Arc Dynamics and Erosion Behavior of Pantograph-Catenary Contacts Under Controlled Humidity Levels

Abstract

1. Introduction

2. Experimental Methodology

2.1. Experimental Materials

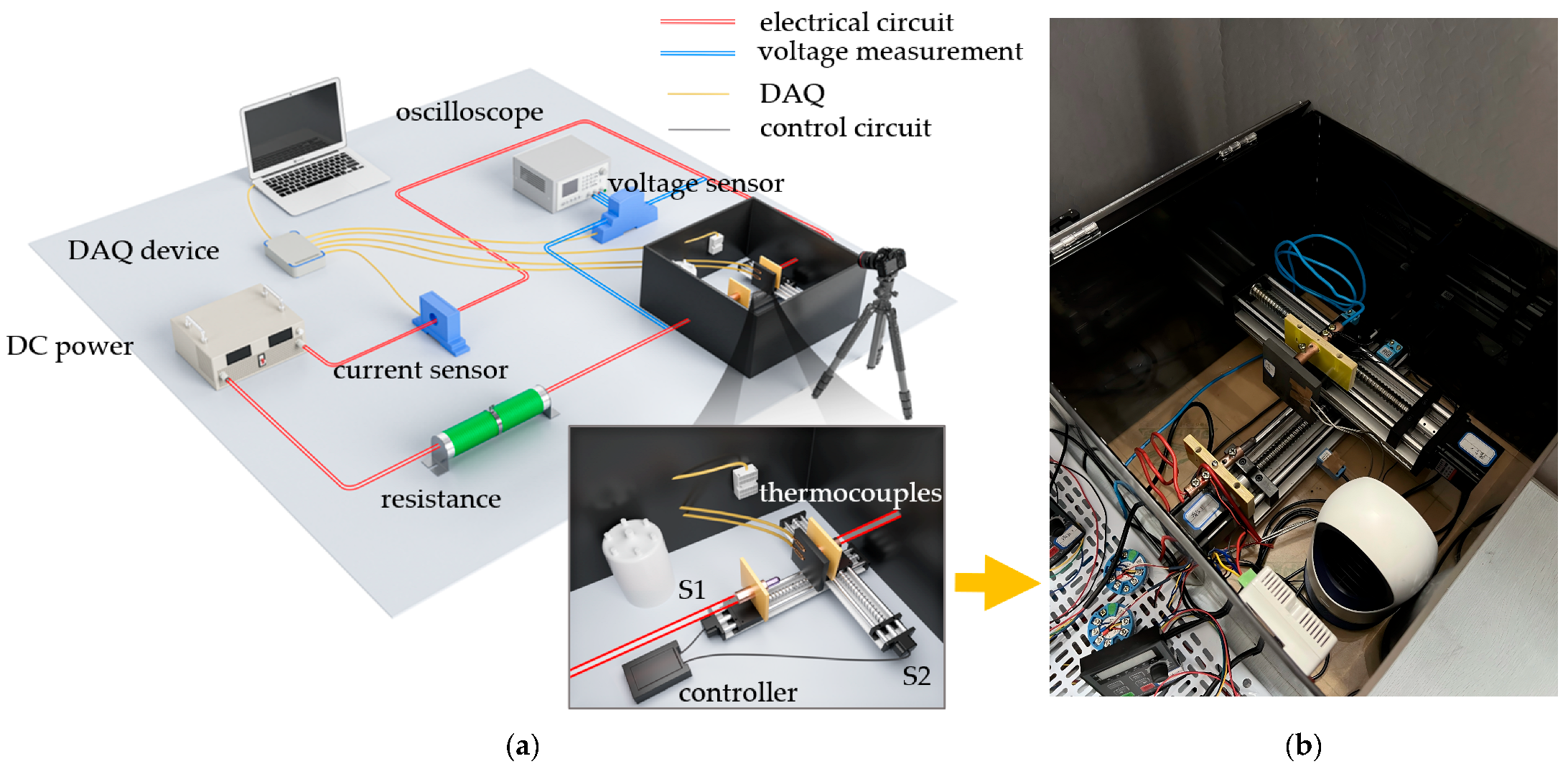

2.2. Experimental Platform

- Hall current sensor (CHB50-SF, SENSOR Electronics, China)

- Hall voltage sensor (CHV-50P, SENSOR Electronics, China)

