Intelligent Identification of Internal Leakage of Spring Full-Lift Safety Valve Based on Improved Convolutional Neural Network

Abstract

1. Introduction

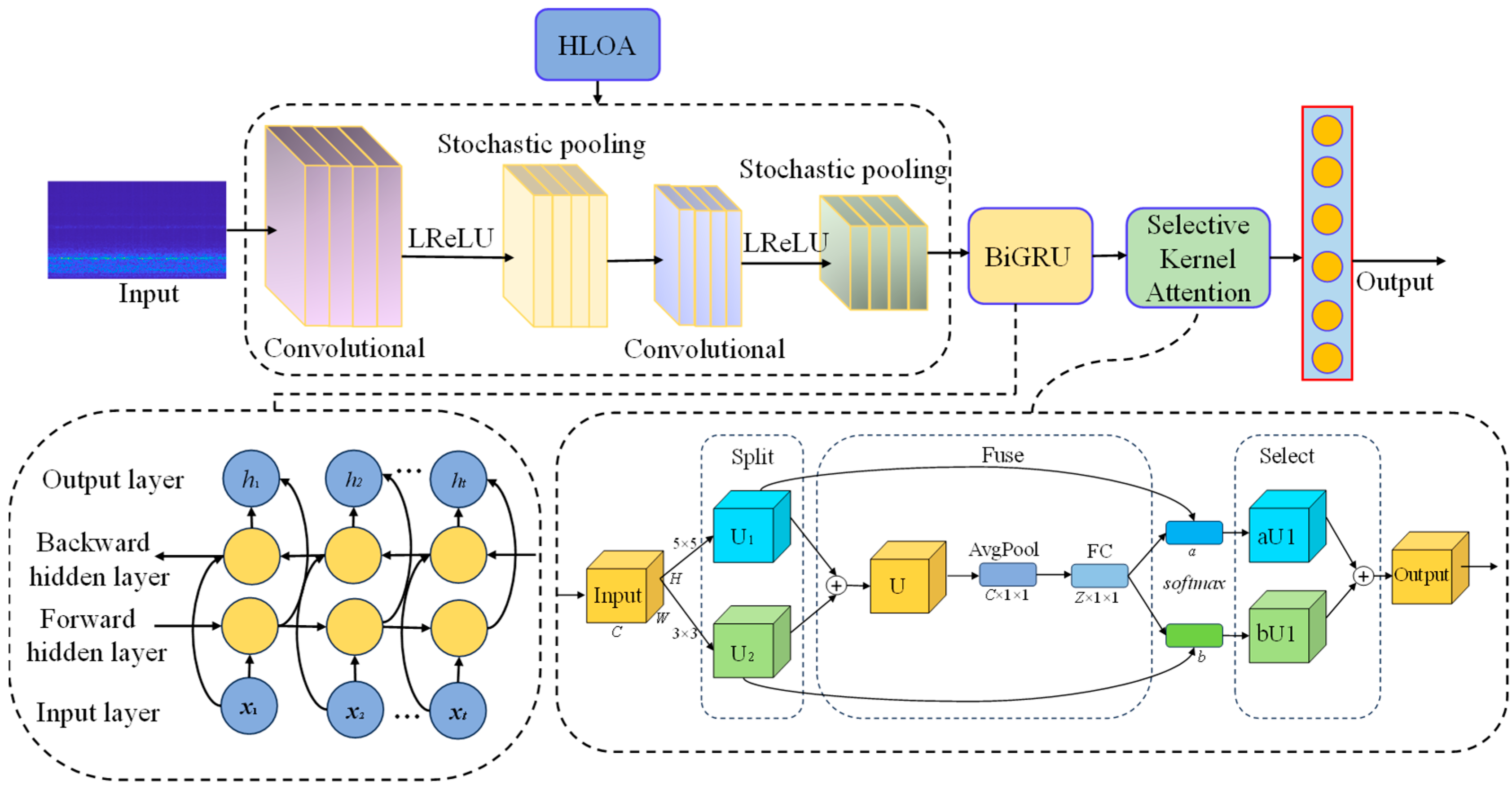

- The composite characteristics of “high-frequency transient pulse” and “multi-scale energy distribution” of the acoustic emission signal of the internal leakage of the safety valve: This paper dynamically adapts HLOA and CNN for the first time—optimizes the learning rate and regularization coefficient in CNN by dynamically switching between local fine-tuning and global exploration, so that it can accurately match the characteristic distribution of high-frequency acoustic emission signals—by integrating the BiGRU-SKAM mechanism of “bidirectional time series capture + multi-scale spatial weighting” to extract the time series and spatial features of high-frequency signals of valve leakage. The HLOA-CNN-BiGRU-SKAM collaborative framework is constructed to solve the parameter optimization problem of high-frequency acoustic emission signals and the limitations of feature extraction.

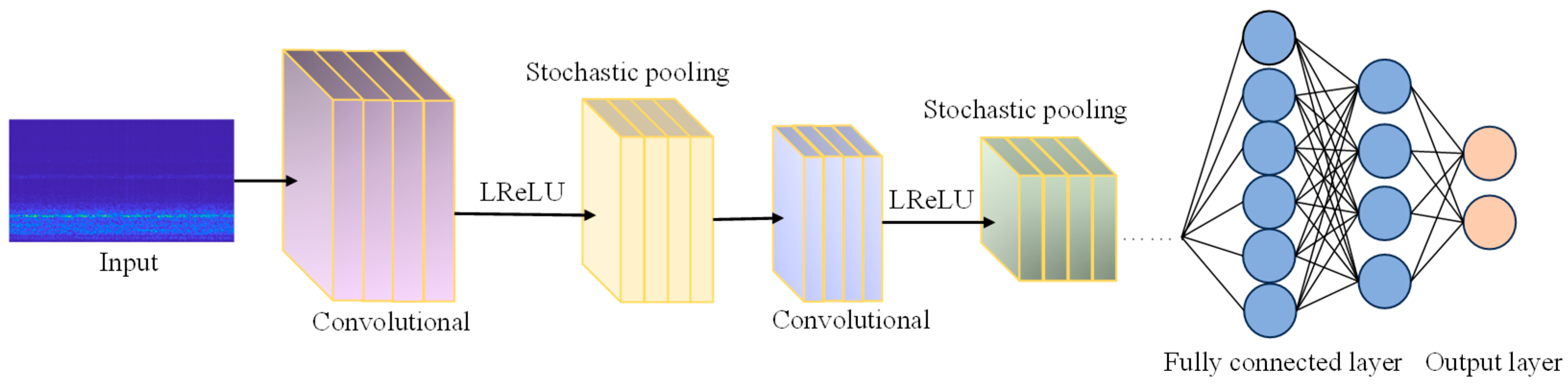

- According to the time–frequency characteristics of different internal leakage states of safety valves, this paper designs a mixed convolution kernel and applies the combination of random pooling and the LReLU activation function to high-frequency acoustic emission signal processing to enhance the characteristic response of high-frequency acoustic emission signals in weak leakage.

- The constructed HLOA-CNN-BiGRU-SKAM collaborative framework model is used for the first time in the field of high-frequency acoustic emission signal diagnosis of safety valve internal leakage, which solves the problem of micro-damage detection of the safety valve sealing surface and provides a reusable solution for acoustic emission diagnosis of micro-leakage high-pressure equipment.

2. Improved CNN Algorithm Establishment

2.1. Horned Lizard Optimization Algorithm

- (1)

- Darkening or lightening of skin color

- (2)

- Blood spray defense

- (3)

- Moving to escape

- (4)

