IDD-DETR: Insulator Defect Detection Model and Low-Carbon Operation and Maintenance Application Based on Bidirectional Cross-Scale Fusion and Dynamic Histogram Attention

Abstract

1. Introduction

- Feature-Focused Diffusion Network (FFDN): This replaces traditional PAFPN, constructing a bidirectional interaction mechanism from top-down and bottom-up, improving the efficiency of multi-scale feature fusion, solving the problem of small target feature degradation, and laying the foundation for accurate detection.

- Dynamic-Range Histogram Self-Attention (DHSA): This separates defects and background features through brightness sorting, enhancing texture response in low-brightness areas, improving the detection rate of low-contrast defects, and fundamentally reducing the risk of failures caused by missed detections.

2. Related Work

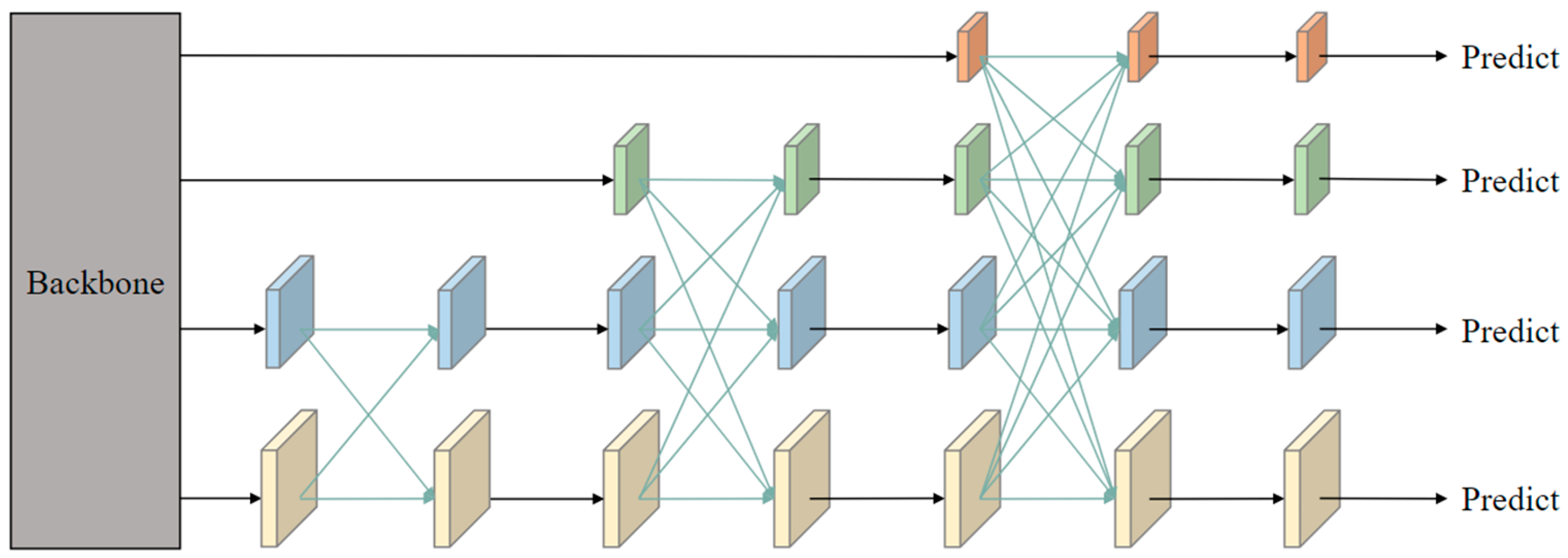

2.1. Characteristic Pyramid Network

2.2. Feature Fusion Module

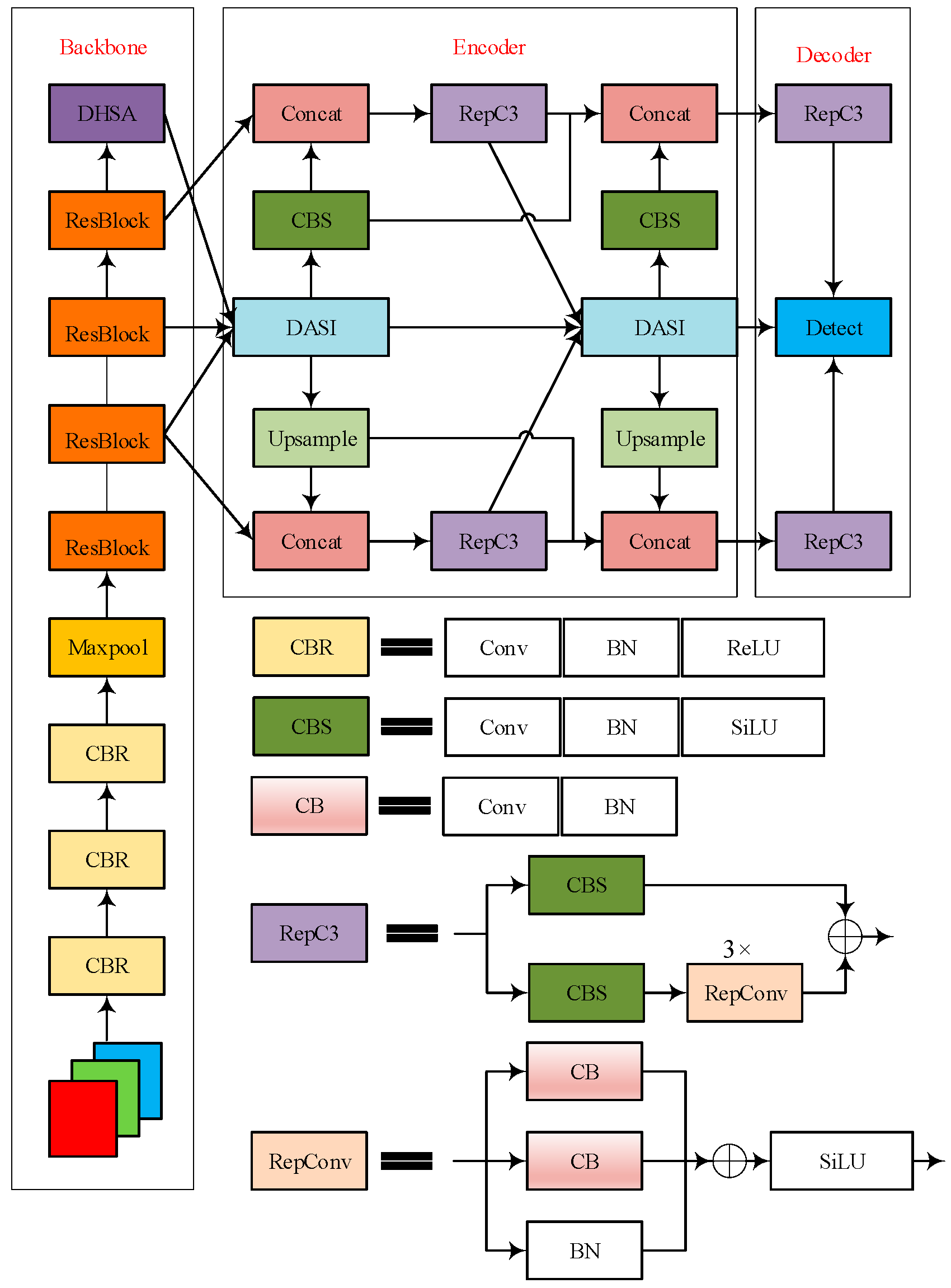

3. Model Architecture

3.1. Overall Network Architecture Design

- Replacing the original feature fusion network with a Feature-Focused Diffusion Network (FFDN) and improving cross-scale fusion efficiency through bidirectional feature interaction;

- Designing a feature-focusing module to enhance multi-scale feature complementarity with dynamic weights and improve small target detail capture;

- Introducing Dynamic-Range Histogram Self-Attention (DHSA) to optimize low-contrast defect modeling and reduce background interference.

