Mathematical Model of Contact Resistance for Brush and Slip Ring System Considering the Impact of Marine Environment

Abstract

1. Introduction

2. Materials and Methods

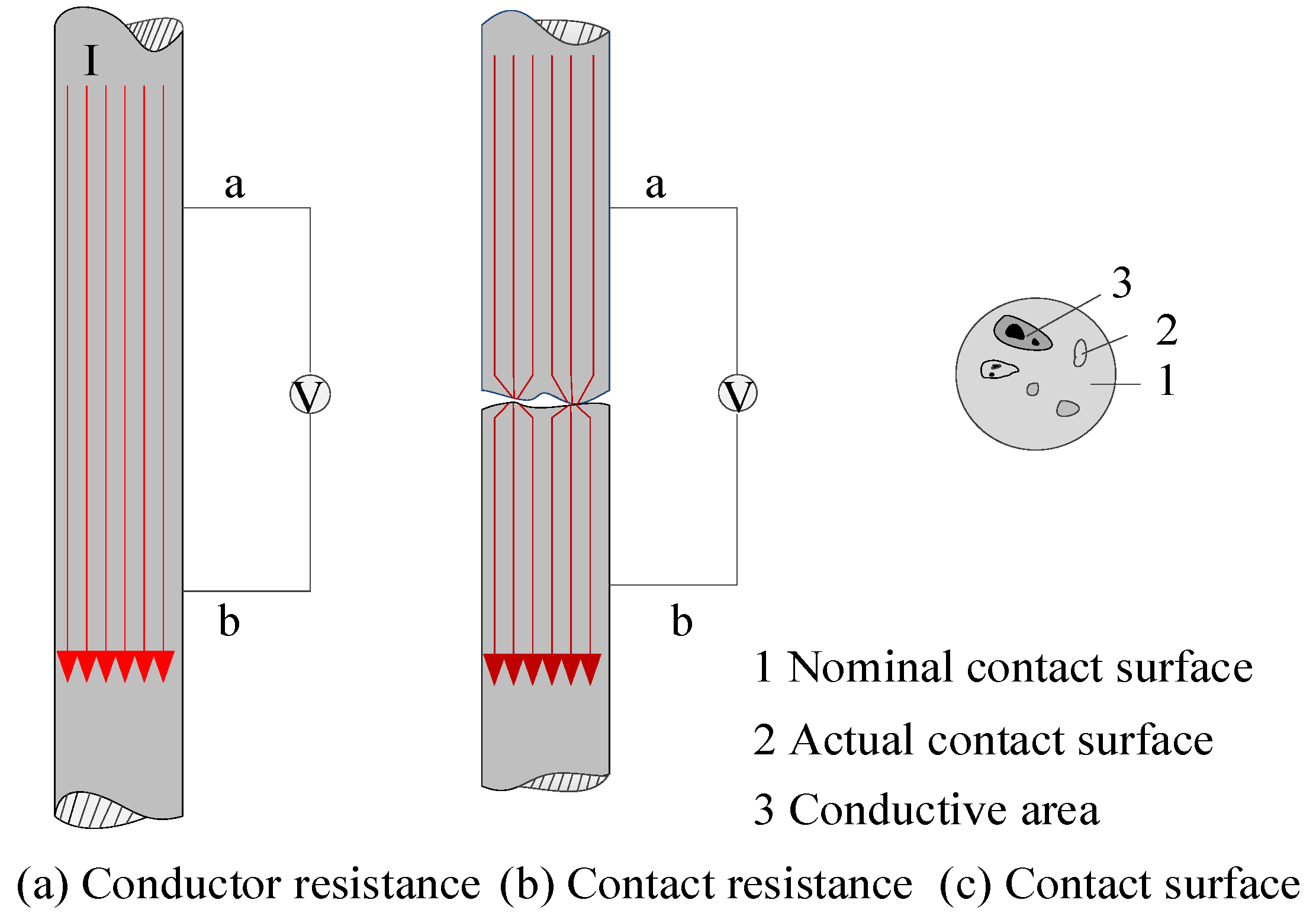

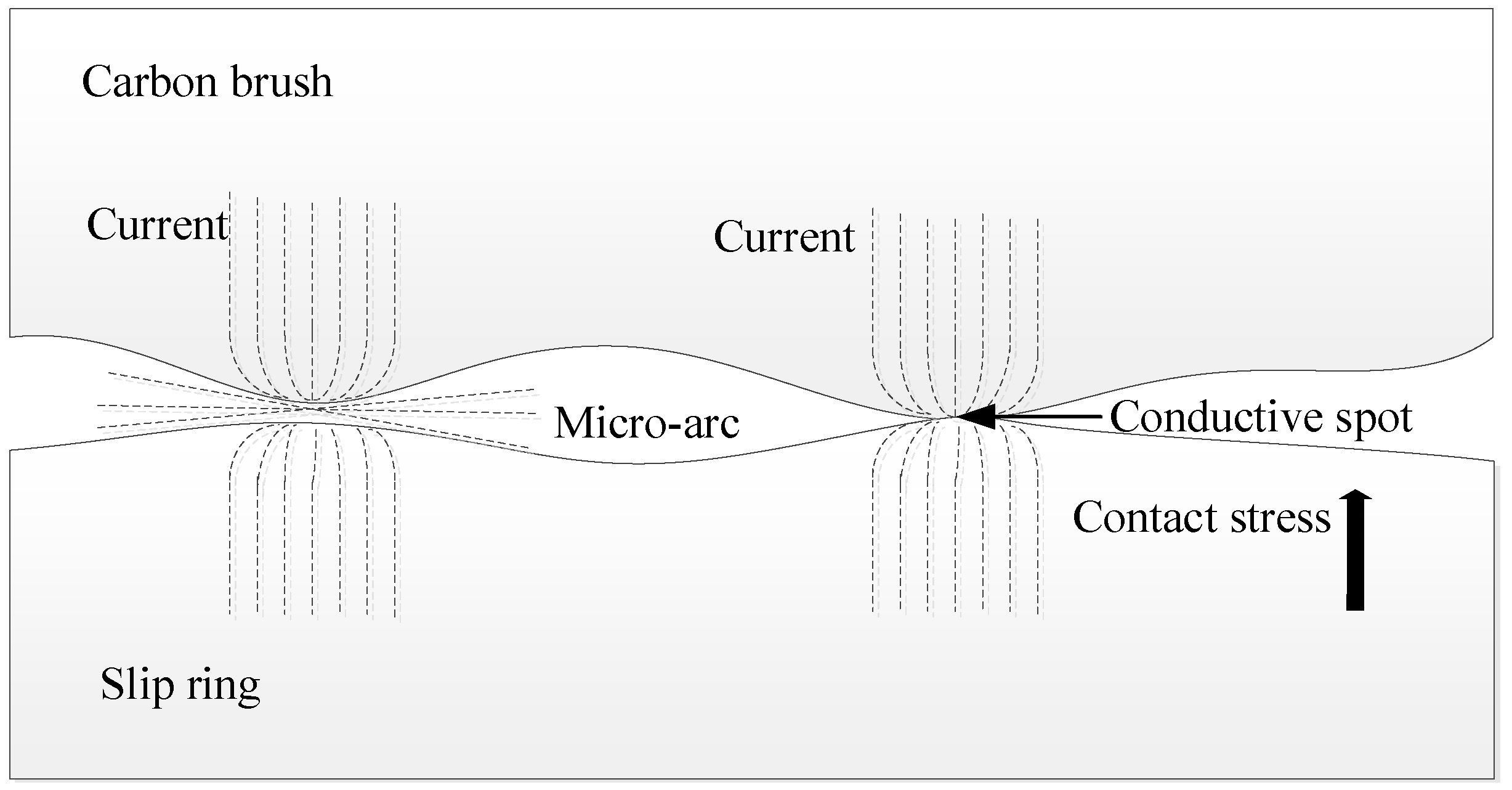

2.1. Contact Resistance

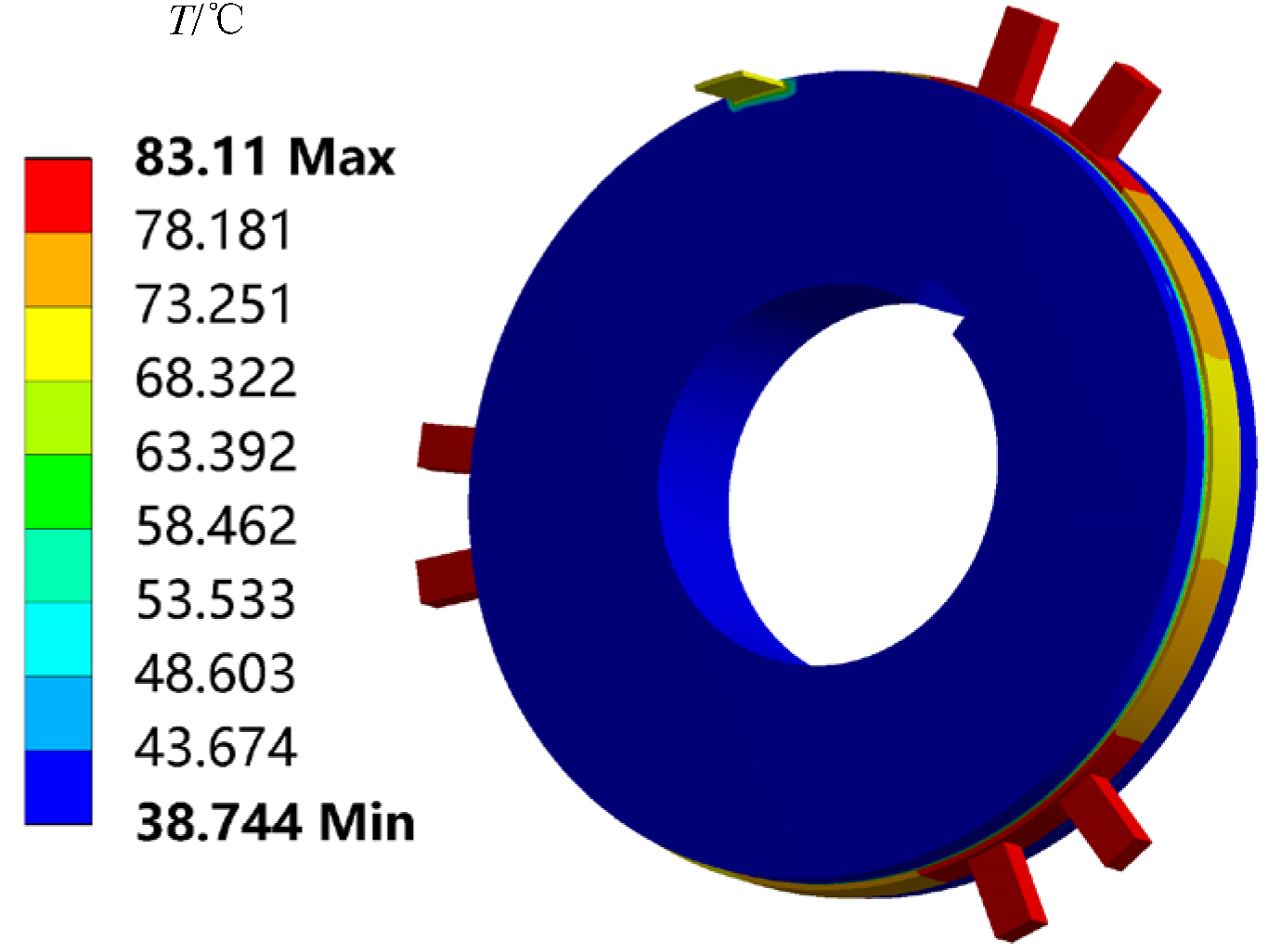

2.2. Contact Resistance Modeling

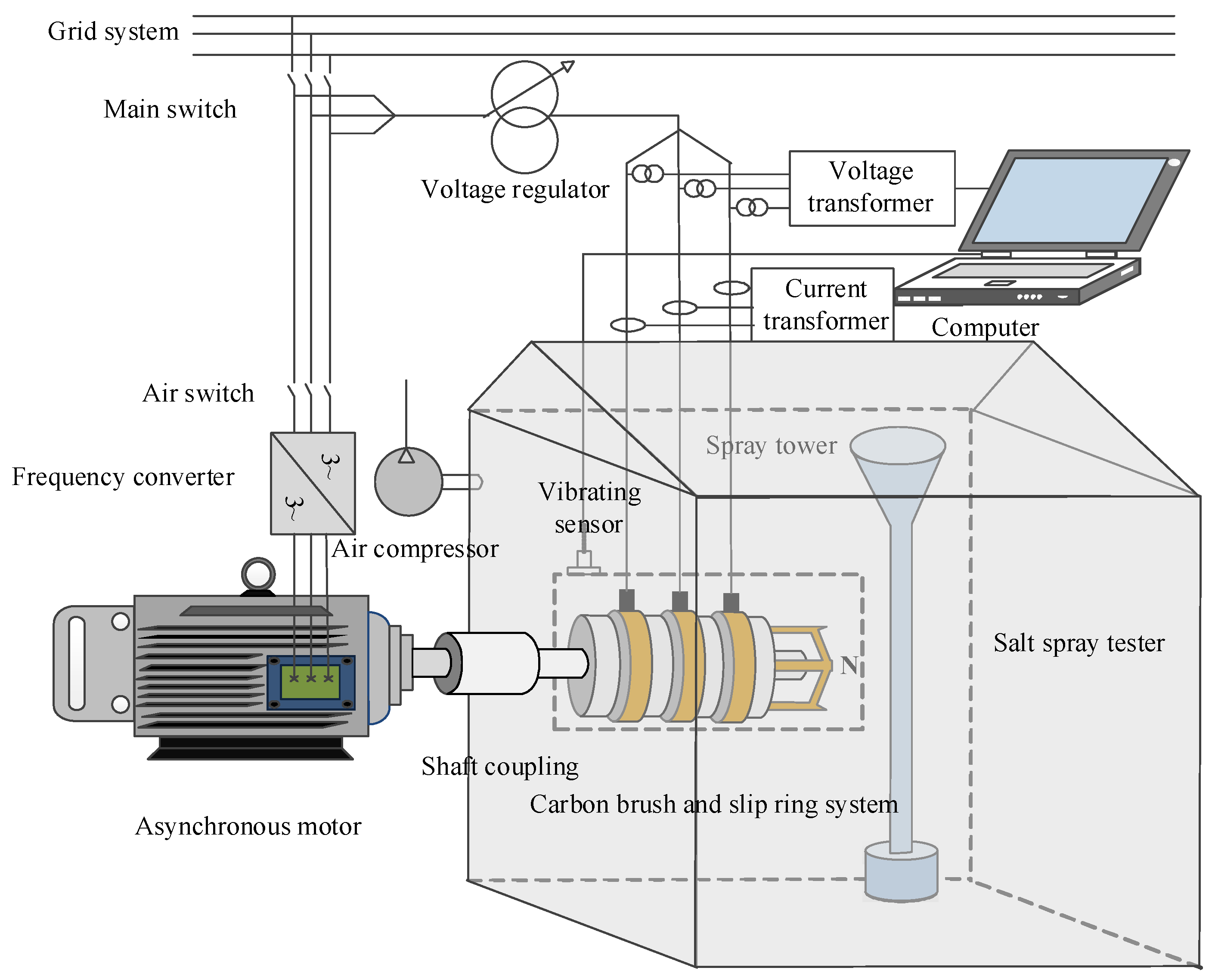

2.3. Experimental Device

