Investigation on the Vibration Induced by the Rotary-Shaft-Seal Condition in a Centrifugal Pump

Abstract

1. Introduction

2. Theory

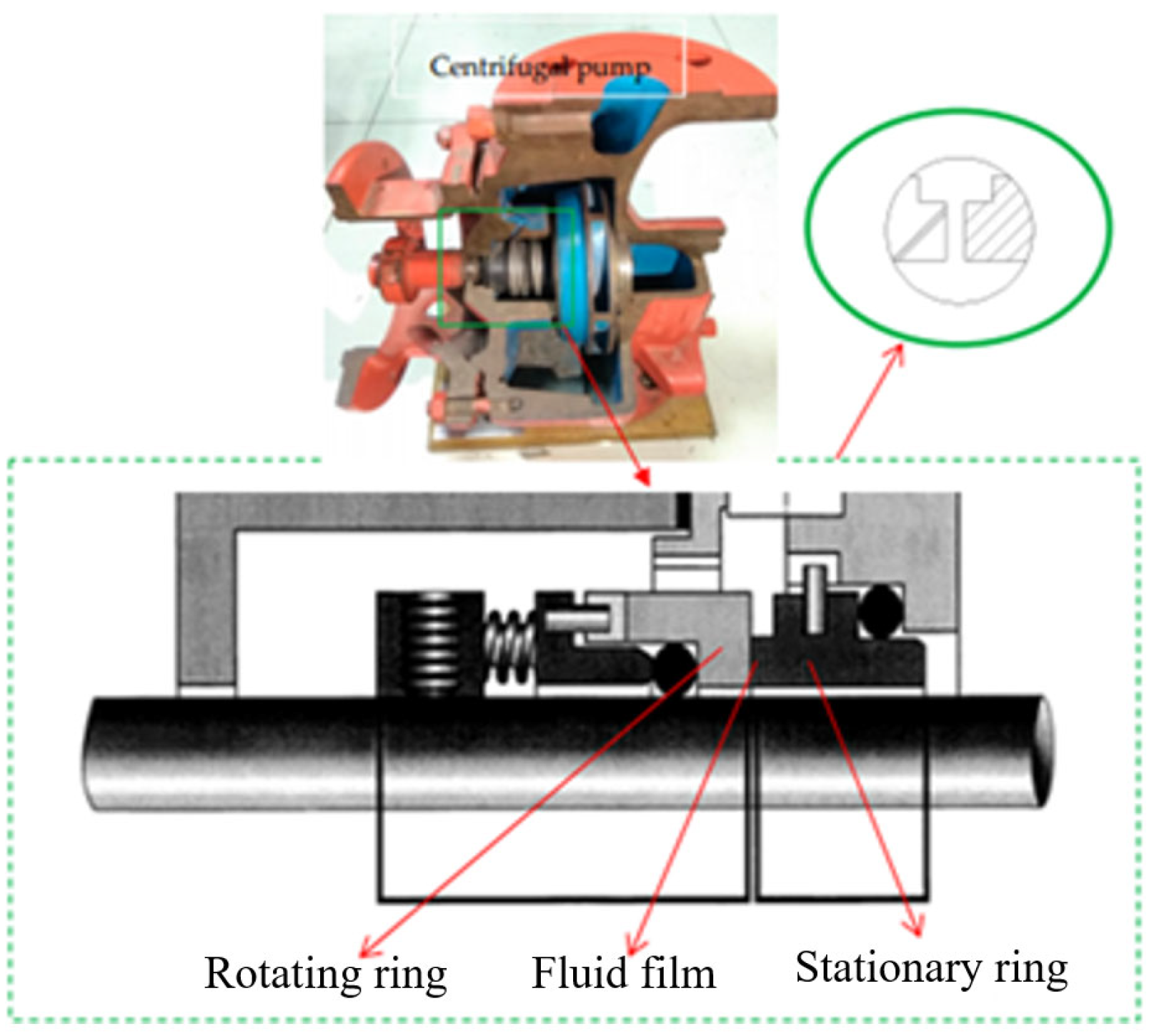

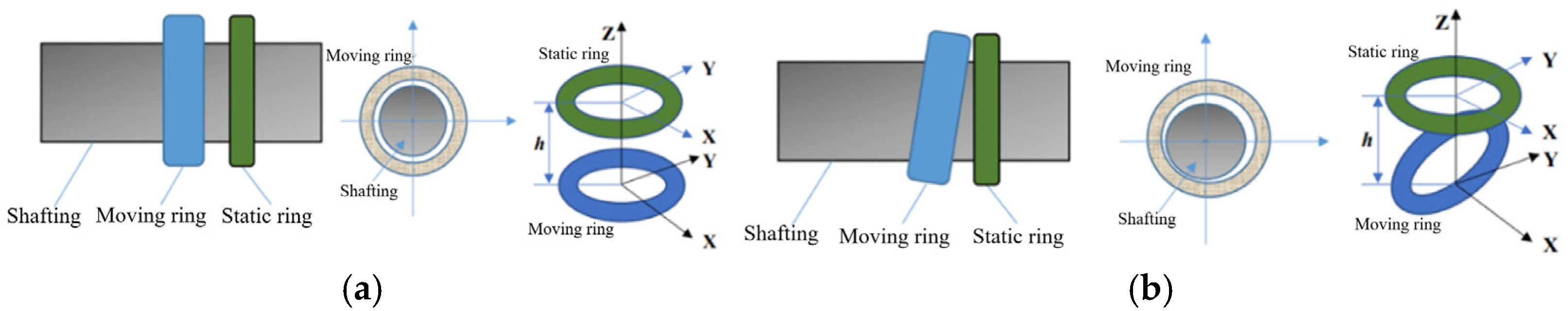

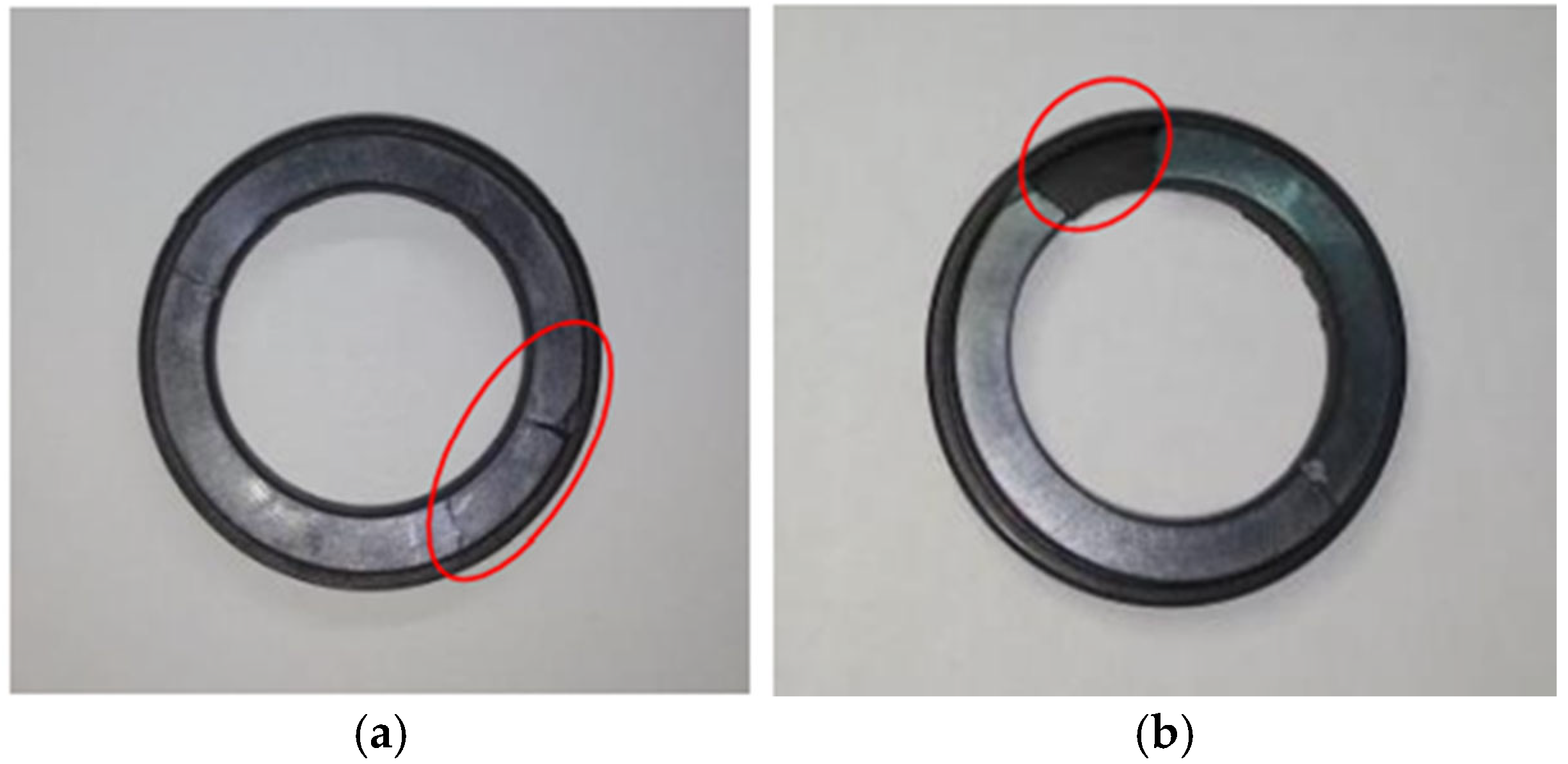

2.1. Faults in Rotary Shaft Seals

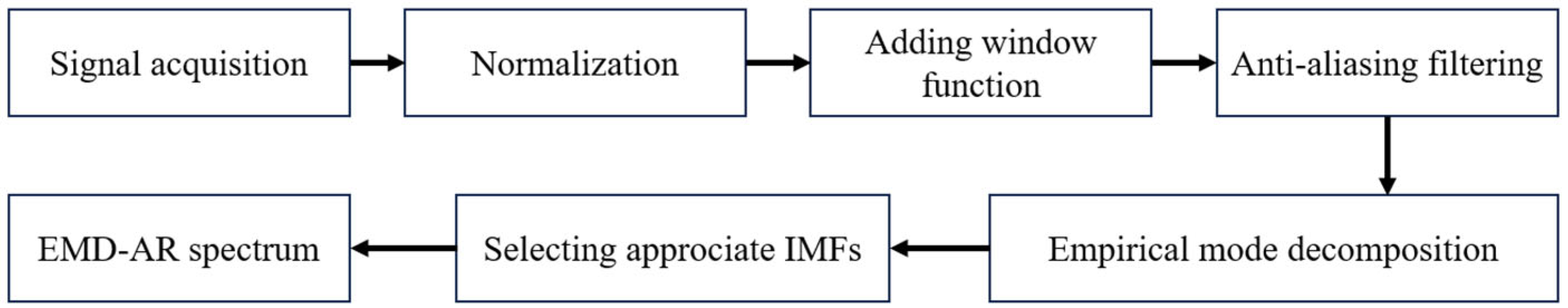

2.2. Signal Preprocessing

- (1)

- Normalization:

- (2)

- Windowing:

- (3)

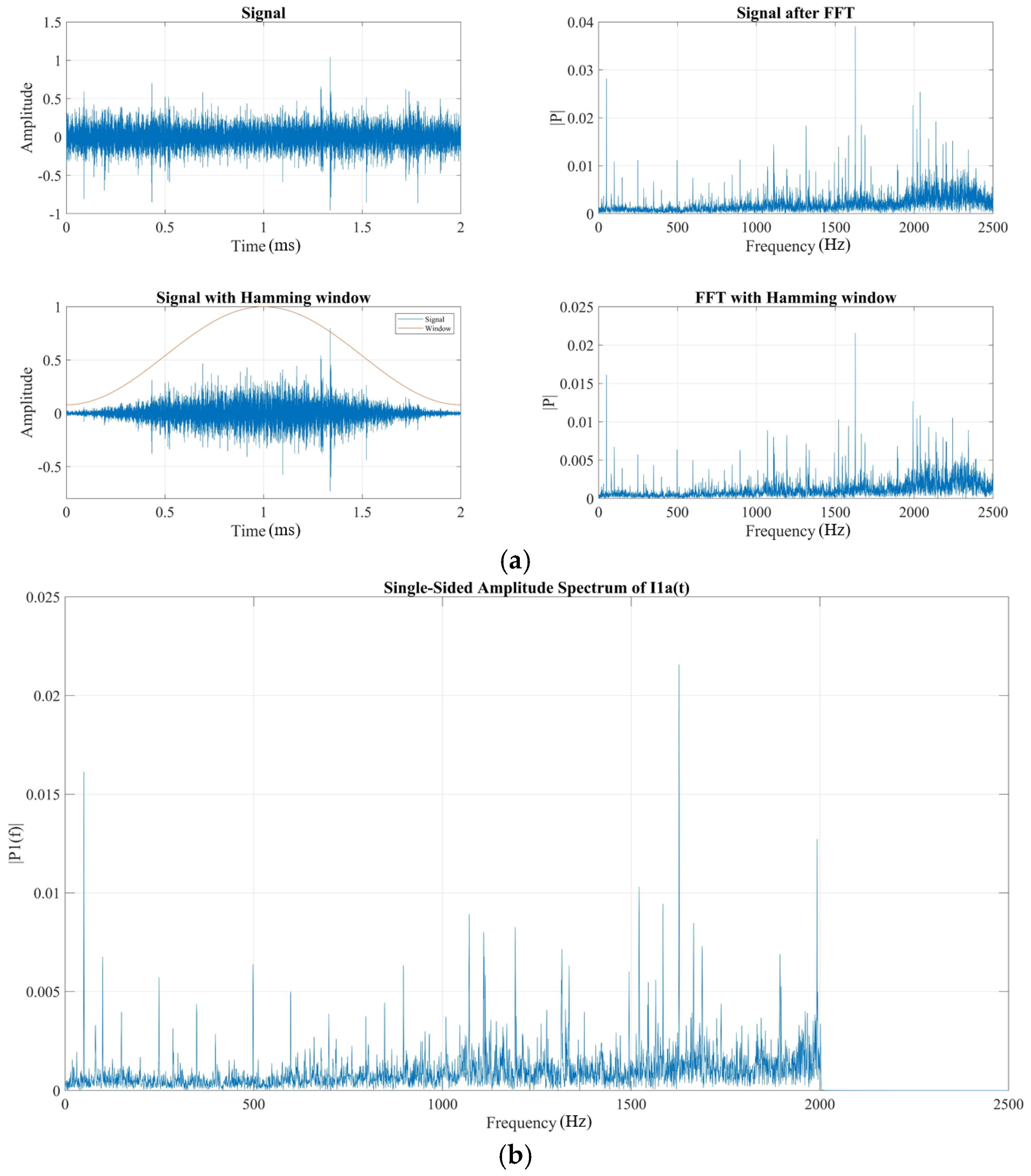

- Anti-Aliasing Filtering:

2.3. Theories Related to Time–Frequency Joint Analysis

- (1)

- Instantaneous frequency:

- (2)

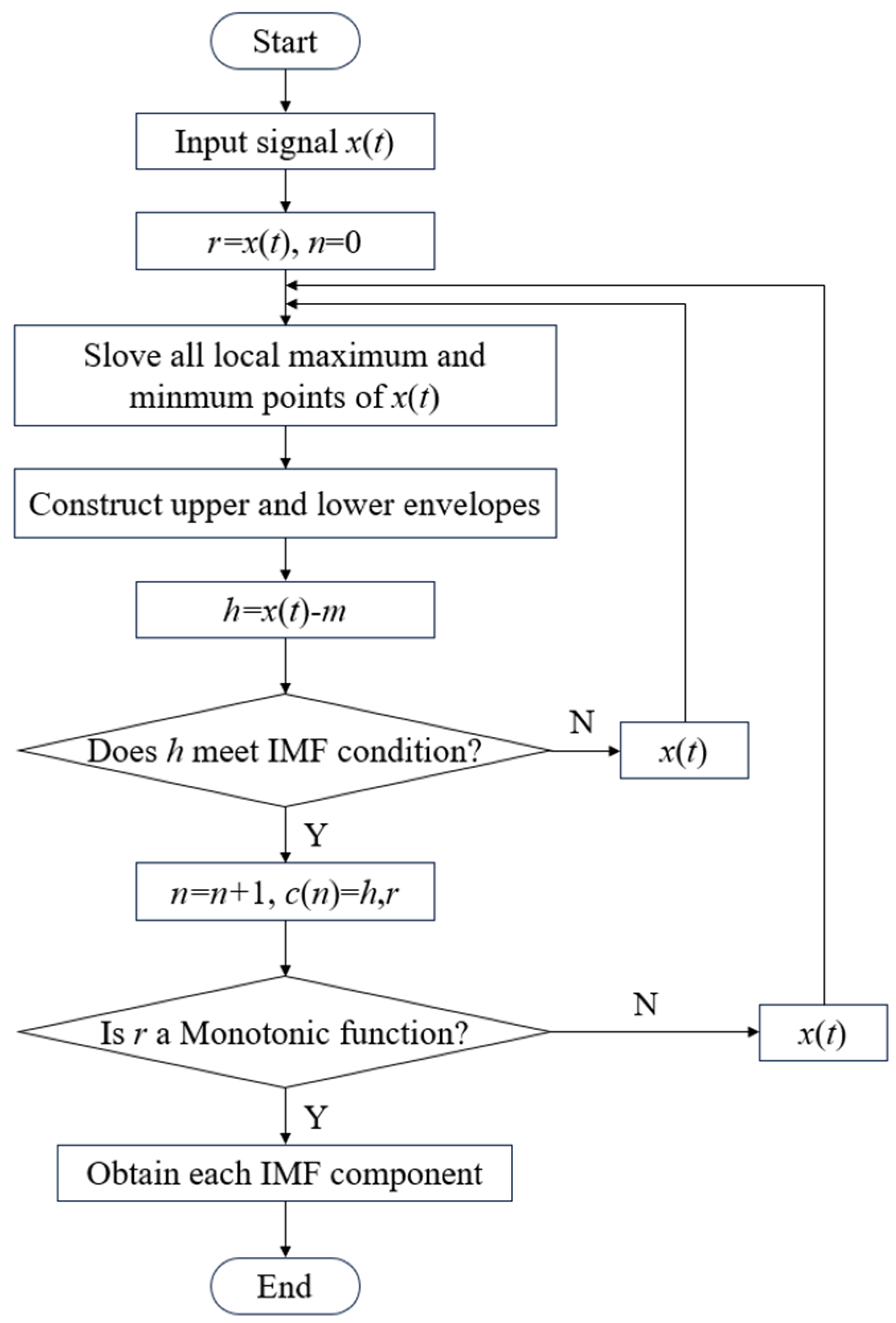

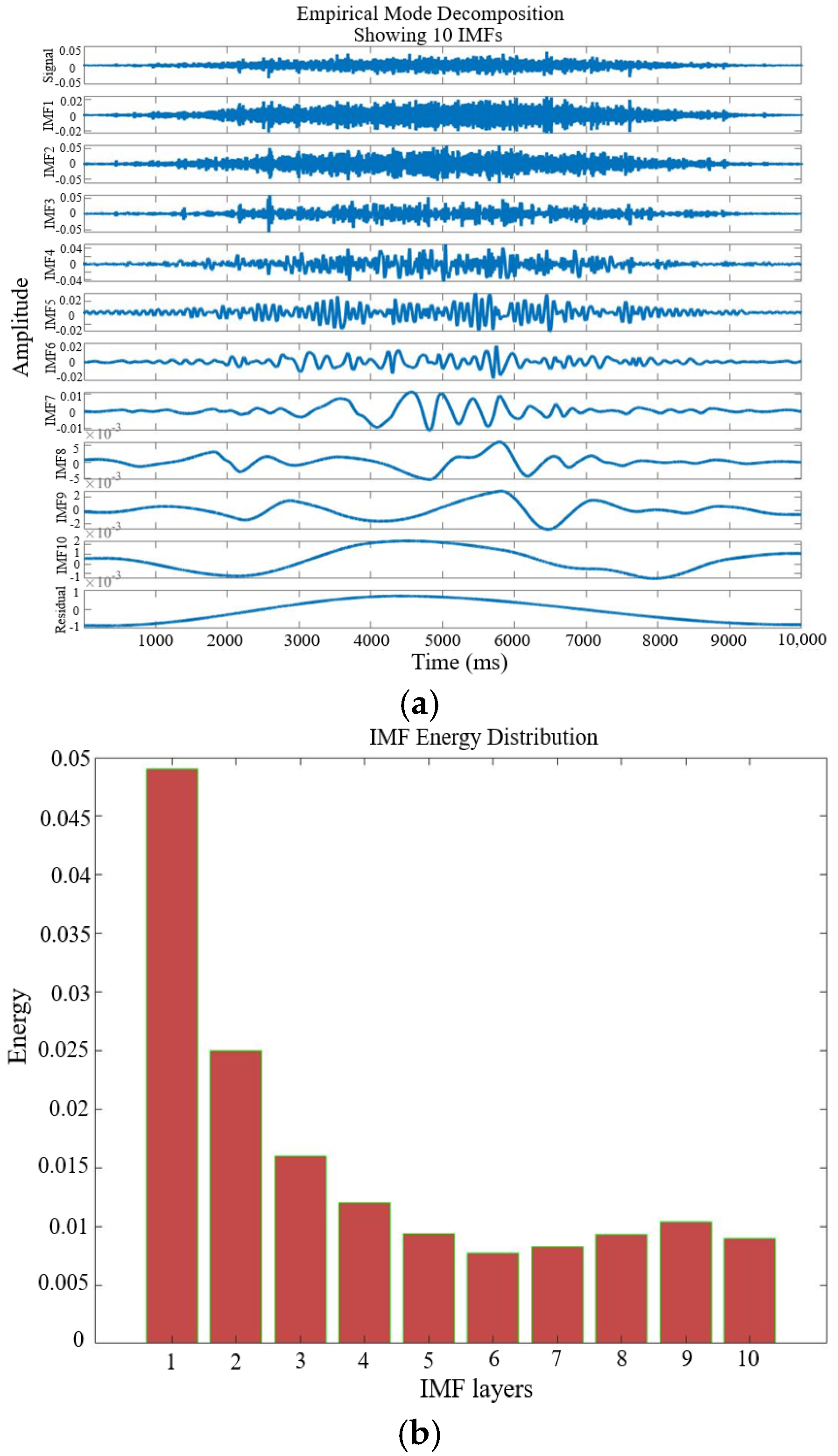

- EMD decomposition principle:

- ①

- Identify all local maxima and minima within the signal.

