Trajectory Tracking Control of High-Speed Vehicles on Wet and Slippery Roads

Abstract

Highlights

- In response to the limited existing research on high-speed autonomous driving under low-adhesion, slippery road conditions, a novel MPC-PID fused trajectory tracking control algorithm is proposed. This approach significantly enhances tracking accuracy and vehicle stability under such complex scenarios.

- Joint simulation results demonstrate that the proposed method improves trajectory tracking accuracy by at least 22.2%, while comfort, fuel economy, and safety are improved by 9.4%, 19.8%, and 5.3%, respectively.

- This work provides theoretical support and simulation validation for high-speed trajectory tracking control under low-adhesion conditions, offering high engineering applicability and practical significance.

- The proposed approach facilitates real-time, precise, and robust autonomous driving in dynamically complex environments, promoting the deployment of high-performance control strategies in real-world applications.

Abstract

1. Introduction

- Path tracking study of autonomous vehicles under high-speed driving conditions on wet and slippery roads. At present, there is a lack of in-depth research on these kinds of working conditions in the field of autonomous vehicles, but solving any issues related to these conditions is crucial for the promotion of autonomous vehicles in the future, and this study effectively fills this research gap, which is of great significance and value to engineering practice;

- Joint controller design of MPC and PID control. By effectively combining the advantages of MPC’s high accuracy and PID control’s low response delay, the joint controller shows excellent performance under high-speed driving conditions on slippery roads. Moreover, due to the real-time adjustable parameters of PID control, the joint controller has good scalability and has strong potential for other complex tracking paths and complex working conditions;

- Comprehensive evaluation index for multi-objective co-optimization. In this study, the comprehensive evaluation indexes of path tracking accuracy, comfort, economy, and safety are constructed, which can provide an objective and comprehensive performance evaluation of the designed controllers as well as of multiple sets of controller parameters, vehicle speeds, and roadway adhesion coefficients.