2.4. Experimental Methods

3. Results and Discussion

3.1. Influence of Salt Spray Concentration on Contact Resistance

- (1)

- Salt spray deposition corrodes the oxide film on the contact surface, replacing it with salt compounds such as copper chloride [24], which reduces conductivity and increases contact resistance.

- (2)

- Salt spray forms sodium chloride particles that intensify mechanical wear, deepen surface scratches, reduce the actual contact area, decrease the number of conductive spots, and ultimately increase contact resistance.

- (3)

- The accumulation of salt spray accelerates carbon brush wear; the combined presence of dust and oxide film further reduces actual contact and the number of conductive spots, thereby raising contact resistance.

- (4)

- As mechanical wear intensifies, the temperature field of the carbon brush–slip ring system rises, promoting oxide film formation and increasing contact resistance.

- (5)

- As temperature rises, the hardness of the carbon brush and slip ring decreases, which can lead to an increase in the actual contact area and number of conductive spots, thereby slightly reducing contact resistance under certain conditions.

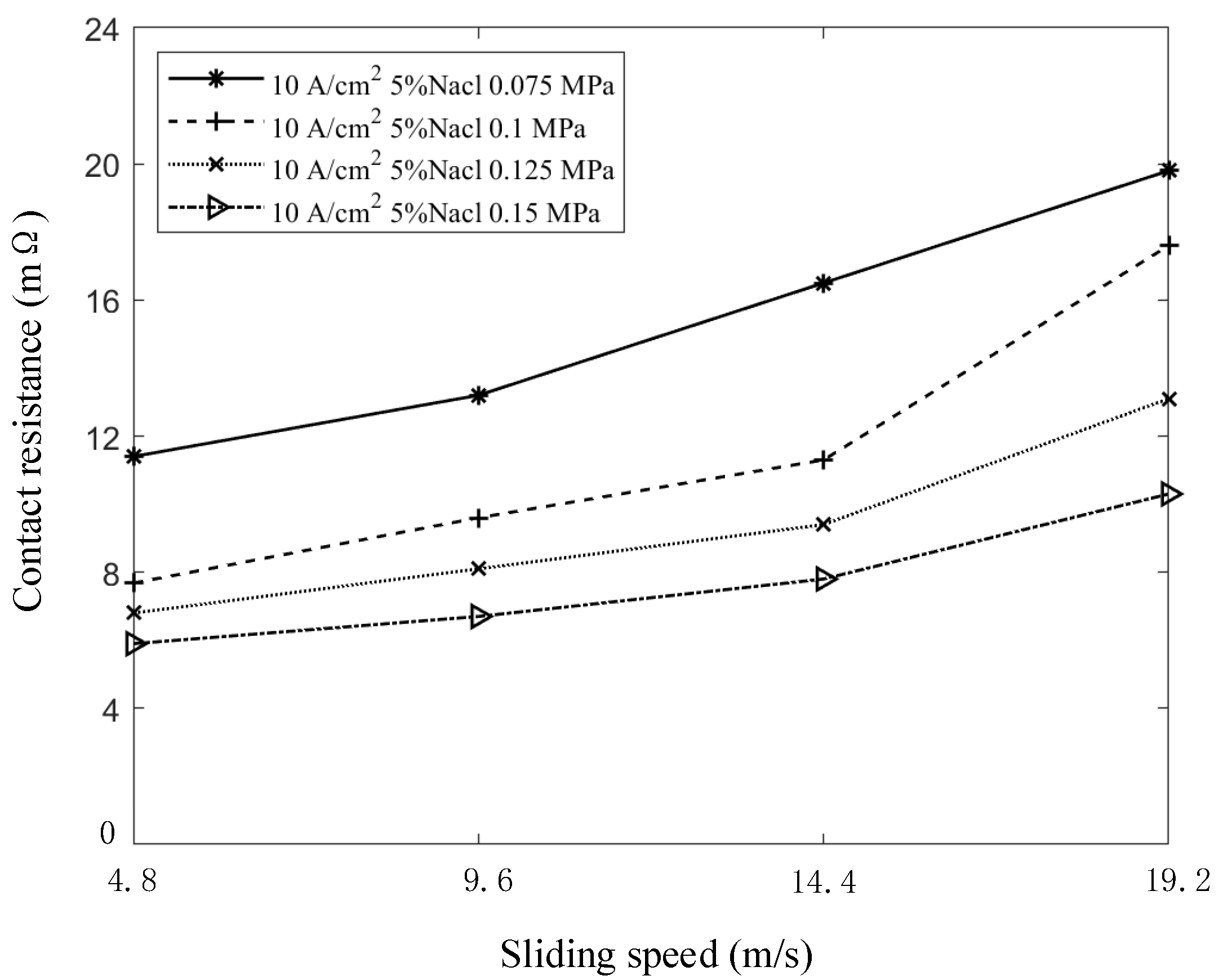

3.2. Influence of Sliding Speed on Contact Resistance

- (1)