- K-type thermocouples

- Temperature-humidity sensor

- Thin-film pressure sensor

2.3. Experimental Conditions

3. Results and Discussion

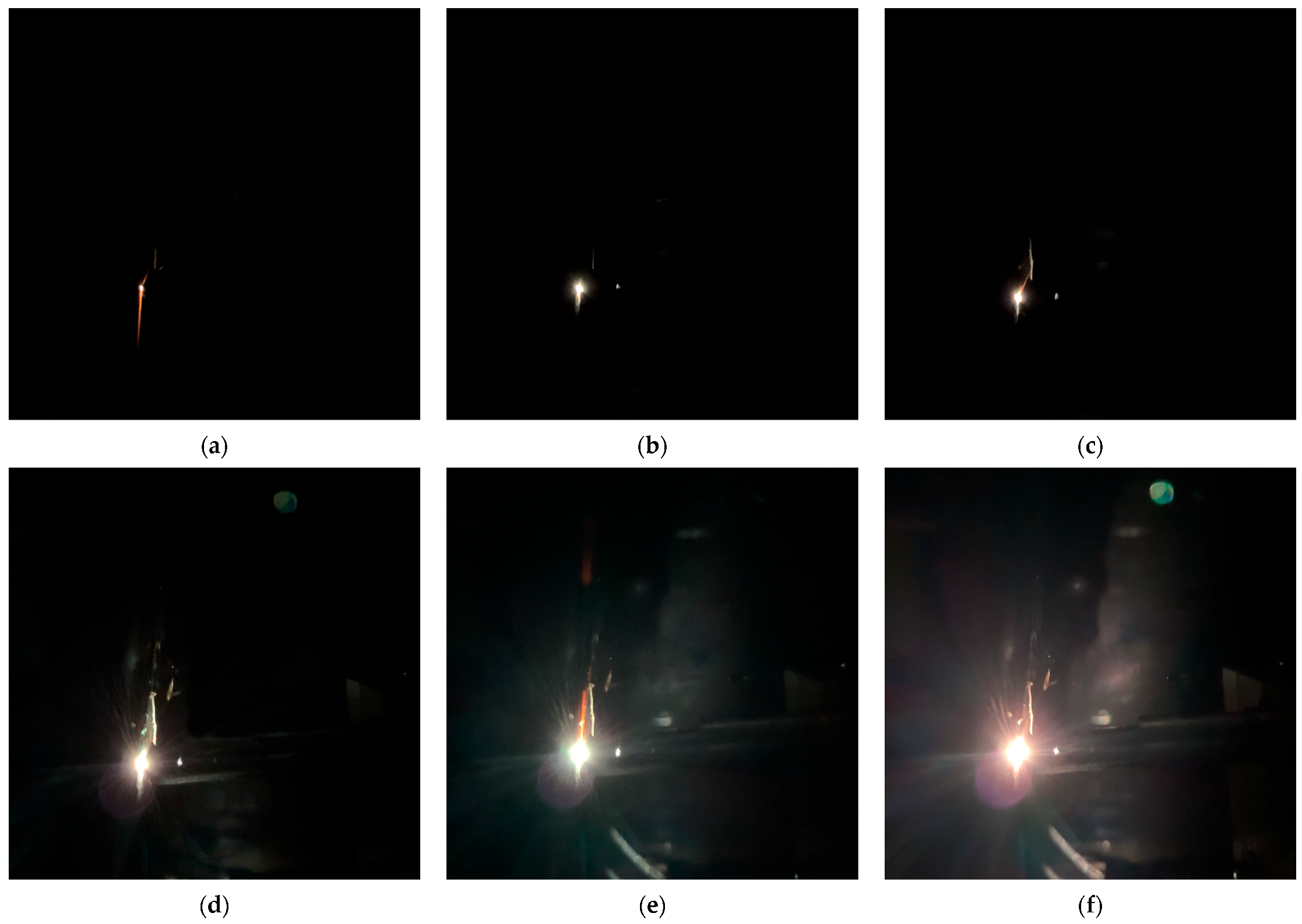

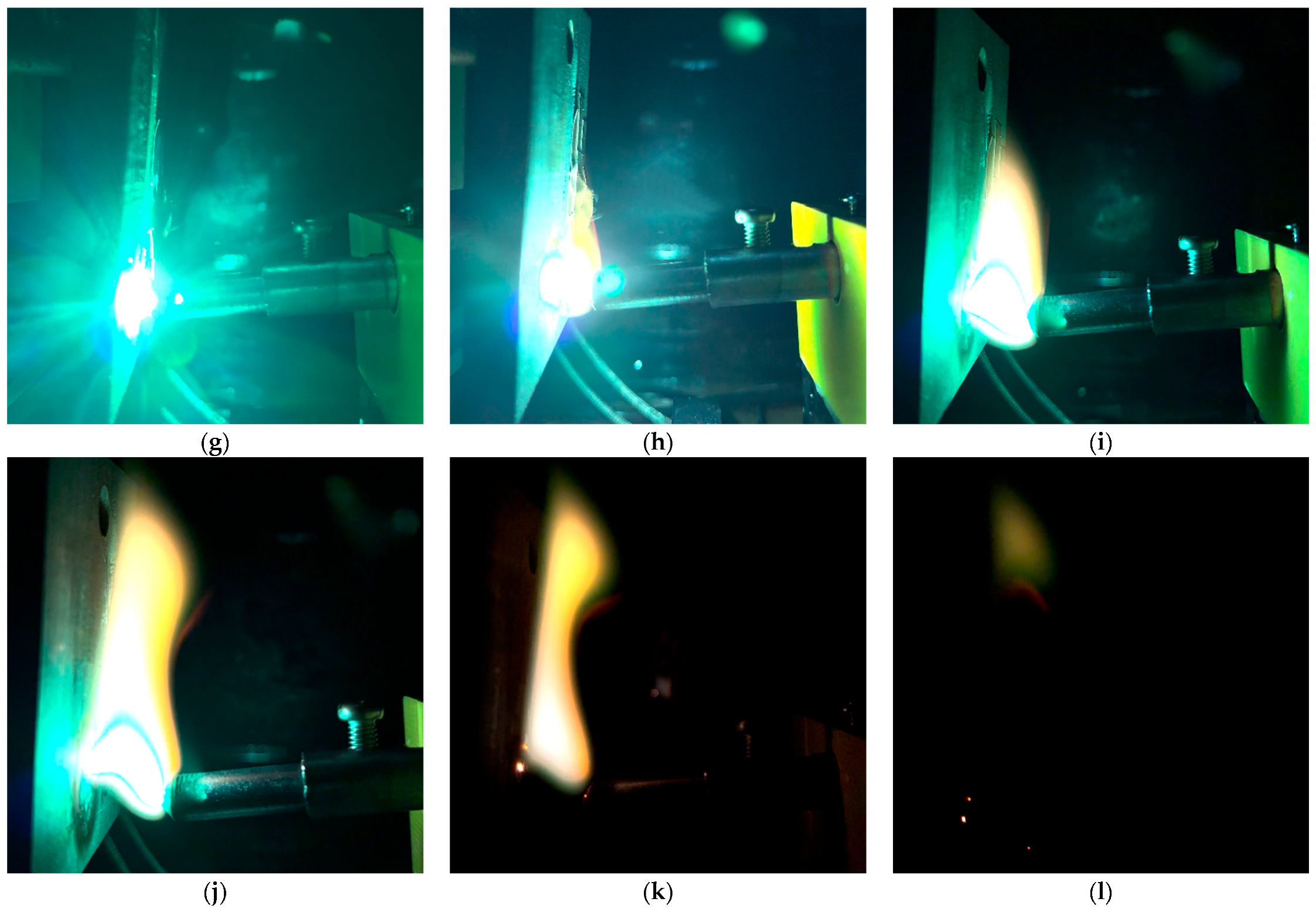

3.1. Arc Morphology and Its Evolution

- Arc Triggering Stage: During the relative sliding contact motion of the friction pair electrode materials, friction causes the carbon plate contact surface to become microscopically uneven. As the pantograph-catenary system moves offline, the contact pressure between the electrodes decreases, and the electric field intensity between the electrodes meets the gas breakdown conditions, triggering the arc. As shown in Figure 3a–c, the arc exhibits a longitudinal stretching trend during the sliding contact.

- Arc Diffusion Stage: Under the combined effects of the electric field force and thermal diffusion, the arc rapidly expands outward, transforming from an irregular light spot into a single elliptical shape. As shown in Figure 3d–f, the arc area and brightness increase continuously, accompanied by significant changes in the current and voltage between the electrodes.

- Arc Stabilization Stage: As the input current stabilizes, the arc enters a steady combustion phase. At this stage, a large amount of heat is generated between the friction pair, and factors such as contact wire vibration and material irregularities cause the deformation of the arc column. The arc root undergoes displacement, and the arc light appears blue-green, indicating the formation of a large number of carbon-containing free radicals during combustion. As shown in Figure 3g–i, the single elliptical arc undergoes elongation and twisting, with the arc root moving in the longitudinal direction.

- Arc Extinction Stage: As shown in Figure 3j–l, the arc continues to stretch, and the arc light area increases as the plasma density decreases. As the current weakens instantaneously, the arc energy sharply decreases, causing the arc column to shrink and the arc light to dim, leading the arc to gradually extinguish. This stage occurs relatively quickly.