- ②

- Apply the cubic spline function for interpolating all maximum and minimum points, fitting both the upper and lower envelopes, and calculating the average value (m1) of these envelopes. Subsequently, perform the necessary calculations:

- ③

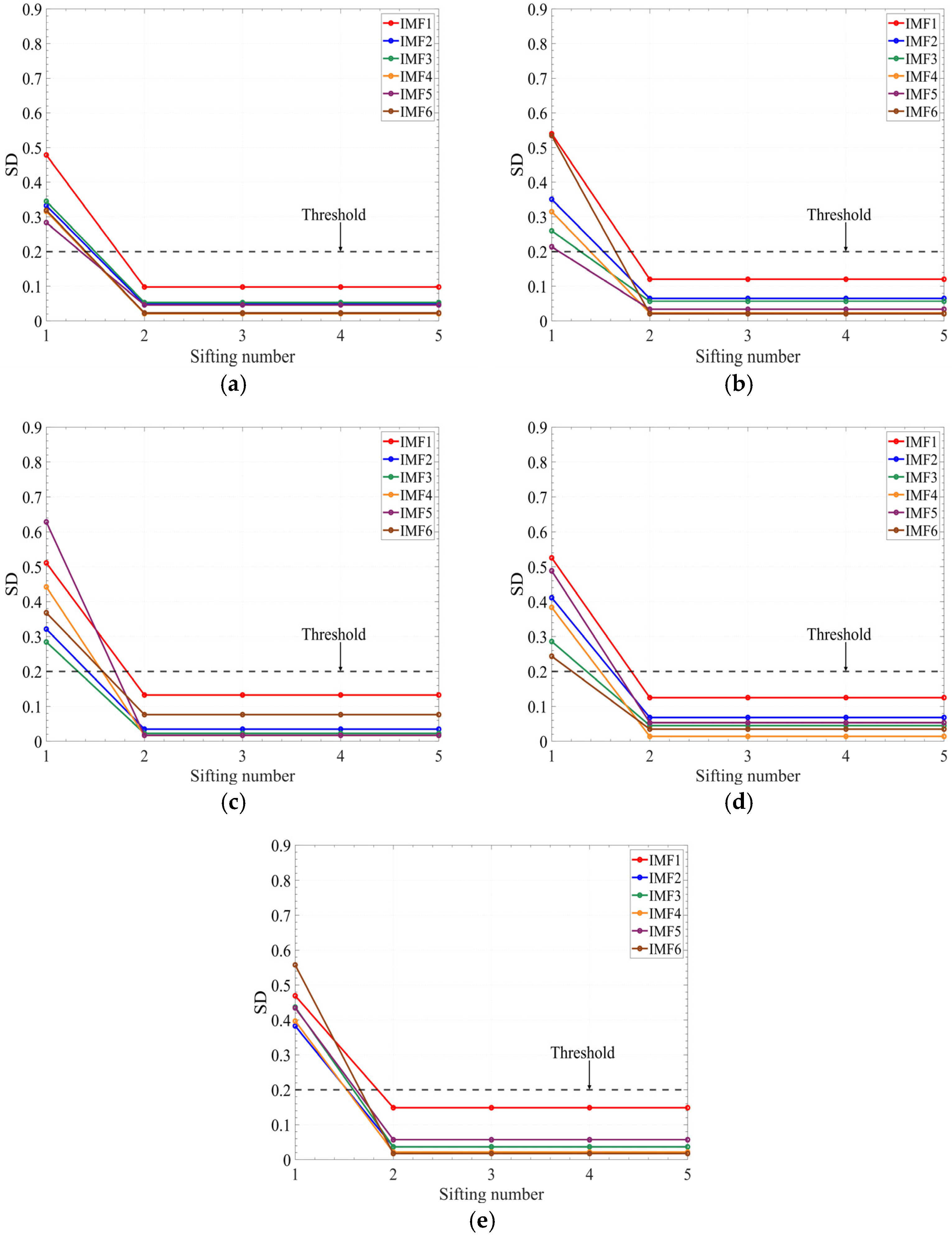

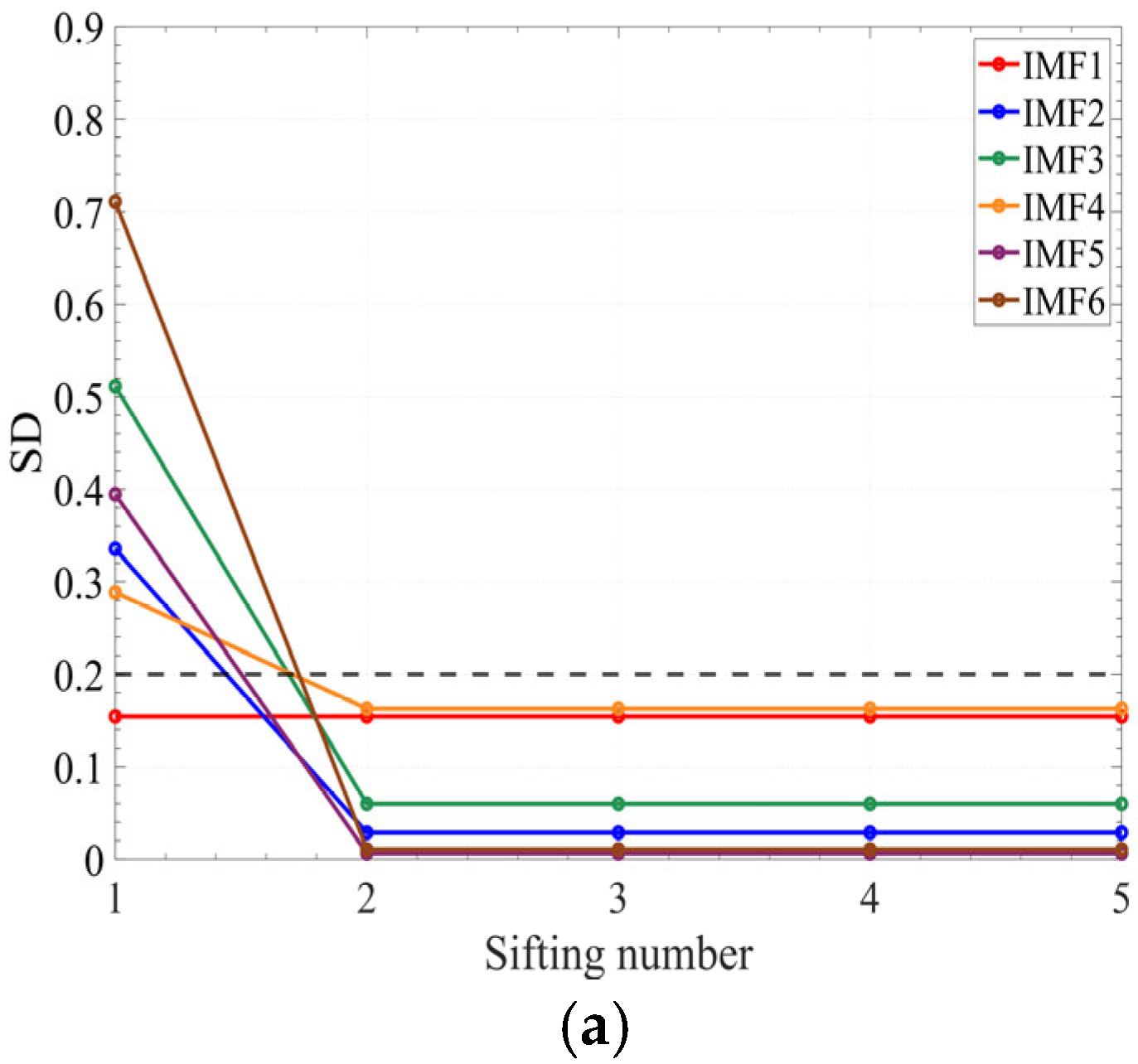

- If h1 satisfies the conditions of an Intrinsic Mode Function (IMF), it is designated as the first IMF component of x(t). If h1 is not an IMF, repeat the sifting process k times using the current data as the new input, until an IMF is obtained. The final result is the following:

- ④

- Subtract c1 from x(t) to get the residual:

- (3)

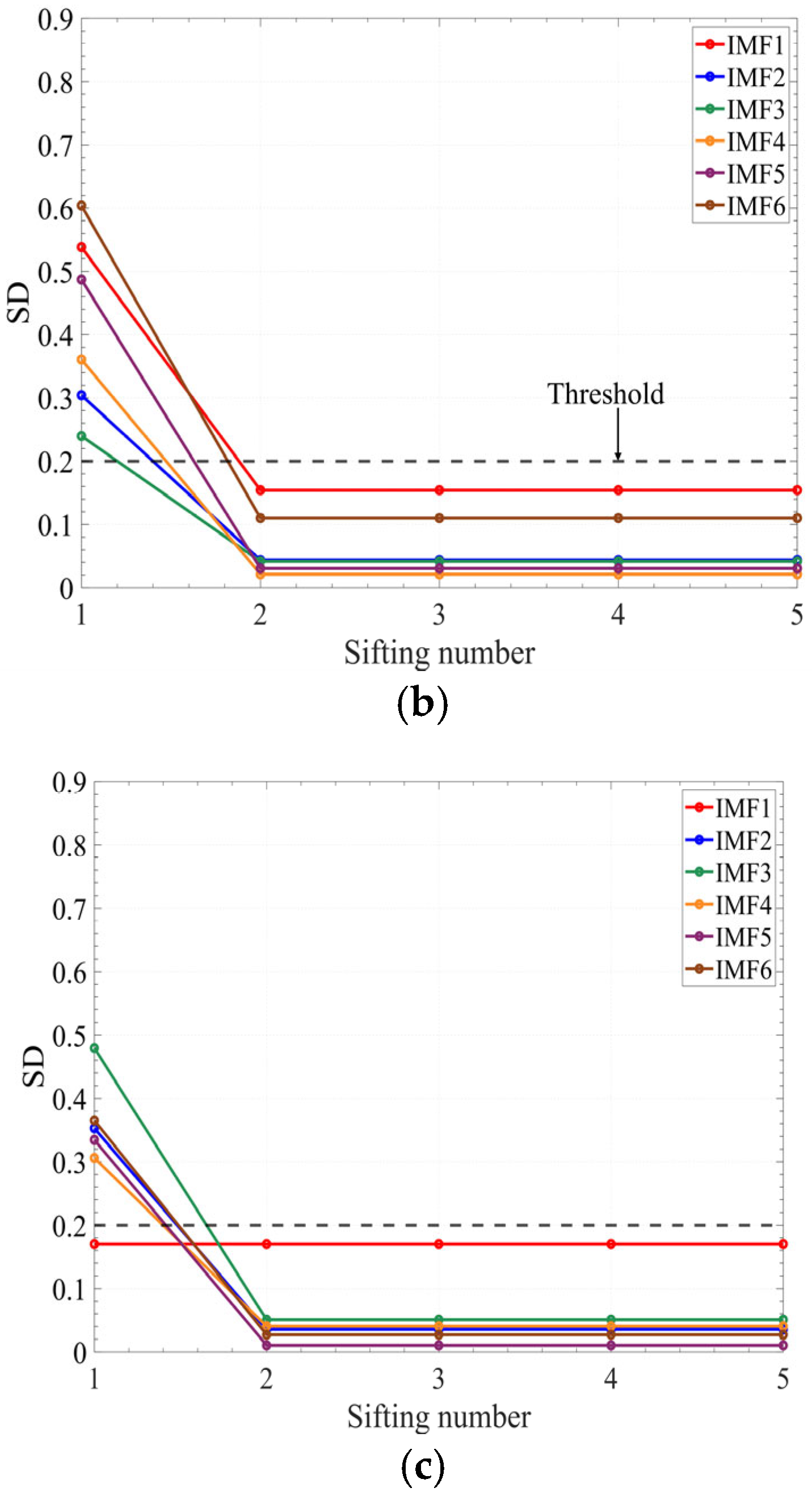

- Guidelines for determining the IMF components

- (4)

