| LL | Line Length (burst detection feature) |

| NT | Notch/Notches (defect label) |

| PSD | Power Spectral Density |

| RCF | Rolling Contact Fatigue |

| ROC | Receiver Operating Characteristic |

| RMS | Root-Mean-Square |

| SNR | Signal-to-Noise Ratio |

| SP | Spalls (defect label) |

| SRC | Shattered Rim Crack |

| STD | Standard Deviation |

| STE | Short-Time Energy (burst detection feature) |

| SVM | Support Vector Machine |

| UAE | Ultrasonic Acoustic Emission |

| UT | Ultrasonic Testing |

| VSR | Vertical Split Rim |

| CI | Confidence Interval |

Appendix A. Preliminary Design Calculations for Cylindrical Waveguide

Appendix A.1. Governing Relations

- D = 44 mm: sensor diaphragm/throat diameter (fixed),

- : diaphragm-to-mouth effective length,

- = : CM24 polar response (±20° total aperture),

- c ≈ 343 m/s

Appendix A.2. Fixed Inputs

- Sensor throat/mouth: D = 44 mm

- Stand-off: R = 1.27 m

- Sensor polar: ±20° (total 40°).

- Frequency range of interest: 20-80 kHz.

- Train speed range (initial validation): 20-40 mph (8.9–17.9 m/s).

Appendix A.3. Selection Chart

| f (kHz) | Used (deg at 20/40/80 kHz) | Footprint @ R = 1.27 m (cm) | T @ 20 mph (ms) | T @ 30 mph (ms) | T @ 40 mph (ms) | ||

|---|---|---|---|---|---|---|---|

| 20 | 60 | 20-80 | 20 | ~92–95 | 185–190 | 123–127 | 92–95 |

| 12 | 105 | 20–80 | 12/8.7/4.3 | 53/39/19 | 106/78/38 | 71/52/25 | 53/39/19 |

| 10 | 125 | 20–80 | 10/8.7/4.3 | 45/39/19 | 91/78/38 | 61/52/25 | 45/39/19 |

| 8 | 157 | 20–80 | 8/8.7/4.3 | 36/39/19 | 73/78/38 | 49/52/25 | 36/39/19 |

Appendix A.4. Recommended Geometry

- Narrows acceptance compared to the bare sensor polar (improving SNR),

- Preserves sufficient time window for decay-rate analysis,

- Is compact, rugged, and practical for trackside deployment.

References

- Anders, E. Rolling Contact Fatigue of Railway Wheels Towards Tread Life Prediction through Numerical Modelling Considering Material Imperfections, Probabilistic Loading and Operational Data; Chalmers University of Technology: Goteborg, Sweden, 2000. [Google Scholar]

- Wheel Failure Investigation Program: Phase I|FRA n.d. Available online: https://railroads.dot.gov/elibrary/wheel-failure-investigation-program-phase-i (accessed on 3 September 2025).

- Wheel Failure Investigation Program: Phase 2|FRA n.d. Available online: https://railroads.dot.gov/elibrary/wheel-failure-investigation-program-phase-2 (accessed on 3 September 2025).

- Rolling Contact Fatigue: A Comprehensive Review|FRA n.d. Available online: https://railroads.dot.gov/elibrary/rolling-contact-fatigue-comprehensive-review (accessed on 1 September 2025).

- Tawfik, M.N.; Padzi, M.M.; Abdullah, S.; Harmanto, D.; Firdaws, M.N.; Hapaz, H. A Review of the Rolling Contact Fatigue of Rail Wheels Under Various Stresses. J. Fail. Anal. Prev. 2022, 23, 16–29. [Google Scholar] [CrossRef]

- Cong, T.; Han, J.; Hong, Y.; Domblesky, J.P.; Liu, X. Shattered rim and shelling of high-speed railroad wheels in the very-high-cycle fatigue regime under rolling contact loading. Eng. Fail. Anal. 2019, 97, 556–567. [Google Scholar] [CrossRef]

- Broken Rims in Railroad Wheels|FRA n.d. Available online: https://railroads.dot.gov/elibrary/broken-rims-railroad-wheels (accessed on 3 September 2025).

