Design of a Rapid and Accurate Calibration System for Pressure Sensors with Minimized Temperature Variation

Abstract

1. Introduction

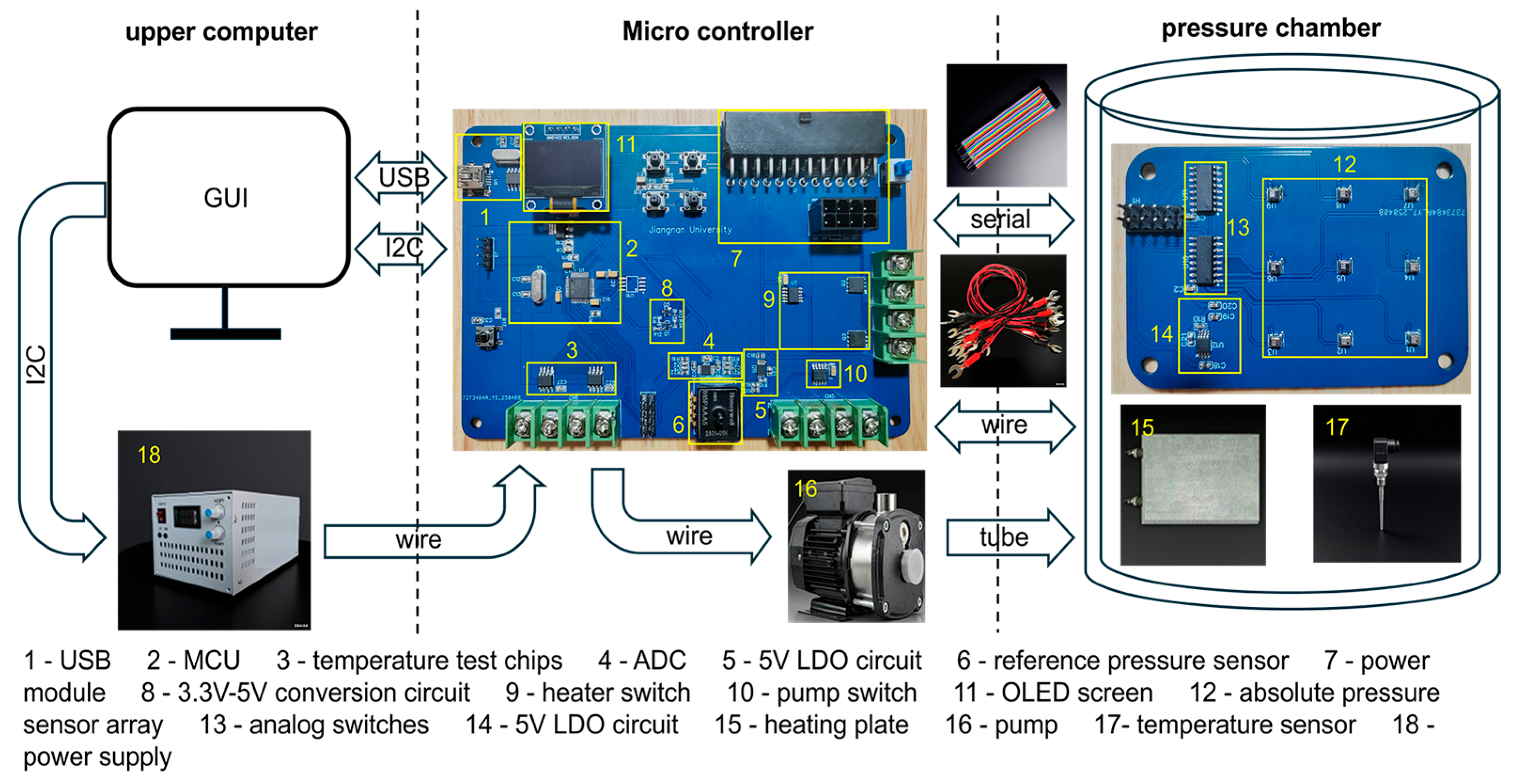

2. System Design

- (1)

- A PC with measuring and calibrating program;

- (2)

- Programmable power supply;

- (3)

- Vacuum pump;

- (4)

- Embedded system module for temperature and pressure monitoring and control;

- (5)

- Pressure chamber;

- (6)

- Heaters.