- α-Melanocyte stimulating hormone (α-MSH) secretion rate

2.2. Convolutional Neural Network Improvement Strategies

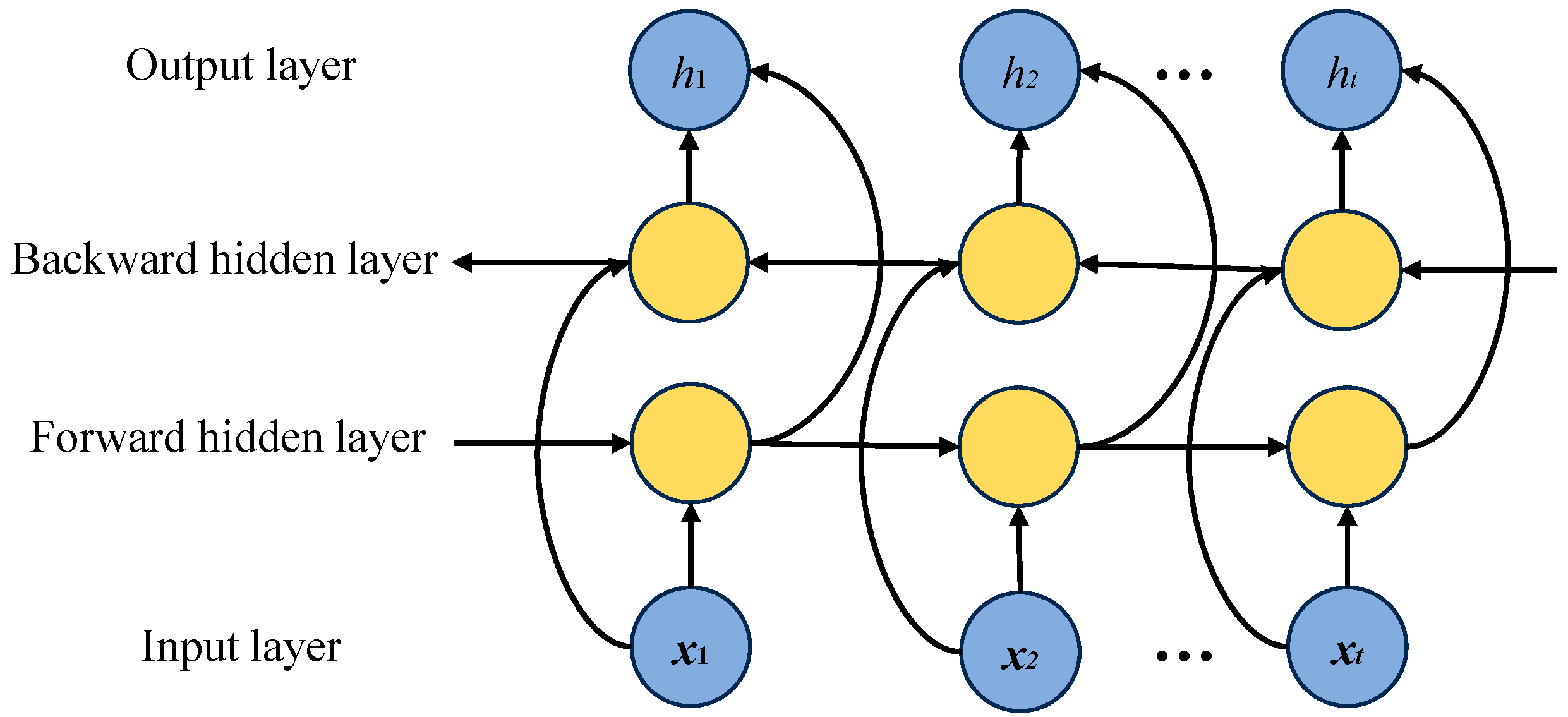

2.3. Bidirectional Gated Recurrent Unit

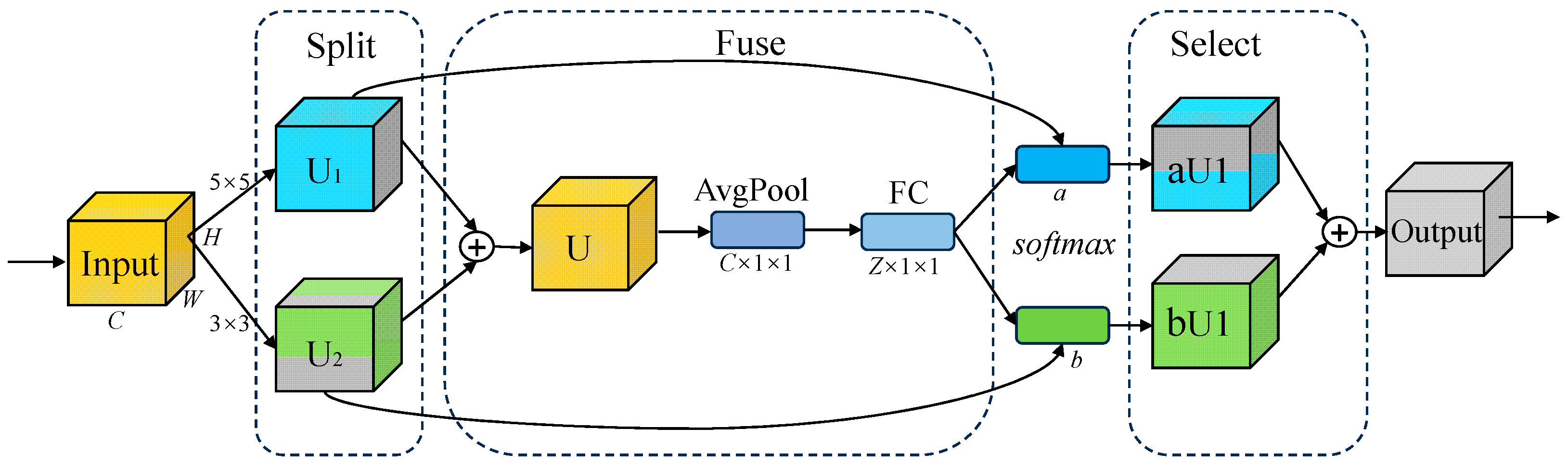

2.4. Selective Kernel Attention Module

2.5. Improved 2D CNN Model Framework

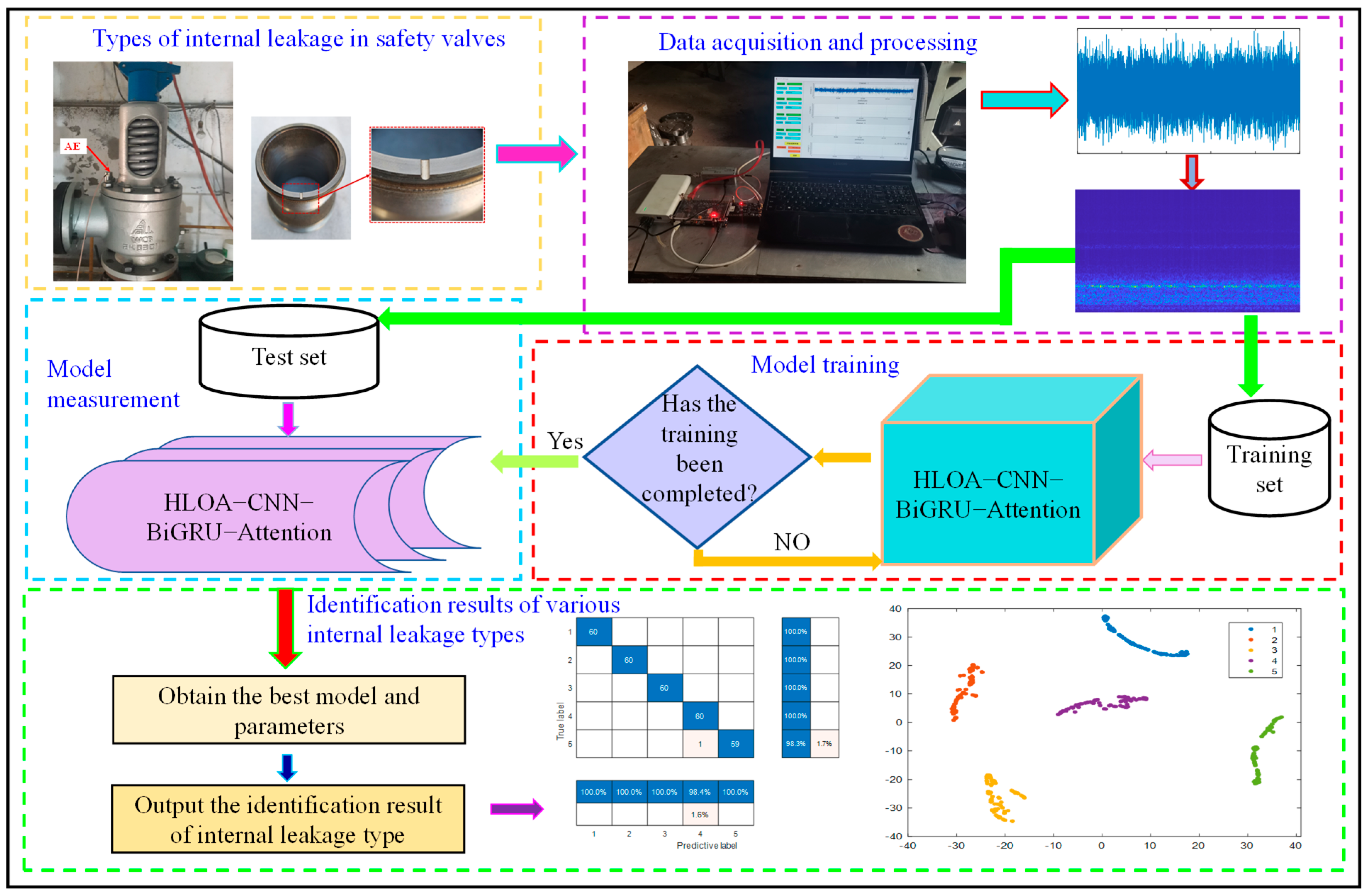

2.6. The Overall Process of Identifying Internal Leakage of Spring Full-Lift Safety Valve

3. Acoustic Emission Test Data Collection and Preprocessing of the Healthy and Internal Leakage States of the Safety Valve

