Sensor Arrays: A Comprehensive Systematic Review

Abstract

1. Introduction

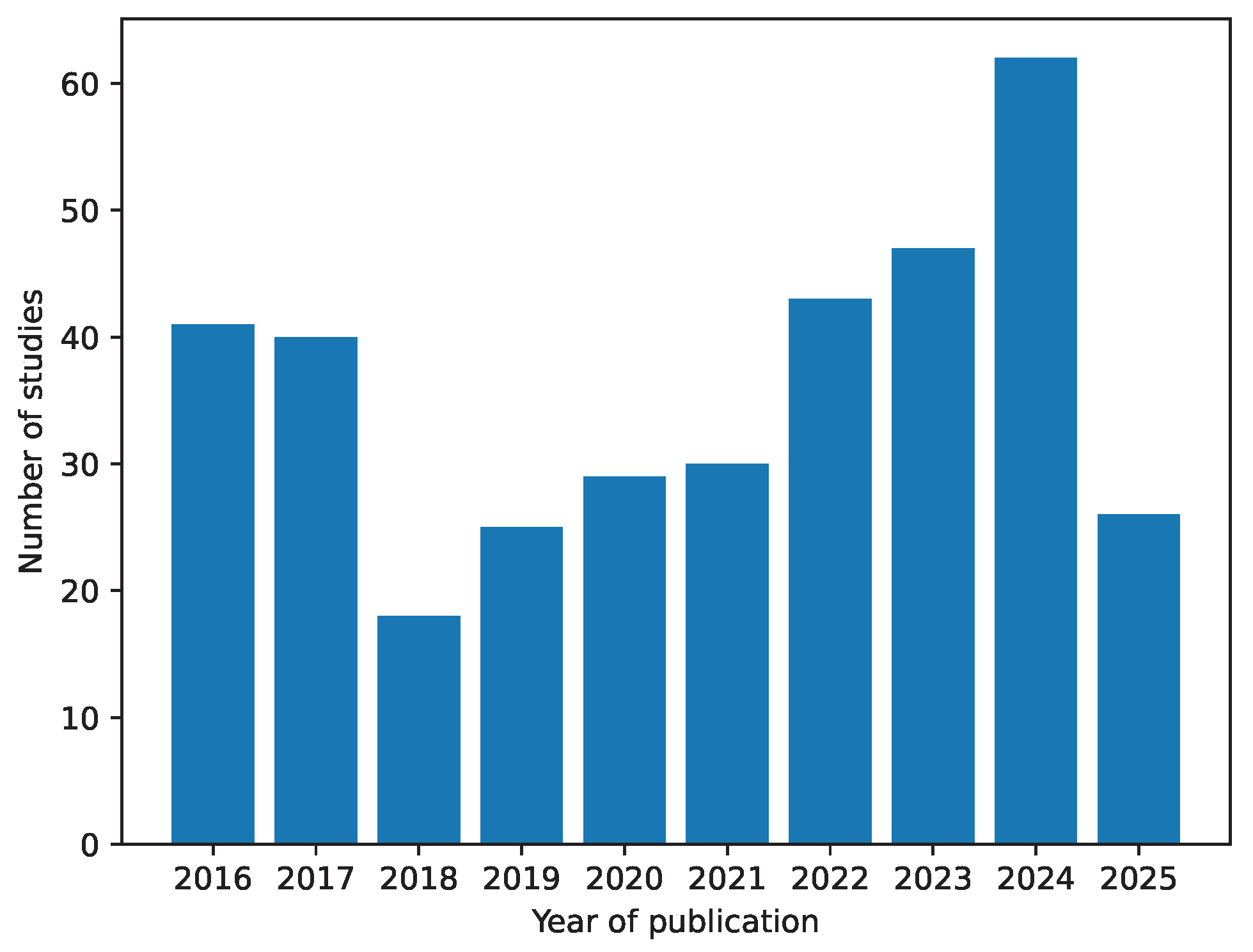

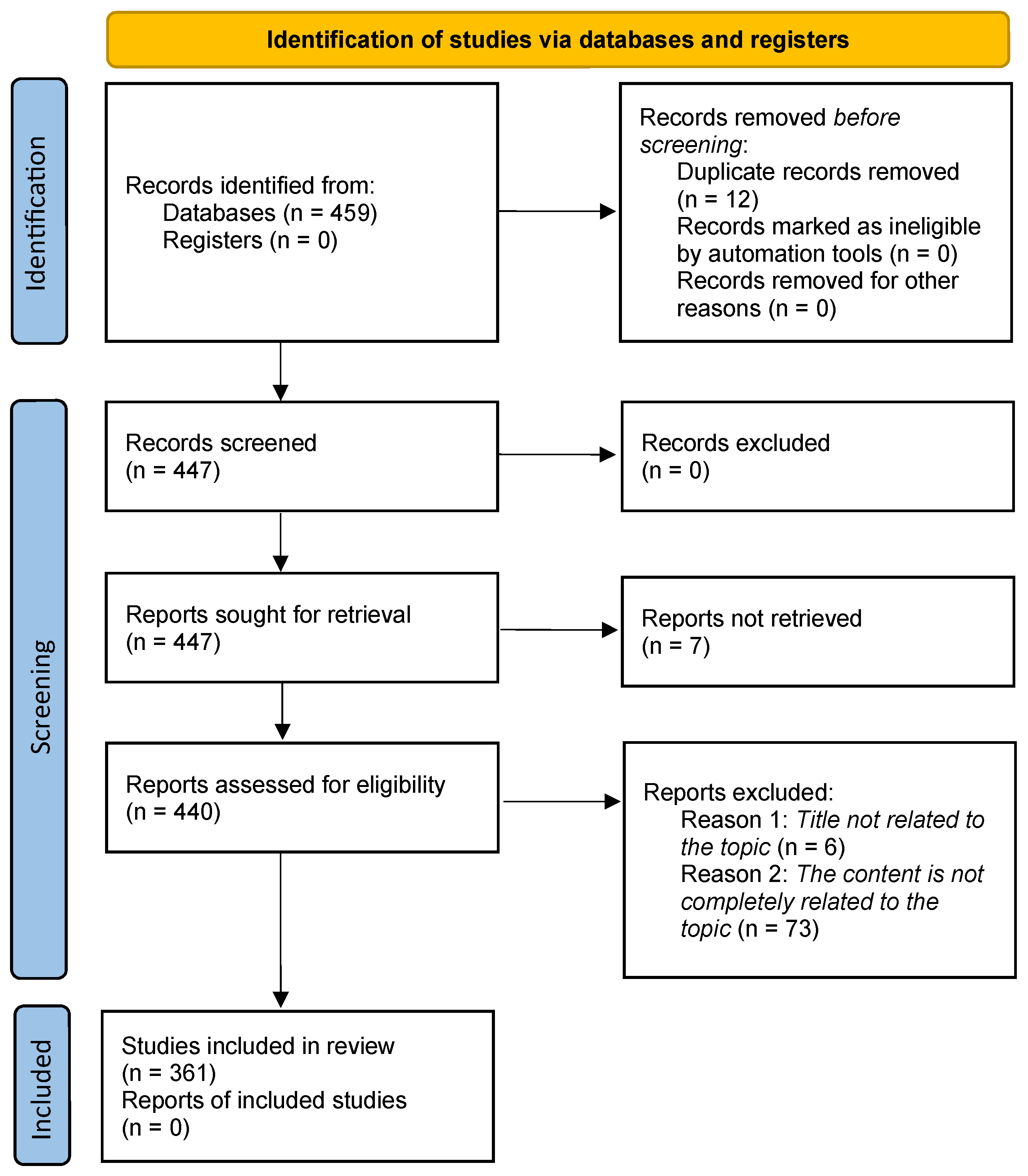

2. Materials and Methods

2.1. Search and Selection Procedure

- 1.

- “resistive” plus “sensor” plus “array”;

- 2.

- “piezoresistive” plus “sensor” plus “array”;

- 3.

- “capacitive” plus “sensor” plus “array”;

- 4.

- “inductive” plus “sensor” plus “array”;

- 5.

- “diode” plus “sensor” plus “array”;

- 6.

- “transistor” plus “sensor” plus “array”;

- 7.

- “piezoelectric” plus “sensor” plus “array”;

- 8.

- “triboelectric” plus “sensor” plus “array”;

- 9.

- “fiber” plus “optic” plus “sensor” plus “array”;

- 10.

- “hall” plus “effect” plus “sensor” plus “array”;

- 11.

- “bioimpedance” plus “sensor” plus “array”;

- 12.

- “sensor” plus “array” plus “review”.

2.2. Review Structure

- Sensing technologies (Section 3): it presents the various state-of-the-art sensing technologies in sensor arrays.

- Sensor array applications (Section 4): this section presents the applications of sensor arrays found in existing studies.

- Validation experiments (Section 5): this section presents the different sensor array validation techniques used in the studies carried out in this field.

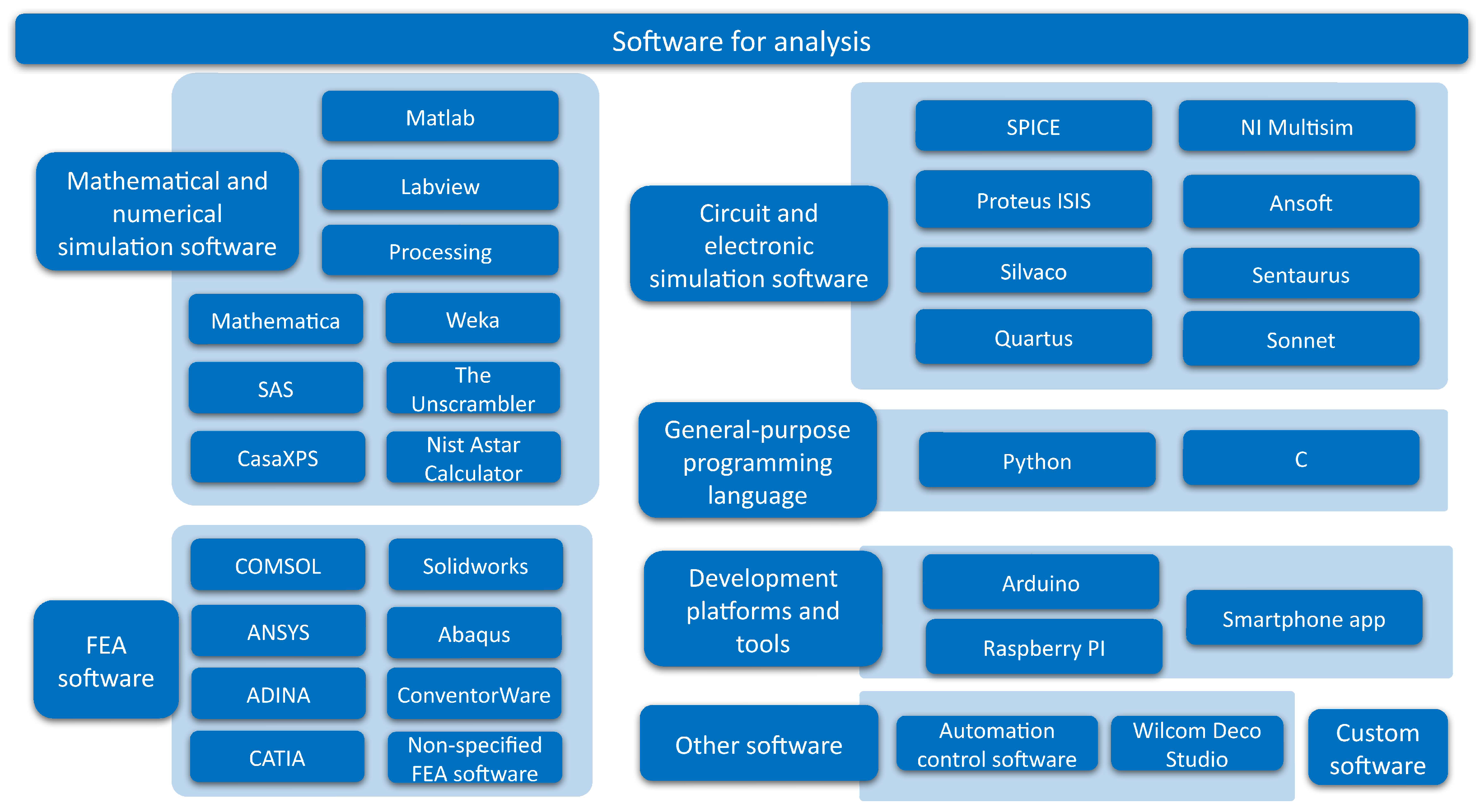

- Software for analysis (Section 6): this section presents the software tools used to analyze the sensor array signals or process the derived data.

- Sensor array characteristics (Section 7): this section presents the different physical characteristics of the sensor arrays.

- Sensor array performance metrics (Section 8): this section presents the figures of merit to evaluate the performance of the sensor arrays.

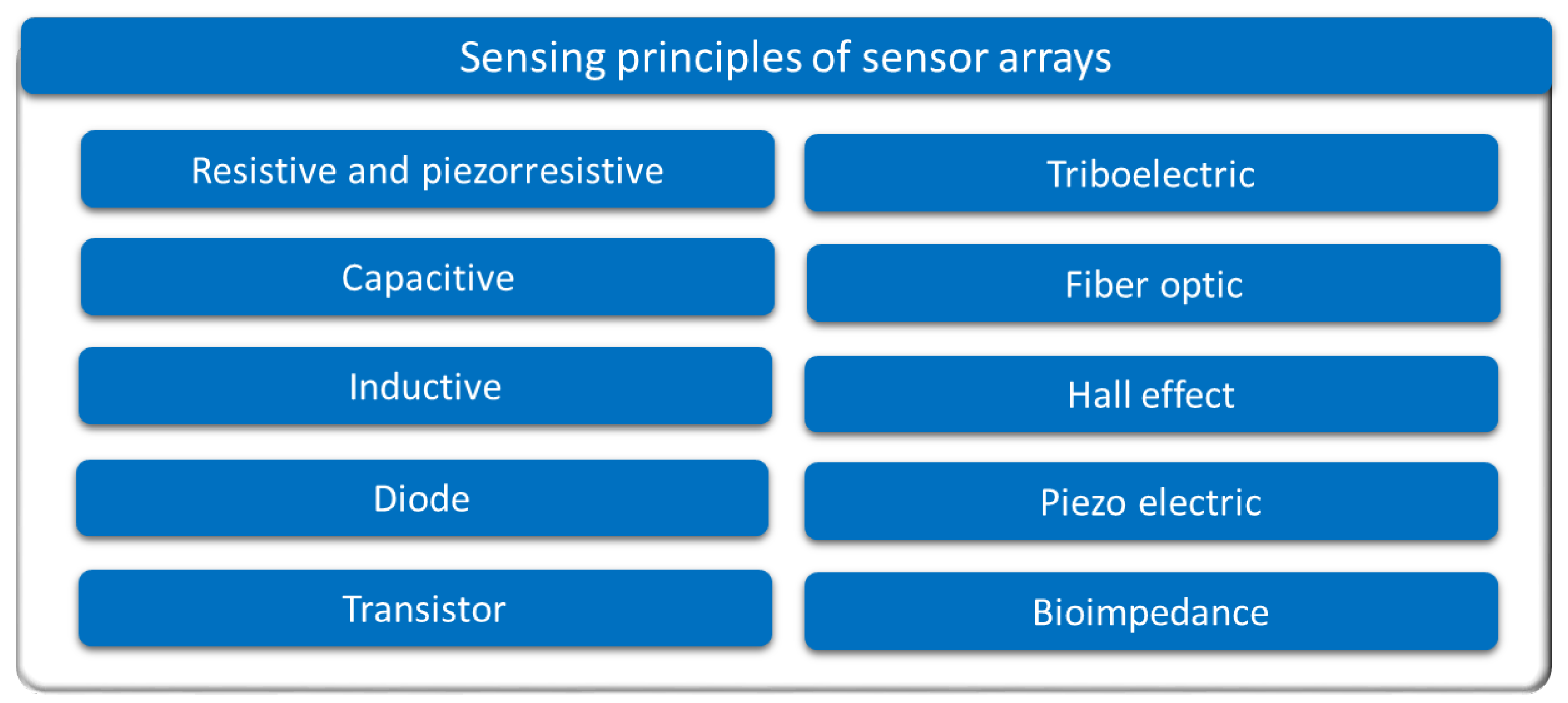

3. Sensing Technologies

- Sensing principle;

- Array size;

- Electrode manufacturing material (electrical connection to the readout circuit);

- Sensing material.

3.1. Results of the Analysis

3.1.1. Resistive and Piezoresistive Sensor Arrays

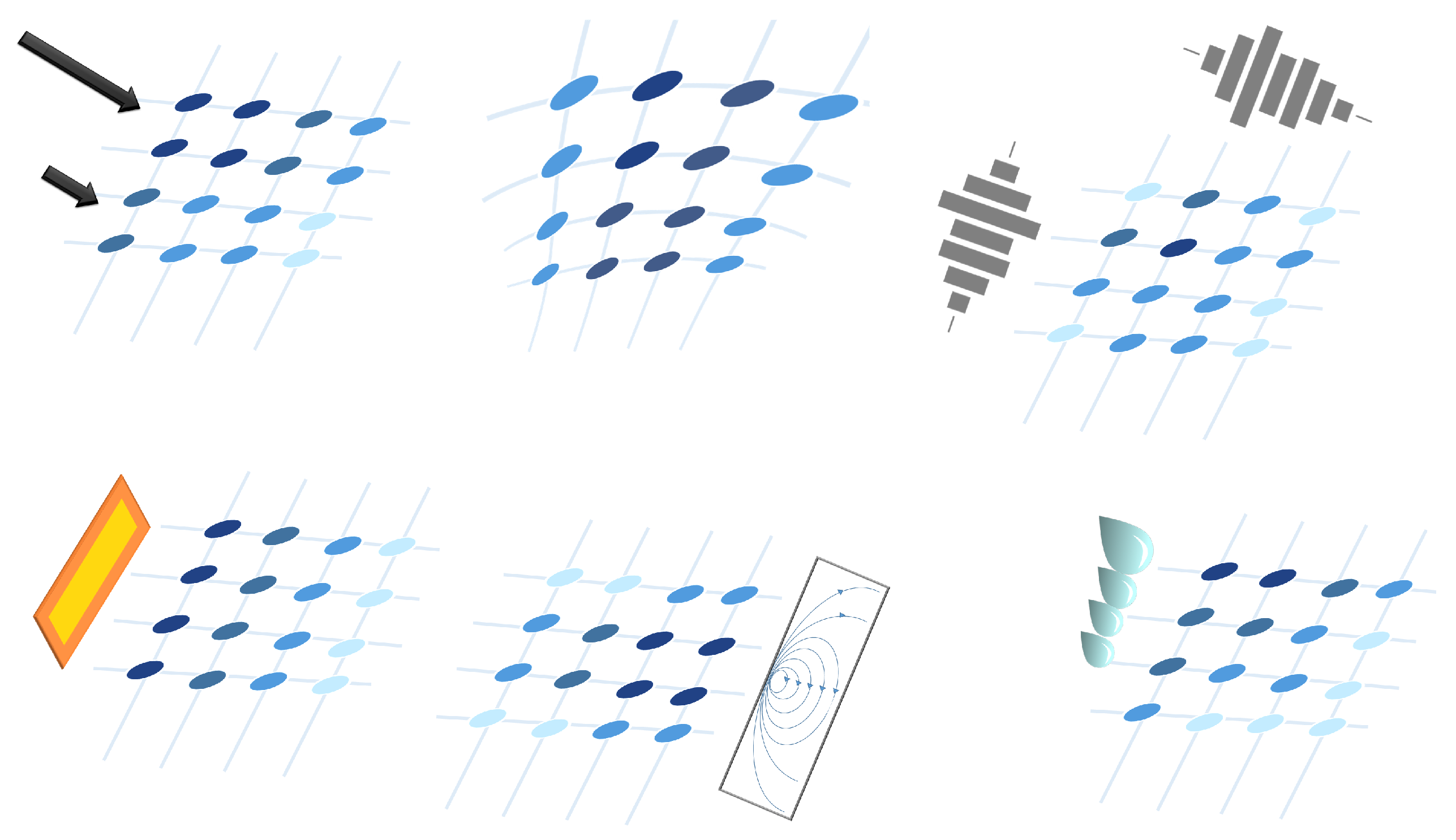

- Resistance changes due to pressure or force: Several studies have designed sensor arrays with materials that experience a change in their electrical conductivity when strained or compressed. This is the piezoresistive effect [8,46,47,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87]. Gong et al. [88] presented a triaxial force-sensitive mat to recognize the shape, size, and curvature of external objects. A similar approach was followed by Jeon et al. [55], where bending angles were measured by attaching the sensor to a moving part. In this regard, Matsuda et al. [89] developed a deformable sensor to detect wrist flexion. The work of Jain & Bhatia [90] improved the sensitivity of a tactile sensor using a mechanical structure that increased the deformation of the sensing element. Wang et al. [48] optimized force sensing in a micro electro-mechanical system (MEMS) piezoresistive array using novel force transfer structures. In this sense, Islam et al. [58] developed a piezoresistive sensor array for monitoring pressure during sleep. Fluids such as water [3] or air [91,92] can also exert pressure on piezoresistive sensor arrays. Finally, Hailiang et al. [93] developed a force-sensitive sensor array that normally operated on a capacitive principle. However, when the external load exceeded a certain value, the capacitor turned into a short-circuit, activating a resistive sensing principle.

- Resistance changes due to temperature: These sensor arrays are based on thermistors [94,95]. The relationship between resistance and temperature can be expressed by the temperature coefficient of resistance (TCR; see the section titled Effects of Environmental Conditions (ECs)) [94,95]. In the work of Demori et al. [96], the temperature inside a food box was read using a commercial NTC thermistor. Meanwhile, Fan et al. [97] conducted a study on a new reading method using a 5-by-5 thermal resistive sensor array, which was made using Pt100 thermistors.

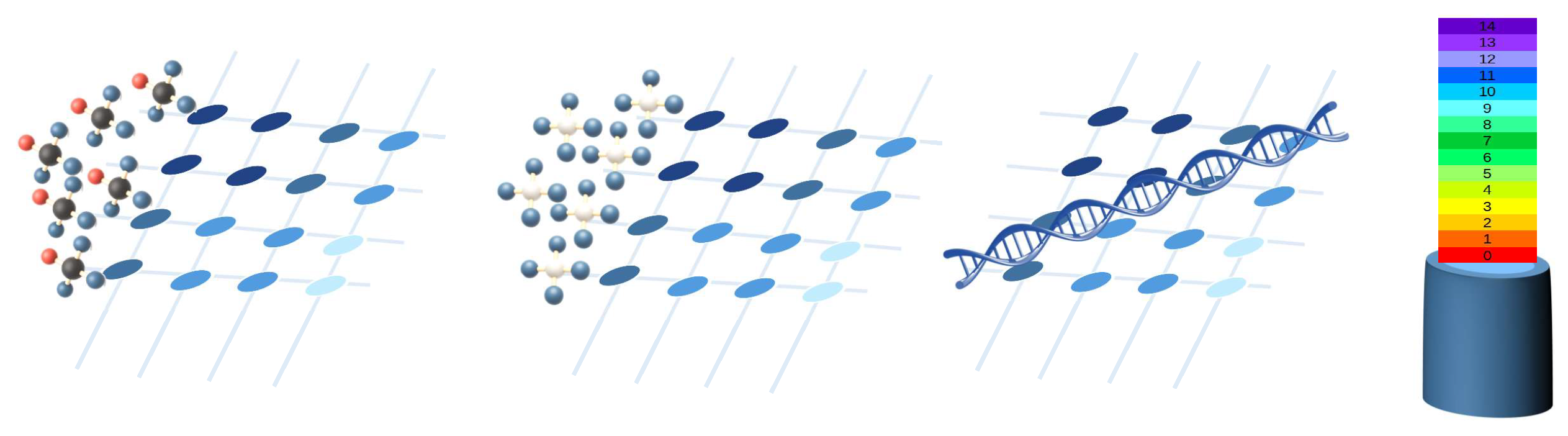

- Resistance changes due to the presence of chemical compounds: Chemiresistive sensor arrays are sensitive to a target analyte [18]. Their working principle is based on the absorption of the chemical substance or the production of a chemical reaction that caused a change in resistance in the arrays. These properties were used, for example, to classify gases [7,98]. Gong et al. [99] measured particle concentration using a piezoresistive array. In turn, Bassi & Ozev [100] detected changes in the surface resistance of a sensor array due to the release of electrons for conduction. In this regard, Mishra et al. [101] developed an ion-sensitive resistive sensor array consisting of two types of sensors: one sensitive to Zn(II) and the other to Cu(II). Wang et al. [102] proposed a resistive sensor array based on MXene driven by adjacent triboelectric elements.

- Resistance changes due to magnetic field: Magnetic field-sensitive resistive sensor arrays have also been developed. Näf et al. [103] presented a customized biochip consisting of 144 spin-valve magnetoresistive sensors. This sensor array was read using a carrier suppression technique.