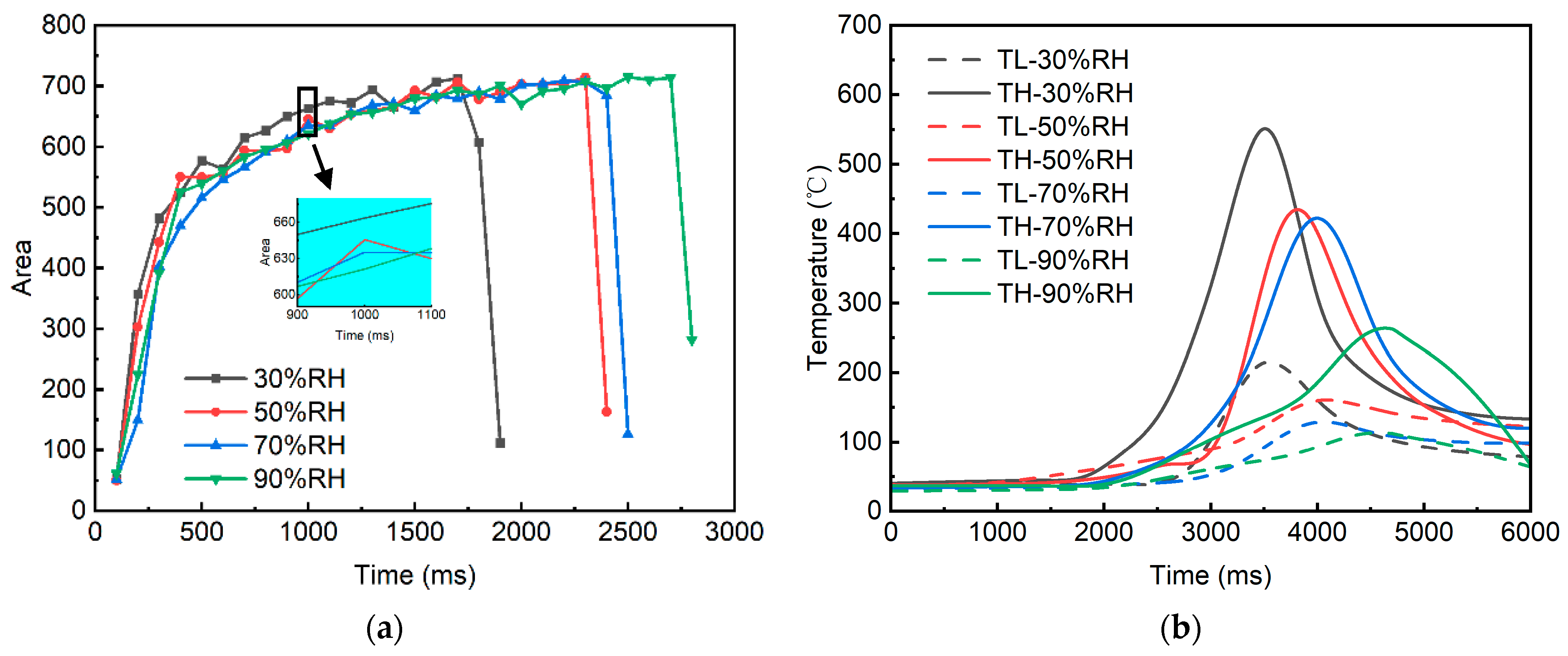

3.2. Arc Intensity and Temperature Characteristics

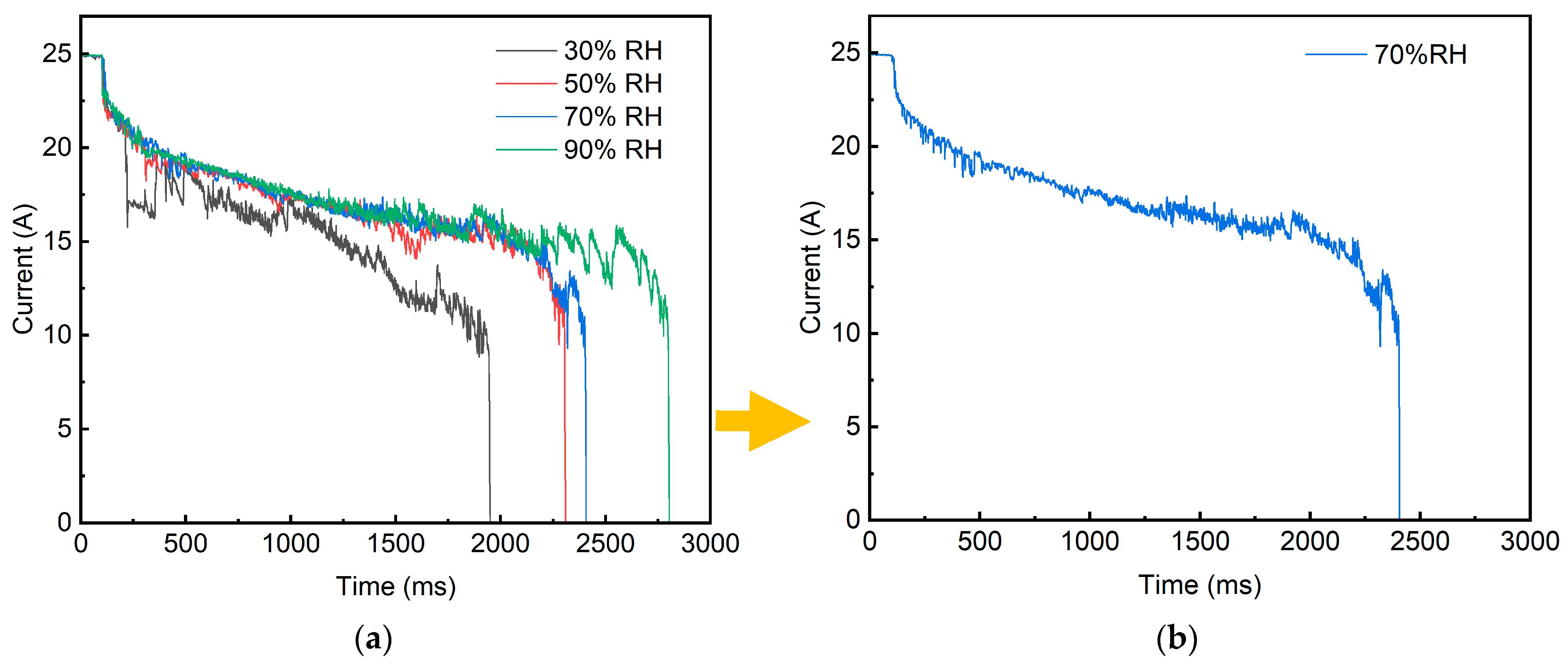

3.3. Arc Discharge Characteristic

- 0–100 ms: The frictional electrode materials maintain good sliding contact, and the current value remains at 25 A.

- 100–200 ms: The electrode materials go offline, and the arc is triggered instantaneously, with the current rapidly decreasing to 22 A.