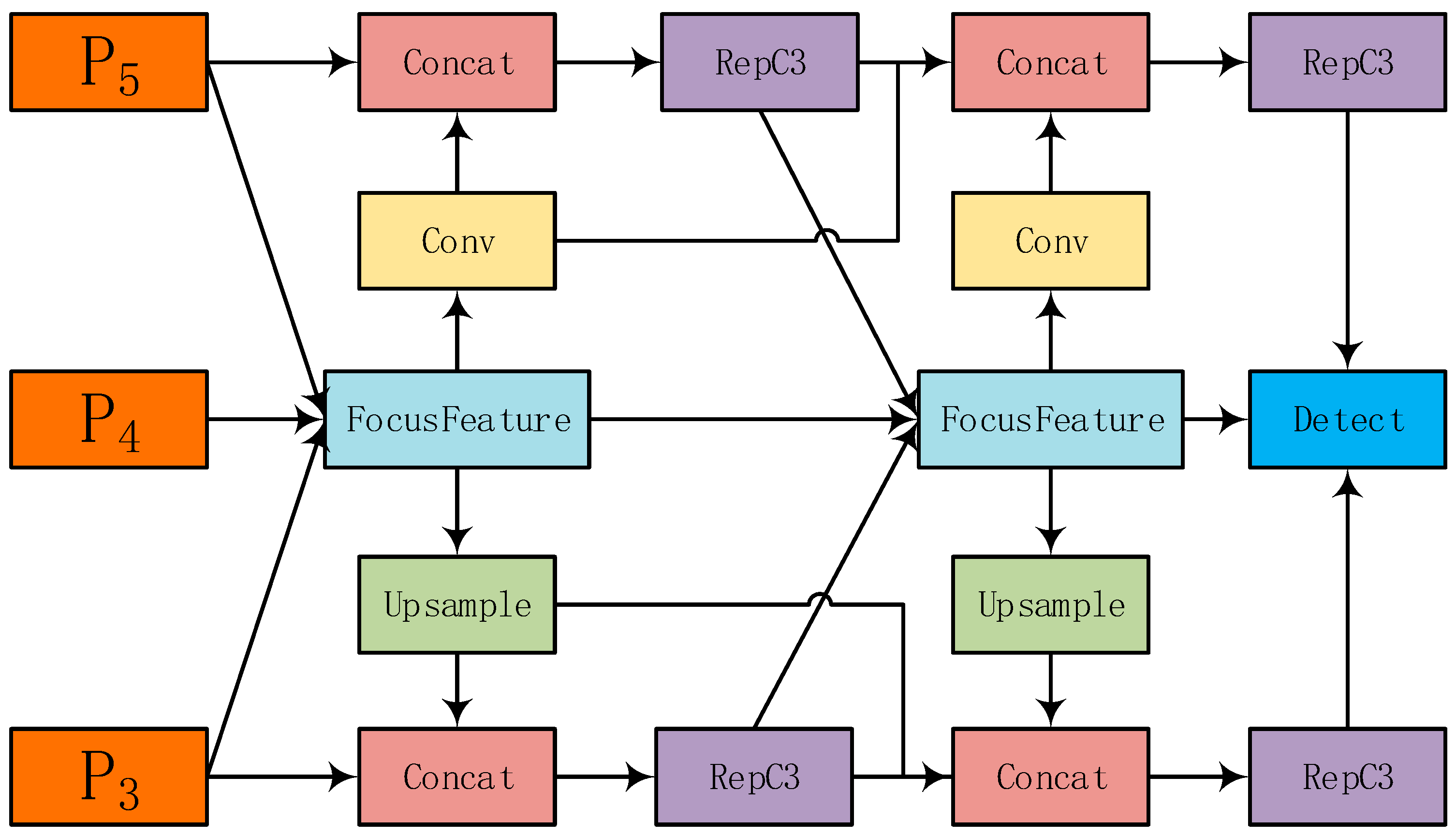

3.2. Improvement of Multi-Scale Feature Fusion Network

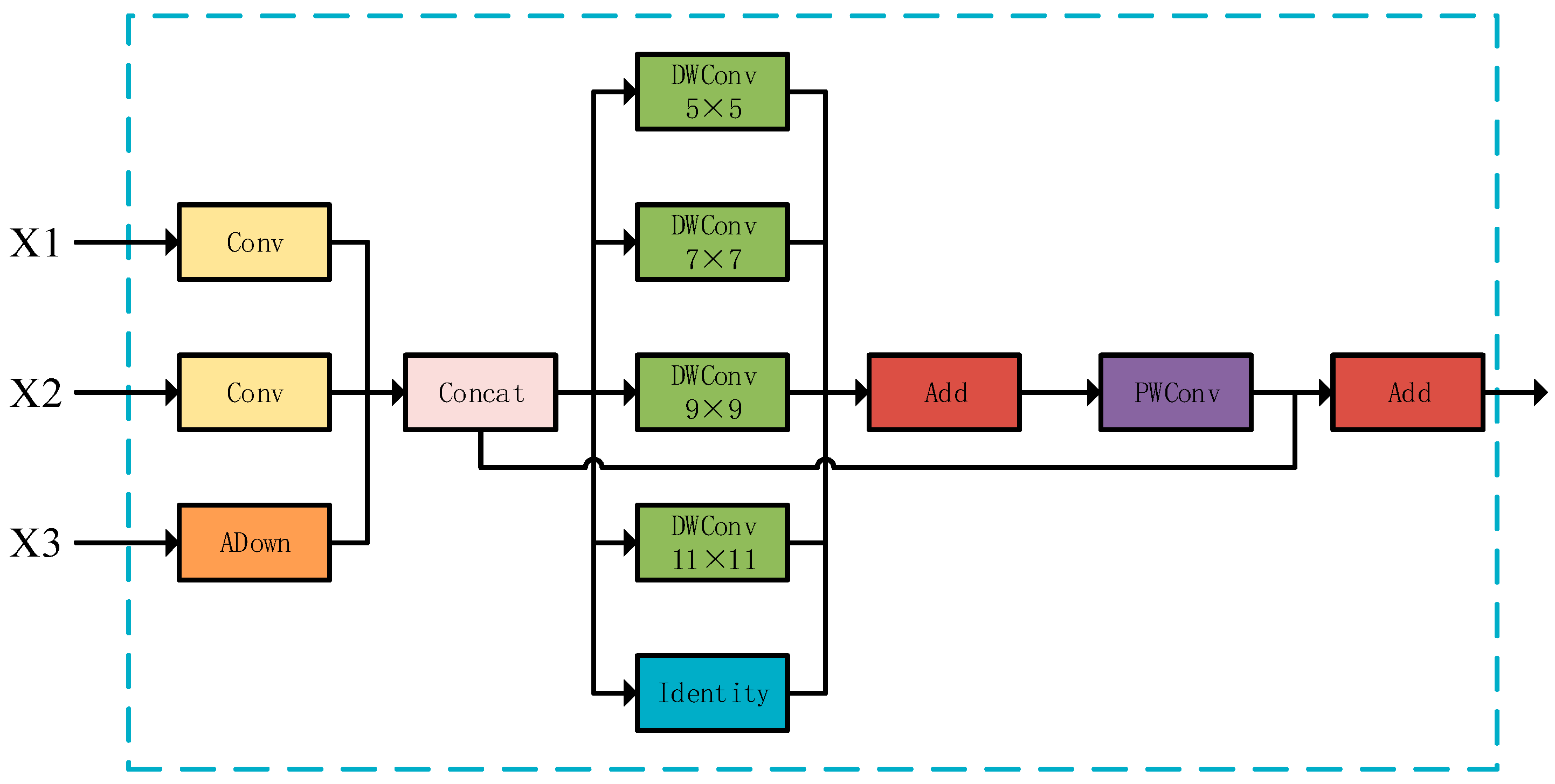

3.2.1. Feature-Focused Diffusion Network

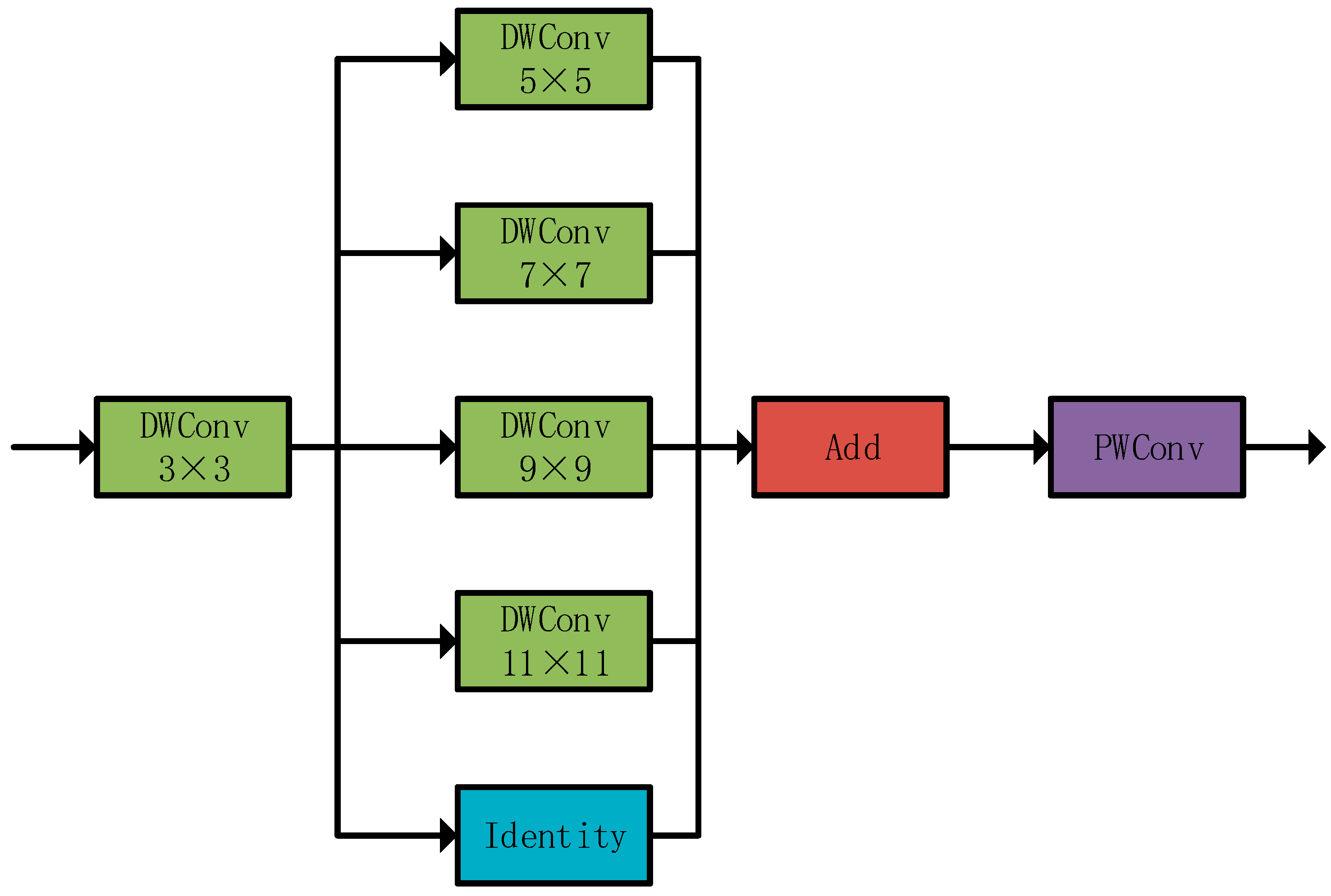

3.2.2. Feature-Focusing Module

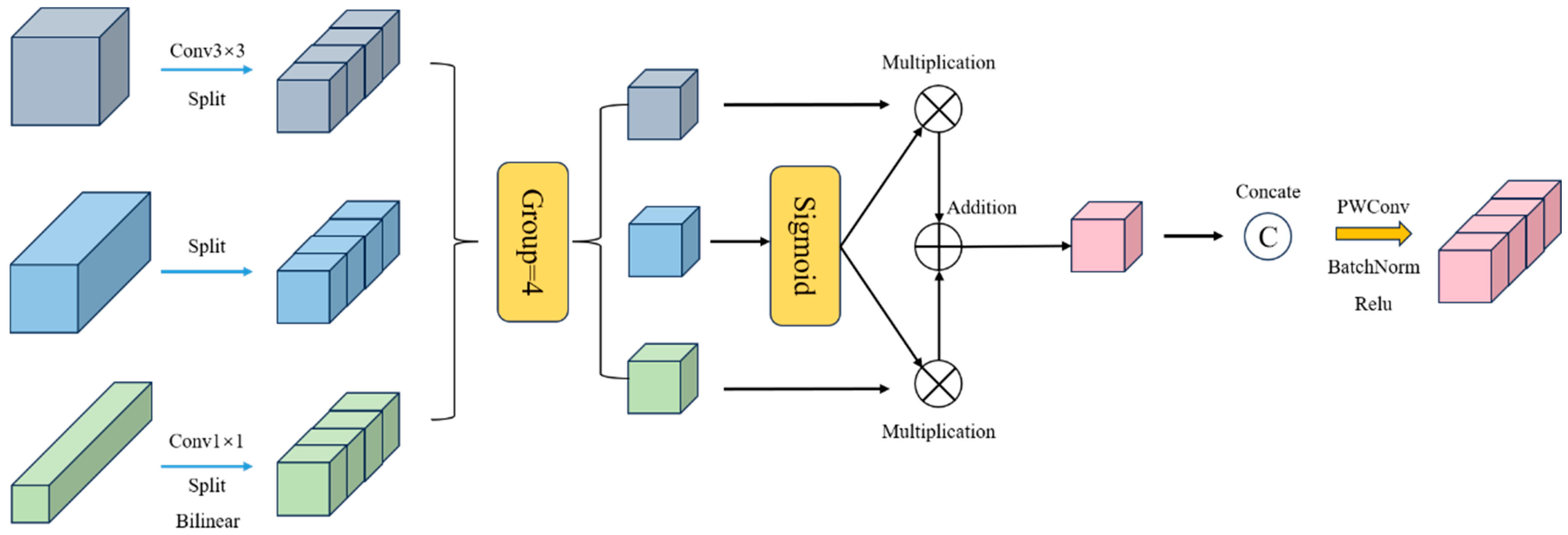