3.1.2. Capacitive Sensor Arrays

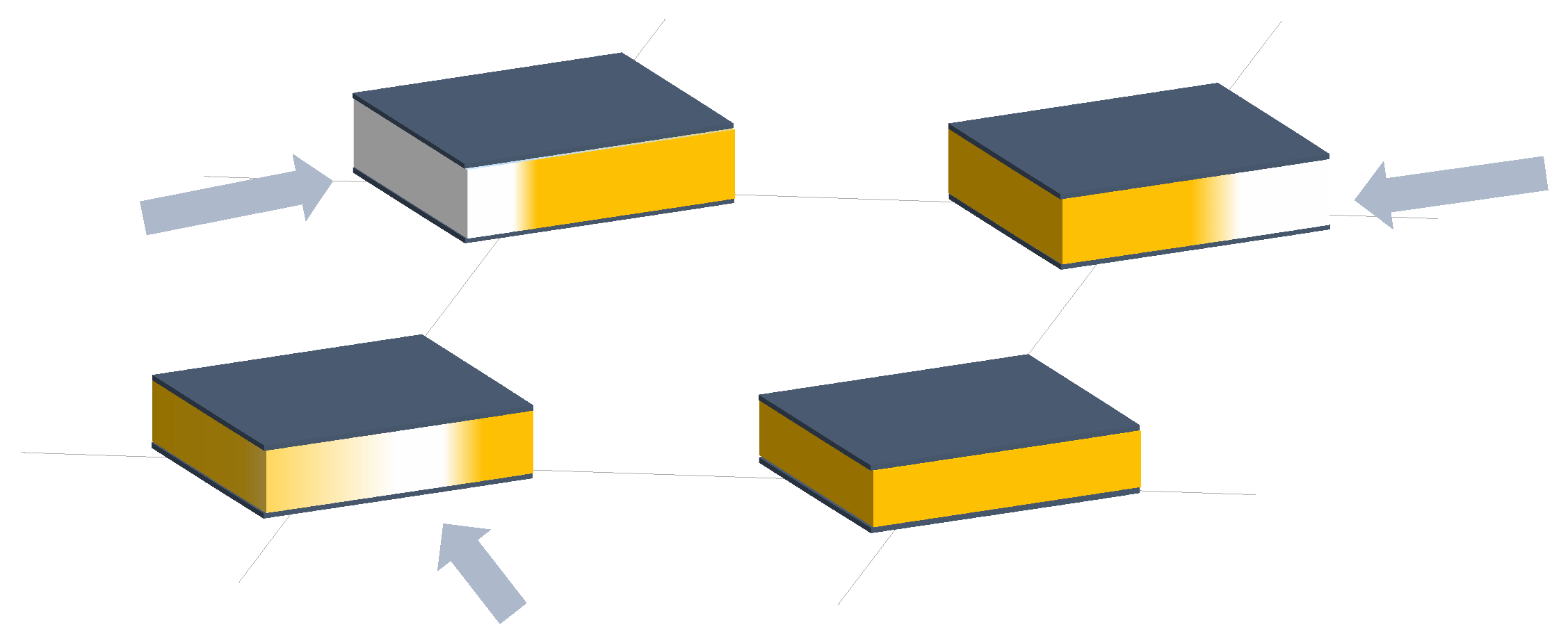

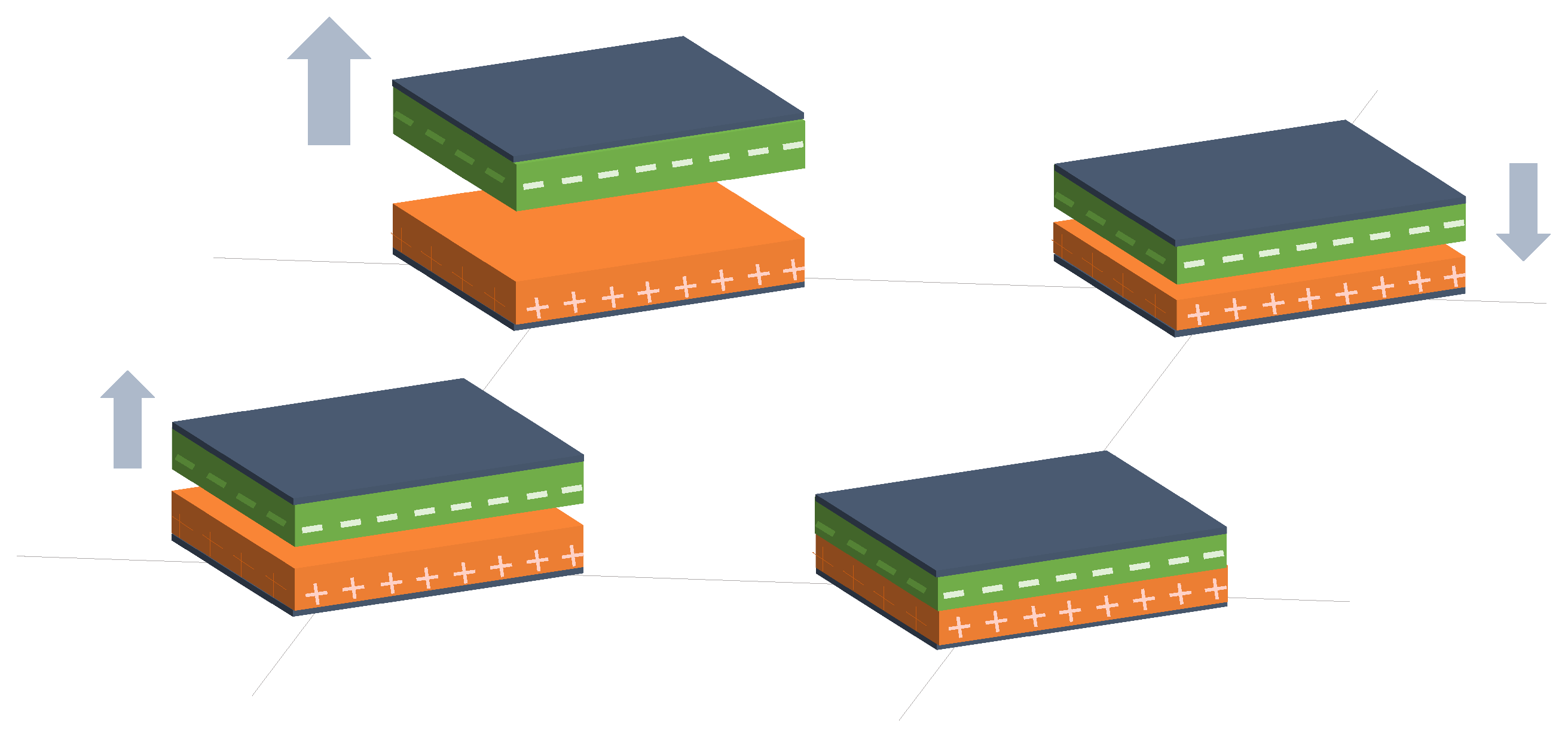

- Variation in d in capacitive sensor arrays (Figure 6): This is a common operating principle in PSMs, since d can be varied simply by applying pressure to the matrix [35,37,38,62,63,142,143,144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164]. The capacitance of the tactile arrays [61,165,166,167,168,169] increases with finger touch as d decreases. In [92,170,171,172,173], capacitive sensors subjected to strain forces also experience a variation in their dielectric thickness. The strain also produces an increase in A [174]. In this sense, bending or stretching the arrays also affected the d parameter, leading to capacitance changes. These changes can be used for gesture detection [142,150,175]. Similarly, Weichart et al. [176] proposed a bump-type sensor with spring geometry. Under an external force, the capacitance read between its different lines changed as the bump was displaced. The spring geometry allowed the structure to recover its original shape when the force disappeared. This was equivalent to modifying the parameter d between adjacent electrodes. In this sense, Chattopadhyay & Chowdhury [177] developed a capacitive resonator to measure heart rate. The arterial pulse caused the diaphragm to vibrate, resulting in a change in capacitance.

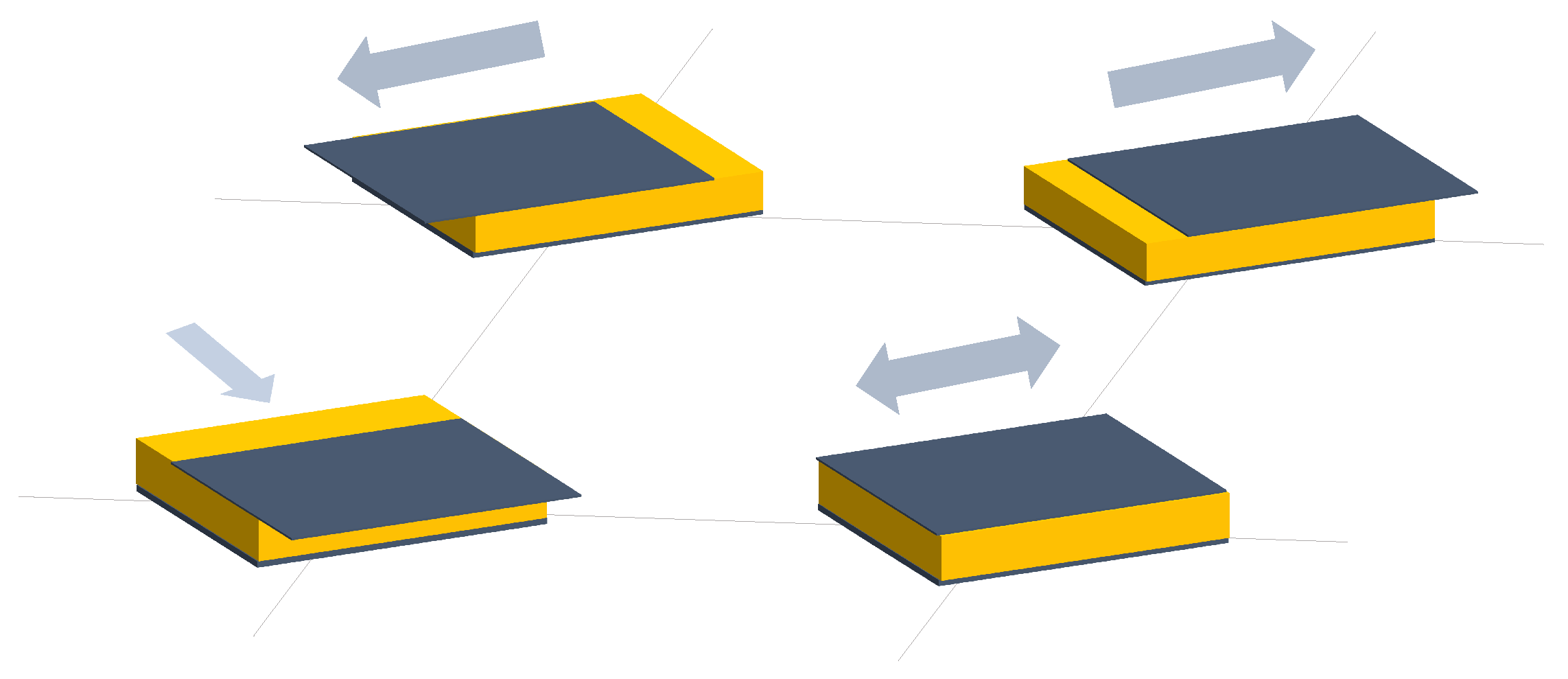

- Variation in A in capacitive sensor arrays (Figure 7): Another way to vary the capacitance is to modify the area A between the electrodes. This can be obtained by misaligning the two conductive plates of the capacitors, as carried out by Fernandes et al. [178]. An external force displaced the upper plate of a capacitor array, changing the effective area between parallel electrodes. This caused changes in capacitance that depended on the magnitude and direction of the applied force, resulting in a three-axis force reading application. Pu et al. [179] also applied this principle to fabricate a capacitive encoder. In this sense, Fang et al. [10] designed a petal-shaped array for robot fingertip sensing. The structure mimicked human fingertip cells and detected vibrations and the direction of the force. The top layer of the capacitive array was displaced by the action of these external forces, resulting in a change in capacitance. The operating principle was similar to other studies [178,179]. Finally, Kim et al. [61] proposed a capacitive sensor array formed by crossing wires. These wires contained coaxially wrapped conductive and dielectric parts. The contact area between the touching wires determined the capacitance of a cell. This array also measured other magnitudes through resistive and piezoelectric effects.

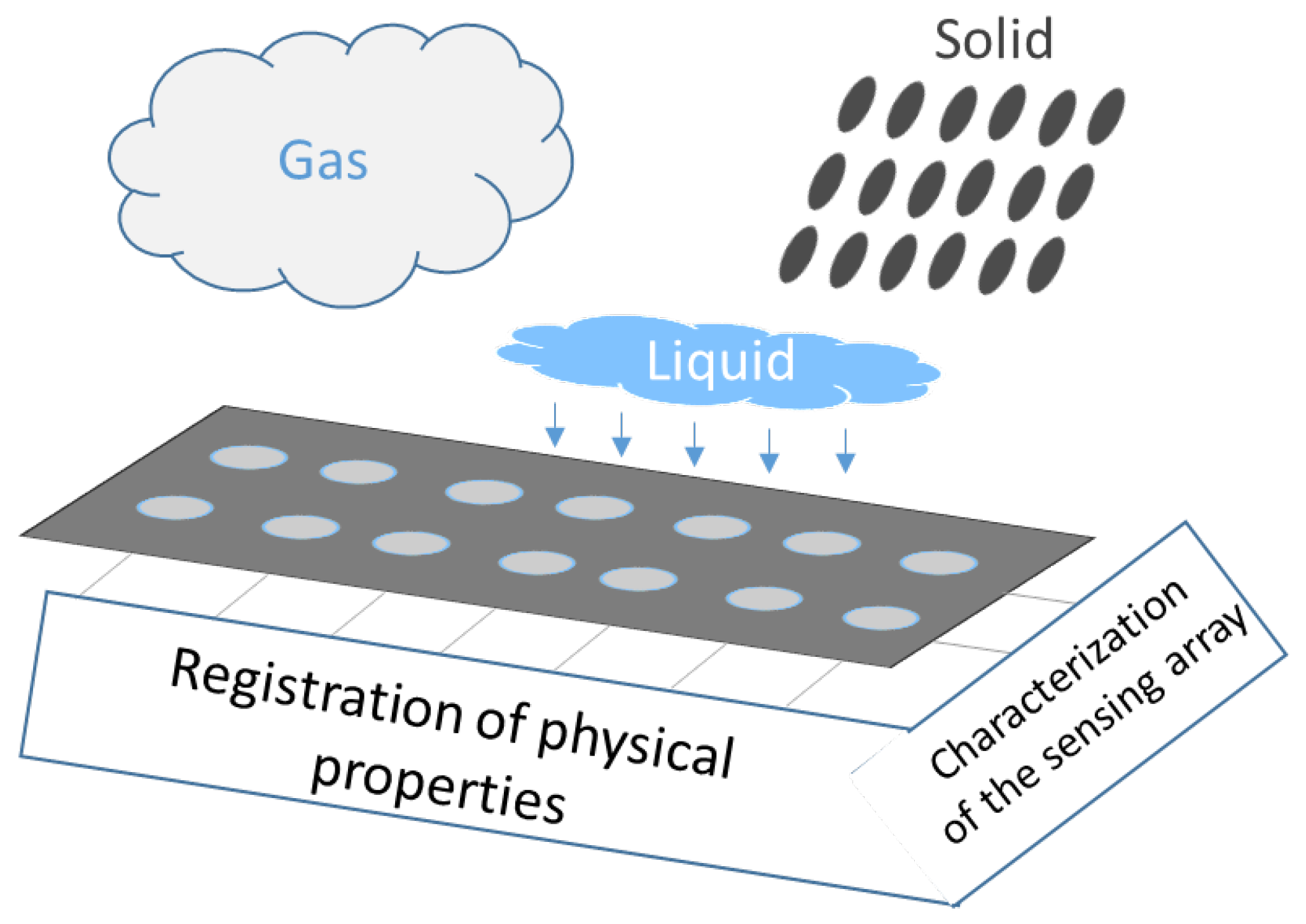

- Variation in in capacitive sensor arrays (Figure 8): Changes in can be used to detect variations in the dielectric material between the two metal plates of each sensor in the array [158]. The studies of Wang et al. [180] and Ye et al. [181] used the variation in the electric field between electrodes to detect an object or substance. In those studies, the object or substance to be detected acted as the “dielectric” of the sensing array. This idea was used to implement tactile capacitive arrays, which detected finger touches through the variation in the electric field [182,183,184,185,186]. A similar approach was presented in [187,188,189,190]. They proposed a contactless imaging system based on changes in the electrical permittivity of the surrounding medium. By reading the capacitance between different electrodes, the presence of an object could be detected. This technique is called electrical capacitance tomography (ECT). Sun & Sun [36] studied several algorithms to improve the co-planar array capacitive imaging technique (CACT), which is based on ECT. On the other hand, Luo et al. [191] presented a capacitive sensor array focused on detecting variations in both and d due to pressure changes. The sensitivity was increased by using two parameters at the same time. The humidity variation can also be registered as a variation [96,192]. Tabrizi et al. [193] developed a CMOS capacitive array whose permittivity depended on the concentration of certain solvents in the water droplets. Similarly, Zhu et al. [194] detected particle concentration by this principle in gas–solid flows.

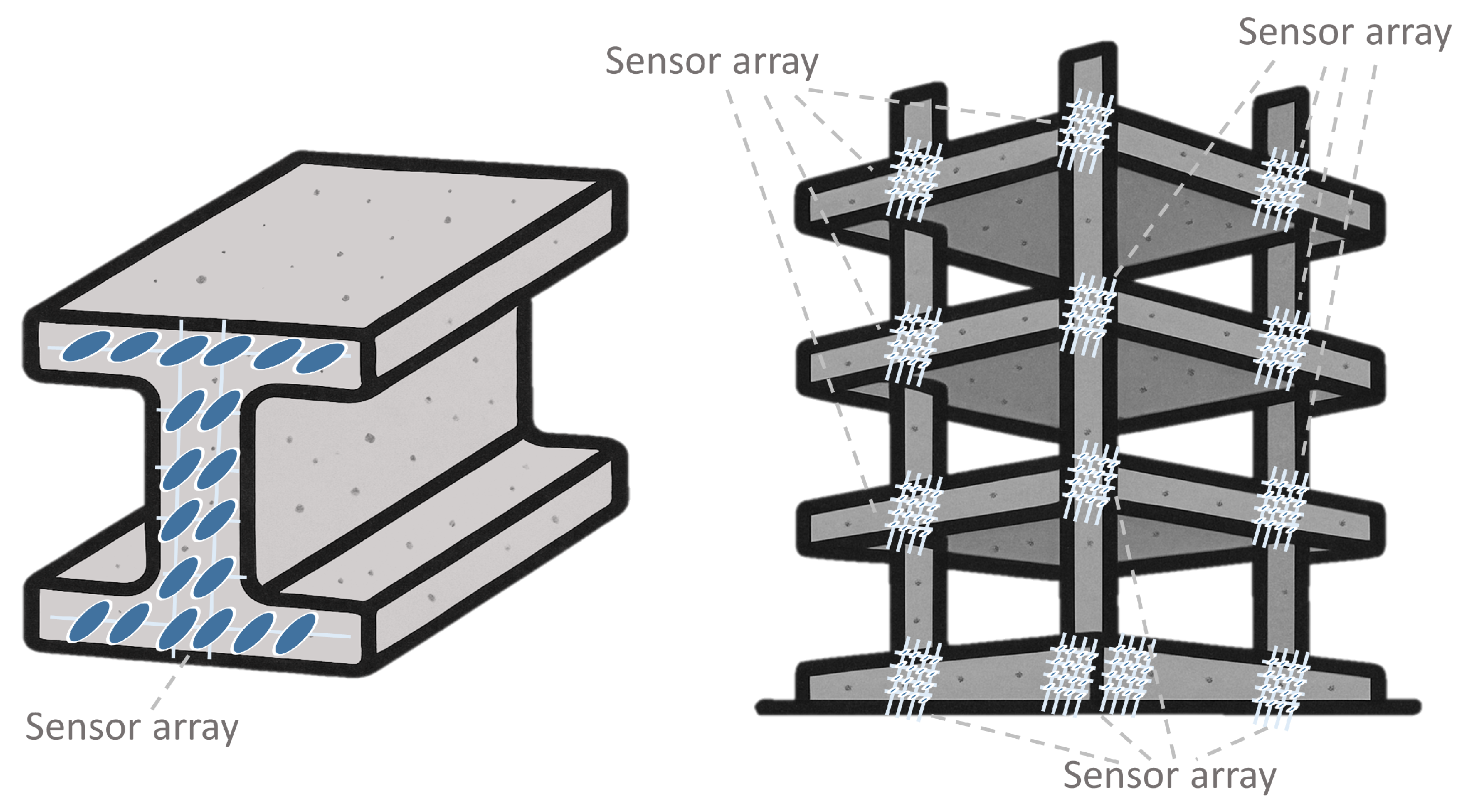

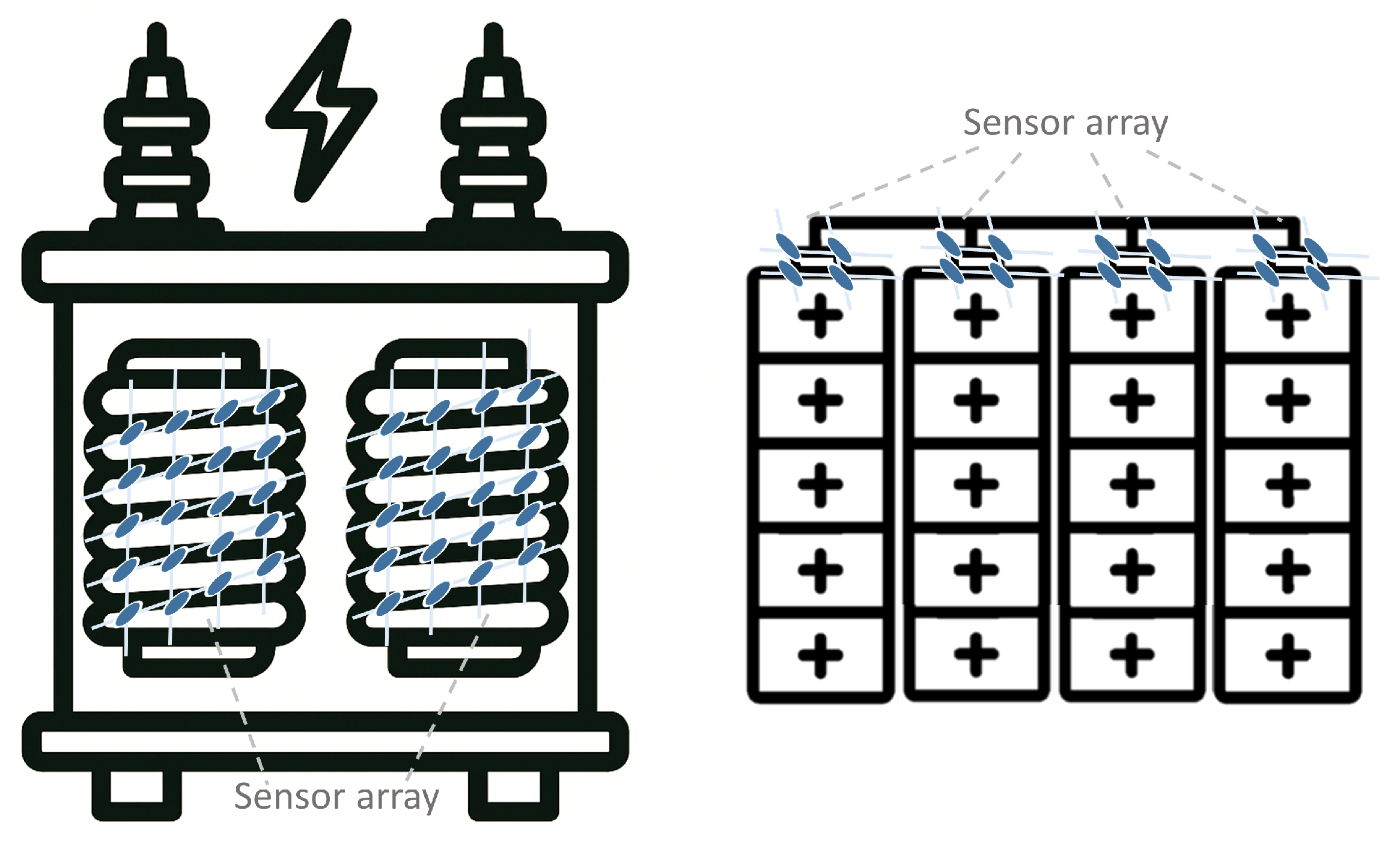

- Variation in charge or voltage (C variation): Another subset of studies on capacitive sensor arrays measured charge or voltage changes between capacitor plates. In [195], when pressure is exerted on the capacitive array, the charge is displaced toward the contact point, which generates currents on the sensor surface. The measurement of charge variations is a suitable sensing approach for the detection of molecules or cells. Several studies [196,197,198,199] developed a CMOS-based cell detector. The systems detected charge changes in the sensing electrodes caused by chemical reactions, analytes or cells. In this regard, Poghossian et al. [200] developed an array of field-effect electrolyte–insulator–semiconductor capacitors (EISCAP) comparable to an Ion-Sensitive Field-Effect Transistor (ISFET; see Section 3.1.5), but with a simpler structure that facilitated fabrication processes. The presence of a chemical organic substance, and its biochemical reactions modified the charge (and potential) on one of the capacitor electrodes, changing the capacitance C of the sensor array. As a novelty, each capacitor was individually addressable. Similarly, Karschuck et al. [201] proposed a 4-by-4 EISCAP array that allowed the detection of pH and Au nanoparticles. On the other hand, in the field of electrical engineering, Wang et al. [9] presented a capacitive array to detect transients in a transformer. They used the stray capacitances formed in the transformer windings. Equivalent capacitors were considered between the transformer winding and a readout electrode.

