Design of a PEBA–Silicone Composite Magneto-Sensitive Airbag Sensor for Simultaneous Contact Force and Motion Detection

Abstract

1. Introduction

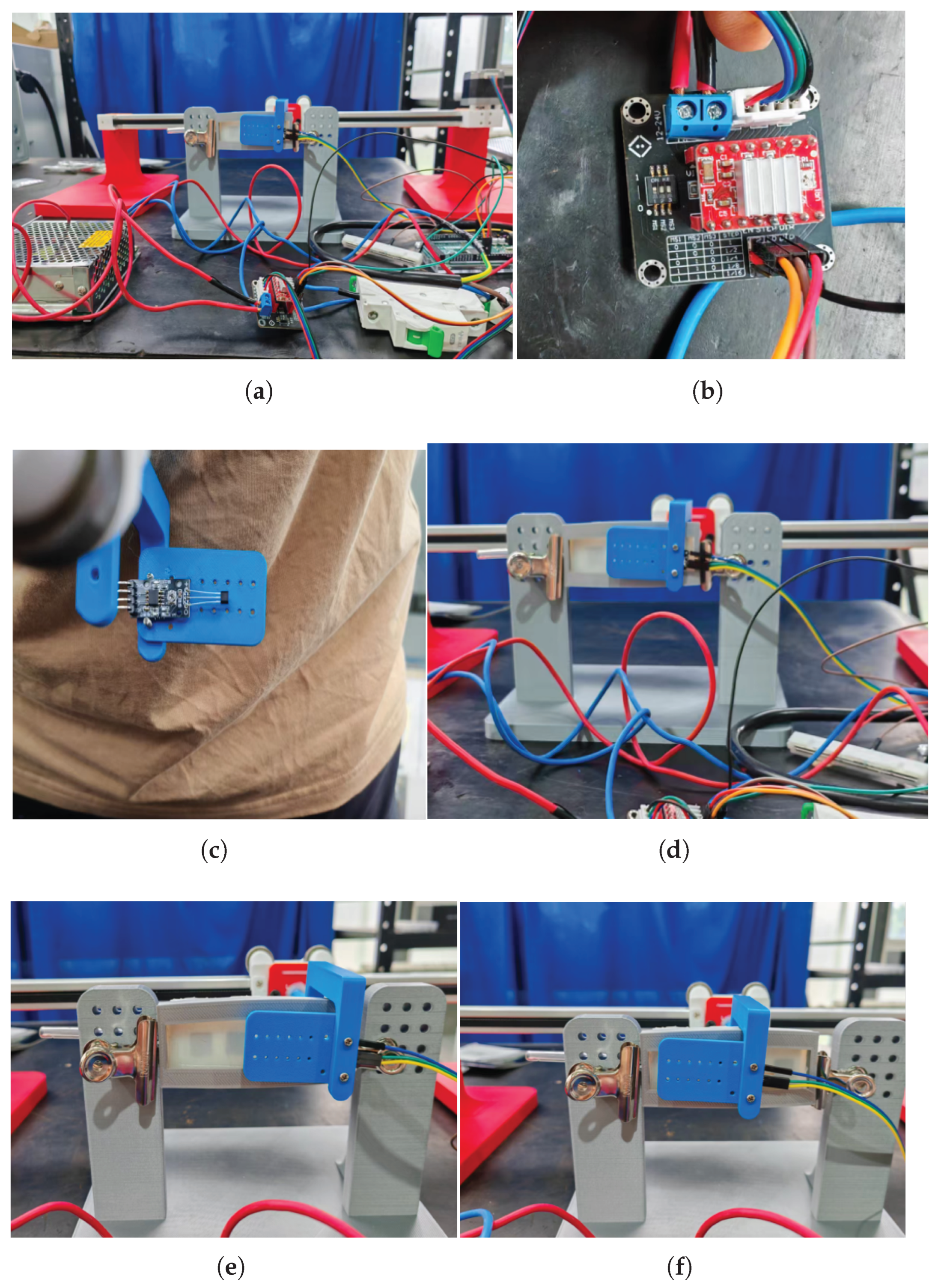

2. Materials and Methods