- Speed influences the dynamic behavior of conductive spots on the contact surface. As speed increases, abrasive wear intensifies, leading to the accumulation of dust and oxide films that degrade the conductivity of the contact spots [25], thereby increasing contact resistance.

- (2)

- Higher speeds generate more heat due to increased mechanical friction between the brush and slip ring. Elevated temperatures reduce material hardness, which allows some nominal contact areas to become actual contact areas, increasing the number of conductive spots and consequently reducing contact resistance.

- (3)

- Changes in speed can also cause the oxide film to detach from the contact surface. The reduction in film resistance as a result leads to a decrease in overall contact resistance.

3.3. Influence of Contact Current on Contact Resistance

- (1)

- With increasing current, the occurrence of micro-arcing leads to more pitting on the surface, reducing the actual contact area between the brush and slip ring, which results in increased contact resistance.

- (2)

- As current increases, the temperature of the brush and slip ring system rises, leading to a decrease in material hardness. This softening enhances the actual contact area and increases the number of conductive spots, thereby reducing contact resistance [26].

- (3)

- When the current increases, the temperature increases, which also promotes the formation of oxide films on the contact surface, which in turn increases contact resistance.

- (4)

- As the current increases, the higher temperature strengthens the adhesion of dust and oxide films, further reducing the effective contact area and increasing contact resistance.