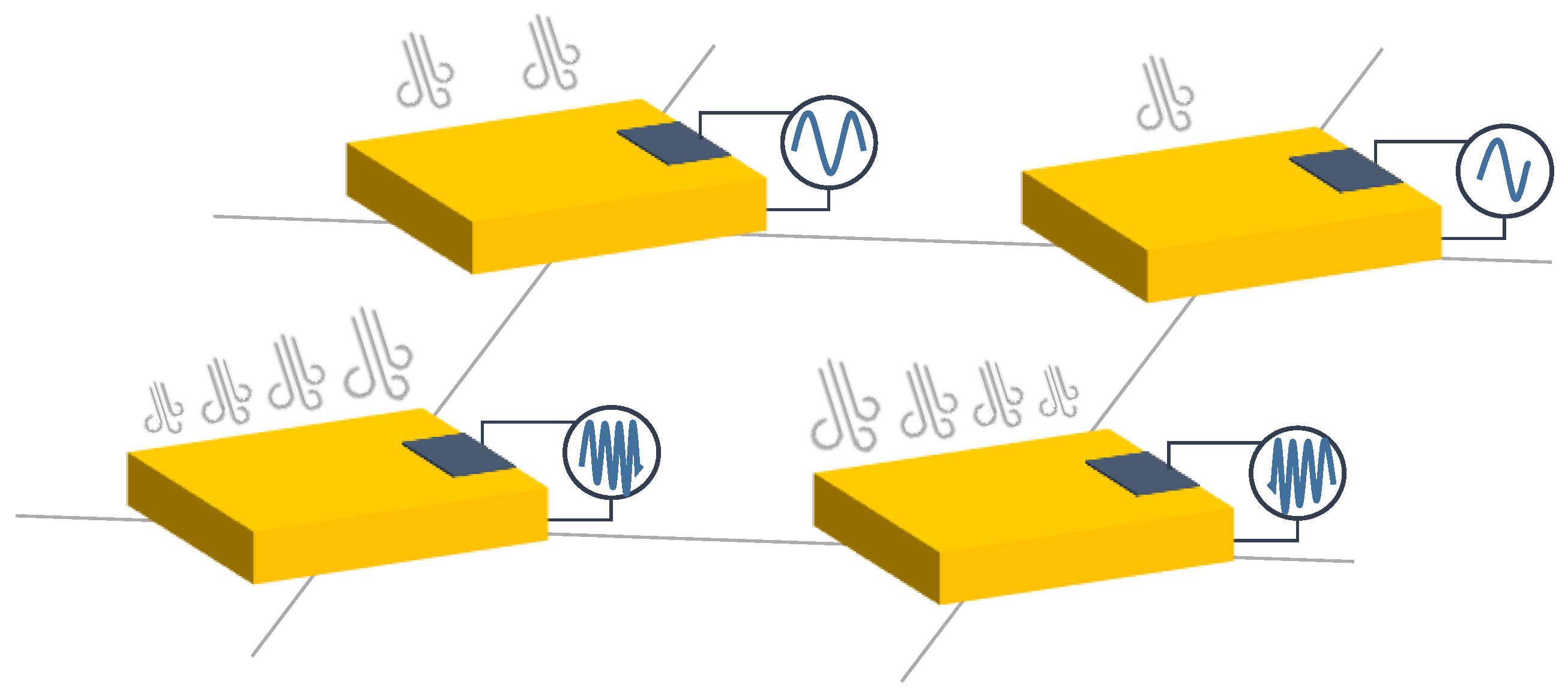

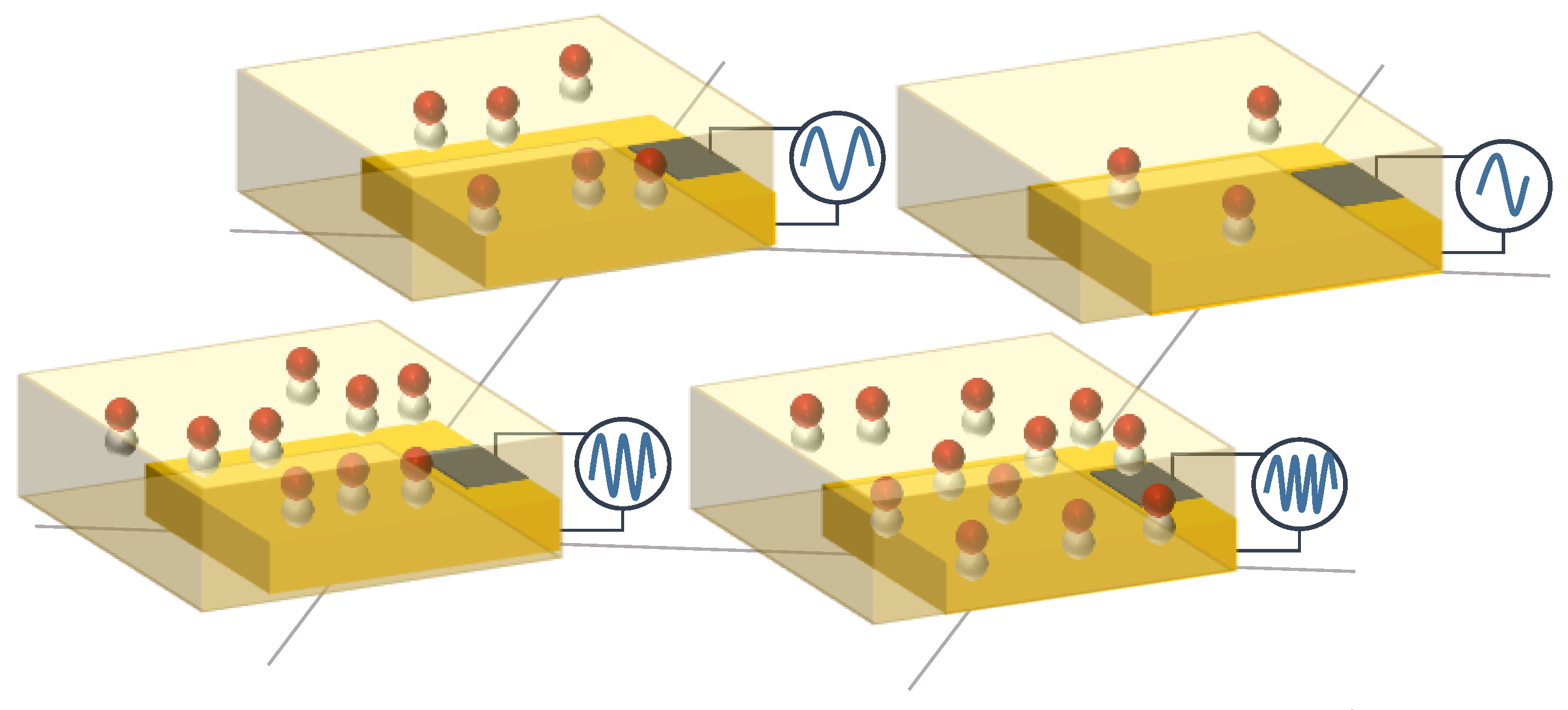

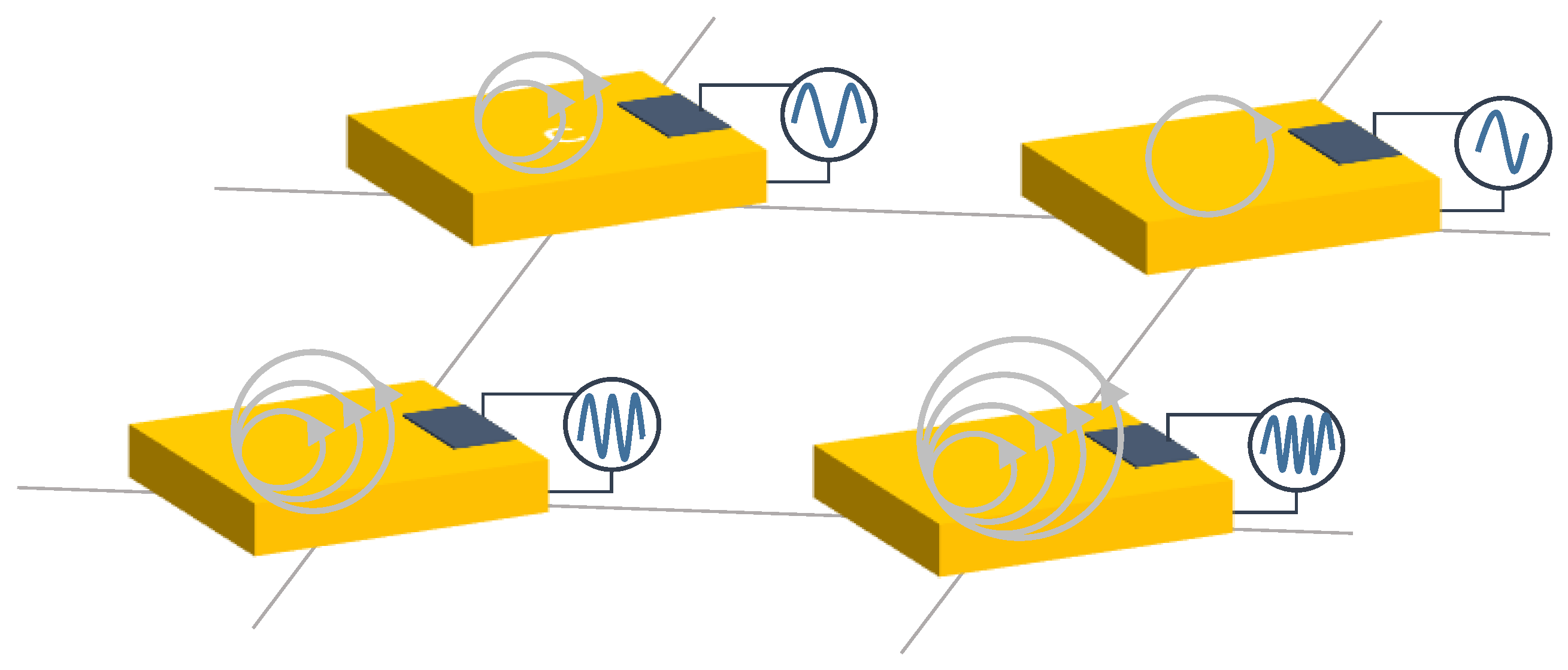

- Capacitor as oscillator or part of it: In a set of works, capacitive sensors were part of a resonator whose resonant frequency depended on the variable of interest. In several studies [202,203], these sensors were referred to as Capacitive Micromachined Ultrasonic Transducers (CMUT). Seok et al. [202] developed a gas detection system that changed the resonant frequency of each CMUT depending on the surrounding gas. In other works [203,204,205,206], VOCs modified the resonant frequency of the system. Wang et al. [180] developed a sensing system capable of detecting objects in a four-sided cube. To avoid interference between sensors, an inductive element was added in series with each capacitor so that the resonant frequency of each side of the cube was different. Elzaidi et al. [207] made a distinction between the water and ice layer in marine applications using a capacitive array. A Hartley oscillator was used to measure its capacitance.

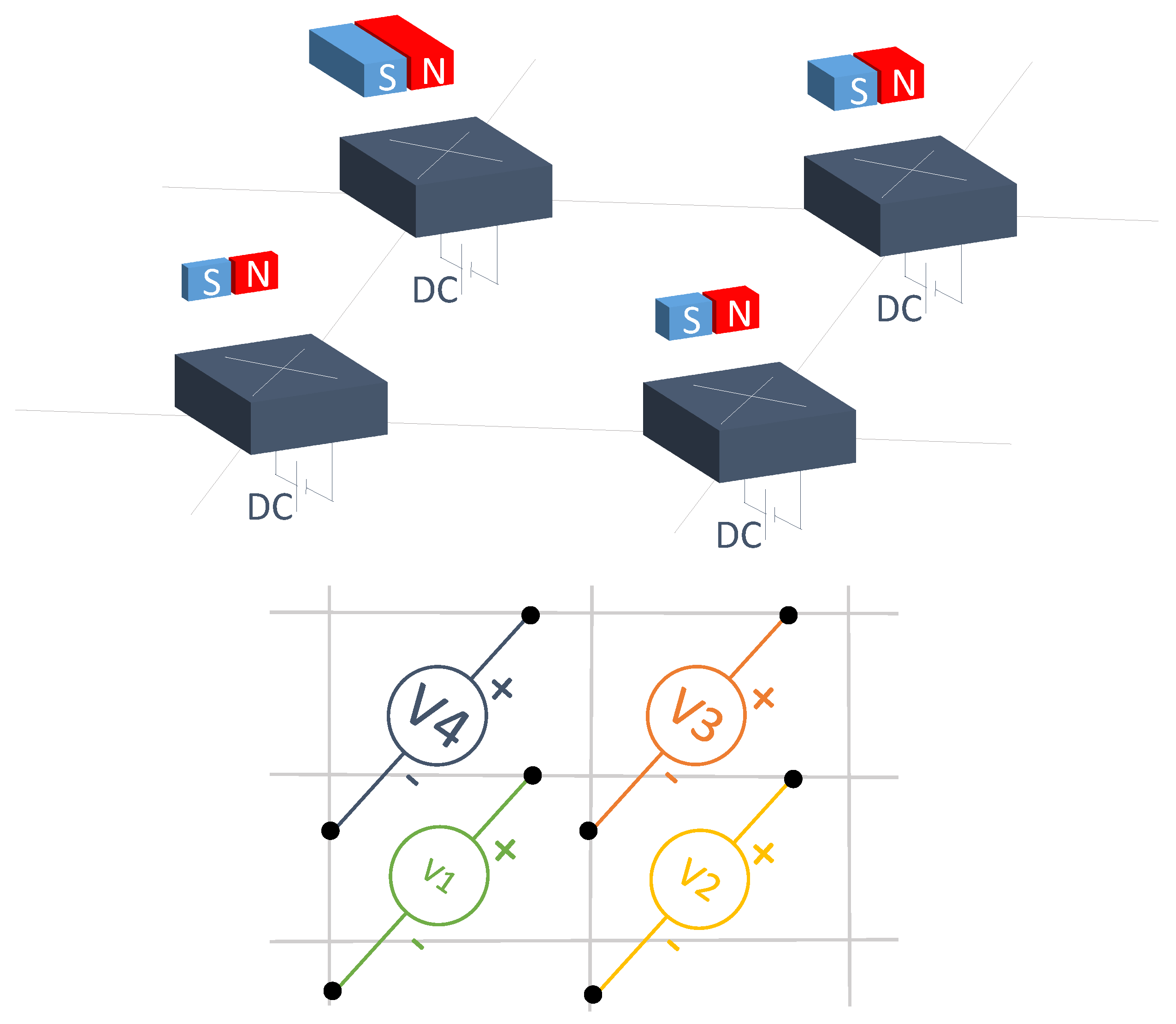

3.1.3. Inductive Sensor Arrays

3.1.4. Diode Sensor Arrays

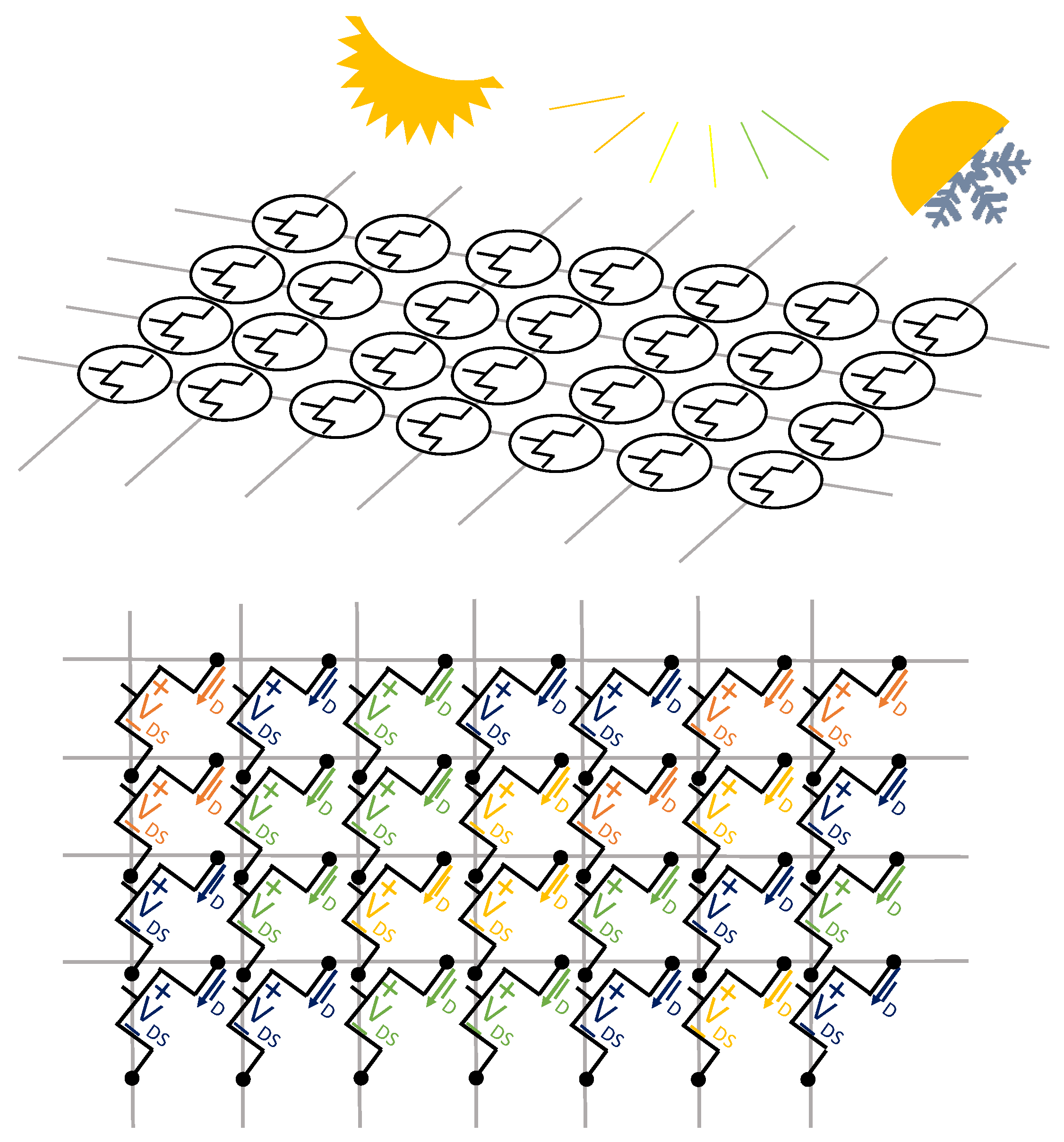

3.1.5. Transistor Sensor Arrays

- change detection: A subset of works transduced the variable of interest into a change in the drain current of the array transistors. This parameter is usually related to in - characteristic curves. Depending on the operating principle that produced this change in , the studies can be classified as follows:

- –

- Variation in due to pressure or stretching: If pressure is applied to the transistor, the distance between the gate and source–drain electrodes decreases and, acting as a parallel plate capacitor, its capacitance increases [221,222]. Due to this increase in capacitance, the charge inside the FET also increases, resulting in a higher drain current . Unlike piezoresistive sensors, FET-based pressure arrays are active arrays, which can themselves avoid crosstalk [222]. Similarly, moving-gate FETs (MG-FETs) allow movement of their gate as a way of measuring directional force [223]. Moving the gate of an FET also causes a capacitance change, triggering the same chain of effects that was explained above. In turn, Su et al. [76] presented self-healable, printable polymers whose conductivity reacted to stretching or pressure. These materials were used to form organic electrochemical transistors, resulting in stretchable self-healable tactile arrays. In this sense, Ren et al. [224] proposed an electret sensor array. In this type of array, the gate of each transistor was connected to a charge induction electrode. When the sensor was pressed, a charge redistribution occurred between the electrode and the transistor gate. This allowed the transistor to drive a higher than in the relaxed state.

- –

- Variation in due to chemical phenomena: The work of Bhat et al. [225] presented a ZnO nanorod FET array to detect analytes. The drain current increased significantly with the presence of these analytes. Hsu et al. [226] proposed high-electron mobility transistor (HEMT) array biosensors that showed an increase in when exposed to an exciting buffer solution. This current was controlled through .

- –

- Variation in due to optical phenomena: Flexible imaging sensors were developed by Chen et al. [227] using Organic Thin-Film Transistors (OTFTs). changed depending on the intensity of the incident laser. In the field of imaging, Hu et al. [228] presented an array composed of dual-gate TFT (DG-TFT). In that array, several diodes acted as photodetectors, controlling the conductivity between the two gates and allowing the TFT drive current to flow between the drain and the source. In the work of Kim et al. [229] arrays of organic photomemory transistors contained organic light-sensitive semiconductors, allowing conductivity between their main terminals when exposed to light. This was a new approach that integrated both the photodiode and an additional memory device in the same transistor. Tang et al. [230] implemented radiation strike sensor arrays using a two-transistor structure. The electrical variable that transduced these radiation strikes was the charge accumulated in the transistors. These transistors operated digitally, imitating a random access memory (RAM) array.

- –

- frequency detection: Sensor arrays can also measure the frequency of the variation in . Hessel et al. [231] presented a cantilever FET (CFET) array that had oscillatory behavior in the presence of certain adsorbates. The electrostatic forces inside the transistor caused self-oscillation, which directly resulted in a variation in . When the mass on the cantilever changed, there was a shift of the vibration frequency. This work provided the relationship between cantilever mass variation and frequency shift. The circuit proposed by Hessel et al. [231] generated a square signal whose frequency depended on this concentration. This square signal was the result of placing two CFET output signals on AND gate inputs.

- change detection: Several sensor array studies used the gate voltage as the physical variable transducer. Some of them were based on ISFETs. For example, pH sensor arrays featured a sensitive gate, whose voltage varied as a function of the free hydrogen ions in the medium [217,232]. In the work of Yuan et al. [233], chloride ions were detected using these ISFETs. Similarly, electrolyte-gated carbon nanotube (CNT) FETs showed good performance in sensing the enzyme reaction [234]. These transistors did not depend on pH variations to detect enzymatic reactions, which is the typical approach [234]. These transistors were also applied in the work of Zou et al. [235] for gas detection. When gas molecules approached the sensing layer (the sensitive gate), charges were distributed along the oxide layer, so that conductivity was produced. In this sense, Zhai et al. [236] proposed an array for detection. It was observed that shifted with its concentration. A similar idea was presented by Tao et al. [237] for antibiotic detection. This principle of operation can be likened to a capacitor model [237]. Liu et al. [238] also developed a gas-sensitive transistor array was based on this principle. Electronic noses (e-noses) are a typical application of transistor arrays [34]. Gao et al. [239] proposed a DNA-sensitive biosensor. It was based on graphene-FETs (GFETs). A specific parameter of GFETs is the Dirac voltage, which is the voltage at which the conductivity of graphene is minimal [239]. In that work, this parameter changes depending on the concentration of complementary target DNA. In this sense, Li et al. [240] proposed a dopamine-sensitive array. The oxidation of dopamine in contact with the electrode generated a potential change.