2.1. Preparation of the Airbags

2.1.1. Silicone Airbag

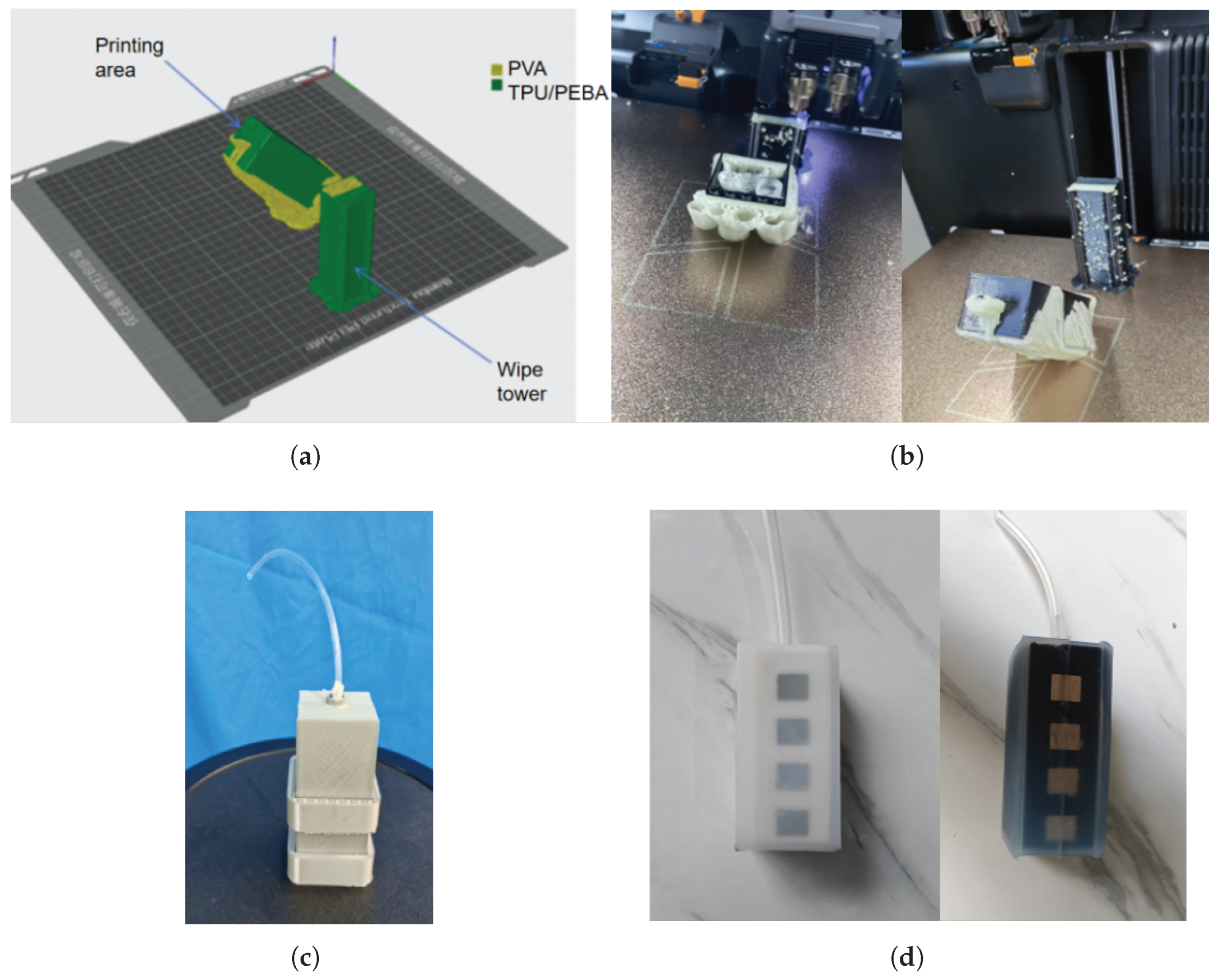

2.1.2. TPU–Silicone Composite and PEBA–Silicone Composite Airbags

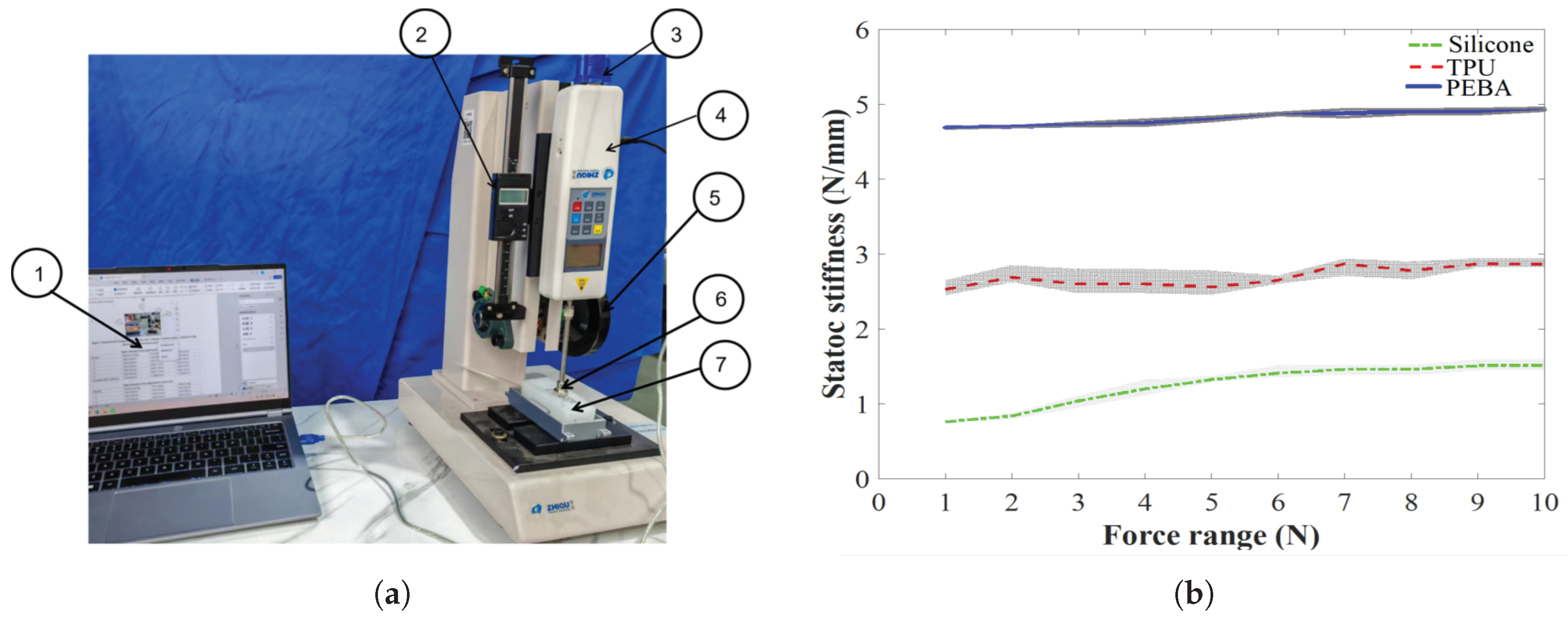

- 1.