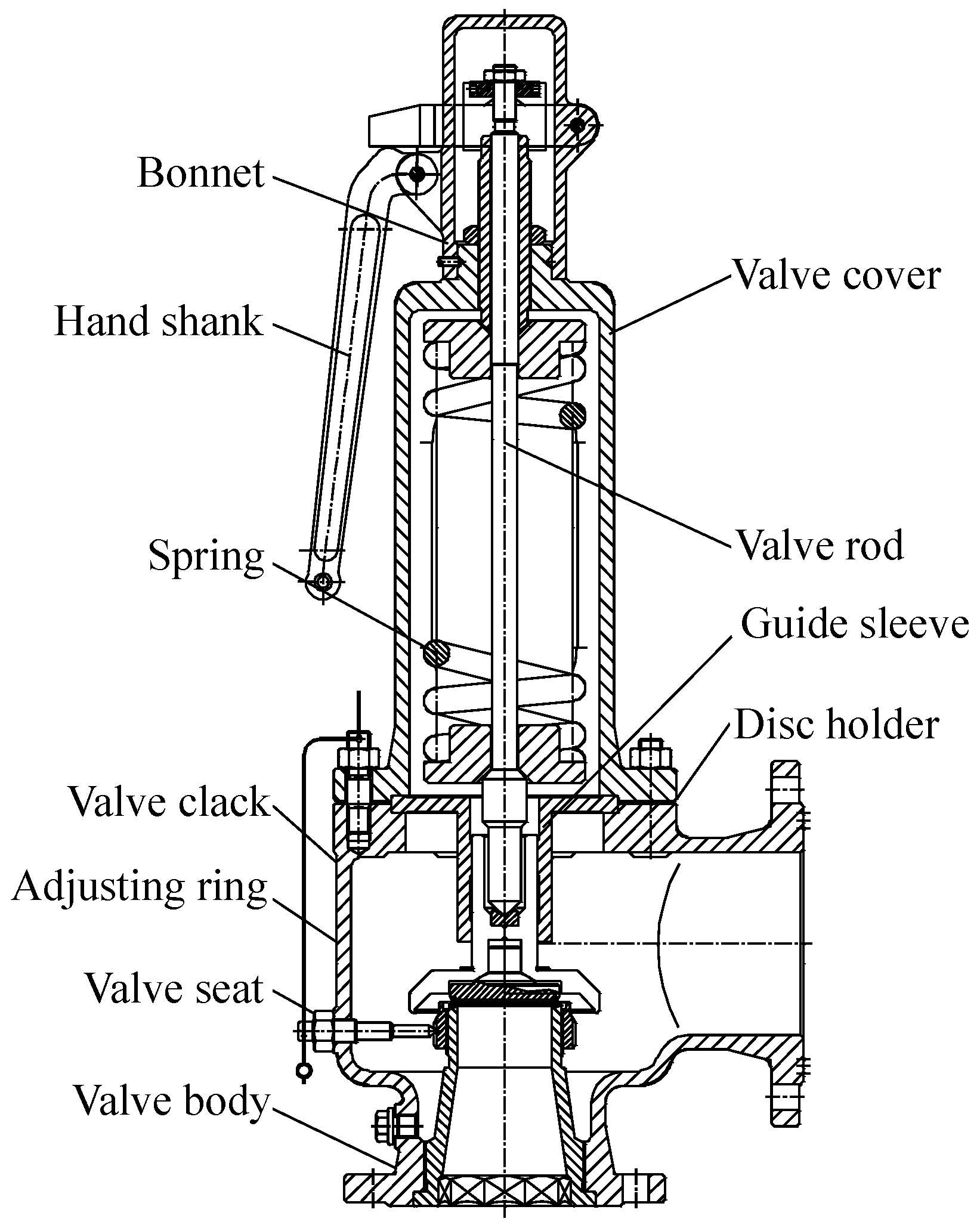

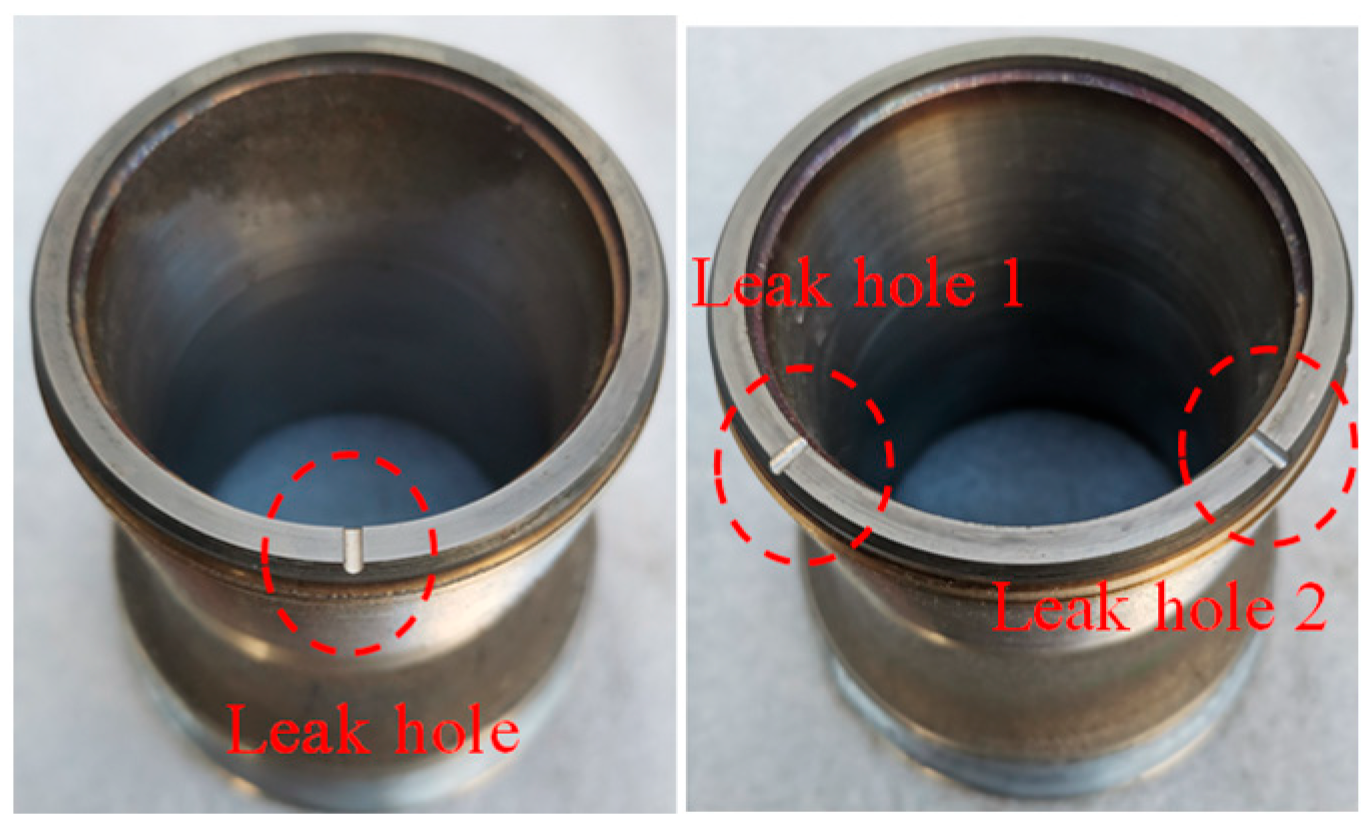

3.1. Fault Presetting of Safety Valves in Different Internal Leakage States

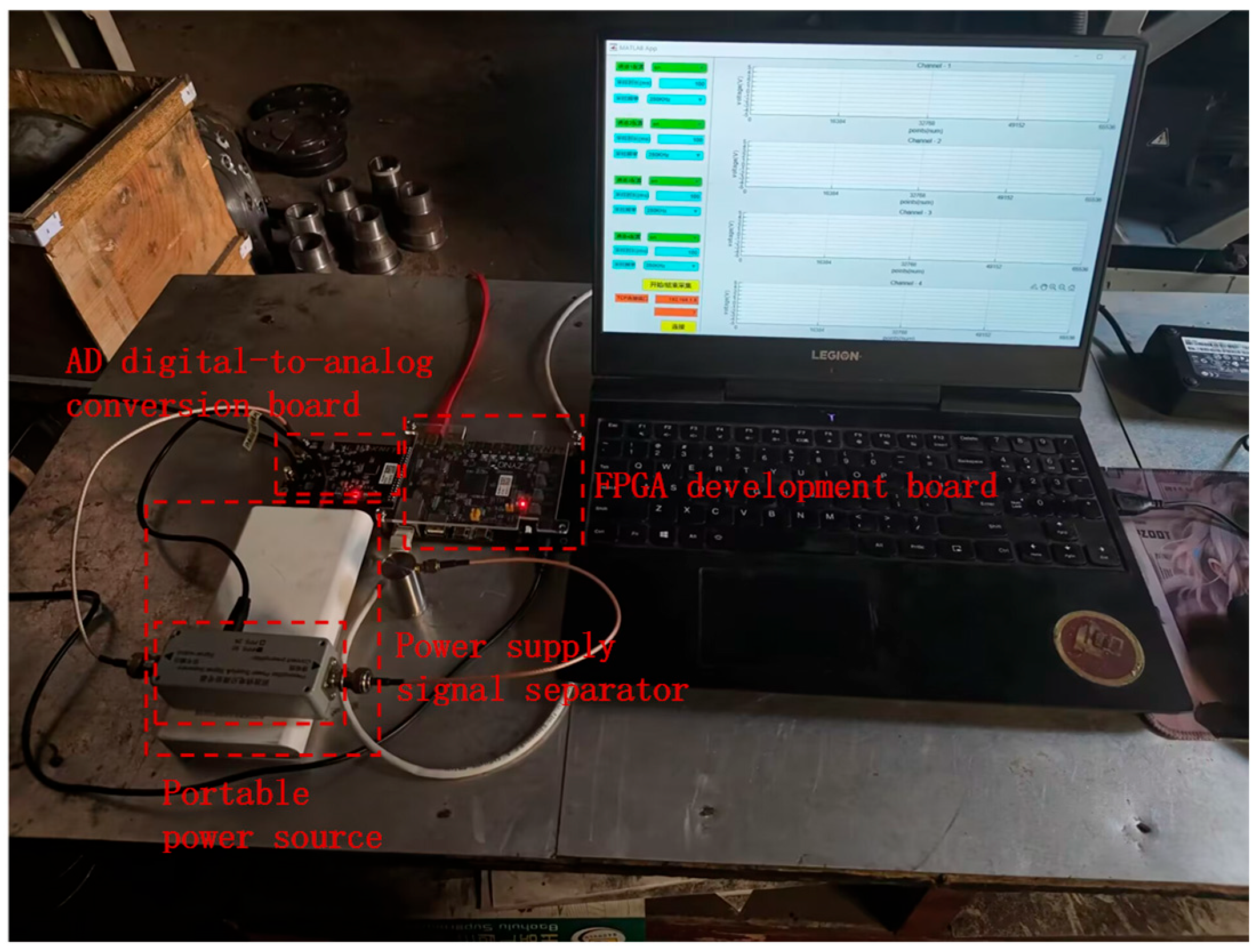

3.2. Signal Acquisition Experiment Under Different Internal Leakage Forms of Safety Valve

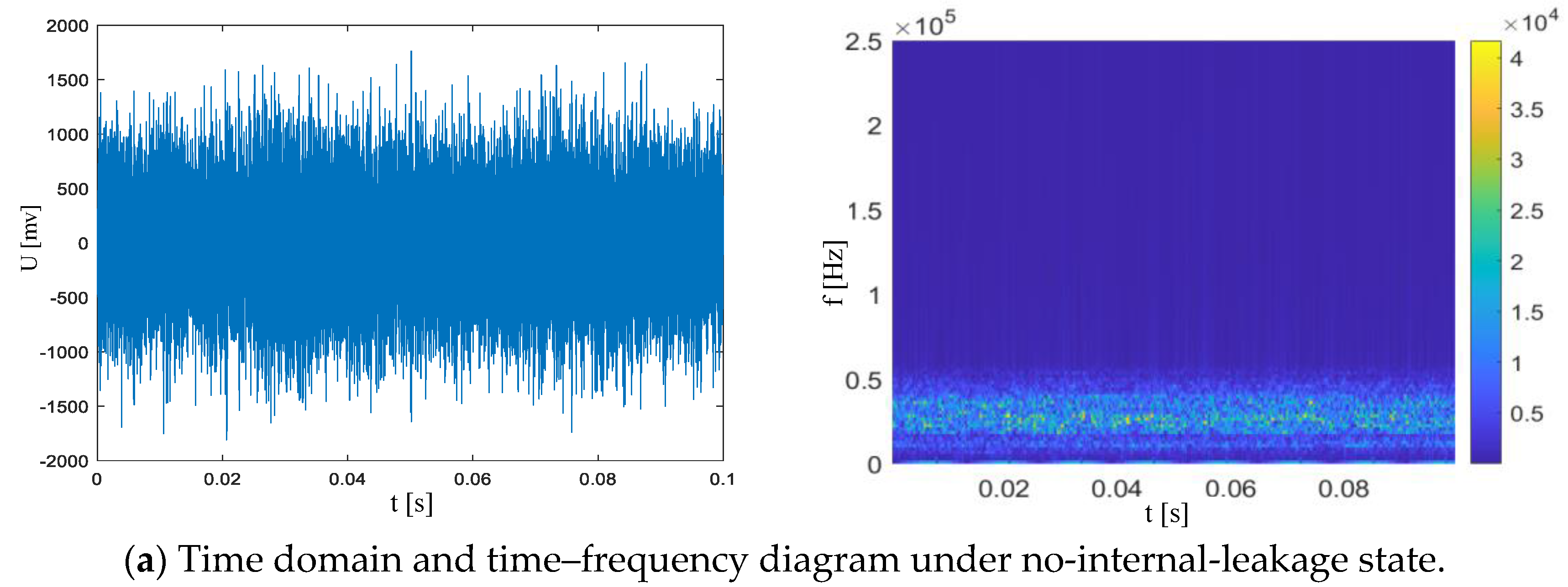

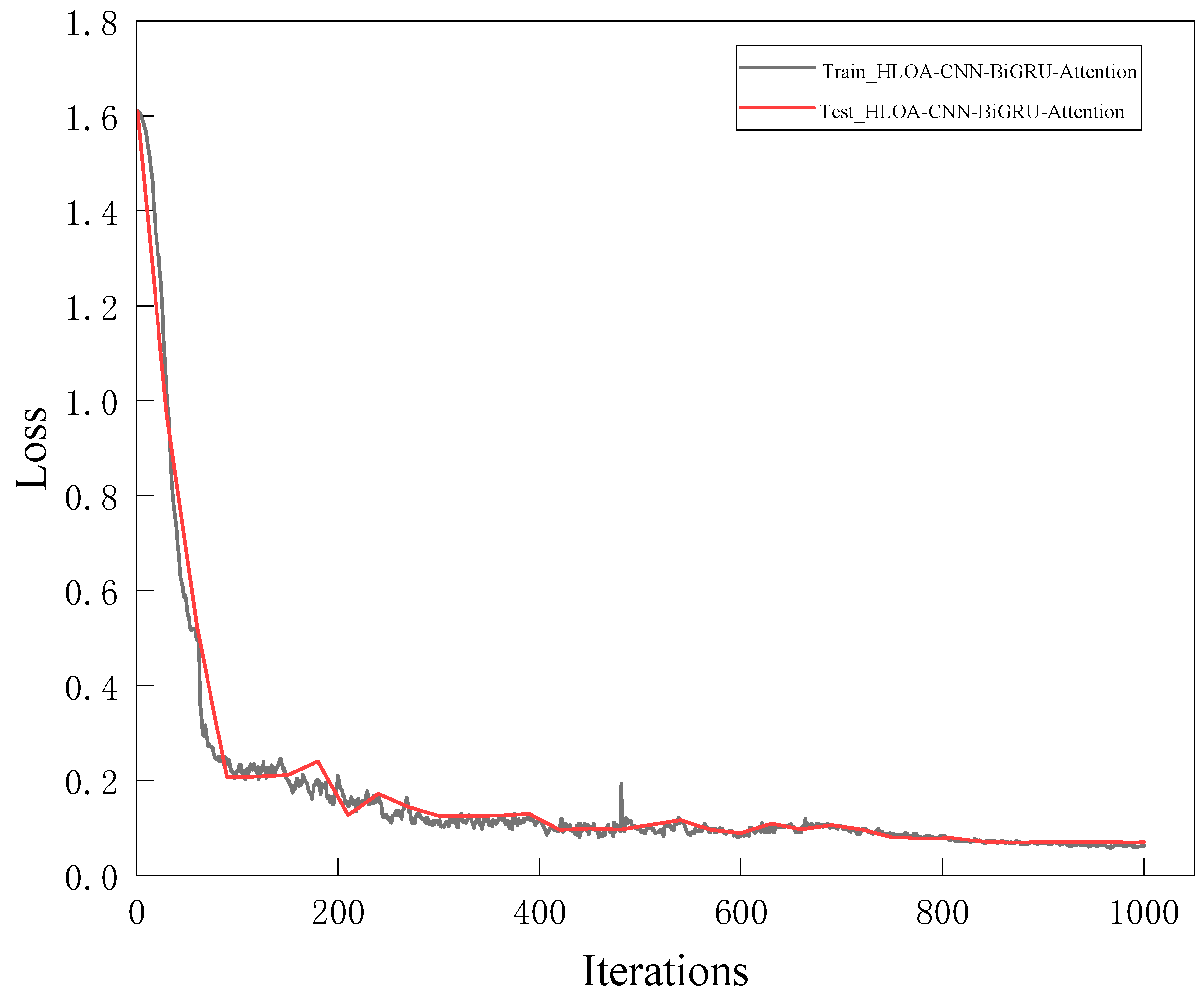

3.3. Time Domain and Short-Time Fourier Time–Frequency Transform Analysis of Acoustic Emission Signals of Different Internal Leakage Types