3.1.6. Piezoelectric Sensor Arrays

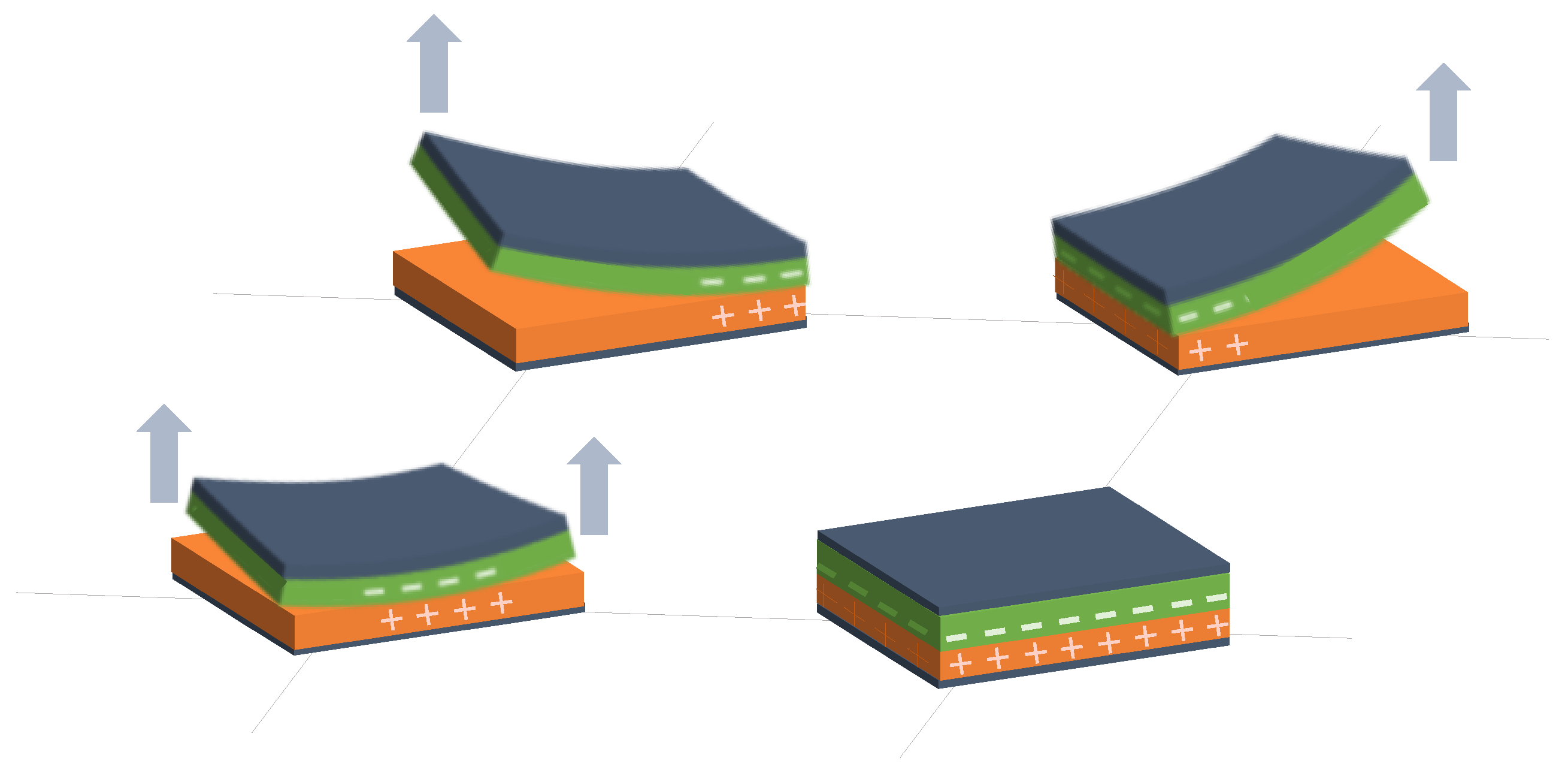

- Mechanical piezoelectric arrays: The operating principle is based on the generation of a voltage spike when a sensor of the array is pressed and the generation of another voltage spike but of opposite sign when the sensor is released [63,156,241,242,243,244,245,246,247,248,249,250,251,252,253,254,255,256,257,258,259,260,261,262,263]. Thus, if pressure is periodically applied to the sensor (e.g., through a pressure machine or due to human movement), the generated signal is also periodic. In fact, the output signal would have the same period as the pressure event [264]. In this regard, the measurement of triaxial forces was performed by Yu et al. [265] with an external shaker applying a periodic force of 20 Hz to a piezoelectric array to detect shear and vertical forces. Similarly, Chen et al. [266] designed a piezoelectric array also for the measurement of the triaxial force. To test the sensor, they used a flexible NdFeB-polydimethylsiloxane (NdFeB-PDMS) magnetic bar that was placed on top of the sensor and then moved under an external magnetic field. In the work of Kim et al. [267] a piezoelectric array was used to obtain the strain vs. stress curve but not by monitoring the voltage output of the array, but rather its impedance. In the work of Lei et al. [268], piezo-capacitors were used to develop a pressure-sensitive array. The structure was driven by amorphous In-Tin-ZnO DG-TFTs. Luo et al. [269] developed a piezoelectric resonator whose resonance frequency was strain-dependent.The bending of the array also triggers the piezoelectric effect [251,261,270,271]. In this sense, a mass that moves over a piezoelectric surface and bends also acts as a variable force [272,273,274]. For example, a roughness-sensitive robot fingertip was developed by Liu et al. [275]. The operating principle was based on moving the array on a rough surface. Grasping a rough surface generated a variable force on the sensor array. Several commercially available sensors are used in [276,277] to detect gestures by reading muscle deformation in the wrist, as this force generates an upward and downward signal in the sensor.In the field of biomedical engineering, a pulsating 3D heart model also produced a variable force on the sensor array, so an electrocardiogram signal could be obtained without external feeding circuits [282]. In the work of Tian et al. [283], a new technique was proposed to fabricate strain-sensitive piezoelectric arrays. The fabricated array was used to measure heartbeats in a simulated heart. Similarly, pulse can be measured with piezoelectric arrays [266,284,285]. Iizuka et al. [286] developed a pressure sensor array for the detection of laryngeal movements. A set of works used the pressure exerted on the sensor array when breathing. In this sense, Tamiziniyan & Febina [287] integrated the piezoelectric array into a quilt. In this way, obstructive sleep apneas (OSAs) were detected. The work of Feng & Su [288] developed a piezoelectric sensor array in which respiratory air flow generated a pressure difference on both sides of the sensor and caused deformation of the piezoelectric membrane. These sensing principles are schematized in Figure 12.

- Airflow-based piezoelectric arrays: Bian et al. [6] proposed a piezoelectric array inspired by the structure of cricket airflow detectors. Piezoelectric sensors were cylinders that bent under the force of the wind. This bending also generated a voltage signal in the material. In this sense, Cong & Jing [289] presented a piezoelectric array inside an axial flow compressor to detect the vibrations of the blades and the noise generated by these vibrations. The array was excited by the airflow inside the compressor. This sensing principle is schematized in Figure 13.

- Sound-based piezoelectric arrays: Piezoelectric arrays have been used to measure sound [290] since they are sensitive to vibratory movements [291,292]. Holeczek et al. [293] used piezoelectric sensor–actuator arrays to test composites for ultrasonic applications. The array performed both sound generation and measurement of the associated vibration. Similarly, in the work of Si & Wang [294], PZT actuators vibrated at a given frequency to test laminated composites. Zhen et al. [271] also presented a PZT array for sound detection. In turn, Nagai et al. [295] developed a piezoelectric sensor array capable of extracting Young’s modulus and viscosity of a material by analyzing the peaks of the output voltage signal. In addition, several studies [4,296,297,298,299,300] have used piezoelectric sound arrays based on the generation of ultrasonic waves inside materials to detect faults [291,294,296,297,298,299,300,301], obtain an image of damage [297,299,302,303,304], or perform voice recognition [305].

- Gas-based piezoelectric arrays: Piezoelectric Quartz Resonators (PQRs) are piezoelectric sensors that are sensitive to gas concentration. Shuba et al. [306], and Kuchmenko et al. [307] presented PQR arrays that were modified using thin films of sorbents. This modification allowed them to change their vibration frequency depending on the type of gas. From the frequency value, several types of gases could be distinguished. In the case of [307], Helicobacter pyroli was detected by gas concentration. A similar working principle appeared in the work of Li et al. [2], where a cantilever resonator array was used. The cantilever oscillated at different frequencies in the presence of different gases. The cantilever contained five electrodes to maximize the amplitude of the resonance peaks. Finally, Lamb wave resonators (LWR), a type of piezoelectric sensor, were also found to be sensitive to different ambient gas concentrations [308]. This sensing principle is schematized in Figure 14.

- Electromagnetic-based piezoelectric arrays: Ferromagnetic-piezoelectric (FMPE) sensor arrays are systems that generate an output voltage when deformed by a variable external magnetic field [309]. These devices exhibit cross-coupling between electric and magnetic fields, given by the magnetoelectric voltage coefficient [309], according to Equation (3). In that equation, is the derivative of the electric field versus the magnetic field, is the derivative of the output voltage versus the magnetic field, and t is the thickness of the piezoelectric layer.

- Humidity-based piezoelectric arrays: Sensor arrays consisting of piezoelectric membranes change their resonant frequency when absorbing water molecules due to a change in the mass of the membrane [310,311]. These devices are called pMUTs (piezoelectric micromachined ultrasonic transistors), similar to CMUTs. In this way, humidity can be measured. The same principle was followed by Feng & Su et al. [312] to develop a rhinomanometer with an integrated humidity sensor.

- Self-harvesting sensor arrays: Piezoelectric arrays have the potential to be self-harvestable, as they can produce their own voltage [63,292]. In this sense, Kumar et al. [313] presented an Internet of Things (IoT) system based on piezoelectric arrays placed under the roads of a smart city. The proposal was to convert mechanical energy from cars that drive on the roads into electricity. Kim & Yun [63] combined triboelectric and piezoelectric arrays to harvest energy.

3.1.7. Triboelectric Sensor Arrays

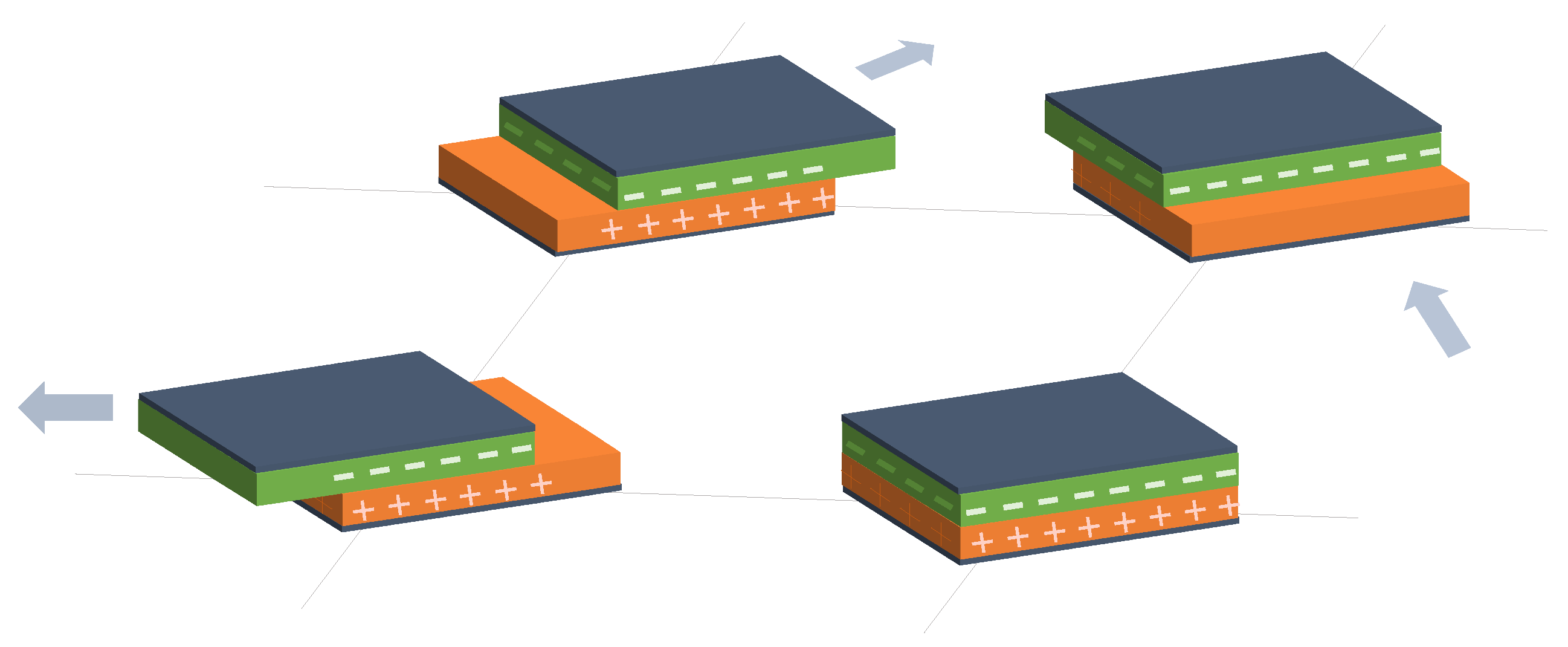

- Triboelectric effect by separation (Figure 16): Gao et al. [320] measured the pressure using a triboelectric array. A sandwich structure composed of polyvinylidene fluoride (PVDF)-PDMS, nylon, and aluminum, in this order, was presented. PVDF-PDMS was a negatively charged triboelectric polymer, nylon was positively charged, and aluminum was also negatively charged. When the PVDF-PDMS layer was pressed against the nylon layer, the positive charges of the nylon layer shifted toward the PVDF-PDMS layer, and the negative charges of the PVDF-PDMS layer did the same toward the nylon layer. The aluminum layer was held with a near neutral charge. When the PVDF-PDMS layer was released, the nylon layer rearranged its positive charges on the contact surface with the aluminum layer. In this way, a potential difference in the aluminum layer was obtained, and from this, the value of the pressure exerted on the triboelectric array could be obtained. Unlike piezoelectric arrays, triboelectric sensor arrays can generate voltage in a static state. Chen et al. [321] followed a similar principle to measure force, but using a glass-based single electrode TEG. Chen et al. [45] implemented a 3-by-3 triboelectric array in which the negative material was PDSM, and the positive materials were Cu and water. Yang et al. [318] developed a smart traffic monitoring system using silver electrodes, PVDF and a polyethylene terephthalate (PET) substrate; all embedded with a Raspberry Pi. Jang et al. [322] performed ultraviolet (UV) patterning to control the sensitivity of a stretchable triboelectric array subjected to touches. This array could detect slippage, pressure, and grip. Yan et al. [315] develop a 16-by-16 dense triboelectric array with laser-induced graphene electrodes that was immune to bending and also followed this principle. This effect was also used by Lee et al. [323] to develop a plantar pressure system that performed equally well in atmosphere and in water. Wang et al. [324] presented a TENG array combined with FETs to amplify the output signal. The TENG powered the FET gate to develop a digital keyboard and analogue pressure systems. Similarly, Li et al. [30] developed a cyber-secure numeric keyboard. Yang et al. [325] presented a cuboid TENG array using silicon rubber to improve the output voltage under pressure. Ahmed et al. [326] and Liu et al. [30] developed computer keyboards using the same principle. The contact separation principle prevails in pressure triboelectric arrays [39,40,41,42,43,44,163,224,327,328,329,330,331]. A similar operation concept was followed by Wang et al. [102] to develop a resistive gas sensor array driven by TENGs. These TENGs generated power from wind motion.

- Triboelectric effect by sliding (Figure 17): Two triboelectric materials generate a voltage signal when they slide. This signal varies according to the amount of material in contact. This operating principle was used by Qin et al. [316] to detect gestures in human-machine interface (HMI) applications.

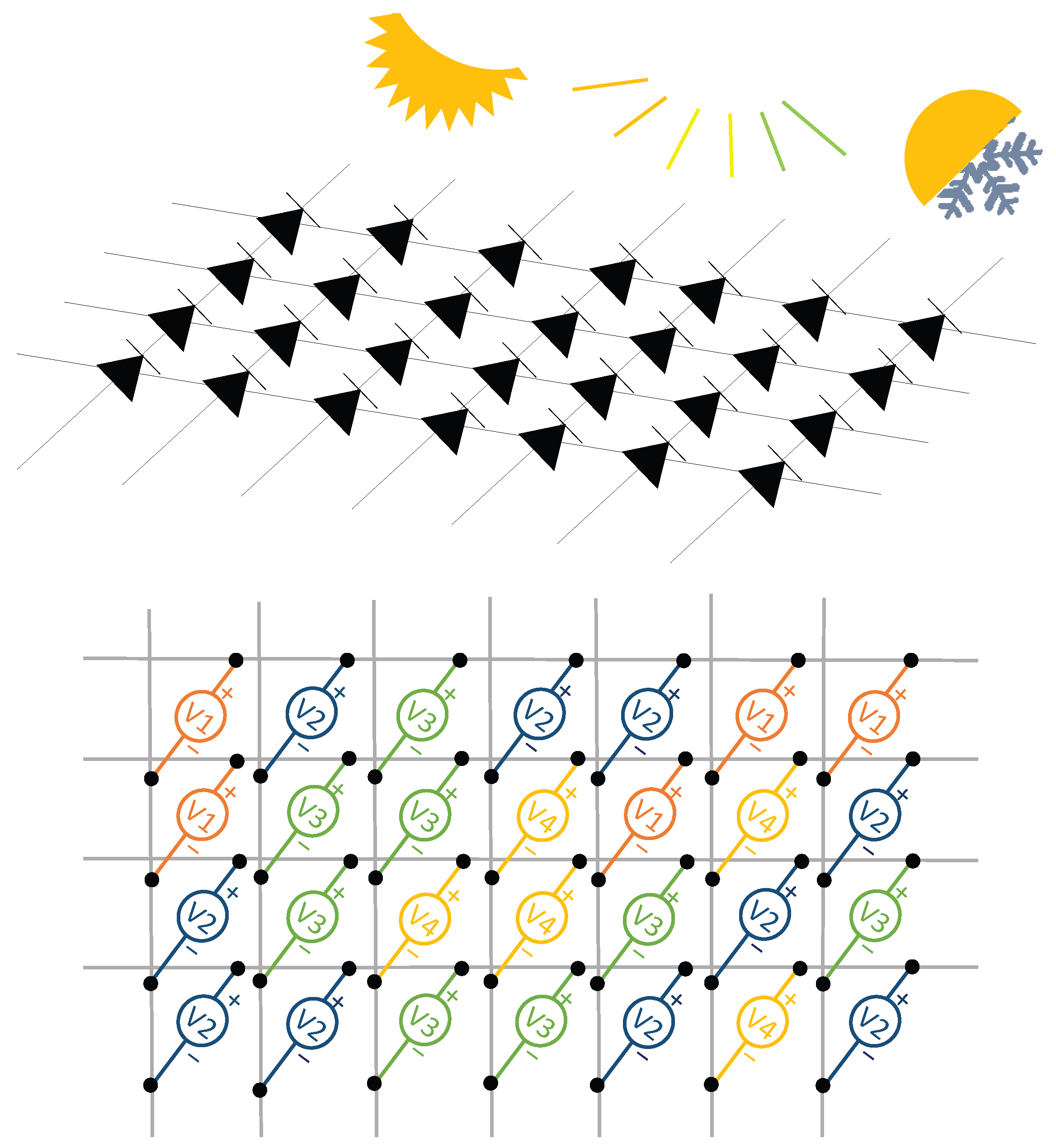

- Triboelectric effect by flapping (Figure 18): Ko et al. [317] developed a flap-based triboelectric array to measure wind speed and direction. The flaps are thin triangular surfaces of triboelectric material that are attached to the rest of the structure on only one side of the sensor. They are presented in a circular array. The flaps (made of Al and PET) bend as a result of air movement. The flaps are initially rolled up and do not touch the circular base of the array, made of polytetrafluoroethylene (PTFE) and Cu. When the wind blows against the flaps, they unroll and touch the base of the array. The potential difference between the base and the flap is greater with a higher wind speed, as the contact surface is larger.

