Abstract

Industry 5.0 introduces a new paradigm where digital technologies support sustainable and human-centric industrial development. Within this context, resilience-based maintenance (RBM) emerges as a forward-looking maintenance strategy focused on system adaptability, fault tolerance, and recovery capacity under uncertainty. This article presents a systematic literature review (SLR) on RBM in the context of Maintenance 5.0. The review follows the PRISMA methodology and incorporates bibliometric and content-based analyses of selected publications. Key findings highlight the integration of AI methods, such as machine learning and digital twins, in enhancing system resilience. The results demonstrate how RBM aligns with the pillars of Industry 5.0, sustainability, and human-centricity, by reducing resource consumption and improving human–machine interaction. Research gaps are identified in AI explainability, sector-specific implementation, and ergonomic integration. The article concludes by outlining directions for developing Maintenance 5.0 as a strategic concept for resilient, intelligent, and inclusive industrial systems.

1. Introduction

The dynamic evolution of industrial systems has been shaped by the shift from Industry 4.0, focused on digitalization, automation, and connectivity, to the emerging paradigm of Industry 5.0, which integrates technological progress with sustainability, resilience, and human-centricity [1,2]. Rather than replacing Industry 4.0, Industry 5.0 builds on its foundations, refocusing priorities toward well-being, environmental responsibility, and socio-technical balance.

In this evolving context, traditional maintenance approaches, focused on minimizing downtime or maximizing reliability through reactive, preventive, or predictive strategies, are no longer sufficient. Maintenance must evolve toward a more adaptive and systemic form capable of supporting resilience in complex, volatile environments [3,4,5].

One promising approach is resilience-based maintenance (RBM), which emphasizes a system’s ability to withstand disturbances, recover operational capabilities, and learn from disruptions [6]. RBM incorporates adaptability, redundancy, and self-organization principles beyond fault prediction and condition monitoring [7]. The growing importance of AI in this context is central—artificial intelligence (AI), machine learning (ML), and digital twins (DTs) offer new capabilities to model, predict, and manage maintenance under uncertainty [8], directly supporting the development of RBM.

Despite the increasing attention to sustainable maintenance in recent literature, most existing systematic reviews remain fragmented or domain-specific, lacking a comprehensive framework that bridges resilience, sustainability, and AI integration. For example, Campos and Simon [9] discuss the insertion of sustainability concepts in maintenance strategies, while Zhao et al. [10] and Hallioui et al. [11] review sustainable maintenance practices for specific systems or approaches such as sustainable total productive maintenance (STPM). Vasić et al. [12] conducted an umbrella review on sustainability adoption criteria, and Madreiter et al. [13] identified technology drivers enabling positive sustainable impact in manufacturing. However, none of these works offer a holistic integration of sustainability with resilience and AI-based decision-making under the Industry 5.0 paradigm. Therefore, while sustainability is often addressed in separate maintenance strategies [1,9,10,11,14,15], integrated perspectives combining it with resilience and digital intelligence remain rare.

Similarly, recent reviews have explored predictive maintenance (PdM) (see, e.g., [16,17,18,19,20]), reliability-centered maintenance (RCM) (see, e.g., [14,21,22]), or AI applications in diagnostics (see, e.g., [23,24,25,26]). Analyses of the evolution of maintenance practices from Industry 4.0 to Industry 5.0 context are presented, e.g., in [15,27,28]. In addition, recent developments in the area of Maintenance 5.0 concept implementation challenges and possibilities are discussed, e.g., in [29,30]. However, they rarely connect technological advancements with the societal goals emphasized in Industry 5.0.

Some recent works have begun to address broader conceptual frameworks, such as Maintenance 5.0 or smart maintenance, in relation to sustainability and resilience. For example, Jasiulewicz-Kaczmarek et al. [31,32] explored how Maintenance 4.0 technologies support sustainability goals, while Werbińska-Wojciechowska and Winiarska [3] provided a bibliometric and systematic analysis of smart maintenance performance in Industry 4.0 environments. Saihi et al. [33] presented a modeling-based review of sustainable maintenance, identifying key indicators and trade-offs. Bastas [34] contributed to understanding sustainability-oriented production technologies without directly addressing maintenance. In addition, sustainable maintenance in the context of Industry 4.0 concept implementation is also discussed, e.g., in [35,36,37]. The aspects of resilience-based maintenance are reviewed, e.g., in [7,38].

It is worth taking note that there are also works on human-centricity in maintenance management. For example, the authors in [39] focused on the Operator 4.0 concept, analyzing the occupational risks workers face and the proposed solutions to support them by leveraging the key enabling technologies of Industry 4.0. This problem is continued in [40], where the authors provided a literature review on human-centricity in Industry 5.0. Socio-economic dimensions are also reviewed in [41]. Recent reviews from 2024 to 2025 have further highlighted the growing focus on digital sustainable maintenance [42], prescriptive maintenance [43,44], and umbrella reviews of reviews [45,46], confirming that while the literature continues to expand rapidly few studies offer an integrative view that combines resilience, sustainability, and human-centricity with AI-based tools under the unified framework of Maintenance 5.0. However, these existing contributions offer only fragmented perspectives and do not provide a structured approach to integrating resilience, sustainability, and human-centricity into maintenance strategies. Moreover, they often lack a dedicated focus on the domain of industrial maintenance, which is a critical enabler of operational continuity, especially under disruptive conditions. There is a notable gap in the literature regarding linking these principles with modern AI-based tools to form a cohesive framework that aligns with the Industry 5.0 paradigm.

This article addresses this gap by introducing a structured and focused approach to Resilience-Based Maintenance in industrial maintenance management. The study’s novelty lies in its comprehensive examination of RBM as a strategic concept for ensuring operational continuity, system resilience, and sustainable development, supported by AI technologies and embedded within the Industry 5.0 vision. A comparative overview of recent review publications supporting this gap identification is presented in Appendix A.1 (Table A1). Table A1 summarizes existing review articles exploring key directions in the evolution of maintenance, particularly regarding resilience, sustainability, and AI integration. While each of these studies addresses a subset of the domain, none has provided an integrative view of RBM, sustainability, and Maintenance 5.0 under a unified framework, which this paper aims to develop and present.

In response, this study presents the results of a systematic literature review (SLR) on RBM in the context of Maintenance 5.0 and its pillars: resilience, sustainability, and human-centricity. It aims to synthesize the state of knowledge and propose a structured perspective on how RBM can support adaptability, long-term value creation, and robust decision-making using AI. This leads to the following research questions:

- RQ1: What is the current state of research on resilience-based maintenance in industrial and infrastructure systems?

- RQ2: Which artificial intelligence methods and tools are employed in RBM to support decision-making, adaptability, and learning?

- RQ3: How is RBM aligned with the pillars of Industry 5.0, particularly sustainability and human-centricity?

- RQ4: What are the key research challenges, gaps, and directions for future studies in this area?

To answer these questions, a systematic review was carried out using the PRISMA protocol [47], supported by snowball sampling to ensure inclusion of relevant but non-indexed studies [48]. The content of selected articles was analyzed using a dual approach: bibliometric analysis to identify publication trends and clusters, and content-based analysis to extract thematic insights and assess the role of AI in RBM implementation.

While RBM is applied across diverse sectors, this study deliberately adopts a cross-sectoral approach to identify transferable principles and challenges shared between industrial and infrastructure maintenance.

The structure of the paper is organized as follows: Section 2 presents the theoretical background of maintenance evolution, the concept of Maintenance 5.0, and a detailed overview of RBM. Section 3 explains the review methodology, including data sources, inclusion criteria, and analytical procedures. Section 4 summarizes the results of the SLR, combining bibliometric and content-based perspectives. Section 5 discusses the findings regarding the research questions, including identifying knowledge gaps and future development areas. Section 6 explores the implications of RBM in the context of sustainability and human-centric industrial systems. Finally, Section 7 concludes the paper by highlighting key contributions and recommendations for researchers and practitioners.

2. Theoretical Background

2.1. Evolution of Maintenance Concepts

Maintenance strategies have been profoundly transformed over the past decades, evolving from reactive, corrective practices into data-driven and intelligence-supported approaches that contribute directly to industrial systems’ performance, sustainability, and resilience [3,49]. According to IEC 60300-3-14, maintenance can be defined as the combination of all technical, administrative, and managerial actions intended to retain or restore an item to a state where it can perform its required function [50]. As industrial environments have become increasingly complex and digitalized, maintenance has shifted from a reactive necessity to a strategic, proactive, and knowledge-based function [51].

The historical development of maintenance strategies is often described through the lens of generational models [52]. The first generation was characterized by reactive maintenance, where interventions were implemented only after failure. While once acceptable in the era of simple machinery and short production cycles, this approach resulted in significant losses, safety risks, and unplanned costs. The second generation introduced preventive maintenance based on predefined schedules and usage intervals. Although more systematic, this model often led to unnecessary component replacements and did not account for system condition variability [53].