2. Control Strategies for High-Speed Driving on Wet and Slippery Roads

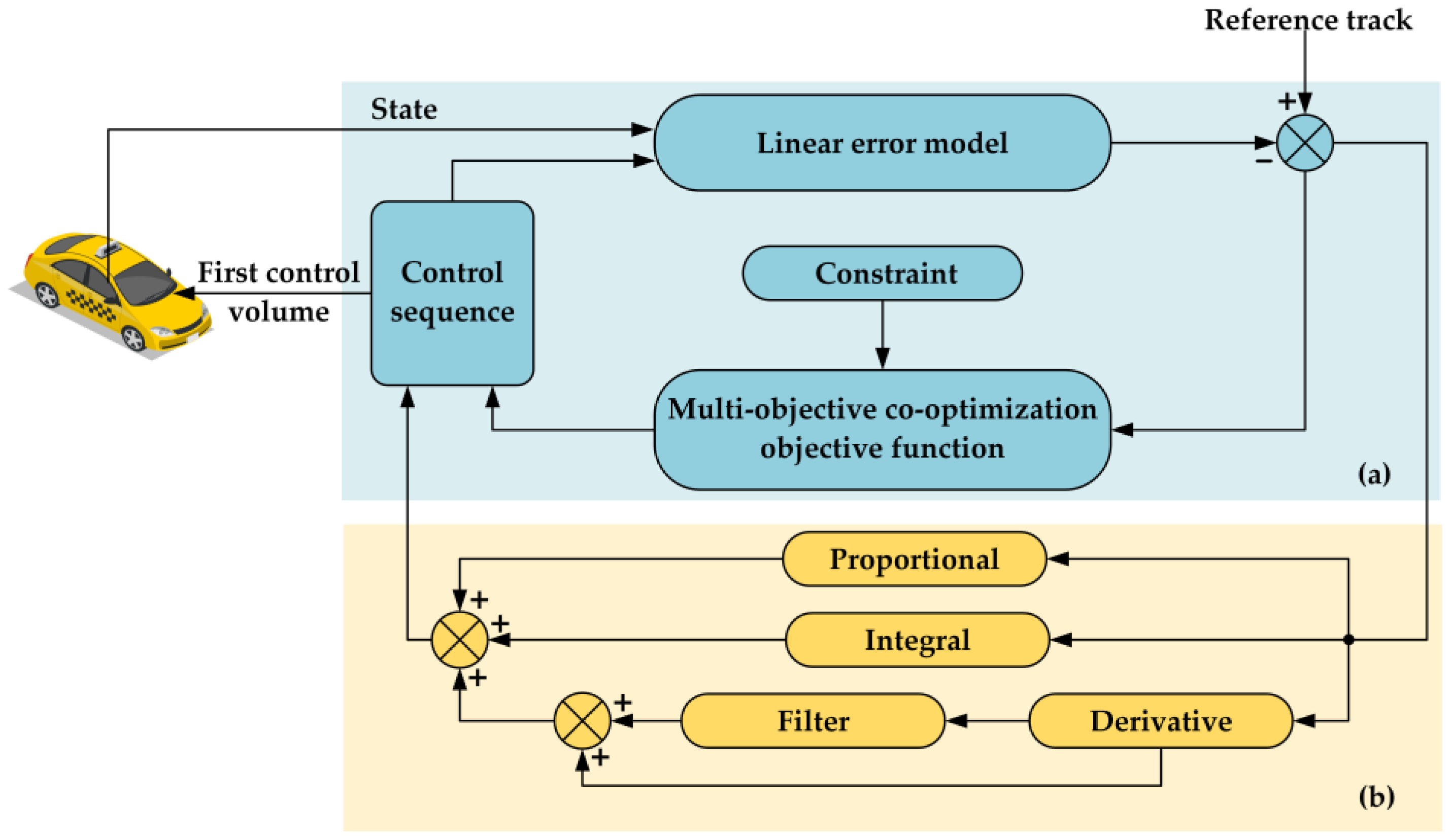

3. Joint Controller Design for MPC and PID Control

3.1. MPC Controller Design

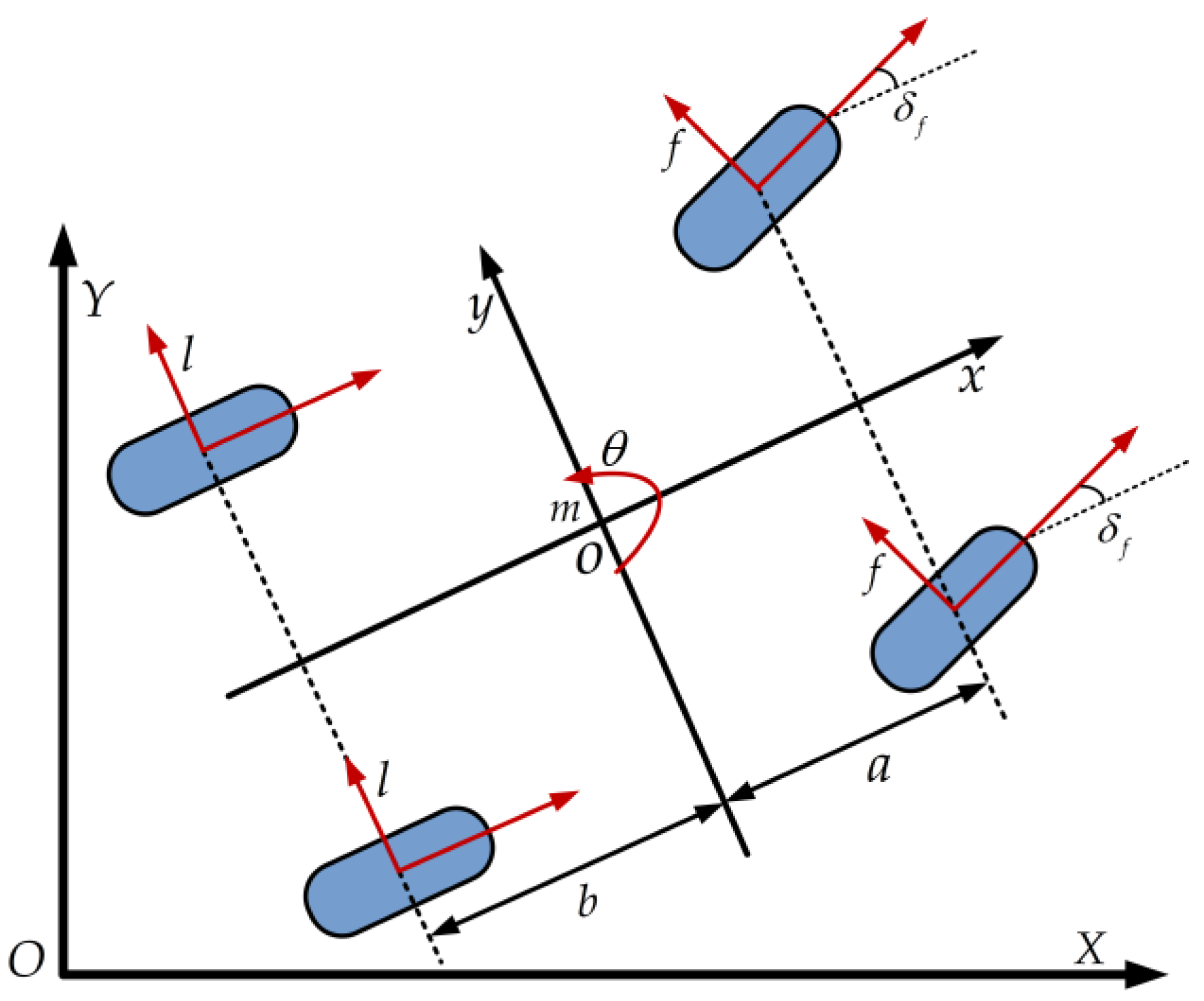

3.1.1. Linear Error Model

- The vehicle travels on a flat road surface with no vertical motion;

- The suspension and vehicle body are considered rigid;

- The coupling between longitudinal and lateral tire forces is neglected, and only lateral slip behavior is modeled;

- A 3-DOF (three-Degree-Of-Freedom) bicycle model is used to describe lateral, longitudinal, and yaw motion;

- Load transfer between the front and rear axles is ignored;

- Vehicle speed is assumed to vary slowly, and aerodynamic effects in both directions are neglected.