- (1)

- EUT is fixed in the pressure chamber;

- (2)

- The program in the upper computer sends measurement series to the embedded system;

- (3)

- The embedded system generates the control signals for temperature and pressure control;

- (4)

- The embedded system acquires the measured data and sends it back to the upper computer;

- (5)

- The upper computer program calculates the calibration coefficient according to the measured data.

3. Simulation Analysis for Thermal Control

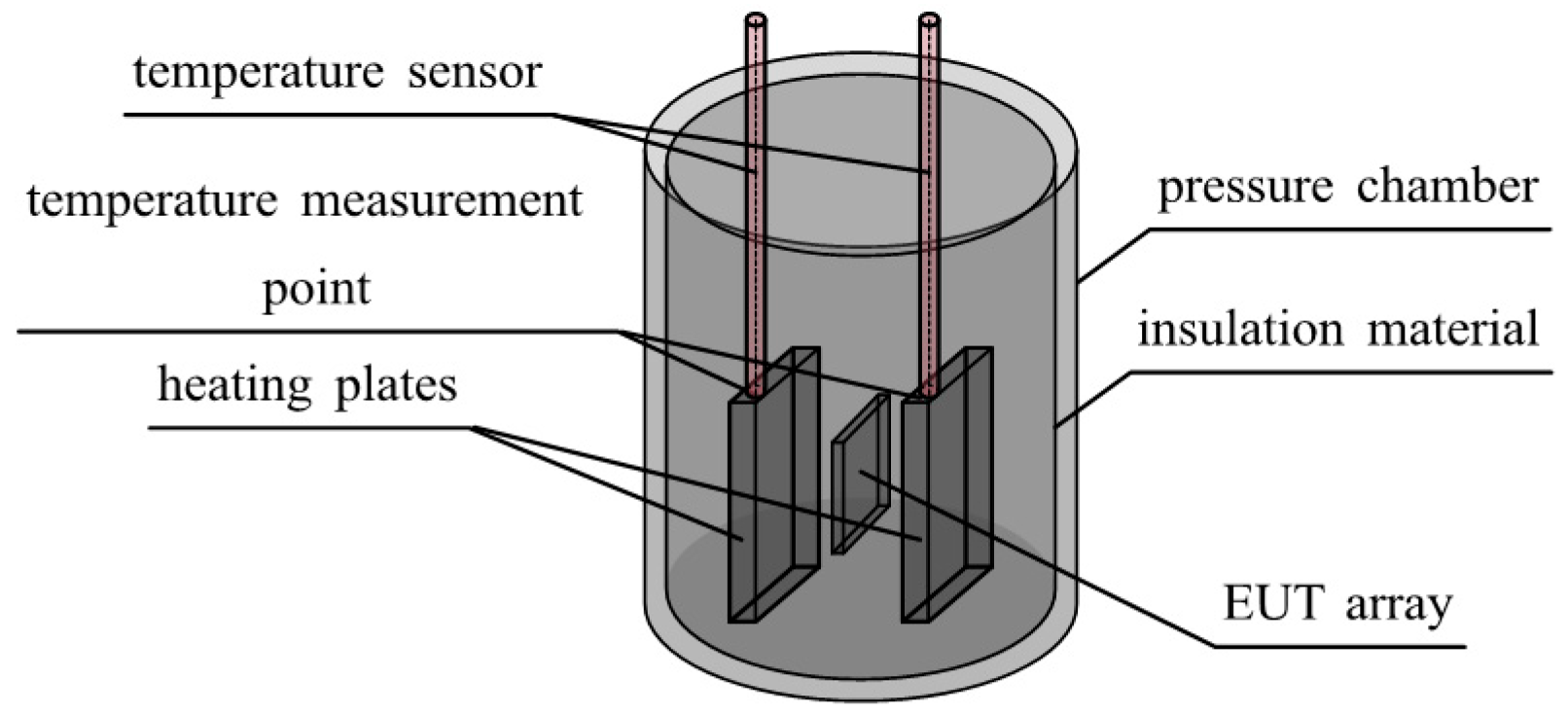

3.1. Simulation Settings

3.1.1. Heat Source

3.1.2. Conduction and Convection

3.2. Simulation Results

- (1)