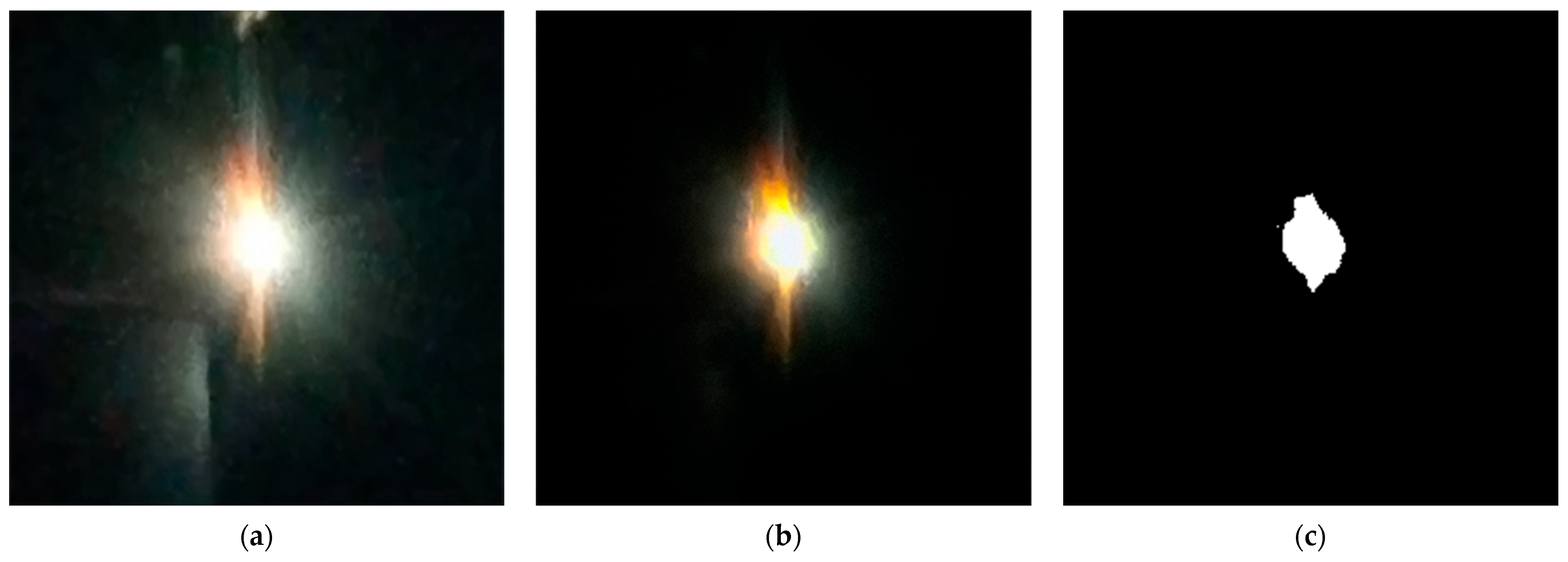

- 200–480 ms: During the arc diffusion phase, the current shows “intermittent spiking” with a decelerating rate of change. This phase represents the first unstable arc combustion stage, where sparks, as shown in Figure 4a, are observed.

- 480–2320 ms: The arc current fluctuates in a relatively stable pattern, with the rate of change slowing down again. This phase releases a substantial amount of heat, with the current dropping to 15 A. From 2180 ms onwards, the arc begins to diffuse again, and the current experiences significant fluctuations, with a maximum drop of 9 A, indicating the arc reignition phenomenon.

- 2320–2400 ms: The arc extinguishes abruptly, and the current sharply decreases from 13 A to 0 A.

- DAQ quantization error: High-frequency sampling by the DAQ may exhibit minor serrated fluctuations in current waveforms due to signal transmission quantization.

- Motion precision error: Minor trajectory deviations during sliding-offline transitions on the biaxial orthogonal slides may cause instantaneous current spikes.

- Sensor intrinsic error: While individual sensor errors remain within acceptable limits (≤0.8%), cumulative error propagation could influence arc evaluation metrics. Calculated cumulative effects fall within tolerable thresholds.

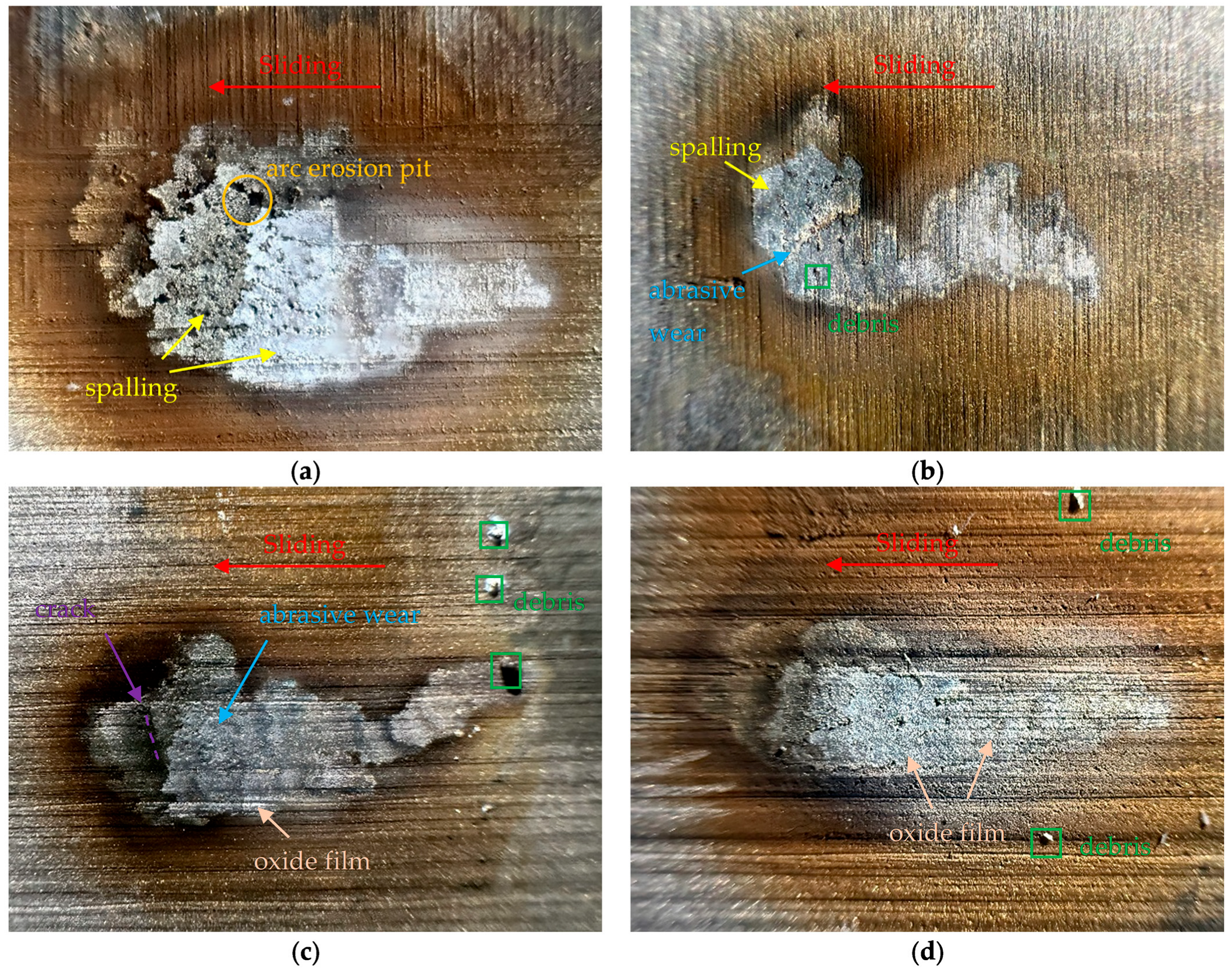

3.4. Erosion Characteristics of Carbon Electrodes

4. Conclusions

- Arc Morphology Evolution: The arc morphology evolution exhibits a tendency toward convergence. As the humidity increases, the arc’s “thermal tip” becomes more concentrated, and the arc column shape narrows, resulting in a more uniform temperature distribution in the arc vicinity and enhanced arc persistence.