A paradigm shift occurred with the advent of condition-based and predictive maintenance strategies, marking the beginning of the third generation. These approaches leverage sensor data, diagnostic methods, and statistical models to assess the equipment’s condition and anticipate failures [54,55]. Predictive maintenance, in particular, utilizes machine learning algorithms, prognostic models, and remaining useful life (RUL) estimations to support timely and cost-effective interventions. Integrating such approaches with enterprise resource planning (ERP) and computerized maintenance management systems (CMMSs) laid the foundation for a more intelligent and responsive maintenance function [16].

The fourth generation of maintenance emerged in Industry 4.0, characterized by integrating cyber-physical systems, industrial IoT, and cloud computing. This model, known as smart maintenance, emphasizes connectivity, autonomy, and real-time decision-making. Maintenance is no longer seen as a standalone function but as part of a continuous cyber-physical production ecosystem in which machines, sensors, and algorithms interact. This generation introduced advanced tools such as digital twins, augmented reality, and edge analytics, enabling real-time diagnostics, prescriptive maintenance, and system-level optimization [56,57,58].

Today, industrial systems are entering the fifth generation of maintenance development—commonly referred to as Maintenance 5.0. This emerging paradigm aligns with the broader principles of Industry 5.0, which emphasize sustainability, resilience, and human-centricity [1]. In this context, maintenance is expected to contribute to environmental goals, system robustness, and ethical integration of automation with human work. Maintenance 5.0 integrates sustainability principles through life cycle-aware planning, resource efficiency, and environmental impact assessment. Simultaneously, it supports human well-being and agency by embedding ergonomics, transparency, and collaborative interfaces into maintenance processes. It also embraces resilience engineering, recognizing the necessity of adapting to disruptions, managing complexity, and recovering from unforeseen events [15,59].

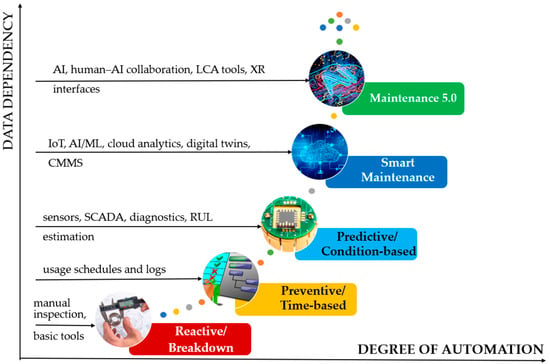

To support the clarity of this conceptual development, a graphical illustration (Figure 1) depicts the evolution of maintenance strategies from the first to the fifth generation, highlighting the main drivers, technologies, and goals associated with each stage. In addition, a comparative table (Table 1) synthesizes the distinguishing features across these generations in terms of dominant paradigms, maintenance objectives, enabling technologies, data requirements, and the role of human operators.

Figure 1.

Evolution of maintenance strategies. Source: own contribution based on [3,53].

Table 1.

Evolution of maintenance strategies: from reactive to Maintenance 5.0. Source: own contribution based on [3,49,60].

Recent review articles underscore this transition and identify the need for integrated maintenance strategies that combine technological innovation with resilience and sustainability. For instance, Aktef et al. [4] stress that transitioning to Maintenance 5.0 requires not only digital transformation but also embedding human-centric and sustainable values into maintenance strategies. Murtaza et al. [15] argue that predictive models must evolve into context-aware, adaptive systems that support long-term resilience.

Farsi et al. [14] suggest that reliability-centered maintenance should account for environmental and social impact, not just cost-risk tradeoffs. Kans and Campos [28] highlight organizational gaps in aligning digitalization with sustainability goals. Aktef et al. [29], through fuzzy MICMAC analysis, show that successful Maintenance 5.0 adoption depends as much on organizational readiness as on technological capability.

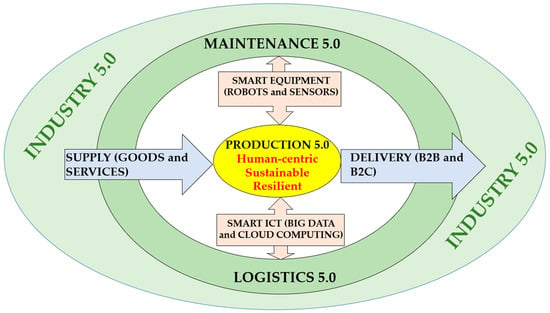

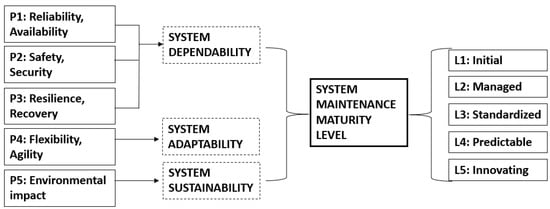

To consolidate these insights, Figure 2 presents a conceptual framework for Maintenance 5.0, positioning sustainability, resilience, and human-centricity as its core pillars. These elements are further explored in the following subsections.

Figure 2.

Maintenance 5.0 in the context of Industry 5.0. Source: own contribution based on [1,3].

2.2. Resilience-Based Maintenance Approach

Maintenance strategies have gradually evolved from reactive and scheduled maintenance to more proactive, data-driven approaches, such as predictive and condition-based maintenance. However, as industrial systems become increasingly complex, interconnected, and exposed to uncertain disruptions, traditional maintenance frameworks often prove insufficient in ensuring long-term system robustness and adaptability [53]. In response, resilience-based maintenance (RBM) emerges as a forward-looking strategy that enhances system capability to absorb, adapt, recover, and learn from disturbances [6].

The theoretical foundations of RBM are deeply rooted in resilience engineering [61,62,63], complex systems theory [64,65], and risk-informed asset management [66,67]. Here, resilience denotes a system’s ability to maintain or rapidly restore function amid disruptions [68,69]. RBM expands beyond fault prediction by integrating four core resilience capabilities [68,70,71]:

- Adaptability: The ability to adjust maintenance strategies and resource allocations dynamically in response to changing operational environments,

- Redundancy: The design and maintenance of alternative pathways or components (e.g., backup pumps, auxiliary control systems) to ensure continued function during partial failures,

- Learning: The use of historical and real-time data to continuously improve maintenance policies and failure response mechanisms,

- Recovery: The capacity to restore full system functionality rapidly following an adverse event.

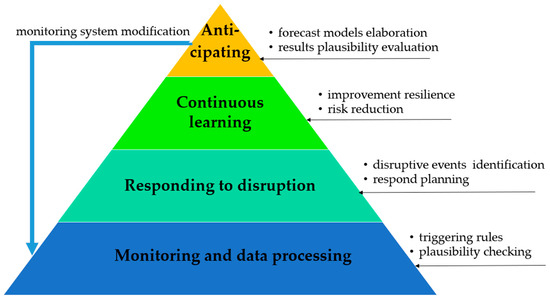

These capabilities, well-established in safety-critical domains [68,71,72], are now increasingly transferred to industrial maintenance, especially in high-reliability sectors [73]. Figure 3 illustrates the layered architecture of RBM.

Figure 3.

A layered architecture of RBM. Source: own contribution based on [6,74].

RBM is gaining momentum as a research field. For example, Leng et al. [75] and Pawar et al. [76] map resilience strategies in manufacturing and maintenance, while [77] and [78] explore maintenance resilience under Industry 4.0 and 5.0 visions. These studies underscore the need to link resilience thinking with asset management and uncertainty response [6,7,79].

RBM distinguishes itself from reliability-centered maintenance and predictive maintenance (PdM) because of its explicit focus on system-level adaptability and human–machine interaction under dynamic and uncertain conditions [80,81]. While RCM relies primarily on structured failure mode analysis and expert knowledge to design preventive strategies [82,83,84], it often lacks the flexibility to respond to emerging disruptions. Predictive maintenance, on the other hand, utilizes sensor data and machine learning techniques to estimate the remaining useful life of components, offering significant benefits in condition monitoring. Yet, it focuses on specific assets or subsystems rather than the broader organizational context. RBM, in contrast, incorporates systemic foresight, learning feedback loops, and flexible resource reallocation, aligning with the principles of resilient socio-technical systems.

In recent years, the emergence of prescriptive maintenance (RxM) has further extended the capabilities of traditional predictive maintenance (PdM) [43]. While PdM focuses on estimating remaining useful life (RUL) and anticipating failures based on condition data, RxM introduces a decision-making layer that suggests or autonomously initiates optimal maintenance actions. This includes selecting corrective strategies, scheduling interventions, and even reconfiguring systems in real time based on risk, cost, and performance trade-offs. Prescriptive analytics leverages reinforcement learning, simulation-based optimization, and AI planning to enable autonomous maintenance decisions, often without human intervention. As such, RxM aligns closely with the adaptability and learning dimensions of resilience-based maintenance. However, unlike RBM, it typically lacks an explicit system-level perspective on socio-technical interactions, redundancy design, and organizational learning. Therefore, while RxM can be viewed as a technological enabler of RBM, it does not substitute the broader resilience paradigm. Integrating prescriptive maintenance within RBM frameworks offers a promising direction for developing intelligent, adaptive, and ethically grounded maintenance strategies [85,86].