3.1.2. Multi-Objective Co-Optimization Objective Function and Constraints

3.2. Design of PID Controller with Forward Feedback

4. Multi-Objective Collaborative Optimization Index

4.1. Tracking Accuracy Evaluation Index

4.2. Comfort Evaluation Index

4.3. Vehicle Economy Evaluation Index

4.4. Vehicle Safety Indicators

5. Analysis of Influencing Factors of Control Effect

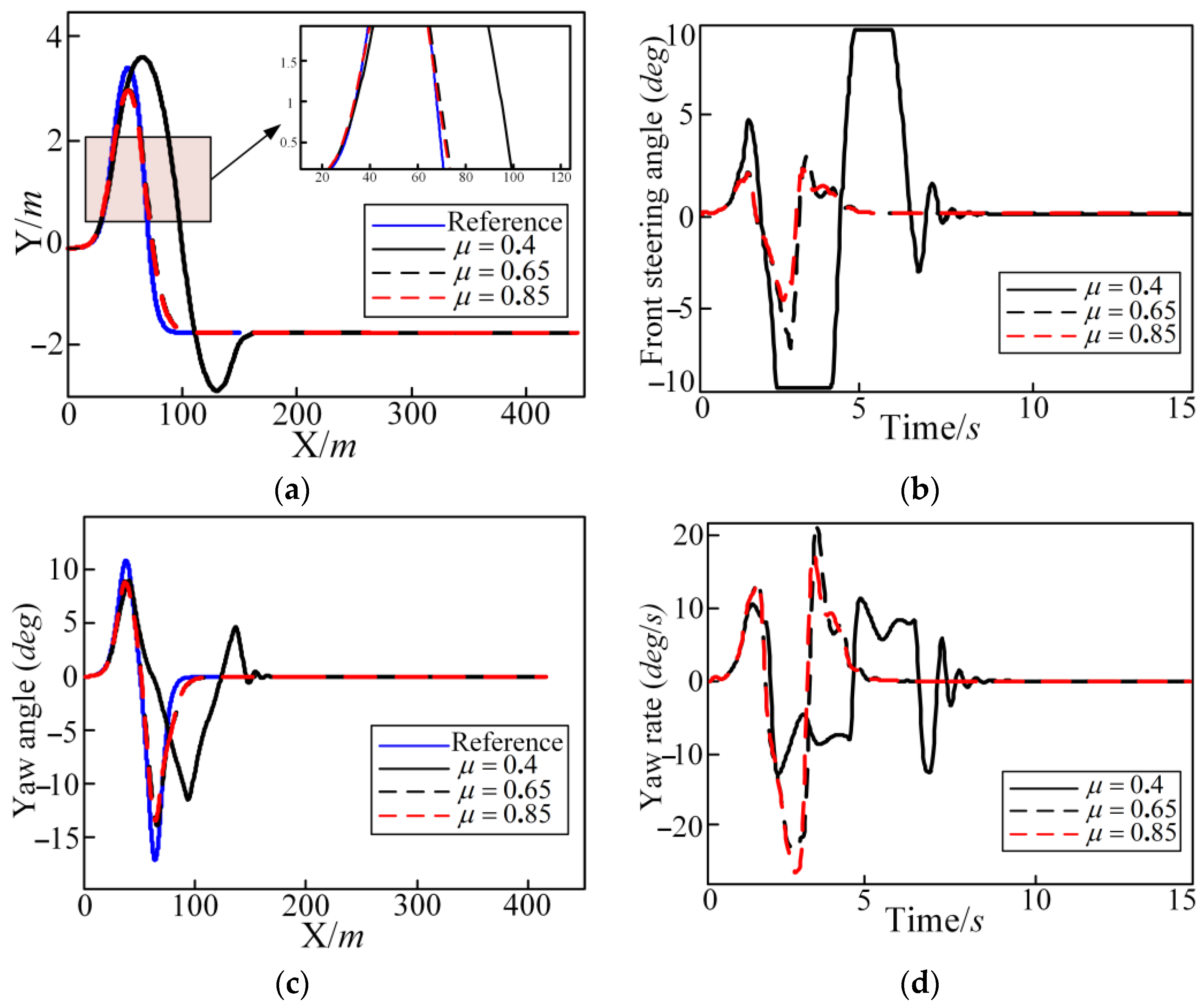

5.1. Influence Law of Road Adhesion Coefficient on Tracking Control

