A Novel Method for Localizing PD Source in Power Transformer: Considering NLOS Propagation of Electromagnetic Waves

Abstract

1. Introduction

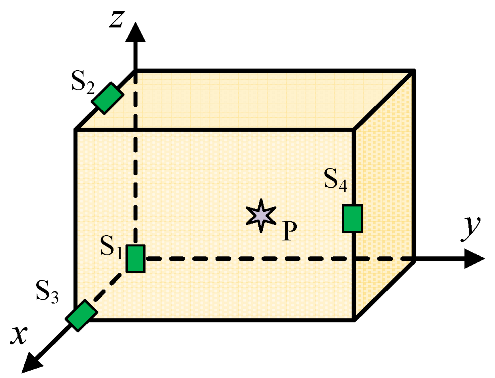

2. Localization Model of Transformer Partial Discharge Source

2.1. Mathematical Model

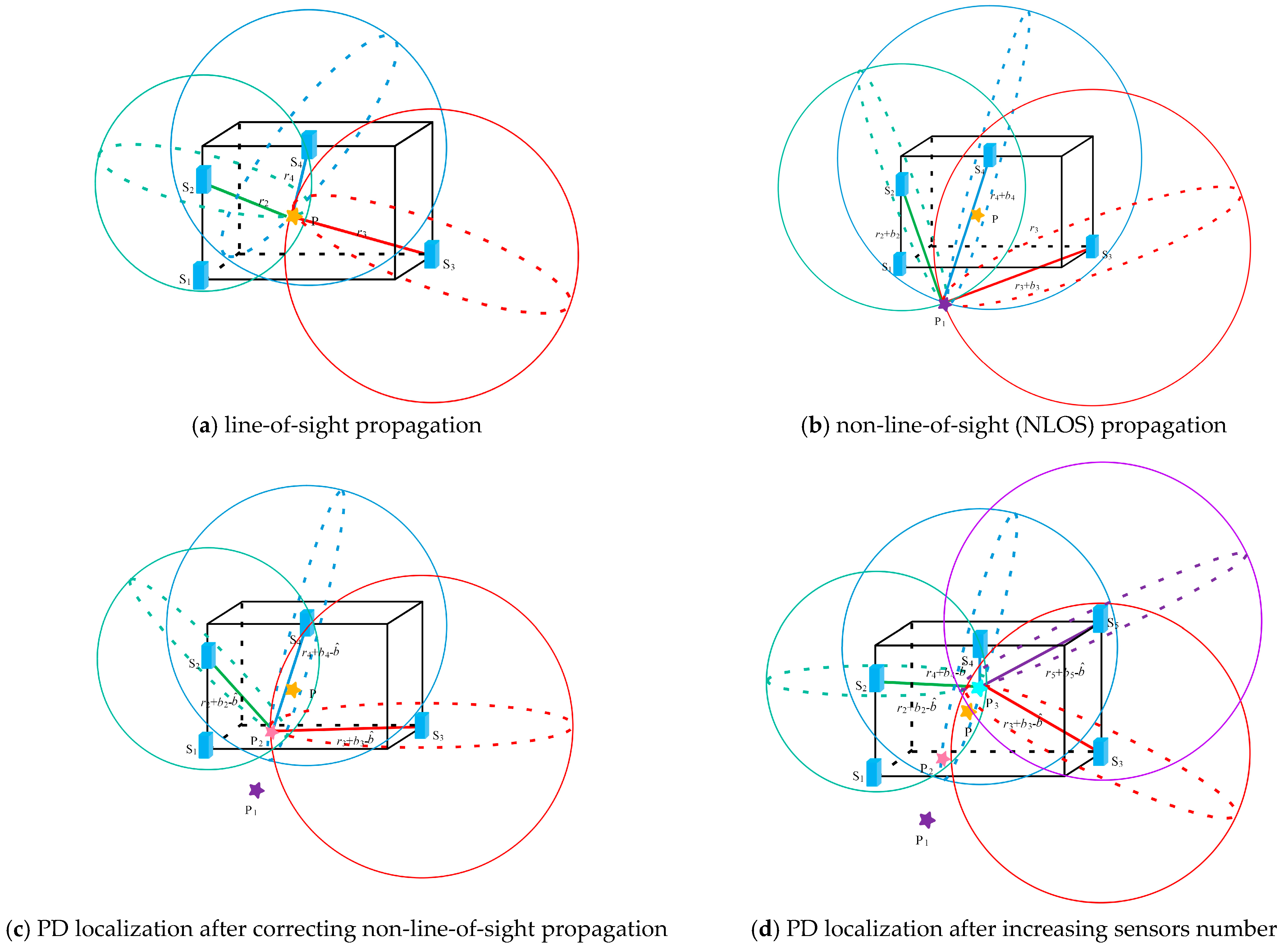

2.2. Geometrical Model

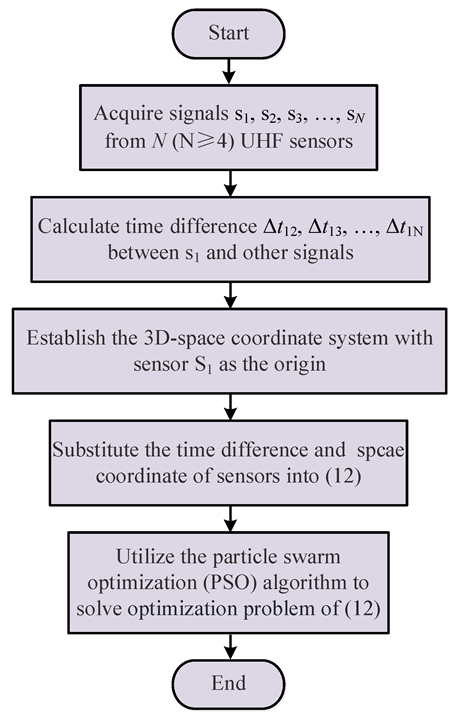

2.3. Localization Process of PD Source

3. Experimental Study on Factors Influencing Localization Accuracy

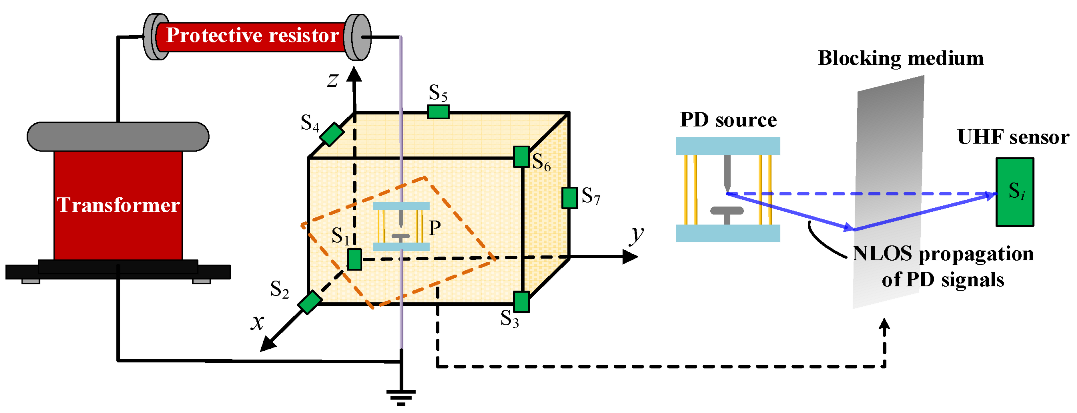

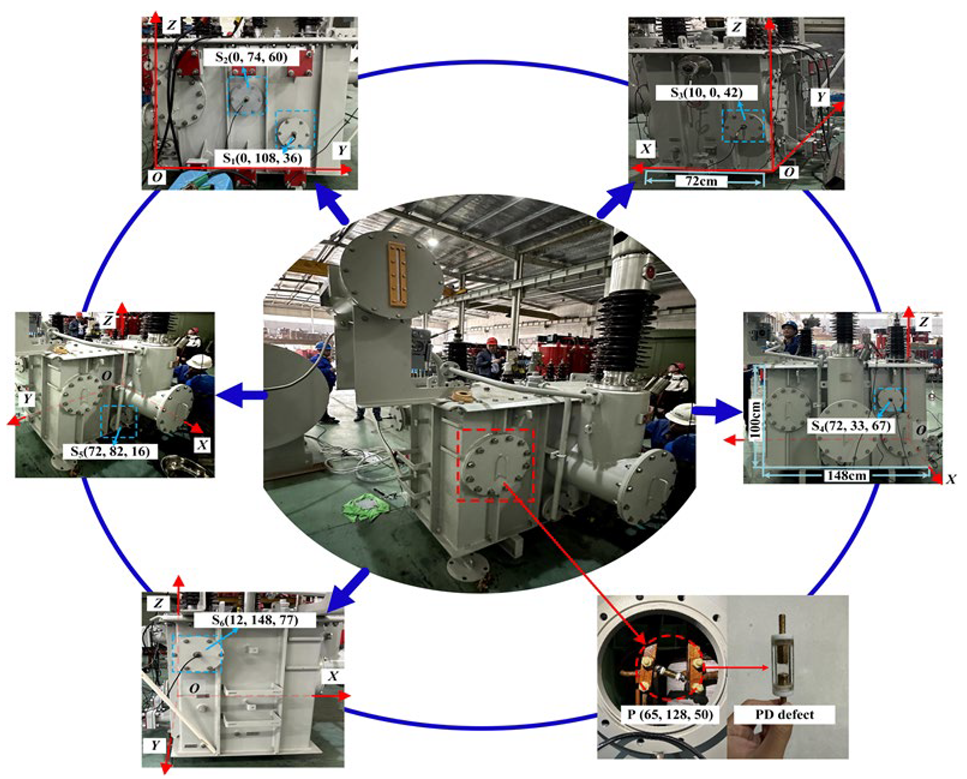

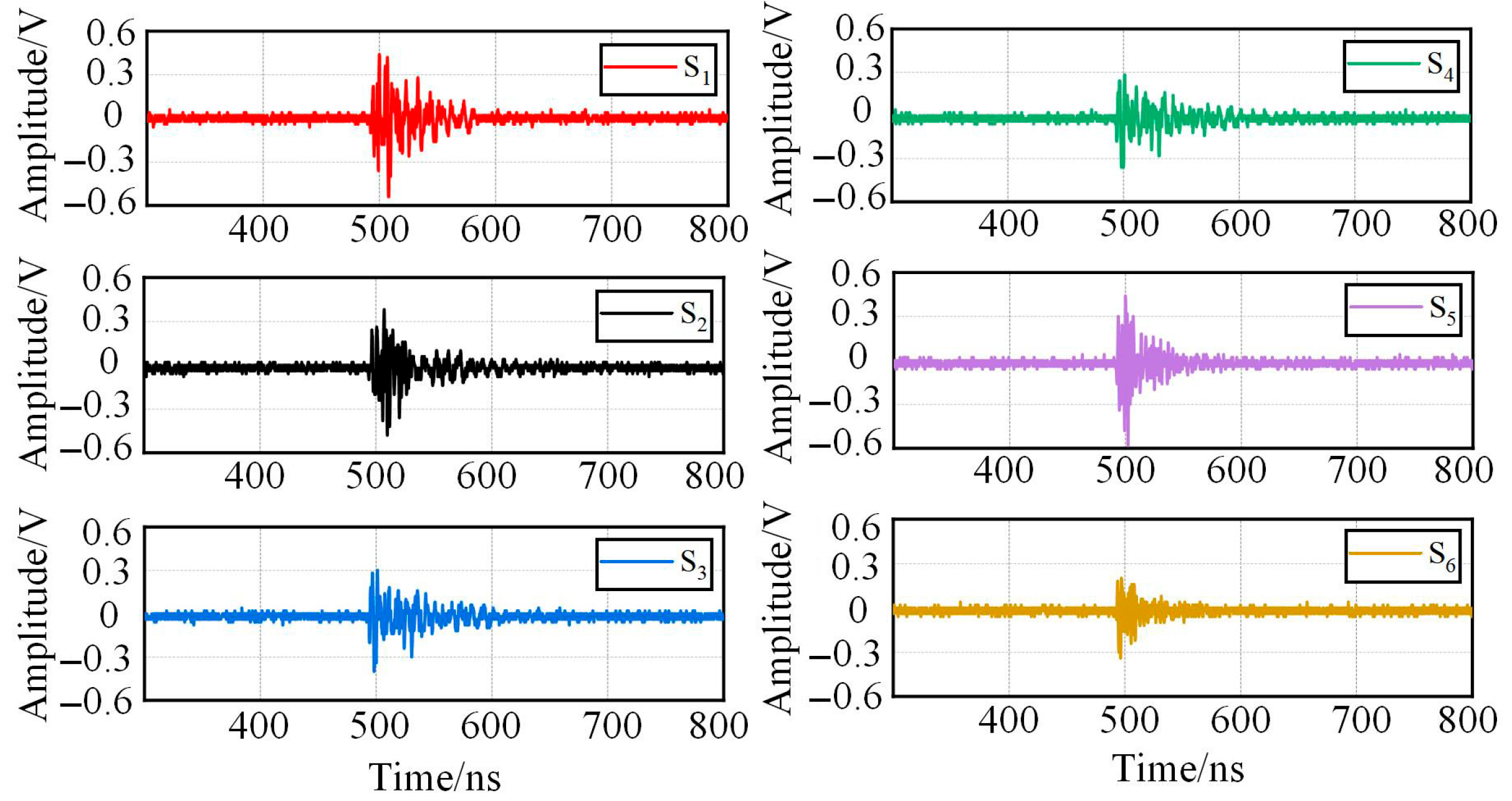

3.1. Experimental Platform

3.2. The Effect of NLOS Propagation of UHF Signals on Localization Accuracy

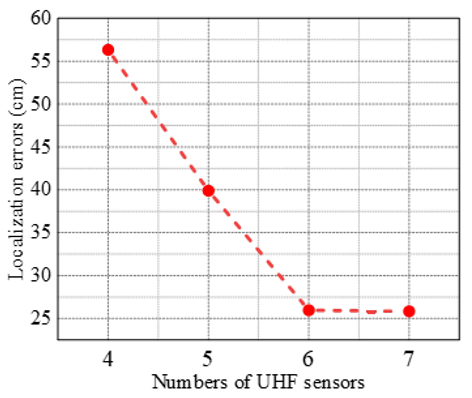

3.3. The Effect of the Number of Sensors on the Localization Accuracy of the NLOS Path Correction Method

