Preparation and Applications of Silver Nanowire-Polyurethane Flexible Sensor

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Chemicals

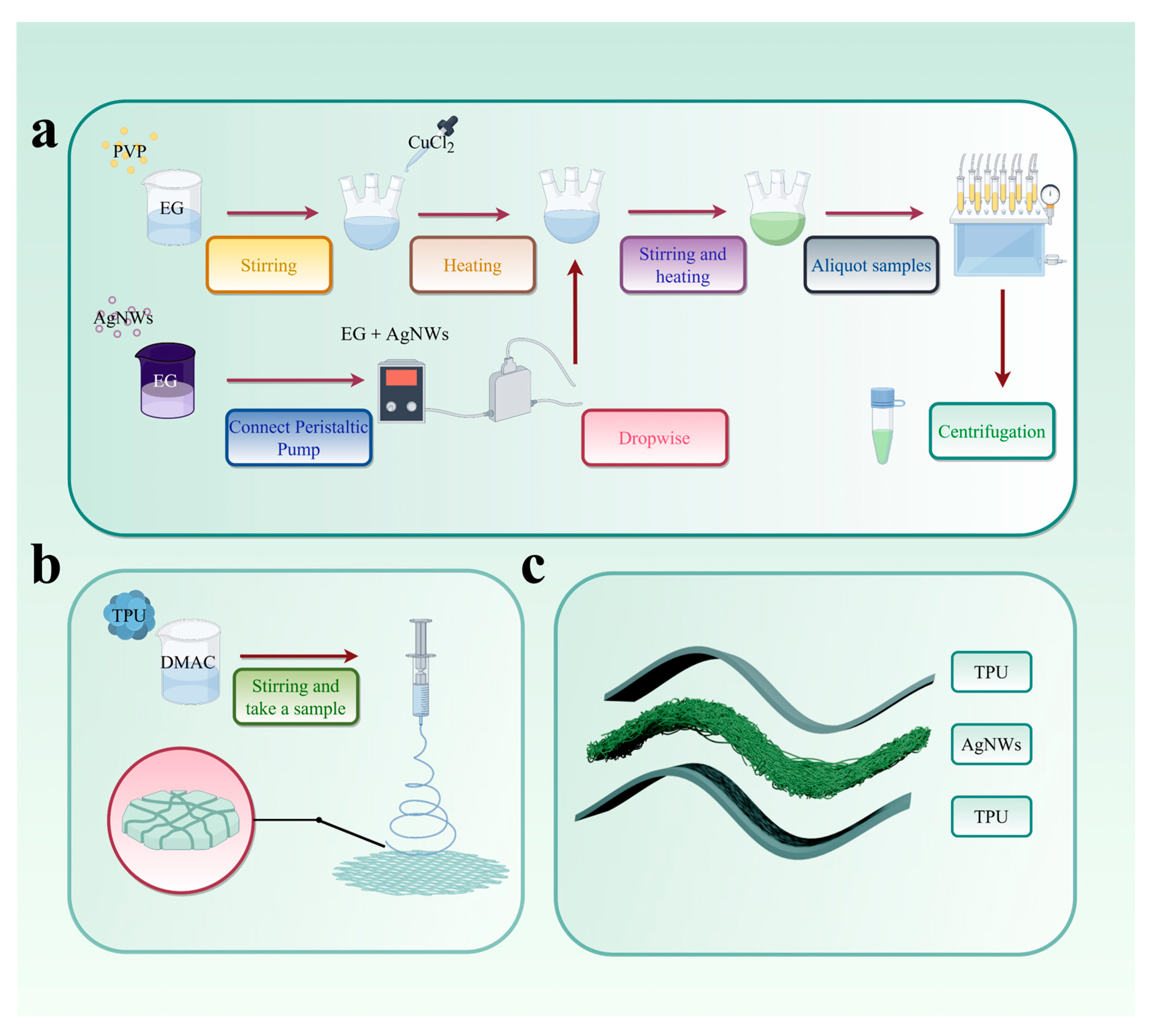

2.2. Preparation of TPU Membranes and Nanofiber Membranes

2.3. The Preparation of AgNWs

2.4. The Fabrication of Flexible Sensors

3. Results and Discussion

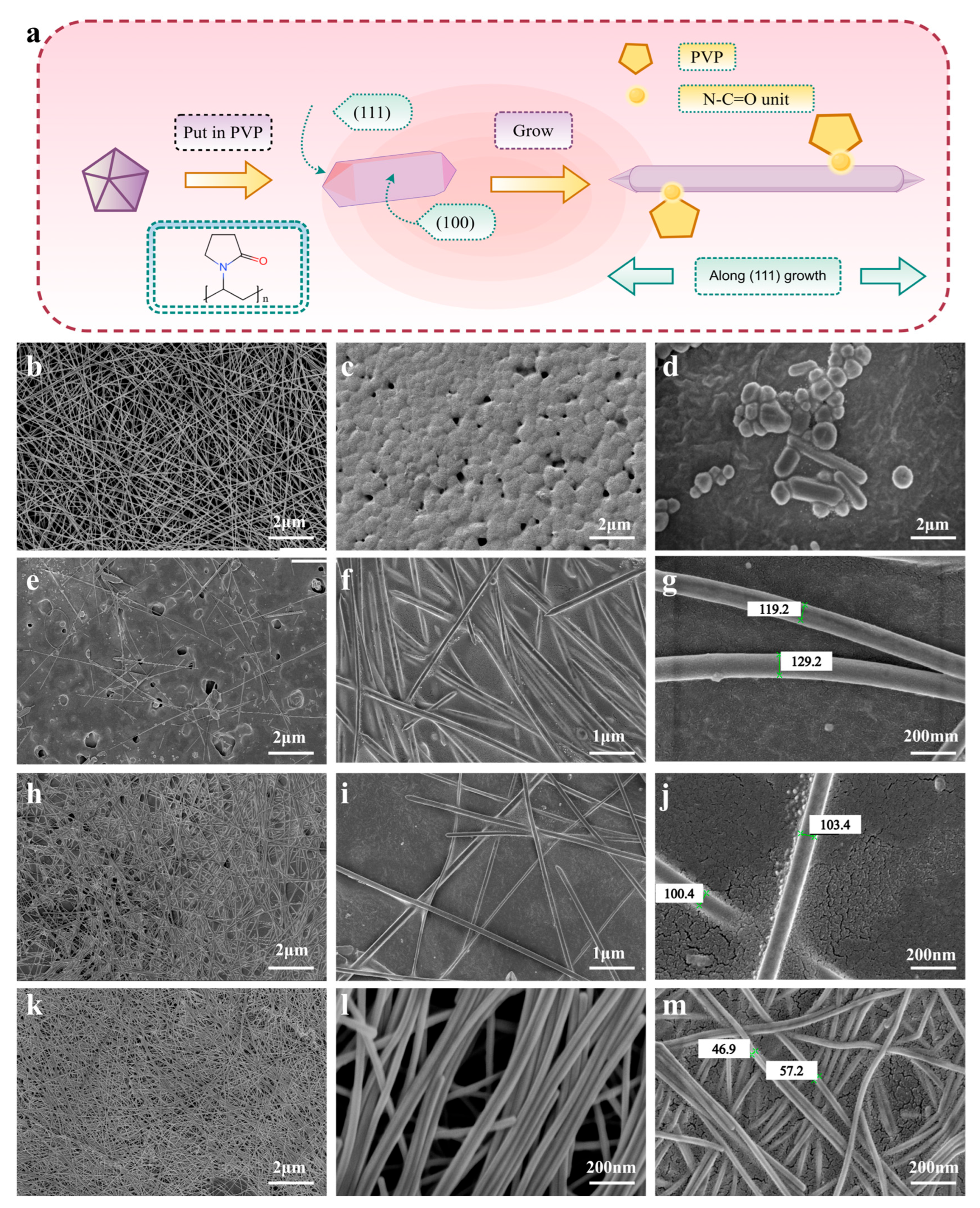

3.1. Analysis of TPU and AgNW SEM Image

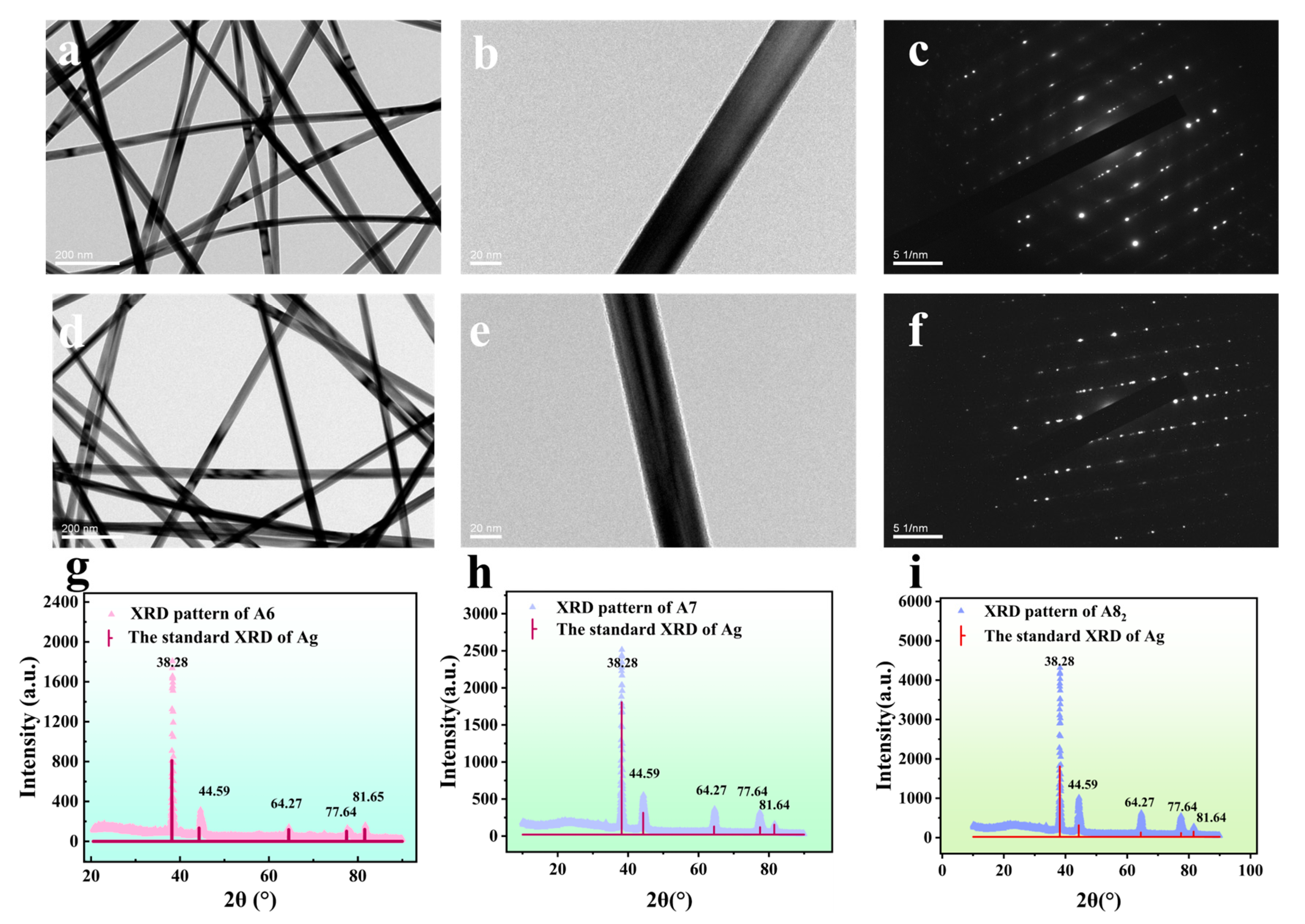

3.2. Analysis of TEM Images of AgNWs

3.3. XRD Analysis of AgNWs

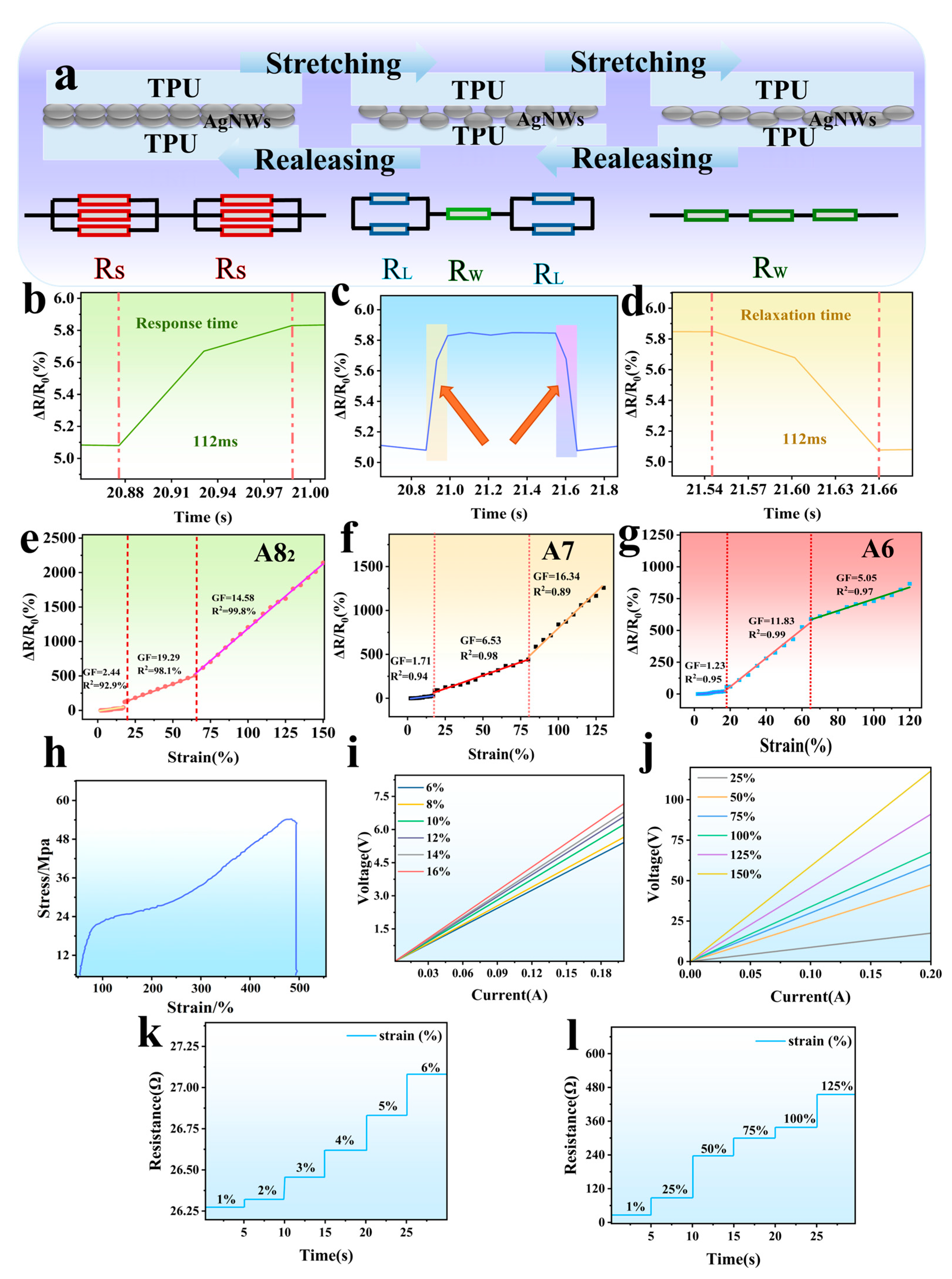

3.4. Visualization of the Performance of AgNW-TPU Flexible Sensors