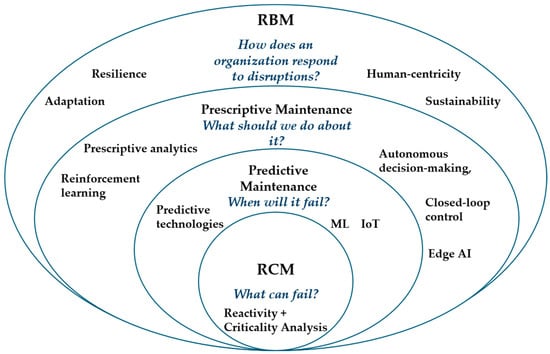

To better understand the positioning of RBM in the landscape of maintenance strategies, it is essential to compare it with two established approaches, reliability-centered maintenance (RCM), predictive maintenance (PdM), and prescriptive maintenance (RxM) in a tabular form (Table 2). To clarify the conceptual evolution and scope of resilience-based maintenance (RBM), a concentric model has been introduced (Figure 4). This schematic visualizes how RBM builds upon the foundations of reliability-centred maintenance (RCM), predictive maintenance (PdM), and prescriptive maintenance (RxM), extending their focus beyond equipment-level reliability and prediction. RBM addresses systemic responses to disruptions, embedding resilience, flexibility, and sustainability into maintenance strategies. It also highlights the shift toward human-centric and ethically aligned asset management in Industry 5.0 contexts.

Table 2.

Comparison of RCM, PdM, RxM, and RBM. Source: own contribution based on [6,74].

Figure 4.

Conceptual boundaries and evolution from reliability-centred maintenance (RCM), predictive maintenance, and prescriptive maintenance (RxM) towards resilience-based maintenance (RBM).

Despite rising interest, RBM remains fragmented in application. Existing literature often addresses resilience dimensions in isolation, e.g., AI for adaptability or learning, without integrating them into a unified operational framework. Moreover, few studies examine how RBM can be embedded within human-centric and sustainability-oriented strategies characteristic of Industry 5.0.

This article addresses these gaps by conducting a systematic literature review (SLR) on RBM and its intersection with AI, sustainability, and human-centricity in industrial maintenance. By synthesizing theoretical and practical developments, it proposes a structured framework to support adaptive and resilient maintenance in Industry 5.0 environments.

In summary, RBM offers a paradigm shift, from reactive interventions to proactive resilience orchestration, ensuring not only technical reliability but also long-term sustainability and human-centered design. This section lays the conceptual foundation for the subsequent classification and analysis of AI-based RBM strategies.

2.3. Sustainable Maintenance Approach

The concept of sustainability has become an indispensable element in transforming maintenance strategies, particularly within the Maintenance 5.0 paradigm [1,15]. As industries strive to meet environmental responsibility requirements, economic viability, and social equity, maintenance is no longer viewed solely as a technical function but as a strategic enabler of sustainable value creation. Sustainable maintenance refers to systematically integrating environmental, economic, and social criteria into maintenance planning, execution, and evaluation, ensuring that maintenance contributes to industrial systems’ long-term resilience and ethical operation [33,87].

The importance of sustainable maintenance has been addressed in several previous literature reviews, which provide a foundation for its conceptualization, challenges, and implementation. For instance, Campos and Simon [9] systematically examined how sustainability concepts are embedded into maintenance strategies in the context of sustainable manufacturing. Saihi et al. [33] conducted a modeling-based systematic review that identifies trade-offs and gaps in sustainable maintenance approaches. Zhao et al. [10] reviewed sustainable strategies for single and multicomponent equipment, while Hallioui et al. [11] analyzed total productive maintenance (TPM) in light of sustainability objectives. Vasić et al. [12] conducted an umbrella review that outlines critical criteria for adopting sustainable maintenance practices.

Additionally, several conceptual and application-oriented studies have contributed to the evolution of sustainable maintenance thinking. Durán and Durán [88] proposed a prioritization model for physical assets to align maintenance with sustainability goals in manufacturing. Kayan [89] introduced the notion of “green maintenance” from a conservation planning perspective, emphasizing material reuse and minimal environmental impact in repair processes. Olugu et al. [90] developed an integrated fuzzy Delphi–TOPSIS framework to identify sustainability indicators for maintenance in the oil and gas sector. Singh and Gupta [91] applied ISM–fuzzy MICMAC and TOPSIS to model interrelations among sustainable maintenance factors.

Recent research has also focused on the use of emerging digital tools to support sustainable maintenance. Rojek et al. [92] explored how digital twins can be applied across the product lifecycle to enhance maintenance planning and sustainability. Wu et al. [93] proposed a real-time, condition-based sustainable maintenance strategy using energy and performance data for milling processes. Patra and Dinesh Kumar [94] discussed opportunistic and delayed maintenance as tactical methods to optimize resource use and minimize disruptions, especially in constrained environments. Suresh and Dharunanand [95] identified key influencing factors for sustainable maintenance in manufacturing industries, including top management support, workforce competence, and regulatory pressure.

These contributions collectively demonstrate the broadening scope of sustainable maintenance, from environmental impact reduction to strategic integration of sustainability principles into decision-making, asset prioritization, and digitalization. However, they also reveal persisting challenges in harmonizing frameworks, metrics, and implementation tools across sectors and system scales.

In addition, recent surveys on sustainable maintenance problems are presented, e.g., in [31,32,33,35]. These prior works highlight the diversity of approaches and indicate that sustainable maintenance is not a single strategy but a multidimensional paradigm. Key issues include six main research areas investigated: green maintenance circular economy approach, energy efficiency, human-centered approach, life cycle assessment (LCA) principles implementation, and Industry 4.0 technologies. Additionally, regulatory and policy compliance ensures maintenance aligns with environmental regulations and corporate sustainability goals [96].

Among the emerging paradigms in sustainable maintenance, energy-based maintenance (EBM) has gained increasing scholarly attention as an integrative strategy linking maintenance practices with energy efficiency and sustainability goals. Unlike traditional predictive maintenance applied in energy systems [97,98], EBM explicitly focuses on energy consumption patterns as diagnostic indicators and bases maintenance decisions on energy-related metrics, such as power anomalies, energy efficiency trends, or energy-based availability of assets [99,100,101,102,103,104].

EBM is typically implemented through continuous monitoring of energy consumption, supported by smart metering infrastructure and advanced analytics. It enables the early detection of inefficiencies or degradation by correlating energy deviations with equipment health. This not only enhances equipment performance and reduces operational costs but also contributes to broader decarbonization and cleaner production objectives [105,106,107,108,109,110].

Recent studies have further advanced the EBM paradigm. For example, Orošnjak et al. [105,106,109] propose EBM as a step beyond predictive maintenance in achieving functional productiveness and cleaner production. Holmer et al. [104] introduce energy-based survival models for remaining useful life estimation, while Hoang et al. [102] apply EBM for decision support in manufacturing platforms. Moreover, researchers such as Erguido et al. [101] and Jiang et al. [103] integrate energy-efficiency considerations directly into opportunistic or condition-based maintenance policies. The strategic relevance of EBM has also been emphasized in sectors like wind farms [101], hydraulic machinery [106], PV plants [100], and conveyor systems [103].

As such, EBM reflects a paradigm shift from reliability-centric to energy-centric maintenance frameworks, combining operational performance with environmental responsibility. It aligns closely with the principles of Industry 5.0 by integrating AI-driven diagnostics, energy-aware modeling, and sustainability-centered decision-making.

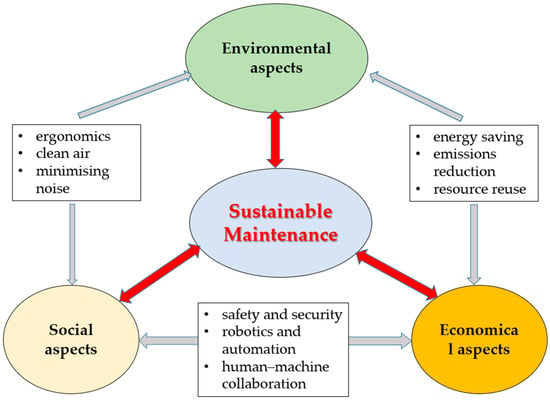

Figure 5 illustrates the conceptual framework of sustainable maintenance, structured around the three core pillars of the triple bottom line (TBL) [111]: environmental, economic, and social sustainability. The model highlights how maintenance practices can simultaneously contribute to ecological efficiency, economic performance, and social responsibility. In addition, Table 3 introduces the key indicators of sustainable maintenance under the TBL Framework.

Figure 5.

Conceptual model of sustainable maintenance integrating environmental, economic, and social dimensions within Industry 5.0. Source: own contribution based on [87,96,112].

Table 3.