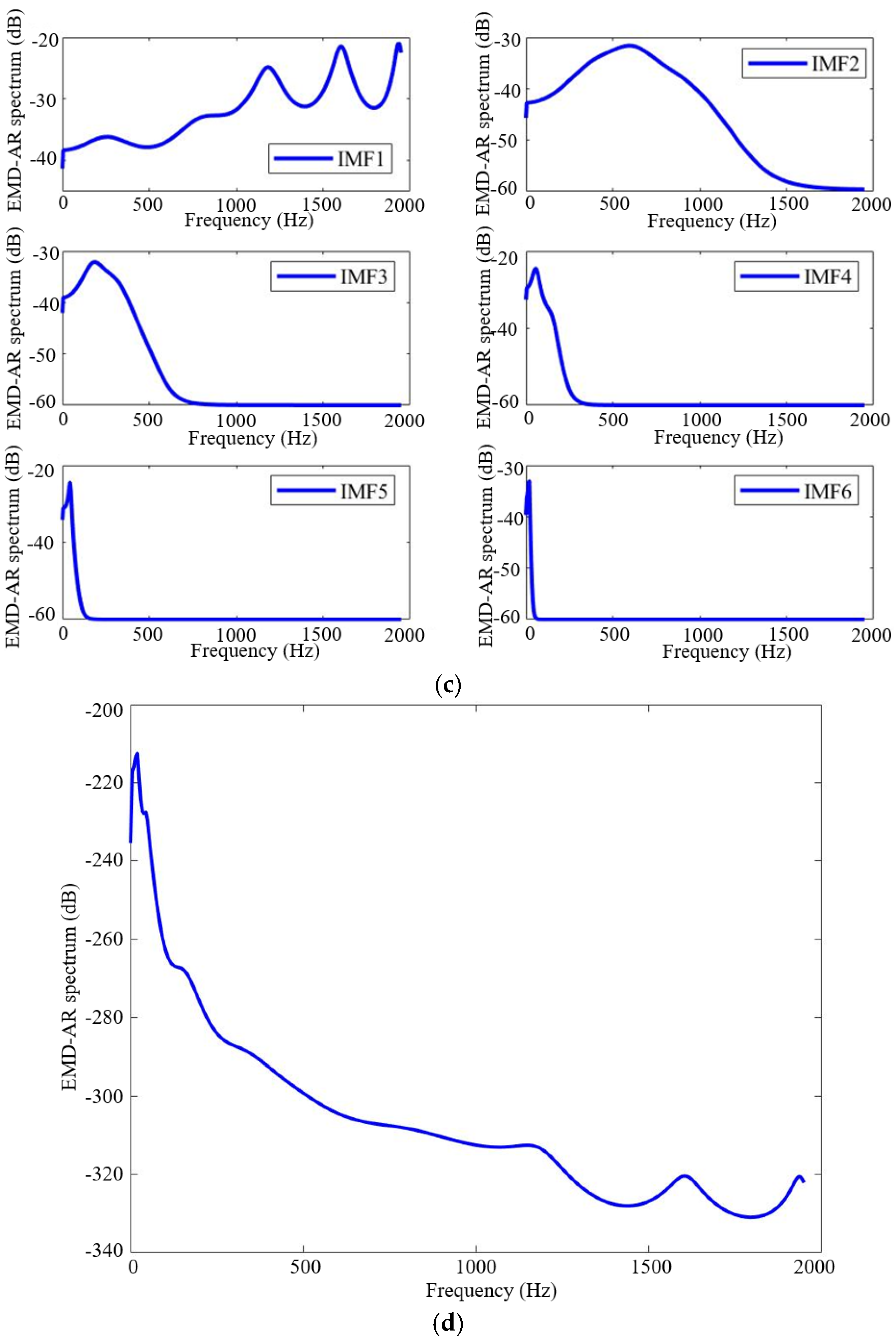

- EMD-AR spectrum

- ①

- Establish the excitation–response characteristics of the system by generating a stationary signal sequence x(n) from a white noise sequence u(n).

- ②

- Estimate the parameters of the system H(z) using the known signal sequence x(n) or its autocorrelation function.

- ③

- Estimate the power spectrum of the sequence x(n) based on the parameters of H(z).