3.5. Performance Analysis of Flexible Sensors

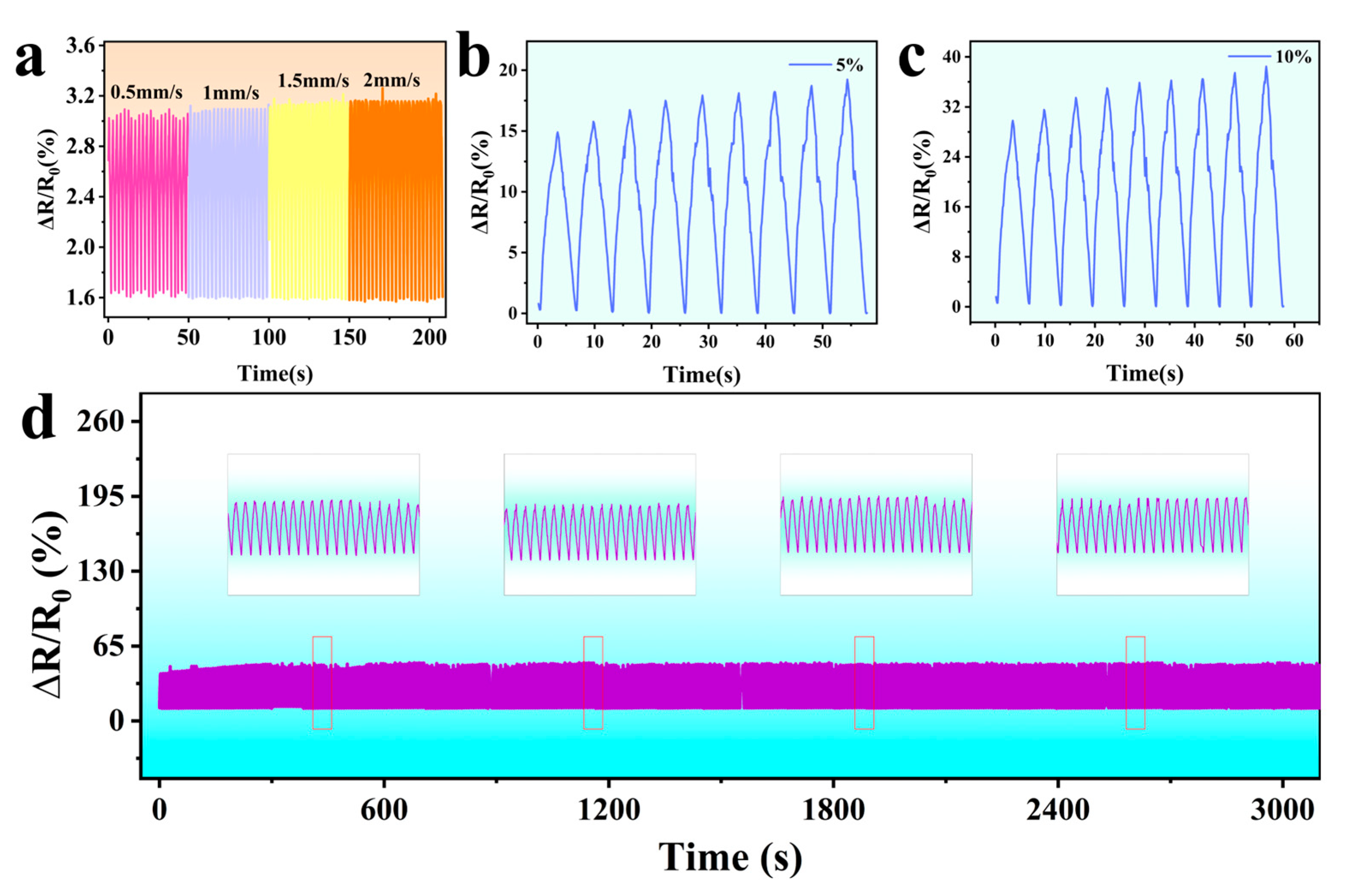

3.6. Cyclic Stability of the Sensor

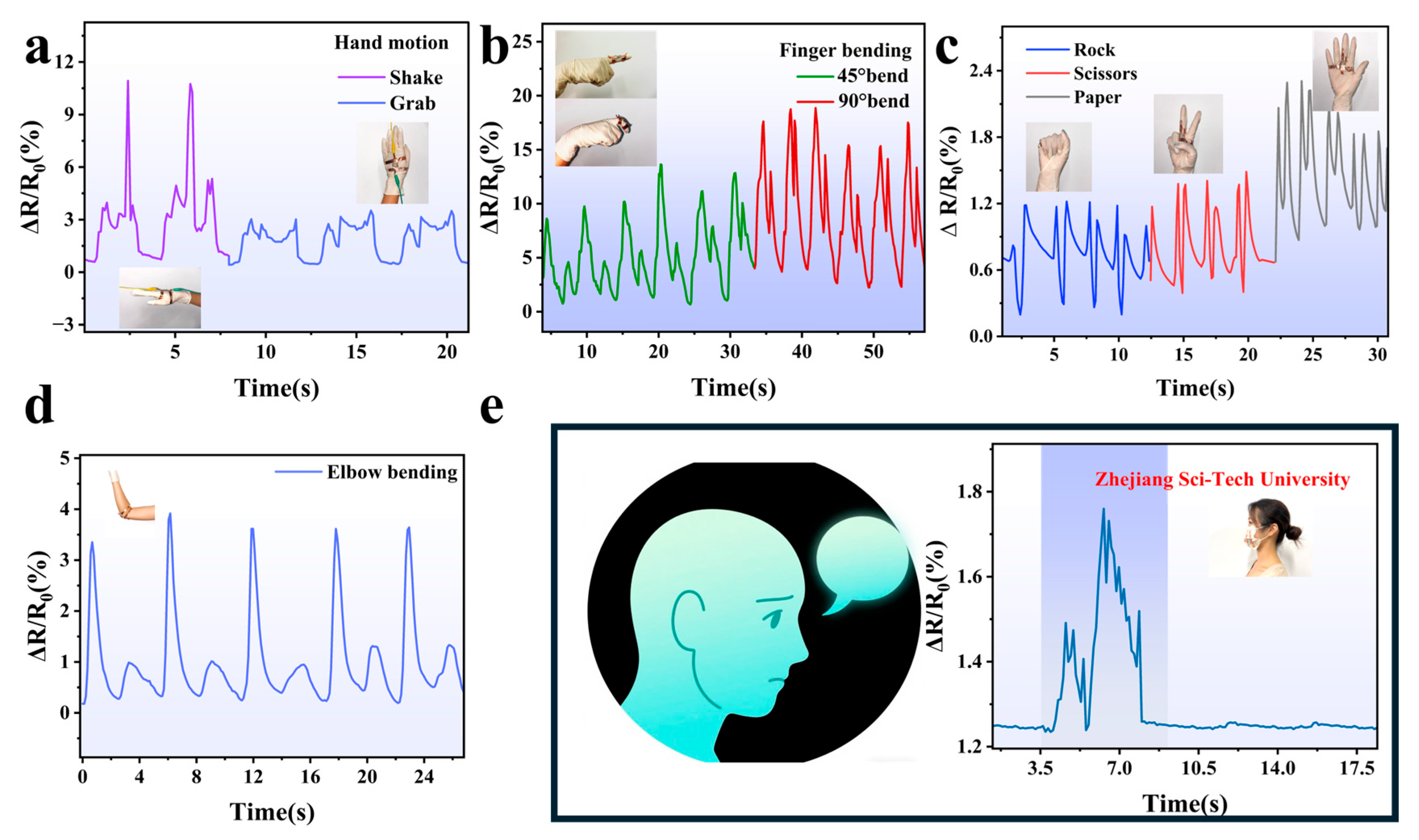

3.7. Monitoring of Human Health

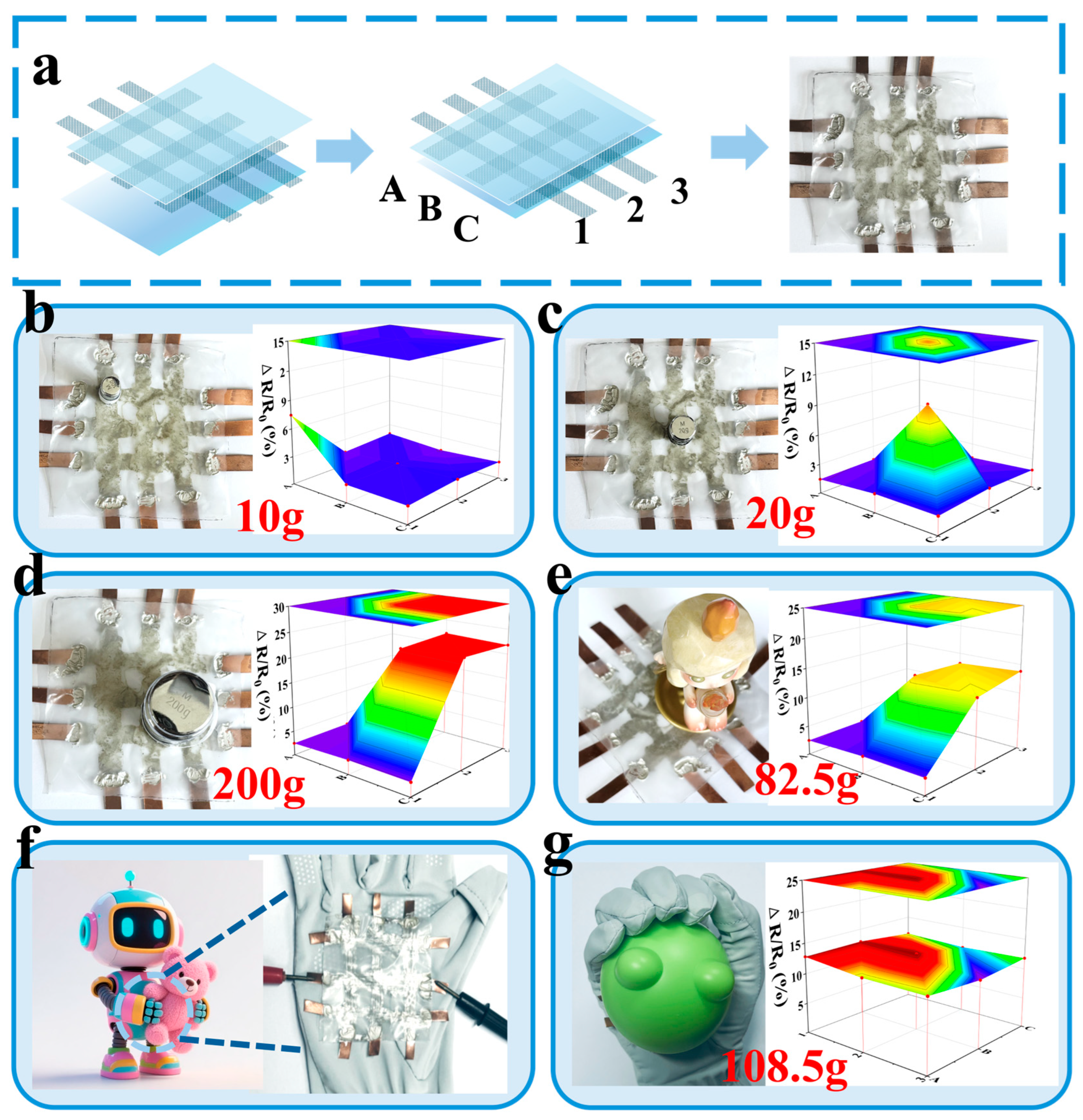

3.8. Application of AgNW-TPU Sensor Arrays

3.9. Field of Human–Machine Interaction

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Han, S.T.; Peng, H.; Sun, Q.; Venkatesh, S.; Chung, K.S.; Lau, S.C.; Zhou, Y.; Roy, V.A.L. An overview of the development of flexible sensors. Adv. Mater. 2017, 29, 1700375. [Google Scholar]

- Li, D.; Fan, Y.; Han, G.; Guo, Z. Superomniphobic Silk Fibroin/Ag Nanowires Membrane for Flexible and Transparent Electronic Sensor. ACS Appl. Mater. 2020, 12, 10039–10049. [Google Scholar] [CrossRef]