4. Experimental Verification and Results

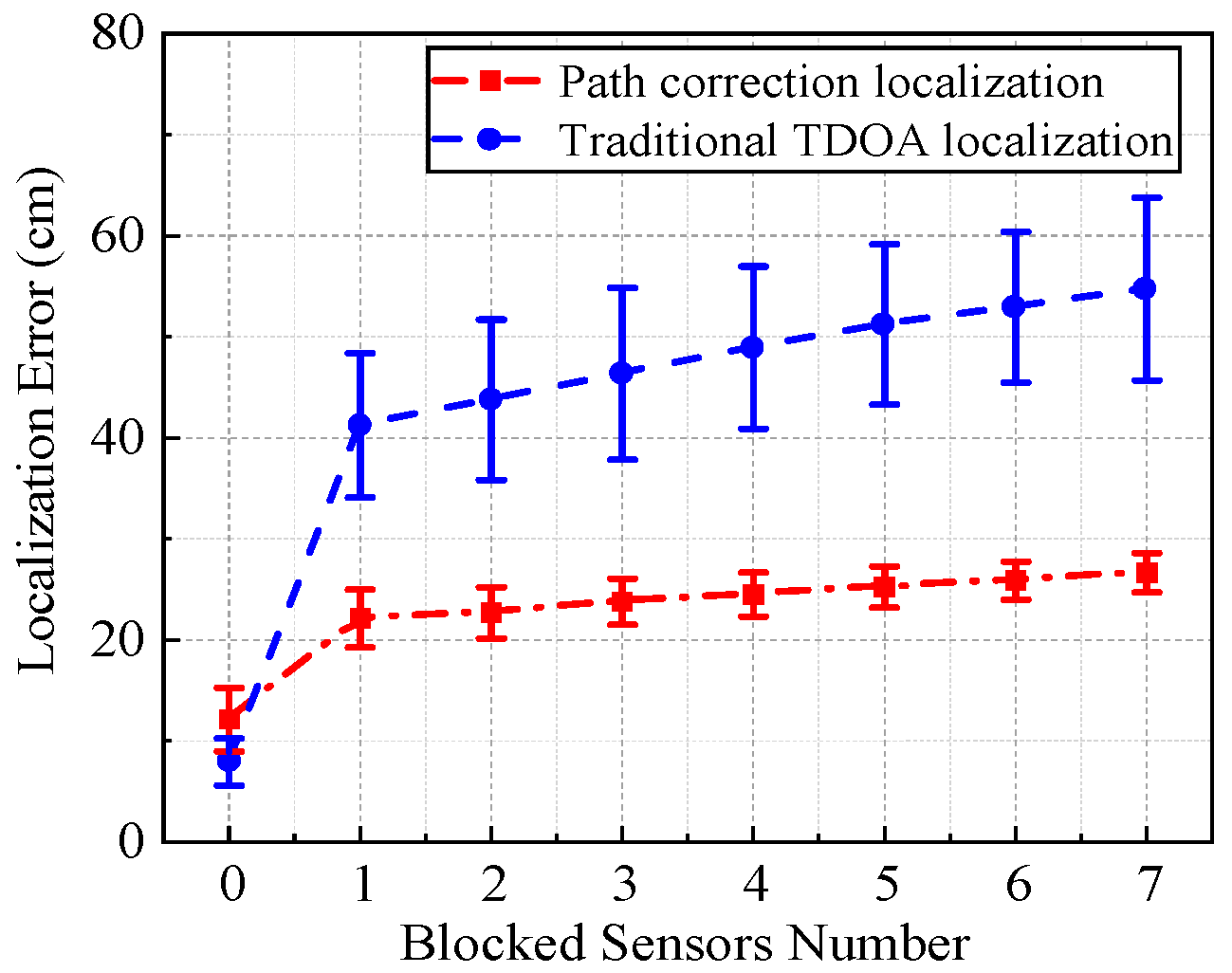

4.1. Comparison Between the Traditional TDOA Method

4.2. Influence of the Sensors’ Number on Calculated Accuracy of the Proposed NLOS Path Correction Method

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.; Han, X.; Liu, Z.; Yao, X. A novel GIS partial discharge detection sensor with integrated optical and UHF methods. IEEE Trans. Power Deliv. 2016, 33, 2047–2049. [Google Scholar] [CrossRef]

- Thiviyanathan, V.A.; Ker, P.J.; Leong, Y.S.; Abdullah, F.; Ismail, A.; Jamaludin, M.Z. Power transformer insulation system: A review on the reactions, fault detection, challenges and future prospects. Alex. Eng. J. 2022, 61, 7697–7713. [Google Scholar] [CrossRef]