- Arc Current Behavior: The arc current shows an overall “intermittent” decreasing fluctuation trend. As humidity increases from 30% RH to 90% RH, the region of intense current fluctuation gradually shifts from the early to the late stages of the arc development. At medium humidity levels (50% RH, 70% RH), current fluctuations are the most stable, indicating the most stable arc combustion.

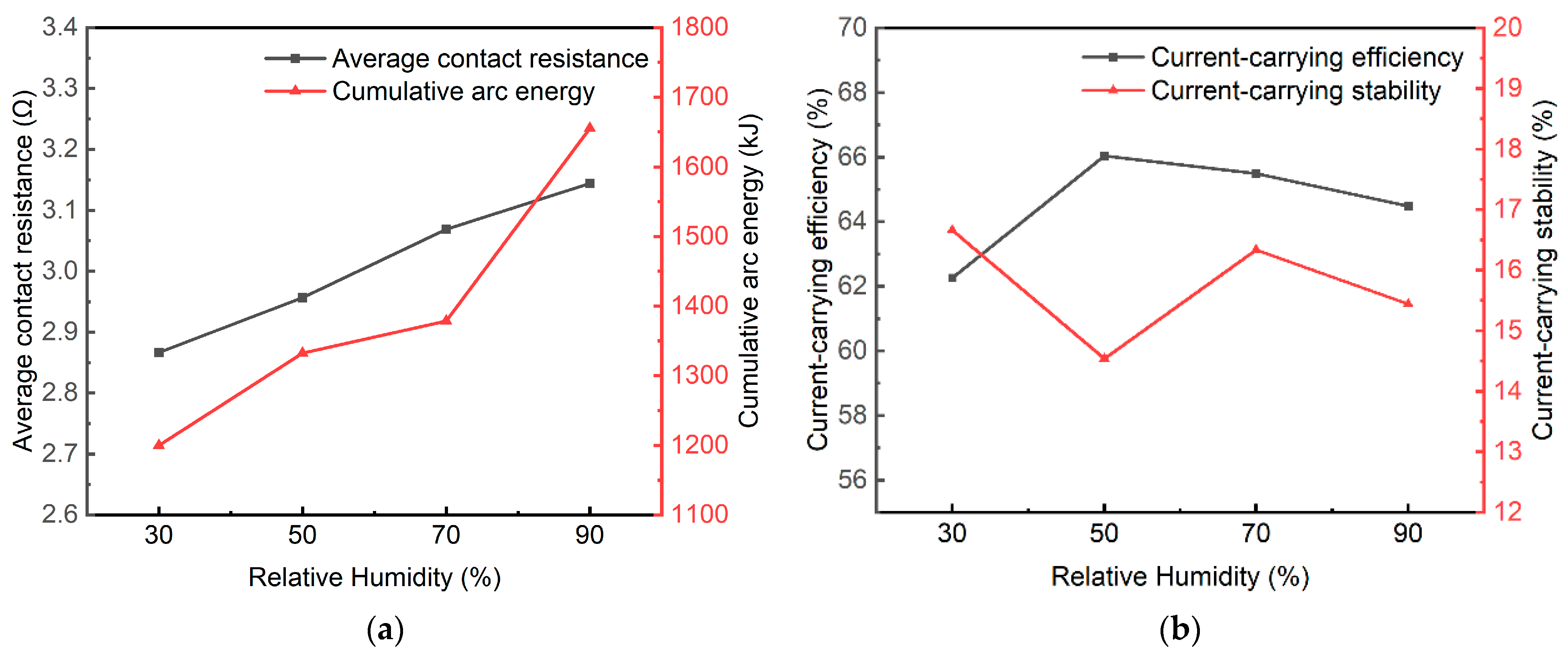

- Impact on Electrical Performance: High humidity significantly increases both contact resistance and accumulated arc energy. This conclusion is consistent with the experimental results of Song et al., which found that increasing surface humidity reduces the conductivity of electrode materials [14]. However, in terms of current-carrying quality, the current-carrying efficiency reaches its peak at 50% RH (66%), while the current-carrying stability (loss rate) is lowest at 14.5%, indicating the optimal current-carrying quality. This suggests the presence of an “optimal arc combustion zone” at 50% RH.

- Material Erosion Analysis: Based on material erosion observations, the arc root exhibits a longitudinal motion migration characteristic. As humidity increases, the arc erosion marks become narrower and longer. At low humidity, electrode material erosion is primarily characterized by abrasive and adhesive wear. At high humidity, the participation of water vapor leads to a transition towards electrochemical oxidation wear, accompanied by copper material transfer phenomena. This specific conclusion exhibits partial similarity to the findings of Fan et al. [16], where water molecules and oxygen jointly induce the formation of hydroxylated copper species from copper nanoparticles, thereby accelerating the migration of copper atoms across metal support surfaces.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Nomenclature

| PCS | Pantograph-Catenary System |

| DC | Direct Current |

| AC | Alternating Current |

| RH | Relative Humidity, % |

| XPS | X-ray Photoelectron Spectroscopy |

| Cu-CATH-2 | Cathode copper |

| AFGs | Arc Fault Generators |

| PET | Polyethylene Terephthalate, the chemical formula is (C10H8O4)n |

| DAQ | Data acquisition |

| TH | Temperature at a height of 20 mm on the carbon-copper electrode contact surface, °C |

| TL | Temperature at a height of 40 mm on the carbon-copper electrode contact surface, °C |

| px | Pixels |

| NPs | Nanoparticles |

Appendix A

References

- Mariscotti, A. The Electrical Behaviour of Railway Pantograph Arcs. Energies 2023, 16, 1465. [Google Scholar] [CrossRef]