3.3. Improvement of Feature Focusing Module

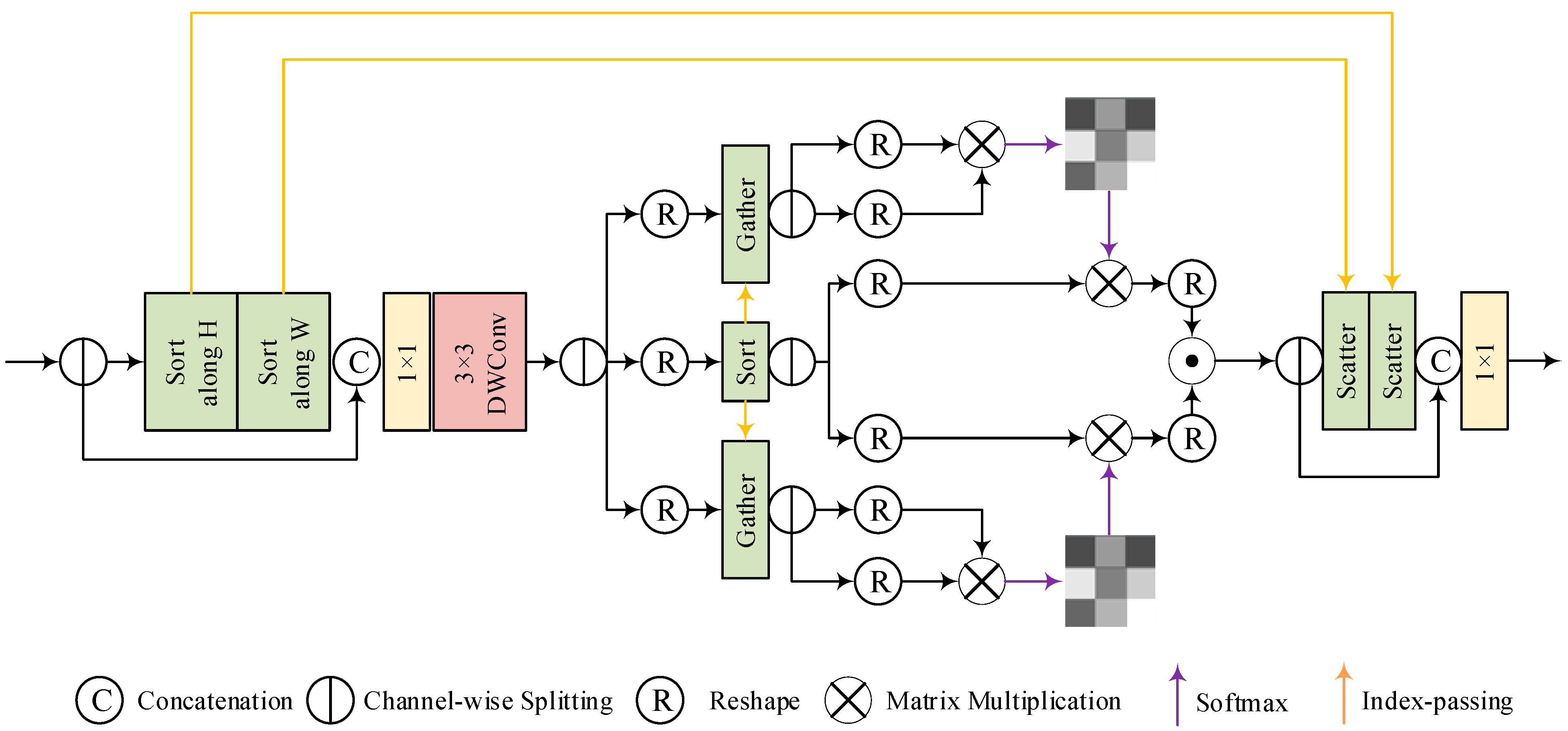

3.4. Improvement of AIFI Module and Dynamic Histogram Attention Mechanism

3.4.1. Dynamic-Range Convolution

3.4.2. Histogram Self-Attention

- Number of boxes and filling rules

- 2.

- Dual-path binning direction (matching BHR and FHR)

- 3.