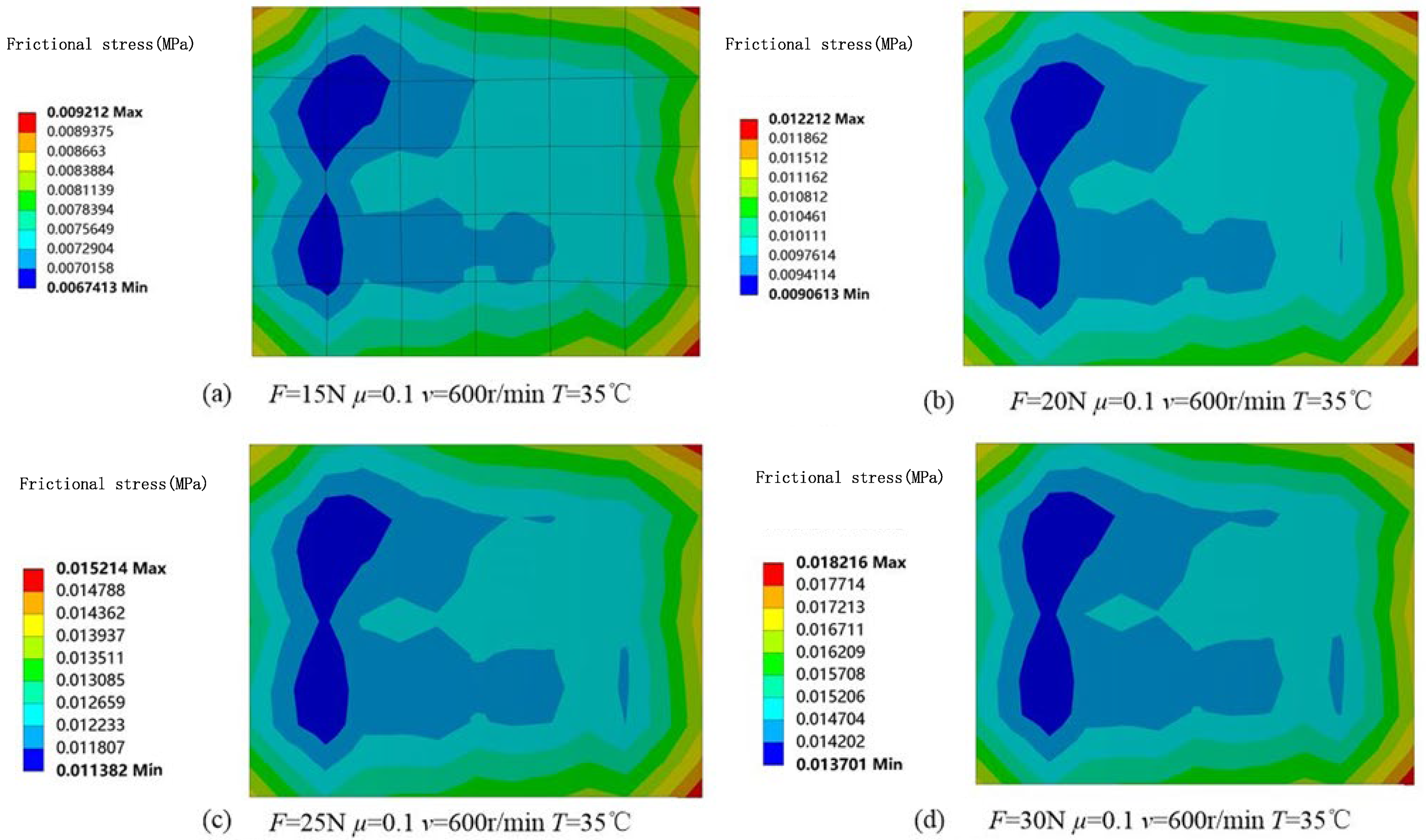

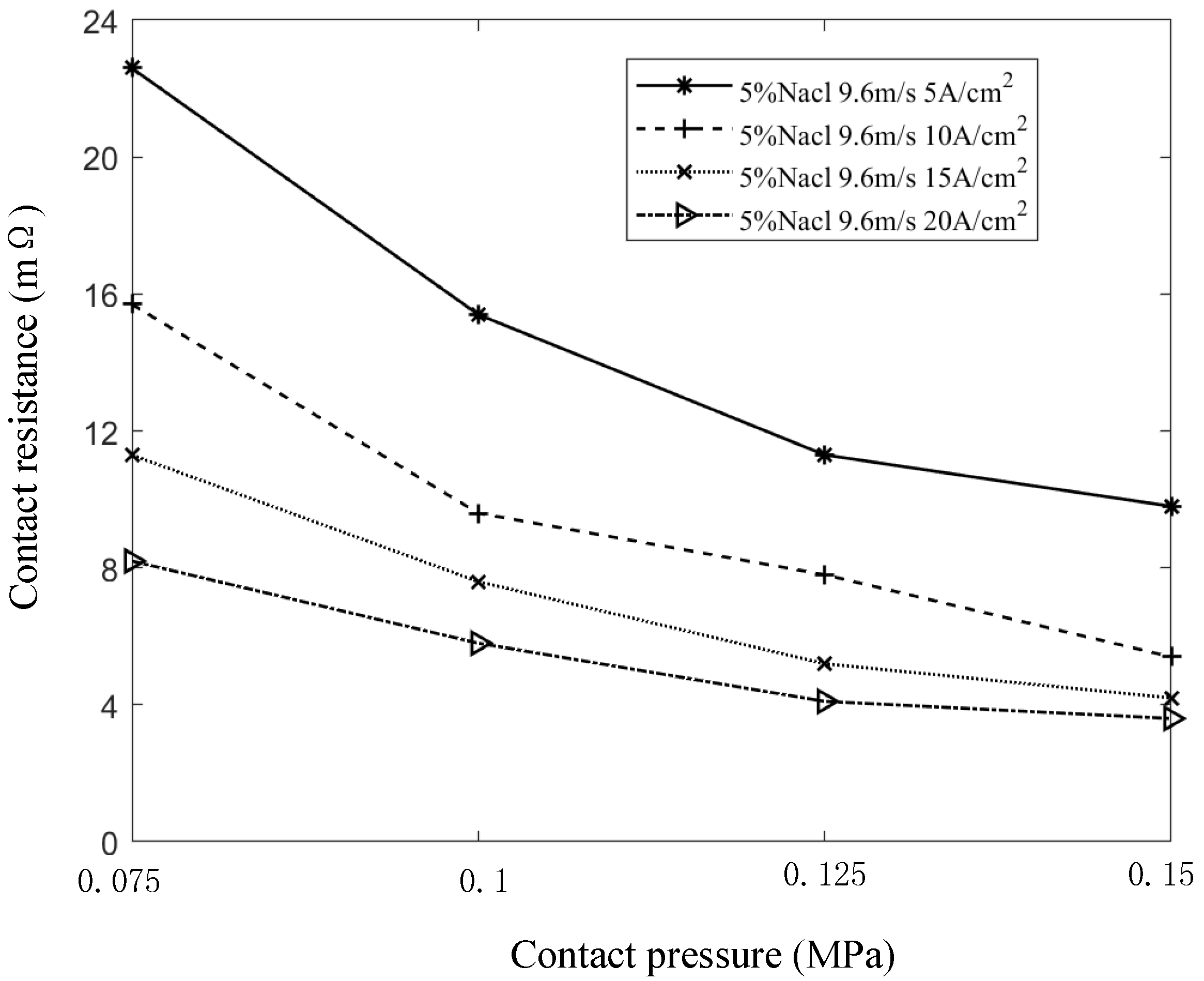

3.4. Influence of Contact Pressure on Contact Resistance

4. Establish the Contact Resistance Model

4.1. Contact Resistance Model for Salt Spray Concentration

4.2. Contact Resistance Model for Sliding Speed

4.3. Contact Resistance Model for Contact Current

4.4. Contact Resistance Model for Contact Pressures

5. Calculation of Contact Resistance Model Parameters

5.1. Calculation of Parameter

5.2. Experimental Verification

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ECR | Electrical Contact Resistance |

| MSE | Mean Square Error |

References

- Zhong, S.; Xie, J. Analysis and solutions of slip ring and carbon brush faults of doubly-fed wind turbines. Wind. Energy 2018, 8, 98–100. [Google Scholar]