- Collina, A.; Lo Conte, A.; Carnevale, M. Effect of Collector Deformable Modes in Pantograph—Catenary Dynamic Interaction. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2009, 223, 1–14. [Google Scholar] [CrossRef]

- Li, S.; Yang, X.; Kang, Y.; Li, Z.; Li, H. Progress on Current-Carry Friction and Wear: An Overview from Measurements to Mechanism. Coatings 2022, 12, 1345. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, G.; Wei, W.; Yang, Z.; Xie, W.; Dong, K.; Ma, Y.; Yang, Y.; Wu, G. Characteristics of Pantograph-catenary Arc under Low Air Pressure and Strong Airflow. High Volt. 2022, 7, 369–381. [Google Scholar] [CrossRef]

- Yao, Y.; Zhou, N.; Mei, G.; Zhang, W. Dynamic Analysis of Pantograph-Catenary System Considering Ice Coating. Shock. Vib. 2020, 2020, 8887609. [Google Scholar] [CrossRef]

- Wang, W.; Liang, Y.; Zhang, W.; Iwnicki, S. Experimental Research into the Low-Temperature Characteristics of a Hydraulic Damper and the Effect on the Dynamics of the Pantograph of a High-Speed Train Running in Extreme Cold Weather Conditions. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 234, 896–907. [Google Scholar] [CrossRef]

- Wang, H.; Gao, G.; Wei, W.; Yang, Z.; Yin, G.; Xie, W.; He, Z.; Ni, Z.; Yang, Y.; Wu, G. Influence of the Interface Temperature on the Damage Morphology and Material Transfer of C–Cu Sliding Contact under Different Current Amplitudes. J. Mater. Sci. 2022, 57, 5006–5021. [Google Scholar] [CrossRef]

- Liu, X.; Hu, M.; Li, Z.; Zhou, C.; Xiao, Q.; Yang, W.; Chen, D. Effect of Copper Contents on the Current-Carrying Wear Properties of Carbon Brush under Different Temperatures Conditions. J. Mater. Res. Technol. 2021, 15, 3110–3121. [Google Scholar] [CrossRef]

- Dong, K.; Wu, G.; Qian, P.; Ma, Y.; Yang, Z.; Wei, W.; Gao, G. Research on Motion Characteristics of Arc at Low Air Pressure. In Proceedings of the 2023 Panda Forum on Power and Energy (PandaFPE), Chengdu, China, 27–30 April 2023; pp. 1218–1222. [Google Scholar]

- Yamamura, S. Immobility Phenomena and Reverse Driving Phenomena of the Electric Arc. J. Appl. Phys. 1950, 21, 193–196. [Google Scholar] [CrossRef]

- Benilov, M.S.; Hartmann, W.; Kaufmann, H.T.C.; Benilova, L.G. On the Mechanism of Retrograde Motion of Cathode Spots of Vacuum Arcs. In Proceedings of the 2018 28th International Symposium on Discharges and Electrical Insulation in Vacuum (ISDEIV), Greifswald, Germany, 23–28 September 2018; pp. 353–356. [Google Scholar]

- Wu, R.; Song, C.; Wu, H.; Lv, B.; Zhang, Y.; Zhang, Y. Effect of Relative Humidity on the Current-Carrying Tribological Properties of Cu–C Sliding Contact Pairs. Wear 2022, 492–493, 204219. [Google Scholar] [CrossRef]

- Sun, Y.; Song, C.; Liu, Z.; Li, J.; Sun, Y.; Shangguan, B.; Zhang, Y. Effect of Relative Humidity on the Tribological/Conductive Properties of Cu/Cu Rolling Contact Pairs. Wear 2019, 436–437, 203023. [Google Scholar] [CrossRef]

- Song, C.; Sun, Y.; Zhang, Y.; Pang, X.; Chen, T.; Sun, C.; Zhang, Y. Current-Carrying Property and Damage Mechanism of Rolling Contact Pairs in Different Water Conditions: From Vapor to Liquid. Wear 2021, 477, 203857. [Google Scholar] [CrossRef]

- Fu, H.; Liu, H.; Wang, X.; Zhang, W.; Zhang, H.; Luo, Y.; Deng, X.; King, G.; Chen, N.; Wang, L.; et al. Reverse Hydrogen Spillover on Metal Oxides for Water-Promoted Catalytic Oxidation Reactions. Adv. Mater. 2024, 36, 2407534. [Google Scholar] [CrossRef] [PubMed]

- Fan, Y.; Li, R.; Wang, B.; Feng, X.; Du, X.; Liu, C.; Wang, F.; Liu, C.; Dong, C.; Ning, Y.; et al. Water-Assisted Oxidative Redispersion of Cu Particles through Formation of Cu Hydroxide at Room Temperature. Nat. Commun. 2024, 15, 3046. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Zhang, Z.; Shi, W.; Li, Y.; Xue, C.; Hu, Y.; Ding, M.; Zhang, Z.; Liu, Z.; Fu, Y.; et al. Enhanced Copper Anticorrosion from Janus-Doped Bilayer Graphene. Nat. Commun. 2023, 14, 7447. [Google Scholar] [CrossRef]

- Midya, S.; Bormann, D.; Schutte, T.; Thottappillil, R. Pantograph Arcing in Electrified Railways—Mechanism and Influence of Various Parameters—Part I: With DC Traction Power Supply. IEEE Trans. Power Deliv. 2009, 24, 1931–1939. [Google Scholar] [CrossRef]