3. Experiment

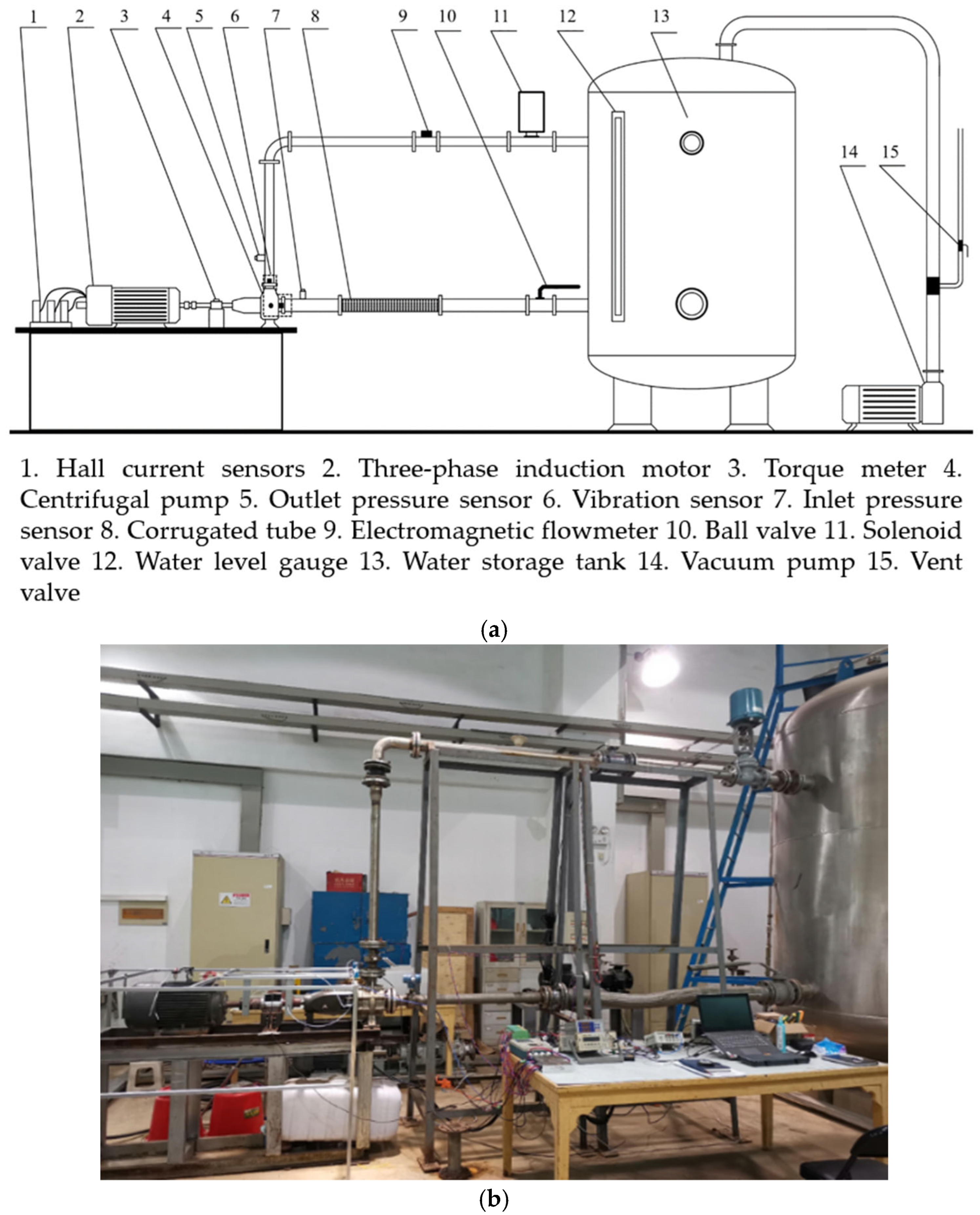

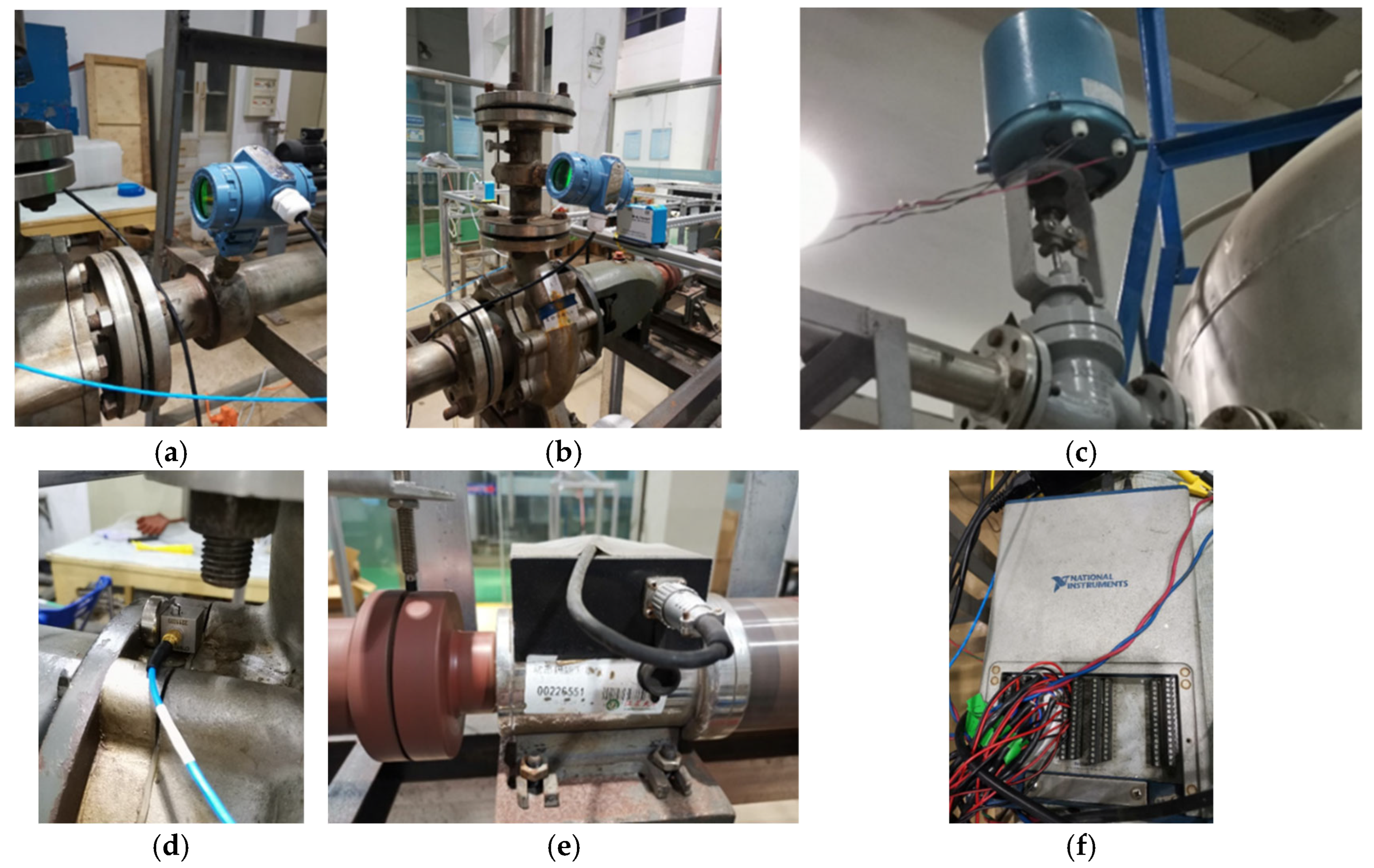

3.1. Experimental Bench

3.2. Design of the Experiment

- 1.

- Fully open the ball valve in the inlet pipeline and ensure that the liquid level pressure in the water storage tank is approximately equal to atmospheric pressure;

- 2.

- Turn on the centrifugal pump unit, inspect the hydraulic circulation system for any leaks, verify the stability of the data acquisition card during data collection, and calibrate each sensor;

- 3.

- The flow rate of the centrifugal pump is treated as an independent variable, with the rated flow rate Qd serving as the reference. The full flow range along the horizontal axis is divided into 14 operating points: 0, 0.1Qd, 0.2Qd, 0.3Qd, 0.4Qd, 0.5Qd, 0.6Qd, 0.7Qd, 0.8Qd, 0.9Qd, 1.0Qd, 1.1Qd, 1.2Qd, and 1.3Qd;

- 4.

- Adjust the analog voltage output from the data acquisition card to control the solenoid valve opening, thereby regulating the centrifugal pump’s flowrate. Starting from working point 0, power on the system and initiate signal acquisition once the operating parameters stabilize;

- 5.

- Adjust the voltage signal generator to regulate the valve opening, thereby controlling the flow rate. Open the ball valve briefly to purge trapped air, then close it. Once the signals stabilize, begin data acquisition to simultaneously collect inlet and outlet pressure, flow rate, speed, torque, and other key parameters of the centrifugal pump;

- 6.

- Repeat step 5 for each of the 14 operating points until data collection is completed for all operation conditions.

- 7.

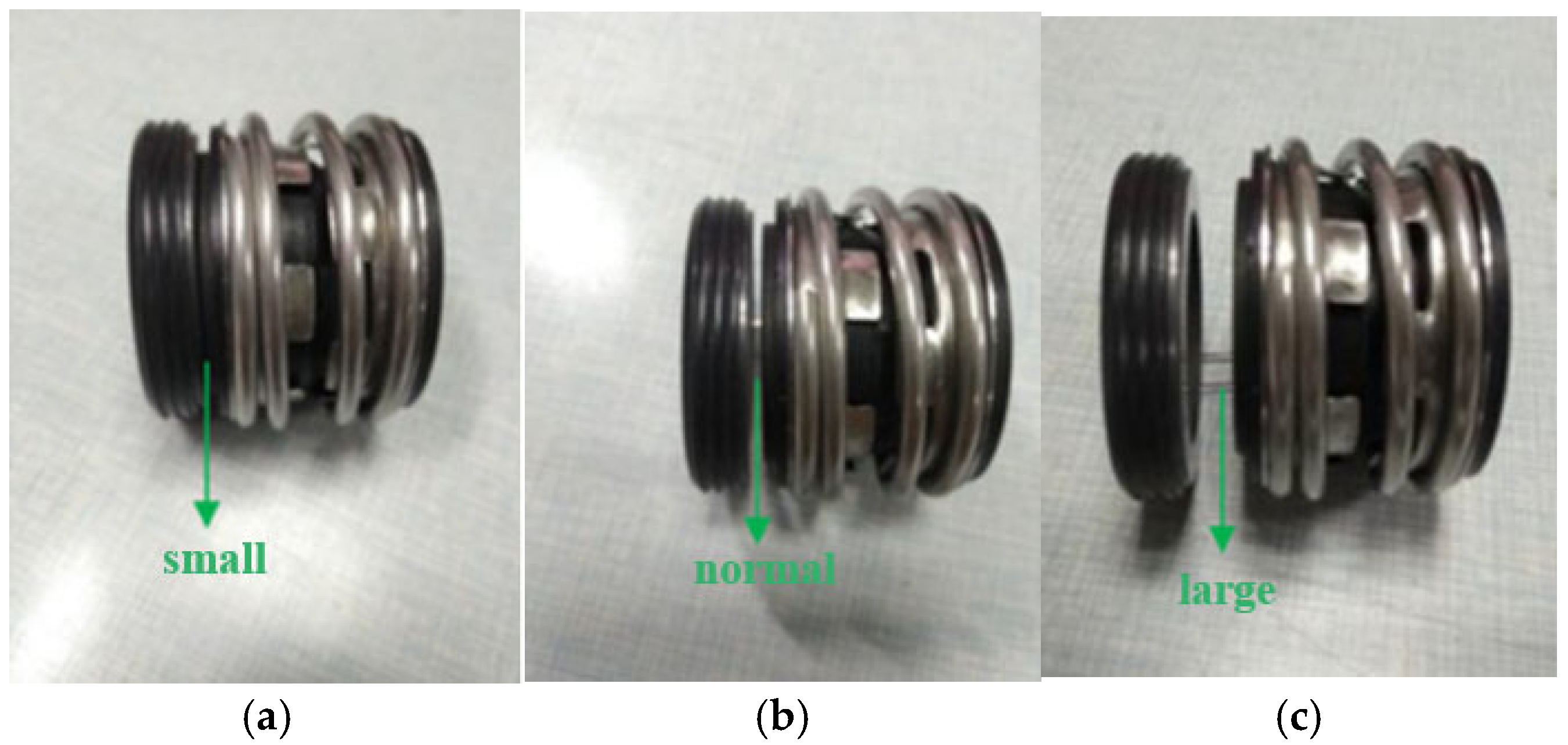

- Using the collected inlet and outlet pressure, flowrate, speed, and torque data under different working conditions, apply Formulas (9)–(14) to compute the corresponding performance parameters. To measure pump performance under mild rotary-shaft-seal failure, first power off the system, remove the standard rotary shaft seal, and replace it with a slightly damaged one (as shown in Figure 8). Then, power on the system and repeat steps 3 to 7.