- Zheng, Q.; Lee, J.; Shen, X.; Chen, X.; Kim. Graphene-based wearable piezoresistive physical sensors. Mater. Today 2020, 36, 158–179. [Google Scholar] [CrossRef]

- Huang, C.Y.; Chiu, C.W. Facile fabrication of a stretchable and flexible nanofiber carbon film-sensing electrode by electrospinning and its application in smart clothing for ECG and EMG monitoring. ACS Appl. Electron. Mater. 2021, 3, 676–686. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, J.; Huang, Z.; Zheng, G.; Dai, K.; Liu, C.; Shen, C. Flexible electrically resistive-type strain sensors based on reduced graphene oxide-decorated electrospun polymer fibrous mats for human motion monitoring. Carbon 2018, 126, 360–371. [Google Scholar] [CrossRef]

- Tee1, B.C.-K.; Chortos, A.; Berndt, A.; Nguyen, A.K.; Tom, A.; McGuire, A.; Lin, Z.C.; Tien, K.; Bae, W.-G.; Wang, H. A skin-inspired organic digital mechanoreceptor. Science 2015, 350, 313–316. [Google Scholar] [CrossRef]

- Di, C.A.; Zhang, F.; Zhu, D. Multi-functional integration of organic field-effect transistors (OFETs): Advances and perspectives. Adv. Mater. 2013, 25, 313–330. [Google Scholar] [CrossRef]