Key indicators of sustainable maintenance under the triple bottom line (TBL) framework. Source: own contribution based on [111,113].

From an environmental standpoint, sustainable maintenance emphasizes minimizing ecological footprints through energy-efficient processes, life cycle-oriented spare part management, reduced material consumption, and the prevention of environmentally harmful failures. This includes the application of predictive and prescriptive analytics to optimize asset life cycles, using biodegradable lubricants or recyclable components, and the implementation of condition-based interventions that reduce unnecessary resource use [114]. Additionally, integrating digital technologies allows organizations to track environmental impacts in real time and align maintenance operations with broader sustainability reporting frameworks [32].

Economically, sustainable maintenance aims to reduce the total cost of ownership (TCO) by extending asset life, preventing costly breakdowns, and optimizing resource allocation [115]. Tools such as life cycle costing (LCC), risk-based maintenance, and AI-driven decision support systems contribute to achieving cost-efficient and performance-driven maintenance strategies. These tools also support better inventory management, spare parts logistics, and service contract optimization, directly linking maintenance actions with financial performance and asset management efficiency [116,117,118,119].

The social dimension of sustainable maintenance encompasses human well-being, ethical working conditions, and competence development. As outlined by the principles of Industry 5.0, sustainable maintenance recognizes the role of maintenance personnel as executors of tasks and critical knowledge holders and co-creators of intelligent systems. This involves promoting safety, ergonomics, transparency in decision-making, inclusion of workers in the design of smart maintenance tools, and lifelong learning opportunities. Worker-centric approaches, such as integrating augmented reality (AR) for task assistance or collaborative robots (cobots) in physically demanding tasks, also reduce physical and cognitive strain while enhancing job satisfaction and retention [120,121].

To better understand the distinguishing characteristics and underlying paradigms of evolving maintenance approaches, a comparative overview is presented in Table 4. This table contrasts the traditional, smart (Industry 4.0-based), and sustainable (Industry 5.0-aligned) maintenance models across key dimensions such as strategic focus, decision-making logic, enabling technologies, environmental and social considerations, and the role of human operators. By synthesizing the evolution from cost- and availability-driven strategies to those embedding broader values of sustainability and resilience, this comparative framework highlights how maintenance practices are progressively aligning with the principles of long-term value creation, ethical responsibility, and adaptive capability. The table serves as a conceptual bridge connecting technological transformation with the expanding expectations of industrial maintenance in the context of digitalization and socio-environmental responsibility.

Table 4.

Comparative overview of traditional, smart, and sustainable maintenance approaches. Source: own contribution based on [87,96,112].

Despite the growing interest in sustainable maintenance, recent literature highlights several challenges, including the lack of standardized indicators, fragmented data on environmental and social impacts, and limited integration of sustainability metrics in current maintenance management systems [111]. Multi-criteria decision-making (MCDM) methods (e.g., [112]), fuzzy logic-based evaluation models (e.g., [122]), and hybrid sustainability frameworks (e.g., [8]) are being proposed to overcome these barriers. These methods allow for aggregating qualitative and quantitative sustainability indicators and help organizations balance competing objectives across the triple bottom line (TBL).

In summary, sustainable maintenance is a multidimensional concept extending traditional maintenance boundaries toward broader sustainability goals. It operates at the intersection of ecological responsibility, economic efficiency, and social equity, thus aligning maintenance operations with the principles of Industry 5.0. The use of earlier systematic reviews in this field confirms the need for more integrative frameworks that connect sustainability, resilience, and AI-enabled maintenance management. In the following sections, the interconnections between sustainable maintenance, resilience engineering, and human-centric approaches are further examined, particularly in the context of AI-enabled decision-making and system adaptability. The interconnections between sustainable maintenance, resilience engineering, and human-centric approaches are further examined in subsequent sections, particularly in the context of AI-enabled decision-making and system adaptability.

2.4. Human-Centric Maintenance

As industrial systems evolve toward Industry 5.0, the human dimension becomes central to the design, implementation, and evaluation of advanced maintenance strategies [41]. Human-centric maintenance emphasizes the well-being, competence, and ethical inclusion of human operators in technologically advanced environments [20,123]. It acknowledges that while digital tools—such as AI, IoT, and cyber-physical systems—enhance decision-making and efficiency, they must support rather than replace human agency [124].

Moreover, socio-technical factors such as trust, explainability, and perceived control are critical for the successful implementation of AI-enabled resilience-based maintenance (RBM) strategies [125].

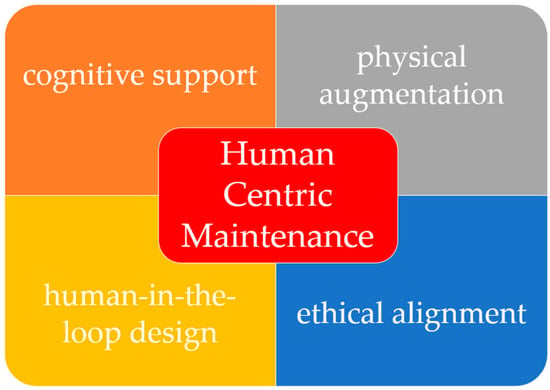

Figure 6 illustrates the key dimensions of human-centric maintenance, highlighting the interaction between cognitive support, physical augmentation, human-in-the-loop (HITL) design, and ethical alignment. This conceptualization places the operator at the core of intelligent maintenance systems, emphasizing transparency, adaptability, and shared control. To illustrate these dimensions in practice, Table 5 maps selected technologies—such as AR, VR, and AI decision tools—to their human-centered features, including ergonomic support, transparency, and cognitive assistance.

Figure 6.

Key Dimensions of human-centric maintenance. Source: own contribution based on: [20,126,127].

Table 5.

Human-centric elements in maintenance technologies. Source: own contribution based on [20,124,128].

Human-centric enablers often overlap with those used in RBM, such as AI, digital twins, machine learning, and knowledge graphs [4,14,26,29]. These technologies facilitate human–machine collaboration, maintain situational awareness, and support shared decision-making.

Recent studies have begun to explore these AI-driven capabilities within the RBM paradigm. The work of Kaewunruen et al. [129] highlights the potential of digital twins in enhancing resilience in railway maintenance, while studies by Ejjami & Khaoula [130] and Wiese [131] examine how AI-driven predictive maintenance can be used for improving the resilience of critical infrastructure and manufacturing systems. Additionally, the potential of AI in enhancing resilience across multiple domains is developed in [132].

This approach is closely linked to the Operator 4.0 concept, introduced by Romero et al. [133], which describes a set of human roles augmented by smart technologies in the context of smart factories. Within maintenance, Operator 4.0 may act as a super-strength operator (supported by exoskeletons), virtual operator (interacting through AR/VR), collaborative operator (working alongside robots or cobots), or analytical operator (supported by AI-based decision tools). These roles expand human capabilities while preserving the need for meaningful human participation, especially in decision-critical maintenance tasks.

A key principle of human-centric maintenance is human-in-the-loop (HITL) design. This involves embedding human operators into feedback loops within AI and automated maintenance systems, ensuring that human judgment can override, refine, or contextualize algorithmic decisions [134]. HITL is crucial for scenarios involving safety, ethical ambiguity, or uncertainty, where rigid automation might fall short. It also supports explainability, allowing users to understand how maintenance recommendations are generated and to trust AI systems accordingly [125,135]. The implementation of humans-in-the-loop in maintenance contexts is critically analyzed in works such as [136] and, more broadly, in production automation in [137].

Recent systematic literature reviews have highlighted the growing importance of this paradigm. For example, in [125], the authors focus on integrating AI with humans to enhance sustainability and customization in manufacturing. Human-centered AI issues are also reviewed in [138,139]. Another review by Verma [127] focused on human-centric and sustainable industrial revolutions in relation to the Industry 5.0 concept. It emphasizes that Industry 5.0’s human-centricity is not merely about user interfaces but a shift toward organizational culture, governance models, and participatory design. Similarly, the authors in [128,140] review human-centric smart manufacturing, emphasizing that the sustainability of human-centered systems and collaboration in hybrid environments will pose major challenges in future industrial systems. In addition, Pizon et al. [141] focus on the challenges of human-centered manufacturing, classifying them into four groups: social, technical, safety-related, and legal and ethical dimensions.

Furthermore, human-centric maintenance prioritizes ergonomics, safety, and worker satisfaction [142]. It calls for both efficient but physically and cognitively adaptive systems, reducing fatigue, preventing injuries, and minimizing stress caused by complex digital interfaces. This includes intuitive HMIs (human–machine interfaces), AR-assisted diagnostics, and digital twins that help visualize machine states in user-friendly formats [143,144]. In addition to ergonomic and cognitive considerations, human-centric maintenance must also address the evolving standards of worker safety in increasingly automated and AI-driven environments. As maintenance systems become more complex and autonomous, ensuring safety requires compliance not only with traditional occupational health and safety standards (e.g., ISO 45001 [145], IEC 61508 [146]), but also with emerging guidelines on AI governance and ethics, such as the ISO/IEC 42001:2023 [147] standard for AI management systems and the EU AI Act [148]. These frameworks aim to support the safe, transparent, and accountable deployment of AI technologies in industrial settings. However, current documentation and regulatory texts may be subject to ambiguous interpretations, especially in hybrid human–machine contexts [149]. This complexity poses a challenge for practitioners seeking to ensure compliance while adopting cutting-edge AI-based tools in maintenance.

