RAPSO: An Integrated PSO with Reinforcement Learning and an Adaptive Weight Strategy for the High-Precision Milling of Elastic Materials

Abstract

1. Introduction

1.1. State of the Art in Elastic and Flexible Material Machining

1.2. Path Planning and Optimization for Machining

1.3. Reinforcement Learning and Dynamic Compensation

1.4. Critical Gaps in Existing Research

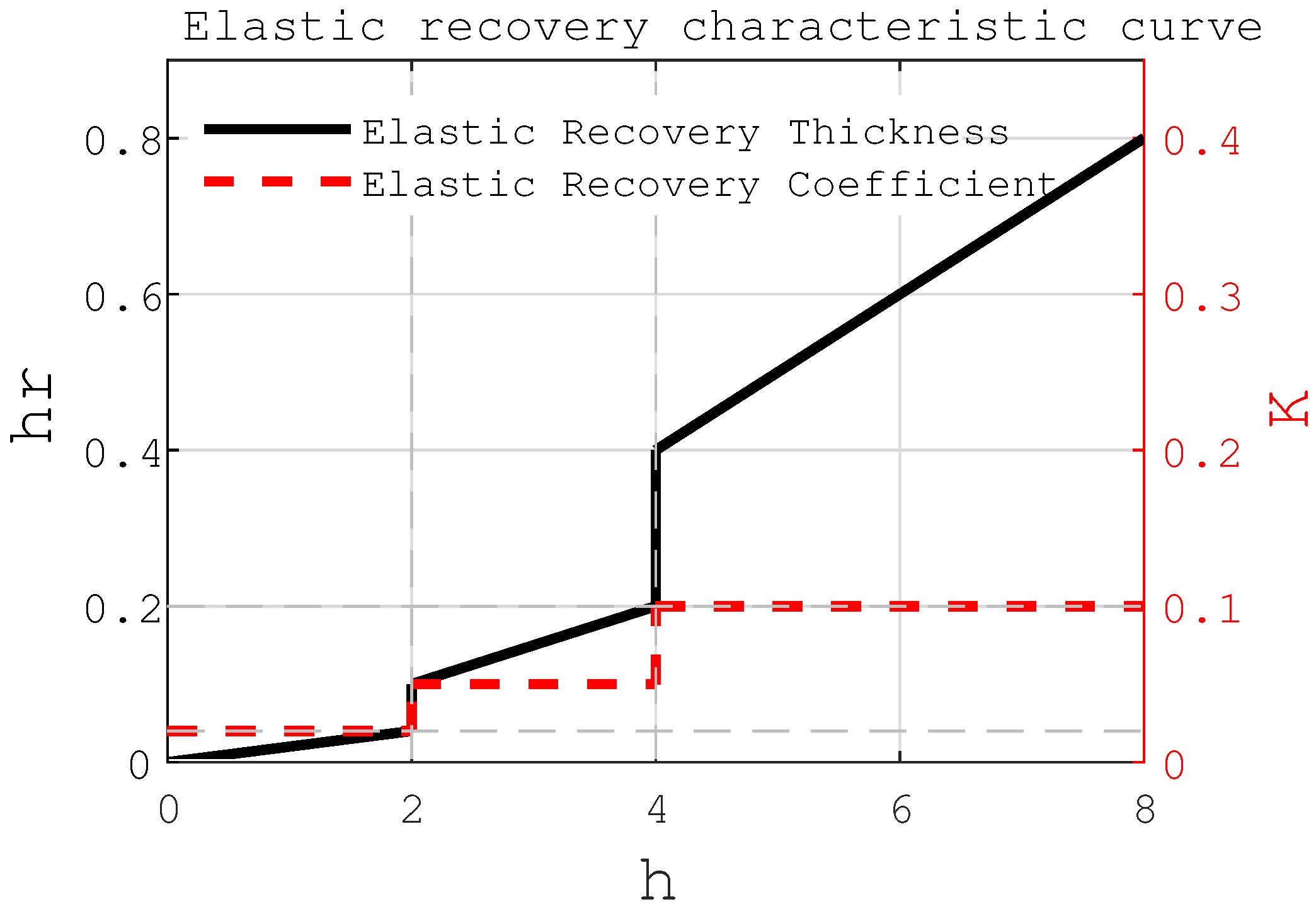

- Inadequate Springback Modeling. Most existing models (e.g., [6,9]) rely on simplified assumptions or empirical coefficients for elastic recovery, failing to capture its dynamic dependence on cutting thickness and material properties. For example, Liu et al. (2004) established a micro-end-milling force model but did not extend it to predict post-machining springback in viscoelastic materials [29].

1.5. Objectives and Contributions of This Study

- Residual Definition Milling Model. A resilient milling model based on residual definition is constructed, which can predict the deformation and rebound behavior of elastic materials. This model provides a theoretical foundation for addressing machining accuracy issues caused by material characteristics during the milling process of elastic materials, contributing to improved dimensional accuracy and surface quality of the final product.