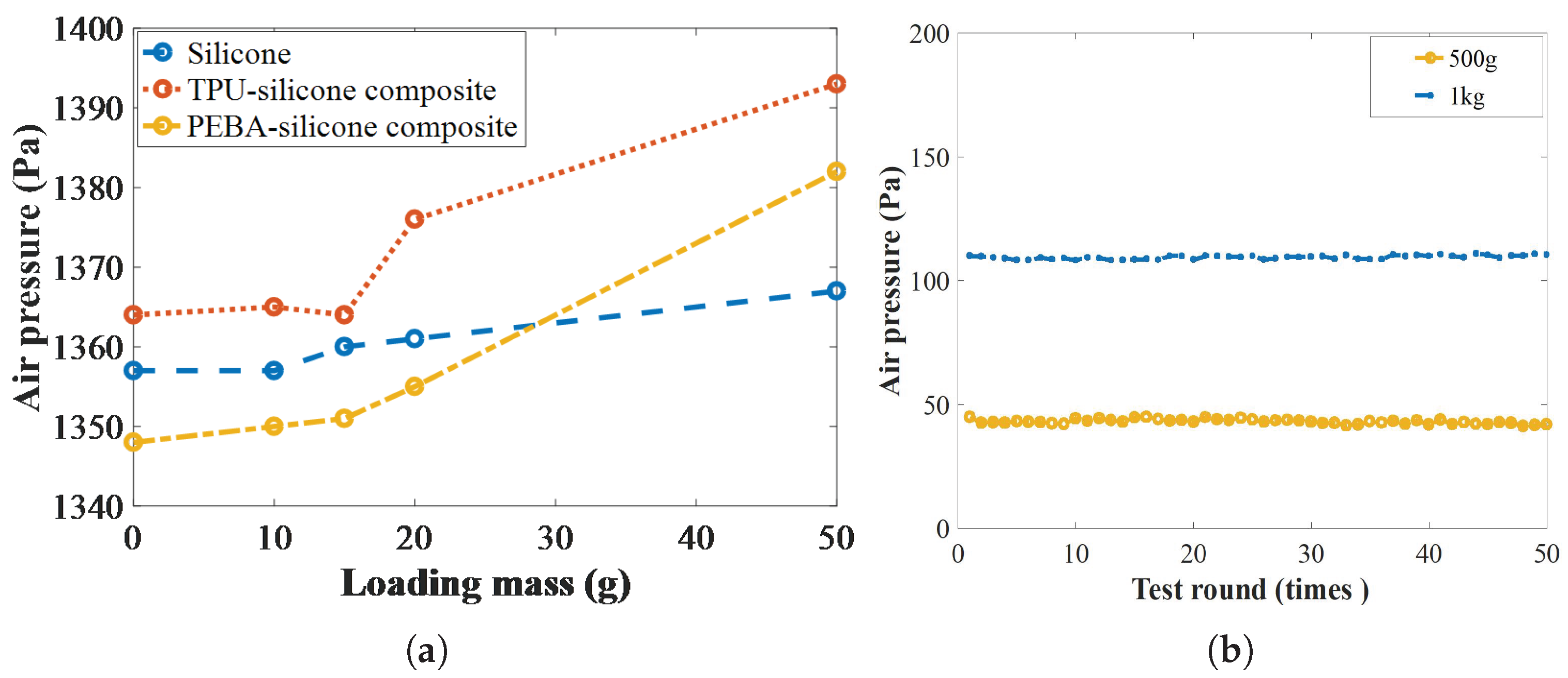

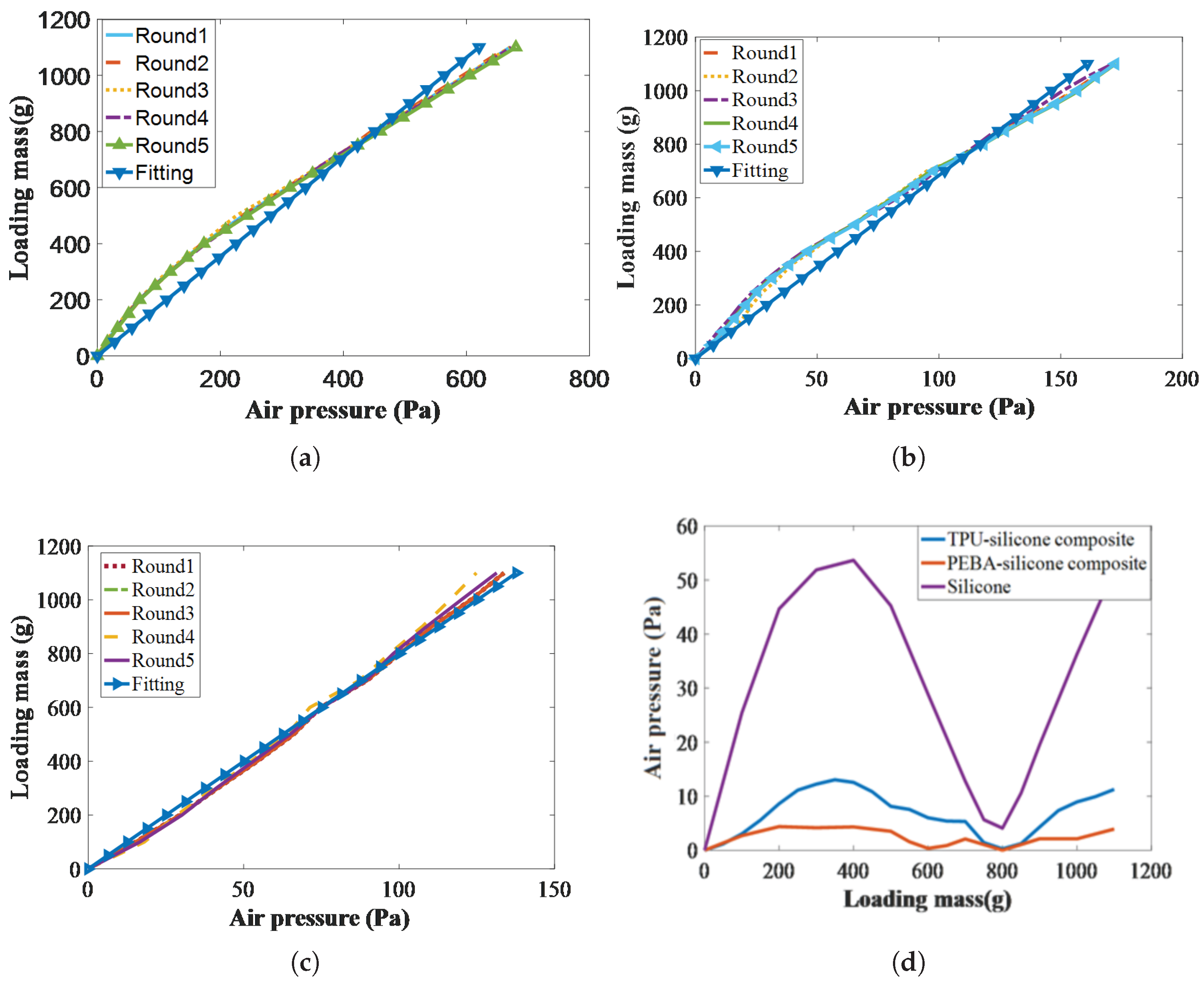

- The first five stiffness measurements of the pure silicone airbag were all below its average stiffness of 1.25 N/mm, reflecting pronounced nonlinearity.

- 2.

- Owing to its greater hardness, the variance of the PEBA–silicone composite exhibited a lower value than that of the TPU–silicone composite airbag and the pure silicone airbag (0.0059 < 0.0141 < 0.0744). Meanwhile, the PEBA–silicone composite airbag achieved the best average stiffness (4.82 N/mm) and retention capacity among the three airbags under loads from 0 to 10 N.