- Attention and feature restoration within the box

4. Experiment-Related Work

4.1. Experimental Environment Configuration

4.2. Dataset Construction and Feature Analysis

4.2.1. Data Source and Scale

4.2.2. Data Partitioning and Enhancement Trade-Offs

4.3. Evaluating Indicator

4.4. Experiment and Result Analysis

4.4.1. Comparative Experiment on Improvement of Attention Mechanism

4.4.2. Ablation Experiment: Validation of Module Effectiveness

4.4.3. Comparison of Mainstream Target Detection Networks

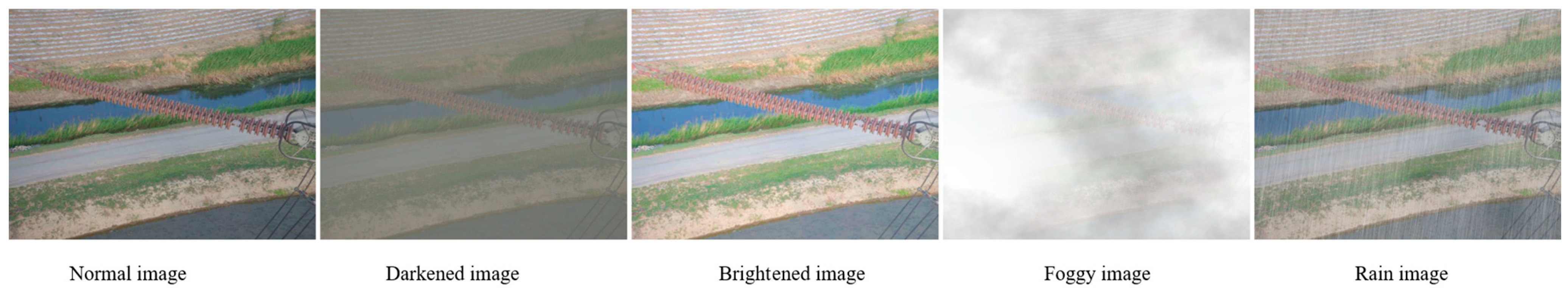

4.4.4. Robustness Test in Complex Environment

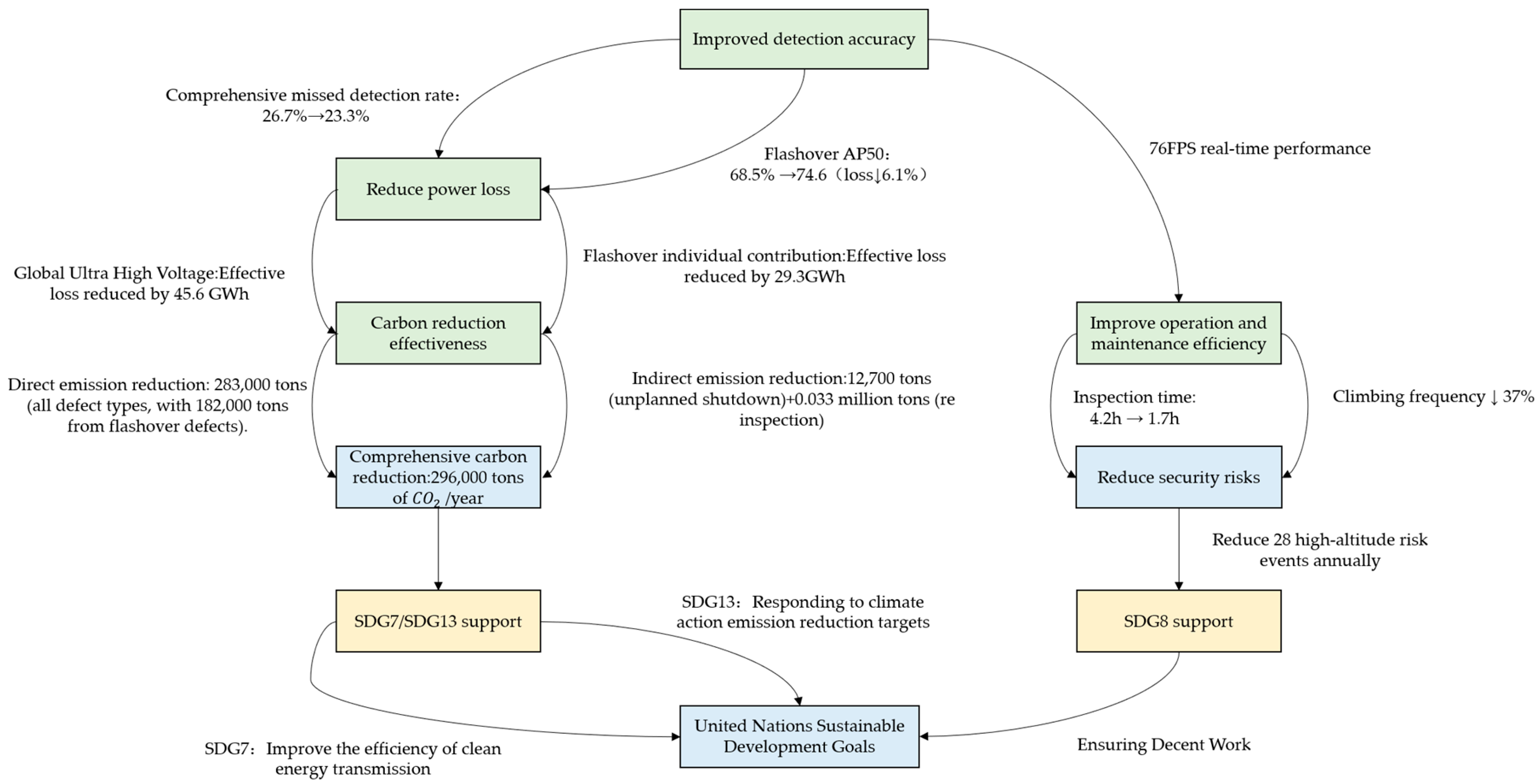

4.4.5. Quantification of Environmental Benefits and Synergy with SDGs