- Zhou, L.; Bai, L.; Zhang, J.; Cao, W.; Xiang, E. Measurement and diagnosis of PD characteristics of industrial cable terminations in extreme cold environment. IEEE Trans. Instrum. Meas. 2020, 70, 1500211. [Google Scholar] [CrossRef]

- Shahsavarian, T.; Pan, Y.; Zhang, Z.; Pan, C.; Naderiallaf, H.; Guo, J.; Li, C.; Cao, Y. A review of knowledge-based defect identification via PRPD patterns in high voltage apparatus. IEEE Access 2021, 9, 77705–77728. [Google Scholar] [CrossRef]

- Siegel, M.; Beltle, M.; Tenbohlen, S.; Coenen, S. Application of UHF sensors for PD measurement at power transformers. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 331–339. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, J.; Li, J.; Yang, X.; Bie, Y.; Ranjan, P. Partial discharge detection and diagnosis of transformer bushing based on UHF method. IEEE Sens. J. 2021, 21, 16798–16806. [Google Scholar] [CrossRef]

- Jangjoo, M.A.; Allahbakhshi, M.; Mirzaei, H.R. UHF sensors positioning on the power transformer tank to enhance the partial discharge localization accuracy. Electr. Power Syst. Res. 2023, 218, 109174. [Google Scholar] [CrossRef]

- Dhara, S.; Koley, C.; Chakravorti, S. UHF Sensors Based Localization of Partial Discharge Sources in Air-Insulated Electrical Substation Using TDOA and Relative RSS Information. IEEE Trans. Instrum. Meas. 2023, 72, 3509909. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, W.; Wu, K.; Liu, H.; Chen, X.; Jiang, T. Novel approach for partial discharge localization based on fiber-optic F–P sensing array and modified TDOA in a 110-kV transformer. IEEE Trans. Instrum. Meas. 2024, 73, 9517711. [Google Scholar] [CrossRef]

- Xavier, G.V.; de Oliveira, A.C.; Silva, A.D.; Nobrega, L.A.; da Costa, E.G.; Serres, A.J. Application of time difference of arrival methods in the localization of partial discharge sources detected using bio-inspired UHF sensors. IEEE Sens. J. 2020, 21, 1947–1956. [Google Scholar] [CrossRef]

- Xue, N.; Yang, J.; Shen, D.; Xu, P.; Yang, K.; Zhuo, Z.; Zhang, L.; Zhang, J. The location of partial discharge sources inside power transformers based on TDOA database with UHF sensors. IEEE Access 2019, 7, 146732–146744. [Google Scholar] [CrossRef]

- Jangjoo, M.A.; Allahbakhshi, M.; Mirzaei, H.R. Ultra-high frequency sensors positioning on the power transformer to mitigate the negative effects on the partial discharge localization accuracy. IET Gener. Transm. Distrib. 2024, 18, 585–595. [Google Scholar] [CrossRef]

- Gao, Y.; Shen, Y.; Xia, F.; Jiang, H.; Zhou, Y.; Liu, D. GIS partial discharge signal monitoring device and localization method based on UHF sensor. J. Electr. Eng. 2022, 17, 244–250. (In Chinese) [Google Scholar]