- Jiang, H. Talking about the common failure causes and countermeasures of the generator slip ring carbon brush system. Technol. Wind. 2020, 19, 139. [Google Scholar]

- Zeng, R.; Zhou, P.; Wang, S.; Li, Z.; Zhang, B. Simulation model of contact resistance in grounding system and analysis of its influencing factors. High Volt. Technol. 2010, 36, 2393–2397. [Google Scholar]

- Hiroki, N.; Koiji, K. Wear mechanism of copper alloy wire sliding against current collector materials. Wear 1998, 21, 179–183. [Google Scholar]

- Biele, L.; Schaaf, P.; Schmid, F. Influence of Contact Pressure on the Specific Electrical Contact Resistance of Copper. IEEE Trans. Compon. Packag. Manuf. Technol. 2022, 12, 973–980. [Google Scholar] [CrossRef]

- Feng, C.; Lin, X.; Xu, Y.; Zhu, F. Investigation on Contact Resistance of Connector Based on FEM. In Proceedings of the 2020 IEEE 22nd Electronics Packaging Technology Conference (EPTC), Singapore, 2–4 December 2020; pp. 403–405. [Google Scholar]

- Hu, J.; Feng, C.; Shen, B.; Hu, Z.; Zhu, F. Investigation Regarding the Influence of Contact Condition on the Thermal Contact Resistance Between Copper and Indium. IEEE Trans. Electron Devices 2021, 68, 4028–4032. [Google Scholar] [CrossRef]

- Wang, H.; Zhao, X.; Cao, Y. Review of Research status of Influencing Factors of contact resistance of bow mesh System. Transp. Sci. Technol. Manag. 2024, 5, 182–184. [Google Scholar]

- Zhang, D.; Li, X.; Zhang, H.; Zhang, H.; Wu, H.; Wang, X. Research on Mathematical Model of contact resistance of bow mesh in Subway Train. Intell. Comput. Appl. 2022, 12, 165–169. [Google Scholar]

- Ren, W.; Du, D.; Du, Y. Electrical Contact Resistance of Connector Response to Mechanical Vibration Environment. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 212–219. [Google Scholar] [CrossRef]

- Ren, W.; Chen, Y.; Wang, Z.; Xue, S.; Zhang, X. Electrical Contact Resistance of Coated Spherical Contacts. IEEE Trans. Electron Devices 2016, 63, 4373–4379. [Google Scholar] [CrossRef]

- Shen, Q.; Lv, K.; Liu, G.; Qiu, J. Dynamic Performance of Electrical Connector Contact Resistance and Intermittent Fault Under Vibration. IEEE Trans. Compon. Packag. Manuf. Technol. 2018, 8, 216–225. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, Q.; Guo, F.; Tang, A.; Wang, X.; Chen, X. Mathematical Model of Contact Resistance in Pantograph-Catenary System Considering Rough Surface Characteristics. IEEE Trans. Transp. Electrif. 2022, 8, 455–465. [Google Scholar] [CrossRef]

- Wenfu, W.; Zefeng, Y.; Guangning, W. Characteristics of Sliding Electric Contact between Couples of Carbon and Metal Materials. In Proceedings of the 2018 IEEE Holm Conference on Electrical Contacts, Albuquerque, NM, USA, 14–18 October 2018; pp. 439–443. [Google Scholar]

- Watanabe, Y. High-speed sliding characteristics of Cu-Sn-based composite materials containing lamellar solid lubricants by contact resistance studies. Wear 2008, 264, 624–631. [Google Scholar] [CrossRef]

- Chen, Z.; Quartz, L.; Shi, S.; Wang, Z.; Kang, L. Calculation model of contact resistance between pantograph sliding plate and catenary wire. J. Electrotech. Technol. 2013, 28, 188–195. [Google Scholar]

- Li, C.; Zhu, N.; Wu, G.; Gao, G.; Wu, J. Research on the mathematical model of dynamic contact resistance of pantograph and catenary system. High Volt. Technol. 2015, 41, 3554–3560. [Google Scholar]

- Shi, S.; Chen, Z.; Guo, F.; Hui, L.; Dang, W. Characteristics and modeling of pantograph-catenary contact resistance under fluctuating load. J. Electrotech. Technol. 2019, 34, 2287–2295. [Google Scholar]

- Chen, Z.; Wang, Y.; Yang, C.; Shi, G.; Hui, L. Research on dynamic contact resistance characteristics of pantograph under fluctuating load. High Volt. Electr. Appl. 2019, 55, 148–155+163. [Google Scholar]