3.1.8. Fiber-Optic Sensor Arrays

3.1.9. Hall Effect Sensor Arrays

3.1.10. Bioimpedance Sensor Arrays

3.2. Brief Conclusion of Sensing Technologies

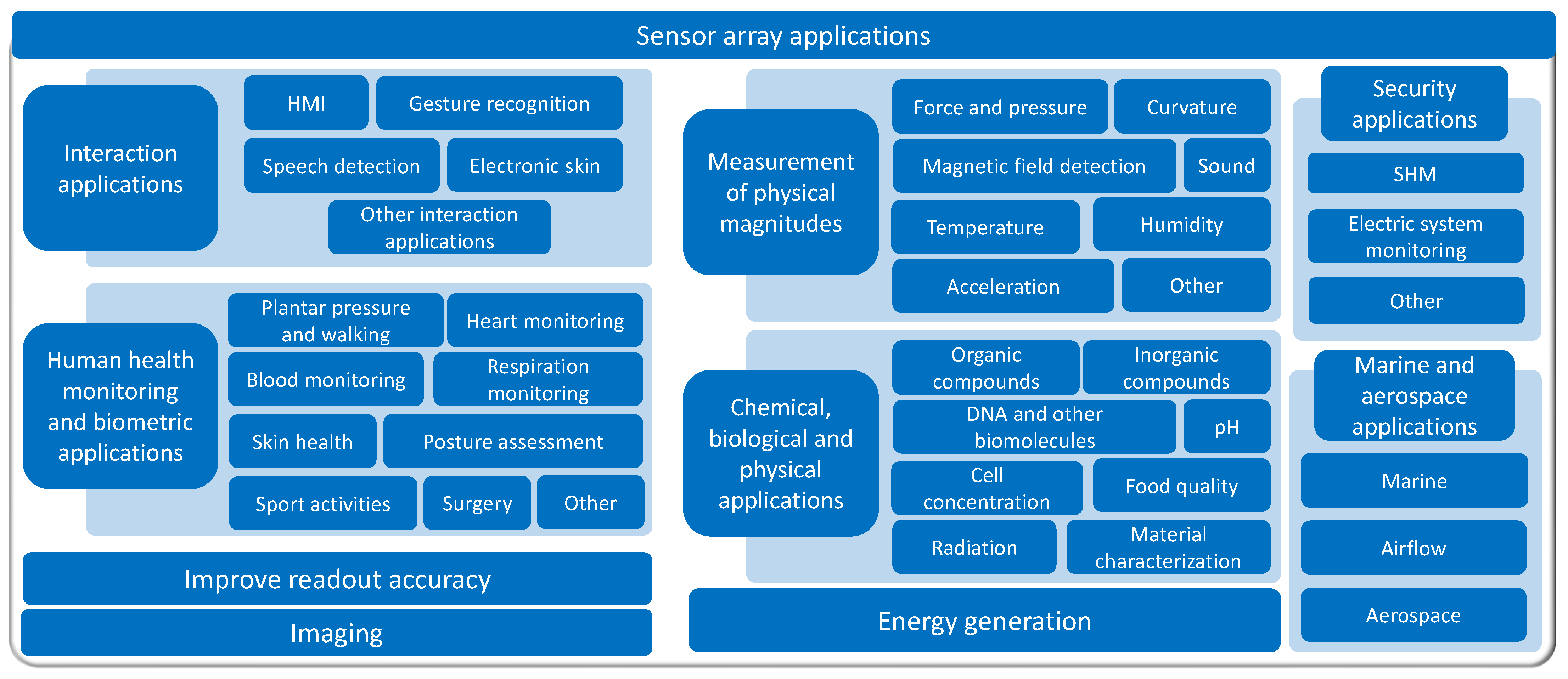

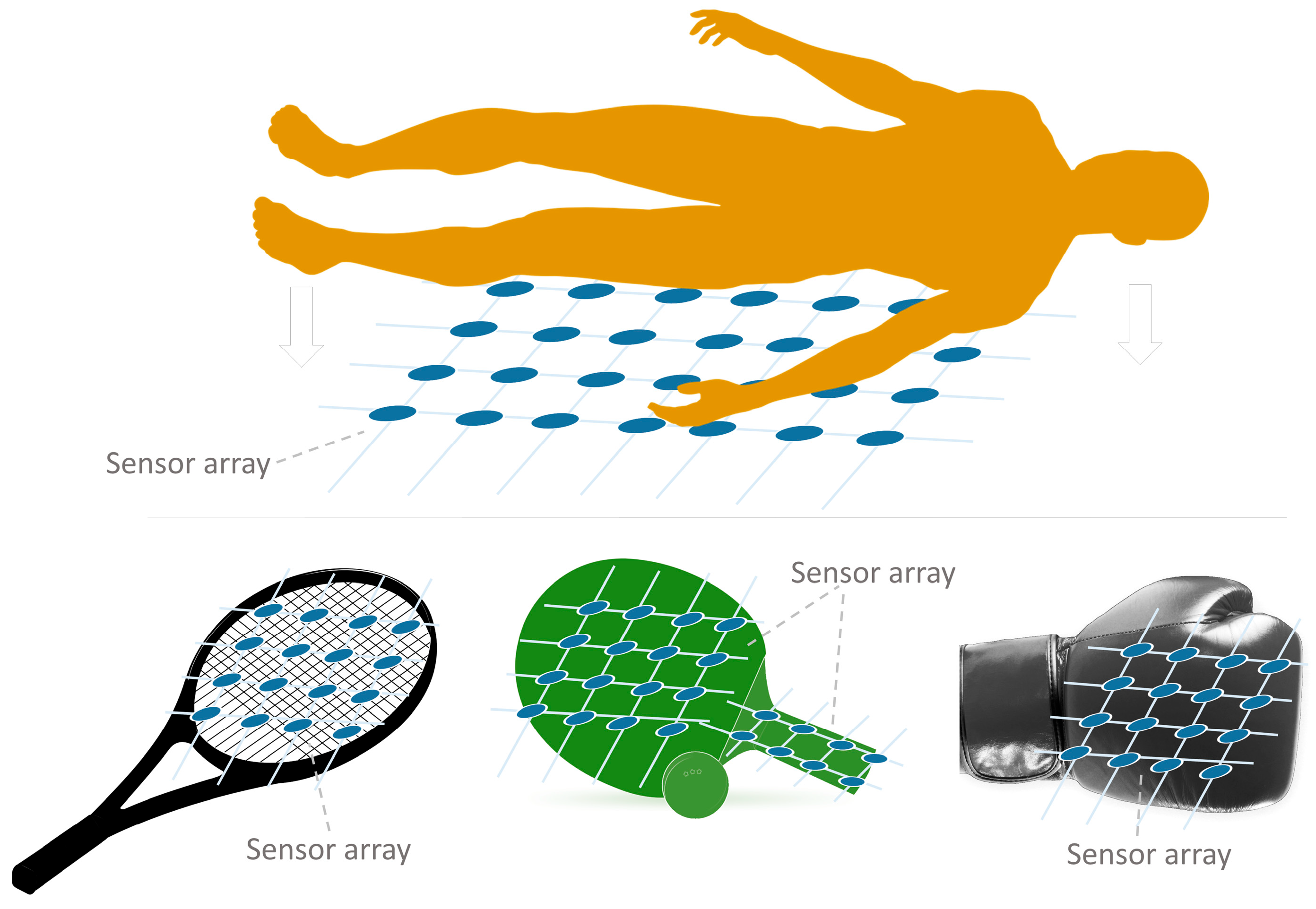

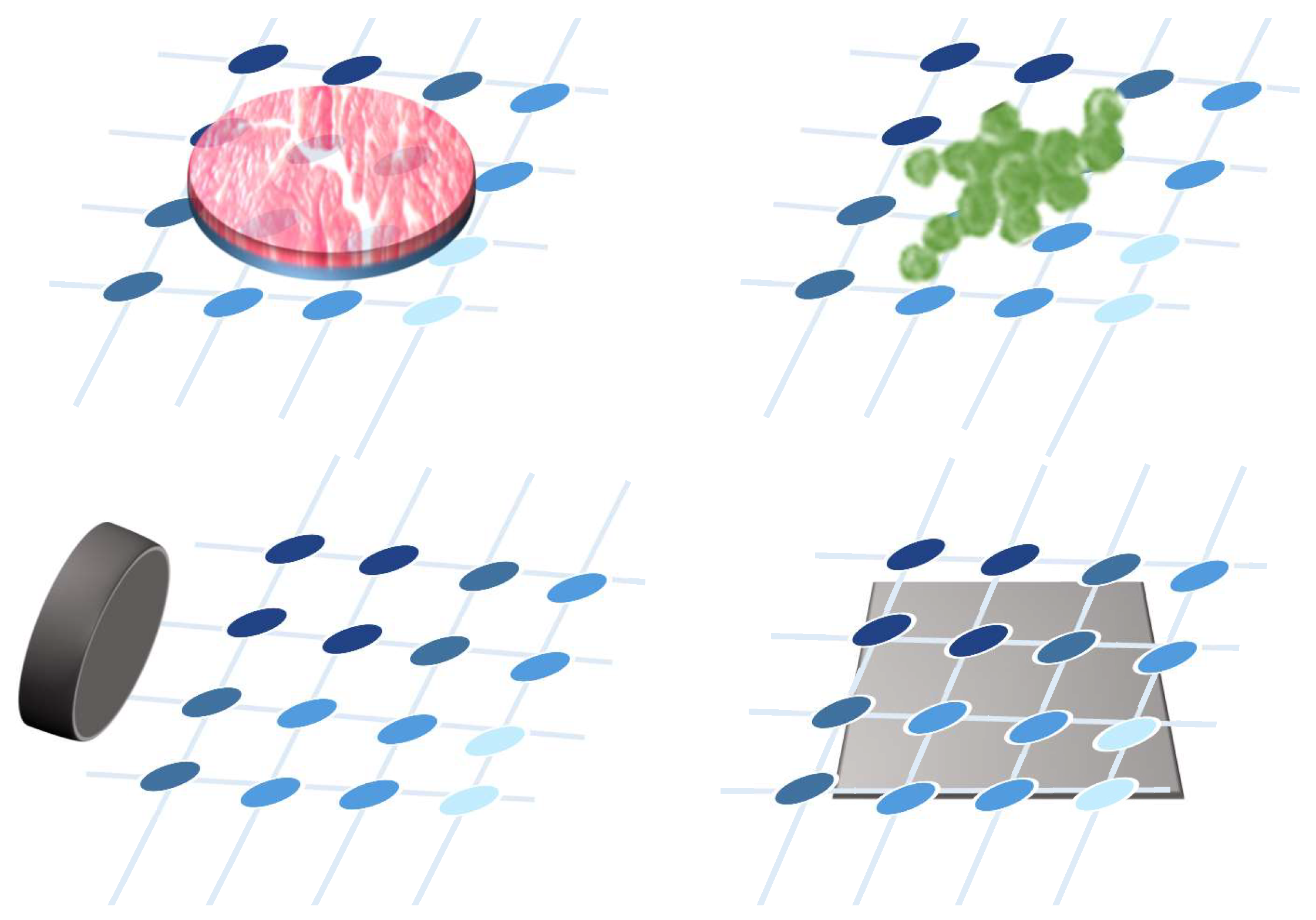

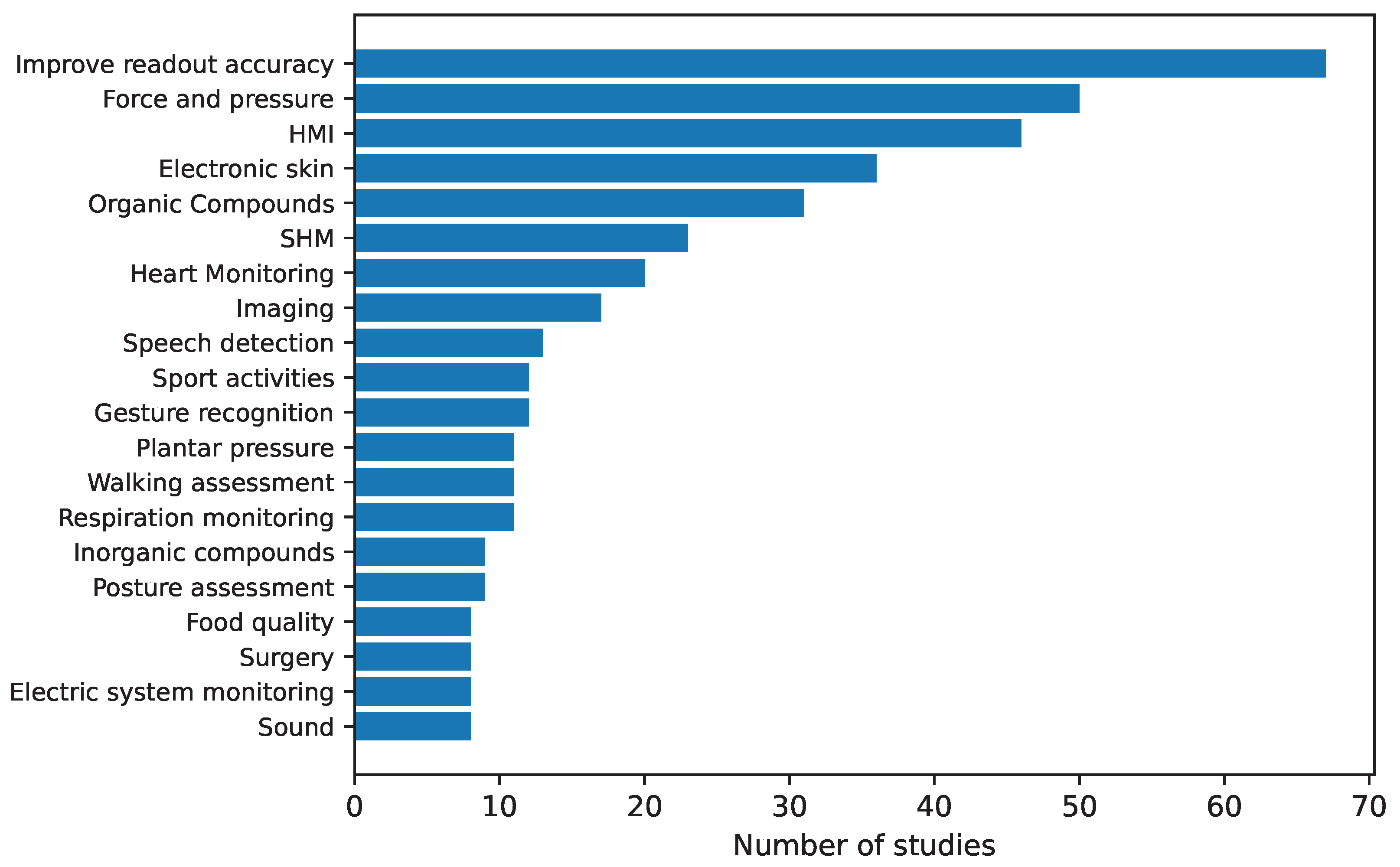

4. Sensor Array Applications

4.1. Results of the Analysis

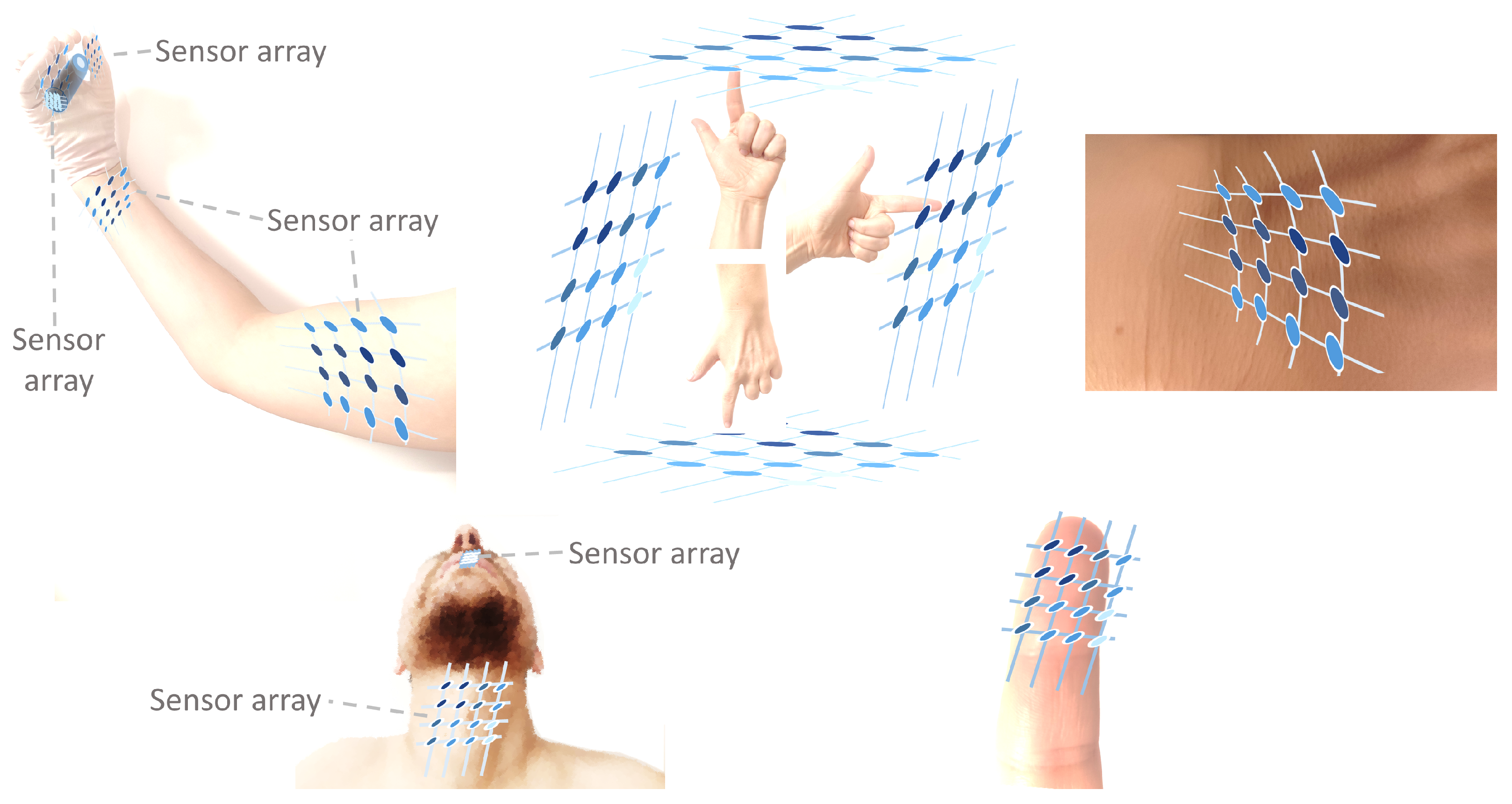

4.1.1. Interaction Applications

Human–Machine Interface (HMI)

Gesture Recognition

Electronic Skin

Speech Detection

Other Interaction Applications

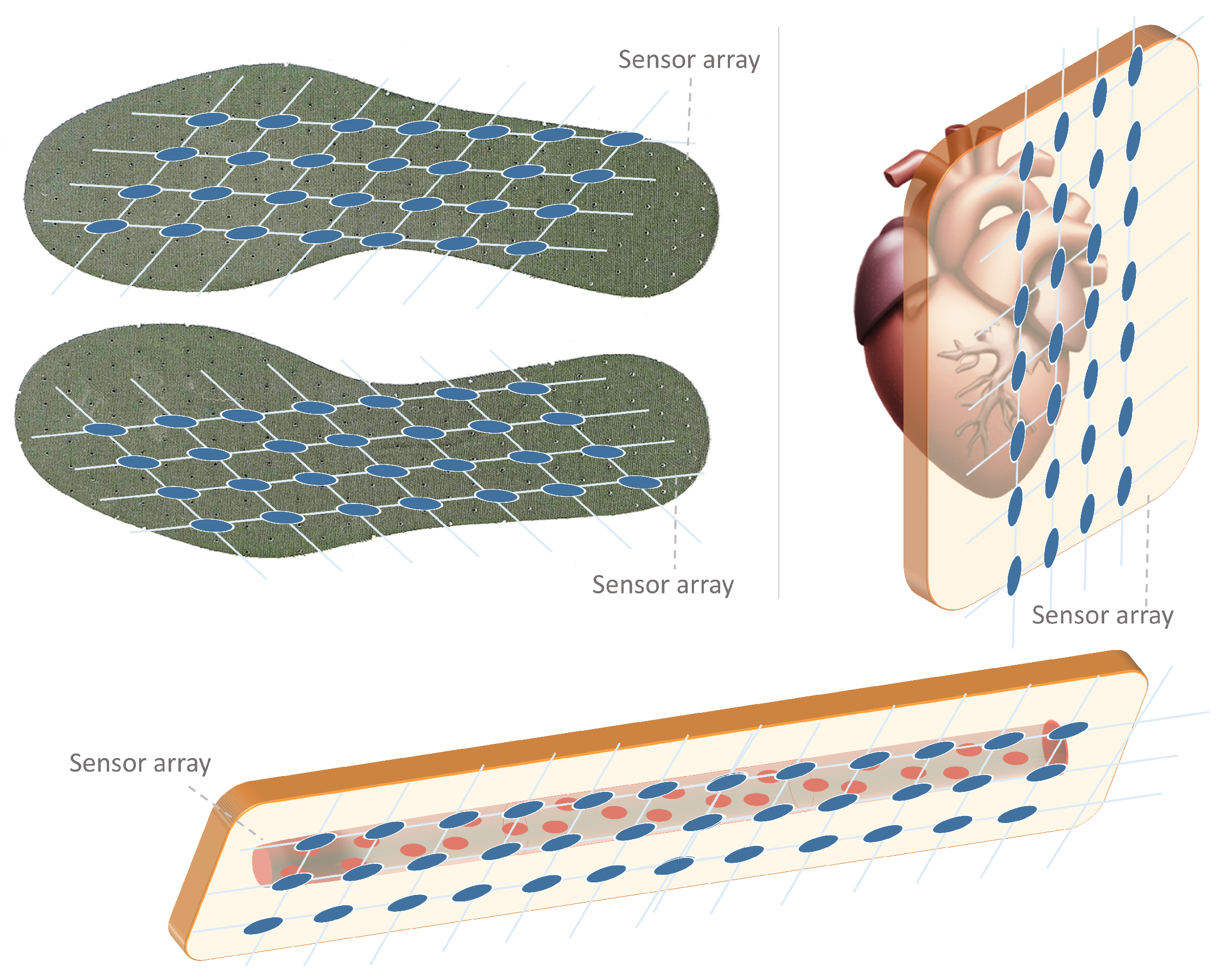

4.1.2. Human Health Monitoring and Biometric Applications

Plantar Pressure and Walking Assessment

Heart Monitoring

Blood Monitoring

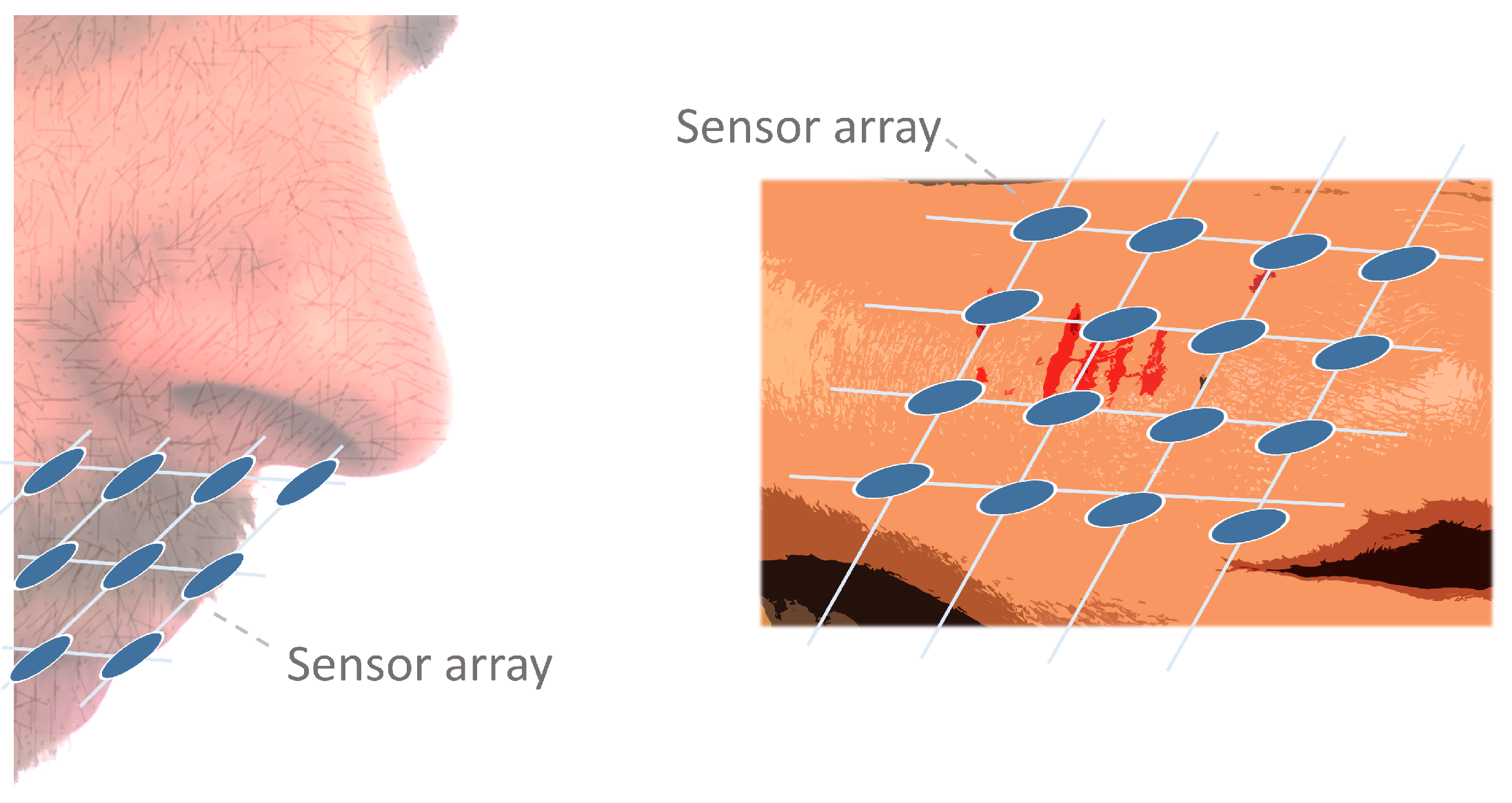

Respiration Monitoring

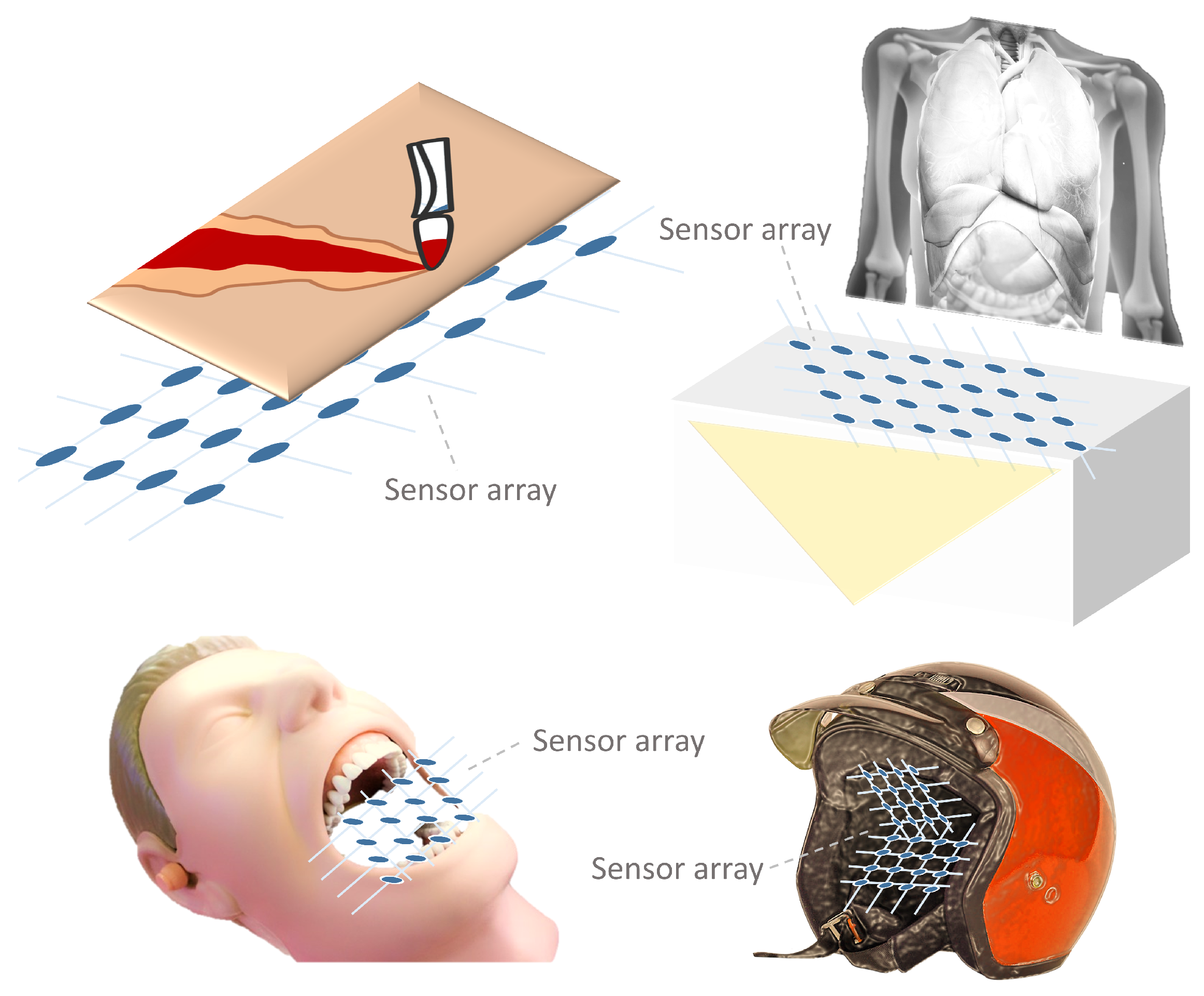

Skin Health

Posture Assessment

Sport Activities

Surgery

Other Health-Related Applications

4.1.3. Measurement of Physical Magnitudes

Force and Pressure

Curvature

Sound

Temperature

Magnetic Field Detection

Humidity

Other Applications Related to Physical Magnitudes

4.1.4. Chemical, Biological and Physical Applications

Organic Compounds

Inorganic Compounds

DNA and Other Biomolecules

pH

Cell Concentration

Food Quality

Radiation

Material Characterization

4.1.5. Security

Structural Health Monitoring (SHM)