As emphasized by Khurram et al. [149], aligning Maintenance 4.0 practices with human-centric values and safety standards requires an integrative approach that combines predictive technologies with explainability, fail-safes, and risk-aware system design. This includes embedding worker-safety protocols in autonomous operations and ensuring that decision-support systems enhance, rather than obscure, human oversight. As such, human-centric maintenance is inseparable from the broader regulatory ecosystem shaping the industrial application of AI. Recent reviews that summarize a human-centric approach in Industry 5.0 are, among others, [150,151].

Table 6 presents a comparative view of human-centric attributes across maintenance generations from Maintenance 1.0 to Maintenance 5.0, aiming to contextualize the evolving role of the human within maintenance practices. This idealized, strategic model illustrates the shift from reactive, physically demanding maintenance toward ethically integrated, cyber-physical systems that protect and empower workers within intelligent infrastructures. It is essential to recognize that the model is normative in nature—it does not depict the current state of industrial practice but rather outlines a desired trajectory. As such, it serves a forward-looking, strategic function: to support organizations in identifying development gaps, planning transformation pathways, and assessing their readiness to move toward higher levels of maturity in maintenance. In practice, however, progress toward Maintenance 5.0 is rarely linear and is often obstructed by organizational resistance, skill mismatches, trust issues surrounding AI, and high implementation costs. These challenges, captured in the “Transition Barriers” row, are consistent with broader findings in current literature and include not only socio-technical resistance, but also the regulatory uncertainty associated with interpreting and applying evolving AI and safety standards in practice. For instance, the European Commission [2] emphasizes that the success of Industry 5.0 hinges not only on technological readiness but also on managing social and ethical transitions, including workforce acceptance and the responsible deployment of AI technologies. Similarly, McKinsey & Company [152] highlights that many firms face deep-seated cultural and operational obstacles that require comprehensive change management strategies. Empirical studies echo these concerns, identifying a lack of trust, digital skill shortages, and resistance to change as critical barriers to transformation [153]. By framing the model as an inspirational planning tool, rather than a descriptive snapshot, it becomes a valuable aid for aligning strategic vision with actionable steps toward more human-centric and sustainable maintenance systems.

Table 6.

Human-centricity across maintenance generations (1.0–5.0). Source: own contribution based on [3,140].

In summary, human-centric maintenance provides the ethical and operational foundation for integrating AI into maintenance in a way that empowers people, enhances system adaptability, and supports the Industry 5.0 vision. It is inseparable from RBM and sustainability, forming a key pillar of Maintenance 5.0.

3. Review Methodology

3.1. Review Design and Protocol

This systematic literature review was conducted in accordance with the preferred reporting items for systematic reviews and meta-analyses (PRISMA 2020) guidelines [47,154], which provide a structured and transparent framework for reporting evidence-based reviews. Adopting this protocol ensures methodological rigor, transparency of reporting, and reproducibility of the search and selection processes, minimizing bias and improving the validity of findings.

The overarching aim of this review was to critically examine the evolution and current state of resilience-based maintenance (RBM) within the broader transition toward Maintenance 5.0. Particular attention was paid to integrating artificial intelligence (AI) technologies, human-centric and sustainable design principles, and their interplay with resilience engineering and maintenance strategy development. The review also identifies gaps, limitations, and future research directions by mapping existing studies to key theoretical domains and application areas.

This review does not limit the analysis to a particular sector, as the focus is on conceptual developments and methodological frameworks of RBM. Therefore, relevant studies from the infrastructure, manufacturing, and energy domains were included.

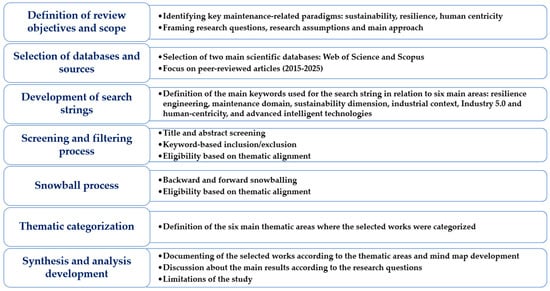

A structured review protocol was developed to guide the process in five main stages and was designed according to the principles given in [155,156,157,158]. These stages are illustrated in Figure 7, which presents the overall methodological framework used in this review:

Figure 7.

Research framework and methods/tools used for systematic literature review. Source: own contribution.

- Definition of research objectives and questions—establishing the scope of the evaluation, including the conceptual focus on RBM and its relation to other maintenance paradigms under Industry 5.0.

- Search strategy development—formulating a comprehensive query string and selecting relevant databases (Scopus, Web of Science).

- Screening and eligibility assessment—applying inclusion and exclusion criteria, removing duplicates, and performing title/abstract and full-text screenings,

- Supplementary search—using snowballing techniques (both backward and forward citation tracking) to enhance literature coverage.

- Data extraction, synthesis, and classification—analyzing and categorizing the final set of articles by themes, methods, application domains, and contributions.

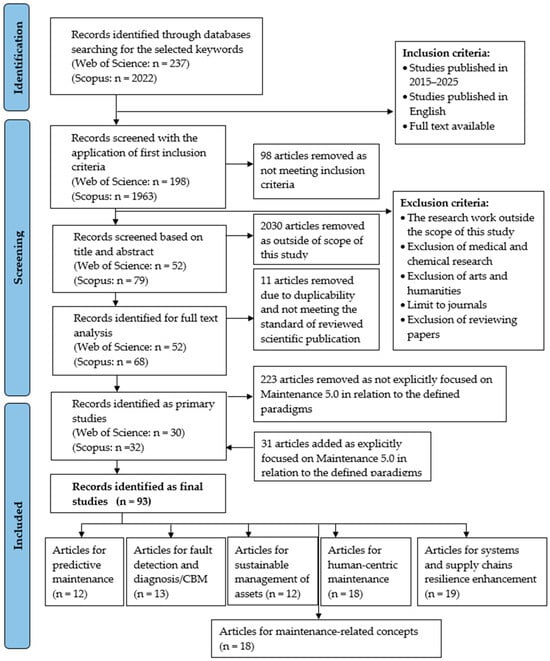

This five-step workflow enabled a focused and replicable identification of scholarly contributions relevant to RBM, emphasizing theoretical advancements and practical implementations. In subsequent sections, the detailed execution of each stage is described, and the search results are summarized using a PRISMA flow diagram (Figure 8). The PRISMA checklist is given in Table S1 in the Supplementary Material.

Figure 8.

PRISMA-based flowchart of systematically selecting relevant studies in the analyzed research area. Source: own contribution based on [47].

3.2. Identification—Search Strategy

The identification stage of this systematic literature review focused on capturing a broad yet thematically coherent set of publications relevant to the evolving field of resilience-based maintenance (RBM) within the context of Industry 5.0. The search strategy was designed to reflect the interdisciplinary nature of the subject, combining technical, organizational, and human-centric perspectives.

To ensure methodological transparency and relevance, the search process was carried out in two leading academic databases: Web of Science (WoS) and Scopus. These databases were selected due to their comprehensive indexing of high-impact, peer-reviewed publications across engineering, manufacturing, and management domains. The searches were conducted during the period from 1 June 2025 to 15 June 2025.

The selection of keywords and Boolean logic operators was based on an initial scoping review of the literature, during which representative papers from different disciplines (maintenance engineering, resilience theory, human factors, AI applications) were reviewed to identify recurring terms, concepts, and taxonomy. This preliminary phase ensured that the final query captured the diversity of terminologies used across academic communities while aligning with the conceptual focus of this study.

The final search string was organized around six major thematic blocks, using the ALL fields search mode:

- Resilience engineering: Resilience OR robustness OR adaptability OR recoverability,

- Maintenance domain: Maintenance OR upkeep OR repair OR service OR fault OR failure OR diagnostics OR diagnosis OR prognosis OR inspection OR monitoring,

- Sustainability dimension: Sustainable OR eco-friendly OR green OR environmental-friendly OR circular OR energy-efficient,

- Industrial context: Industrial systems OR manufacturing OR production OR operations OR industrial processes,

- Industry 5.0 and human-centricity: Industry 5.0 OR human-centric OR human-centered OR user-centered OR people-oriented OR social OR human factor OR human–machine interaction OR human-in-the-loop OR anthropocentric OR ergonomics,

- Advanced intelligent technologies: Artificial intelligence OR AI OR digital twin OR smart system OR intelligent system OR machine learning OR cyber-physical system OR IoT OR big data OR cloud computing OR edge computing OR augmented reality OR AR OR virtual reality OR VR OR blockchain.