- Yao, X.; Herrera, L.; Huang, Y.; Wang, J. The Detection of DC Arc Fault: Experimental Study and Fault Recognition. In Proceedings of the 2012 Twenty-Seventh Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Orlando, FL, USA, 5–9 February 2012; pp. 1720–1727. [Google Scholar]

- Huajun, D.; Yu, F.; Yingjie, G.; Wenyu, D.; Fangzhun, G. Vacuum Switches Arc Images Pre–Processing Based on MATLAB. MATEC Web Conf. 2015, 35, 03006. [Google Scholar] [CrossRef]

- Alazizi, A.; Draskovics, A.; Ramirez, G.; Erdemir, A.; Kim, S.H. Tribochemistry of Carbon Films in Oxygen and Humid Environments: Oxidative Wear and Galvanic Corrosion. Langmuir 2016, 32, 1996–2004. [Google Scholar] [CrossRef] [PubMed]

- Nituca, C. Thermal Analysis of Electrical Contacts from Pantograph–Catenary System for Power Supply of Electric Vehicles. Electr. Power Syst. Res. 2013, 96, 211–217. [Google Scholar] [CrossRef]

- Mei, G.; Fu, W.; Chen, G.; Zhang, W. Effect of High-Density Current on the Wear of Carbon Sliders against Cu–Ag Wires. Wear 2020, 452–453, 203275. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Song, C. Arc Discharges of a Pure Carbon Strip Affected by Dynamic Contact Force during Current-Carrying Sliding. Materials 2018, 11, 796. [Google Scholar] [CrossRef]

- Dehghani, P.; Ami Ahmadi, H.; Hosseinalipour, S.M.; Akbari, H. Impact of Relative Humidity, Temperature Difference, and Surface Type on Humid Air Condensation Heat Transfer. Int. J. Therm. Sci. 2024, 203, 109168. [Google Scholar] [CrossRef]

- Ding, T.; Chen, G.X.; Bu, J.; Zhang, W.H. Effect of Temperature and Arc Discharge on Friction and Wear Behaviours of Carbon Strip/Copper Contact Wire in Pantograph–Catenary Systems. Wear 2011, 271, 1629–1636. [Google Scholar] [CrossRef]

- A Manaf, N.D.; Fukuda, K.; Subhi, Z.A.; Mohd Radzi, M.F. Influences of Surface Roughness on the Water Adsorption on Austenitic Stainless Steel. Tribol. Int. 2019, 136, 75–81. [Google Scholar] [CrossRef]

- Huang, M.; Yang, B.; Rong, Y.; Zhao, L.; Xiao, S. Study on Friction and Wear Properties of Copper-Impregnated Carbon Slide Plate Under Different Humidity Conditions. Tribol. Trans. 2023, 66, 953–964. [Google Scholar] [CrossRef]

- Wang, X.; Yang, Z.; Gao, G.; Wang, H.; Deng, L.; Wei, W. Effect of Wet Condition on the Wear Performance of Carbon Strip and Metal Contact Wire with Electric Current. In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Kim, J.Y.; Ahn, H.S.; Bard, A.J. Surface Interrogation Scanning Electrochemical Microscopy for a Photoelectrochemical Reaction: Water Oxidation on a Hematite Surface. Anal. Chem. 2018, 90, 3045–3049. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Song, C.; Liu, Z.; Li, J.; Wang, L.; Sun, C.; Zhang, Y. Tribological and Conductive Behavior of Cu/Cu Rolling Current-Carrying Pairs in a Water Environment. Tribol. Int. 2020, 143, 106055. [Google Scholar] [CrossRef]

| Material Parameters | Pure Carbon | Cu-CATH-2 |

|---|---|---|

| Hardness (107 N·m−2) | 67 | 96 |

| Specific Heat Capacity (J·kg−1·K−1) | 710 | 380 |

| Density (kg·m−3) | 1.82 | 8.9 |

| Electrical Resistivity (µΩ·m) | 12 | 0.017 |

| Thermal conductivity (W·m−1·K−1) | 90 | 390 |

| Bending Strength (MPa) | 48.1 | / |

| Temperature (°C) | Humidity (% RH) | Offline Velocity (mm/s) | Sliding Velocity (mm/s) | Initial Contact Pressure (N) |

|---|---|---|---|---|

| 25 | 30, 50, 70, 90 | 5 | 10 | 50 |

| Humidity (% RH) | THmax (°C) | TLmax (°C) | THmax-TLmax (°C) |

|---|---|---|---|

| 30 | 551 | 215 | 336 |

| 50 | 434 | 160 | 274 |

| 70 | 394 | 129 | 265 |

| 90 | 288 | 120 | 168 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, B.; Zhao, Y.; Ji, R.; Dong, H.; Wei, N. Arc Dynamics and Erosion Behavior of Pantograph-Catenary Contacts Under Controlled Humidity Levels. Sensors 2025, 25, 5208. https://doi.org/10.3390/s25165208

Li B, Zhao Y, Ji R, Dong H, Wei N. Arc Dynamics and Erosion Behavior of Pantograph-Catenary Contacts Under Controlled Humidity Levels. Sensors. 2025; 25(16):5208. https://doi.org/10.3390/s25165208

Chicago/Turabian StyleLi, Bingquan, Yijian Zhao, Ran Ji, Huajun Dong, and Ningning Wei. 2025. "Arc Dynamics and Erosion Behavior of Pantograph-Catenary Contacts Under Controlled Humidity Levels" Sensors 25, no. 16: 5208. https://doi.org/10.3390/s25165208

APA StyleLi, B., Zhao, Y., Ji, R., Dong, H., & Wei, N. (2025). Arc Dynamics and Erosion Behavior of Pantograph-Catenary Contacts Under Controlled Humidity Levels. Sensors, 25(16), 5208. https://doi.org/10.3390/s25165208