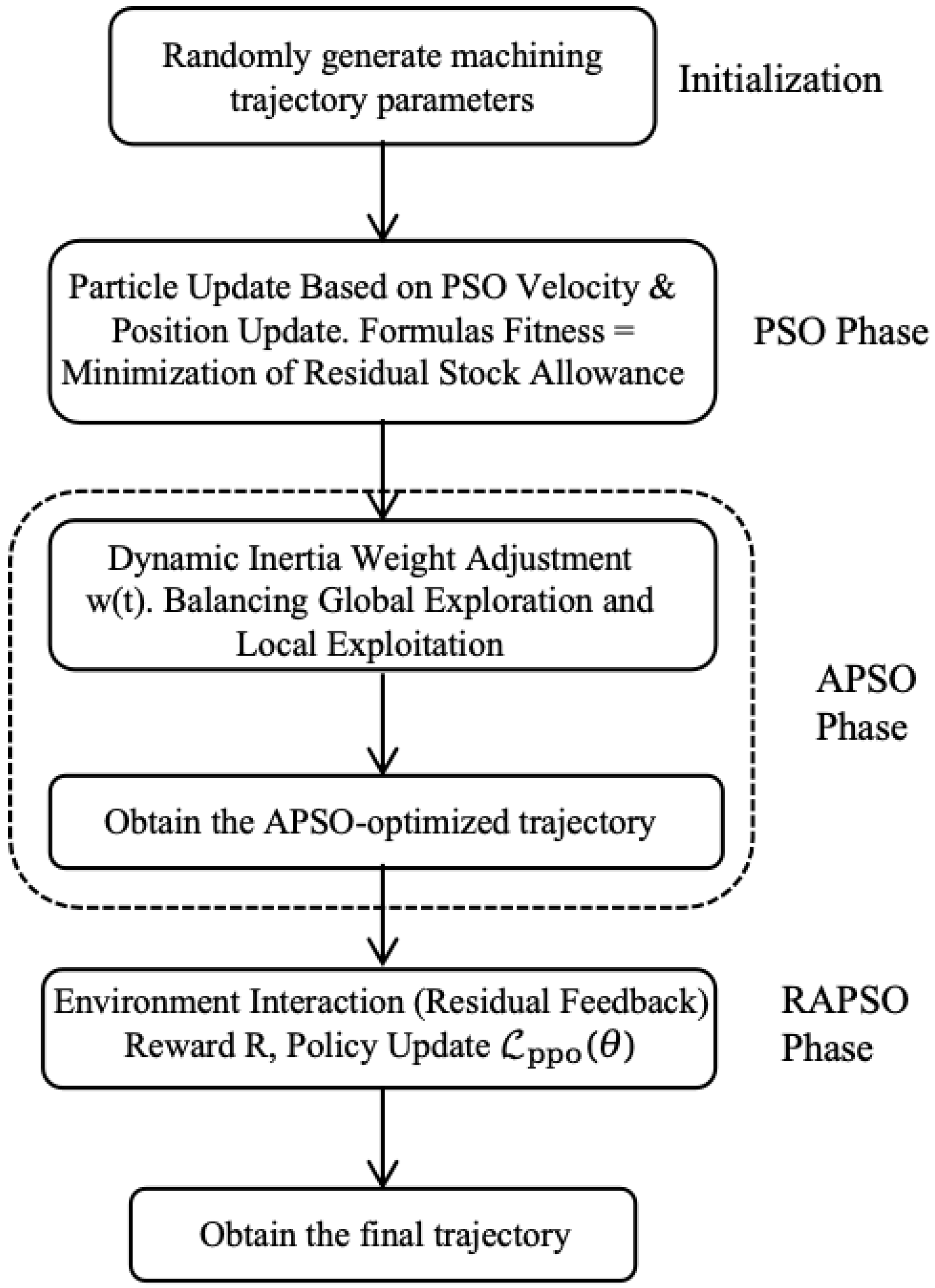

- Adaptive Weight PSO Algorithm. An improved particle swarm optimization algorithm is proposed, which incorporates an adaptive inertia weight strategy for path planning. By dynamically adjusting the inertia weight, this algorithm can broadly explore the solution space in the early stages and refine the search later on, accelerating convergence and improving cutting precision.

- Compensation Module Based on Reinforcement Learning. A reinforcement learning compensation module using Proximal Policy Optimization (PPO) is integrated. This module is capable of dynamically adjusting strategies based on real-time feedback, reducing processing errors caused by springback and overcutting, thereby further enhancing machining accuracy and surface smoothness.