- Carbon reduction benefits of insulator defect detection

- (1)

- Baseline Model (Experiment 1):

- (2)

- IDD-DETR Model (Experiment 5):

- 2.

- Computational efficiency and green computing advantages

- 3.

- Indirect carbon reduction value of environmental robustness

- 4.

- The social value of improving operational efficiency and reducing security risks

- 5.

- Collaborative contribution with SDGs

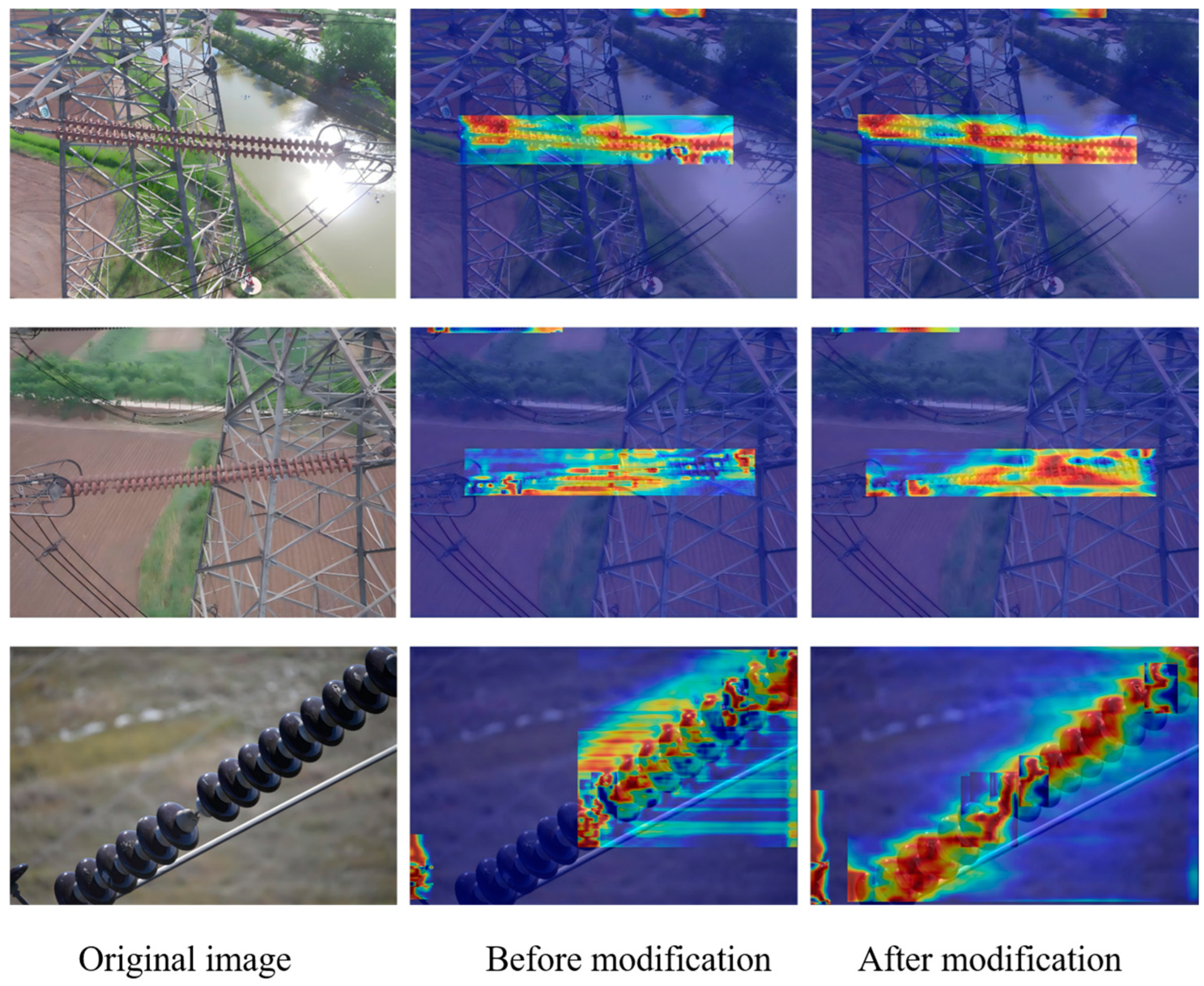

4.5. Visualization Analysis

4.5.1. Comparison and Verification of Heatmaps

4.5.2. Visual Analysis of Detection Capability

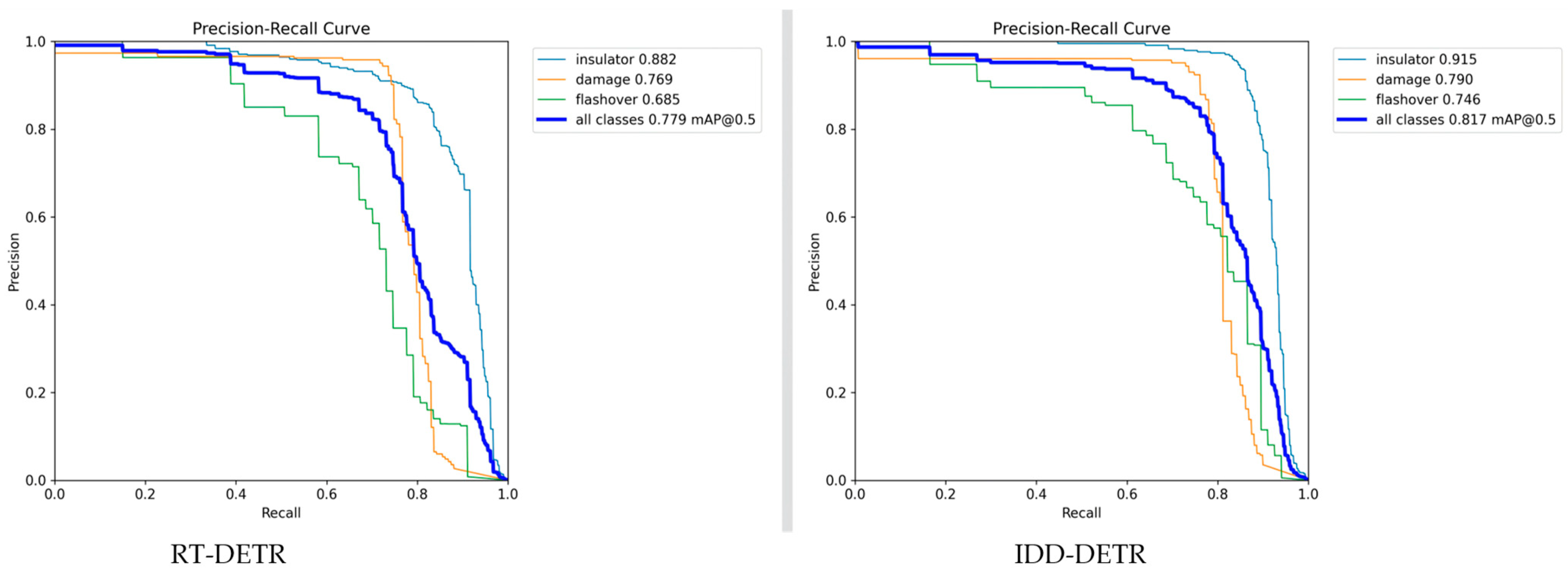

4.5.3. Precision–Recall Curves

- Overall performance comparison

- 2.