- The maximum temperature differences (difference between the maximum and minimum temperature inside the pressure chamber) in the pressure chamber at each temperature testing point are: 0 °C, 4.55 °C, 8.73 °C, 12.59 °C, 16.15 °C, and 19.46 °C by using a single heating plate, and are: 0 °C, 3.79 °C, 7.25 °C, 10.42 °C, 13.35 °C, and 16.27 °C by using two heating plates. From the above data, it can be seen that the extreme temperature difference in the pressure chamber at six different temperature testing points when using two heating plates is smaller than that when using a single heating plate. This reflects that using two heating plates can make the temperature distribution in the pressure chamber more uniform.

- (2)

- The temperature error (temperature difference between EUT and temperature measurement point) is: 0 °C, 0.41 °C, 0.79 °C, 1.13 °C, 1.44 °C, and 1.72 °C by using a single heating plate, and is: 0 °C, 0.05 °C, 0.1 °C, 0.14 °C, 0.18 °C, and 0.21 °C by using two heating plates. By comparing the above data, it can be concluded that the temperature difference between the EUT and the temperature measurement point with two heating plates is smaller than that using a single heating plate. This reflects that using dual heating plates can reduce temperature testing errors.

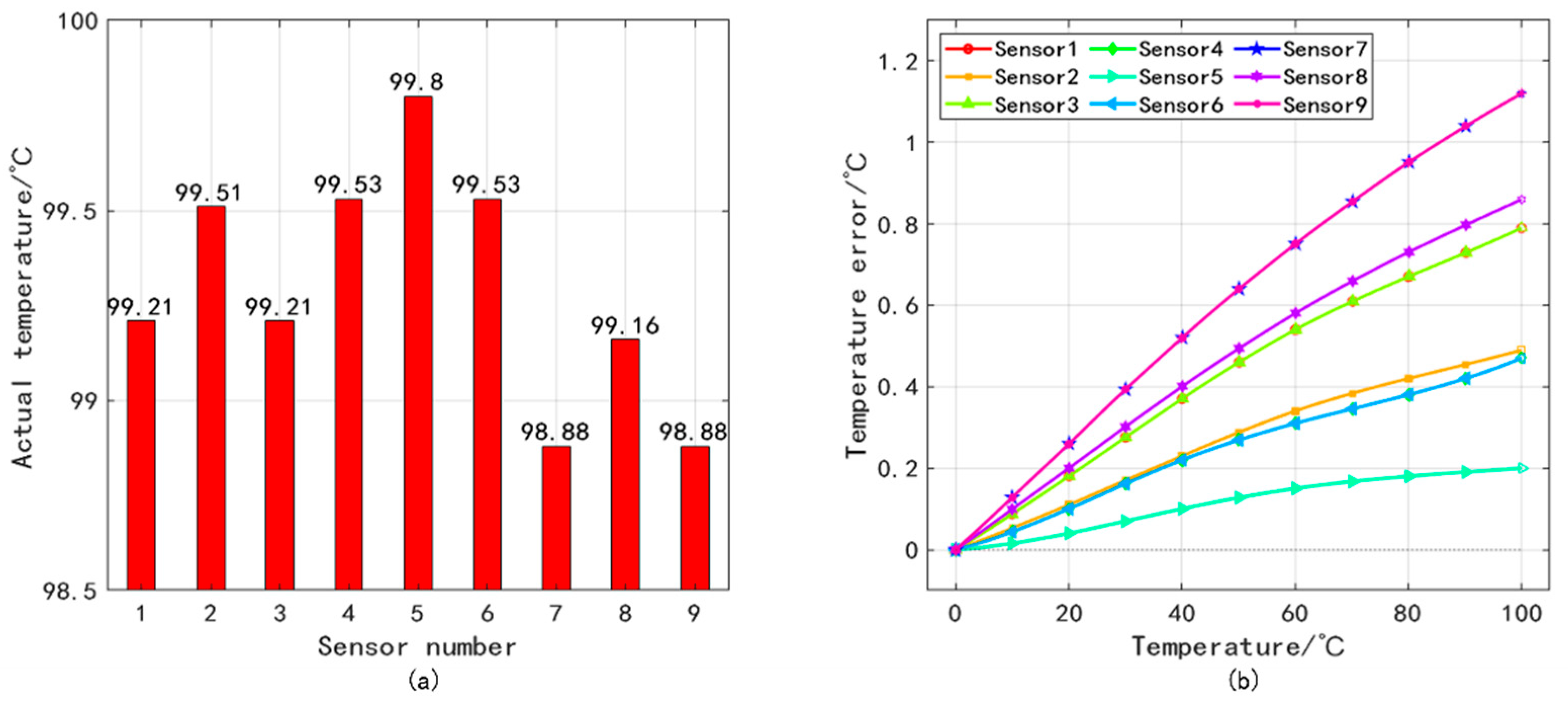

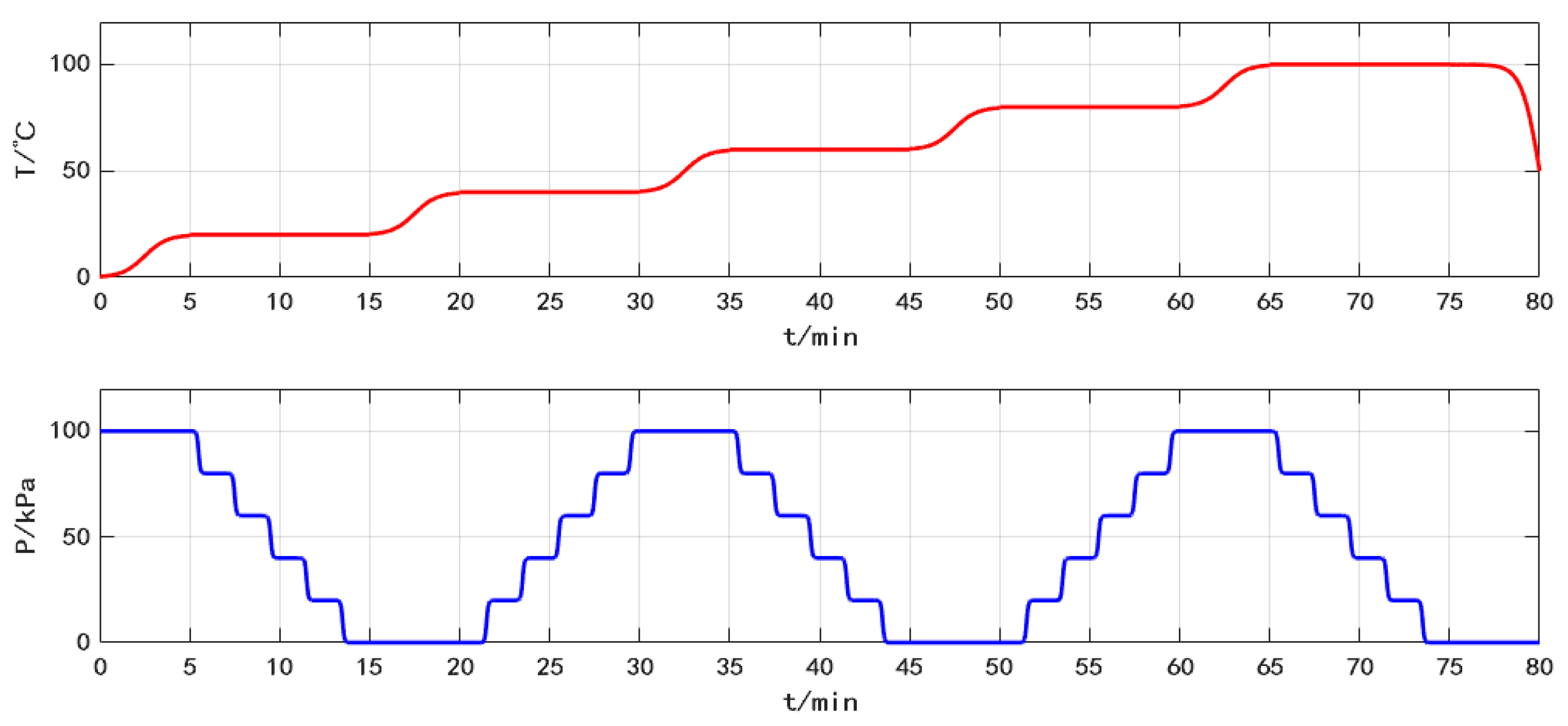

4. Experiment

4.1. Calibration Algorithm

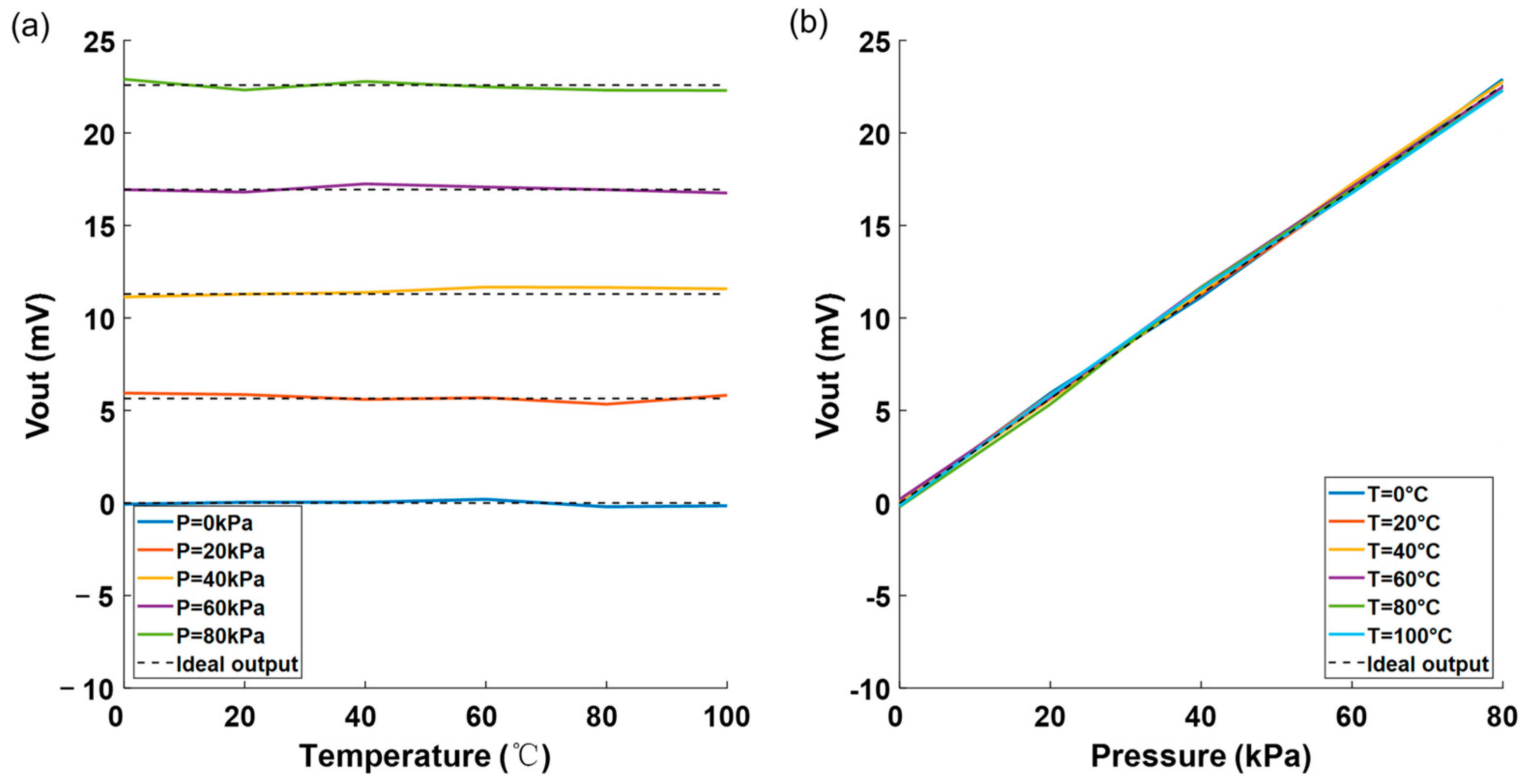

4.2. Experimental Results and Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Ruan, Y.; Yuan, L.; Yuan, W.; He, Y.; Lu, L. Temperature Compensation and Pressure Bias Estimation for Piezoresistive Pressure Sensor Based on Machine Learning Approach. IEEE Trans. Instrum. Meas. 2021, 70, 1–10. [Google Scholar] [CrossRef]

- Song, P.; Ma, Z.; Ma, J.; Yang, L.; Wei, J.; Zhao, Y.; Zhang, M.; Yang, F.; Wang, X. Recent Progress of Miniature MEMS Pressure Sensors. Micromachines 2020, 11, 56. [Google Scholar] [CrossRef]