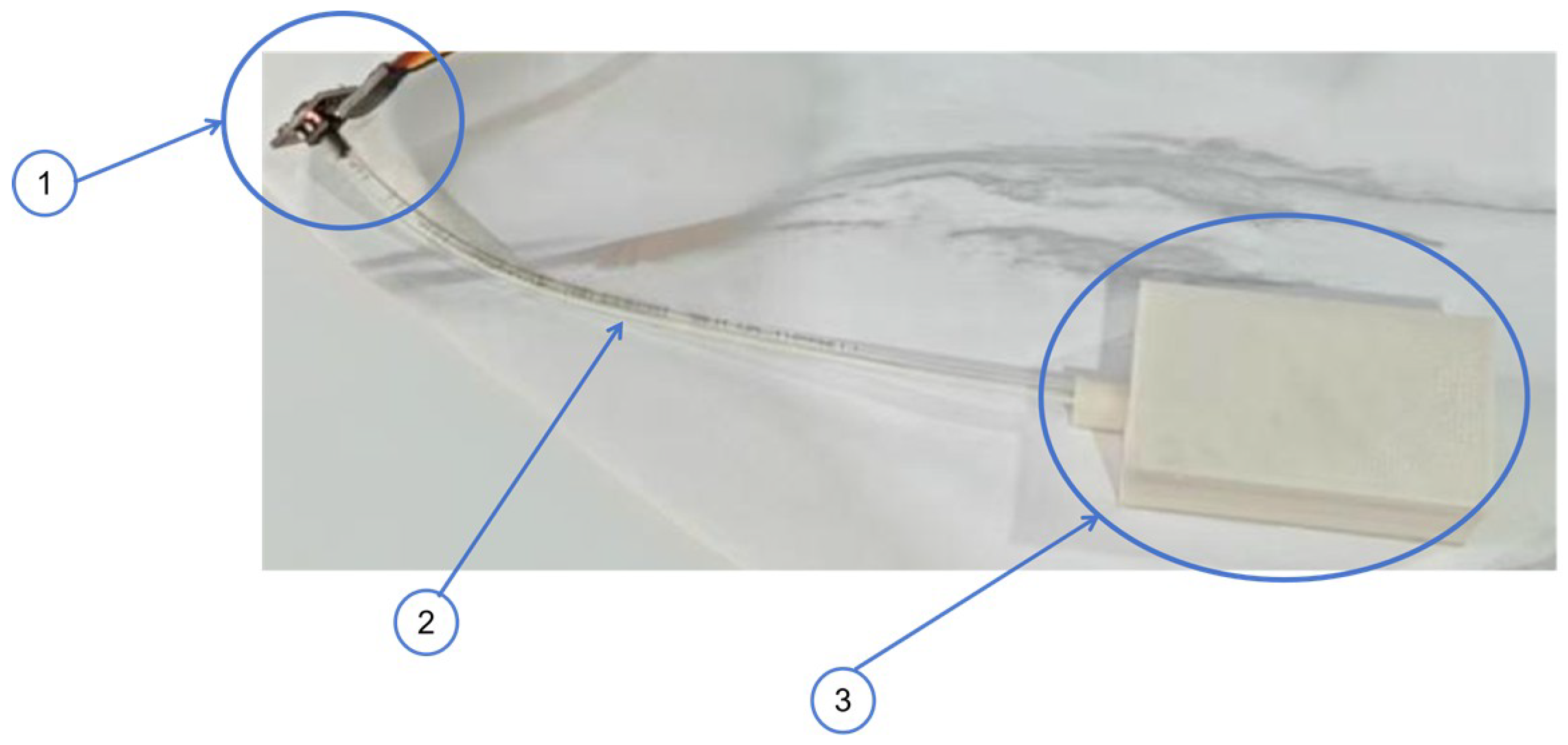

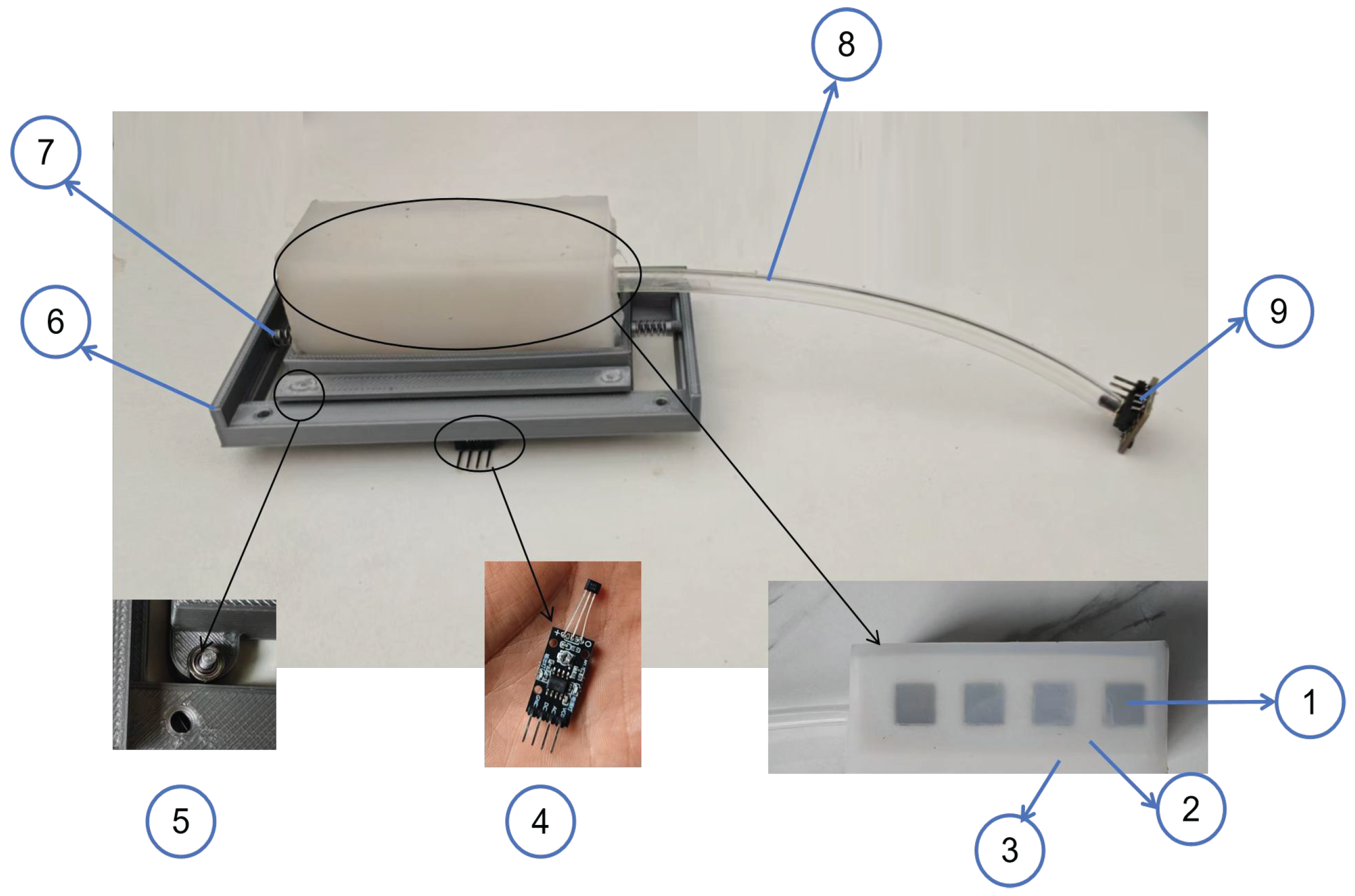

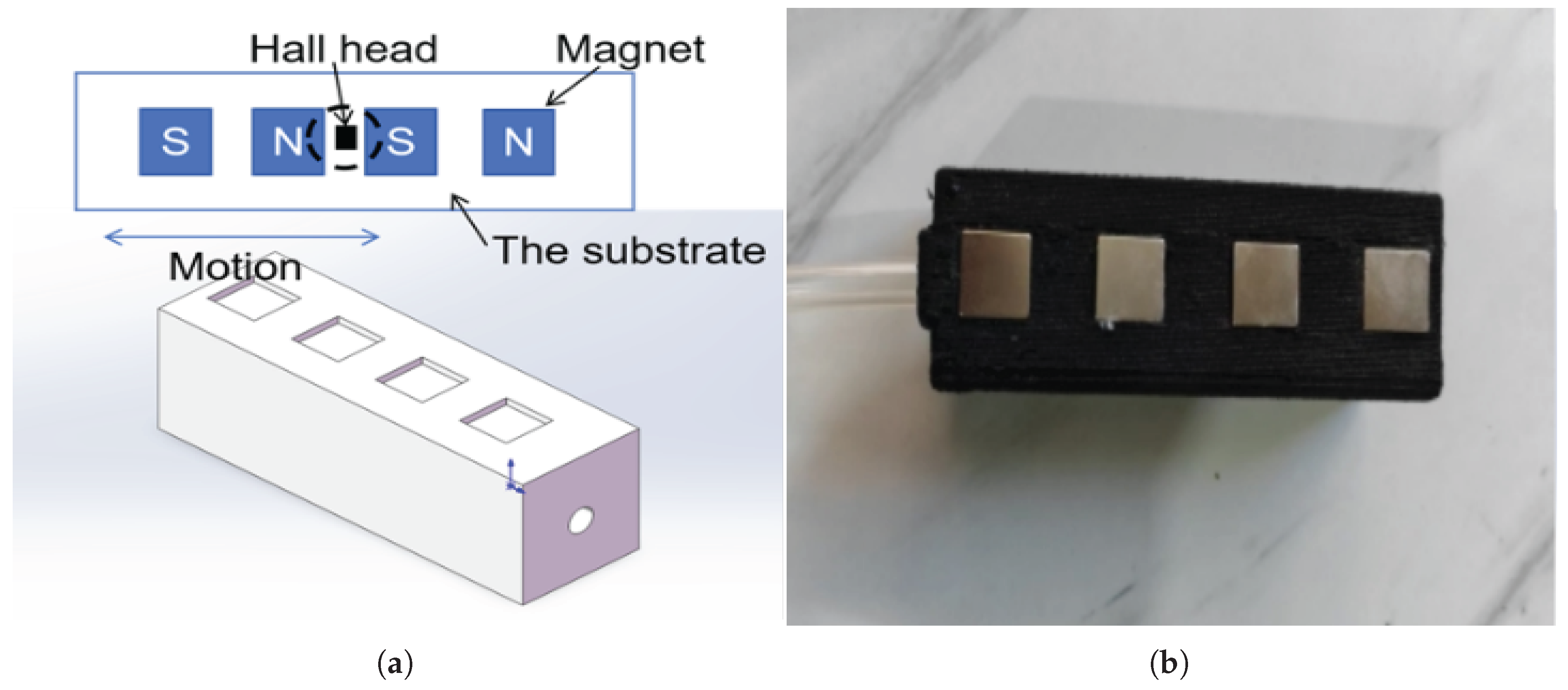

2.2. The Magneto-Sensitive Substrate

3. Experiments and Results

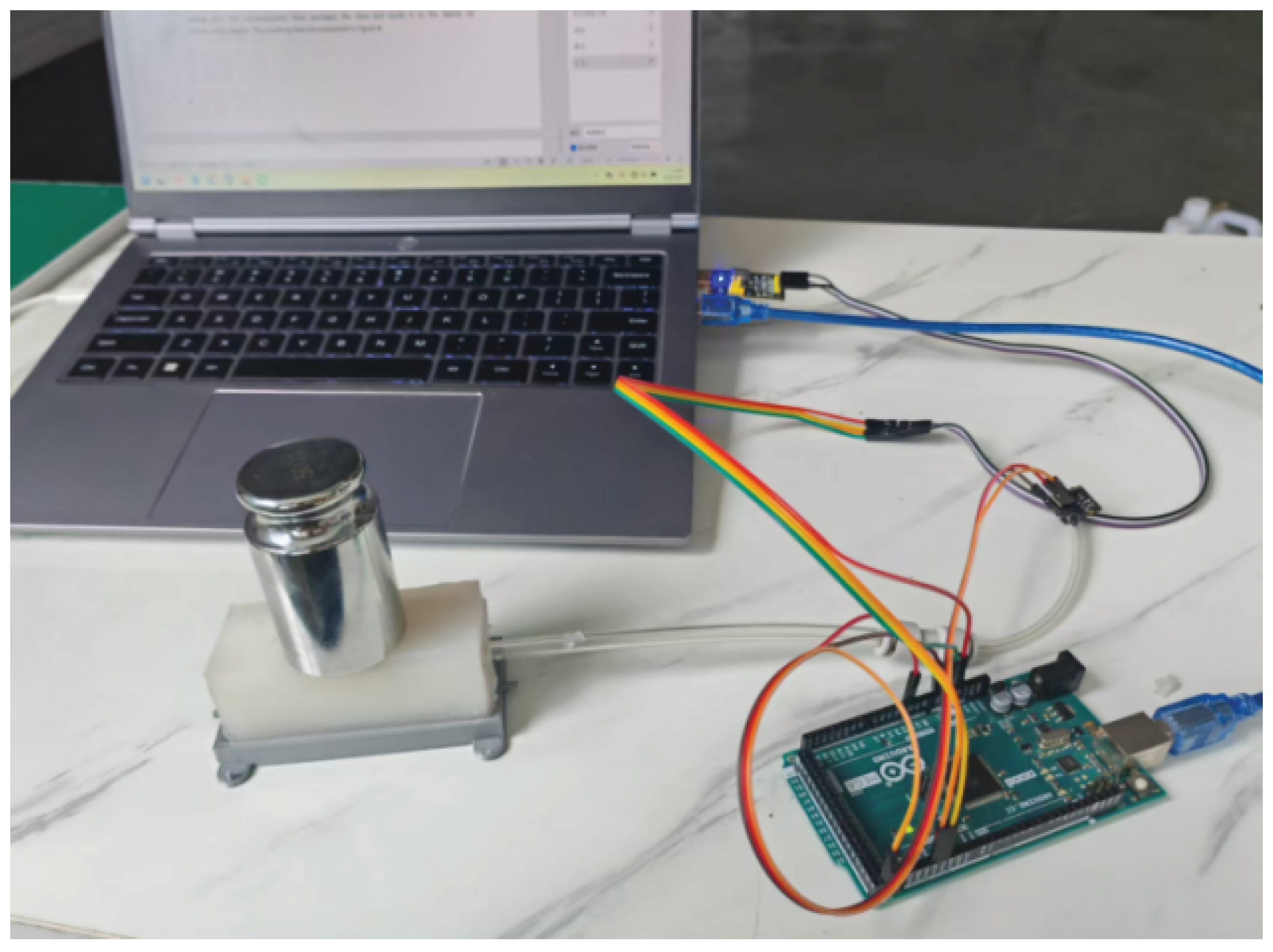

3.1. Contact-Force Experiment