2. Identifying Dynamic Parameters

2.1. Material-Specific Machining Behavior Analysis

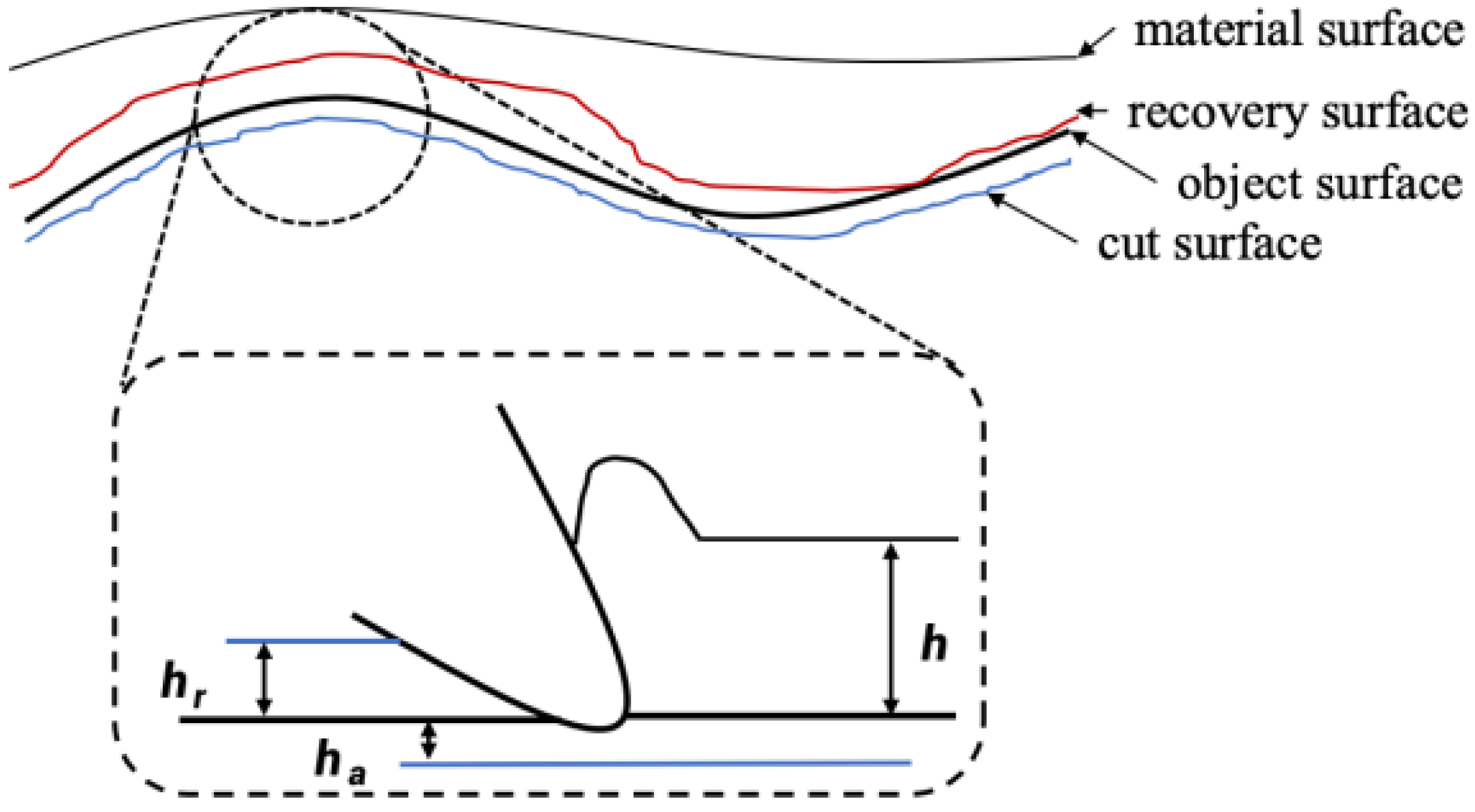

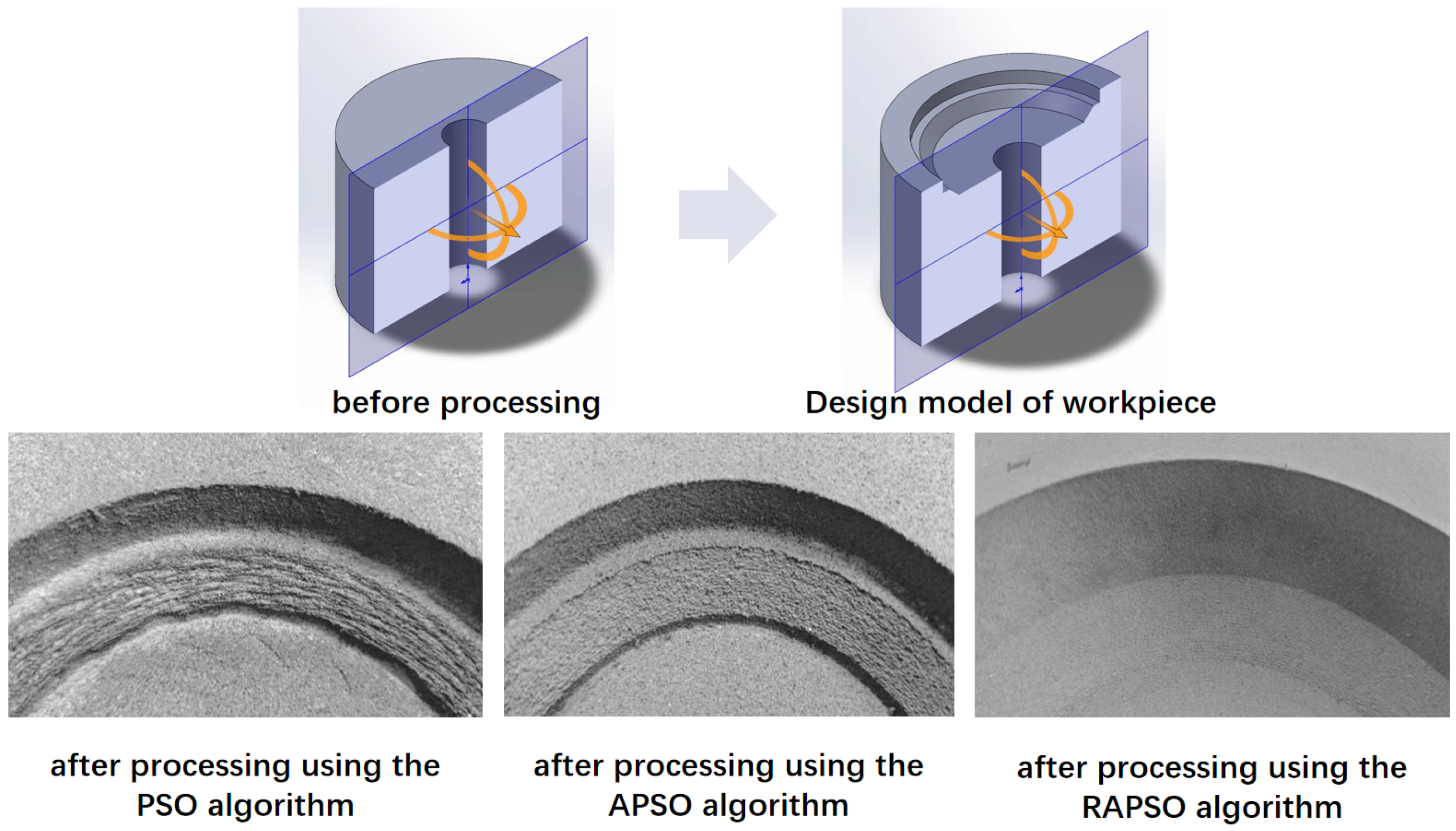

2.2. Milling Allowance Definition

2.3. Cutting Constraints and Objectives