4. Identification of Internal Leakage Status of Spring Full-Lift Safety Valve

4.1. Establishment of Data Set and Label for Identification of Internal Leakage Status of Spring Full-Lift Safety Valve

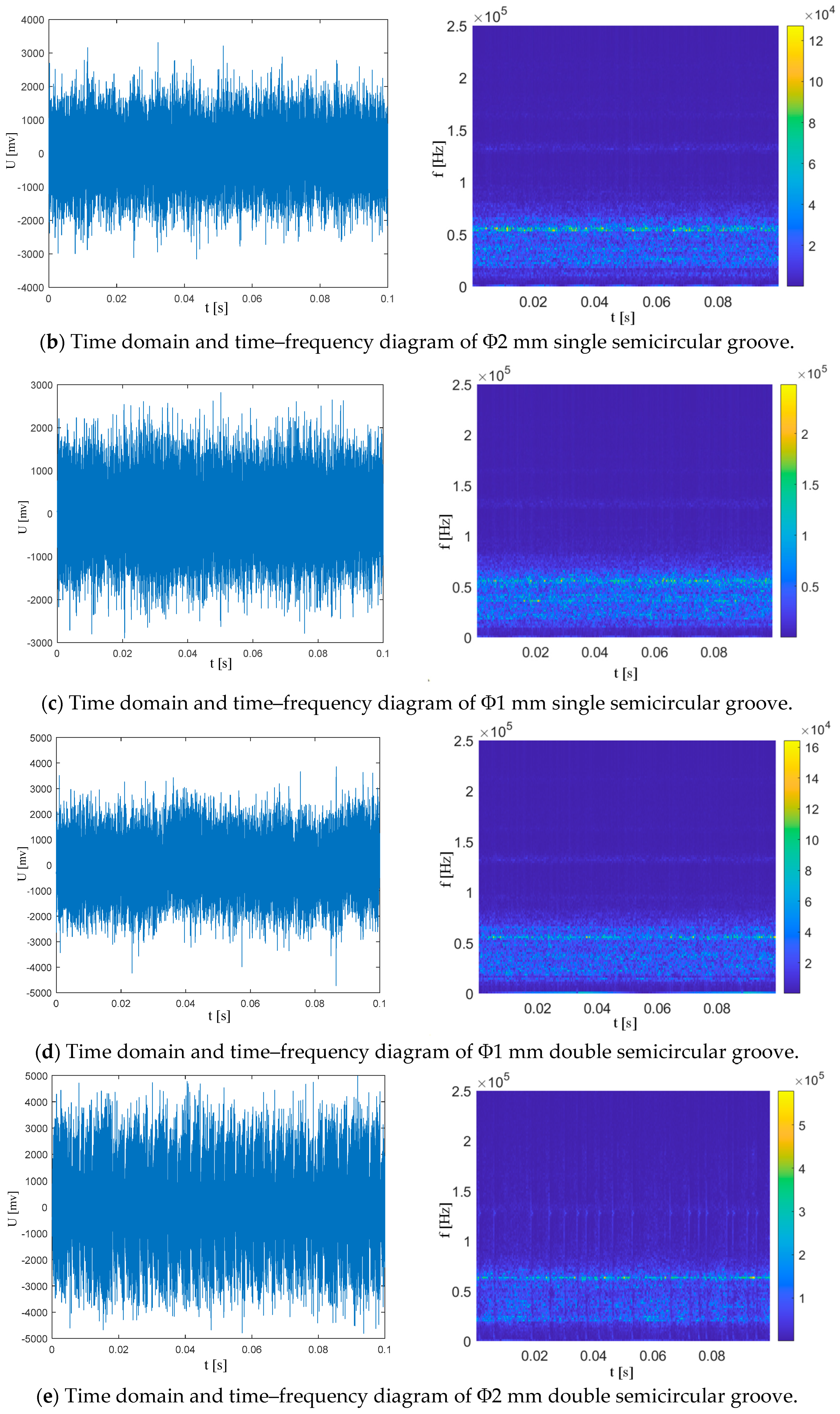

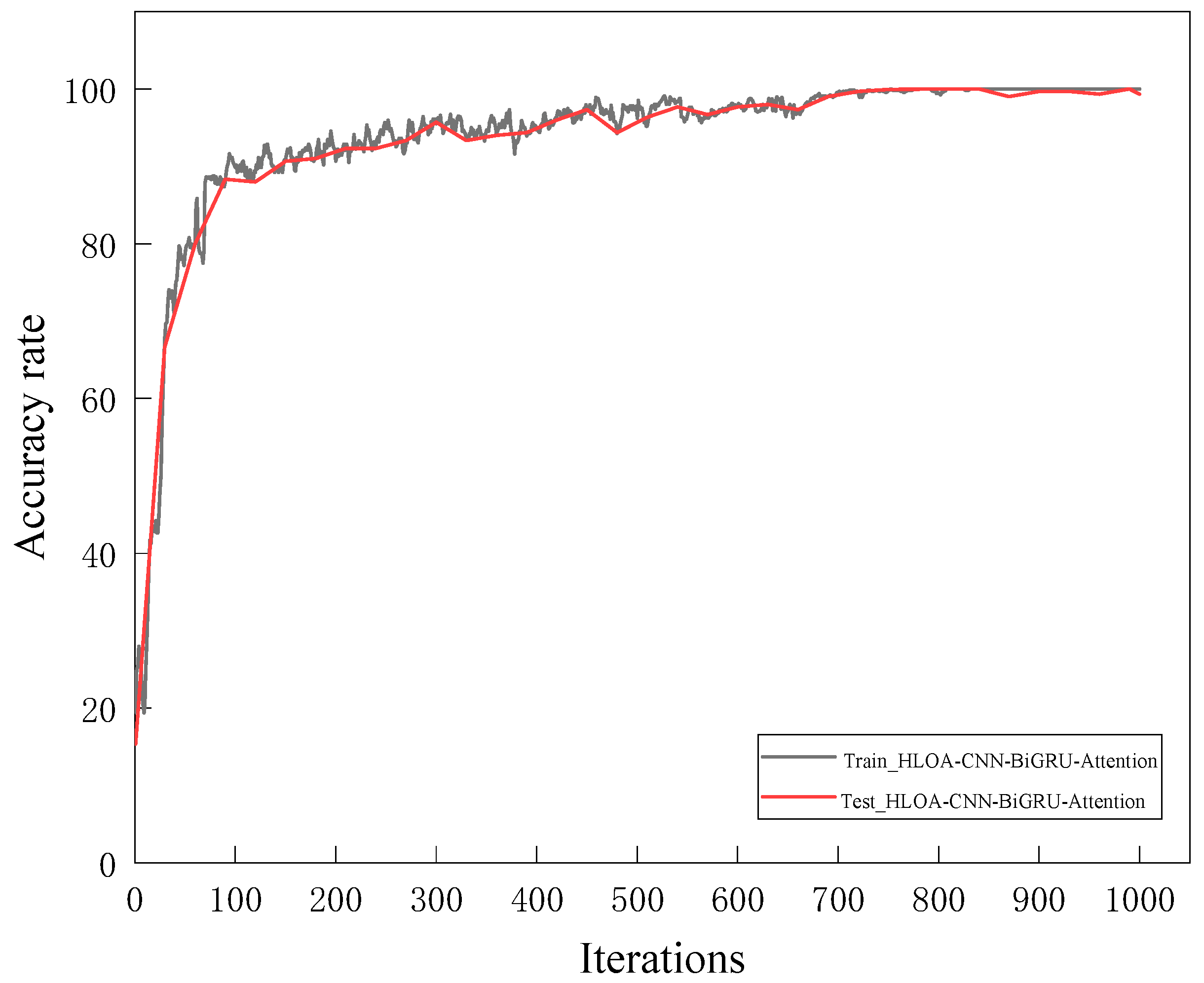

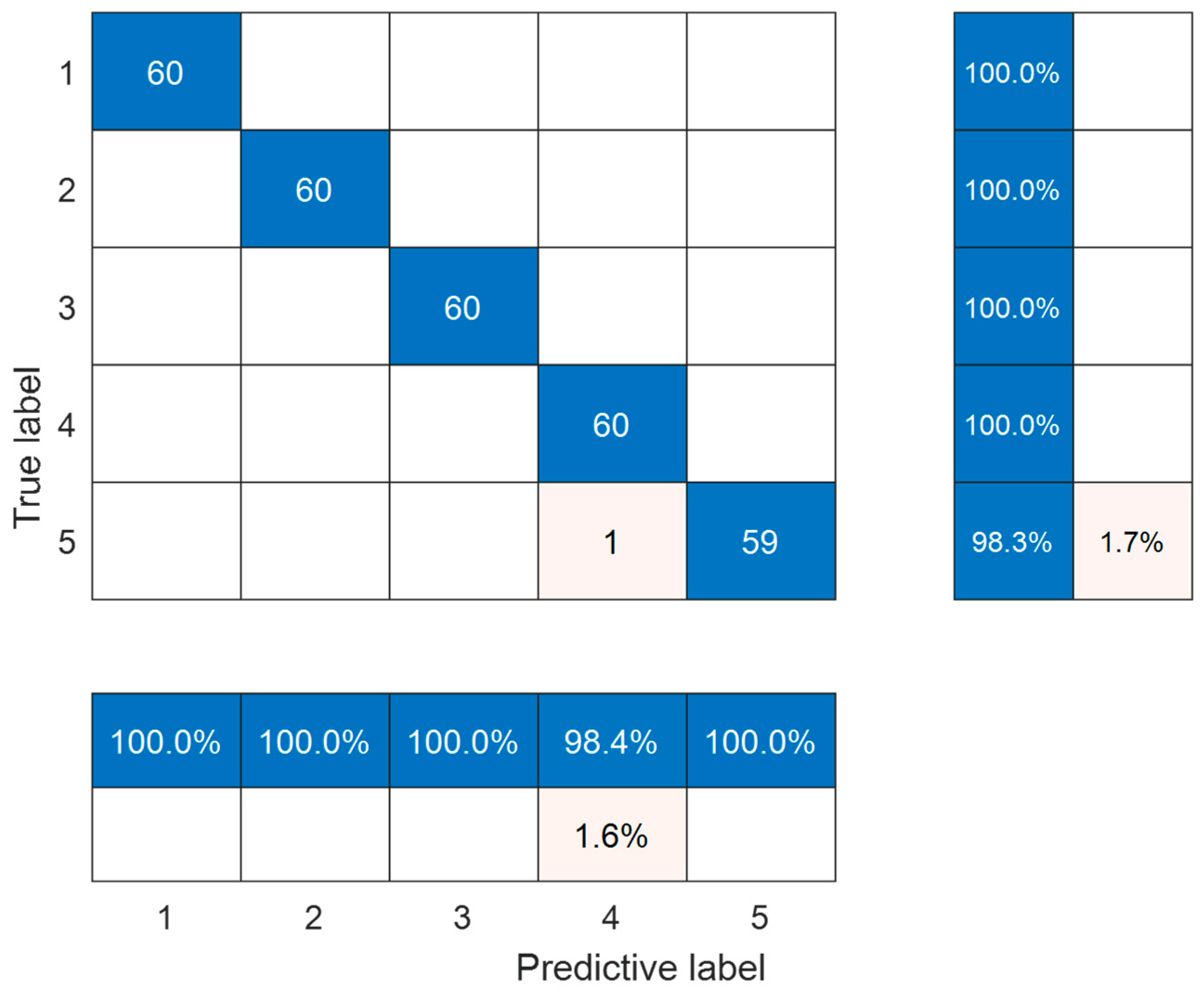

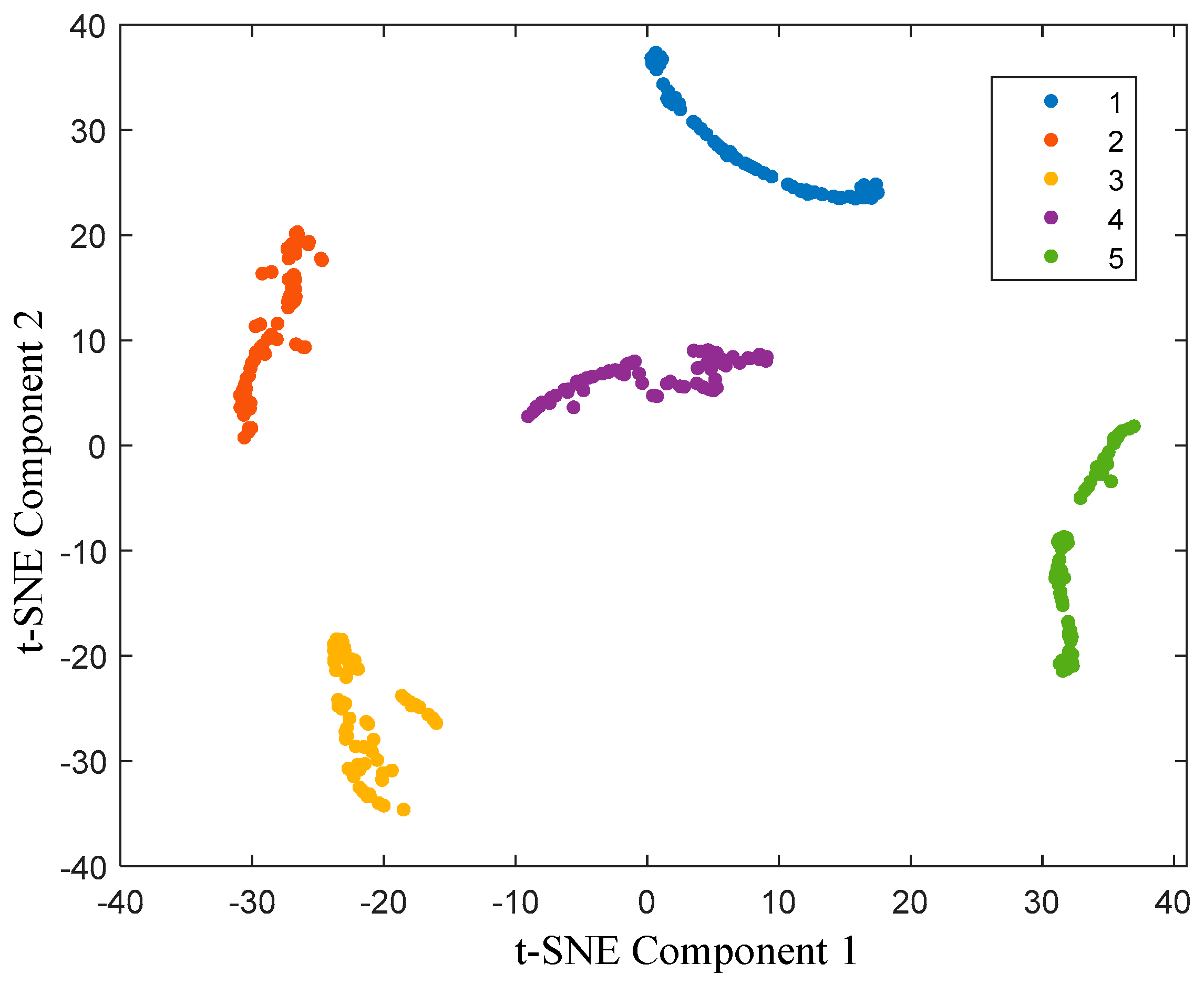

4.2. Analysis on the Accuracy of Internal Leakage Identification of Spring Full-Lift Safety Valve

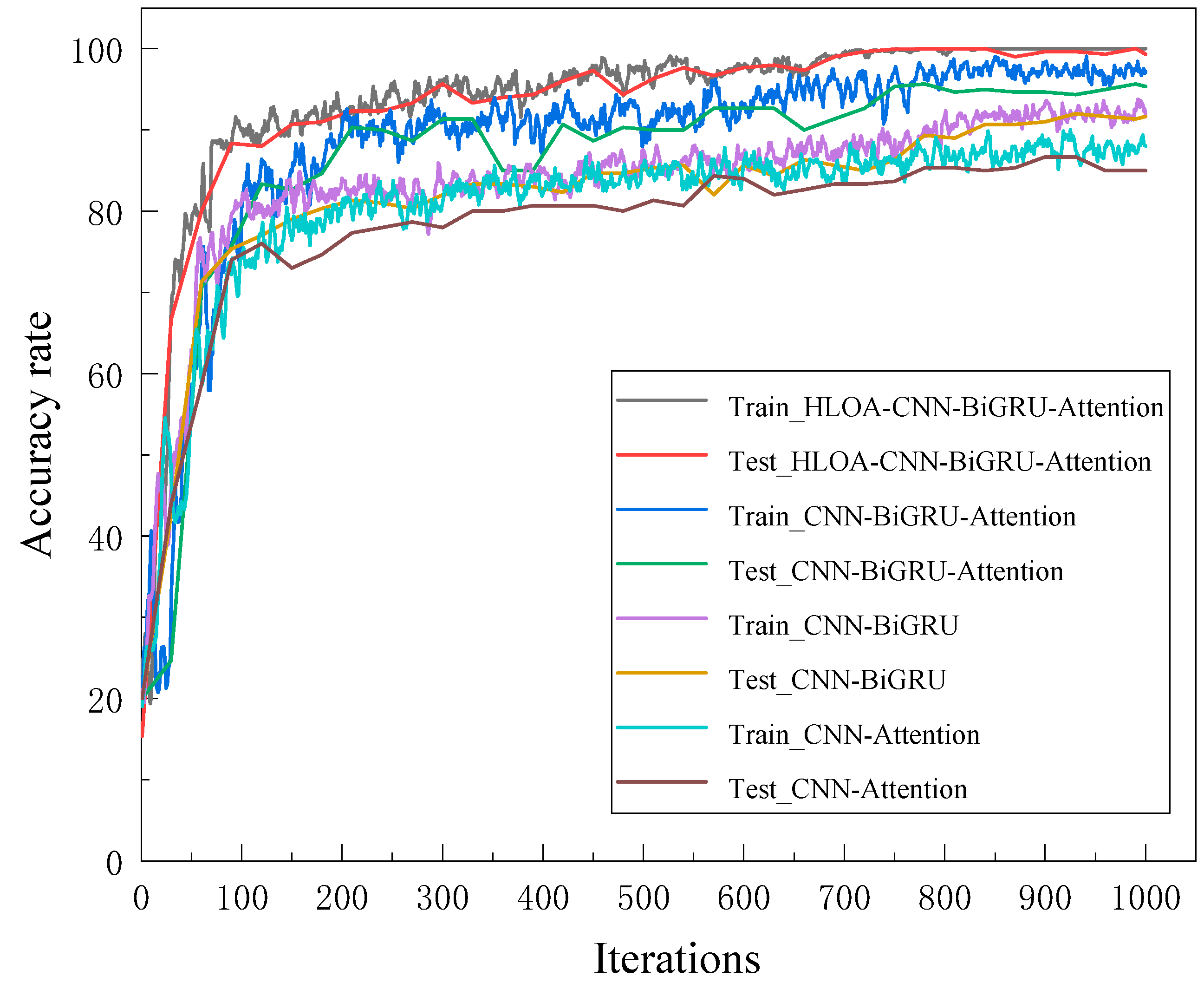

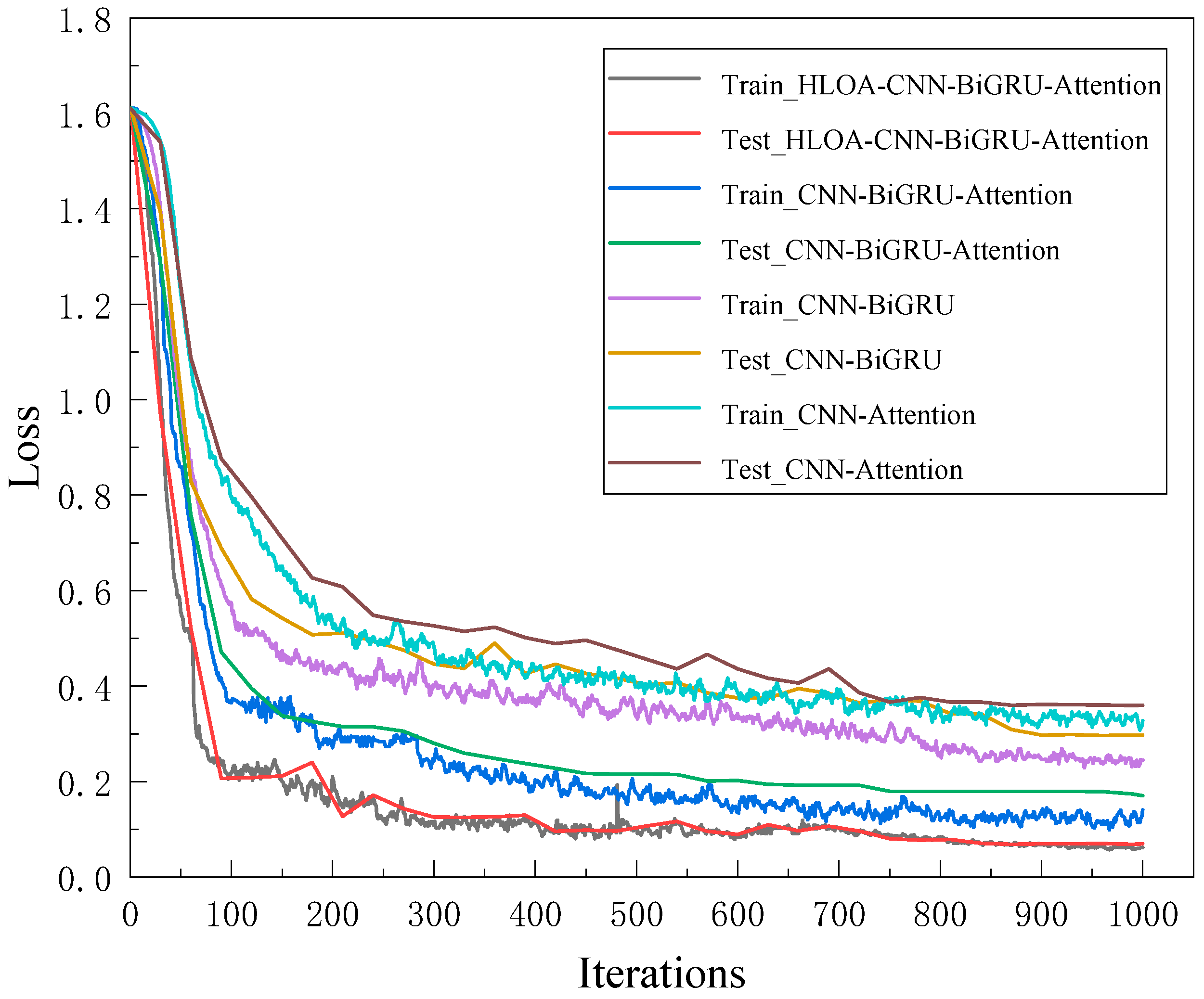

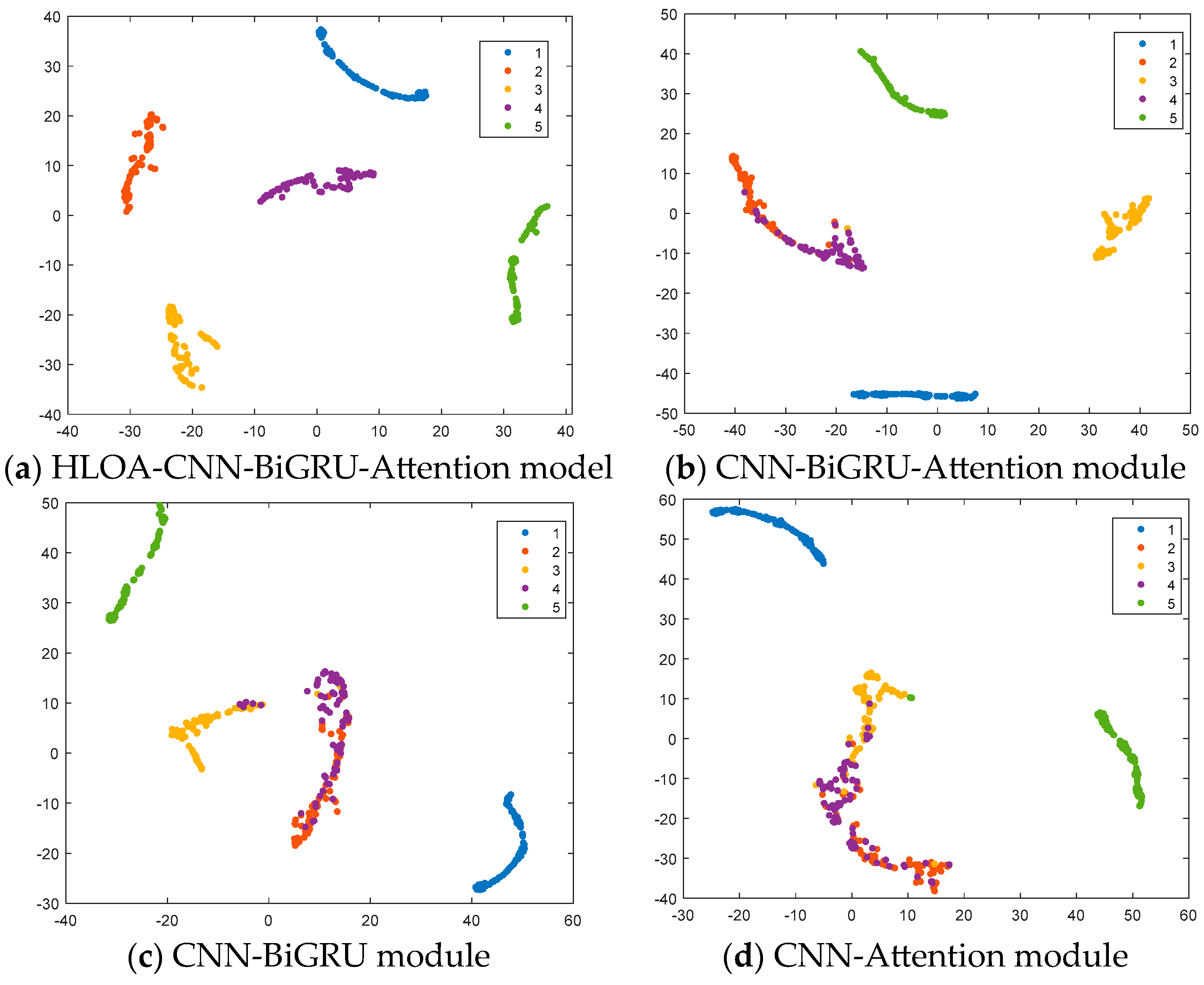