- Bert, S.; Keller, C.; Parsons, O.; Randall, M.; Poslusny, J.; Lahare, A.; Salunke, M.; Searcy, S.; Findley, D. Comprehensive Cost of Rail Incidents in North Carolina; United States Department of Transportation: Washington, DC, USA, 2020. Available online: https://rosap.ntl.bts.gov/view/dot/60784 (accessed on 3 September 2025).

- Berger, H. Nondestructive Testing of Railroad Rail. Transp. Res. Rec. 1980, 744, 22–26. [Google Scholar]

- Poudel, A. "EMAT NDE for In-Motion Wheel Defect Detection," MxV Rail Technology Digest, no. TD22-021, Aug. 1. 2022. [Online]. Available online: https://www.mxvrail.com/technology-digests/emat-nde-for-in-motion-wheel-defect-detection (accessed on 3 September 2025).

- Datta, D.; di Scalea, F.L. High-Speed Inspection of Rails by Passive Ultrasonic Monitoring. J. Nondestruct. Eval. Diagn. Progn. Eng. Syst. 2022, 5, 041007. [Google Scholar] [CrossRef]

- Kenderian, S.; Djordjevic, B.B.; Cerniglia, D.; Garcia, G. Dynamic railroad inspection using the laser-air hybrid ultra-sonic technique. Insight-Non-Destructive Test. Cond. Monit. 2006, 48, 336–341. [Google Scholar] [CrossRef]

- Siddiqui, A.J.; Mammeri, A.; Liu, Y. Automated Machine Vision Inspection Systems in Railways – Literature Review; National Research Council Canada; Transport Canada: Ottawa, Canada, 2021; Available online: https://publications.gc.ca/collections/collection_2025/cnrc-nrc/NR16-483-2021-eng.pdf (accessed on 3 September 2025).

- Olivier, B.; Guo, F.; Qian, Y.; Connolly, D.P. A Review of Computer Vision for Railways. IEEE Trans. Intell. Transp. Syst. 2025, 26, 11034–11065. [Google Scholar] [CrossRef]

- Xing, Z.; Zhang, Z.; Yao, X.; Qin, Y.; Jia, L. Rail wheel tread defect detection using improved YOLOv3. Measurement 2022, 203, 111959. [Google Scholar] [CrossRef]

- Fu, W.; He, Q.; Feng, Q.; Li, J.; Zheng, F.; Zhang, B. Recent Advances in Wayside Railway Wheel Flat Detection Techniques: A Review. Sensors 2023, 23, 3916. [Google Scholar] [CrossRef] [PubMed]

- Amini, A.; Entezami, M.; Huang, Z.; Rowshandel, H.; Papaelias, M. Wayside detection of faults in railroad axle bearings using time spectral kurtosis analysis on high-frequency acoustic emission signals. Adv. Mech. Eng. 2016, 8, 1687814016676000. [Google Scholar] [CrossRef]

- Barat, V.; Marchenkov, A.; Ushanov, S.; Bardakov, V.; Elizarov, S. Investigation of Acoustic Emission of Cracks in Rails under Loading Close to Operational. Appl. Sci. 2022, 12, 11670. [Google Scholar] [CrossRef]

- Thakkar, N.A.; Steel, J.A.; Reuben, R.L. A laboratory study of rail-wheel interaction monitoring using acoustic emission: Effect of rolling conditions with and without lateral rattling. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2012, 227, 161–175. [Google Scholar] [CrossRef]

- Shaikh, M.Z.; Ahmed, Z.; Chowdhry, B.S.; Baro, E.N.; Hussain, T.; Uqaili, M.A. State-of-the-Art Wayside Condition Monitoring Systems for Railway Wheels: A Comprehensive Review. IEEE Access 2023, 11, 13257–13279. [Google Scholar] [CrossRef]