5.2. Influence of Driving Speed on Tracking Control of Controller

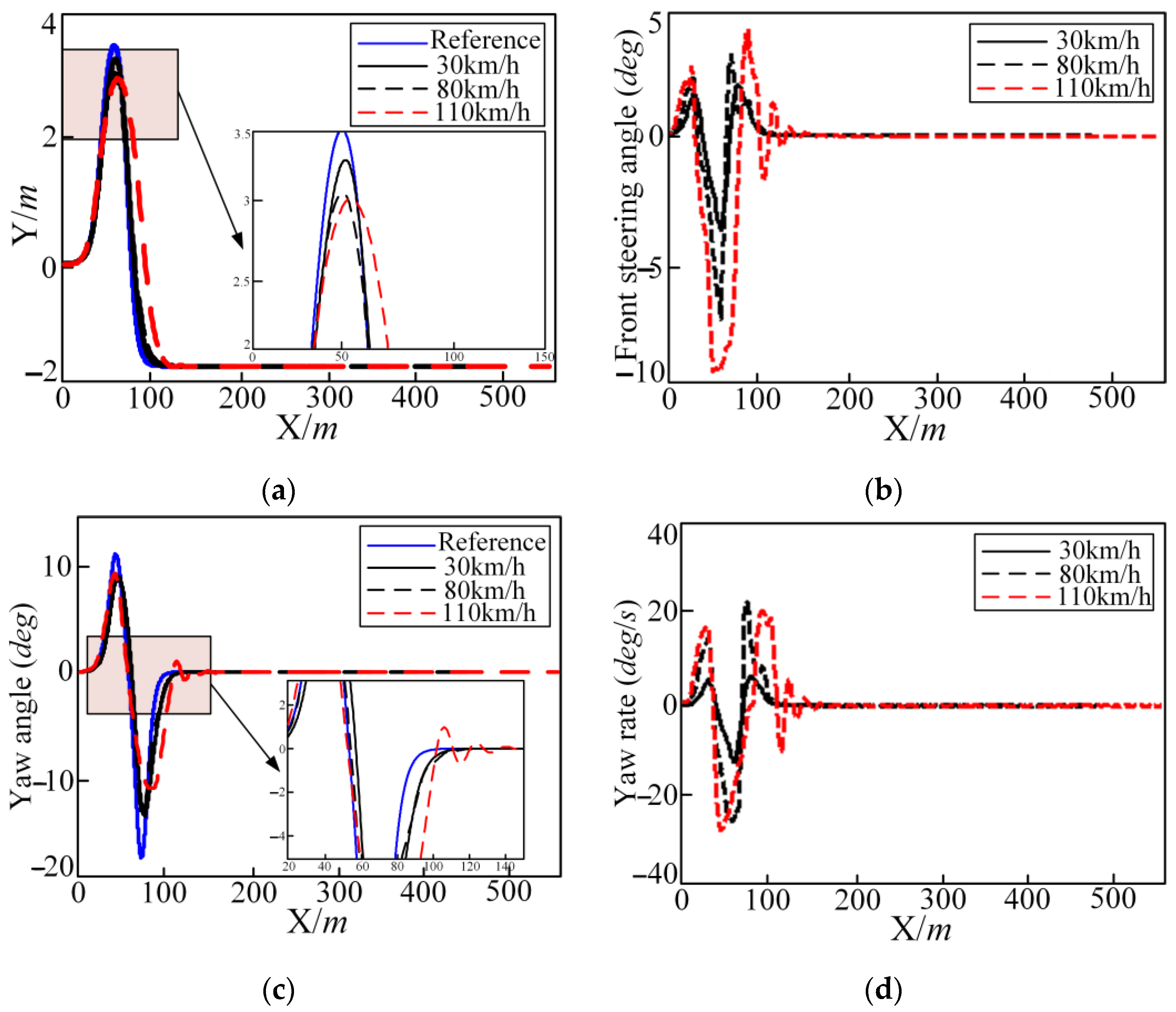

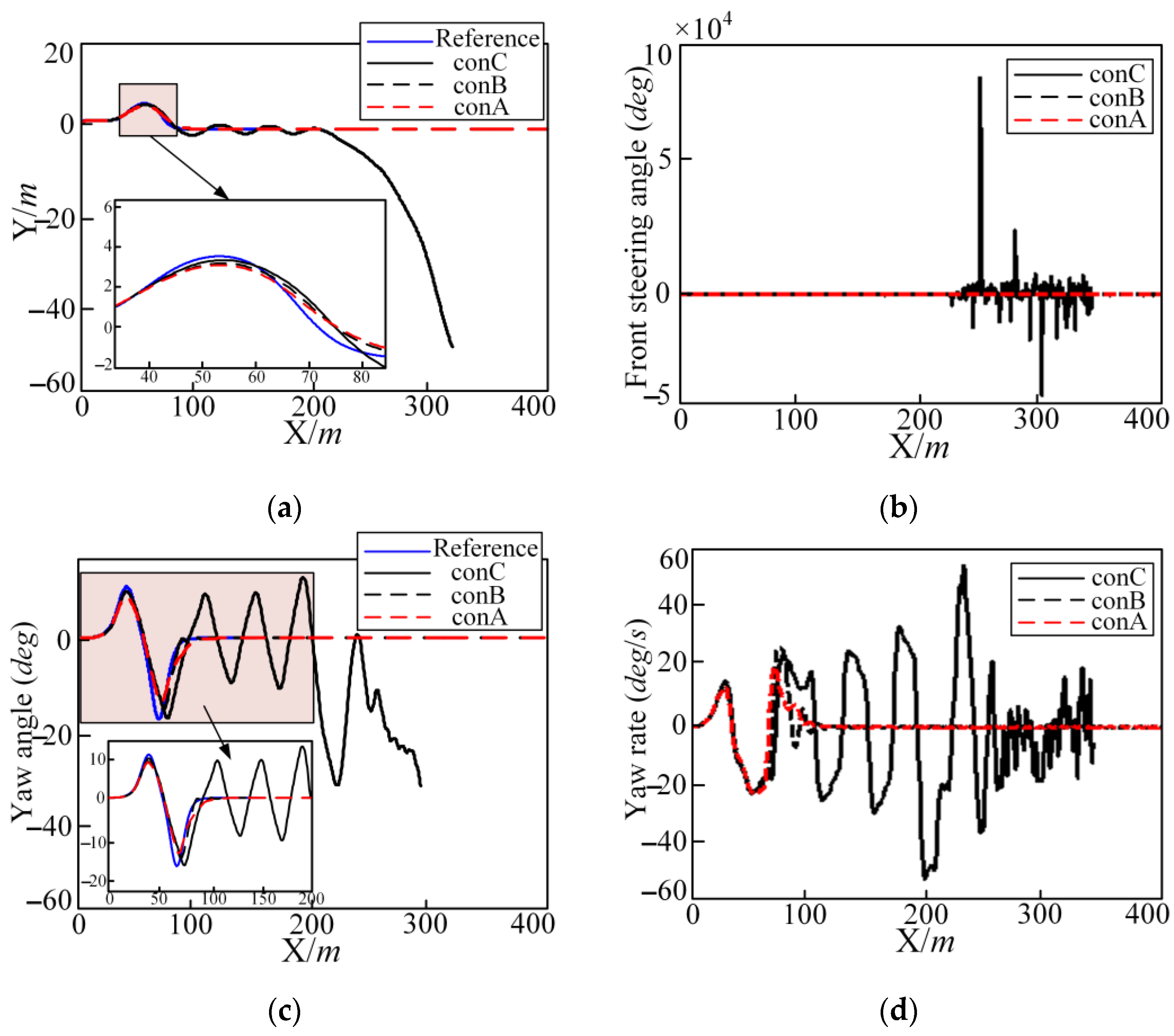

5.3. Influence of Tracking Controller Parameters

- The parameters of tracking controller A: sampling time interval , , , , and ;

- The parameters of tracking controller B: sampling time interval , , , , and ;

- The parameters of tracking controller C: sampling time interval , , , , and .