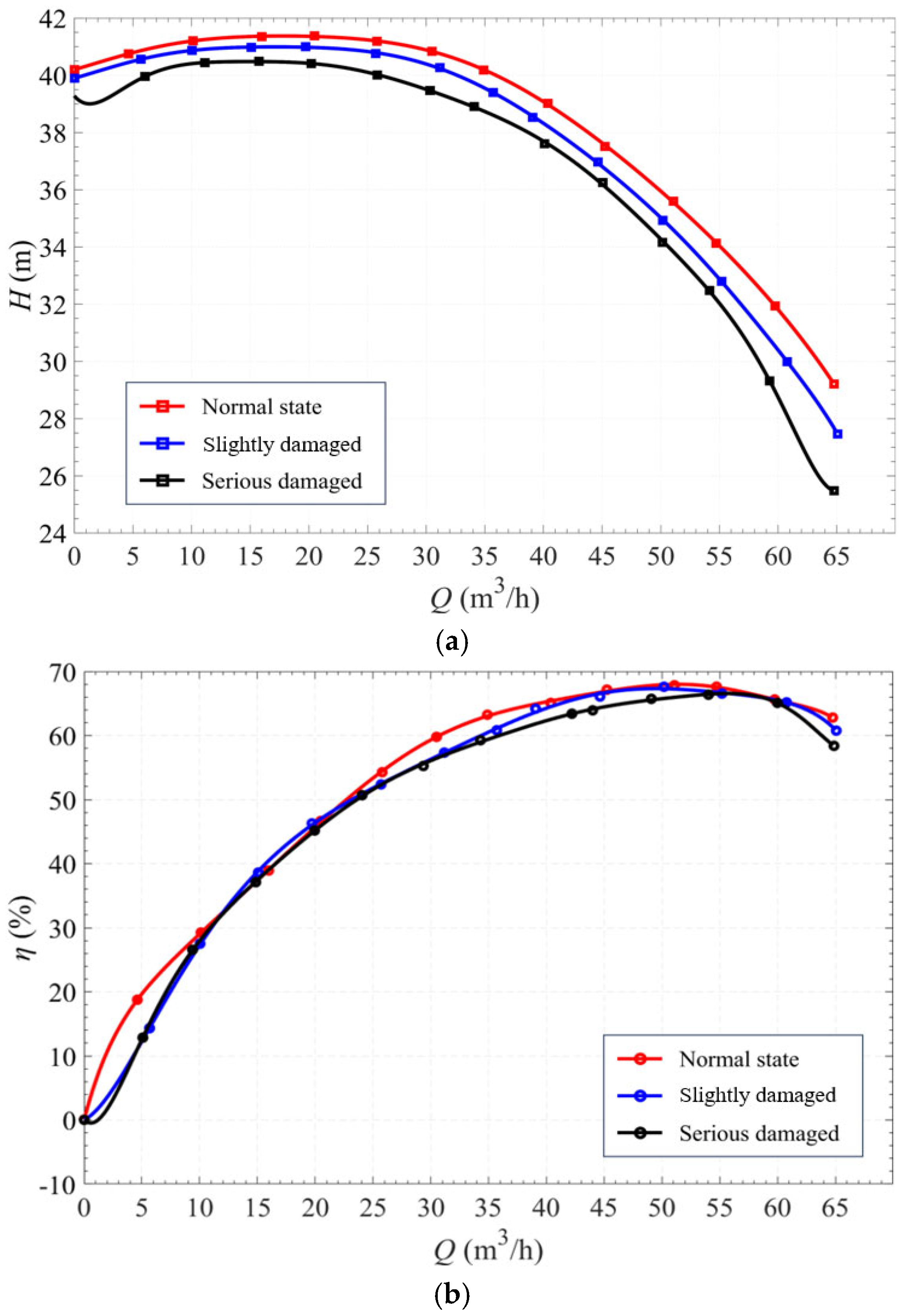

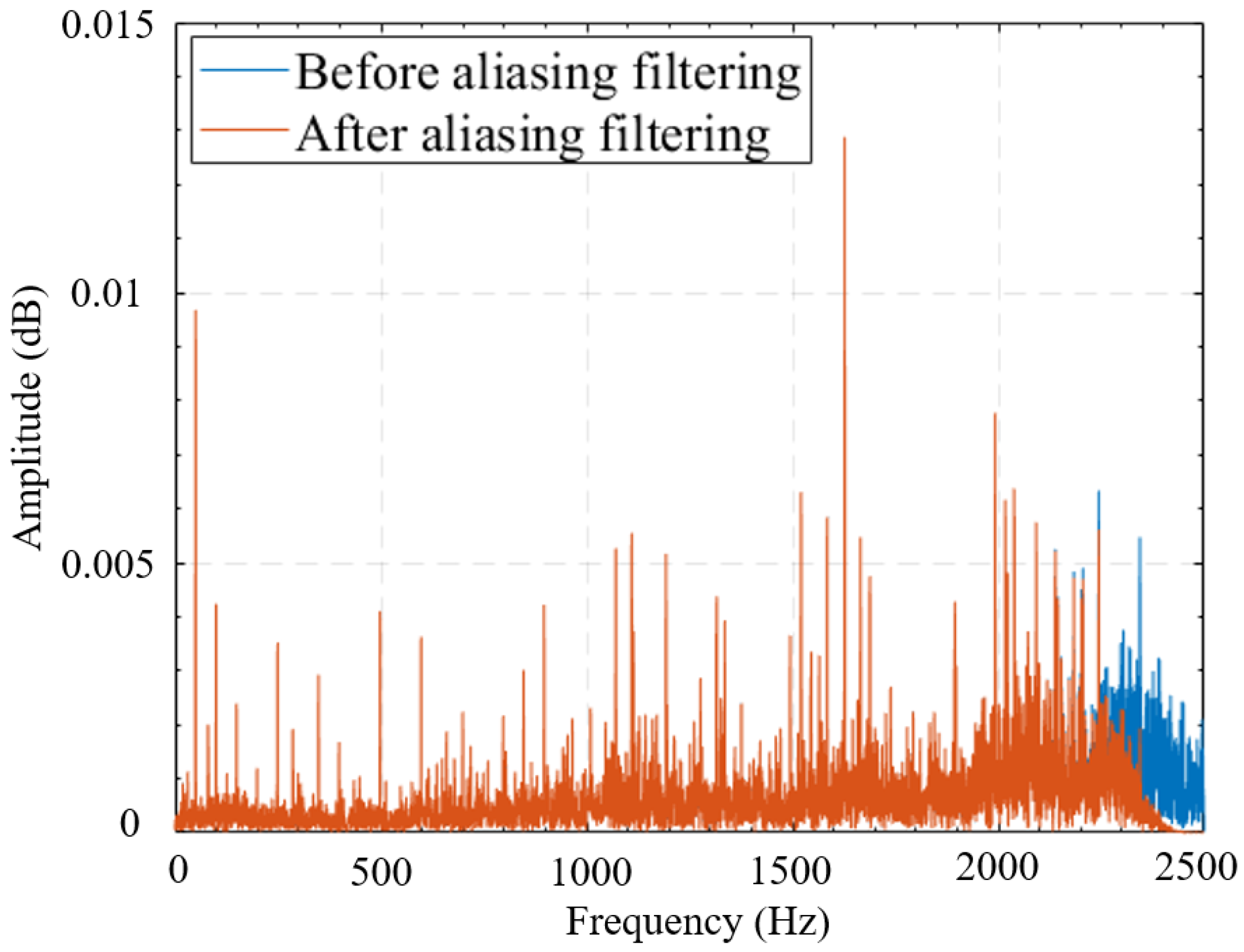

3.3. Experiment Results

4. Vibration Signals Analysis

- 1.

- Consistent rotary-shaft-seal conditions with different flow rates;

- 2.

- Consistent flowrate with different rotary-shaft-seal states. By processing and analyzing the vibration signals, distinctive and representative indicators can be identified to accurately assess the system’s operational state. The following section presents the signal processing procedure under normal rotary-shaft-seal conditions and standard operating parameters.