- Du, J.; Zhang, Y.; Chen, Q.; Tian, H. Electrochemical corrosion of aluminum alloy for aviation in acidic salt spray environment. J. Aeronaut. Mater. 2017, 37, 33–38. [Google Scholar]

- Huang, H.; Yin, H.; Zhang, X.; Jie, P. Discussion on measures to prevent salt fog in offshore wind power generation facilities. Manag Technol. SME 2017, 6, 172–173. [Google Scholar]

- Wang, F. Research on Sliding Contact Resistance of Pantograph Under Fluctuating Load; Liaoning University of Engineering and Technology: Fuxin, China, 2018. [Google Scholar]

- Zhu, N. Research on Contact Resistance Characteristics of Pantograph and Catenary System and Its Influence Mechanism; Southwest Jiaotong University: Chengdu, China, 2015. [Google Scholar]

- Li, M.; Xu, Q.; Han, J. Progress of corrosion and protection for offshore wind power. Corros. Prot. 2014, 5, 584–589+622. [Google Scholar]

- Rosenkranz, A.; Reinert, L.; Gachot, C.; Mücklich, F. Alignment and wear debris effects between laser-patterned steel surfaces under dry sliding conditions. Wear 2014, 27, 49–61. [Google Scholar] [CrossRef]

- Merchant, H.D.; Murty, G.S.; Bahadur, S.N.; Dwivedi, L.T.; Mehrotra, Y. Hardness-temperature relationships in metals. J. Mater. Sci. 1973, 8, 437–442. [Google Scholar] [CrossRef]

- Xu, L.; Lu, N.; Lin, X.; Kong, Z. Electric Contact Theory, Application and Technology; Machinery Industry Press: Beijing, China, 2010. [Google Scholar]

- Li, H.; Lei, B.; Li, Z.; Zhang, Q.; Zhu, R. Contact resistance characteristics of the interface between armature and rail in electromagnetic railgun launching tests. High Volt. Eng. 2013, 39, 911–915. [Google Scholar]

- Gu, W. System parameter identification based on least square method. Off. Informatiz. 2017, 21, 41–43+49. [Google Scholar]

- Chatterjee, S.; Hadi, A.S. Regression Analysis by Example; Zhang, Z.; Xu, J., Translators; China Machine Press: Beijing, China, 2013; pp. 62–70. [Google Scholar]

| Structure Name | Parameter/(Unit) | Parameter Value |

|---|---|---|

| Brush | Length L1/(mm) | 32 |

| Height B1/(mm) | 12.5 | |

| Width W1/(mm) | 16 | |

| Density /(kg·m3) | 3000 | |

| Temperature coefficient/(°C−1) | 0.0019 | |

| Electrical resistivity /(Ω·m) | 9.5 × 10−6 | |

| Slip ring | Inner diameter R1/(mm) | 290 |

| Outside diameter R2/(mm) | 300 | |

| Ring width B2/(mm) | 20 | |

| Density /(kg·m3) | 8670 | |

| Temperature coefficient/(°C−1) | 0.0043 | |

| Electrical resistivity /(Ω·m) | 1 × 10−8 |

| Parameter | Output Value |

|---|---|

| p | 1003.94714094166 |

| q | 2.194594913744752 |

| m | 0.002610903057224 |

| k | 5.520640713625986 × 10−4 |

| γ | 0.375277889478294 |

| a | 8.093303281884793 × 10−6 |

| b | −0.004806427413361 |

| c | 4.842509636721836 |

| Statistic | Output Value |

|---|---|

| Mean square error (MSE) | 1.6986 |

| Residual sum of squares (SSE) | 96.8198 |

| Correlation coefficient (r) | 0.9716 |

| Square of correlation coefficient (R2) | 0.9441 |

| F statistic | 160.324 |

| p value | 8.2 × 10−8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, S.; Zhang, J.; Lyu, Y.; Zhao, L.; Wang, H.; Sun, F.; Lin, J. Mathematical Model of Contact Resistance for Brush and Slip Ring System Considering the Impact of Marine Environment. Sensors 2025, 25, 5939. https://doi.org/10.3390/s25195939

Zhao S, Zhang J, Lyu Y, Zhao L, Wang H, Sun F, Lin J. Mathematical Model of Contact Resistance for Brush and Slip Ring System Considering the Impact of Marine Environment. Sensors. 2025; 25(19):5939. https://doi.org/10.3390/s25195939

Chicago/Turabian StyleZhao, Shuai, Juntao Zhang, Yuting Lyu, Lala Zhao, Huanping Wang, Feng Sun, and Jianjun Lin. 2025. "Mathematical Model of Contact Resistance for Brush and Slip Ring System Considering the Impact of Marine Environment" Sensors 25, no. 19: 5939. https://doi.org/10.3390/s25195939

APA StyleZhao, S., Zhang, J., Lyu, Y., Zhao, L., Wang, H., Sun, F., & Lin, J. (2025). Mathematical Model of Contact Resistance for Brush and Slip Ring System Considering the Impact of Marine Environment. Sensors, 25(19), 5939. https://doi.org/10.3390/s25195939