4.3. Ablation Experiment Analysis of HLOA-CNN-BiGRU-Attention Model

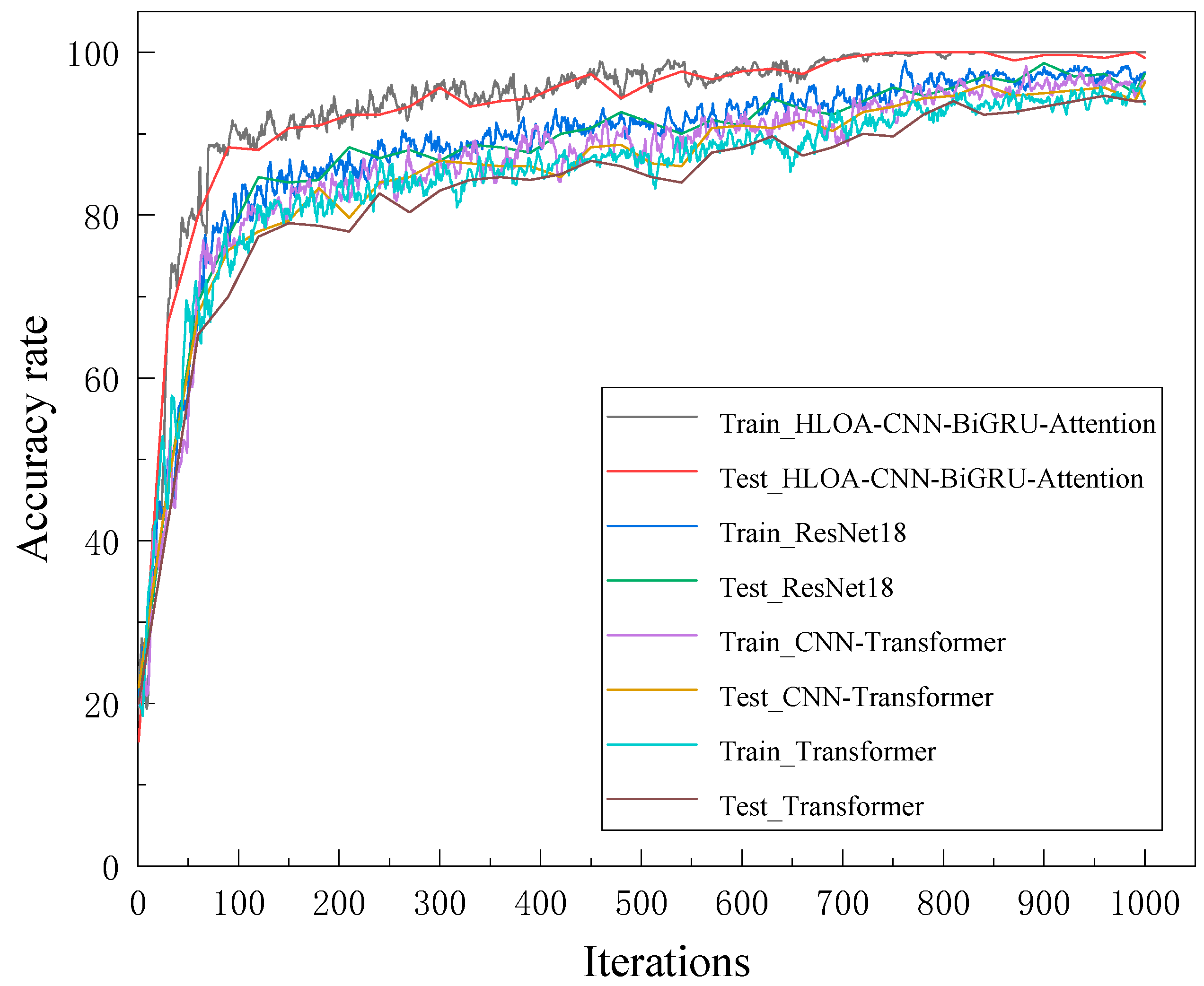

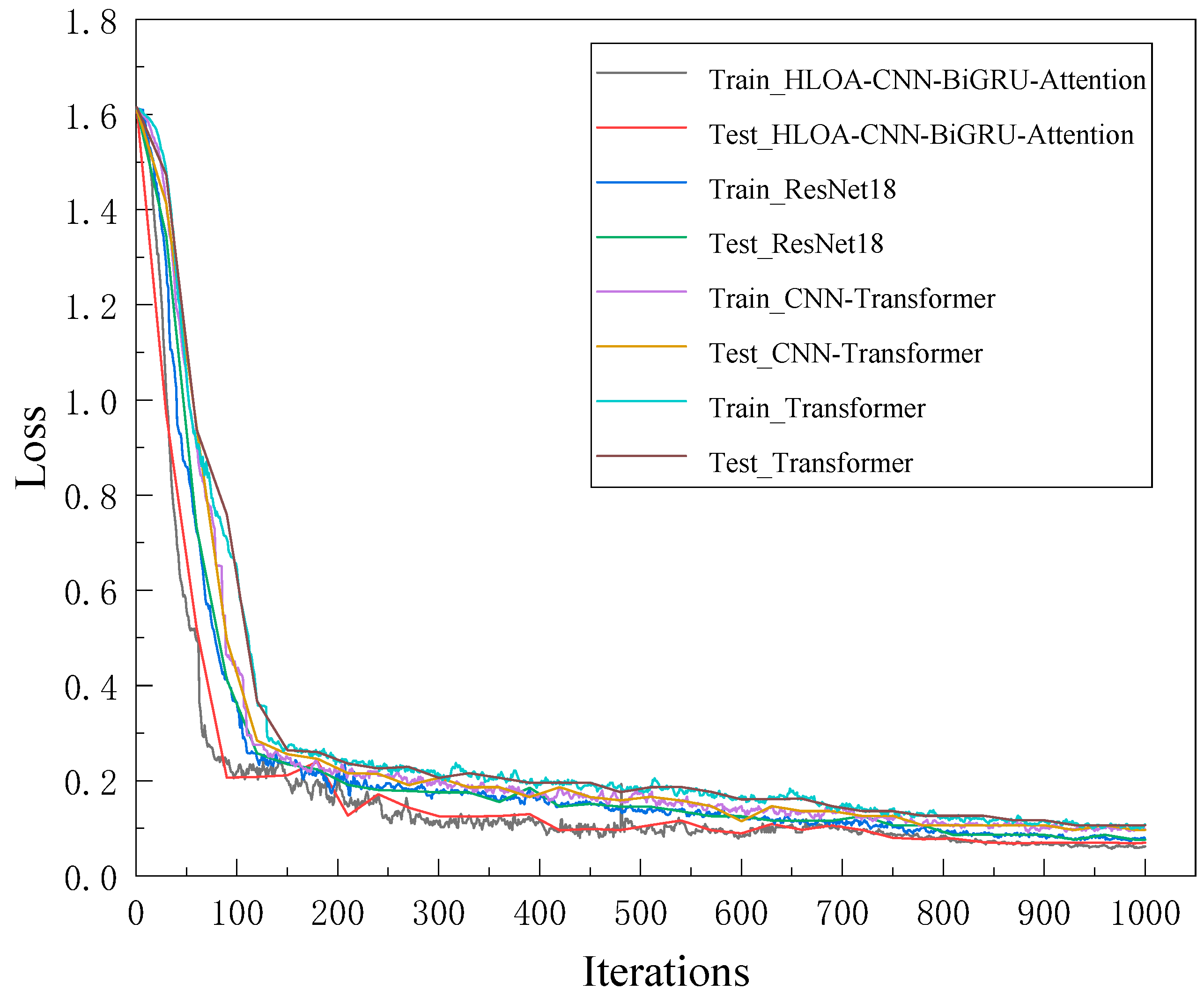

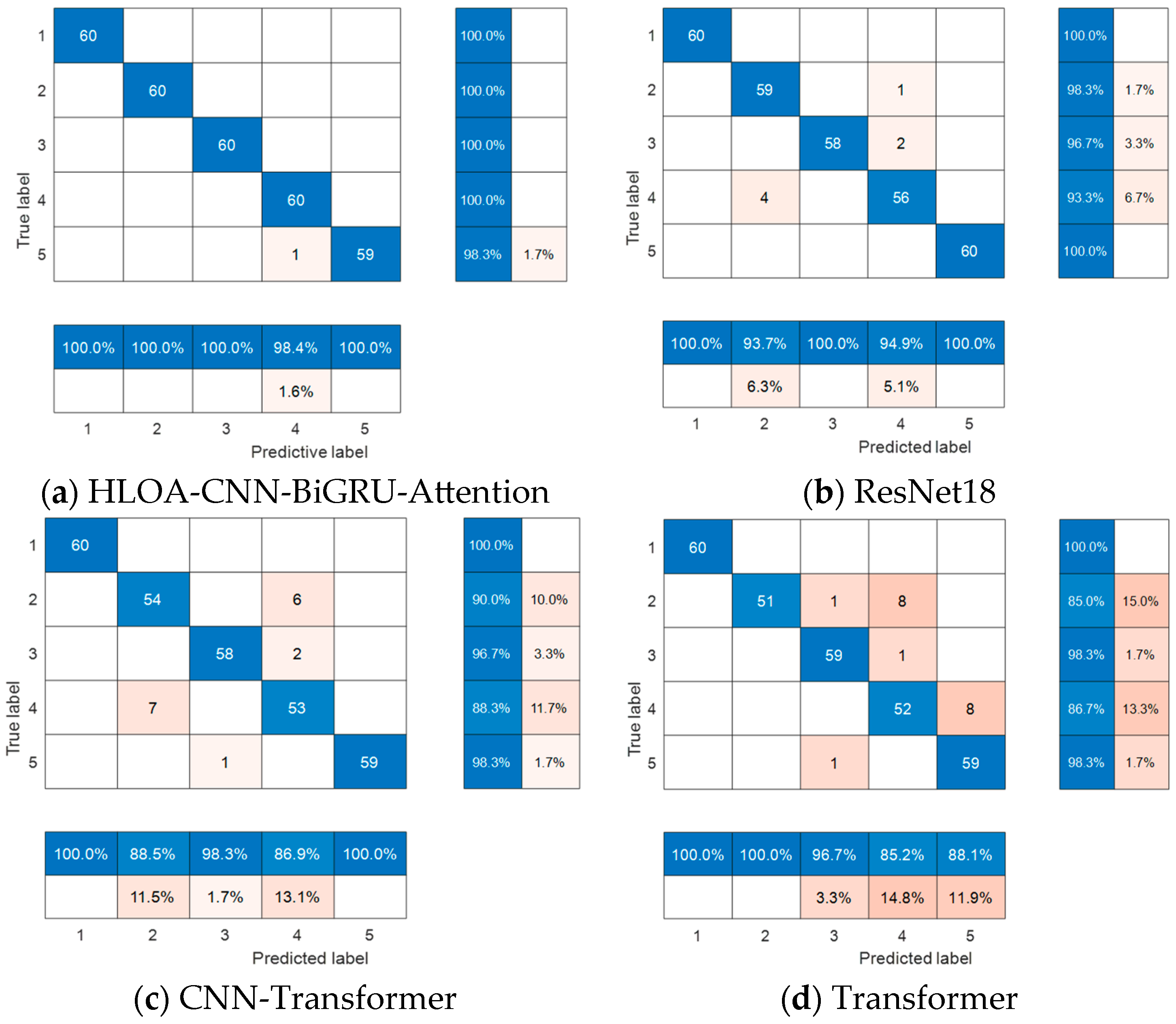

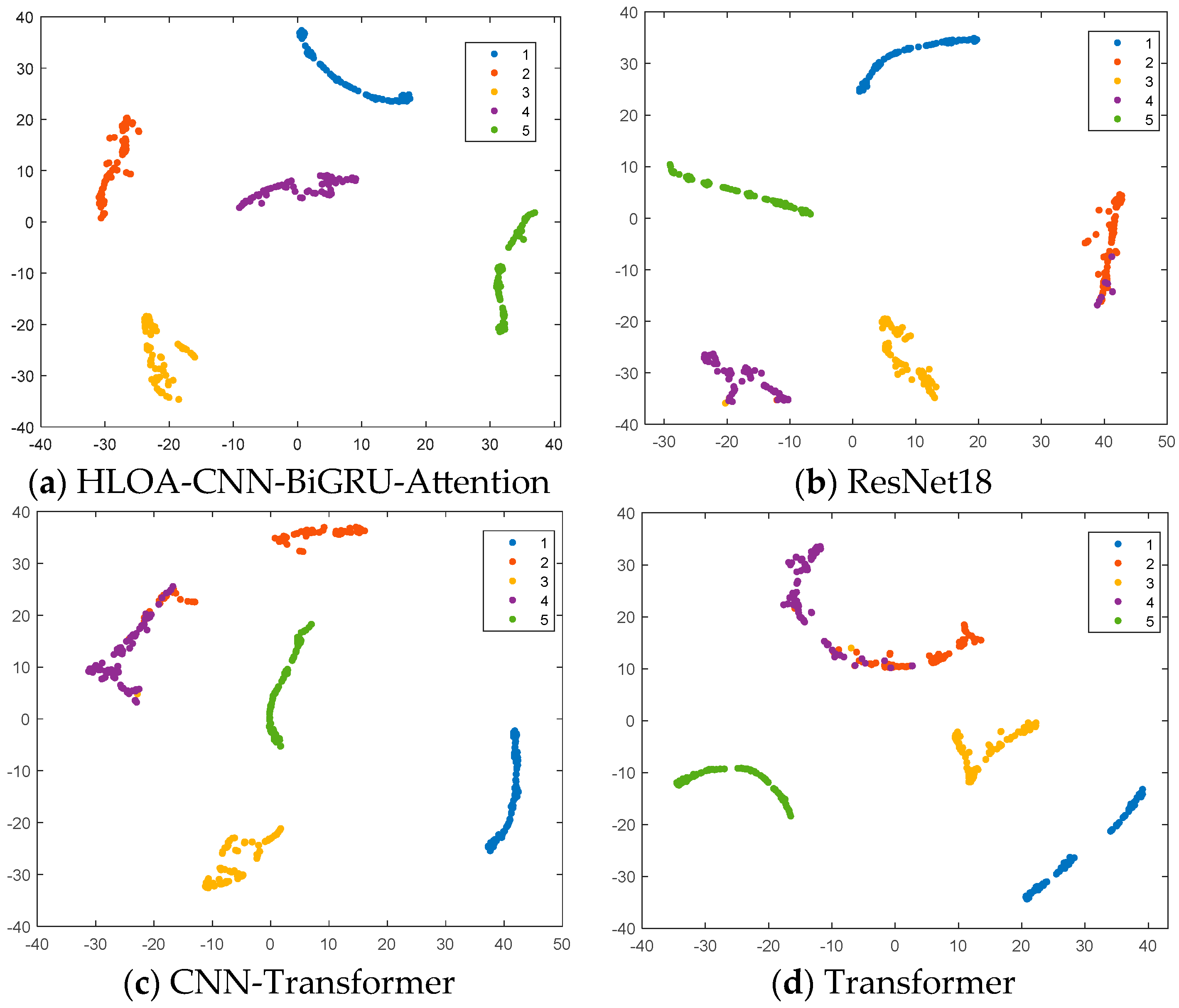

4.4. Analysis of Algorithm Superiority

5. Discussion of Limitations

6. Conclusions

- (1)

- Based on the horned lizard optimization algorithm (HLOA) and the improved two-dimensional convolutional neural network (CNN), the bidirectional gated recurrent unit (BiGRU) and SK attention module are synergistically integrated to construct a deep learning internal leakage intelligent recognition model of HLOA-CNN-BiGRU-Attention. This model uses HLOA to optimize the initial learning rate and L2 regularization coefficient of CNN through dynamic switching between local fine-tuning and global exploration, thereby increasing the training accuracy and convergence speed of the model. The LReLU activation function is used in the hybrid convolution kernel neural network to solve the problem of neuron death during negative input, strengthen the characteristic response to weak leakage signals, enhance the nonlinear expression ability, introduce random pooling to fuse all feature elements to prevent overfitting, and improve the robustness of feature extraction. The BiGRU network and SK attention module are synergistically integrated to enhance the ability to extract the temporal and spatial features of the signal while improving the model’s ability to capture multi-scale features, reducing the omission of key information, and solving the parameter optimization problem of high-frequency acoustic emission signals and the limitations of feature extraction.