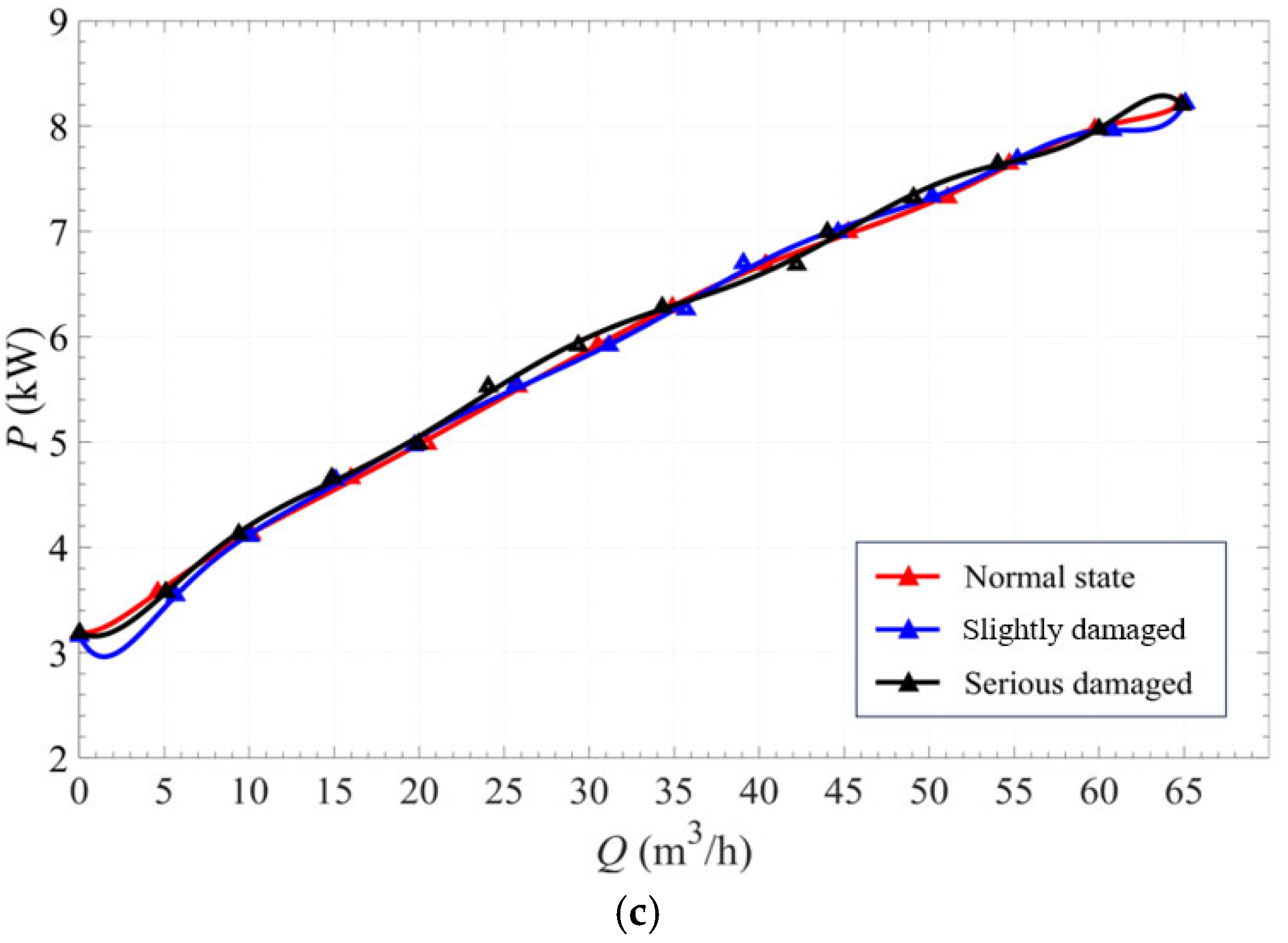

4.1. Preprocessing

4.2. Time–Frequency Joint Analysis

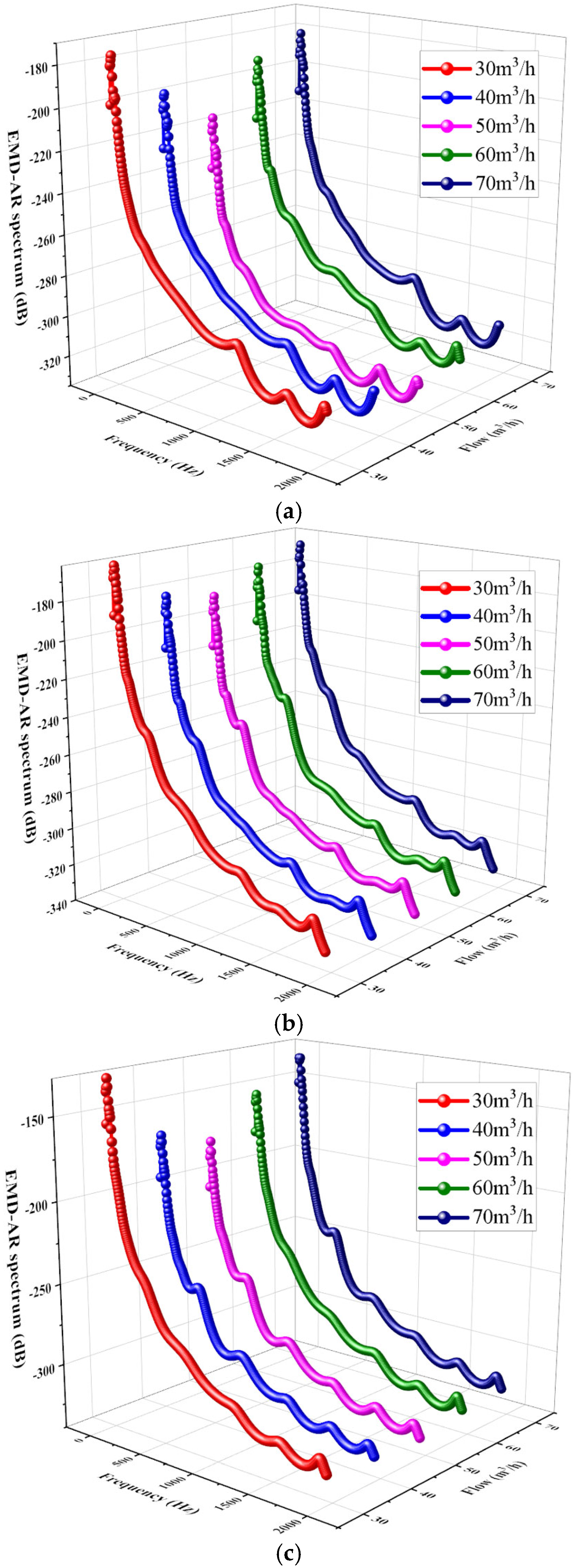

4.3. Analysis Results at Different Flowrates

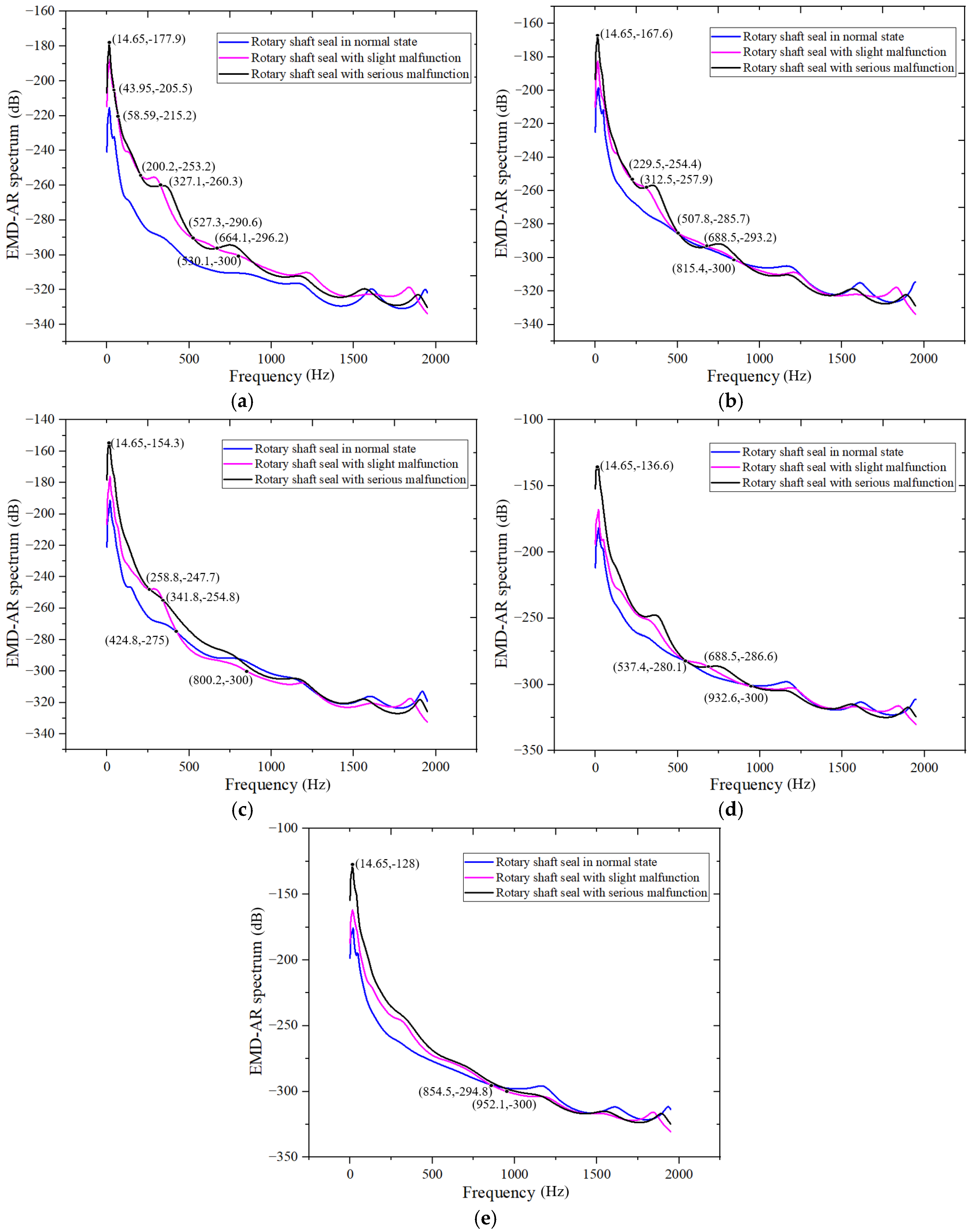

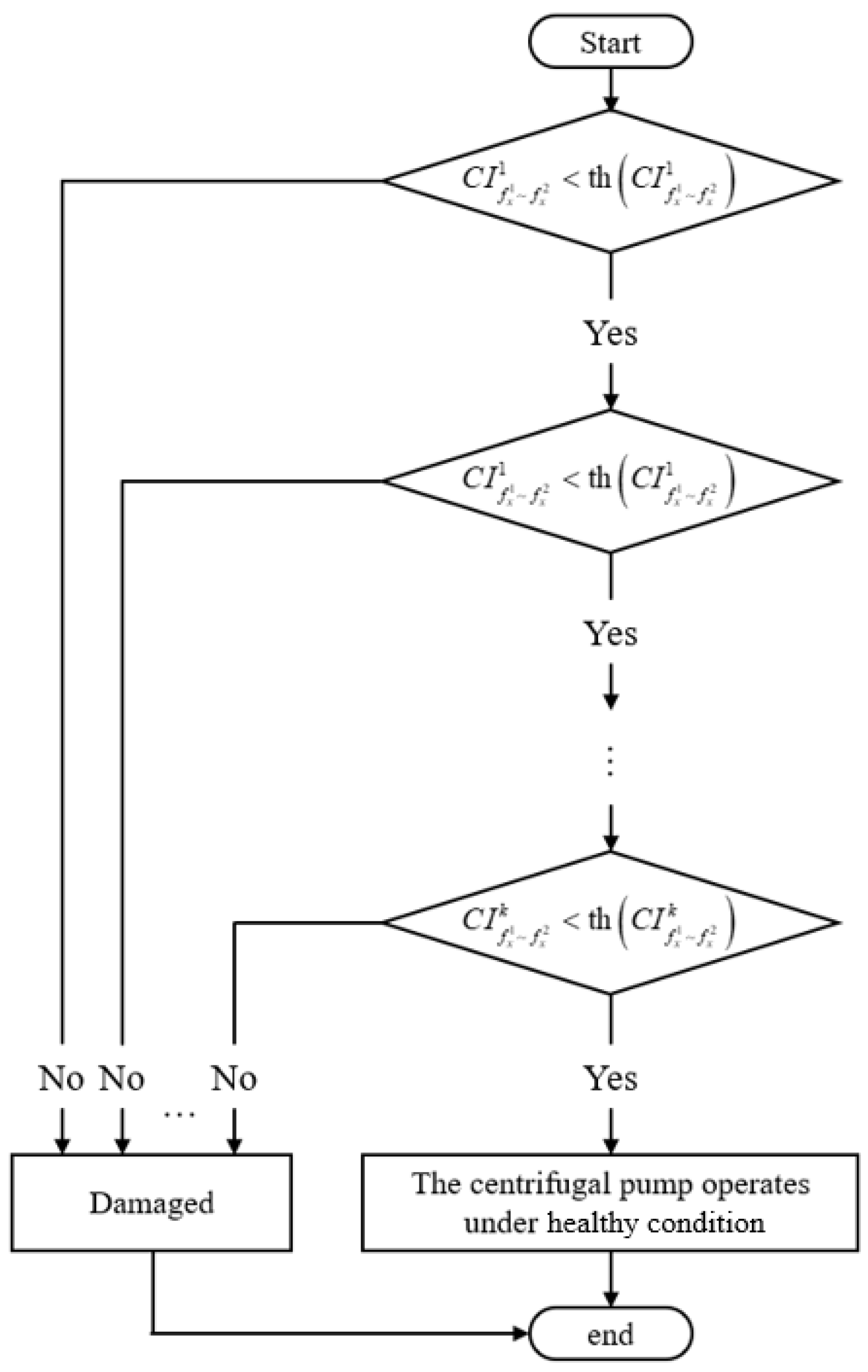

4.4. Analysis Results at Different Rotary-Shaft-Seal States

5. Conclusions

- 1.

- The impact of rotary-shaft-seal failure on key performance indicators follows a descending order of sensitivity: head, efficiency, and shaft power. With increasing severity of rotary-shaft-seal failure, both the head and efficiency exhibit a declining trend, whereas the shaft power remains relatively unchanged. These findings suggest that shaft seal failures result in internal fluid leakage, leading to unsteady flow patterns and non-uniform loading on the impeller and blades. As a result, the overall hydraulic and mechanical performance of the pump is adversely affected.

- 2.

- The vibration signals are preprocessed as follows: First, the original vibration signal is normalized to a range between −1 and +1, which eliminates scale differences and enhances both comparability and interpretability of the data, thereby facilitating more effective analysis and model development. Next, a window function is applied to concentrate the signal’s energy in the main lobe, thereby reducing spectral leakage. Finally, an anti-aliasing filter is applied to suppress noise and interference outside the useful signal bandwidth.

- 3.

- After preprocessing, time–frequency analysis is conducted on the vibration signal. First, EMD is applied to the signal to extract IMF components at each level. The first six IMF components, representing the primary oscillatory modes of the non-stationary vibration signal, are selected to construct their corresponding EMD–autoregressive (EMD-AR) spectra.

- 4.

- Under identical rotary-shaft-seal conditions, when the centrifugal pump operates within its specified design parameters, the amplitude of the EMD-AR spectrum is at its lowest. This indicates minimal vibration and suggests that the system is relatively stable. When operating conditions deviate slightly from the design point, the spectral energy increases slightly compared to the design condition, but the rise is not substantial. In contrast, a significant deviation from the design condition leads to a marked increase in vibration energy, indicating intensified vibrations and reduced system stability. It is particularly important to avoid operating the pump under low-flow conditions. Instead, operation should be maintained at or slightly above the design flow rate to ensure minimal vibration and improved system stability. The EMD-AR spectrum offers a more accurate representation of the operational stability of centrifugal pumps based on vibration signal analysis.

- 5.