- Schwartz, G.; Tee, B.C.K.; Mei, J.; Appleton, A.L.; Kim, D.H.; Wang, H.; Bao, Z. Flexible polymer transistors with high pressure sensitivity for application in electronic skin and health monitoring. Nat. Commun. 2013, 4, 1859. [Google Scholar] [CrossRef]

- Yao, Y.; Dai, H.; Ji, M.; Han, Y.; Jiang, B.; Cheng, C.; Song, X.; Song, Y.; Wu, G. Flexible Strain Sensor Based on AgNWs/MXene/SEBS with High Sensitivity and Wide Strain Range. Electron. Mater. Lett. 2024, 20, 684–693. [Google Scholar] [CrossRef]

- Sun, Y.; Mayers, B.; Herricks, T.; Xia, Y. Polyol synthesis of uniform silver nanowires: A plausible growth mechanism and the supporting evidence. Nano Lett. 2003, 3, 955–960. [Google Scholar] [CrossRef]

- Shi, L.; Zhang, N.; Li, L.; Ding, S.; Li, W.; Li, K. Printed flexible temperature sensors: Principles, materials, processes, and applications. Appl. Mater. Today 2025, 43, 102665. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, H.; Yang, Z.; Yang, J.; Wang, Z.; Gao, K. Highly flexible and sensitive wearable strain and pressure sensor based on porous graphene paper for human motion. J. Mater. Sci. Mater. Electron. 2022, 33, 17637–17648. [Google Scholar] [CrossRef]

- Zhu, M.; Yu, H.; Tang, F.; Li, Y.; Liu, Y.; Yao, J. Robust Natural Biomaterial Based Flexible Artificial Skin Sensor with High Transparency and Multiple Signals Capture. Chem. Eng. J. 2020, 394, 124855. [Google Scholar] [CrossRef]