- Curve shape and improved logic

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akella, R.; Gunturi, S.K.; Sarkar, D. Enhancing Power Line Insulator Health Monitoring with a Hybrid Generative Adversarial Network and YOLO3 Solution. Tsinghua Sci. Technol. 2024, 29, 1796–1809. [Google Scholar] [CrossRef]

- Liang, H.; Zuo, C.; Wei, W. Detection and Evaluation Method of Transmission Line Defects Based on Deep Learning. IEEE Access 2020, 8, 38448–38458. [Google Scholar] [CrossRef]

- Liu, C.; Wu, Y.; Liu, J.; Sun, Z.; Xu, H. Insulator Faults Detection in Aerial Images from High-Voltage Transmission Lines Based on Deep Learning Model. Appl. Sci. 2021, 11, 4647. [Google Scholar] [CrossRef]

- Nguyen, V.N.; Jenssen, R.; Roverso, D. Automatic Autonomous Vision-Based Power Line Inspection: A Review of Current Status and the Potential Role of Deep Learning. Int. J. Electr. Power Energy Syst. 2018, 99, 107–120. [Google Scholar] [CrossRef]

- Liu, X.; Miao, X.; Jiang, H.; Chen, J. Data Analysis in Visual Power Line Inspection: An in-Depth Review of Deep Learning for Component Detection and Fault Diagnosis. Annu. Rev. Control. 2020, 50, 253–277. [Google Scholar] [CrossRef]

- National Energy Administration. 2024 Annual Report on National Power Reliability; National Energy Administration: Beijing, China, 2024. (In Chinese)

- Carion, N.; Massa, F.; Synnaeve, G.; Usunier, N.; Kirillov, A.; Zagoruyko, S. End-to-End Object Detection with Transformers. In Computer Vision—ECCV 2020; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Jahromi, A.N. Detection and Classification of Defects in Ceramic Insulators Using RF Antenna. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 183–190. [Google Scholar] [CrossRef]

- Yin, J.; Lu, Y.; Gong, Z.; Jiang, Y.; Yao, J. Edge Detection of High-Voltage Porcelain Insulators in Infrared Image Using Dual Parity Morphological Gradients. IEEE Access 2019, 7, 32728–32734. [Google Scholar] [CrossRef]

- Huang, Y.-P.; Bhalla, K. Automatic Generation of Laser Cutting Paths in Defective TFT-LCD Panel Images by Using Neutrosophic Canny Segmentation. IEEE Trans. Instrum. Meas. 2022, 71, 5012816. [Google Scholar] [CrossRef]

- Deng, Z.; Li, X.; Yang, R. RML-YOLO: An Insulator Defect Detection Method for UAV Aerial Images. Appl. Sci. 2025, 15, 6117. [Google Scholar] [CrossRef]

- Shen, J.; Liu, N.; Sun, H.; Li, D.; Zhang, Y.; Han, L. An Algorithm Based on Lightweight Semantic Features for Ancient Mural Element Object Detection. npj Herit. Sci. 2025, 13, 70. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, D. AdIn-DETR: Adapting Detection Transformer for End-to-End Real-Time Power Line Insulator Defect Detection. IEEE Trans. Instrum. Meas. 2024, 73, 3528511. [Google Scholar] [CrossRef]

- Shen, J.; Zhou, W.; Liu, N.; Sun, H.; Li, D.; Zhang, Y. An Anchor-Free Lightweight Deep Convolutional Network for Vehicle Detection in Aerial Images. IEEE Trans. Intell. Transp. Syst. 2022, 23, 24330–24342. [Google Scholar] [CrossRef]

- Liu, C.; Yi, W.; Liu, M.; Wang, Y.; Hu, S.; Wu, M. A Lightweight Network Based on Improved YOLOv5s for Insulator Defect Detection. Electronics 2023, 12, 4292. [Google Scholar] [CrossRef]

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Jin, J.; Zhang, Y.; Sun, C. WRRT-DETR: Weather-Robust RT-DETR for Drone-View Object Detection in Adverse Weather. Drones 2025, 9, 369. [Google Scholar] [CrossRef]

- Xue, R.; Hua, S.; Xu, H. FECI-RTDETR a Lightweight Unmanned Aerial Vehicle Infrared Small Target Detector Algorithm Based on RT-DETR. IEEE Access 2025, 13, 9578–9591. [Google Scholar] [CrossRef]

- Feng, F.; Yang, X.; Yang, R.; Yu, H.; Liao, F.; Shi, Q.; Zhu, F. An Insulator Defect Detection Network Combining Bidirectional Feature Pyramid Network and Attention Mechanism in Unmanned Aerial Vehicle Images. Eng. Appl. Artif. Intell. 2025, 152, 110745. [Google Scholar] [CrossRef]

- Zhao, G.; Ge, W.; Yu, Y. GraphFPN: Graph Feature Pyramid Network for Object Detection. In Proceedings of the 2021 IEEE/CVF International Conference on Computer Vision (ICCV), Montreal, QC, Canada, 10–17 October 2021; pp. 2743–2752. [Google Scholar]

- Zheng, Z.; Wang, P.; Ren, D.; Liu, W.; Ye, R.; Hu, Q.; Zuo, W. Enhancing Geometric Factors in Model Learning and Inference for Object Detection and Instance Segmentation. IEEE Trans. Cybern. 2022, 52, 8574–8586. [Google Scholar] [CrossRef]

- Tang, H.; Jiang, Y. An Improved YOLOv8n Algorithm for Object Detection with CARAFE, MultiSEAMHead, and TripleAttention Mechanisms. In Proceedings of the 2024 7th International Conference on Computer Information Science and Application Technology (CISAT), Hangzhou, China, 12–14 July 2024; pp. 119–122. [Google Scholar]

- Shen, J.; Liu, N.; Sun, H.; Li, D.; Zhang, Y. An Instrument Indication Acquisition Algorithm Based on Lightweight Deep Convolutional Neural Network and Hybrid Attention Fine-Grained Features. IEEE Trans. Instrum. Meas. 2024, 73, 5008516. [Google Scholar] [CrossRef]

- Wei, X.; Yin, L.; Zhang, L.; Wu, F. DV-DETR: Improved UAV Aerial Small Target Detection Algorithm Based on RT-DETR. Sensors 2024, 24, 7376. [Google Scholar] [CrossRef]

- Gan, Y.; Xu, W.; Su, J. SFPN: Semantic Feature Pyramid Network for Object Detection. In Proceedings of the 2020 25th International Conference on Pattern Recognition (ICPR), Milan, Italy, 10–15 January 2021; pp. 795–802. [Google Scholar]

- Li, T.; Wang, J.; Zhang, T. L-DETR: A Light-Weight Detector for End-to-End Object Detection With Transformers. IEEE Access 2022, 10, 105685–105692. [Google Scholar] [CrossRef]

- Liu, X.; Yang, X.; Shao, L.; Wang, X.; Gao, Q.; Shi, H. GM-DETR: Research on a Defect Detection Method Based on Improved DETR. Sensors 2024, 24, 3610. [Google Scholar] [CrossRef]