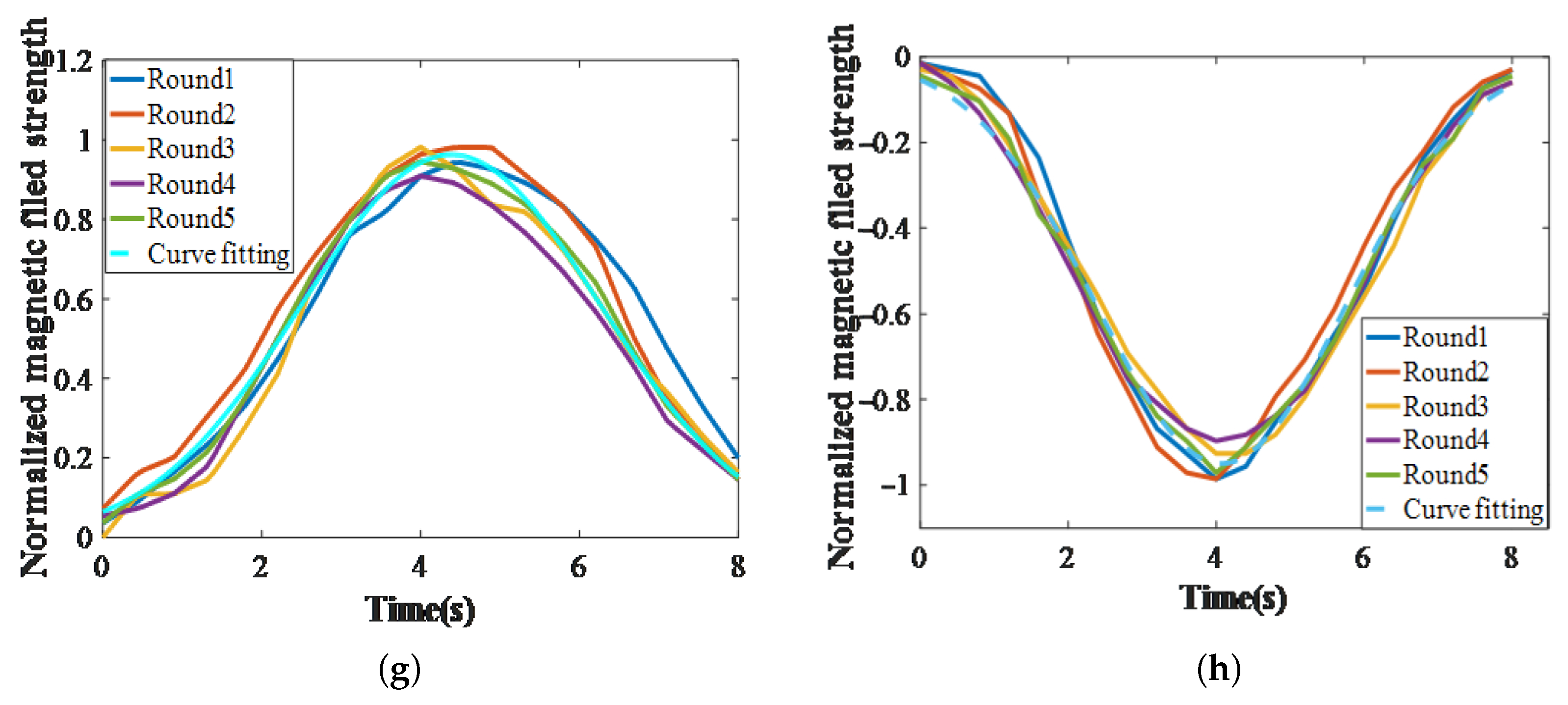

3.2. Motion Detection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 3D | Three-Dimensional |

| PEBA | Polyether Block Amide |

| TPU | Thermoplastic Polyurethane |

| PLA | Polylactic Acid |

| PVA | Polyvinyl Alcohol |

References

- Gierlak, P.; Szuster, M. Adaptive Position/Force Control of a Robotic Manipulator in Contact with a Flexible and Uncertain Environment. Robot. Auton. Syst. 2017, 95, 80–101. [Google Scholar] [CrossRef]