- Under identical flow rate conditions, the EMD-AR spectrum demonstrates smooth and well-defined characteristics with high spectral resolution. It effectively identifies rotary-shaft-seal faults across a broad frequency range and serves as a reliable diagnostic indicator for fault detection. Experimental data analysis reveals that the power amplitude energy of the EMD-AR spectrum under rotary-shaft-seal faults is predominantly concentrated within the low-frequency range below 1000 Hz. Specifically, the frequency bands of 0–45 Hz, 60–200 Hz, and 342–425 Hz are identified as characteristic bands that enable effective diagnosis of the severity of rotary-shaft-seal failures.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, Y.; Yuan, J.; Luo, Y.; Zou, J. Operation diagnosis for centrifugal pumps using stator current-based indicators. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 237, 1075–1087. [Google Scholar] [CrossRef]

- Luo, Y.; Yuan, S.; Yuan, J.; Lu, J. Research on Characteristic of the Vibration Spectral Entropy for Centrifugal Pump. Adv. Mech. Eng. 2014, 12, 326–334. [Google Scholar] [CrossRef]

- Ning, B.; Cheng, X.; Wu, S. Research on centrifugal pump monitoring system based on virtualization technology. Procedia Eng. 2011, 15, 1077–1081. [Google Scholar] [CrossRef]

- Luo, Y.; Fan, Y.; Han, Y.; Zhang, W.; Acheaw, E. Research on the Dynamic Characteristics of Mechanical Seal under Different Extrusion Fault Degrees. Processes 2020, 8, 1057. [Google Scholar] [CrossRef]

- Zou, J.; Luo, Y.; Han, Y.; Fan, Y. Research on stator current characteristics of centrifugal pumps under different mechanical seal failures. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 5748–5762. [Google Scholar] [CrossRef]

- Luo, Y.; Sun, H.; Lu, J.; Yuan, S.; Yuan, J.; Zou, J.; Liu, Y.; Wu, J.; Chen, L.; Zhang, Y. A review on the application of sensorless monitoring technology in centrifugal pumps. Chin. J. Drain. Irrig. Mech. Eng. 2015, 33, 547–552. [Google Scholar]

- Yuan, S. Pump Theory and Design, 1st ed.; Machinery Industry Press: Beijing, China, 2014; pp. 278–280. [Google Scholar]

- Zhang, S. Research on State Monitoring and Identification Method of Hydraulic Reciprocating Seal. Master’s Thesis, Wuhan University, Wuhan, China, 2019. [Google Scholar]

- Chen, M.; Zhang, Q.; Cai, J.; Li, S.; Geng, Z. Gas end face sealing test equipment. Fluid Mach. 2005, 33, 14–16. [Google Scholar]

- Chen, X. Failure Diagnosis and Solution of High Temperature Centrifugal Pump mechanical seal. Pump Technol. 2016, 5, 46–48. [Google Scholar]

- Salem, A. Detection and Diagnosis of Cavitation in Centrifugal Pumps. Ph.D. Thesis, The University of Manchester, Manchester, UK, 2005. [Google Scholar]

- Xia, X. Research on Operation Status Monitoring and Fault Diagnosis Technology of Gas Seal Face. Master’s Thesis, Beijing University of Chemical Technology, Beijing, China, 2012. [Google Scholar]

- Anderson, W.; Salant, R. A condition monitor for liquid lubricated mechanical seals. ASLE Trans. 2001, 44, 479–483. [Google Scholar] [CrossRef]

- Duan, L.; Chen, R.; Zhang, L.; Wang, Z.; Li, X.; Zhao, H.; Liu, Y.; Yang, J.; Sun, B.; Guo, Q.; et al. Research on Adaptive Variable Sampling Algorithm for Mechanical Equipment Vibration Monitoring. Instrum. Technol. Sens. 2019, 7, 121–126. [Google Scholar]

- Wei, X. Analysis and Research on Vibration Signals of Typical Faults of Centrifugal Pumps Based on Wavelet Transform. Master’s Thesis, Nanchang Institute of Technology, Nanchang, China, 2020. [Google Scholar]

- Zhu, L.; Zhong, B.; Jia, M.; Chen, X.; Wang, Y.; Li, H.; Liu, Q.; Zhang, P.; Sun, J.; Zhao, T.; et al. Short-time Analysis Method of Vibration Signal and Its Application in Mechanical Fault Diagnosis. J. Vib. Eng. 2000, 3, 80–85. [Google Scholar]

- Chen, X.; Lv, B.; Ji, C.; Zhou, G.; Zhang, Y.; Wang, J.; Liu, H.; Li, Q.; Yang, Z.; Zheng, K.; et al. Influence of Rotor Cantilever Ratio on Hydraulic Vibration of Nuclear Main Pump. Nucl. Sci. Technol. 2019, 53, 673–681. [Google Scholar]

- Peng, Y. Research on Condition Monitoring and Optimal Operation of Centrifugal Pump Units. Master’s Thesis, East China University of Science and Technology, Shanghai, China, 2015. [Google Scholar]

- Yuan, S.; Yuan, J.; Pei, J. Internal Flow and Operation Energy Saving of Centrifugal Pump, 1st ed.; Science Press: Beijing, China, 2016. [Google Scholar]

- Sun, H. Investigation on Operation Condition Detection and Fault Diagnosis for Centrifugal Pumps by Sensorless Detection Technology. Ph.D. Thesis, Jiangsu University, Zhenjiang, China, 2018. [Google Scholar]

- Hodkiewicz, M.; Norton, M. The effect of change in flow rate on the vibration of double-suction centrifugal pumps. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2002, 216, 47–58. [Google Scholar] [CrossRef]

- Hodkiewicz, M. The Effect of Partial-Flow Operation on the Axial Vibration of Double-Suction Centrifugal Pumps. PhD’s Thesis, The University of Western Australia, Perth, Australia, 2004. [Google Scholar]

- Hodkiewicz, M.; Pan, J. Identification of transient axial vibration on double-suction pumps during partial flow operation. Acoust. Aust. 2004, 32, 25–32. [Google Scholar]

- Lu, J.; Liu, X.; Zeng, Y.; Zhu, B.; Hu, B.; Yuan, S.; Hua, H. Detection of the Flow State for a Centrifugal Pump Based on Vibration. Energies 2019, 12, 3066. [Google Scholar] [CrossRef]

- Chen, J.; Li, Y.; Liu, X. Vibration characteristic test of double-suction centrifugal pump under multiple working conditions. J. Jiangsu Univ. (Nat. Sci. Ed.) 2021, 42, 526–532. [Google Scholar]

- Lin, Z.; Yang, F.; Ding, P.; Teng, J.; Yuan, Y.; Jin, Y. Analysis of pressure pulsation and energy characteristics of guide vane for axial flow pump based on Hilbert–Huang transform considering impeller–guide vane interaction. Sci. Prog. 2023, 106, 1–37. [Google Scholar] [CrossRef]

- Przystupa, K.; Bartłomiej, A.; Grzegorz, L. Diagnostics of transient states in hydraulic pump system with Short Time Fourier Transform. Adv. Sci. Technol. 2020, 14, 178–183. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Lin, Z.; Ding, P.; Jin, X.; Tang, F.; Yuan, Y. Time–frequency signal analysis of flow pulsation in siphon outlet conduit based on HHT considering the pump-conduit interaction. Energy Sci. Eng. 2023, 11, 2013–2038. [Google Scholar] [CrossRef]

- Fan, Y. Research on Fault Status Monitoring of Centrifugal Pump Mechanical Seal Based on Sensorless Technology. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2021. [Google Scholar]

- Yang, C.; Wang, B. Transient 3D Numerical Simulation of Centrifugal Pump During Startup. Chin. J. Drain. Irrig. Mech. Eng. 2010, 2, 122–126. [Google Scholar]

- Zhang, K. The Application of MCSA in the Fault Diagnosis of Asynchronous Motor Drive Equipment. Ph.D. Thesis, Northeastern University, Shenyang, China, 2007. [Google Scholar]

- Tan, X. Learn NVH from here, 1st ed.; Machinery Industry Press: Beijing, China, 2018. [Google Scholar]

- Zhao, H. Research on Unsteady Vibration Signal Analysis and Intelligent Fault Diagnosis of Diesel Engine. PhD’s Thesis, Tianjin University, Tianjin, China, 2011. [Google Scholar]

- Zhang, Y.; Li, X.; Zuo, Y. HHT Analysis and Application of Blasting Vibration Signal, 1st ed.; Metallurgical Industry Press: Beijing, China, 2008. [Google Scholar]

- Yang, S.; Wu, Y.; Xuan, J. Engineering Applications of Time Series Analysis, 2nd ed.; Huazhong University of Science and Technology Press: Wuhan, China, 2007. [Google Scholar]

- Mohanty, A.; Pradhan, P.; Pradhan, N.; Dastidar, S.G. Fault detection in a centrifugal pump using vibration and motor current signature analysis. Int. J. Autom. Control. 2013, 6, 261–276. [Google Scholar] [CrossRef]

| Parameter | Symbol (Unit) | Value |

|---|---|---|

| Impeller inlet diameter | D1 (mm) | 74 |

| Impeller outlet diameter | D2 (mm) | 174 |

| Blade outlet width | b2 (mm) | 12 |

| Number of blades | Z | 6 |

| Rated flow | Qd (m3/h) | 50 |

| Rated head | Hd (m) | 34 |

| Rated speed | N (r/min) | 2980 |

| Rated efficiency | η (%) | 72.8 |

| Sensor | Parameter | Value |

|---|---|---|

| YJ-208 static pressure sensor | Range | 0–1.0 MPa |

| Output signal | 4–20 mA | |

| Measurement accuracy | 0.5% | |

| JDG-SIN-CN65-Z2 electromagnetic flowmeter | Range | 0–100 m3/h |

| Output signal | 4–20 mA | |

| Measurement accuracy | 0.5% | |

| Supply voltage | AC 220 V | |

| CT1020LC acceleration transducer | Sensitivity | 200 mV/g |

| Range | 25 g | |

| Bandwidth resolution | 0.25 mg | |

| SGDN-50 dynamic torque sensor | Output frequency | 5–15 kHz |

| Measurement accuracy | 0.3% | |

| NI USB-6343 multifunctional data acquisition card | Analog output signal | 32 channels, 16-bit resolution |

| Analog input signal | 4 channels, 16-bit resolution | |

| Input signal voltage range | −10–10 V | |

| Digital I/O interface | 48 channels |

| Q | Frequency Band of Energy Concentration | Characteristic Frequency Band |

|---|---|---|

| 50 m3/h | 0–530 Hz | 0–45 Hz, 60–200 Hz, 328–528 Hz |

| 40 m3/h | 0–816 Hz | 0–230 Hz, 313–508 Hz, 689–816 Hz |

| 60 m3/h | 0–800 Hz | 0–259 Hz, 342–425 Hz |

| 70 m3/h | 0–933 Hz | 0–538 Hz, 689–933 Hz |

| 30 m3/h | 0–952 Hz | 0–855 Hz |

| Q | TPR | SPC |

|---|---|---|

| 50 m3/h | 94.3% | 97.8% |

| 40 m3/h | 95.0% | 98.3% |

| 60 m3/h | 93.5% | 96.2% |

| 70 m3/h | 93.8% | 97.0% |

| 30 m3/h | 95.4% | 97.4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, J.; Luo, Y.; Han, Y.; Fan, Y.; Wang, C. Investigation on the Vibration Induced by the Rotary-Shaft-Seal Condition in a Centrifugal Pump. Sensors 2025, 25, 5399. https://doi.org/10.3390/s25175399

Zou J, Luo Y, Han Y, Fan Y, Wang C. Investigation on the Vibration Induced by the Rotary-Shaft-Seal Condition in a Centrifugal Pump. Sensors. 2025; 25(17):5399. https://doi.org/10.3390/s25175399

Chicago/Turabian StyleZou, Jiamin, Yin Luo, Yuejiang Han, Yakun Fan, and Chao Wang. 2025. "Investigation on the Vibration Induced by the Rotary-Shaft-Seal Condition in a Centrifugal Pump" Sensors 25, no. 17: 5399. https://doi.org/10.3390/s25175399

APA StyleZou, J., Luo, Y., Han, Y., Fan, Y., & Wang, C. (2025). Investigation on the Vibration Induced by the Rotary-Shaft-Seal Condition in a Centrifugal Pump. Sensors, 25(17), 5399. https://doi.org/10.3390/s25175399