- Du, J.; Chen, W.; Cui, L.; Zhang, Z.; Tenbohlen, S. Investigation on the propagation characteristics of PD-induced electromagnetic waves in an actual 110 kV power transformer and its simulation results. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1941–1948. [Google Scholar] [CrossRef]

- Jia, J.; Hu, C.; Yang, Q.; Lu, Y.; Wang, B.; Zhao, H. Localization of partial discharge in electrical transformer considering multimedia refraction and diffraction. IEEE Trans. Ind. Inform. 2020, 17, 5260–5269. [Google Scholar] [CrossRef]

- Su, Z.; Shao, G.; Liu, H. A soft-minimum method for NLOS error mitigation in TOA systems. In Proceedings of the 2016 IEEE 84th Vehicular Technology Conference (VTC-Fall), Montreal, QC, Canada, 18–21 September 2016; pp. 1–4. [Google Scholar]

- Deb, K. An efficient constraint handling method for genetic algorithms. Comput. Methods Appl. Mech. Eng. 2000, 186, 311–338. [Google Scholar] [CrossRef]

- Tang, J.; Xie, Y. Partial discharge location based on time difference of energy accumulation curve of multiple signals. IET Electr. Power Appl. 2011, 5, 175–180. [Google Scholar] [CrossRef]

- Judd, M.; Farish, O.; Hampton, B. The excitation of UHF signals by partial discharges in GIS. IEEE Trans. Dielectr. Electr. Insul. 1996, 3, 213–228. [Google Scholar] [CrossRef]

- Schiewaldt, K.; de Castro, B.A.; Ardila-Rey, J.A.; Franchin, M.N.; Andreoli, A.L.; Tenbohlen, S. Assessment of UHF Frequency Range for Failure Classification in Power Transformers. Sensors 2024, 24, 5056. [Google Scholar] [CrossRef] [PubMed]