3. Methodology

3.1. Particle Swarm Optimization Algorithm

3.2. Adaptive Weight Particle Swarm Optimization Algorithm

3.3. Reinforcement Learning Optimization Module

| Algorithm 1 PPO-based Milling Path Compensation Module |

|

4. Experiment and Analysis

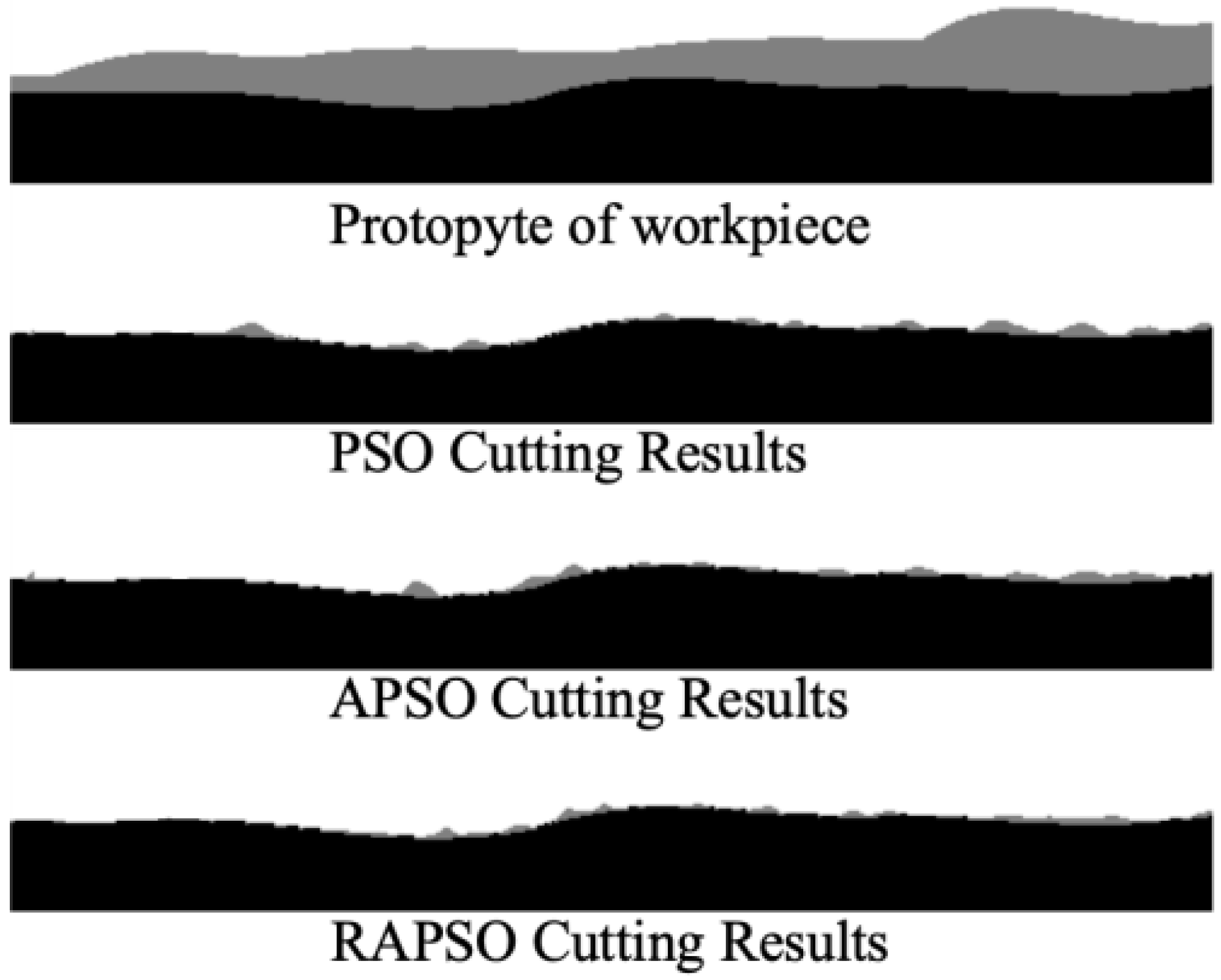

4.1. Typical Scenarios

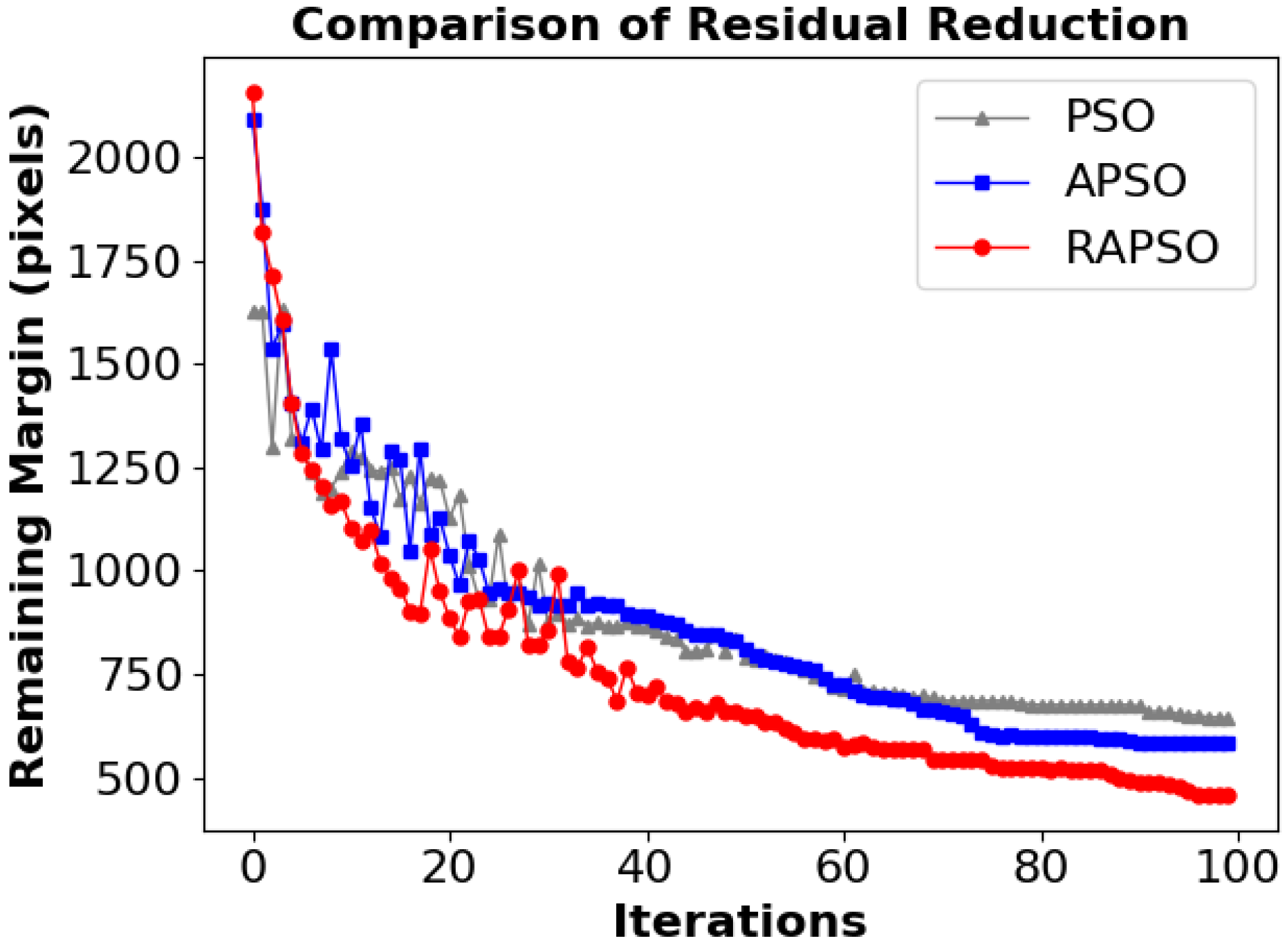

4.2. Multiple Scene Statistics Results

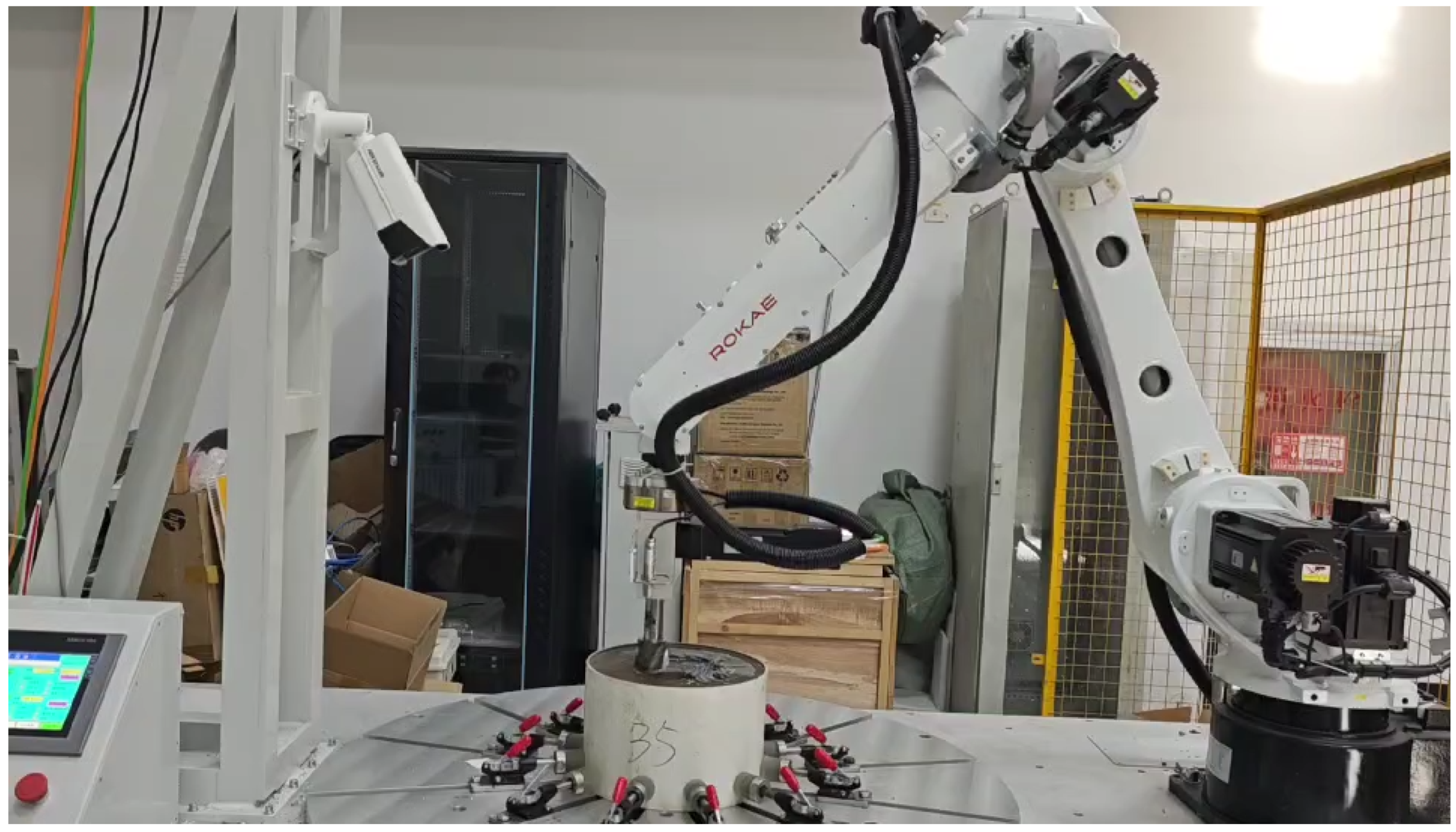

4.3. Experimental Validation of Robotic Machining System

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.C.; Kuo, P.H.; Chen, G.Y. Machine learning prediction of turning precision using optimized xgboost model. Appl. Sci. 2022, 12, 7739. [Google Scholar] [CrossRef]