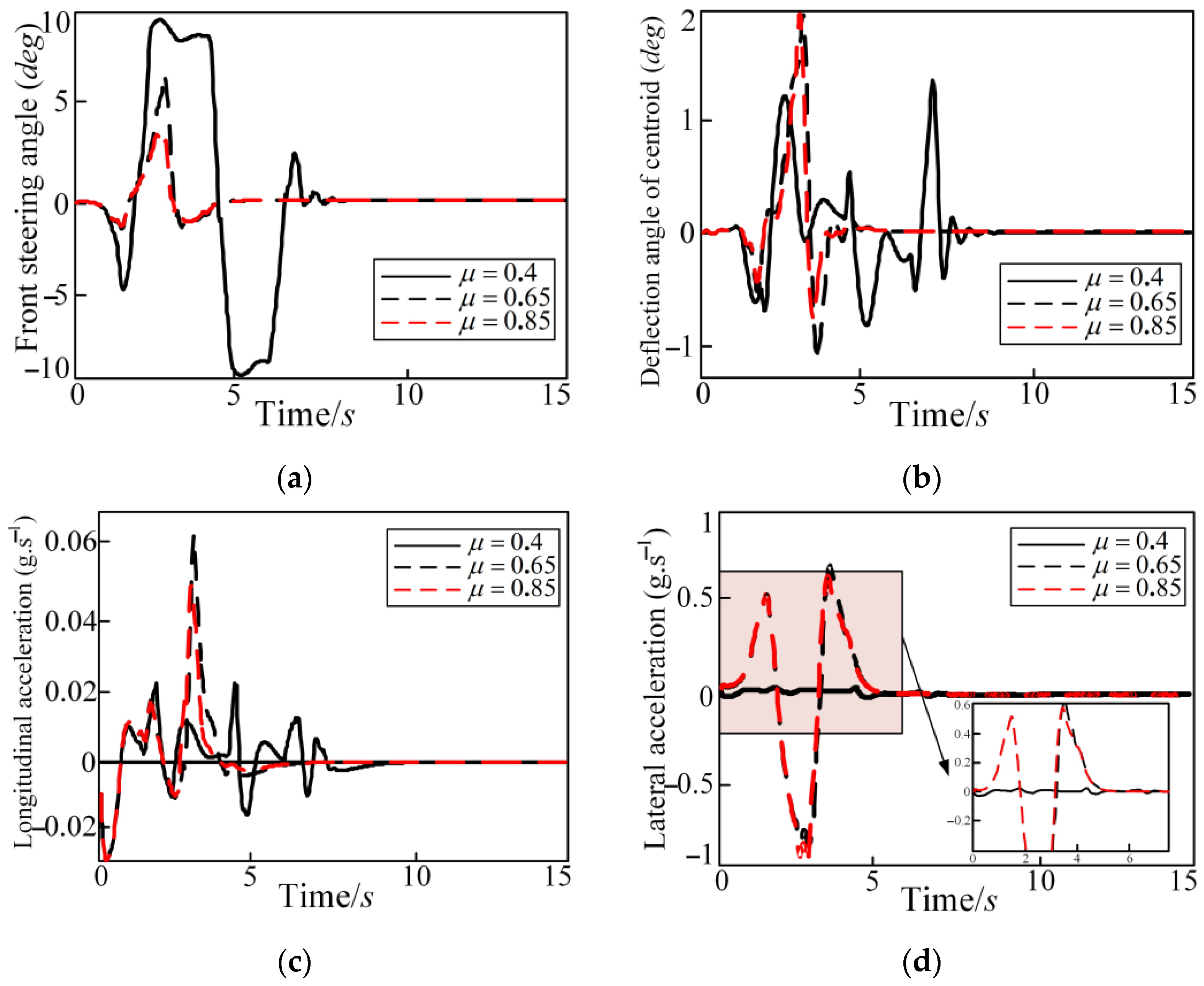

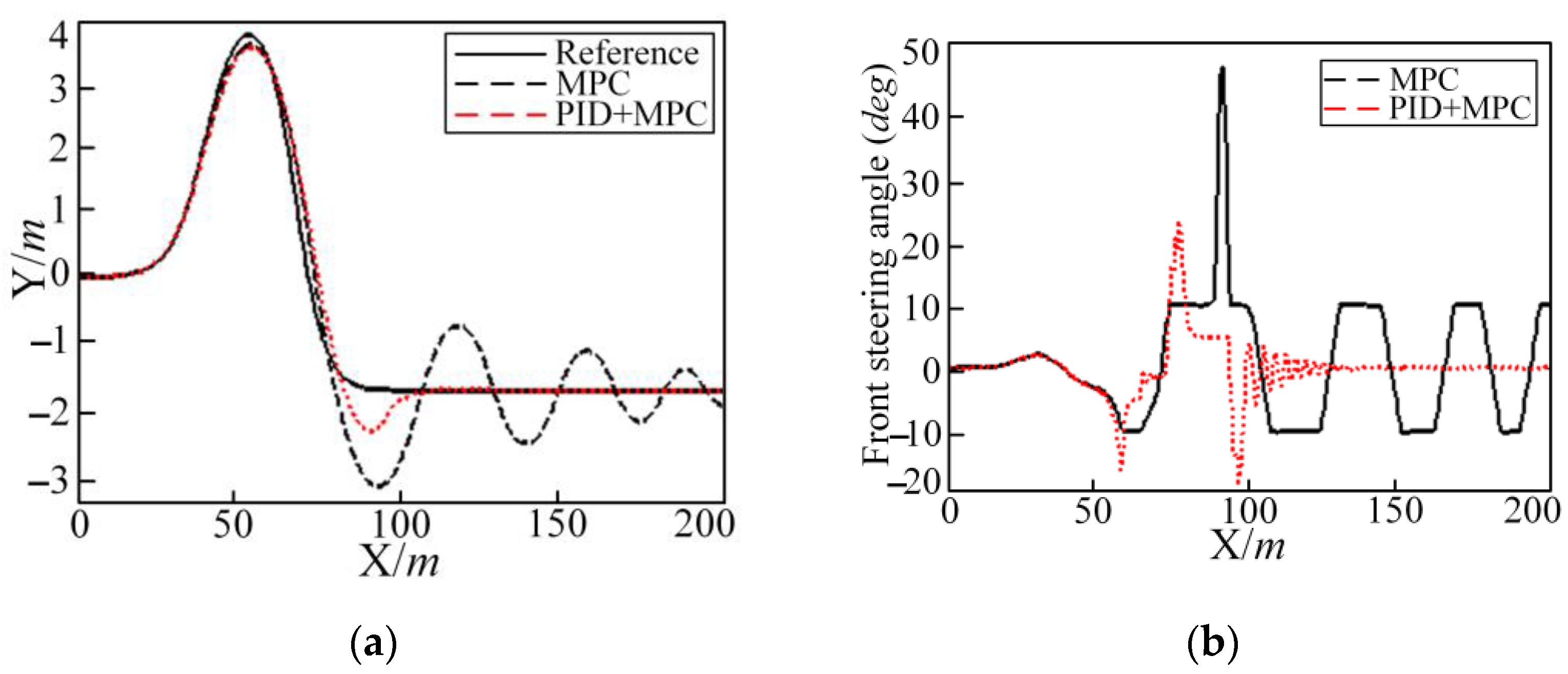

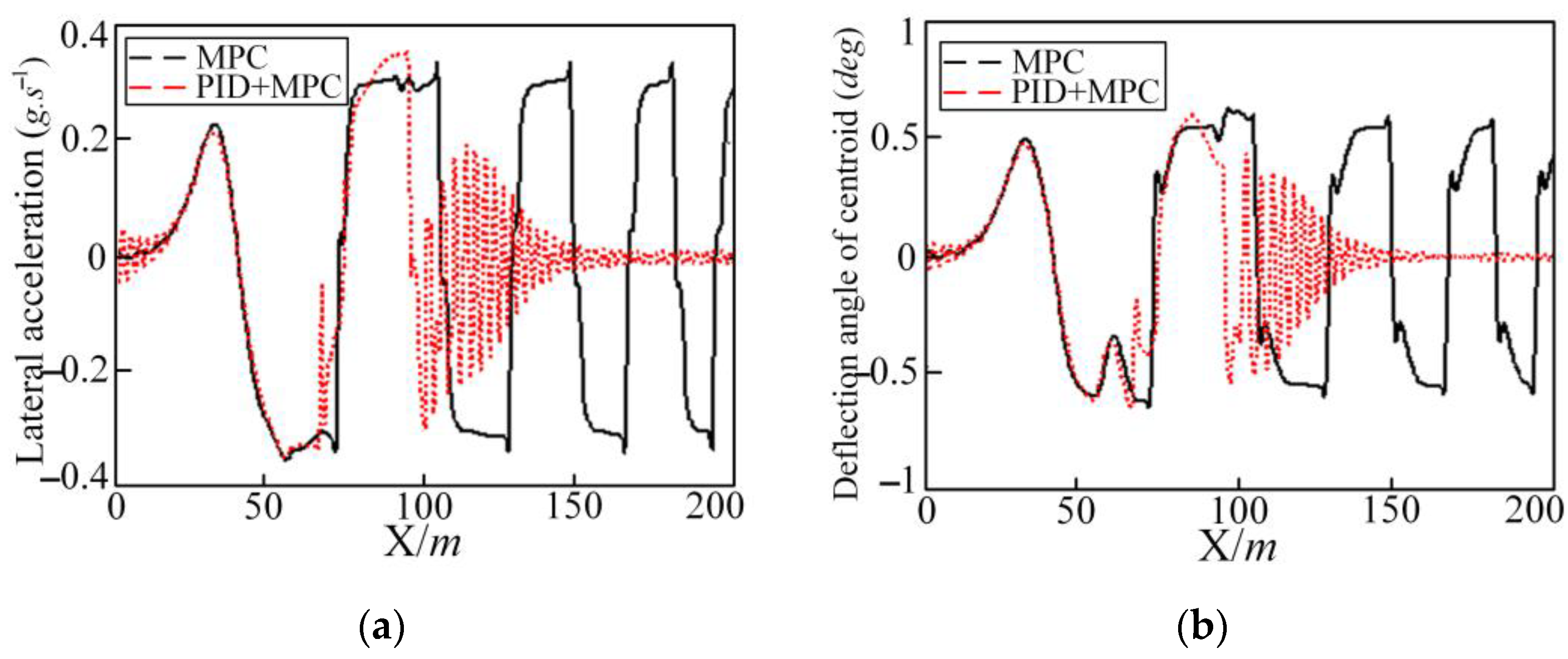

5.4. Simulation Results of Combined Controller of MPC and PID Control on Wet and Slippery Roads

6. Conclusions

- The vehicle dynamics model is used as the basis of the predictive model controller. The trajectory tracking controller under the high-speed driving conditions is designed to improve the controller’s ability to predict the future behavior of the vehicle and ensure the stability of the vehicle. In order to achieve a good multi-objective cooperative control effect, the control constraints, state constraints, and the initial and end state constraints are imposed on the control objective function. The multi-objective performance evaluation indicators are designed.

- The simulation test is carried out on the DLC condition. The influence of the road adhesion coefficient, driving speed, and controller parameters on the control effect under different driving conditions are analyzed. The evaluation index values are calculated to compare and analyze the influence of the various factors on the control effect of the controller.

- The combined controller method of PID control and MPC is proposed when the level of wet and slippery roads and the controller hardware is low. However, the research results show that the simple MPC controller has a better control effect on good roads and that the combined controller of PID control and MPC can make up for shortcomings of simple the MPC controller under high-speed driving conditions on wet and slippery roads, making the vehicle trajectory tracking more efficient, comfortable, and economical. The safety control indicators have been significantly optimized. The controller parameters are set to and ; the longitudinal vehicle speed is 50 km/h; and the road adhesion coefficient . After adding the PID joint controller, the tracking accuracy index is increased by 36.3%. An examination of the data reveals a marked increase in comfort, economy, and safety indicators, with respective growth rates of 38.6%, 19.8%, and 8.7%. The controller parameters are , , the road adhesion coefficient , and the tracking accuracy index is increased by 53.9% at 50 km/h. An examination of the data reveals a marked increase in comfort, economy, and safety indicators, with respective growth rates of 87.4%, 52.1%, and 47.5%. At 85 km/h, the tracking accuracy index is increased by 22.2%. An examination of the data reveals a marked increase in comfort, economy, and safety indicators, with respective growth rates of 9.4%, 51%, and 5.3%. Based on the above experimental data, it is shown that the joint controller of MPC and PID control can effectively improve the comprehensive performance of the path tracking