- Cai, X.; Lai, Q.; Wang, Y.; Wang, W.; Sun, Z.; Yao, Y. Poly Kernel Inception Network for Remote Sensing Detection. In Proceedings of the 2024 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Seattle, WA, USA, 16–22 June 2024. [Google Scholar]

- Li, H.; Ma, J.; Zhang, J. ELNet: An Efficient and Lightweight Network for Small Object Detection in UAV Imagery. Remote Sens. 2025, 17, 2096. [Google Scholar] [CrossRef]

- Shen, J.; Liu, N.; Xu, C.; Sun, H.; Xiao, Y.; Li, D.; Zhang, Y. Finger Vein Recognition Algorithm Based on Lightweight Deep Convolutional Neural Network. IEEE Trans. Instrum. Meas. 2022, 71, 5000413. [Google Scholar] [CrossRef]

- Kong, Y.; Shang, X.; Jia, S. Drone-DETR: Efficient Small Object Detection for Remote Sensing Image Using Enhanced RT-DETR Model. Sensors 2024, 24, 5496. [Google Scholar] [CrossRef]

- Sun, S.; Ren, W.; Gao, X.; Wang, R.; Cao, X. Restoring Images in Adverse Weather Conditions via Histogram Transformer. In Computer Vision—ECCV 2024; Springer: Cham, Switzerland, 2024. [Google Scholar]

- Lewis, D.; Kulkarni, P. Insulator Defect Detection 2021. Available online: https://ieee-dataport.org/competitions/insulator-defect-detection (accessed on 27 April 2025).

- Roy, S.; Bhalla, K.; Patel, R. Mathematical Analysis of Histogram Equalization Techniques for Medical Image Enhancement: A Tutorial from the Perspective of Data Loss. Multimed. Tools Appl. 2024, 83, 14363–14392. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Global Review of Smart Grid Technologies: Patent Trends and Innovation Hotspots; International Energy Agency: Paris, France, 2024. [Google Scholar]

- International Renewable Energy Agency (IRENA). Renewable Capacity Statistics 2023; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2023. [Google Scholar]

- Intergovernmental Panel on Climate Change (IPCC). 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2019. [Google Scholar]

- IEC 62271-203:2022; International Electrotechnical Commission. High-Voltage Switchgear and Controlgear—Part 203: AC Gas-Insulated Metal-Enclosed Switchgear for Rated Voltages Above 52 kV. International Electrotechnical Commission (IEC): Geneva, Switzerland, 2022.

- Global Computing Coalition (GCC). Green Computing Industry Development White Paper 2024; Global Computing Coalition: Beijing, China, 2024. [Google Scholar]

- IEEE Std 1621-2023; Carbon Emission Accounting Standard for Power Equipment. IEEE: New York, NY, USA, 2023.

- State Grid Corporation of China. 2024 White Paper on Low-Carbon Operation and Maintenance of UHV Transmission Lines; State Grid Corporation of China: Beijing, China, 2024. (In Chinese) [Google Scholar]

- National Energy Administration. 2024 Guidelines on Power Safety Production Risk Prevention and Control; National Energy Administration: Beijing, China, 2024. (In Chinese)

- State Grid Hubei Electric Power Company Limited. “E-Dian-Hui-Tu” Smart Inspection System Application Case; State Grid Hubei Electric Power Company Limited: Wuhan, China, 2025. (In Chinese) [Google Scholar]

- State Grid Jiangsu Electric Power Company Limited. Air-Space-Ground Integrated Smart Inspection Technology Application Report; State Grid Jiangsu Electric Power Company Limited: Nanjing, China, 2024. (In Chinese) [Google Scholar]

- United Nations Sustainable Development Group (UNSDG). 2024 Report on SDG Implementation and Climate Action; United Nations: New York, NY, USA, 2024. [Google Scholar]

- International Labour Organization. Occupational Safety and Health Convention, 1981 (No. 155); International Labour Organization: Geneva, Switzerland, 1981. [Google Scholar]

- National Energy Administration & China Electric Power Press. Operation and Maintenance Index System for UHV Transmission Lines (Announcement No. 3, 2024); National Energy Administration & China Electric Power Press: Beijing, China, 2024. (In Chinese)

| Parameter | Allocation |

|---|---|

| Operating system | Windows 10 Professional 22H2 |

| CPU | 12th Gen Intel(R) Core(TM) i5-12490F |

| GPU | NVIDIA GeForce RTX3060-12G |

| Torch | 2.0.1 |

| CUDA | 11.7 |

| Python | 3.8.18 |

| Optimization algorithm | SGD |

| Learning rate attenuation strategy | step |

| Initial Learning Rate | 0.01 |

| Final Learning Rate Coefficient | 1.0 |

| Momentum | 0.937 |

| Warmup Initial Momentum | 0.8 |

| Weight Decay | 0.0005 |

| Warmup Epochs | 2000 |

| Warmup Initial Bias Learning Rate | 0.1 |

| Nominal Batch Size | 64 |

| Batch size | 16 |

| Epochs | 300 |

| Evaluating Indicator | Meaning |

|---|---|

| Parameters (M) | Network Parameter Quantity |

| FLOPs (G) | Network Floating Point Operations |

| Precision (%) | Accuracy Rate |

| Recall (%) | Recall |

| Average Precision, AP (%) | Average Accuracy |

| Mean Average Precision, mAP (%) | Mean Average Precision |

| FPS | Network Detection Speed |

| Network | Multi-Head Self-Attention | AP50 Insulator | AP50 Damage | AP50 Flashover | mAP50 (%) |

|---|---|---|---|---|---|

| RT-DETR | CGA | 89.3 | 79.3 | 64.3 | 77.7 |

| DMHA | 89.8 | 80.3 | 64.9 | 78.4 | |

| HiLo | 89.1 | 78.5 | 64.5 | 77.4 | |

| EAA | 90.2 | 79.8 | 65.9 | 78.6 | |

| DHSA | 91.1 | 76.8 | 63.3 | 77.1 | |

| IDD-DETR | CGA | 90.6 | 78.1 | 66.4 | 78.3 |

| DMHA | 90.8 | 80.5 | 63.1 | 78.2 | |

| HiLo | 90.1 | 78.1 | 66.4 | 78.2 | |

| EAA | 90.1 | 80.0 | 62.5 | 77.5 | |

| DHSA | 91.5 | 79.0 | 74.6 | 81.7 |

| Experiment | FFDN | DASI | DHSA | AP50 Insulator | AP50 Damage | AP50 Flashover | mAP50 (%) | Parameters (M) | FLOPs (G) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 88.2 | 76.9 | 68.5 | 77.9 | 20.2 | 59.6 | |||

| 2 | √ | 88.9 | 79.0 | 67.3 | 78.4 | 22.5 | 68.2 | ||

| 3 | √ | 90.4 | 78.3 | 63.7 | 77.5 | 20.3 | 59.0 | ||

| 4 | √ | √ | 90.3 | 82.0 | 70.6 | 81.0 | 21.4 | 65.4 | |

| 5 | √ | √ | √ | 91.5 | 79.0 | 74.6 | 81.7 | 21.6 | 65.7 |

| Indicator Dimension | RT-DETR | IDD-DETR | Relative Improvement |

|---|---|---|---|

| mAP@0.50:0.95 | 49.7 | 55.2 | +11.1% |

| mAP@0.50 (mAP50) | 77.9 | 81.7 | +4.9% |

| mAP@0.75 | 52.3 | 57.3 | +9.6% |

| AP_small (area < 322) | 3.0 | 8.0 | +166.7% |

| AP_medium (322 < area < 962) | 29.9 | 32.0 | +7.0% |

| AP_large (area > 962) | 45.8 | 52.1 | +13.7% |

| AR@1 (single object) | 37.7 | 40.8 | +8.2% |

| AR@10 (multiple objects) | 61.2 | 66.2 | +8.2% |

| Detection Network | AP50 Insulator | AP50 Damage | AP50 Flashover | mAP50 (%) | Parameters (M) | FLOPs (G) | Speed (FPS) |