- Lu, F.; Zhou, G.; Zhang, C.; Liu, Y.; Chang, F.; Lu, Q.; Xiao, Z. Energy-efficient tool path generation and expansion optimisation for five-axis flank milling with meta-reinforcement learning. J. Intell. Manuf. 2025, 36, 3817–3841. [Google Scholar] [CrossRef]

- Cetin, A.; Atali, G.; Erden, C.; Ozkan, S.S. Assessing the performance of state-of-the-art machine learning algorithms for predicting electro-erosion wear in cryogenic treated electrodes of mold steels. Adv. Eng. Inform. 2024, 61, 102468. [Google Scholar] [CrossRef]

- Bravo, U.; Altuzarra, O.; De Lacalle, L.L.; Sánchez, J.; Campa, F. Stability limits of milling considering the flexibility of the workpiece and the machine. Int. J. Mach. Tools Manuf. 2005, 45, 1669–1680. [Google Scholar] [CrossRef]

- Budak, E. Analytical models for high performance milling. Part I: Cutting forces, structural deformations and tolerance integrity. Int. J. Mach. Tools Manuf. 2006, 46, 1478–1488. [Google Scholar] [CrossRef]

- Campa, F.; De Lacalle, L.L.; Celaya, A. Chatter avoidance in the milling of thin floors with bull-nose end mills: Model and stability diagrams. Int. J. Mach. Tools Manuf. 2011, 51, 43–53. [Google Scholar] [CrossRef]

- Marin, F. Five-Axis Milling of Rough and PBF-LB Parts with Free-Form Surfaces Using Ball-End and Circle-Segment end Mills. Ph.D. Thesis, European Humanities University (EHU), Vilnius, Lithuania, 2024. [Google Scholar]

- Varga, J.; Demko, M.; Kaščák, L.; Ižol, P.; Vrabel’, M.; Brindza, J. Influence of Tool Inclination and Effective Cutting Speed on Roughness Parameters of Machined Shaped Surfaces. Machines 2024, 12, 318. [Google Scholar] [CrossRef]

- Urbikain-Pelayo, G.; Olvera-Trejo, D.; de Lacalle, L.N.L.; Elías-Zuñiga, A.; Cabanes, I. Mill+, an intuitive tool for simulating the milling process: Vibrations, cutting forces and surface quality control. SoftwareX 2025, 30, 102114. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, C.; Hu, L.; Qiu, G. Inverse kinematics problem of industrial robot based on PSO-RBFNN. In Proceedings of the 2020 IEEE 4th Information Technology, Networking, Electronic and Automation Control Conference (ITNEC), Chongqing, China, 12–14 June 2020; IEEE: Piscataway, NJ, USA, 2020; Volume 1, pp. 346–350. [Google Scholar]

- Bai, Y.; Yuan, Z.; Yan, Y.; Liu, S. Multiobjective optimization for the bed structure of a CNC gantry machine tool based on neural networks and intelligent optimization algorithms. Sci. Prog. 2025, 108, 00368504251359073. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y. Optimization of machining path for integral impeller side milling based on SA-PSO fusion algorithm in CNC machine tools. Front. Mech. Eng. 2024, 10, 1361929. [Google Scholar] [CrossRef]

- Li, B.; Tian, X. An effective PSO-LSSVM-based approach for surface roughness prediction in high-speed precision milling. IEEE Access 2021, 9, 80006–80014. [Google Scholar] [CrossRef]

- Abualigah, L. Particle Swarm Optimization: Advances, Applications, and Experimental Insights. Comput. Mater. Contin. 2025, 82, 1539–1592. [Google Scholar] [CrossRef]

- Pajaziti, A.; Tafilaj, O.; Gjelaj, A.; Berisha, B. Optimization of Toolpath Planning and CNC Machine Performance in Time-Efficient Machining. Machines 2025, 13, 65. [Google Scholar] [CrossRef]

- Abbas, A.T.; Abubakr, M.; Hassan, M.A.; Luqman, M.; Soliman, M.S.; Hegab, H. An adaptive design for cost, quality and productivity-oriented sustainable machining of stainless steel 316. J. Mater. Res. Technol. 2020, 9, 14568–14581. [Google Scholar] [CrossRef]

- Kaood, A.; Abubakr, M.; Al-Oran, O.; Hassan, M.A. Performance analysis and particle swarm optimization of molten salt-based nanofluids in parabolic trough concentrators. Renew. Energy 2021, 177, 1045–1062. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, S.; Liu, H.; Wang, M.; Li, G.; Wang, Y. A jerk-limited heuristic feedrate scheduling method based on particle swarm optimization for a 5-DOF hybrid robot. Robot. Comput.-Integr. Manuf. 2022, 78, 102396. [Google Scholar] [CrossRef]

- Liu, G.; Li, Q.; Yang, B.; Zhang, H.; Fang, L. An efficient linear programming-based time-optimal feedrate planning considering kinematic and dynamics constraints of robots. IEEE Robot. Autom. Lett. 2024, 9, 2742–2749. [Google Scholar] [CrossRef]