- Urrea, C.; Kern, J. Recent Advances and Challenges in Industrial Robotics: A Systematic Review of Technological Trends and Emerging Applications. Processes 2025, 13, 832. [Google Scholar] [CrossRef]

- Xu, P.; Xia, D.; Li, J.; Zhou, J.; Xie, L. Execution and perception of upper limb exoskeleton for stroke patients: A systematic review. Intell. Serv. Robot. 2022, 15, 567–578. [Google Scholar] [CrossRef]

- Huang, P.; Li, Z.; Zhou, M.C.; Li, X.; Cheng, M. Fuzzy enhanced adaptive admittance control of a wearable walking exoskeleton with step trajectory shaping. IEEE Trans. Fuzzy Syst. 2022, 30, 1541–1552. [Google Scholar] [CrossRef]

- Furukawa, J.I.; Morimoto, J. Transformer-based multitask assist control from first-person view image and user’s kinematic information for exoskeleton robots. NPJ Robot. 2025, 3, 13. [Google Scholar] [CrossRef]

- Ren, J.L.; Wang, A.H.; Li, H.Y.; Yue, X.B.; Meng, L. A Transformer-Based Neural Network for Gait Prediction in Lower Limb Exoskeleton Robots Using. Sensors 2023, 23, 6547. [Google Scholar] [CrossRef]

- Ge, Q.; Jian, B.; Li, H. Shaping soft materials via digital light processing-based 3D printing: A review. Forces Mech. 2022, 6, 100074. [Google Scholar] [CrossRef]

- Rim, Y.S.; Bae, S.H.; Chen, H.; De Marco, N.; Yang, Y. Recent progress in materials and devices toward printable and flexible sensors. Adv. Mater. 2016, 28, 4415–4440. [Google Scholar] [CrossRef]

- Anver, H.M.C.M.; Mutlu, R.; Alici, G. 3D printing of a thin-wall soft and monolithic gripper using fused filament fabrication. In Proceedings of the International Conference on Advanced Intelligent Mechatronics, Munich, Germany, 3–7 July 2017. [Google Scholar]

- Zhang, X.; Yu, S.; Dai, J.; Oseyemi, A.E.; Liu, L.; Du, N.; Lv, F. A modular soft gripper with combined pneu-net actuators. Actuators 2023, 12, 172. [Google Scholar] [CrossRef]

- Yang, M.; Wu, J.; Jiang, W.; Hu, X.; Iqbal, M.I.; Sun, F. Bioinspired and hierarchically textile-structured soft actuators for healthcare wearables. Adv. Funct. Mater. 2023, 33, 2210351. [Google Scholar] [CrossRef]

- Soomro, A.M.; Lee, J.W.; Memon, F.H.; Ahmed, F.; Hussain, K.; Choi, K.H. Bioinspired multi-material polyjet-printed frog robot for synchronous and asynchronous swimming. J. Bionic Eng. 2022, 20, 923–930. [Google Scholar] [CrossRef]

- Yue, T.; Lu, C.; Tang, K.; Qi, Q.; Lu, Z.; Lee, L.Y.; Bloomfield-Gadlha, H.; Rossiter, J. Embodying soft robots with octopus-inspired hierarchical suction intelligence. Sci. Robot. 2025, 10, eadr4264. [Google Scholar] [CrossRef]

- Evans, J. Silicones for medical applications. Polim. Med. 1974, 4, 135–144. [Google Scholar] [CrossRef]

- Xifeng, G.; Yao, S.; Lina, H.; Hui, Y.; Yang, C.; Chaoqun, X. A new soft pneumatic elbow pad for joint assistance with application to smart campus. IEEE Access 2018, 6, 38967–38976. [Google Scholar] [CrossRef]

- Keong, B.A.W.; Hua, R.Y.C. A novel fold-based design approach toward printable soft robotics using flexible 3d printing materials. Adv. Mater. Technol. 2018, 3, 1700172. [Google Scholar] [CrossRef]

- Luo, J.; Xu, C.; Wu, J.; Levine, S. Precise and dexterous robotic manipulation via human-inthe-loop reinforcement learning. Robotics 2025, 10, eads5033. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Feng, M.; Gu, G. High Stroke, High Output Force, Fabric Lattice Artificial Muscles for Soft Robots. Adv. Mater. 2024, 36, 2306928. [Google Scholar] [CrossRef] [PubMed]

- Lai, J.; Song, A.; Wang, J.; Lu, Y.; Wu, T.; Li, H.; Xu, B.; Wei, X. A novel soft glove utilizing honeycomb pneumatic actuators (HPAs) for assisting activities of daily living. IEEE Trans. Neural Syst. Rehabil. Eng. 2023, 31, 3223–3233. [Google Scholar] [CrossRef]

- Yang, H.; Chen, Y.; Sun, Y.; Hao, L. A novel pneumatic soft sensor for measuring contact force and curvature of a soft gripper. Sens. Actuators A Phys. 2017, 266, 318–327. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, J.; Yang, H.; Gao, X.; Liu, J.; Liu, W. A novel variable stiffness soft gripper based on air-quicksand: Design, analysis, and validation. Smart Mater Struct 2024, 33, 055020. [Google Scholar]

- Liu, J.; Ma, Z.; Wang, Y.; Zuo, S. Reconfigurable self-sensing pneumatic artificial muscle with locking ability based on modular multi-chamber soft actuator. IEEE Robot. Autom. Lett. 2022, 7, 8635–8642. [Google Scholar] [CrossRef]

- Hao, L.; Zhao, Z.; Li, X.; Liu, M.; Sun, Y. A safe human–robot interactive control structure with human arm movement detection for an upper-limb wearable robot used during lifting tasks. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420937570. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, X.; Liu, M.; Li, X.; Gao, H.; Hao, L. A novel human-robot interface based on soft skin sensor designed for the upper-limb exoskeleton. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 566–578. [Google Scholar] [CrossRef]

- Zhai, Y.; De Boer, A.; Yan, J.; Shih, B.; Faber, M.; Speros, J.; Gupta, R.; Tolley, M.T. Desktop fabrication of monolithic soft robotic devices with embedded fluidic control circuits. Sci. Robot. 2023, 8, eadg3792. [Google Scholar] [CrossRef]

- Yap, Y.L.; Sing, S.L.; Yeong, W.Y. A review of 3D printing processes and materials for soft robotics. Rapid Prototyp. J. 2020, 26, 1345–1361. [Google Scholar] [CrossRef]