- Jena, S.; Gupta, A. Review on Pressure Sensors: A Perspective from Mechanical to Micro-Electro-Mechanical Systems. Sens. Rev. 2021, 41, 320–329. [Google Scholar] [CrossRef]

- Kang, K.; Park, J.; Kim, K.; Yu, K.J. Recent Developments of Emerging Inorganic, Metal and Carbon-Based Nanomaterials for Pressure Sensors and Their Healthcare Monitoring Applications. Nano Res. 2021, 14, 3096–3111. [Google Scholar] [CrossRef]

- Von Däniken, E.; Mikhaylov, D.; Moallemi, A.; Polonelli, T.; Magno, M. Tiny On-Device Structural Health Monitoring for Wind Turbines Using MEMS Pressure Sensors. In Proceedings of the 2024 IEEE Sensors Applications Symposium (SAS), Naples, Italy, 23–25 July 2024; pp. 1–6. [Google Scholar]

- Soy, H.; Toy, İ. Design and Implementation of Smart Pressure Sensor for Automotive Applications. Measurement 2021, 176, 109184. [Google Scholar] [CrossRef]

- Qian, J.; Kim, D.-S.; Lee, D.-W. On-Vehicle Triboelectric Nanogenerator Enabled Self-Powered Sensor for Tire Pressure Monitoring. Nano Energy 2018, 49, 126–136. [Google Scholar] [CrossRef]