- Carboni, M.; Zamorano, M. On monitoring fretting fatigue damage in solid railroad axles by acoustic emission with unsupervised machine learning and comparison to non-destructive testing techniques. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2023, 238, 256–267. [Google Scholar] [CrossRef]

- Han, D.; Qi, H.; Hou, D.; Wang, S.; Kong, J.; Xu, X.; Wang, C. Dynamic detection mechanism model of acoustic emission for high-speed train axle box bearings with local defects. Mech. Syst. Signal Process. 2025, 235, 112943. [Google Scholar] [CrossRef]

- Piñal-Moctezuma, F.; Delgado-Prieto, M.; Romeral-Martínez, L. An acoustic emission activity detection method based on short-term waveform features: Application to metallic components under uniaxial tensile test. Mech. Syst. Signal Process. 2020, 142, 106753. [Google Scholar] [CrossRef]

- Karjalainen, M.; Ansalo, P.; Mäkivirta, A.; Peltonen, T.; Välimäki, V. Estimation of Modal Decay Parameters from Noisy Response Measurements. J. Audio Eng. Soc. 2002, 50, 867–878. [Google Scholar]

- Oo, A.T.; Mon, A.; Tun, M.Z. Induction Motor Fault Detection and Classification System Using Proposed Fusion Features and Machine Learning Techniques. In Proceedings of the 2024 26th International Conference on Digital Signal Processing and Its Applications, DSPA, Moscow, Russia, 27–29 March 2024. [Google Scholar] [CrossRef]

- Stefaniak, P.; Koperska, W.; Skoczylas, A.; Stachowiak, M. Application of Spectral Entropy in Haul Truck Joint Damage Detection. Sensors 2022, 22, 7358. [Google Scholar] [CrossRef] [PubMed]

- 1.3.5.10. Levene Test for Equality of Variances n.d. Available online: https://www.itl.nist.gov/div898/handbook/eda/section3/eda35a.htm (accessed on 23 August 2025).

- McKnight, P.E.; Najab, J. Mann-Whitney U Test. In The Corsini Encyclopedia of Psychology; Wiley: Hoboken, NJ, USA, 2010. [Google Scholar] [CrossRef]

- Cohen, J. Statistical Power Analysis for the Behavioral Sciences, 2nd ed.; Routledge: London, UK, 2013. [Google Scholar]

- Çorbacıoğlu, Ş.K.; Aksel, G. Receiver operating characteristic curve analysis in diagnostic accuracy studies: A guide to interpreting the area under the curve value. Turk. J. Emerg. Med. 2023, 23, 195–198. [Google Scholar] [CrossRef] [PubMed]

- Kinsler, L.E.; Frey, A.R.; Coppens, A.B.; Sanders, J.V. Fundamentals of Acoustics, 4th ed.; Wiley: New York, NY, USA, 2000. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shaju, A.; Kumar, N.; Mantovani, G.; Southward, S.; Ahmadian, M. Practical Application of Passive Air-Coupled Ultrasonic Acoustic Sensors for Wheel Crack Detection. Sensors 2025, 25, 6126. https://doi.org/10.3390/s25196126

Shaju A, Kumar N, Mantovani G, Southward S, Ahmadian M. Practical Application of Passive Air-Coupled Ultrasonic Acoustic Sensors for Wheel Crack Detection. Sensors. 2025; 25(19):6126. https://doi.org/10.3390/s25196126

Chicago/Turabian StyleShaju, Aashish, Nikhil Kumar, Giovanni Mantovani, Steve Southward, and Mehdi Ahmadian. 2025. "Practical Application of Passive Air-Coupled Ultrasonic Acoustic Sensors for Wheel Crack Detection" Sensors 25, no. 19: 6126. https://doi.org/10.3390/s25196126

APA StyleShaju, A., Kumar, N., Mantovani, G., Southward, S., & Ahmadian, M. (2025). Practical Application of Passive Air-Coupled Ultrasonic Acoustic Sensors for Wheel Crack Detection. Sensors, 25(19), 6126. https://doi.org/10.3390/s25196126