Electric System Monitoring

Other Security Applications

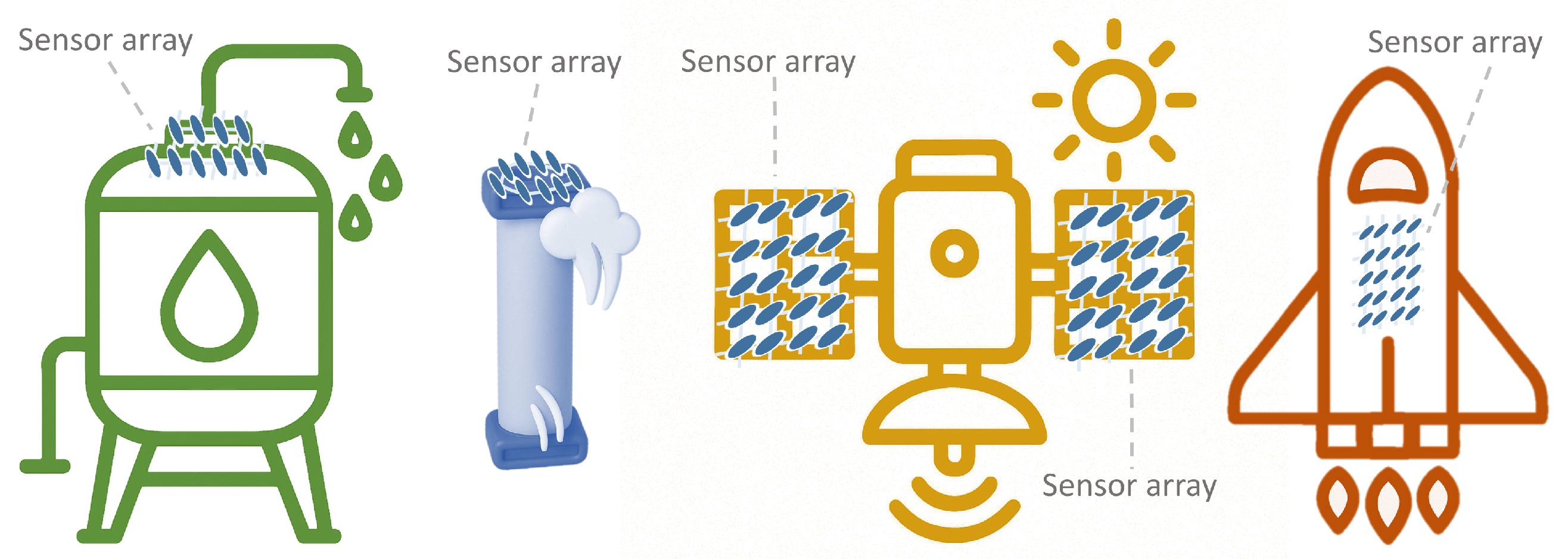

4.1.6. Marine and Aerospace Applications

Marine Applications

Airflow Applications

Aerospace Applications

4.1.7. Improve Readout Accuracy

4.1.8. Imaging

4.1.9. Energy Generation

4.2. Brief Conclusion of Sensor Array Applications

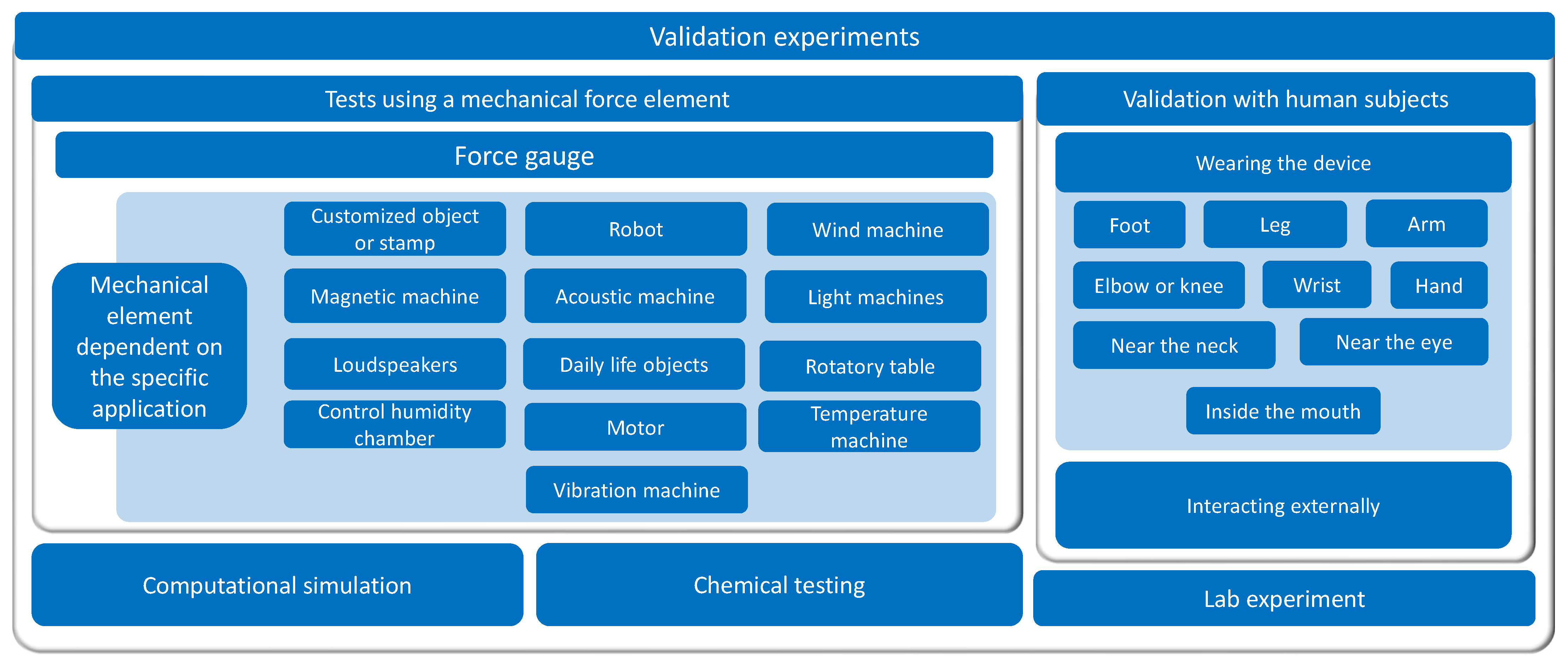

5. Validation Experiments

5.1. Results of the Analysis

5.1.1. Computational Simulation

5.1.2. Tests Using a Mechanical Force Element

Force Gauge

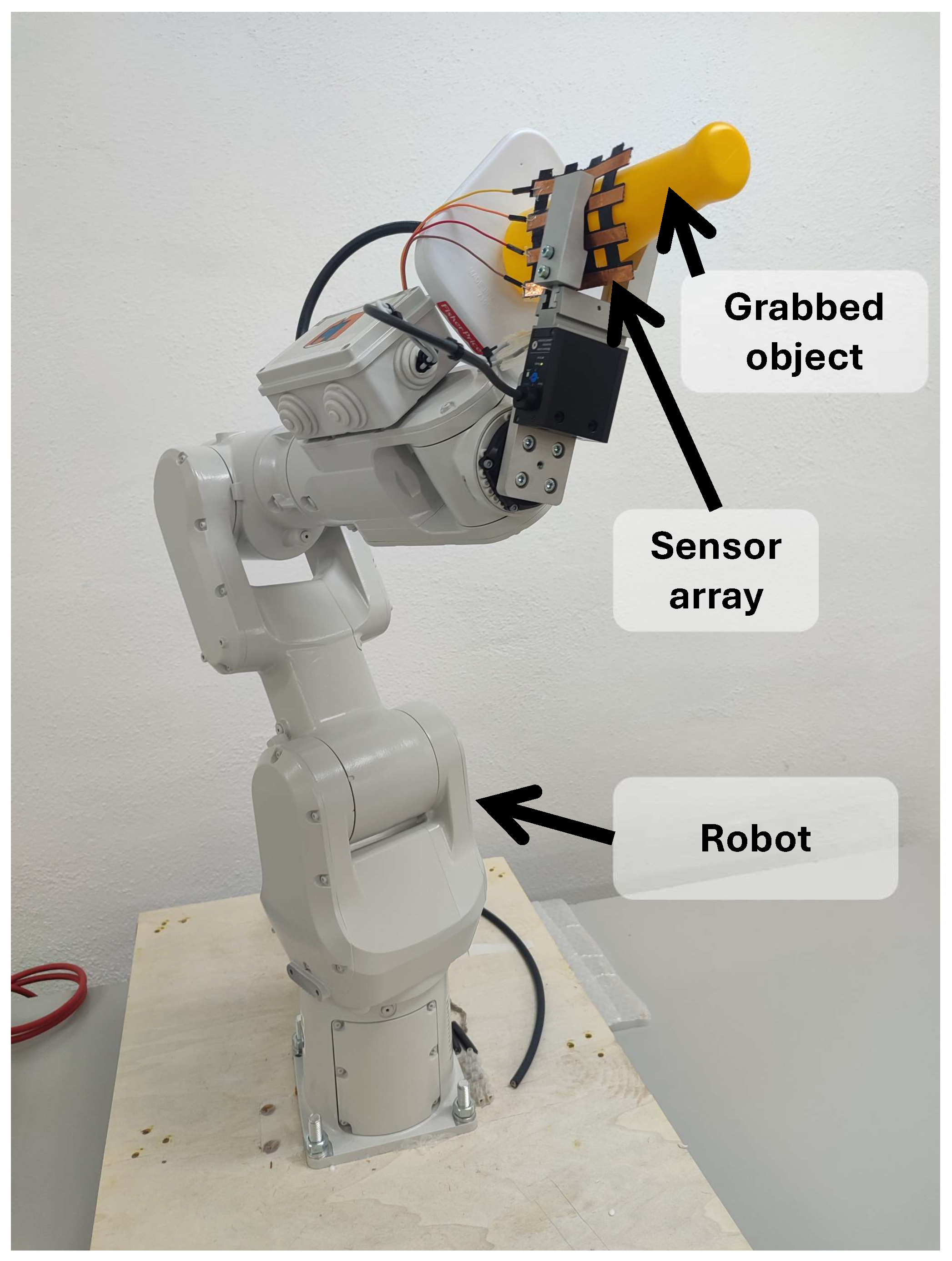

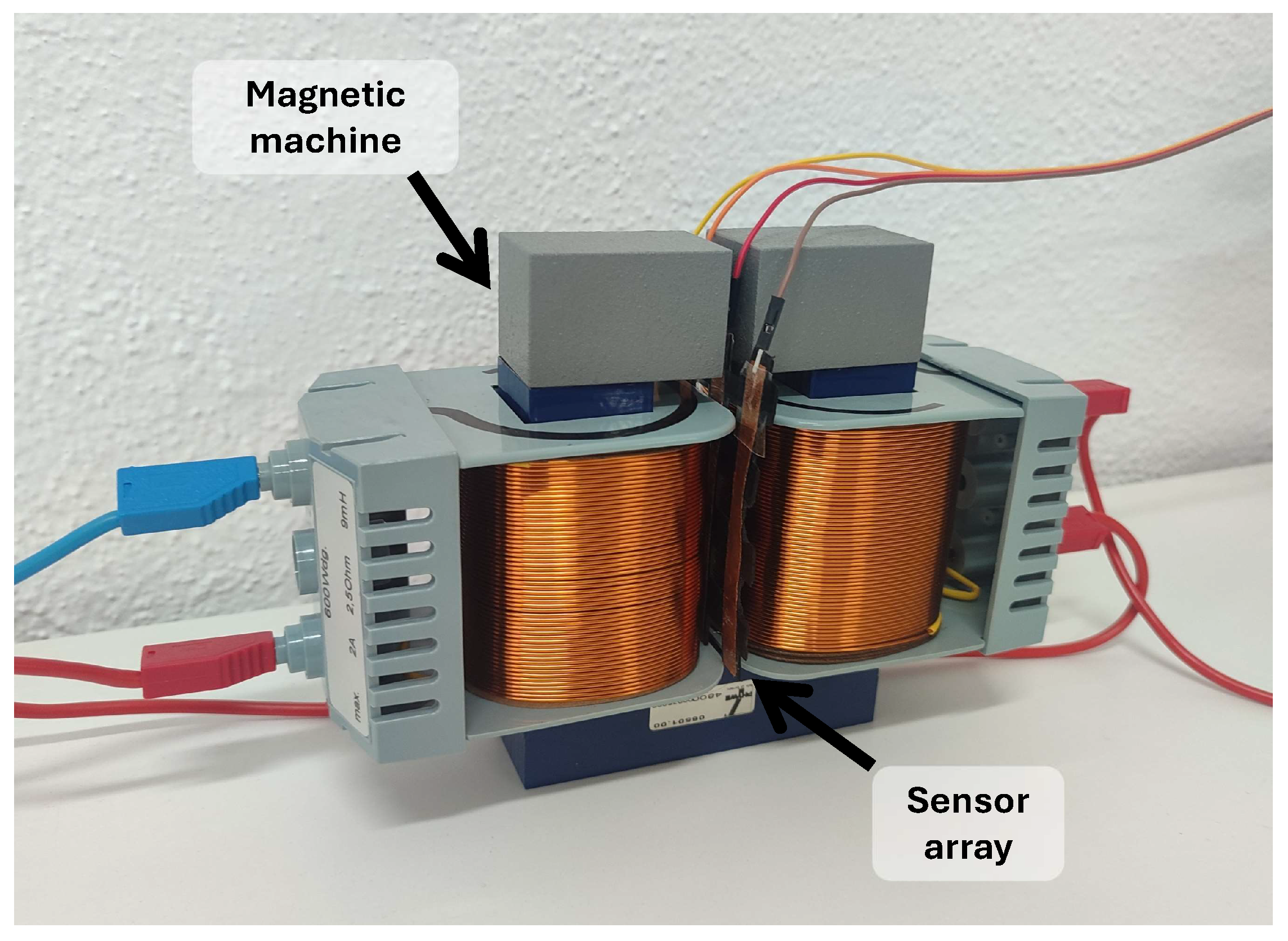

Mechanical Element Dependent on the Specific Application

5.1.3. Chemical Testing

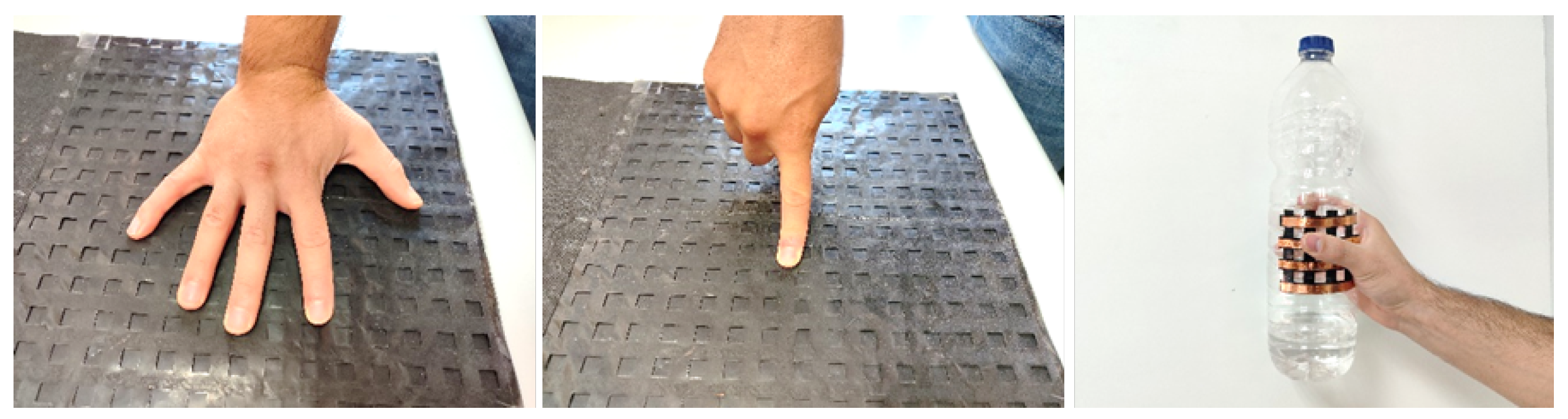

5.1.4. Validation with Human Subjects

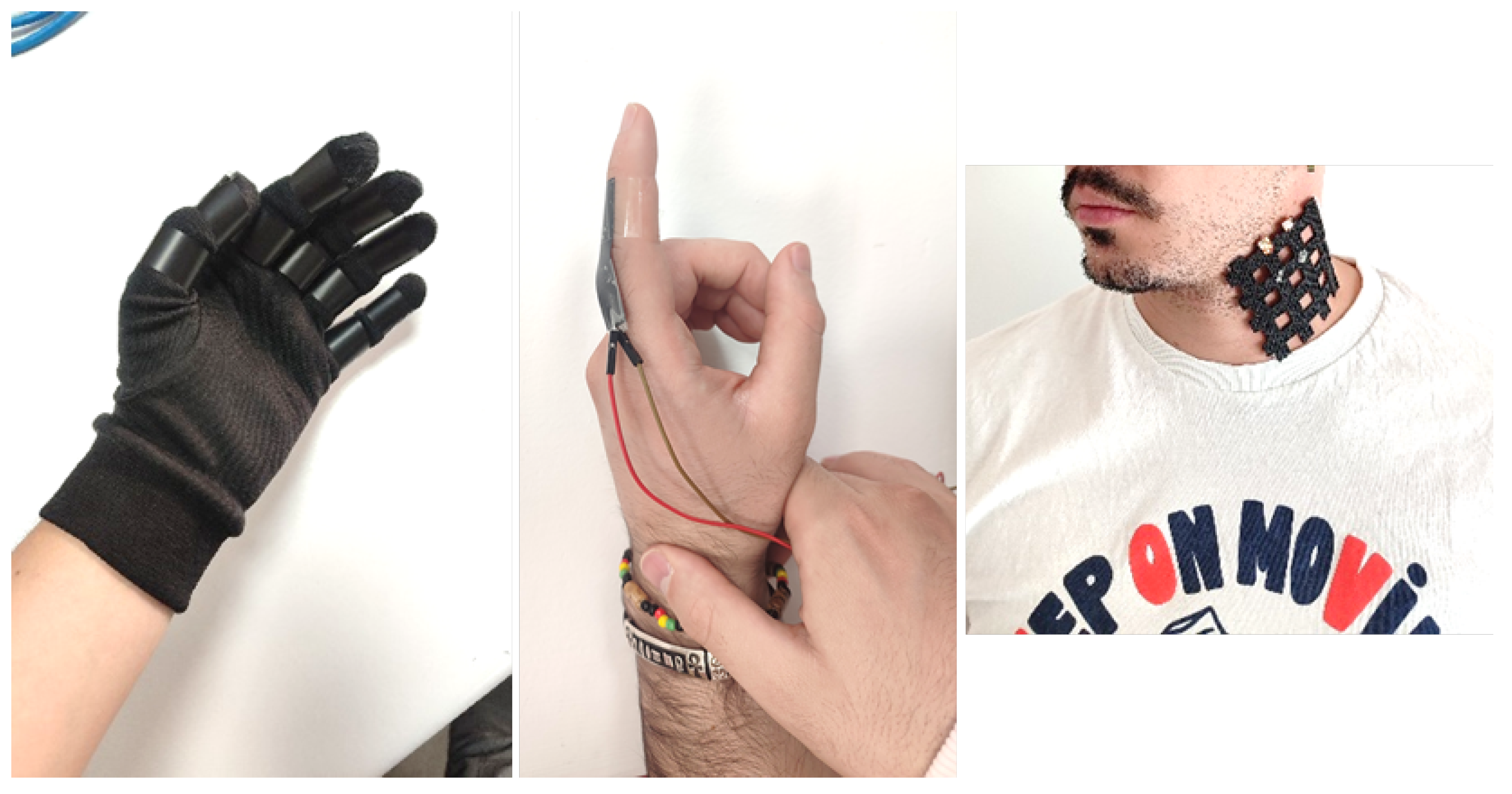

Subjects Wearing the Device

Subjects Interacting Externally with the Device

5.1.5. Lab Experiment

5.2. Brief Conclusion of Sensor Array Validation

6. Software for Analysis

6.1. Results of the Analysis

6.1.1. Mathematical or Numerical Simulation Software

MatLab

LabView

- IoT applications [318].

Processing

Mathematica

Weka

SAS

The Unscrambler

CasaXPS

Nist Astar Calculator

6.1.2. Finite-Element Analysis (FEA) Software

COMSOL

SolidWorks

ANSYS

ABAQUS

ADINA

CATIA

ConventorWare

Non-Specified FEA Software

6.1.3. Electronic and Circuit Simulation Software

SPICE

NI Multisim

Proteus

Ansoft

Silvaco

Sentaurus

Quartus

Sonnet

6.1.4. General-Purpose Programming Languages

Python

- Automatic sensor characterization [201].

C Programming Language

6.1.5. Development Platforms and Tools

Arduino

Raspberry PI

Smartphone Apps

6.1.6. Custom Software

- DeTECT (Demining Technology ECT): it was a new software presented in the work of Tholin & Soleimani [187]. It used a simulation method called the Finite Difference Method (FDM) to obtain the spatial permittivity distribution of a capacitive sensor array.

- In the work of Zafeirakis et al. [206] a customized software for visualization and frequency calculation was presented. It allowed measurement of the capacitance of a sensor array, sending the data to a remote computer via SSH, since it was running on an embedded Linux system.

6.1.7. Other Software

- Automation control software: In the humidity sensor array system for the CERN’s high-energy detector [192], a WinCC Open Architecture SCADA (Supervisory Control And Data Acquisition) software was used to command the PLC involved in the control process.

- Wilcom Deco Studio: This software was used by Gleskova et al. [168] for the design of the electrode embroidery of an all-textile capacitive sensor array.

6.2. Brief Conclusion of Software for Analysis

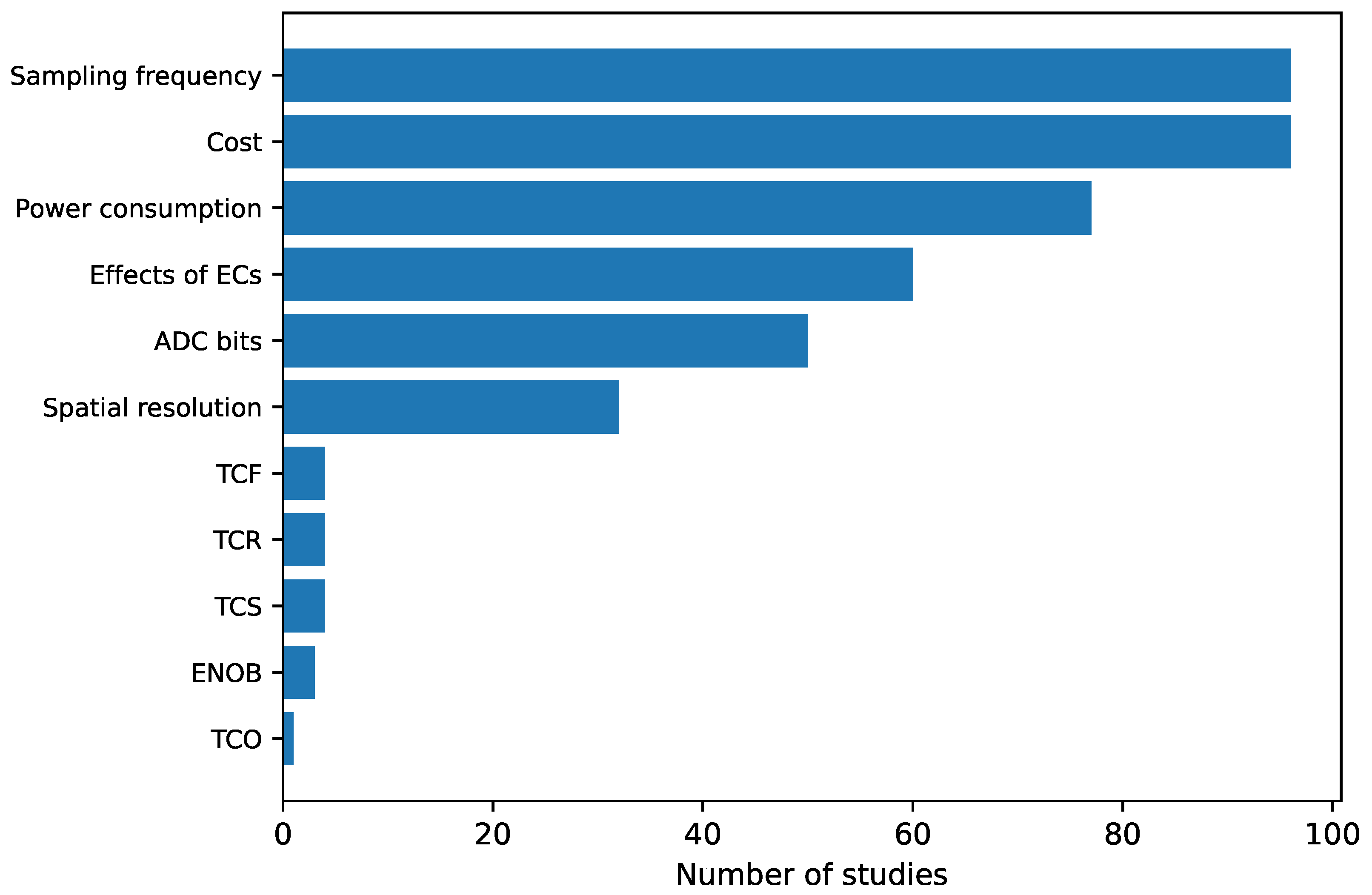

7. Sensor Array Characteristics

- Sensor characteristics. This group comprises different items: array size, sensor size, sensing area, effect of ECs, power consumption, and cost.