Each term group was connected using the Boolean AND operator to ensure conceptual coherence across resilience, maintenance, sustainability, human-centric design, and smart technologies.

In Web of Science, this initial query returned 237 records. Applying a publication date filter (2015–2025) narrowed this number to 198. Review papers and non-original research documents were then excluded, yielding 174 articles. Subsequently, publications falling outside the technical and engineering scope (particularly in medicine and chemistry) were eliminated, leaving 174 (unchanged due to query refinement). A detailed relevance screening based on titles, abstracts, and keywords led to the selection of 52 articles for full-text review.

In Scopus, the initial search retrieved 2022 records, spanning publication years from 1963 to 2025. These were first limited to the 2015–2025 range and filtered by document type, excluding review papers, book chapters, and conference papers. This reduced the dataset to 827 documents. Further exclusions targeted irrelevant subject areas such as medicine, humanities, and the arts, leaving 762 articles. Additional filters were applied to ensure consistency: only English-language documents (755) published in peer-reviewed journals (706) were retained. Following the same screening process based on titles, abstracts, and keywords, 79 articles were deemed relevant for full-text analysis. After removing 11 duplicates across both databases, a final pool of 120 unique publications was established for in-depth evaluation.

3.3. Screening—Eligibility Criteria

The screening process consisted of two phases: (a) preliminary filtering based on metadata and (b) content-based eligibility assessment, conducted to ensure methodological rigor and thematic consistency.

In the preliminary phase, exclusion criteria were applied to eliminate documents that did not meet basic methodological or topical thresholds. Specifically, papers that were (1) not published in peer-reviewed journals, (2) not written in English, or (3) classified as review articles, conference papers, book chapters, or editorials were excluded. Subject area filters were also employed to discard articles unrelated to engineering, manufacturing, operations, or maintenance, most notably those focused on medical, biological, or chemical applications. To increase transparency and facilitate replicability, the inclusion and exclusion criteria applied during the screening process are summarized in Table 7.

Table 7.

Inclusion and exclusion criteria used in the screening process.

In the second phase, all remaining articles were evaluated for eligibility based on thematic relevance, using a set of predefined inclusion criteria. Publications were retained if they addressed one or more of the following topics:

- Resilience, robustness, adaptability, or recovery in the context of industrial maintenance,

- Integration of sustainable or circular principles into maintenance strategies,

- Human-centric approaches (e.g., human-in-the-loop, Operator 4.0, ergonomics) in industrial systems,

- Application of smart or intelligent technologies such as AI, digital twins, IoT, or cyber-physical systems in maintenance practices.

This phase relied on a detailed manual review of titles, abstracts, and keywords. The process was guided by a protocol aimed at maximizing both precision (removal of non-relevant articles) and recall (preservation of diverse but related studies).

Ultimately, 120 articles (after removing duplications) met all eligibility criteria and formed the basis for the subsequent synthesis and classification phases of the review.

3.4. Inclusion—Full-Text Review and Selection

The final step of the selection process involved a full-text review of the remaining articles, ensuring that each included study met the quality standards and contributed substantially to the review’s objectives.

A total of 120 records (68 from Scopus and 52 from Web of Science) were considered for full-text evaluation. After detailed reading and critical appraisal, approximately 62 publications were retained for qualitative synthesis. These studies provided a comprehensive representation of current trends, challenges, and future directions in resilience-based maintenance and related approaches under digital, sustainable, and human-centered paradigms.

The full-text review followed these detailed criteria:

- Relevance: Articles had to present explicit models, frameworks, case studies, or methodologies related to RBM, predictive maintenance, or sustainability in industrial systems.

- Methodological soundness: Publications were assessed for clarity of objectives, rigor in methodology, and robustness of results.

- Contribution to knowledge: Only articles that offered conceptual advances, empirical findings, or practical insights were included.

The evaluation was performed by two independent reviewers with expertise in the fields of maintenance engineering and system resilience. A collaborative spreadsheet was used to track decisions and notes, and any discrepancies were resolved through dialogue and reference to the study’s relevance criteria.

This multi-stage inclusion process ensured a rigorous and transparent selection of high-quality sources that formed the foundation for the subsequent synthesis and discussion. Additionally, although PRISMA guidelines recommend measuring interrater agreement to assess the consistency between reviewers, no formal interrater agreement score (e.g., Cohen’s kappa) was calculated in this review. The screening process was conducted jointly by two authors, who discussed and resolved inclusion decisions collaboratively. This approach, while transparent, may introduce potential subjectivity in the eligibility assessment.

3.5. Snowball Process—Final Selection

To complement the database-driven search strategy and to ensure the inclusion of relevant but potentially overlooked literature, the snowballing technique was employed as an additional retrieval method. This approach followed guidelines proposed by Wohlin [48] for systematic literature reviews in software and engineering domains, and it was executed in both backward and forward directions.

Backward snowballing involved screening the reference lists of all publications that were shortlisted after the full-text review stage (Section 3.4). Each cited work was evaluated for potential relevance to resilience-based maintenance (RBM), predictive or sustainable maintenance approaches, and applications within industrial contexts aligned with Industry 4.0 and 5.0 paradigms. If a referenced article met the previously established inclusion criteria (e.g., relevance, peer-reviewed status, methodological rigor), it was retrieved and subjected to the same screening and inclusion process.

Forward snowballing was conducted using Scopus citation tracking tools, which allowed for the identification of publications that had cited the initially selected core articles. This step was particularly useful for identifying emerging studies published after the core literature, including high-impact conceptual or empirical contributions to the development of RBM, AI-enhanced maintenance strategies, and the integration of human-centric or sustainable principles.

Through snowballing, an additional set of relevant articles was retrieved and considered for inclusion. While the majority of relevant literature was captured through the structured search queries in Scopus and WoS, snowballing added both depth and breadth to the review, uncovering niche studies and older seminal works frequently cited in contemporary research. Finally, 15 articles were selected for final review.

3.6. Documenting the SLR Study

This stage corresponds to steps 7, 8, and 9 of the systematic literature review (SLR) process and focuses on the documentation, analysis, and synthesis of the selected literature. Following the selection of eligible papers, a bibliometric analysis was conducted to gain deeper insight into the intellectual structure and thematic distribution of the field. Bibliometric methods, widely used in scientometric research, apply statistical and mathematical techniques to assess scientific activity and identify trends, influential contributors, institutional affiliations, and geographic distribution of research outputs.

In this study, bibliometric mapping and analysis were performed using VOSviewer (v. 1.6.18) [159] and Microsoft Excel (Professional Plus 2019). VOSviewer enables the construction and visualization of bibliometric networks, particularly focusing on co-authorship, keyword co-occurrence, citation relationships, and country-level collaboration [160]. These analyses helped identify dominant research clusters, recurring keywords (e.g., “resilience,” “predictive maintenance,” “Industry 5.0”), and key contributing countries and institutions. The keyword co-occurrence map and author collaboration network generated in VOSviewer are presented and discussed in Section 4.

The selected corpus of articles was further organized and managed using Mendeley reference management software [161], which facilitated both qualitative review and traceability. Each entry was tagged with metadata such as publication year, journal or conference source, research type (empirical, conceptual, review), and relevance to the key research themes outlined in Section 2.

Step 8 of the SLR process involved the content-based synthesis of findings in alignment with the review’s objectives and guiding questions. The synthesis process examined how the themes of resilience, AI integration, and sustainable maintenance were conceptualized and operationalized across various studies. These insights inform the thematic analysis presented in Section 4 and Section 5.

Finally, step 9 involved the reflection on limitations and the identification of future research directions. Limitations included a potential exclusion of relevant works not indexed in the selected databases or published in non-English languages, as well as the inherent subjectivity in interpreting conceptual overlap across domains such as resilience and predictive maintenance. These limitations and the derived future research avenues are critically discussed in Section 6.

4. Systematic Literature Review Results

This section includes the results of the conducted systematic review according to the defined research methodology (Figure 7). As a result, in the next subsections, bibliometric analysis and content-based analysis are presented.

4.1. Bibliometric Analysis

This section presents the quantitative and network-based characteristics of the selected literature to provide an overview of the scientific landscape in the field of resilience-based maintenance (RBM) within the broader context of Industry 5.0, which integrates sustainability, human-centricity, and intelligent technologies.

The bibliometric analysis was performed on a consolidated dataset of 93 unique articles, retrieved from the Scopus and Web of Science (WoS) databases, including snowball analysis and covering the publication period 2015–2025. The bibliographic data were exported in compatible formats and processed using VOSviewer (version 1.6.18), a specialized tool for constructing and visualizing bibliometric maps. The largest number of articles (19 papers) was in two of the defined areas: systems and supply chains resilience enhancement, and maintenance-related aspects. The number of analyzed publications in the other areas is as follows: human-centric maintenance—18 papers; fault detection and diagnostics/CBM—13 papers; predictive maintenance in Industry 4.0—12 publications; and sustainable management of assets and environmental impact—12 publications.