- (2)

- This study converts the one-dimensional acoustic emission signal into a two-dimensional time–frequency feature image through short-time Fourier transform, effectively retains the signal time–frequency domain information, and provides high-quality input data for the deep learning model. The proposed method can be extended to other complex fault diagnosis scenarios of mechanical equipment based on time series signals or image features. In future research, we will explore lightweight network structures to improve the real-time performance of the model, and at the same time, multi-source sensor data will be used to further improve the robustness of diagnosis.

- (3)

- The average recognition accuracy of the healthy state and internal leakage state of the spring full-lift safety valve using the improved model is 99.7%. The ablation experiment and the mainstream algorithm ResNet-18—97.5%, CNN-Transformer—95.9%, and Transformer—92.9% comparison verifies that the improved convolutional neural network algorithm has advantages in prediction accuracy. Therefore, this method can achieve high-precision fault recognition of different internal leakage states of the spring full-lift safety valve.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Lin, M. Research on robustness of five typical data-driven fault diagnosis models for nuclear power plants. Ann. Nucl. Energy 2022, 165, 108639. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Gao, R.X.; Zhang, F. Hybrid physics-based and data-driven models for smart manufacturing: Modeling, simulation, and explainability. J. Manuf. Syst. 2022, 63, 381–391. [Google Scholar] [CrossRef]

- Wen, L.; Li, X.; Gao, L.; Zhang, Y. A new convolutional neural network-based data-driven fault diagnosis method. IEEE Trans. Ind. Electron. 2017, 65, 5990–5998. [Google Scholar] [CrossRef]

- Li, Z.; Liu, K.; Li, Y.-X.; Wang, Y.; Liu, L. A data-driven robust fault detection method for linear systems with full-order sensors. Circuits Syst. Signal Process. 2022, 41, 5428–5443. [Google Scholar] [CrossRef]

- Li, L.; Ding, S.X.; Peng, X. Distributed data-driven optimal fault detection for large-scale systems. J. Process Control 2020, 96, 94–103. [Google Scholar] [CrossRef]

- Li, Z.; Jiang, W.; Zhang, S.; Sun, Y.; Zhang, S. A hydraulic pump fault diagnosis method based on the modified ensemble empirical mode decomposition and wavelet kernel extreme learning machine methods. Sensors 2021, 21, 2599. [Google Scholar] [CrossRef]

- Araste, Z.; Sadighi, A.; Jamimoghaddam, M. Fault diagnosis of a centrifugal pump using electrical signature analysis and support vector machine. J. Vib. Eng. Technol. 2023, 11, 2057–2067. [Google Scholar] [CrossRef]

- Naimi, A.; Deng, J.; Doney, P.; Sheikh-Akbari, A.; Shimjith, S.R.; Arul, A.J. Machine learning-based fault diagnosis for a PWR nuclear power plant. IEEE Access 2022, 10, 126001–126010. [Google Scholar] [CrossRef]

- Potočnik, P.; Olmos, B.; Vodopivec, L.; Susič, E.; Govekar, E. Condition classification of heating systems valves based on acoustic features and machine learning. Appl. Acoust. 2021, 174, 107736. [Google Scholar] [CrossRef]

- Duan, A.; Guo, L.; Gao, H.; Wu, X.; Dong, X. Deep focus parallel convolutional neural network for imbalanced classification of machinery fault diagnostics. IEEE Trans. Instrum. Meas. 2020, 69, 8680–8689. [Google Scholar] [CrossRef]

- Yu, Z.; Bo, J.; Xiao-Xuan, J.; Yu-Ting, H.; Hong-Da, S.; Jie, B. Fault Diagnosis of Airborne Fuel Pumps Based on Improved CNN-SVM. Noise Vib. Control 2022, 42, 137–149. [Google Scholar]

- Jiang, W.; Li, Z.; Zhang, S.; Wang, T.; Zhang, S.; Zhou, L. Hydraulic pump fault diagnosis method based on EWT decomposition denoising and deep learning on cloud platform. Shock Vib. 2021, 21, 6674351. [Google Scholar] [CrossRef]

- Dao, F.; Zeng, Y.; Qian, J. Fault diagnosis of hydro-turbine via the incorporation of bayesian algorithm optimized CNN-LSTM neural network. Energy 2024, 290, 130326. [Google Scholar] [CrossRef]

- Zhong, S.-S.; Fu, S.; Lin, L. A novel gas turbine fault diagnosis method based on transfer learning with CNN. Measurement 2023, 137, 435–453. [Google Scholar] [CrossRef]

- Than, N.-L.; Nguyen, V.Q.; Truong, G.-B.; Pham, V.-T.; Tran, T.-T. Mixmamba-fewshot: Mamba and attention mixer-based method with few-shot learning for bearing fault diagnosis. Appl. Intell. 2025, 55, 1–22. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Hou, J.; Wang, J.; Zhao, M. Intelligent identification of internal leakage in natural gas pipeline control valves based on Mamba-ARN. Process Saf. Environ. Prot. 2025, 198, 107113. [Google Scholar] [CrossRef]

- Bellacci, G.; Baldanzini, N.; Pugi, L. On the Use of Wavelet Analysis for the Detection and Position Estimation of Short Wavelength Rail Head Faults. Mech. Mach. Sci. 2025, 180, 588–595. [Google Scholar]

- Liang, P.; Wang, W.; Yuan, X.; Liu, S.; Zhang, L.; Cheng, Y. Intelligent fault diagnosis of rolling bearing based on wavelet transform and improved ResNet under noisyl abels and environment. Eng. Appl. Artif. Intell. 2022, 115, 105269. [Google Scholar] [CrossRef]

- Elfatimi, E.; Eryigit, R.; Elfatimi, L. Classification of bean leaf diseases using MobileNet model. IEEE Access 2022, 10, 9471–9482. [Google Scholar] [CrossRef]

- Bouguezzi, S.; Fredj, H.B.; Belabed, T.; Valderrama, C.; Faiedh, H.; Souani, C. An Efficient FPGA-Based Convolutional Neural Network for Classification: Ad-MobileNet. Electronics 2021, 10, 2272. [Google Scholar] [CrossRef]

- Alajlan, N.N.; Ibrahim, D.M. DDD TinyML: A TinyML-Based Driver Drowsiness Detection Model Using Deep Learning. Sensors 2023, 23, 5696. [Google Scholar] [CrossRef]

- Yan, S.; Wei, H.; Yang, C.; Liu, Z.; Zhang, S.; Zhao, L. Fault Diagnosis of Rolling Bearing Based on CBAM-ICNN. In Proceedings of the 2024 39th Youth Academic Annual Conference of Chinese Association of Automation (YAC), Dalian, China, 7–9 June 2024; pp. 1420–1425. [Google Scholar]

- Sun, C.; Zhou, X.; Zhang, M.; Qin, A. SE-VisionTransformer: Hybrid Network for Diagnosing Sugarcane Leaf Diseases Based on Attention Mechanism. Sensors 2023, 23, 8529. [Google Scholar] [CrossRef] [PubMed]

- Peraza-Vázquez, H.; Peña-Delgado, A.; Merino-Treviño, M.; Morales-Cepeda, A.B.; Sinha, N. A novel metaheuristic inspired by horned lizard defense tactics. Artif. Intell. Rev. 2024, 57, 59. [Google Scholar] [CrossRef]

- Shao, H.; Xia, M.; Han, G.; Zhang, Y.; Wan, J. Intelligent Fault Diagnosis of Rotor-Bearing System Under Varying Working Conditions With Modified Transfer Convolutional Neural Network and Thermal Images. IEEE Trans. Ind. Inform. 2020, 17, 3488–3496. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, Z.; Wang, C.; Zhao, D.; Li, Y. Prediction of precipitation-type landslide displacement using CNN-BIGRU-Attention considering hysteresis effect. People’s Yellow River 2025, 47, 135–140+145. [Google Scholar]

- Li, J.J.; Peng, Y.M.; Ren, H.B. Prediction of remaining life of diaphragm pump check valve based on Bi-GRU. J. Yunnan Univ. (Nat. Sci. Ed.) 2025, 1–8. [Google Scholar] [CrossRef]

- Wang, W.; Sun, Y.; Qi, Q.; Meng, X. Text sentiment classification model based on BiGRU-attention neural network. Comput. Appl. Res. 2019, 36, 3558–3564. [Google Scholar]

- Haixiu, C.; Lei, L. Underwater image enhancement based on SK attention residual network. J. Nanjing Univ. Inf. Sci. Technol. (Nat. Sci. Ed.) 2023, 15, 524–533. [Google Scholar]

- Li, X.; Wang, W.; Hu, X.; Yang, J. Selective Kernel Networks. 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Long Beach, CA, USA, 15–21 June 2019; pp. 510–519. [Google Scholar]

| Working Conditions | Internal Leakage Forms |

|---|---|

| Working conditions 1 | Valve seat sealing surface is not damaged |

| Working conditions 2 | Φ1 mm single semicircular groove |

| Working conditions 3 | Φ2 mm single semicircular groove |

| Working conditions 4 | Φ1 mm double semicircular groove |

| Working conditions 5 | Φ2 mm double semicircular groove |

| Internal Leakage Form | Number of Training Sets | Number of Test Sets | Total Sample Size | Sample Proportion | Label |

|---|---|---|---|---|---|

| Valve seat sealing surface is not damaged | 140 | 60 | 200 | 20% | 1 |

| Φ1 mm single semicircular groove | 140 | 60 | 200 | 20% | 2 |

| Φ2 mm single semicircular groove | 140 | 60 | 200 | 20% | 3 |

| Φ1 mm double semicircular groove | 140 | 60 | 200 | 20% | 4 |

| Φ2 mm double semicircular groove | 140 | 60 | 200 | 20% | 5 |

| Label | Number of Samples | TP | FP | FN | Accuracy | Recall | F1 Score |

|---|---|---|---|---|---|---|---|

| 1 | 60 | 60 | 0 | 0 | 1.00 | 1.00 | 1.00 |

| 2 | 60 | 60 | 0 | 0 | 1.00 | 1.00 | 1.00 |

| 3 | 60 | 60 | 0 | 0 | 1.00 | 1.00 | 1.00 |

| 4 | 60 | 60 | 1 | 0 | 0.984 | 1.00 | 0.992 |

| 5 | 60 | 59 | 0 | 1 | 1.00 | 0.983 | 0.991 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Yuan, K.; Hou, J.; Meng, X. Intelligent Identification of Internal Leakage of Spring Full-Lift Safety Valve Based on Improved Convolutional Neural Network. Sensors 2025, 25, 5451. https://doi.org/10.3390/s25175451

Li S, Yuan K, Hou J, Meng X. Intelligent Identification of Internal Leakage of Spring Full-Lift Safety Valve Based on Improved Convolutional Neural Network. Sensors. 2025; 25(17):5451. https://doi.org/10.3390/s25175451

Chicago/Turabian StyleLi, Shuxun, Kang Yuan, Jianjun Hou, and Xiaoqi Meng. 2025. "Intelligent Identification of Internal Leakage of Spring Full-Lift Safety Valve Based on Improved Convolutional Neural Network" Sensors 25, no. 17: 5451. https://doi.org/10.3390/s25175451

APA StyleLi, S., Yuan, K., Hou, J., & Meng, X. (2025). Intelligent Identification of Internal Leakage of Spring Full-Lift Safety Valve Based on Improved Convolutional Neural Network. Sensors, 25(17), 5451. https://doi.org/10.3390/s25175451