- Characteristics of the acquisition system. This includes the sampling frequency and the number of bits of the ADC.

7.1. Results of the Analysis

7.1.1. Sensor Characteristics

Sensor Dimension

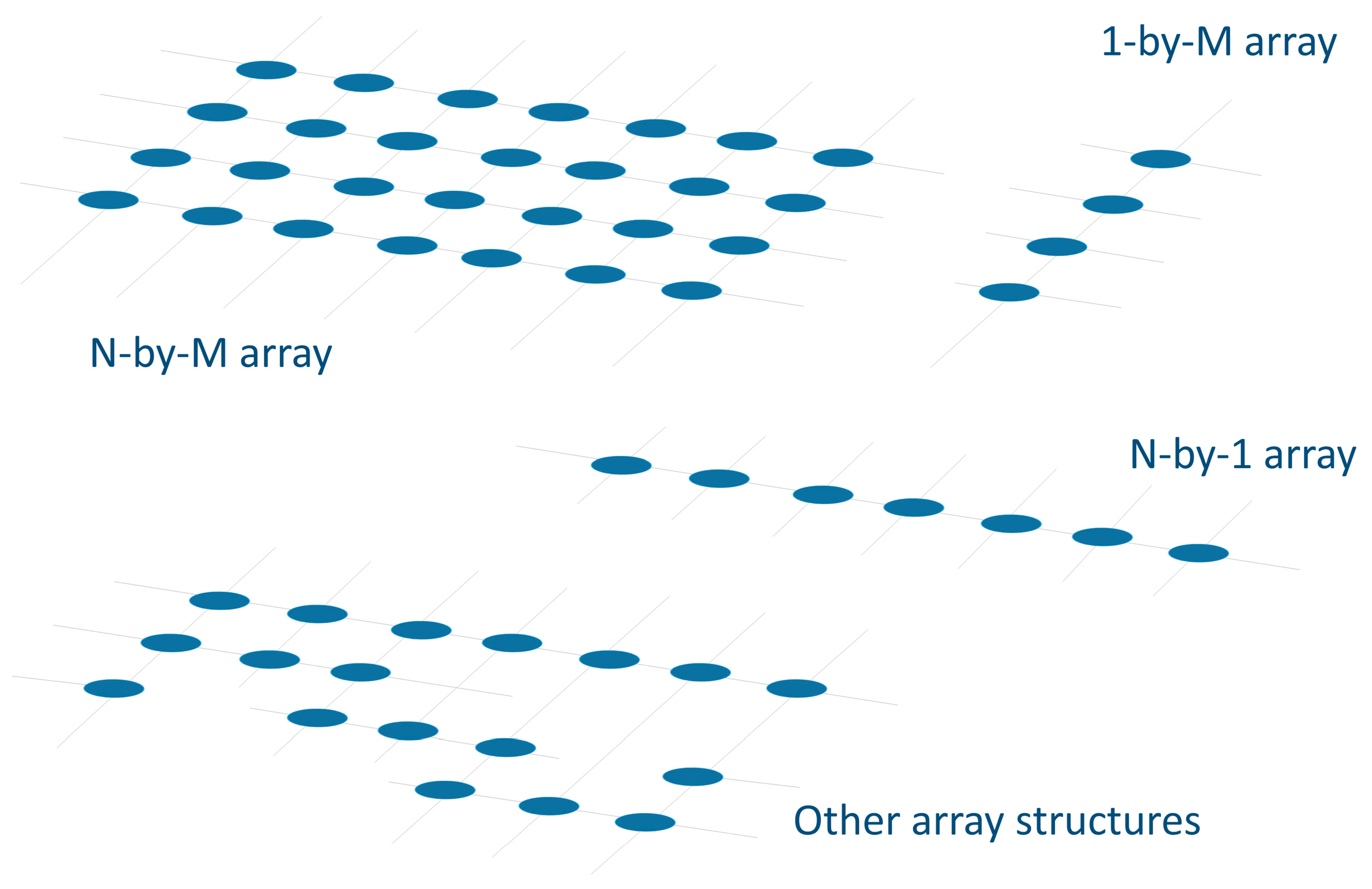

- Array size: An important comparison feature is the number of rows and columns in the sensor array. This parameter is almost always indicated in sensor array studies [8,12,15,20,30,31,32,33,34,35,36,37,38,39,40,42,43,45,46,47,48,49,50,52,53,55,56,57,58,60,61,64,65,67,69,70,71,73,75,76,77,78,79,81,82,84,85,87,88,93,94,96,97,98,100,101,104,105,106,107,108,109,111,112,113,114,115,117,119,120,121,122,123,124,125,126,127,128,129,132,133,134,135,136,138,139,140,143,144,145,146,147,149,150,151,152,155,156,158,159,160,161,162,163,164,165,167,169,172,173,174,180,181,182,183,185,186,188,189,190,193,194,196,197,198,200,201,204,205,210,211,212,213,214,215,216,218,221,223,224,225,229,230,233,236,237,238,240,242,243,244,245,248,251,252,255,256,259,260,261,262,263,268,269,270,271,272,274,280,281,283,285,287,288,297,304,305,306,314,319,320,323,324,325,327,328,330,332,334,336,340,342,344,346,348,349,353,357,358,359,361,363,365,368,370]. It is used specially for comparison in studies focused on improving readout accuracies. Studies that present new methods or techniques often test them on arrays of different sizes [8,12,15,20,50,53,55,56,57,58,60,61,64,65,67,69,70,71,73,75,76,88,94,97,98,104,105,106,111,112,113,114,115,117,119,120,121,122,123,124,125,126,127,128,129,132,133,134,135,136,139,140,150,151,152,155,156,158,159,160,161,162,165,167,169,172,173,174,180,181,188,196,197,198,200,204,205,210,211,213,216,221,223,225,229,230,233,252,256,259,260,261,262,263,268,270,272,274,283,287,288,297,306,320,323,324,325,332,334,348,349,353,357,359,361,368,370]

- Sensor size: The size of a single sensor in the array (a single cell) is also an important parameter. It is given as an area or as the length of the cell sides (length of the beam in the case of a fiber-optic array) [30,33,36,37,41,43,45,48,50,52,56,58,70,71,76,81,86,88,92,94,114,116,146,147,150,152,155,158,160,161,162,163,166,167,170,171,175,177,178,180,181,182,183,186,187,196,198,201,205,209,212,214,215,216,217,221,222,223,235,240,242,244,245,248,251,252,256,257,258,260,268,271,281,286,287,288,291,311,319,323,332,341,342,349,353,357,360]. This parameter affects the effective sensing area.

- Sensing area: It is the area covered by the whole array. A larger area does not necessarily means that the array has more sensors, as the sensor size must also be taken into account [7,8,10,12,36,42,56,57,58,61,63,65,66,70,71,75,81,82,88,92,94,112,116,142,144,150,151,155,156,160,161,162,167,168,171,173,181,182,186,188,209,210,215,216,222,223,224,225,226,230,232,233,240,243,244,246,248,253,254,255,256,258,259,260,261,268,269,282,287,291,292,298,305,314,320,321,324,327,328,330,331,340,349,353,357,359,360,361,366,367,370]. This parameter, together with the sensor size, determines the effective sensing area, which can be obtained from Equation (5).where is the effective sensing area, N and M are the number of rows and columns of the sensor array, respectively, is the area of one sensor, and is the sensing area (the area covered by the entire array).

Effects of Environmental Conditions (ECs)

- Temperature Coefficient of Frequency(TCF): The resonant frequency of certain sensor arrays can be sensitive to temperature variations according to Equation (7) [2,249,308,310], where is the fundamental resonant frequency of a pMUT and is the frequency variation associated with a temperature variation .

- Temperature Coefficient of Sensitivity (TCS): The sensitivity of a sensor may also depend on temperature [151,167]. Chen et al. [332] conducted a study on the influence of temperature on strain measurements using fiber-optic arrays. Similarly, Zhang et al. [69] observed that their pressure piezoresistive array changed its sensitivity for different temperatures.

- Temperature Coefficient of Offset (TCO): In the work of Hsieh et al. [167], the TCO was provided for a capacitive pressure array. The TCO indicated the base capacity value in the absence of pressure for a range of temperatures. In this case, the coefficient was −3.79 fF/°C.

Power Consumption

Cost

7.1.2. Acquisition System Characteristics

Number of ADC Bits

Sampling Frequency

7.2. Brief Conclusion of Sensor Array Characteristics

8. Sensor Array Performance Metrics

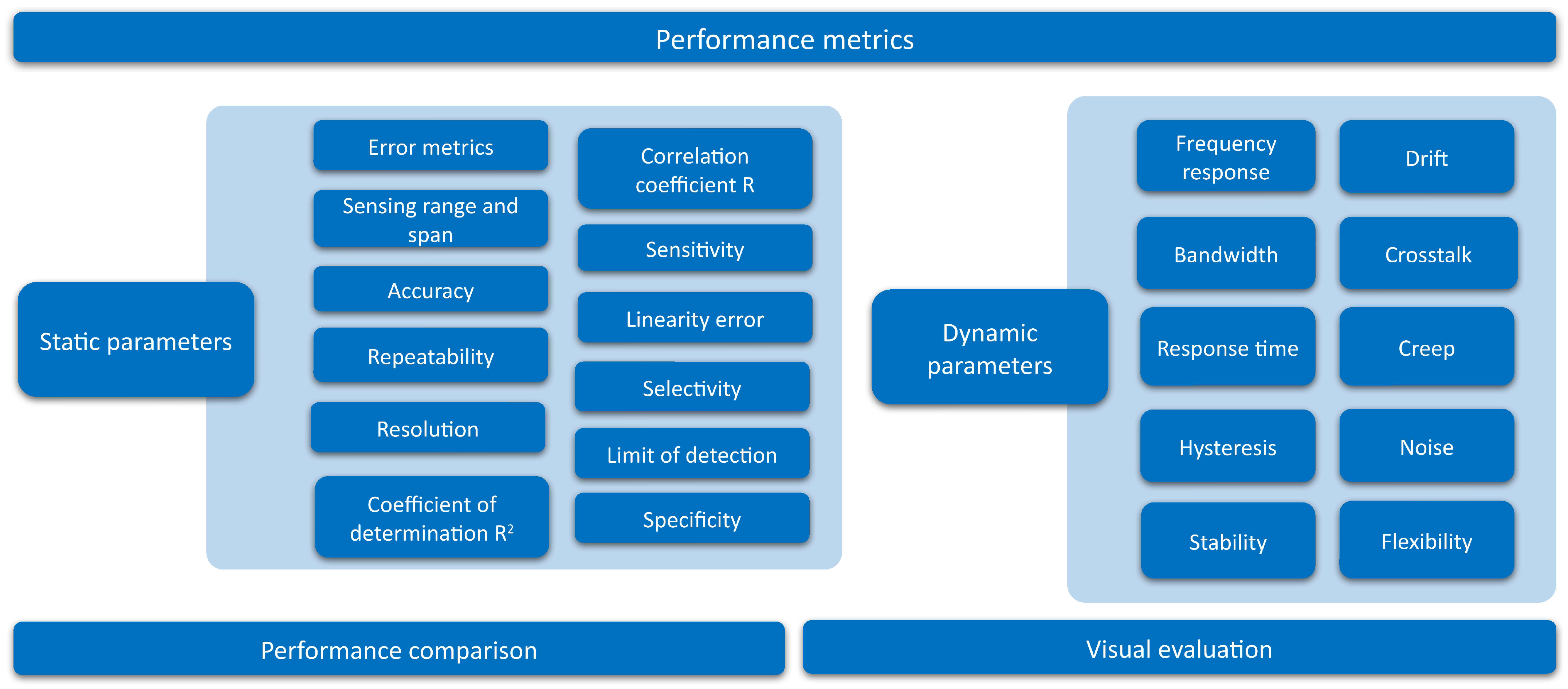

- Static performance metrics: These include error metrics, sensing range and span, accuracy, repeatability, sensitivity, resolution, coefficient of determination, correlation coefficient, linearity error, selectivity, limit of detection, and specificity.

- Dynamic performance metrics: This group considers frequency response, bandwidth, response time, hysteresis, stability, drift, crosstalk, creep, noise, and flexibility.

8.1. Results of the Analysis

8.1.1. Performance Metrics: Static Parameters

Error Metrics

Sensing Range and Span

Accuracy

Repeatability

Sensitivity

Resolution

Coefficient of Determination (CD, )

Correlation Coefficient (R)

Linearity Error

Selectivity

Limit of Detection (LOD)

Specificity

8.1.2. Performance Metrics: Dynamic Parameters

Frequency Response

Bandwidth (BW)

Response Time

Hysteresis

Stability

Drift

- In the case of piezoresistive technology, there are several studies considered state-of-the-art that analyze the effects of drift. Zhang et al. [69] studied temperature drift by placing the piezoresistive array inside a temperature chamber. Then it was compensated by a NN. In turn, Mirza et al. [64] pre-heated the sensor array and circuitry to prevent thermal drift. Sensor arrays using OAs (typical of resistive sensor arrays) may experience temperature drift [113,117,119]. This effect is difficult to calibrate and compensate for. Li et al. [79] avoided temperature drift by using a capacitive trans-impedance feedback amplifier (CTIA).

- In the case of Hall effect technology, Luca et al. [362] reported drift in a Hall effect sensor array, which was due to time and temperature.

- In VOC-sensitive piezoelectric resonators, drift can appear as a shift in the original frequency of the sensors after exposure to aggressive sorbates [307]

Crosstalk

- Many studies on resistive/piezoresistive sensor arrays have dealt with crosstalk and proposed new techniques to compensate for it (referred to as “compensated” in Table 6 and Table A3) [8,50,51,59,64,72,75,93,96,97,99,104,105,106,107,109,110,111,112,113,114,115,117,118,119,120,121,122,123,124,125,126,127,128,129,130,131,132,133,134,135,136,138,139,140,141,310,370].

- In fiber-optic sensor arrays, TDM or wave-division multiplexing are techniques used to reduce crosstalk [32,33,49,348,349]. They allow several signals to be transported within the same fiber beam. Meanwhile, Park et al. [353] reduced crosstalk between near scintillators placing reflectors between them.

Creep

Noise

- The influence of noise is usually quantified by the SNR [1,4,8,16,32,33,36,42,47,49,64,69,73,139,163,178,179,181,215,222,228,238,243,252,264,265,291,305,314,342,347]. The SNR in decibels (dB) can be calculated with Equation (31), where and are the power magnitude of the signal and noise, respectively, and and are the amplitude of the signal and noise expressed in any magnitude (voltage, pressure, etc.).Another way to calculate the SNR is with the mean value of the measurements of the sensor array and their standard deviation (Equation (32)) [8,64]. This is a percentage value. This metric assumes that the standard deviation comes from the noise:Proper DAQ electronics design can improve SNR [103].

- Choi et al. [83] performed a logarithmic fit of the applied pressure on a piezoresistive sensor array versus SNR, obtaining an = 0.9861.

- Magnetic noise was obtained in the study of Qu et al. [309]. It can be calculated as , where is the overall noise and is the sensitivity of the system.

- Warnakulasuriya et al. [75] used a fixed resistor array model to prevent manufacturing defects and mismatching between the sensels in the array from interfering with the verification of the readout circuit.

- Yang et al. [318] identified impedance mismatch as the main problem for the commercialization of triboelectric sensor arrays.

- Fernandes et al. [178] presented a capacitive array with electrode cracking due to mismatch in the properties of the adhesion and elastomeric layers. In this sense, Nabovati et al. [197] identified the mismatch in the sensor electrodes as the main source of error in a capacitive array. Other authors [9,193] also reported inaccuracies in capacitive array measurements due to sensor mismatches.

- The work of Tabrizi et al. [205] is particularly interesting, as it is one of the few studies on sensor arrays that quantifies the effects of mismatch between several individual sensor elements. In fact, the standard deviation in the output current due to mismatch is quantified between 9.3 and 10 μA.

- Piron et al. [15] discussed time-to-amplitude converters in their review of diode arrays. They indicated that they were prone to noise and transistor mismatches.

- Su et al. [76] identified the mismatch in Young’s modulus as a major challenge in a transistor-based array.

- The study of Weichart et al. [176] focused on thermal expansion coefficient mismatches in a capacitive sensor array. They proposed minimization strategies based on coefficient matching. In this regard, the works of Verma et al. [84], and Kundu et al. [220] also dealt with compensation and minimization of mismatch. Finally, Faria et al. [215] stated that the effects of channel mismatches were minimal in their inductive array measurement system.

Flexibility

8.1.3. Performance Comparison

8.1.4. Visual Evaluation

8.2. Brief Conclusion of Sensor Array Metrics

9. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ADC | Analogue-to-Digital Converter |

| AE | Absolute Error |

| AFCRS | Array of fiber-optic Cerenkov Radiation Sensor |

| AI | Artificial Intelligence |

| ARE | Absolute Relative Error |

| BAW | Bulk Acoustic Wave |

| BW | Bandwidth |

| CACT | Co-planar array capacitive imaging technique |

| CERN | European Organization for Nuclear Research |

| CFET | Cantilever FET |

| CNN | Convolutional Neural Network |

| CNT | Carbon nanotube |

| CTIA | Capacitive trans-impedance feedback amplifier |

| CV | Coefficient of variation |

| DAQ | Data Acquisition Card |

| DG-TFT | Dual-Gate TFT |

| ECs | Environmental conditions |

| ECT | Electrical capacitance tomography |

| EISCAP | Electrolyte-insulator-semiconductor capacitors |

| EMN | Equivalent magnetic noise |

| ENOB | Effective number of bits |

| E-Nose | Electronic nose |

| FBG | Fiber Bragg Grating |

| FEA | Finite-Element Analysis |

| FEP | Fluorinated Ethylene Propylene |

| FET | Field-Effect Transistor |

| FMPE | Ferromagnetic-piezoelectric |

| FS | Full scale |

| FSO | Full scale output |

| FSR | Force-sensitive resistor |

| HEMT | High-Mobility Electron Transistor |

| HMI | Human-Machine Interface |

| ICC | Intra-Class Correlation Coefficient |

| IGZO | Indium Gallium Zinc oxide |

| IMU | Inertial Measurement Unit |

| IoT | Internet of Things |

| ISFET | Ion-Sensitive FET |

| kNN | k-Nearest Neighbor |

| LMA | Levenberg-Marquardt Algorithm |

| LOD | Limit of detection |

| LSB | Least significant bit |

| LWR | Lamb wave resonator |

| MAE | Mean Absolute Error |

| MARE | Mean Absolute Relative Error |

| MEMS | Micro electro-mechanical system |

| MG-FET | Moving-Gate FET |

| MIP | Molecularly imprinted polymer |

| ML | Machine learning |

| MRE | Mean Relative Error |

| MSE | Mean Squared Error |

| MUSIC | Multiple Signal Classification |

| MWCNT | Multi-walled CNT |

| NECT | Near end crosstalk |

| NEP | Noise equivalent pressure |

| NI | National Instruments |

| NIST | National Institute of Standards and Technology of the United States |

| NRMSE | Normalized root mean squared error |

| NN | Neural Network |

| NW | Nanowires |

| OA | Operational Amplifier |

| OSA | Obstructive Sleep Apnea |

| PAAMPSA | poly(2-acrylamido-2-methyl-1-propanesulfonic acid |

| PAni | polyaniline |

| PBU | polybutadiene-urethane |

| PCA | Principal Component Analysis |

| PCB | Printed Circuit Board |

| PCL | Polycaprolactone |

| PEDOT:PSS | poly (3,4-ethylenedioxythiophene): polystyrene sulfonate (PSS) |

| PEGDA | Poly(ethylene glycol) diacrylate |

| PEO | polyethylene oxide |

| PET | polyethylene terephthalate |

| PDMS | polydimethylsiloxane |

| PMMA | Polymethyl methacrylate |

| PMN–PT | Lead magnesium niobate–lead titanate |

| pMUT | piezoelectric Micromachined Ultrasonic Transducer |

| PQR | Piezoelectric Quartz Resonator |

| PSM | Pressure-sensitive mat |

| PTFE | Polytetrafluoroethylene |

| PVA | Polyvinyl alcohol |

| PVDF | polyvinylidene fluoride |

| PWV | Pulse Wave Velocity |

| RE | Relative Error |

| RMSE | Root Mean Squared Error |

| SAW | Surface Acoustic Wave |

| SHM | Structural Health Monitoring |

| SNR | Signal-to-Noise-Ratio |

| STD | Standard deviation |

| TDM | Time-division multiplexing |

| TEG | Triboelectric Generator |

| TENG | Triboelectric Nano-Generator |

| TFT | Thin-Film Transistor |

| UV | Ultraviolet |

| UXO | Unexploded Ordnance |

| VOC | Volatile Organic Compound |

| VOL | Volatile Organic Liquids |

Appendix A

| Study | Technology | Sensor Dimensions | Electrode | Sensing Material |

|---|---|---|---|---|

| [183] | Capacitive | 5 × 1 (25 × 124 , 24 × 24 per sensor) | Cu | Silicone composite |

| [337] | Fiber Optic | 10 × 10 (10 cm of separation) | Commercial sensor | Commercial sensor |

| [365] | Hall effect | 3 × 3 (7 × 10 ) | - | , Ta, Py |

| [251] | Piezoelectric | 3 × 3 (10 × 12 mm per sensor) | Ag | P(VDF-TrFE), |

| [363] | Hall effect | 6 sensors (elliptical array) | Commercial sensor | Commercial sensor |

| [103] | Resistive | 16 × 16 | Custom magnetic sensor | Custom magnetic sensor |

| [346] | Fiber Optic Piezoelectric | 16 elements | Fiber Optic | Fiber Optic |

| [331] | Triboelectric | 7 × 1 (7 piano keys, 2 per sensor) | Al | rGO, Nylon, Ecoflex, Mo |

| [102] | Resistive Triboelectric (heterogeneous) | 2 × 2 (6 × 3 ) | Ag | Mxene, Metal oxide |

| [330] | Triboelectric | 3 × 2 (area of a bed) | Cu | PDMS, PVDF |

| [248] | Piezoelectric | 4 × 4 (29 × 29 mm, 5 mm × 5 mm per sensor) | AgNW | P(VDF-TrFE), ZnO |

| [329] | Triboelectric | 15 sensors (3 per finger) | Au, Cu | Vertical graphene, FEP |

| [93] | Capacitive Resistive | 5 × 5 | Copper foil, Graphite paint film | Air |

| [328] | Triboelectric | 5 × 3 (20 × 20 ) | Galinstan | PVA |

| [242] | Piezoelectric | 2 × 5 (2 × 2 mm each sensor) | Ti, Pt | V-doped ZnO |

| [301] | Piezoelectric | 7 × 1 (real-life), 8 nodes (simulation, 10 mm spaced) | PZT | PZT |

| [107] | Resistive | 10 × 10 (simulated), 4 × 4 (real) | Commercial resistor | Commercial resistor |

| [163] | Triboelectric Capacitive (heterogeneous) | 4 × 4 (7 × 7 mm per sensor) | EGaIn | Liquid metal, MXene, Silicone |

| [255] | Piezoelectric | 5 × 1 (8 × 6 cm) | Printed Ag | BaTi |

| [319] | Triboelectric | 20 × 20 (32 × 32 ) | Galinstan + Nano iron powders | Nano silica, PTFE, Silicone |

| [285] | Piezoelectric | 3 × 3 (2 mm diameter each sensor) | Cr, Au | PZT |

| [87] | Piezoresistive | 3 × 3 (10 mm × 14 mm) | Cu | Mxene, ZnONW |

| [149] | Capacitive | 16 × 16 (3 cm × 3 cm) | Cu | MWCNT, PDMS |

| [86] | Piezoresistive | 2 × 3 (1 × 1.5 cm, 100 µm electrode size) | ITO | PEO:PAni |

| [280] | Piezoelectric | 24 sensors (circular shape around a bolt) | - | PZT |

| [85] | Piezoresistive | 32 × 32 (0.6 mm pixel spacing) | Ag | Carbon, Graphene |

| [281] | Piezoelectric | 9 sensors (20 × 20 mm each sensor) | - | PMN-PT |

| [84] | Piezoresistive | 5 × 5 | CMOS fabrication | CMOS fabrication |

| [83] | Piezoresistive | 10 × 10 | AgNW-PBU | PBU-MXene |

| [82] | Piezoresistive | 8 × 8 (370 × 470 mm) | Cu | CNT commercial sensor |

| [81] | Piezoresistive | 8 × 1 (8 conductive strips, 180 cm × 90 cm) | Cu | VelostatTM |

| [80] | Piezoresistive | 10 sensors embedded in smart clothing | Cu | PU-MWCNT |

| [141] | Resistive | 16 × 16 | Cu | VelostatTM, Commercial PSM |

| [108] | Resistive | 40 × 240 (35 × 200 cm) | Cu | Caplink |

| [101] | Resistive (heterogeneous) | 2 × 1 (one sensor detects Zn(II) ion, one sensor detects Cu (II) ion) | Au | Device 1: Device 2: |