The analysis of the selected articles focused on the following dimensions:

- Publication dynamics and source distribution—to identify temporal patterns and the increasing attention toward RBM-related topics, as well as to examine the scientific outlets (journals and conference proceedings) in which these studies are most frequently published, thereby revealing the disciplinary focus and visibility of the field.

- Country-level collaboration—to examine the geographic spread and international cooperation in RBM research.

- Co-authorship networks—to explore collaboration patterns among authors and institutions.

- Co-occurrence of keywords—to identify thematic clusters, trends, and emerging research areas.

In particular, keyword co-occurrence analysis was used to visualize the conceptual structure of the field. The threshold was set to include terms appearing at least 1 time in the dataset, which resulted in a network of interconnected keywords grouped into several major clusters. These clusters reflect distinct yet interrelated themes such as Industry 4.0, Industry 5.0, resilience, predictive, and sustainability in industrial systems.

The network visualization maps generated using VOSviewer illustrate the relative importance of terms (node size), their co-occurrence strength (link thickness), and thematic proximity (color-coded clusters). The results provide an empirical foundation for interpreting the knowledge structure of RBM and its positioning within Maintenance 5.0 discourse.

The outputs of the conducted analysis are presented in Figure 9, Figure 10, Figure 11 and Figure 12.

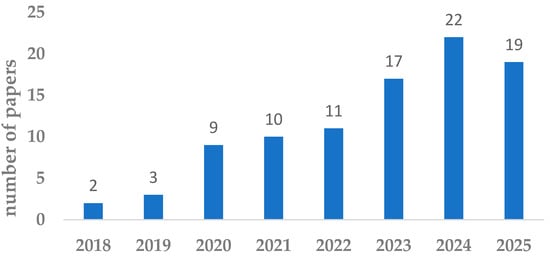

Figure 9.

Distribution of publications by year.

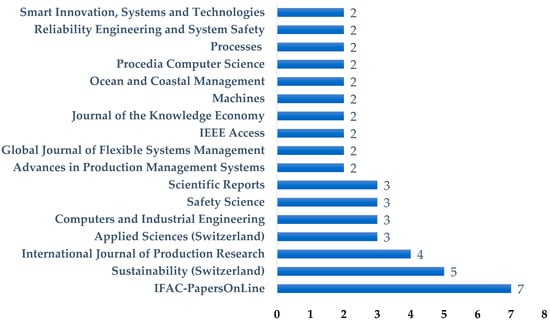

Figure 10.

Number of publications with journal sources (for journals with at least two published articles out of the 93 articles analyzed).

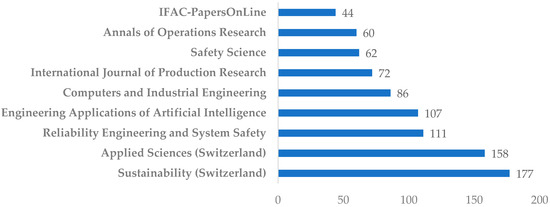

Figure 11.

The number of citations for the analyzed journals (top-cited journals from the dataset).

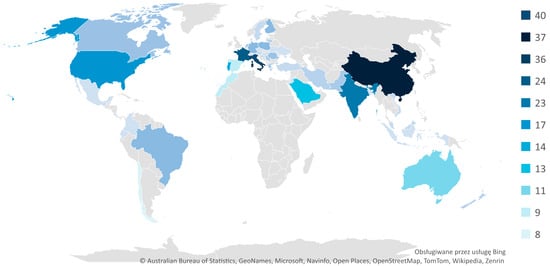

Figure 12.

The number of papers by the location where the investigated study took place.

First, the publication dynamics were investigated. In the conducted review, the authors selected 93 publications that were published between 2015 and 2025. Figure 9 illustrates the distribution of the publications according to their publication year. As we can see, the distribution of publications by year starts from 2018 and is slightly increasing year by year. This is connected with the fact that before 2018, the problem of Maintenance 4.0 in joint relation to resilience and sustainability had not been investigated at all. The first publications in this field were observed in 2018 and related to robustness in terms of resilience or sustainability. The highest number of publications falls within the period 2023–2025, with 58 publications accounting for 62% of all publications selected for analysis. On one hand, the observed trend is consistent with global research and innovation agendas, which have increasingly emphasized resilient, sustainable, and digital industrial systems. On the other hand, the formal introduction of the Industry 5.0 paradigm in 2021 by the European Commission has catalyzed a broader conceptual shift. Since then, greater attention has been directed toward integrating digitalization not only with resilience but also with sustainability and human-centricity.

This renewed focus has significantly influenced the maintenance domain, where traditional optimization-centered strategies are being re-evaluated in light of ethical, environmental, and social considerations. Consequently, scholarly contributions are now more likely to adopt interdisciplinary perspectives that combine artificial intelligence, circular economy principles, and human–machine collaboration, marking a paradigm shift toward Maintenance 5.0.

Moreover, the analyzed articles were published across 55 different journals, reflecting the wide-ranging and interdisciplinary nature of the research on resilience-based maintenance (RBM) within the broader framework of Industry 5.0. Figure 10 illustrates the distribution of journals that included at least two publications relevant to the topic.

In total, 48 articles from 17 journals met this criterion and were considered in the source distribution analysis. The dataset included both journal articles and peer-reviewed conference proceedings, with IFAC-PapersOnLine, a leading venue for automation and control research, being the most represented source.

Among the sources, IFAC-PapersOnLine emerged as the most frequent publication outlet, contributing seven articles to the selected corpus. The journal Sustainability (Switzerland) ranked second with five publications, followed by the International Journal of Production Research with four articles. Additionally, Applied Sciences, Computers and Industrial Engineering, Safety Science, and Scientific Reports each contributed three publications, indicating a consistent, albeit dispersed, interest across various fields.

This broad distribution of publication venues confirms the interdisciplinary character of the field, bridging areas such as industrial engineering, production management, artificial intelligence, safety science, and sustainability. The prominence of IFAC-PapersOnLine underlines the relevance of the topic within automation and control systems communities, while the presence of journals like Sustainability and Scientific Reports suggests an increasing emphasis on the integration of environmental and societal dimensions into maintenance research.

Such dispersion also implies that research on RBM is still emerging and expanding, not yet consolidated around a small number of flagship journals. This may offer opportunities for wider dissemination, but also indicates the need for more focused publication channels as the field matures.

To assess the scientific influence of the reviewed publications, citation metrics were calculated using Scopus citation counts. Among journals with at least three publications in the selected corpus, Sustainability and the International Journal of Production Research (IJPR) stood out in terms of citation performance.

For articles published in Sustainability that have received at least 10 citations, the average citation count was 21.3 citations per article, with a median of 19. In comparison, articles published in IJPR achieved an average of 26.8 citations, with a median of 23. These figures indicate that research on resilience-based maintenance (RBM), particularly when linked to sustainability and production systems, is gaining substantial visibility and scholarly traction. Figure 11 presents the most cited journals from the dataset. Number of citations per selected papers according to Scopus database (papers with minimum 1 citation) is presented in Appendix A.2, Table A2.

The citation performance reflects both the growing relevance of RBM in the context of Industry 5.0 and the role of these journals as preferred publication venues for interdisciplinary studies at the intersection of AI, resilience engineering, and maintenance strategy.

As part of the bibliometric analysis, the geographical origin of the selected publications was examined to understand the global distribution and intensity of research activity related to resilience-based maintenance (RBM) in the context of Industry 5.0. The results show a wide international interest in this emerging area, with contributions from 45 countries across six continents.

Europe is the most prominent region, accounting for approximately 54% of all analyzed publications (175 documents), followed by Asia with 24% (77 publications), and Africa with a notable 9% (28 publications). The remaining contributions are from North and South America (22 and 20 publications, respectively), and Australia/Oceania, which together represent a smaller but still relevant share (14 publications).

At the country level, the top contributors are Italy (40 publications), China (37), and the United Kingdom (36), followed by France (24) and India (23). The United States, often leading in digital innovation, appears with a moderate contribution of 17 publications. Other countries with visible activity include Portugal (14), Saudi Arabia (13), Australia (11), Spain (9), and Morocco (9). Notably, countries such as Germany, Poland, Finland, and Brazil each contributed seven articles, reflecting a balanced representation between highly industrialized nations and those undergoing digital transformation.

This distribution reflects the growing relevance of RBM not only in traditional centers of technological advancement but also in emerging economies and regions where industrial resilience and sustainable practices are becoming increasingly important. The presence of countries such as Morocco, Pakistan, and Romania demonstrates the expanding global engagement with Industry 5.0 principles and maintenance modernization.

From a regional perspective, Europe’s leadership in publication volume may be attributed to its strong policy emphasis on sustainable development, digitalization, and human-centric technologies, as reflected in EU-level initiatives supporting Industry 5.0 research. Asia’s significant share, with major contributions from China and India, indicates the region’s rapid technological adoption and increasing interest in resilience-based strategies across sectors. Africa’s representation, unusually high compared to other technical domains, may point to growing awareness of infrastructure sustainability and capacity-building in critical industries.