- Hasanshahi, B.; Cao, L.; Song, K.Y.; Zhang, W. Design of Soft Robots: A Review of Methods and Future Opportunities for Research. Machines 2024, 12, 527. [Google Scholar] [CrossRef]

- Cao, V.A.; Nguyen, N.K.; Kim, M.; Van, P.C.; Minh, H.N.; Kim, S.Y.; Nah, J. Multifunctional tactile sensor with multimodal capabilities for pressure, temperature, and surface recognition. Nano Energy 2025, 136, 110706. [Google Scholar] [CrossRef]

- Wu, J.Y.; Pancham, P.P.; Hsu, T.Y.; Mukherjee, A.; Lo, C.Y. Capacitive Tactile Sensor with Stacked Structure and Hybrid Fabrication for Multiaxial Force Decoupling. In Proceedings of the 2022 IEEE Sensors, Dallas, TX, USA, 30 October–2 November 2022. [Google Scholar]

- Ge, J.; Wang, X.; Drack, M.; Volkov, O.; Liang, M.; Gilbert, S.C.B.; Rico, I.; Changan, W.; Shengqiang, Z.; Jürgen, F.; et al. A bimodal soft electronic skin for tactile and touchless interaction in real time. Nat. Commun. 2019, 10, 4405. [Google Scholar] [CrossRef]

- Peng, H.; Xiong, P.W.; Zhang, Y.; Hong, J.H.; Xu, J.N.; Song, A.G. Interference-resistant Multimodal Flexible Electronic Skin for Robotic Interactive Recognition. Robot 2025, 47, 55–63. [Google Scholar]

- Pons, J. Wearable Robots: Biomechatronic Exoskeletons; John Wiley & Sons: New York, NY, USA, 2008. [Google Scholar]

- Liu, M.; Hao, L.; Zhang, W.; Zhao, Z. A novel design of shape-memory alloy-based soft robotic gripper with variable stiffness. Int. J. Adv. Robot. Syst. 2022, 17, 1729881420907813. [Google Scholar] [CrossRef]

- Zhang, H.; Qin, L.; Chen, Y.; Long, T.; Guan, R.; Cheng, X.; Chen, B.; Zhou, C. Silicone-enhanced polyvinyl alcohol hydrogels for high performance wearable strain sensors. Mater. Des. 2023, 229, 111911. [Google Scholar] [CrossRef]

- Georgopoulou, A.; Michel, S.; Clemens, F. Sensorized robotic skin based on piezoresistive sensor fiber composites produced with injection molding of liquid silicone. Polymers 2021, 13, 1226. [Google Scholar] [CrossRef]

- Du, X.Y.; Liu, Y.; Mo, S.; He, M.H.; Zhai, L.; Fan, L. Research progress in 3D printing of polyimide material. Scichina 2024, 54, 856–870. [Google Scholar] [CrossRef]

- Li, L.Y.; Han, J.H.; Li, X.P.; Guo, B.; Du, H. Customization and optimization of the upper limb rehabilitation trajectory and compliance tracking control. Adv. Eng. Sci. 2023, 55, 194–203. [Google Scholar]

- Raiola, G.; Cardenas, C.A.; Tadele, T.S.; Vries de, T.; Stramigioli, S. Development of a Safety and Energy Aware Impedance Controller for Collaborative Robots. IEEE Robot. Autom. Lett. 2018, 3, 1237–1244. [Google Scholar] [CrossRef]

| Material | Hardness | Density | Elastic Modulus | Melting Point |

|---|---|---|---|---|

| Silicone | 25A | 1.1 g/ | 0.8 to 1.2 MPa | Not given |

| TPU | 66A | 0.54 g/ | 3.59 MPa | 240 Celsius |

| PEBA | 80A | 0.8 g/ | 9.65 MPa | 245 Celsius |

| Material | Length | Width | Height | Thickness | Mass |

|---|---|---|---|---|---|

| Silicone | 85 mm | 30 mm | 25 mm | 3 mm | 74.77 g |

| TPU–silicone composite | 82 mm | 28 mm | 25 mm | 1.5 mm TPU and 2 mm silicone | 53.12 g |

| PEBA–silicone composite | 82 mm | 28 mm | 26 mm | 1.5 mm PEBA and 2 mm silicone | 56.31 g |

| Vector | (Left/Right) | (Left/Right) | (Left/Right) | r (Left/Right) |

|---|---|---|---|---|

| 1 cm/s | 0.8962/−0.8741 | 0.5414/0.4005 | 0.3422/0.3141 | 0.83/0.89 |

| 0.5 cm/s | 0.8217/−0.7683 | 1.075/0.8358 | 0.6479/0.7728 | 0.91/0.87 |

| 0.25 cm/s | 0.918/−0.9587 | 2/1.952 | 1.144/1.319 | 0.95/0.97 |

| 0.125 cm/s | 0.9625/−0.9496 | 4.068/4.382 | 2.399/2.667 | 0.99/0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Z.; Xia, C.; Zeng, X.; Hou, X.; Hao, L.; Shan, D.; Xu, J. Design of a PEBA–Silicone Composite Magneto-Sensitive Airbag Sensor for Simultaneous Contact Force and Motion Detection. Sensors 2025, 25, 5823. https://doi.org/10.3390/s25185823

Zhao Z, Xia C, Zeng X, Hou X, Hao L, Shan D, Xu J. Design of a PEBA–Silicone Composite Magneto-Sensitive Airbag Sensor for Simultaneous Contact Force and Motion Detection. Sensors. 2025; 25(18):5823. https://doi.org/10.3390/s25185823

Chicago/Turabian StyleZhao, Zhirui, Chun Xia, Xinyu Zeng, Xinyu Hou, Lina Hao, Dexing Shan, and Jiqian Xu. 2025. "Design of a PEBA–Silicone Composite Magneto-Sensitive Airbag Sensor for Simultaneous Contact Force and Motion Detection" Sensors 25, no. 18: 5823. https://doi.org/10.3390/s25185823

APA StyleZhao, Z., Xia, C., Zeng, X., Hou, X., Hao, L., Shan, D., & Xu, J. (2025). Design of a PEBA–Silicone Composite Magneto-Sensitive Airbag Sensor for Simultaneous Contact Force and Motion Detection. Sensors, 25(18), 5823. https://doi.org/10.3390/s25185823