- Li, W.; Lu, W.; Sha, X.; Xing, H.; Lou, J.; Sun, H.; Zhao, Y. Wearable Gait Recognition Systems Based on MEMS Pressure and Inertial Sensors: A Review. IEEE Sens. J. 2022, 22, 1092–1104. [Google Scholar] [CrossRef]

- Cui, X.; Huang, F.; Zhang, X.; Song, P.; Zheng, H.; Chevali, V.; Wang, H.; Xu, Z. Flexible Pressure Sensors via Engineering Microstructures for Wearable Human-Machine Interaction and Health Monitoring Applications. iScience 2022, 25, 104148. [Google Scholar] [CrossRef]

- Tulaev, A.T.; Kozlov, A.S.; Belyaev, J.V.; Loboda, V.V.; Bellavin, M.A.; Korotkov, A.S. MEMS Pressure Sensors Design, Simulation, Manufacturing, Interface Circuits: A Review. IEEE Sens. J. 2024, 24, 7395–7405. [Google Scholar] [CrossRef]

- Pereira, R.D.S.; Cima, C.A. Thermal Compensation Method for Piezoresistive Pressure Transducer. IEEE Trans. Instrum. Meas. 2021, 70, 1–7. [Google Scholar] [CrossRef]

- Li, D.; Li, T.; Zhang, D. A Monolithic Piezoresistive Pressure-Flow Sensor With Integrated Signal-Conditioning Circuit. IEEE Sens. J. 2011, 11, 2122–2128. [Google Scholar] [CrossRef]