- Tian, H.; Shu, Y.; Cui, Y.L.; Mi, W.T.; Yang, Y.; Xie, D. TL Ren Scalable fabrication of high-performance and flexible graphene strain sensors. Nanoscale 2014, 6, 699–705. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, C.; Zhang, L.; Liu, H.; Zhao, Y.; Guo, Y.; Hu, W.; Yu, G.; Liu, Y. Inkjet printing short-channel polymer transistors with high-performance and ultrahigh photoresponsivity. Adv. Mater. 2014, 26, 4683–4689. [Google Scholar] [CrossRef]

- Yan, B.; Guo, Y.; Cheng, S.; Dou, L.; Yang, Y.; Guo, X.; Chen, Y.; Cai, W.; Zhang, Y.; Liu, Z. Ag nanowires boost graphene aerogel as anode for charge-transfer in nonclassical electroactive microbial fuel cells. Fuel 2025, 390, 134650. [Google Scholar] [CrossRef]

- Yang, Z.; Guo, Y.; Guo, W.; Zhao, M.; Wang, H.; Wei, B.; Miao, Y.; Guo, K. MXene/AgNWs/MXene Sandwich-Structured Transparent Electrode for High-Performance Flexible OLED. Small 2025, 21, 2409621. [Google Scholar] [CrossRef] [PubMed]

- Wu, M.; Li, Y.; An, N.; Sun, J. Applied voltage and near-infrared light enable healing of superhydrophobicity loss caused by severe scratches in conductive superhydrophobic films. Adv. Funct. Mater. 2016, 26, 6777–6784. [Google Scholar] [CrossRef]

- Guo, Y. Wearable sensors to monitor plant health. Nat. Food 2023, 4, 350. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, Q.; Du, T.; Xu, Q.; Li, C.; Wu, Z. Development of AgNWs/PDMS flexible strain sensor. Synth. Technol. Appl. 2021, 36, 17–22. [Google Scholar]

- Liu, Z.; Qu, L.; Li, X.; Jiang, X.; Yu, L. PAN/β-CD/MnO2 composite fibers for highly efficient adsorption of heavy metals and absorption of electromagnetic waves. Sep. Purif. Technol. 2025, 363, 132070. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Y. Effect of hierarchical layer structure design on the sensing performances of NaNbO3/P(VDF-TrFE) piezoelectric composite films. J. Alloys Compd. 2025, 1017, 179071. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, C.; Cao, C.; Liu, M.; Liu, Z.; Zhou, P.; Wang, G.; Zhang, T.; Zhang, L.; Qi, Y. Boosting Sensing Performance of Flexible Piezoelectric Pressure Sensors by Sb Nanosheets and BaTiO3 Nanoparticles Co-Doping in P (VDF-TrFE) Nanofibers Mat. Adv. Energy Mater. 2024, 10, 2300718. [Google Scholar] [CrossRef]

- Cai, J.; Huang, S.; Zhou, W.; He, X.; Liang, H.; Zhou, J.; Zhao, C.; Xu, T. A stretchable and self-healing poly(vinyl alcohol)/polyacrylamide/polyaniline multi-network hydrogel for flexible strain sensors. Mater. Today Commun. 2025, 44, 111976. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, Q.; Qu, Z. Controlled Synthesis of Uniform Silver Nanowires via a Simple Polyol Process. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 301. [Google Scholar]

- Sun, Y.; Xia, Y. Shape-Controlled Synthesis of Gold and Silver Nanoparticles. Science 2002, 298, 2176–2179. [Google Scholar] [CrossRef] [PubMed]

- Nikoobakht, B.; El-Sayed, M.A. Preparation and growth mechanism of gold nanorods (NRs) using seed-mediated growth method. Chem. Mater. 2003, 15, 1957–1962. [Google Scholar] [CrossRef]

- Lifshitz, I.M.; Slyozov, V.V. Kinetics of precipitation from supersaturated solid solutions. Phys. Chem. Solids 1961, 19, 35–50. [Google Scholar] [CrossRef]

- Wiley, B.; Sun, Y.; Mayers, B.; Xia, W. Cover Picture: Shape-Controlled Synthesis of Metal Nanostructures: The Case of Silver (Chem. Eur. J. 2/2005). Chem. Eur. J. 2004, 11, 431. [Google Scholar] [CrossRef]

- Murph, S.E.H.; Murphy, C.J.; Leach, A.; Gall, K. A Possible Oriented Attachment Growth Mechanism for Silver Nanowire Formation. Cryst. Growth Des. 2015, 15, 1968–1974. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire-Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Wu, L.; Wang, L.; Guo, Z.; Luo, J.; Xue, H.; Gao, J. Durable and Multifunctional Superhydrophobic Coatings with Excellent Joule Heating and Electromagnetic Interference Shielding Performance for Flexible Sensing Electronics. ACS Appl. Mater. Interfaces 2019, 11, 34338–34347. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Huo, L.; Wang, L.; Huang, X.; Li, J.; Guo, Z.; Gao, Q.; Hu, M.; Xue, H. Superhydrophobic and multi-responsive fabric composite with excellent electro-photo-thermal effect and electromagnetic interference shielding performance. Chem. Eng. J. 2020, 391, 123537. [Google Scholar] [CrossRef]