control of autonomous vehicles when driving at high speeds on wet and slippery roads. This work provides an effective engineering practice reference for the research of autonomous vehicles under complex working conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, D.; Pan, S.; Yu, Y.; Hu, Y.; Yang, J.; Zhang, P.; Xiong, L.; Carbone, G.; Gao, L. A Comparative Study on Trajectory Tracking Control Methods for Automated Vehicles. Sci. Rep. 2025, 15, 17073. [Google Scholar] [CrossRef]

- Huang, Z.; Li, H.; Li, W.; Liu, J.; Huang, C.; Yang, Z.; Fang, W. A New Trajectory Tracking Algorithm for Autonomous Vehicles Based on Model Predictive Control. Sensors 2021, 21, 7165. [Google Scholar] [CrossRef] [PubMed]

- Dong, D.; Ye, H.; Luo, W.; Wen, J.; Huang, D. Fast Trajectory Tracking Control Algorithm for Autonomous Vehicles Based on the Alternating Direction Multiplier Method (ADMM) to the Receding Optimization of Model Predictive Control (MPC). Sensors 2023, 23, 8391. [Google Scholar] [CrossRef] [PubMed]

- Vu, T.M.; Moezzi, R.; Cyrus, J.; Hlava, J.; Petru, M. Feasible Trajectories Generation for Autonomous Driving Vehicles. Applied Sciences 2021, 11, 11143. [Google Scholar] [CrossRef]

- Borri, A.; Bianchi, D.; Di Benedetto, M.D.; Di Gennaro, S. Optimal Workload Actuator Balancing and Dynamic Reference Generation in Active Vehicle Control. J. Frankl. Inst. 2017, 354, 1722–1740. [Google Scholar] [CrossRef]

- Zhang, C.; Chu, D.; Liu, S.; Deng, Z.; Wu, C.; Su, X. Trajectory Planning and Tracking for Autonomous Vehicle Based on State Lattice and Model Predictive Control. IEEE Intell. Transport. Syst. Mag. 2019, 11, 29–40. [Google Scholar] [CrossRef]

- Zhiwei, G.; Jianfeng, D.; Feng, D. Simulation Research on Trajectory Tracking Controller Based on MPC Algorithm. In Proceedings of the 2017 2nd International Conference on Robotics and Automation Engineering (ICRAE), Shanghai, China, 29–31 December 2017; pp. 212–216. [Google Scholar]

- Liu, P.; Wang, Y.; Cong, W.; Lei, W. Grouping-Sorting-Optimized Model Predictive Control for Modular Multilevel Converter with Reduced Computational Load. IEEE Trans. Power Electron. 2016, 31, 1896–1907. [Google Scholar] [CrossRef]

- Tang, L.; Yan, F.; Zou, B.; Wang, K.; Lv, C. An Improved Kinematic Model Predictive Control for High-Speed Path Tracking of Autonomous Vehicles. IEEE Access 2020, 8, 51400–51413. [Google Scholar] [CrossRef]

- Dong, D.; Ye, H.; Luo, W.; Wen, J.; Huang, D. Collision Avoidance Path Planning and Tracking Control for Autonomous Vehicles Based on Model Predictive Control. Sensors 2024, 24, 5211. [Google Scholar] [CrossRef]

- Tan, W.; Wang, M.; Ma, K. Research on Intelligent Vehicle Trajectory Tracking Control Based on Improved Adaptive MPC. Sensors 2024, 24, 2316. [Google Scholar] [CrossRef]