- Wang, Y.; Chodavarapu, V. Differential Wide Temperature Range CMOS Interface Circuit for Capacitive MEMS Pressure Sensors. Sensors 2015, 15, 4253–4263. [Google Scholar] [CrossRef]

- Yao, Z.; Liang, T.; Jia, P.; Hong, Y.; Qi, L.; Lei, C.; Zhang, B.; Li, W.; Zhang, D.; Xiong, J. Passive Resistor Temperature Compensation for a High-Temperature Piezoresistive Pressure Sensor. Sensors 2016, 16, 1142. [Google Scholar] [CrossRef]

- Zou, M.; Xu, Y.; Jin, J.; Chu, M.; Huang, W. Accurate Nonlinearity and Temperature Compensation Method for Piezoresistive Pressure Sensors Based on Data Generation. Sensors 2023, 23, 6167. [Google Scholar] [CrossRef]

- Guo, Z.; Lu, C.; Wang, Y.; Liu, D.; Huang, M.; Li, X. Design and Experimental Research of a Temperature Compensation System for Silicon-on-Sapphire Pressure Sensors. IEEE Sens. J. 2017, 17, 709–715. [Google Scholar] [CrossRef]

- Ali, I.; Asif, M.; Shehzad, K.; Rehman, M.R.U.; Kim, D.G.; Rikan, B.S.; Pu, Y.; Yoo, S.S.; Lee, K.-Y. A Highly Accurate, Polynomial-Based Digital Temperature Compensation for Piezoresistive Pressure Sensor in 180 Nm CMOS Technology. Sensors 2020, 20, 5256. [Google Scholar] [CrossRef] [PubMed]

- Li, B.; Sun, G.; Zhang, H.; Dong, L.; Kong, Y. Design of MEMS Pressure Sensor Anti-Interference System Based on Filtering and PID Compensation. Sensors 2024, 24, 5765. [Google Scholar] [CrossRef] [PubMed]

- Kayed, M.O.; Balbola, A.A.; Lou, E.; Moussa, W.A. Hybrid Smart Temperature Compensation System for Piezoresistive 3D Stress Sensors. IEEE Sens. J. 2020, 20, 13310–13317. [Google Scholar] [CrossRef]

- Almassri, A.M.M.; Wan Hasan, W.Z.; Ahmad, S.A.; Shafie, S.; Wada, C.; Horio, K. Self-Calibration Algorithm for a Pressure Sensor with a Real-Time Approach Based on an Artificial Neural Network. Sensors 2018, 18, 2561. [Google Scholar] [CrossRef]

- Wang, H.; Zeng, Q.; Zhang, Z.; Wang, H. Research on Temperature Compensation of Multi-Channel Pressure Scanner Based on an Improved Cuckoo Search Optimizing a BP Neural Network. Micromachines 2022, 13, 1351. [Google Scholar] [CrossRef]

- Ge, Y.; Shen, L.; Sun, M. Temperature Compensation for Optical Fiber Graphene Micro-Pressure Sensor Using Genetic Wavelet Neural Networks. IEEE Sens. J. 2021, 21, 24195–24201. [Google Scholar] [CrossRef]

- Zhao, X.; Chen, Y.; Wei, G.; Pang, L.; Xu, C. A Comprehensive Compensation Method for Piezoresistive Pressure Sensor Based on Surface Fitting and Improved Grey Wolf Algorithm. Measurement 2023, 207, 112387. [Google Scholar] [CrossRef]

- Pieniazek, J.; Ciecinski, P. Temperature and Nonlinearity Compensation of Pressure Sensor With Common Sensors Response. IEEE Trans. Instrum. Meas. 2020, 69, 1284–1293. [Google Scholar] [CrossRef]

- Madhum, A.S.; Sethuram, D.; Vijayalakshmi, V.; Koppad, P.G. Automatic Pressure Calibration System for Pressure Sensors. FME Trans. 2019, 47, 111–115. [Google Scholar] [CrossRef]

- Lloyd, J.R.; Moran, W.R. Natural Convection Adjacent to Horizontal Surface of Various Planforms. ASME J. Heat Transf. 1974, 96, 443–447. [Google Scholar] [CrossRef]