- Peng, Y.; Yan, B.; Li, Y.; Lan, J.; Shi, L.; Ran, R. Antifreeze and moisturizing high conductivity PEDOT/PVA hydrogels for wearable motion sensor. J. Mater. Sci. 2020, 55, 1280–1291. [Google Scholar] [CrossRef]

- Hong, X.; Zhao, W.; Yu, R.; Wang, Q.; Zeng, F.; Tao, Y.; Jin, Z.; Zhu, C. Multifunctional silver nanowire coated fabric capable of electrothermal, resistance temperature-sensitivity, electromagnetic interference shielding, and strain sensing. J. Ind. Text. 2022, 51 (Suppl. 4), 6153S–6172S. [Google Scholar] [CrossRef]

- Zhu, G.J.; Ren, P.G.; Guo, H.; Jin, Y.L.; Yan, D.X. Highly Sensitive and Stretchable Polyurethane Fiber Strain Sensors with Embedded Silver Nanowires. ACS Appl. Mater. Interfaces 2019, 11, 23649–23658. [Google Scholar] [CrossRef]

- Ouyang, Z.; Li, S.; Liu, J.; Yu, H.-Y.; Peng, L.; Zheng, S.; Xu, D.; Tam, K.C. Bottom-up reconstruction of smart textiles with hierarchical structures to assemble versatile wearable devices for multiple signals monitoring. Nano Energy 2022, 104, 107963. [Google Scholar] [CrossRef]

- Xue, C.; Sun, H.; Tang, Y.; Wei, J.; Guo, J. Self-Powered Photonic Sensor Using Cholesteric Liquid Crystal Elastomer-Based Sandwiched Architecture with Mechanochromism and Triboelectric Response. ACS Appl. Mater. Interfaces 2025, 17, 46226–46237. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, J.; Song, J.; Yang, Z.; Hammad, F.A.; Tian, Y. Microcrack-engineered flexible strain sensors enabled by carbon black/graphene/conductive carbon paste ternary nanocomposites for enhanced sensitivity. J. Mater. Sci. Mater. Electron. 2025, 36, 1315. [Google Scholar] [CrossRef]

- Li, Q.; Li, Y.; Ding, L.; Li, X.; Ma, J.; Minami, T.; Sang, S. Structural optimization of field-effect modulated P3HT OTFT flexible pressure sensors for high sensitivity and rapid response. Microchem. J. 2025, 215, 114484. [Google Scholar] [CrossRef]

- Zhan, Y.; Poisson, J.; Meng, X.; Wang, Z.; Chen, L.; Wu, T.H.; Zhang, K. Electrospun Lignin/ZnO Nanofibrous Membranes for Self-Powered Ultrasensitive Flexible Airflow Sensor and Wearable Device. Adv. Mater. 2025, e2502211. [Google Scholar] [CrossRef] [PubMed]

- Ke, L.; Shen, X.; Xiao, F.; Zhang, Y.; Zhang, Q.; Jiang, H.; Jin, S.; Huang, Y. High-performance dual skin temperature-sweat pH sensor based on ionic conductive hydrogel. Sens. Actuators A Phys. 2025, 393, 116729. [Google Scholar] [CrossRef]

- Eun, R.; Byeong-Ung, H.; Doil, K.; Bo-Yeong, K.; Nae-Eung, L. Stretchable, Transparent, Ultrasensitive, and Patchable Strain Sensor for Human-Machine Interfaces Comprising a Nanohybrid of Carbon Nanotubes and Conductive Elastomers. ACS Nano 2015, 9, 6252–6261. [Google Scholar]

- Wakasugi, K.; Maruo, Y. A Sensor Network Design Consideration Based on Percolation Theory. In B—Abstracts of IEICE TRANSACTIONS on Communications (Japanese Edition); IEICE: Minato-ku, Japan, 2011; Volume J94-B, pp. 61–64. [Google Scholar]

- Zhang, J.; Wang, M.; Yang, Z.; Zhang, X. Highly flexible and stretchable strain sensors based on conductive whisker carbon nanotube films. Carbon 2021, 176, 139–147. [Google Scholar] [CrossRef]

- Shi, J.; Wang, S.; Wang, H.; Gu, J. Mechanically Tough and Highly Stretchable Hydrogels Based on Polyurethane for Sensitive Strain Sensor. Polymers 2023, 15, 3902. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shan, J.; Qian, J.; Lin, L.; Wei, M.; Xia, J.; Fu, L. Preparation and Applications of Silver Nanowire-Polyurethane Flexible Sensor. Sensors 2025, 25, 5191. https://doi.org/10.3390/s25165191

Shan J, Qian J, Lin L, Wei M, Xia J, Fu L. Preparation and Applications of Silver Nanowire-Polyurethane Flexible Sensor. Sensors. 2025; 25(16):5191. https://doi.org/10.3390/s25165191

Chicago/Turabian StyleShan, Jiangyin, Jianhua Qian, Ling Lin, Mengrong Wei, Jingyue Xia, and Lin Fu. 2025. "Preparation and Applications of Silver Nanowire-Polyurethane Flexible Sensor" Sensors 25, no. 16: 5191. https://doi.org/10.3390/s25165191

APA StyleShan, J., Qian, J., Lin, L., Wei, M., Xia, J., & Fu, L. (2025). Preparation and Applications of Silver Nanowire-Polyurethane Flexible Sensor. Sensors, 25(16), 5191. https://doi.org/10.3390/s25165191