- Yang, H.; He, Y.; Xu, Y.; Zhao, H. Collision Avoidance for Autonomous Vehicles Based on MPC with Adaptive APF. IEEE Trans. Intell. Veh. 2024, 9, 1559–1570. [Google Scholar] [CrossRef]

- Domina, Á.; Tihanyi, V. Model Predictive Controller Approach for Automated Vehicle’s Path Tracking. Sensors 2023, 23, 6862. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Valenzuela, J.; Perez-Alcocer, R.; Guerrero-Medina, M.; Dzul, A. Nonlinear PID-Type Controller for Quadrotor Trajectory Tracking. IEEE/ASME Trans. Mechatron. 2018, 23, 2436–2447. [Google Scholar] [CrossRef]

- Shan, Y.; Yang, W.; Chen, C.; Zhou, J.; Zheng, L.; Li, B. CF-Pursuit: A Pursuit Method with a Clothoid Fitting and a Fuzzy Controller for Autonomous Vehicles. Int. J. Adv. Robot. Syst. 2015, 12, 134. [Google Scholar] [CrossRef]

- Morales, S.; Magallanes, J.; Delgado, C.; Canahuire, R. LQR Trajectory Tracking Control of an Omnidirectional Wheeled Mobile Robot. In Proceedings of the 2018 IEEE 2nd Colombian Conference on Robotics and Automation (CCRA), Barranquilla, Colombia, 1–3 November 2018; pp. 1–5. [Google Scholar]

- Chen, J.; Zhan, W.; Tomizuka, M. Autonomous Driving Motion Planning with Constrained Iterative LQR. IEEE Trans. Intell. Veh. 2019, 4, 244–254. [Google Scholar] [CrossRef]

- Shen, C.; Shi, Y.; Buckham, B. Trajectory Tracking Control of an Autonomous Underwater Vehicle Using Lyapunov-Based Model Predictive Control. IEEE Trans. Ind. Electron. 2018, 65, 5796–5805. [Google Scholar] [CrossRef]

- Falcone, P.; Borrelli, F.; Asgari, J.; Tseng, H.E.; Hrovat, D. Predictive Active Steering Control for Autonomous Vehicle Systems. IEEE Trans. Contr. Syst. Technol. 2007, 15, 566–580. [Google Scholar] [CrossRef]

- Bai, G.; Meng, Y.; Liu, L.; Luo, W.; Gu, Q.; Li, K. A New Path Tracking Method Based on Multilayer Model Predictive Control. Appl. Sci. 2019, 9, 2649. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Yang, X.; Hu, F.; Jiang, A.; Yang, C. Trajectory Tracking of an Omni-Directional Wheeled Mobile Robot Using a Model Predictive Control Strategy. Appl. Sci. 2018, 8, 231. [Google Scholar] [CrossRef]

- Weiskircher, T.; Wang, Q.; Ayalew, B. Predictive Guidance and Control Framework for (Semi-)Autonomous Vehicles in Public Traffic. IEEE Trans. Contr. Syst. Technol. 2017, 25, 2034–2046. [Google Scholar] [CrossRef]

- Wu, H.; Si, Z.; Li, Z. Trajectory Tracking Control for Four-Wheel Independent Drive Intelligent Vehicle Based on Model Predictive Control. IEEE Access 2020, 8, 73071–73081. [Google Scholar] [CrossRef]

- Gallep, J.; Govender, V.; Müller, S. Model Predictive Lateral Vehicle Guidance Using a Position Controlled EPS System. IFAC-PapersOnLine 2017, 50, 265–270. [Google Scholar] [CrossRef]

- Paden, B.; Cap, M.; Yong, S.Z.; Yershov, D.; Frazzoli, E. A Survey of Motion Planning and Control Techniques for Self-Driving Urban Vehicles. IEEE Trans. Intell. Veh. 2016, 1, 33–55. [Google Scholar] [CrossRef]

- Zietkiewicz, J.; Owczarkowski, A. Direct Nonlinear Model Predictive Control and Predictive Control with Feedback Linearization. A Comparison of the Approaches. In Proceedings of the 2017 18th International Carpathian Control Conference (ICCC), Sinaia, Romania, 28–31 May 2017; pp. 451–455. [Google Scholar]

- Li, S.; Li, Z.; Yu, Z.; Zhang, B.; Zhang, N. Dynamic Trajectory Planning and Tracking for Autonomous Vehicle with Obstacle Avoidance Based on Model Predictive Control. IEEE Access 2019, 7, 132074–132086. [Google Scholar] [CrossRef]

- Tan, Q.; Dai, P.; Zhang, Z.; Katupitiya, J. MPC and PSO Based Control Methodology for Path Tracking of 4WS4WD Vehicles. Applied Sciences 2018, 8, 1000. [Google Scholar] [CrossRef]

- Rafaila, R.C.; Livint, G. Predictive Control of Autonomous Steering for Ground Vehicles. In Proceedings of the 2015 9th International Symposium on Advanced Topics in Electrical Engineering (ATEE), Bucharest, Romania, 7–9 May 2015; pp. 543–547. [Google Scholar]

- Chen, J.; Lin, C.; Liang, S. Mixed Logical Dynamical Model-Based MPC for Yaw Stability Control of Distributed Drive Electric Vehicles. Energy Procedia 2019, 158, 2518–2523. [Google Scholar] [CrossRef]

- Rafaila, R.C.; Livint, G. Nonlinear Model Predictive Control of Autonomous Vehicle Steering. In Proceedings of the 2015 19th International Conference on System Theory, Control and Computing (ICSTCC), Cheile Gradistei, Romania, 14–16 October 2015; pp. 466–471. [Google Scholar]

- Kayacan, E.; Saeys, W.; Ramon, H.; Belta, C.; Peschel, J.M. Experimental Validation of Linear and Nonlinear MPC on an Articulated Unmanned Ground Vehicle. IEEE/ASME Trans. Mechatron. 2018, 23, 2023–2030. [Google Scholar] [CrossRef]

- Kayacan, E.; Kayacan, E.; Ramon, H.; Saeys, W. Robust Tube-Based Decentralized Nonlinear Model Predictive Control of an Autonomous Tractor-Trailer System. IEEE/ASME Trans. Mechatron. 2015, 20, 447–456. [Google Scholar] [CrossRef]

- Romano, L. Nonlinear Modelling of Transient Tyre Dynamics. Nonlinear Dyn. 2025, 113, 15901–15923. [Google Scholar] [CrossRef]