- Liu, G.; Tan, F.; Zhang, M.; Li, Q.; Fang, L. AS-shaped feedrate based NURBS interpolator for synchronization of robot tool tip trajectory and attitude. Asian J. Control 2025. [Google Scholar] [CrossRef]

- El-Kenawy, E.S.M.; Zerouali, B.; Bailek, N.; Bouchouich, K.; Hassan, M.A.; Almorox, J.; Kuriqi, A.; Eid, M.; Ibrahim, A. Improved weighted ensemble learning for predicting the daily reference evapotranspiration under the semi-arid climate conditions. Environ. Sci. Pollut. Res. 2022, 29, 81279–81299. [Google Scholar] [CrossRef]

- Bashir, R.N.; Khan, F.A.; Khan, A.A.; Tausif, M.; Abbas, M.Z.; Shahid, M.M.A.; Khan, N. Intelligent optimization of Reference Evapotranspiration (ETo) for precision irrigation. J. Comput. Sci. 2023, 69, 102025. [Google Scholar] [CrossRef]

- Xiao, Q.; Li, C.; Tang, Y.; Li, L. Meta-reinforcement learning of machining parameters for energy-efficient process control of flexible turning operations. IEEE Trans. Autom. Sci. Eng. 2019, 18, 5–18. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.; Zhang, S.; Zhang, Y.; Zhou, J.; Wang, Z.; Huang, B.; Huang, R. A novel method based on deep reinforcement learning for machining process route planning. Robot. Comput.-Integr. Manuf. 2024, 86, 102688. [Google Scholar] [CrossRef]

- Kaliyannan, D.; Thangamuthu, M.; Pradeep, P.; Gnansekaran, S.; Rakkiyannan, J.; Pramanik, A. Tool condition monitoring in the milling process using deep learning and reinforcement learning. J. Sens. Actuator Netw. 2024, 13, 42. [Google Scholar] [CrossRef]

- Danket, T.; Tanachutiwat, S.; Rungreunganun, V. Adaptive Production Capacity Planning Under Variable Electricity Cost Using Deep Reinforcement Learning. Int. J. Integr. Eng. 2025, 17, 17–30. [Google Scholar] [CrossRef]

- Choi, G.R.; Yang, H.; Lee, J.H.; Runfa, T.; Cho, I.S.; Park, S.J.; Lee, C.G.; Kang, J.K. Explainable AI-based evaluation of factors affecting heavy metal removal by microalgae-based adsorbents. J. Appl. Phycol. 2025, 1–14. [Google Scholar] [CrossRef]

- Makulavičius, M.; Petkevičius, S.; Rožėnė, J.; Dzedzickis, A.; Bučinskas, V. Industrial robots in mechanical machining: Perspectives and limitations. Robotics 2023, 12, 160. [Google Scholar] [CrossRef]

- Liu, X.; Jun, M.B.; DeVor, R.E.; Kapoor, S.G. Cutting mechanisms and their influence on dynamic forces, vibrations and stability in micro-endmilling. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Anaheim, CA, USA, 13–19 November 2004; Volume 47136, pp. 583–592. [Google Scholar]

| No. | PSO (Pixel) | APSO (Pixel) | RAPSO (Pixel) | Improvement_1 | Improvement_2 |

|---|---|---|---|---|---|

| 1 | 644 | 569 | 364 | 11.65% | 36.03% |

| 2 | 701 | 684 | 573 | 2.43% | 16.23% |

| 3 | 798 | 776 | 465 | 2.76% | 40.08% |

| 4 | 644 | 585 | 459 | 9.16% | 21.54% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Zeng, P.; Wu, Q.; Zhang, Z. RAPSO: An Integrated PSO with Reinforcement Learning and an Adaptive Weight Strategy for the High-Precision Milling of Elastic Materials. Sensors 2025, 25, 5913. https://doi.org/10.3390/s25185913

Li Q, Zeng P, Wu Q, Zhang Z. RAPSO: An Integrated PSO with Reinforcement Learning and an Adaptive Weight Strategy for the High-Precision Milling of Elastic Materials. Sensors. 2025; 25(18):5913. https://doi.org/10.3390/s25185913

Chicago/Turabian StyleLi, Qingxin, Peng Zeng, Qiankun Wu, and Zijing Zhang. 2025. "RAPSO: An Integrated PSO with Reinforcement Learning and an Adaptive Weight Strategy for the High-Precision Milling of Elastic Materials" Sensors 25, no. 18: 5913. https://doi.org/10.3390/s25185913

APA StyleLi, Q., Zeng, P., Wu, Q., & Zhang, Z. (2025). RAPSO: An Integrated PSO with Reinforcement Learning and an Adaptive Weight Strategy for the High-Precision Milling of Elastic Materials. Sensors, 25(18), 5913. https://doi.org/10.3390/s25185913