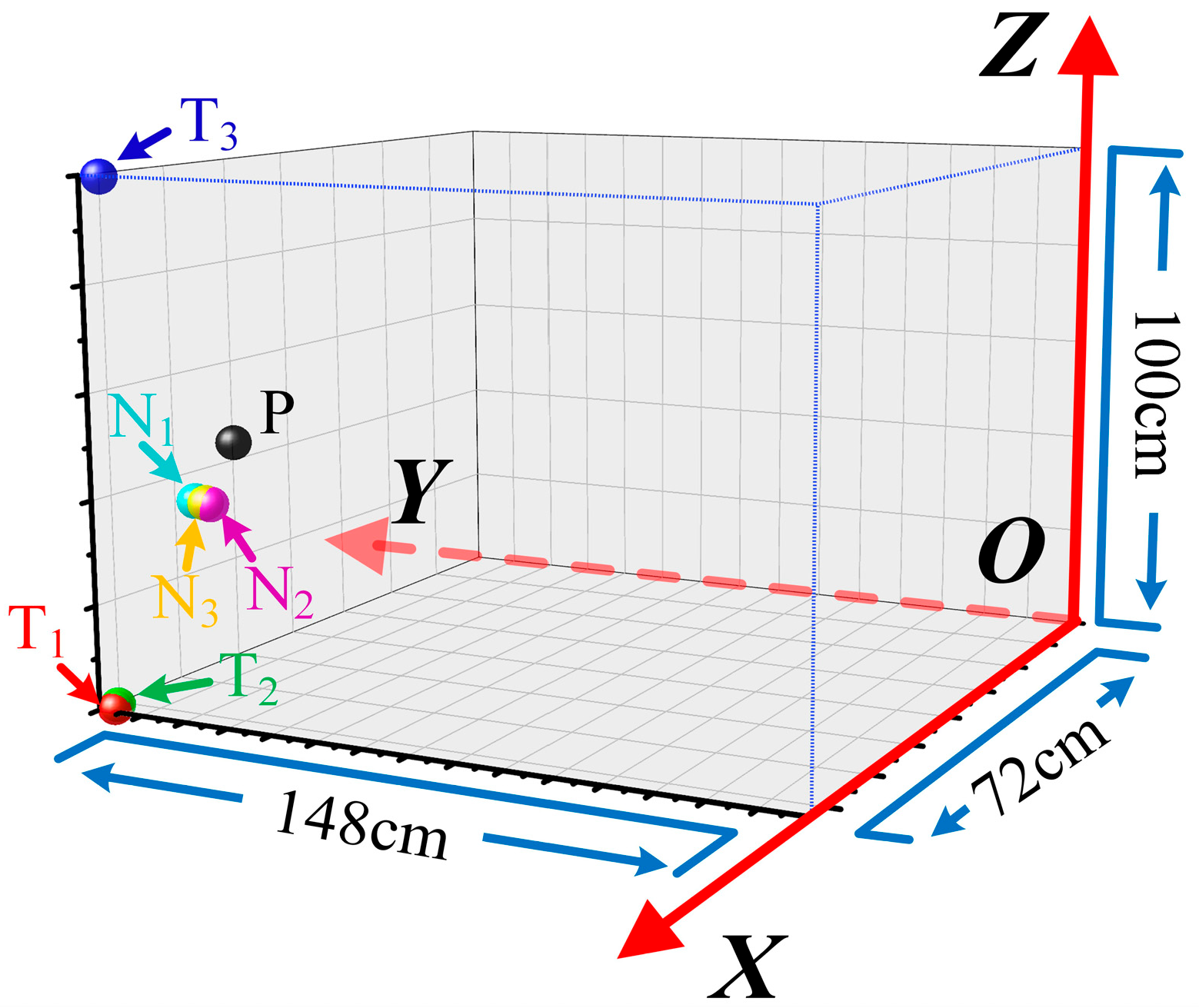

| No. | Traditional TDOA Method | NLOS Path Correction Method |

|---|---|---|

| Experiment 1 | Localization result (cm): T1 (71.91, 147.90, 0.09) Calculated error (cm): 54.17 | Localization result (cm): N1 (71.58, 127.69, 41.34) Calculated error: 10.88 |

| Experiment 2 | Localization result (cm): T2 (71.50, 148.00, 0.44) Calculated error (cm): 53.83 | Localization result (cm): N2 (71.91, 123.70, 41.17) Calculated error (cm): 12.01 |

| Experiment 3 | Localization result (cm): T3 (71.20, 148.00, 99.58) Calculated error (cm): 53.82 | Localization result (cm): N3 (72.00, 124.77, 41.40) Calculated error (cm): 11.54 |