- Lin, F.; Sun, M.; Wu, J.; Qian, C. Path Tracking Control of Autonomous Vehicle Based on Nonlinear Tire Model. Actuators 2021, 10, 242. [Google Scholar] [CrossRef]

- Kim, I.Y.; Yang, K.S.; Joo Baek, J.; Hwang, S.-H. Development of Intelligent Electric Vehicle for Study of Unmanned Autonomous Driving Algorithm. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; pp. 1–6. [Google Scholar]

- Drage, T.; Kalinowski, J.; Braunl, T. Integration of Drive-by-Wire with Navigation Control for a Driverless Electric Race Car. IEEE Intell. Transport. Syst. Mag. 2014, 6, 23–33. [Google Scholar] [CrossRef]

| Technical Approach | Key Parameters | Control Accuracy | Computation Time |

|---|---|---|---|

| Optimal model | Dimensions of the vehicle model Linearization assumption | ||

| predictive time domain adjustment | (Predictive time domain) | ) ) | ) ) |

| Control period adjustment | Control period | (High Frequency PID) (Low frequency MPC) | (High Frequency PID) (Low frequency MPC) |

| Hybrid control structure | Controller division of labor and interconnection mechanisms |

| Parameter/Unit | Value |

|---|---|

| Simulation step/s | 0.05 |

| Road adhesion coefficient | 0.85/0.65/0.4 |

| Weight coefficient Q | |

| Control increment weight coefficient R | 1.1 × 105 |

| Control factor weighting coefficient ρ | 1000 |

| Evaluation Index | ||||

|---|---|---|---|---|

| Tracking Accuracy | 0.4464 | 0.0864 | 0.0789 | |

| 7.9986 | 1.5482 | 1.4138 | ||

| 0.6510 | 0.1609 | 0.1509 | ||

| 11.6641 | 2.8829 | 2.7036 | ||

| 7.0826 | 1.6387 | 1.5279 | ||

| Comfort | 0.0299 | 0.6066 | 0.6926 | |

| Economy | 0.0212 | 0.0472 | 0.0365 | |

| Safety | 1.0178 | 0.9542 | 0.9586 | |

| 1.0042 | 1.2001 | 1.0421 | ||

| 1.0110 | 1.0841 | 1.0012 | ||

| Evaluation Index | 30 km/h | 80 km/h | 110 km/h | |

|---|---|---|---|---|

| Tracking Accuracy | 0.0688 | 0.0864 | 0.2802 | |

| 1.9473 | 1.5482 | 4.1464 | ||

| 0.2568 | 0.1609 | 0.3431 | ||

| 7.2692 | 2.8829 | 5.0780 | ||

| 1.6387 | 3.2854 | 3.7651 | ||

| Comfort | 0.1236 | 0.6066 | 0.6117 | |

| Economy | 0.0215 | 0.0472 | 0.1216 | |

| Safety | 0.9996 | 0.9542 | 1.1400 | |

| 1.0000 | 1.2001 | 1.4010 | ||

| 0.9998 | 1.0841 | 1.2772 | ||

| Evaluation Index | Controller A | Controller B | Controller C | |

|---|---|---|---|---|

| Tracking Accuracy | 0.0864 | 0.0814 | 0.1655 | |

| 1.5482 | 1.4580 | 2.9648 | ||

| 0.1609 | 0.1833 | 0.5293 | ||

| 2.8829 | 3.2842 | 9.4838 | ||

| 1.6387 | 1.7994 | 4.9759 | ||

| Comfort | 0.6066 | 0.6152 | 0.6551 | |

| Economy | 0.0472 | 0.0500 | 0.0765 | |

| Safety | 0.9542 | 1.0109 | 0.9841 | |

| 1.2001 | 1.2244 | 1.5305 | ||

| 1.0841 | 1.1227 | 1.2866 | ||

| Evaluation Index | MPC | PID + MPC | |

|---|---|---|---|

| Tracking Accuracy | 0.1701 | 0.0812 | |

| 3.7220 | 1.7775 | ||

| 0.4767 | 0.3125 | ||

| 10.4335 | 6.8390 | ||

| 5.5445 | 3.536 | ||

| Comfort | 0.2494 | 0.1531 | |

| Economy | 0.0545 | 0.0437 | |

| Safety | 1.0002 | 0.9991 | |

| 0.9705 | 0.8667 | ||

| 0.9855 | 0.8996 | ||

| Evaluation Index | MPC | PID + MPC | |

|---|---|---|---|

| Tracking Accuracy | 0.0794 | 0.1154 | |

| 1.7374 | 2.5254 | ||

| 0.5090 | 0.2076 | ||

| 11.1398 | 4.5444 | ||

| 5.6431 | 2.6022 | ||

| Comfort | 0.2433 | 0.0306 | |

| Economy | 0.0453 | 0.0217 | |

| Safety | 2.5105 | 1.0062 | |

| 1.0006 | 1.0018 | ||

| 1.9110 | 1.0040 | ||

| Evaluation Index | MPC | PID + MPC | |

|---|---|---|---|

| Tracking Accuracy | 0.6760 | 0.4350 | |

| 11.3715 | 7.3175 | ||

| 0.8610 | 0.7327 | ||

| 14.4834 | 12.3253 | ||

| 9.2233 | 7.1796 | ||

| Comfort | 0.2917 | 0.2642 | |

| Economy | 0.2062 | 0.1011 | |

| Safety | 1.0039 | 0.9976 | |

| 1.1030 | 1.0002 | ||

| 1.0546 | 0.9989 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, X.; Chen, K.; Zheng, Y.; Zhang, X. Trajectory Tracking Control of High-Speed Vehicles on Wet and Slippery Roads. Sensors 2025, 25, 5450. https://doi.org/10.3390/s25175450

Song X, Chen K, Zheng Y, Zhang X. Trajectory Tracking Control of High-Speed Vehicles on Wet and Slippery Roads. Sensors. 2025; 25(17):5450. https://doi.org/10.3390/s25175450

Chicago/Turabian StyleSong, Xiaohua, Kuifeng Chen, Yujia Zheng, and Xiaoyan Zhang. 2025. "Trajectory Tracking Control of High-Speed Vehicles on Wet and Slippery Roads" Sensors 25, no. 17: 5450. https://doi.org/10.3390/s25175450

APA StyleSong, X., Chen, K., Zheng, Y., & Zhang, X. (2025). Trajectory Tracking Control of High-Speed Vehicles on Wet and Slippery Roads. Sensors, 25(17), 5450. https://doi.org/10.3390/s25175450