|---|---|---|---|---|---|---|---|

| Faster R-CNN | 89.8 | 64.4 | 66.7 | 73.6 | 28.48 | 941.2 | 11 |

| SSD | 87.5 | 58.4 | 57.9 | 67.9 | 26.29 | 62.7 | 78 |

| YOLOv4-tiny | 86.6 | 77.6 | 59.4 | 74.5 | 6.06 | 7.0 | 189 |

| YOLOv5-s | 91.1 | 79.8 | 63.8 | 78.2 | 7.28 | 17.2 | 106 |

| YOLOv7-tiny | 89.9 | 79.1 | 62.1 | 77.0 | 6.02 | 13.2 | 230 |

| YOLOv8-n | 91.2 | 76.7 | 64.5 | 77.5 | 3.16 | 8.9 | 162 |

| IDD-Net | 90.0 | 79.9 | 73.3 | 81.1 | 5.67 | 12.9 | 180 |

| YOLOv5m | 82.8 | 80.9 | 64.2 | 76.0 | 25.1 | 64.2 | 73 |

| YOLOv6s | 83.8 | 79.6 | 58.9 | 74.1 | 16.5 | 44.9 | 132 |

| YOLOv7 | 91.3 | 81.0 | 62.1 | 78.1 | 37.2 | 105.1 | 51 |

| YOLOv8m | 88.4 | 79.2 | 65.3 | 77.7 | 25.9 | 79.3 | 61 |

| YOLOv9c | 87.3 | 79.4 | 67.3 | 78.0 | 25.6 | 104.0 | 50 |

| YOLOv10l | 87.6 | 80.2 | 59.4 | 75.7 | 25.8 | 127.9 | 43 |

| YOLOv11l | 80.7 | 81.3 | 72.6 | 78.2 | 25.4 | 87.6 | 53 |

| YOLOv12l | 84.9 | 80.6 | 70.4 | 78.7 | 26.5 | 89.7 | 35 |

| YOLOv12s | 89.5 | 79.2 | 74.0 | 80.0 | 9.4 | 21.7 | 132 |

| RT-DETR | 88.2 | 76.9 | 68.5 | 77.9 | 20.2 | 59.6 | 75 |

| LGI-DETR | 90.8 | 78.5 | 72.1 | 80.5 | 22.3 | 68.9 | 70 |

| Deformable DETR | 85.2 | 72.1 | 69.3 | 79.1 | 35.8 | 210.5 | 28 |

| Swin-Tiny | 87.4 | 75.5 | 71.2 | 80.5 | 28.3 | 156.8 | 42 |

| IDD-DETR | 91.5 | 79.0 | 74.6 | 81.7 | 21.6 | 65.7 | 76 |

| Detection Network | Normal Image mAP50 (%) | Darkened Image mAP50 (%) | Brighten Image mAP50 (%) | Foggy Image mAP50 (%) | Rain Image mAP50 (%) |

|---|---|---|---|---|---|

| Faster R-CNN | 73.6 | 70.9 | 70.4 | 69.9 | 73.1 |

| SSD | 67.9 | 67.4 | 66.1 | 65.9 | 68.1 |

| YOLOv4-tiny | 74.5 | 71.4 | 71.1 | 68.3 | 70.2 |

| YOLOv5-s | 78.2 | 70.4 | 69.7 | 68.1 | 71.1 |

| YOLOv7-tiny | 77.0 | 74.2 | 75.7 | 74.2 | 75.9 |

| YOLOv8-n | 77.5 | 69.6 | 75.4 | 72.5 | 74.3 |

| IDD-Net | 81.1 | 75.9 | 78.7 | 76.1 | 78.0 |

| YOLOv5m | 76.0 | 76.9 | 77.1 | 76.8 | 76.3 |

| YOLOv6s | 74.1 | 73.3 | 75.1 | 69.8 | 73.9 |

| YOLOv8m | 77.7 | 78.1 | 78.7 | 77.2 | 77.1 |

| YOLOv9c | 78.0 | 78.8 | 79.8 | 76.9 | 79.7 |

| YOLOv10l | 75.7 | 70.0 | 74.5 | 72.2 | 77.0 |

| YOLOv11l | 78.2 | 72.8 | 78.1 | 75.2 | 75.5 |

| YOLOv12l | 78.7 | 76.7 | 79.6 | 74.6 | 76.1 |

| RT-DETR | 77.9 | 75.7 | 77.3 | 75.6 | 79.0 |

| IDD-DETR | 81.7 | 79.1 | 82.9 | 78.2 | 80.0 |

| Detection Network | Darkened Image mAP50 Percentage Decrease | Brightened Image mAP50 Percentage Decrease | Foggy Image mAP50 Percentage Decrease | Rain Image mAP50 Percentage Decrease | Average Percentage Decline |

|---|---|---|---|---|---|

| Faster R-CNN | 2.7 | 3.2 | 3.7 | 0.5 | 2.525 |

| SSD | 0.5 | 1.8 | 2.0 | -0.2 | 1.025 |

| YOLOv4-tiny | 3.1 | 3.4 | 6.2 | 4.3 | 4.25 |

| YOLOv5-s | 7.8 | 8.5 | 10.1 | 7.1 | 8.375 |

| YOLOv7-tiny | 2.8 | 1.3 | 2.8 | 1.1 | 2.0 |

| YOLOv8-n | 7.9 | 2.1 | 5.0 | 3.2 | 4.55 |

| IDD-Net | 5.2 | 2.4 | 5 | 3.1 | 3.925 |

| YOLOv5m | −0.9 | −1.1 | −0.8 | −0.3 | −0.775 |

| YOLOv6s | 0.8 | −1 | 4.3 | 0.2 | 1.075 |

| YOLOv8m | −0.4 | −1 | 0.5 | 0.6 | −0.075 |

| YOLOv9c | −0.8 | −1.8 | 1.1 | −1.7 | −0.8 |

| YOLOv10l | 5.7 | 1.2 | 3.5 | −1.3 | 2.275 |

| YOLOv11l | 5.4 | 0.1 | 3.0 | 2.7 | 2.8 |

| YOLOv12l | 2.0 | 0.6 | 2.3 | −1.1 | 0.95 |

| RT-DETR | 2.2 | 0.6 | 2.3 | −1.1 | 1.0 |

| IDD-DETR | 2.6 | −1.2 | 3.5 | 1.7 | 1.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Li, S.; Han, X. IDD-DETR: Insulator Defect Detection Model and Low-Carbon Operation and Maintenance Application Based on Bidirectional Cross-Scale Fusion and Dynamic Histogram Attention. Sensors 2025, 25, 5848. https://doi.org/10.3390/s25185848

Chen W, Li S, Han X. IDD-DETR: Insulator Defect Detection Model and Low-Carbon Operation and Maintenance Application Based on Bidirectional Cross-Scale Fusion and Dynamic Histogram Attention. Sensors. 2025; 25(18):5848. https://doi.org/10.3390/s25185848

Chicago/Turabian StyleChen, Weizhen, Shuaishuai Li, and Xingyu Han. 2025. "IDD-DETR: Insulator Defect Detection Model and Low-Carbon Operation and Maintenance Application Based on Bidirectional Cross-Scale Fusion and Dynamic Histogram Attention" Sensors 25, no. 18: 5848. https://doi.org/10.3390/s25185848

APA StyleChen, W., Li, S., & Han, X. (2025). IDD-DETR: Insulator Defect Detection Model and Low-Carbon Operation and Maintenance Application Based on Bidirectional Cross-Scale Fusion and Dynamic Histogram Attention. Sensors, 25(18), 5848. https://doi.org/10.3390/s25185848