Figure 12 presents the distribution of RBM-related publications across the top contributing countries and their relative publication output.

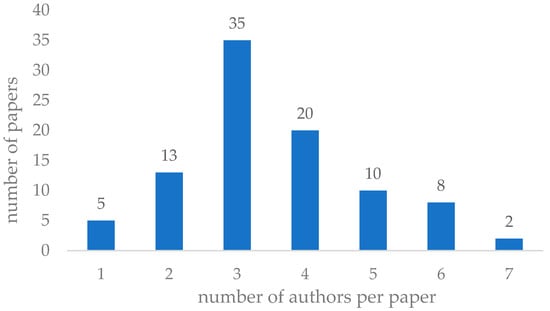

To complement the bibliometric exploration, co-authorship patterns were examined. In total, the dataset included 93 articles, co-authored by a diverse pool of researchers. The number of authors per article was analyzed to identify collaboration intensity. As shown in Figure 13, the most common authorship model includes three authors (35 articles), followed by four (20 articles) and two (13 articles). Notably, single-author contributions were relatively rare (5 articles), suggesting a high degree of collaborative research in the analyzed field. In addition, articles with larger teams (six or more authors) represented only 10.7% of the total sample (10 articles), indicating that although collaboration is prevalent, extensive multi-author projects are less frequent in the RBM and Maintenance 5.0 literature.

Figure 13.

Distribution of publications per number of authors.

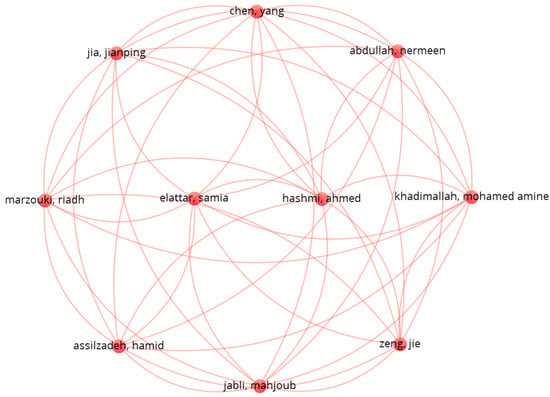

In the next step, a co-authorship network was constructed using VOSviewer to identify the most collaborative researchers within the dataset.

The top 15 authors by total link strength and number of joint publications were extracted. The analysis reveals that collaboration networks are predominantly localized within country-specific clusters (e.g., Italy, China, India), with emerging transnational links in European-funded or interdisciplinary studies.

In order to supplement the conducted analysis, a co-occurrence of authors was investigated using VOSviewer software and Excel software. A total of 328 authors were identified from the selected papers. Figure 14 shows the results for the top 10 authors with the highest number of co-authorship connections. The authors presented in this cluster have the largest total link strength (9).

Figure 14.

The largest set of connected items based on co-authorship links. Source: own development using VOSviewer software [159].

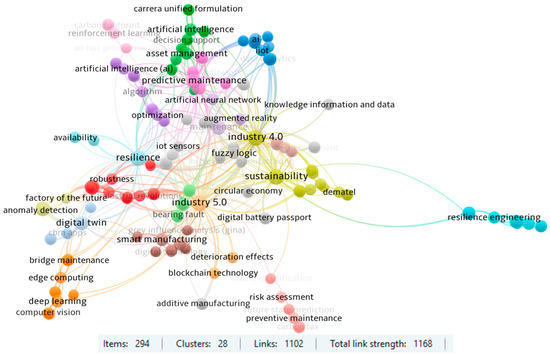

The final part of the bibliometric investigation was dedicated to keyword co-occurrence analysis based on author-provided keywords, using VOSviewer software. In total, 294 unique keywords were identified across the analyzed publications, forming 28 distinct clusters. These clusters were connected through 1102 co-occurrence links with a total link strength of 1168, reflecting a dense and multidimensional thematic structure (Figure 15).

Figure 15.

Mapping of the keywords that have occurred in the selected publications at least once. Source: own development using VOSviewer software [159].

The most frequently used terms included Industry 5.0 (80 links), Industry 4.0 (75), resilience (72), sustainability (66), predictive maintenance (48), and machine learning (43). These keywords clearly reflect the prevailing focus areas within the field, indicating a strong alignment between human-centric innovation, advanced digital technologies, and proactive maintenance strategies.

The largest cluster (red one, 20 items) is centered around the role of human capital and cyber-physical integration in the context of Industry 5.0. It emphasizes the transformation of maintenance systems through technologies such as automation, collaborative robotics (cobots), and advanced cyber-physical systems, supporting human–machine cooperation. The second largest cluster (green one, 19 items) pertains to asset management supported by artificial intelligence, reflecting a growing emphasis on intelligent decision support systems in resilient maintenance frameworks. The third cluster (light blue, 18 items) encompasses terms related to the integration of AI, IoT, and data analytics into predictive maintenance, which form the foundation of many Industry 4.0-driven solutions.

Another important thematic area (yellow cluster, 18 items) highlights sustainability and environmental considerations, emphasizing issues such as circular economy, energy efficiency, and eco-friendly maintenance practices. This is complemented by a fifth cluster (magenta, 17 items) focused on optimization and decision-making, particularly in AI-enabled industrial systems. Equally significant is the sixth cluster (cyan, 17 items), which addresses resilience engineering and risk management, underlining the role of proactive strategies to enhance system reliability under uncertainty. The seventh major cluster (orange, 17 items) shifts attention toward human factors, highlighting topics such as ergonomics, deep learning, and computer vision, especially in the context of monitoring and supporting operator performance.

The remaining clusters, each comprising between three and sixteen keywords, reflect niche areas such as digital twins, maintenance optimization, reliability analysis, and the implementation of circular economy principles. Together, these findings present a comprehensive overview of how research in resilience-based and sustainable maintenance is structured around interconnected yet distinguishable thematic pillars, offering insights into the future directions of the field.

The presented bibliometric investigation enhances understanding of how RBM research has evolved and which directions are emerging, while also supporting the formulation of content-based insights discussed in Section 4.2.

4.2. Content-Based Analysis

As a result of the conducted research, following the methodology adopted (Figure 7), we focus on the content-based analysis.

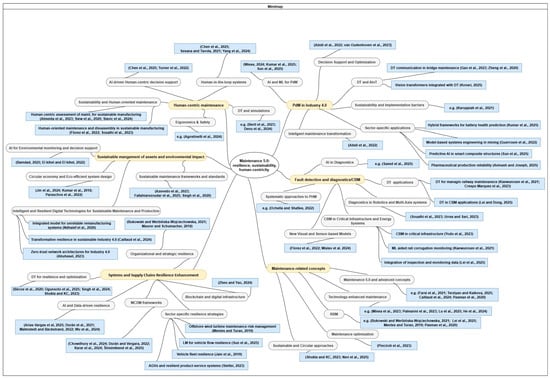

The identification of the main problems and issues raised in the context of Maintenance 5.0 was based on an extensive review of the available literature. As a result of the research carried out, six core research areas were defined, which have been most extensively developed over the last twenty years (Figure 16).

Figure 16.

Mind map presenting the six major thematic areas of resilience-based maintenance (RBM) in the context of Industry 4.0 and 5.0, including key research topics and associated publications. Source: own contribution with the use of the draw.io app.

A significant body of literature within the reviewed sample contributes to the thematic area of Predictive Maintenance in Industry 4.0, revealing a multidimensional and technologically rich research stream. These studies collectively emphasize the integration of artificial intelligence, machine learning, Internet of Things (IoT), and digital twin technologies to support advanced, data-driven maintenance strategies. Many works in this cluster highlight the transition from traditional condition-based monitoring toward more intelligent, predictive, and even proactive maintenance frameworks. For instance, the development of hybrid learning models for lithium-ion batteries [162], integration of predictive algorithms in composite smart structures [163], and the use of model-based systems engineering in mining maintenance [164] illustrate the sector-specific implementations of such approaches.

Moreover, publications increasingly link predictive maintenance to Industry 5.0 principles, such as human-centricity and system adaptability. For example, vision transformers integrated with digital twins are explored in the context of human-in-the-loop maintenance systems [165], while behavioral aspects of predictive maintenance are examined through a work system lens [20]. The role of AIoT communication and digital twin synchronization, as well as IoT, is illustrated in bridge maintenance applications [166,167], while resilient pharmaceutical manufacturing is addressed through digital twin-driven strategies in uncertain environments [168].

Further contributions include conceptual frameworks and applied models that leverage predictive maintenance in the context of Industry 4.0. These range from general strategic models [131,169] to scenario-specific approaches focusing on sustainability [170] and resilience-driven methodologies [171]. Together, this group of publications reflects a research trend toward predictive maintenance as a foundational element of digital transformation in industrial systems, aligning operational goals with sustainability, resilience, and human–system collaboration.