- Churchill, S.W.; Chu, H.H. Correlating Equations for Laminar and Turbulent Free Convection from a Vertical Plate. Int. J. Heat Mass Transf. 1975, 18, 1323–1329. [Google Scholar] [CrossRef]

- Wu, R.; Li, H.; Gao, L. Research on Temperature Drift Mechanism and Compensation Method of Silicon Piezoresistive Pressure Sensors. AIP Adv. 2023, 13, 035323. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| T0 | 273.15 K |

| kair | 0.026 W·m−1·K−1 |

| Rs | 287.05 J·kg−1·K−1 |

| Cp,air | 1005 J·kg−1·K−1 |

| ksteel | 44.5 W·m−1·K−1 |

| ρsteel | 7850 kg·m−3 |

| Cp,steel | 475 J·kg−1·K−1 |

| kcopper | 400 W·m−1·K−1 |

| ρcopper | 8960 kg·m−3 |

| Cp,copper | 385 J·kg−1·K−1 |

| ksponge | 0.08 W·m−1·K−1 |

| ρsponge | 60 kg·m−3 |

| Cp,sponge | 4 J·kg−1·K−1 |

| ksilicon | 130 W·m−1·K−1 |

| ρsilicon | 2329 kg·m−3 |

| Cp,silicon | 700 J·kg−1·K−1 |

| ε | 0.6 |

| σ | 5.67 × 10−8 W·m−2·K−4 |

| ρ | 1.29 kg·m−3 |

| V0 | 0.000036 m3 |

| off | tc1 | tc2 | s0 | ts1 | ts2 | k | ks | kss | |

|---|---|---|---|---|---|---|---|---|---|

| 1 | −2.0706 | −0.1316 | 0 | 0.7501 | −0.0017 | 0 | 0.8583 | 0.0452 | 0.0015 |

| 2 | −2.1023 | −0.1236 | 0 | 0.7500 | −0.0010 | 0 | 0.8475 | 0.0414 | −0.0011 |

| 3 | −2.0245 | −0.1209 | 0 | 0.7324 | 0.0011 | 0 | 0.8356 | 0.0400 | 0.0005 |

| 4 | −2.0923 | −0.1024 | 0 | 0.7421 | 0.0003 | 0 | 0.8876 | 0.0345 | 0.0002 |

| 5 | −2.1124 | −0.1199 | 0 | 0.7642 | −0.0005 | 0 | 0.8723 | 0.0377 | 0 |

| 6 | −2.0894 | −0.1342 | 0 | 0.7749 | −0.0015 | 0 | 0.8766 | 0.0675 | 0 |

| 7 | −2.0907 | −0.1095 | 0 | 0.7295 | 0.0001 | 0 | 0.8459 | 0.0547 | 0.0011 |

| 8 | −2.1010 | −0.1456 | 0 | 0.7468 | −0.0012 | 0 | 0.8378 | 0.0320 | −0.0010 |

| 9 | −2.0698 | −0.1506 | 0 | 0.7197 | 0.0009 | 0 | 0.8897 | 0.0521 | −0.0007 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, J.; Zhang, S.; Jiang, Y. Design of a Rapid and Accurate Calibration System for Pressure Sensors with Minimized Temperature Variation. Sensors 2025, 25, 5288. https://doi.org/10.3390/s25175288

Cui J, Zhang S, Jiang Y. Design of a Rapid and Accurate Calibration System for Pressure Sensors with Minimized Temperature Variation. Sensors. 2025; 25(17):5288. https://doi.org/10.3390/s25175288

Chicago/Turabian StyleCui, Juntong, Shubin Zhang, and Yanfeng Jiang. 2025. "Design of a Rapid and Accurate Calibration System for Pressure Sensors with Minimized Temperature Variation" Sensors 25, no. 17: 5288. https://doi.org/10.3390/s25175288

APA StyleCui, J., Zhang, S., & Jiang, Y. (2025). Design of a Rapid and Accurate Calibration System for Pressure Sensors with Minimized Temperature Variation. Sensors, 25(17), 5288. https://doi.org/10.3390/s25175288