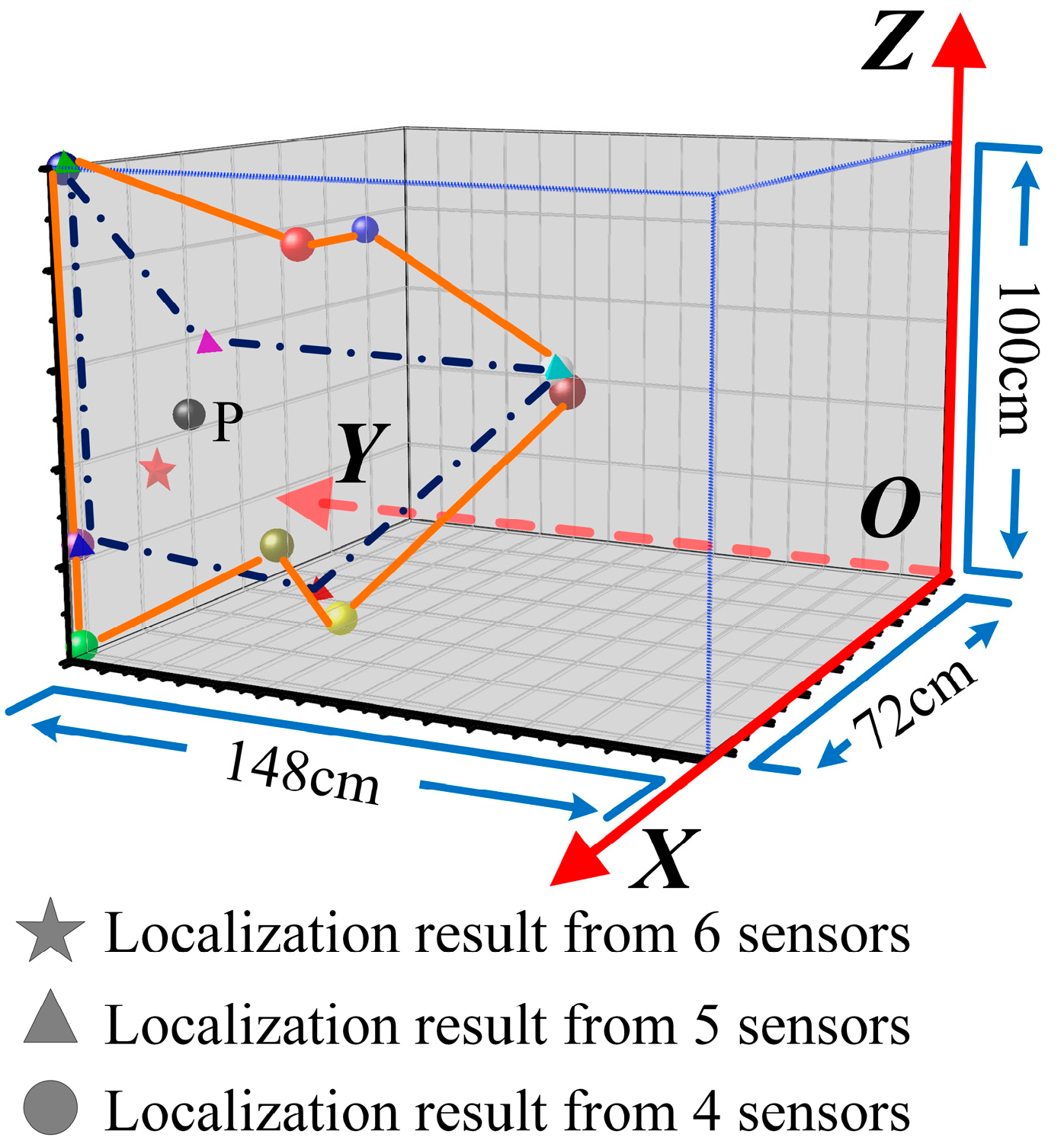

| Sensor Number | The Sensors Participating in Calculations | Localization Result (cm) | Calculation Error (cm) | Average Error (cm) |

|---|---|---|---|---|

| 4 | S1, S2, S3, S4 | (72.00, 90.38, 87.51) | 53.58 | 60.60 |

| S1, S2, S3, S5 | (72.00, 148.00, 2.68) | 51.85 | ||

| S1, S2, S3, S6 | (12.00, 148.00, 77.00) | 62.75 | ||

| S1, S2, S4, S5 | (72.00, 33.00, 67.00) | 96.76 | ||

| S1, S2, S4, S6 | (72.00, 33.00, 67.00) | 96.76 | ||

| S1, S2, S5, S6 | (72.00, 82.00, 16.00) | 57.63 | ||

| S1, S3, S4, S5 | (72.00, 28.87, 96.99) | 38.17 | ||

| S1, S3, S4, S6 | (72.00, 148.00, 100.00) | 54.30 | ||

| S1, S3, S5, S6 | (72.00, 148.00, 23.89) | 33.62 | ||

| S1, S4, S5, S6 | (72.00, 30.66, 63.74) | 98.55 | ||

| 5 | S1, S2, S3, S4, S5 | (72.00, 87.63 20.34) | 50.58 | 51.68 |

| S1, S2, S3, S4, S6 | (72.00, 148.00, 100.00) | 54.30 | ||

| S1, S2, S3, S5, S6 | (72.00, 148.00, 22.94) | 34.37 | ||

| S1, S2, S4, S5, S6 | (72.00, 33.00, 67.00) | 96.76 | ||

| S1, S3, S4, S5, S6 | (71.37, 114.16,66.42) | 22.39 | ||

| 6 | S1, S2, S3, S4, S5, S6 | (71.58, 127.69, 41.34) | 10.88 | 10.88 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Q.; Zhu, M.; Zhu, W.; Gu, C.; Pan, C.; Pan, Z. A Novel Method for Localizing PD Source in Power Transformer: Considering NLOS Propagation of Electromagnetic Waves. Sensors 2025, 25, 5099. https://doi.org/10.3390/s25165099

Zhu Q, Zhu M, Zhu W, Gu C, Pan C, Pan Z. A Novel Method for Localizing PD Source in Power Transformer: Considering NLOS Propagation of Electromagnetic Waves. Sensors. 2025; 25(16):5099. https://doi.org/10.3390/s25165099

Chicago/Turabian StyleZhu, Qingdong, Mengzhao Zhu, Wenbing Zhu, Chao Gu, Cheng Pan, and Zijun Pan. 2025. "A Novel Method for Localizing PD Source in Power Transformer: Considering NLOS Propagation of Electromagnetic Waves" Sensors 25, no. 16: 5099. https://doi.org/10.3390/s25165099

APA StyleZhu, Q., Zhu, M., Zhu, W., Gu, C., Pan, C., & Pan, Z. (2025). A Novel Method for Localizing PD Source in Power Transformer: Considering NLOS Propagation of Electromagnetic Waves. Sensors, 25(16), 5099. https://doi.org/10.3390/s25165099