| [79] | Resistive | 10 × 10 | Cu | - |

| [138] | Resistive | From 4 × 4 to 32 × 32 (simulated), 8 × 8 (real) | Commercial resistor | Commercial resistor |

| [340] | Fiber Optic | 4 sensors (1 m × 1 m × 1 m) | Fiber Optic | Fiber Optic |

| [189] | Capacitive | 8 electrodes (wrapped around a metallic pipe) | Cu | Object to detect |

| [193] | Capacitive | 2 × 8 × 16 (35 µm × 30 µm) | CMOS fabrication | CMOS fabrication |

| [186] | Capacitive | 6 × 6 (94 × 94 , 14 × 14 each taxel, 5 electrodes per sensor) | Cu | Ecoflex gel, conductive fabric |

| [344] | Fiber Optic | 2 × 3 | Fabry-Perot | Fabry-Perot |

| [342] | Fiber Optic | 26 FBGs (20 m long) | FBG | FBG |

| [238] | Transistor | 2 × 2 (4 mm × 4 mm) | Ti, Au | CNT, Au, Cu, Ti |

| [224] | Transistor Triboelectric | 5 × 5 (4 cm × 4 cm) | Mo Ag | IGZO |

| [237] | Transistor | 3 electrodes (3 different antibiotics) | MIP | AuNPs-loaded metal-organic framework |

| [236] | Transistor | 5 × 5 | Au | PCBM-MAPb |

| [52] | Piezoresistive Diode (heterogeneous) | 16 × 16, 8 × 8 (16 × 16 mm) | Mo, ITO | IGZO, MWCNT |

| [240] | Transistor | 16 sensors (7 × 7 ) | Pt, Chitosan, Ag AgCl | PEDOT:PSS |

| [215] | Inductive | 40 sensors (100 × 100 mm, 1 × 0.5 × 0.5 mm per sensor) | Commercial sensor | Commercial sensor |

| [214] | Inductive | 4 sensors (different shapes, wrapped around the elbow) | Cu | Conductive yarn |

| [212] | Inductive | 4 × 4 (cilinders of 5 mm diameter, 6 mm height) | Cu | Ecoflex + Magnetic filler |

| [194] | Capacitive | 6 sensors (concave electrodes around a pipeline) | Cu | Object to detect |

| [336] | Fiber Optic | 8 sensors | Fiber Optic | Fiber Optic |

| [146] | Capacitive | 3 × 3 (10 × 10 mm per sensor) | Printed Ag | PI, PDMS |

| [245] | Piezoelectric | 3 × 3 (3.14 each pixel) | Cr, Au | PZT, PDMS |

| [243] | Piezoelectric | 3 × 1 (2 cm long each sensor) | Cr, Au | PDMS, AlN, AlGaN |

| [77] | Piezoresistive | 30 × 11 | - | VelostatTM |

| [100] | Resistive | 14 × 1 | Commercial sensor | Commercial sensor |

| [190] | Capacitive | 6 (area of the electrode 70 mm × 8 m) | Cu | Object to detect |

| [358] | Hall effect | 4 × 4 (4.5 mm spacing) | Commercial sensor | Commercial sensor |

| [244] | Piezoelectric | 255 sensors (60 × 90 cm, 7 × 32 mm per sensor) | Printed Ag | P(VDF-TrFE), PEDOT:PSS |

| [144] | Capacitive | 6 × 28 (0.36 × 1.82 , in 7 tiles) | Cu | EVA |

| [147] | Capacitive | 8 × 8 (2.5 × 2.5 mm each taxel) | Cu | Air, PI |

| [185] | Capacitive | 137 electrodes distributed in the palm of a hand | Cu | PU, BaTi |

| [184] | Capacitive | 4 × 8 | - | Silicone |

| [182] | Capacitive | 16 × 16 (70 mm × 70 mm) | Ag ink | Object to detect |

| [235] | Transistor | 2 × 2 | Ti, Au | CNT, Si |

| [229] | Transistor | 12 × 12 | Au, Ti | Si, Au, Ti |

| [353] | Fiber Optic | 20 × 1 | Fiber Optic | Fiber Optic |

| [169] | Capacitive | 4 × 3 | AgNW | PDMS |

| [213] | Inductive | 5 × 1 | Commercial sensor | Commercial sensor |

| [199] | Capacitive | 16 × 16 | CMOS fabrication | Object to detect |

| [209] | Inductive | 2 × 1 | CMOS fabrication | CMOS fabrication |

| [174] | Capacitive | 10 × 10 | AgNW | PDMS, BT, Zn, Cu |

| [173] | Capacitive | 3 × 3 | Cu | Silicone, Ag |

| [160] | Capacitive | 4 × 4 | Printed Ag | Printed PDMS, Air |

| [338] | Fiber Optic | 2 × 1 | Fiber Optic | Fiber Optic |

| [198] | Capacitive | 480 × 960 | CMOS fabrication | Object to detect |

| [161] | Capacitive | 2 × 2 | Cu | PET, Silk |

| [113] | Resistive | From 2 × 2 to 12 × 12 | Cu | EGaIn |

| [137] | Resistive | 5 × 5 | AgNW | Al, ITO, PDMS, Si |

| [116] | Resistive | 84 × 80 (90 mm × 90 mm) | - | PET, Si |

| [8] | Resistive | 8 threads (crossing 4 vs. 4) | Cu | Silicone |

| [134] | Resistive | 32 × 32 | - | - |

| [356] | Fiber Optic | 3 × 1 | Fabry-Perot | Fabry-Perot |

| [112] | Resistive | 16 × 8 | Cu | Commercial thin-film resistor |

| [361] | Hall effect | 4 × 4 | Commercial sensor | Commercial sensor |

| [139] | Resistive | 4 × 4, 8 × 8, 16 × 16 | - | - |

| [269] | Piezoelectric | 9 × 9 (1 mm × 1 mm, 50 µm sensor diameter) | Au | Mo, AlN |

| [305] | Piezoelectric | 5 × 1 (1.6 × 2.4 cm) | - | Perovskite rods |

| [304] | Piezoelectric | 8 × 2 (20 cm between columns, 1 column of transmitters, 1 of receivers) | Commercial sensor (PZT) | Commercial sensor (PZT) |

| [271] | Piezoelectric | 6 × 5 (electrode of 2 mm diameter) | Al, Au, Cr | PZT |

| [218] | Diode | 14 × 14 | ITO | IGZO |

| [143] | Capacitive | 6 × 6 | Au | PDMS, PI |

| [145] | Capacitive | 3 × 3 | Cr, Au, Parylene | Porous PDMS NaHC |

| [201] | Capacitive | 4 × 4 (71 mm height, 0.5 electrode size) | Ag AgCl | Si, , Si |

| [164] | Capacitive | 8 × 6 | Conductive ink, conductive textiles, | Ecoflex, PDMS |

| [327] | Triboelectric | 4 × 4 (1 × 1 ) | PEDOT:PSS, glycerol | PMDS, Polycaprolactone |

| [360] | Hall effect | 7 × 4 5 × 3 | Commercial sensor | Commercial sensor |

| [109] | Resistive | From 8 × 1 to 8 × 512 (simulation), 4 × 4 8 × 8 12 × 12 16 × 16 (real) | Commercial resistor | Commercial resistor |

| [78] | Piezoresistive | 4 × 4 | Commercial resistor | Commercial resistor |

| [92] | Capacitive Piezoresistive (heterogeneous) | 2 × 1 | ITO | CNT, PDMS |

| [68] | Piezoresistive (heterogeneous) | 2 × 1 | Ag | MXene |

| [254] | Piezoelectric | Tennis racket shape | Printed Ag | PVDF |

| [253] | Piezoelectric | 3 × 3, 5 × 5 | Au, Ag | (K, Na)Nb |

| [257] | Piezoelectric | 3 × 1 | Cu | PZT |

| [256] | Piezoelectric | 5 × 5 | Cu | PZT |

| [364] | Hall effect | 4 × 1 | Au | Si, Al, Ta, Py |

| [314] | Piezoelectric | 8 × 5 (300 × 340 ) | ITO | P(VDF-TrFE) |

| [247] | Piezoelectric | 1 × 3 | - | Mo |

| [62] | Diode Capacitive Piezoresistive (heterogeneous) | 1 × 1 temperature 1 × 1 pressure 1 × 1 UV light 8 × 8 LED display | Au, Al, CNT | CNT, PVDF, Si ZnONW, PAni |

| [192] | Capacitive | - | - | C0G |

| [114] | Resistive (heterogeneous) | 5 × 4 | Commercial sensor | Commercial sensor |

| [140] | Piezoresistive | 6 × 6 | - | - |

| [315] | Triboelectric | 16 × 16 3 × 3 | Graphene | Kapton, Silicone |

| [317] | Triboelectric | 12 sensors (circular shape) | Al | PTFE |

| [322] | Triboelectric | 6 × 3 0.5 cm per cell | Printed Ag, ITO | PDMS |

| [318] | Triboelectric | 2 × 1, 2 × 1, 4 × 1 | Ag | PVDF, PET |

| [320] | Triboelectric | 5 × 5 (11 × 1 cm2) | Al | PVDF, PDMS, Nylon |

| [268] | Piezoelectric | 8 × 8 | Mo, Al | ITO, Zn, PVDF |

| [228] | Transistor | 256 × 256 | Si | ITO |

| [227] | Transistor | 6250 sensors | Au | ITO |

| [366] | Bioimpedance | 2 × 3 | Ag | Organic tissue |

| [65] | Resistive | 4 × 4 | Cu | rGO |

| [152] | Capacitive | 2 × 2, 5 × 5 (both 9 × 9 cm2) | Printed Ag Cu | Resin |

| [71] | Piezoresistive | 10 × 10 (4.5 × 4.5 cm2) | Au, Printed Ag | Printed CNT |

| [94] | Piezoresistive Resistive (heterogeneous) | 2 × (7 × 4) | MXene | IGZO, PDSM CNT, MXene |

| [205] | Capacitive | 16 × 16 | CMOS fabrication | Object to detect |

| [311] | Piezoelectric | 4 × 1 | - | |

| [347] | Fiber Optic | - | Fiber Optic | Fiber Optic |

| [292] | Piezoelectric | 4 × 4 | Al | Si, Quartz, Ni |

| [4] | Piezoelectric | 16 × 1 circular shape | Commercial sensor | Commercial sensor |

| [2] | Piezoelectric | 5 × 1 | Si | AlN, Graphene oxide, MXene |

| [288] | Piezoelectric | 6 × 1 | Ag | BT, PDMS |

| [354] | Fiber Optic | 2 × 1 | Fiber Optic | Fiber Optic |

| [351] | Fiber Optic | - | Fiber Optic | Fiber Optic |

| [299] | Piezoelectric | 6 × 1, 1 × 1 | Cu | PZT |

| [162] | Capacitive | 4 × 6 × 6 | Cu | PEGDA |

| [258] | Piezoelectric | 5 × 1 | Al | PVDF |

| [1] | Fiber Optic | 4 sensors | Fabry-Perot | Fabry-Perot |

| [334] | Fiber Optic | 3 × 1 | Fiber Optic | Fiber Optic |

| [282] | Piezoelectric | 3 × 3 | Al | PVDF |

| [355] | Fiber Optic | 2 × 1 | Fiber Optic | Au, Fiber Optic Polystyrene |

| [300] | Piezoelectric | 4 × 1 | Cu | PZT |

| [70] | Piezoresistive | 3 × 3 (1 mm × 1 mm) | Au | PEDOT |

| [76] | Transistor Piezoresistive | 5 × 4 | CNT, AgNW | PEDOT, PAAMPSA |

| [56] | Piezoresistive | 4 × 4 | Printed Ag, Cu | PDMS, MWCNT |

| [151] | Capacitive | 32 × 32 (4.8 × 2.4 mm) | Standard CMOS | Standard CMOS |

| [168] | Capacitive | 3 × 3 (30 cm × 30 cm) | Fabric, Al | Polyurethane |

| [97] | Resistive | 5 × 5 | Pt100 | Pt100 |

| [57] | Piezoresistive | 3 × 3 | Cu, Ag | Sponge Polyaniline |

| [91] | Piezoresistive | 4 × 4 (40 mm each sensor) | Cu, Ni, Au | CNT, PDMS |

| [51] | Piezoresistive | 5 × 5 (11.5 × 11.5 cm2) | - | VelostatTM |

| [290] | Piezoelectric | 2 × 1 | - | - |

| [191] | Capacitive | 8 × 8 (1.5 × 1.5 cm2) | PEDOT:PSS, CNT | PVDF, PDMS |

| [316] | Triboelectric | 4 × 1 (one per finger) | Cu | PTFE |

| [176] | Capacitive | 12 × 12 (1 mm × 1 mm) | Ti, Cu | Polyimide |

| [352] | Fiber Optic | 5 × 1 | FBG | FBG |

| [150] | Capacitive | 4 × 4 (0.6 cm2) | CNE | Ecoflex, PET |

| [75] | Piezoresistive | 100 × 300 | Cu | Polymer |

| [55] | Piezoresistive | 5 × 4 | Cu, Ag | CNT, Cotton |

| [297] | Piezoelectric | 6 × 1, 1 × 1 | Cu | PZT |

| [200] | Capacitive | 2 × 2 | Al, Si | Standard CMOS |

| [287] | Piezoelectric | 6 × 4 | - | - |

| [343] | Fiber Optic | 3 × 1 | Fiber Optic | Fiber Optic |

| [204] | Capacitive | 4 × 4 (4 cm × 4 cm) | Printed CNE | Polyurethane |

| [350] | Fiber Optic | 2 × 2 | FBG | FBG |

| [220] | Diode | 3 × 3 | Ti, Ni | Si |

| [246] | Piezoelectric | 5 × 5 | Ag | PDMS, PVDF |

| [263] | Piezoelectric | 5 × 5 | Al | Si, Quartz, Ni |

| [120] | Resistive | 6 × 4 | - | - |

| [178] | Capacitive | 6 × 6, 3 × 3 (33 × 33 mm) | Cu | Ecoflex |

| [225] | Transistor (heterogeneous) | 3 × 1 | Ag | ZnO-NRs |

| [88] | Piezoresistive | 8 × 8 | Copper | CNT, Polyurethane, PDMS |

| [232] | Transistor | 4 × 2 | Au, Cr | |

| [216] | Inductive | 3 × 3 | Commercial sensor | Commercial sensor |

| [233] | Transistor | 42 × 38 | Standard CMOS | Standard CMOS |

| [133] | Resistive | 32 × 32 (7 × 7 mm2) | - | - |

| [362] | Hall effect | 3 × 3 | Commercial sensor | Commercial sensor |

| [221] | Transistor | 20 × 20 (1 × 1 cm2) | ITO | Air, ITO |

| [307] | Piezoelectric (heterogeneous) | 6 × 1 | - | Different coatings for piezoelectric sensors: CNT, Polyethilene glycol, Propolis, bromocresol green, Polystyrene |

| [249] | Piezoelectric | 3 × 3 | Ag | PVDF |

| [117] | Resistive | 8 × 8 | - | - |

| [10] | Capacitive | Petal shaped array 25 sensors Circle of R = 5 cm | Cu | PDMS |

| [111] | Resistive | 8 × 2 | Polymer | - |

| [156] | Capacitive Piezoelectric | 5 × 5 (4 mm2) | AgNW | PET |

| [188] | Capacitive | 4 × 3 | Cu | Object to detect |

| [89] | Resistive | 3 × 3 (5 cm × 2 cm) | PDMS, Ecoflex | CNT |

| [167] | Capacitive | 3 × 3, 4 × 4, 5 × 5 (1 mm × 1 mm) | Standard CMOS | Standard CMOS |

| [104] | Resistive | 52 × 44 (65 × 55 cm2) | - | - |

| [312] | Piezoelectric | 6 sensors (ring shape) | Si | Al, BT |

| [241] | Piezoelectric | 8 × 8 × (6 × 6) 2304 sensors (8 × 8 matrices with 6 × 6 sub matrices) | Au, Ti | Al, PDMS |

| [273] | Piezoelectric | 3 × 1 | Cu | PZT |

| [7] | Resistive | 7 sensors (row of 3 over a row of 4) | Printed Ag | PET |

| [158] | Capacitive | 5 × 5, 10 × 10 mm 5 × 1 for gesture recognition | Cu, Al | PVDF |

| [154] | Capacitive | 12 × 12 (5 × 5 mm2) | Al, Si, Cu | Air |

| [283] | Piezoelectric | 3 × 3 | Au | PZT |

| [324] | Triboelectric | 8 × 8 (38 × 38 cm2) | Fabric | Elastic balls |

| [279] | Piezoelectric | 4 × 4 | Au, Sn | PZT |

| [325] | Triboelectric | 4 × 4 | Cu | Nylon, Kapton, |

| [267] | Piezoelectric | 6 × 6 | Ti, Au | PMN–PT, PZT |

| [99] | Piezoresistive | 10 × 1 | Au | Si |

| [153] | Capacitive | 4 × 1 (heel size) | Cu | - |

| [250] | Piezoelectric | 5 × 4 | Printed Ag, PDMS | Printed PVDF PDMS, PZT |

| [53] | Piezoresistive | 3 × 1 | Commercial sensor | Commercial sensor |

| [66] | Resistive | 4 × 1 (45 × 45 mm2) | Ag | Printed CNT |

| [302] | Piezoelectric | 7 emitters 7 receivers | Cu | PZT |

| [295] | Piezoelectric | 8 sensors | - | - |

| [121] | Resistive | 4 × 4 | - | - |

| [211] | Inductive | 2 × 2 | CMOS fabrication | CMOS fabrication |

| [148] | Capacitive | 8 × 8 (2025 cm2) | Cu | Printed PET |

| [142] | Capacitive | 2 × 2 | Au, PET | PDMS |

| [367] | Bioimpedance | 5 × 5 (95 × 100 mm) | Printed Carbon, Ag | Organic tissue |

| [208] | Inductive | 4 × 4 (27 × 27 mm2) | Ferrite | PET |

| [260] | Piezoelectric | 5 × 4 | Cu | PVDF, PDMS, Ecoflex |

| [313] | Piezoelectric | - | Cu | PZT |

| [210] | Inductive | 2 × 2 | CMOS fabrication | CMOS fabrication |

| [170] | Capacitive | 2 × 2, 10 × 10 (61 × 15 × 15 ) | Carbon | Ethylene |

| [179] | Capacitive | Two circles: D = 254 mm 180 and 179 sensors | Cu | Air |

| [96] | Resistive Capacitive (heterogeneous) | 12 × 1 (6 capacitors and 6 resistors) | Commercial sensor | Commercial sensor |

| [207] | Capacitive | 2 × 3 | Cu | - |

| [159] | Capacitive | 5 sensors (for gesture recognition), 5 × 5 (for weight measurement) | AgNW, PDMS | Fe, Carbon, PDMS |

| [63] | Piezoelectric, Triboelectric, Piezoresistive, Capacitive (heterogeneous) | 10 × 10 | AgNW | CNT, PDMS, PZT, CNT |

| [195] | Capacitive | 2 × 2 | Graphene | Ionic gel |

| [132] | Resistive | 32 × 32 (7 × 7 mm2) | - | - |

| [74] | Piezoresistive | 2 × 3 (shoe shape) | Flexiforce | FlexiForce |

| [203] | Capacitive | 2 × 6 × 3 (2.5 × 5 mm2) | Si, Au, Cr | Air |

| [110] | Resistive | 16 × 16 (32 × 32 cm2) | Cu | VelostatTM |

| [72] | Piezoresistive | 5 × 4 (3 × 4 cm2) | Ag | Printed Carbon, Polymer |

| [197] | Capacitive | 8 × 8 (1 cm × 1 cm) | Standard CMOS | Object to detect |

| [272] | Piezoelectric | 4 × 1 | Cu | PZT |

| [252] | Piezoelectric | 2 × 2 | Au | PVDF, PDMS |

| [266] | Piezoelectric | 2 × 2 | Au | Printed PVDF, PDMS, PtrFE |

| [277] | Piezoelectric | 6 × 1 | Commercial sensor | Commercial sensor |

| [276] | Piezoelectric | 6 × 1 | Commercial sensor | Commercial sensor |

| [175] | Capacitive | 5 × 5, 4 × 1 (30 × 30 mm2) | AgNW | PDMS |

| [172] | Capacitive | 10 × 10 (5 × 5 cm2) | Graphene, PET | Air, PDMS |

| [261] | Piezoelectric | 1 × 4, 3 × 3 | Cu, Pt, Ti, Ag | PZT |

| [206] | Capacitive (heterogeneous) | 4 gas sensors 8 textile tensile sensors | Commercial sensor | Commercial sensor |

| [181] | Capacitive | 4 × 4 (30 × 30 cm2) | FR4 | Object to detect |

| [171] | Capacitive | 11 sensors (approx. 15 × 25 cm) | Cu | - |

| [50] | Piezoresistive | 3 × 1 (5 × 25 mm2) | Cu | Carbon, Si |

| [310] | Piezoelectric | 4 × 1 | Au, Pt, PZT | Graphene, Si, PZT |

| [262] | Piezoelectric | 5 × 5 | Al | Si, Quartz, Ni |

| [118] | Resistive | 8 × 2 | Polymer | - |

| [59] | Piezoresistive | 6 × 8 | Cr, Au | CNT, PDMS |

| [60] | Piezoresistive | 3 × 2 (15 × 20 mm2) | Cu | CNT, PDMS |

| [119] | Resistive | 8 × 8 | - | - |

| [73] | Piezoresistive | 2 × 2 (10 × 10 mm2) | Ag | Si |

| [341] | Fiber Optic | - | Fiber Optic | Fiber Optic |

| [177] | Capacitive | 2 × 1 (one on the wrist and one on the arm) | Standard CMOS | Air |

| [219] | Diode | 100 × 100, 80 × 80, 50 × 50 | Au | Si |

| [155] | Capacitive | 5 × 5 size of a hand | Graphene, AgNW | Polyurethane |

| [187] | Capacitive | 3 × 4 | Cu | - |

| [357] | Hall effect | 8 × 8 | Commercial sensor | Commercial sensor |

| [348] | Fiber Optic | 4 × 1 | Fiber Optic | Fiber Optic |

| [349] | Fiber Optic | 64 sensors | FBG | FBG |

| [339] | Fiber Optic | 8 × 1 | Fiber Optic | Fiber Optic |

| [166] | Capacitive | 3 × 3 | Cu | - |

| [136] | Resistive | 3 × 3 | - | - |

| [278] | Piezoelectric | 3 × 1 | - | PVDF, Zr, Ti |

| [61] | Capacitive Resistive Triboelectric (heterogeneous) | 5 × 5 (60 mm × 60 mm) | AgNW | Silicone |

| [289] | Piezoelectric | 2 × (5 × 4) | Commercial sensor | Commercial sensor |

| [284] | Piezoelectric | 9 × 1 | - | - |

| [105] | Piezoresistive | 7 × 1 | - | - |

| [106] | Piezoresistive | 13 × 5 | - | - |

| [127] | Resistive | 8 × 6 | - | - |

| [54] | Piezoresistive | 12 × 8 | PAM, Tuolene | PEDOT |

| [321] | Triboelectric | 3 × 3 (5 × 5 cm2) | ITO | PDMS, Glass |

| [326] | Triboelectric | PC keyboard | CNT | Silicone, Polyurethane, Air |

| [58] | Piezoresistive | 2 × 2 × 5 (5 sensors in each neuron) | Standard CMOS | Printed Standard CMOS |

| [286] | Piezoelectric | 5 × 1 (1.5 × 53 mm2) | PVDF | Polyurethane |

| [222] | Transistor | 12 × 12, 50 × 50 (2.5 × 2.5 cm2) | AgNW, Cr, Au | Air, PDMS, Graphene |

| [217] | Transistor Diode | 9 × 1 | Custom process (similar to CMOS) | Custom process (similar to CMOS) |

| [231] | Transistor | 2 × 1 | - | Air, Si |

| [226] | Transistor | 8 × 1 | AlGaN GaN | PMMA |

| [230] | Transistor | 32 × 32 | Standard CMOS | Standard CMOS |

| [6] | Piezoelectric | 2 sensors (perpendicular) | Pt | PZT |

| [115] | Resistive | From 8 sensors to 449 sensors | - | - |

| [67] | Piezoresistive | 3 × 4 | FSR | FSR |

| [5] | Piezoelectric | High number of electrodes orientated at, 0°, 30°, 45°, 60°, and 90° | Al, Pt | Al |

| [259] | Piezoelectric | 3 × 3 (12 × 6 cm2) | Cu | PDMS |

| [264] | Piezoelectric | 3 × 3, 6 × 6 | Au | ZnONW |

| [275] | Piezoelectric | 4 × 4 | Al | PET |

| [135] | Resistive | 4 × 4 | - | - |

| [298] | Piezoelectric | 8 × 1 | Cu | - |

| [223] | Transistor | 11 × 1 | - | , Air |

| [69] | Piezoresistive | 2 × 2 (4 × 4 mm2) | Al | Air |

| [98] | Resistive (heterogeneous) | 6 × 1 | Commercial sensor | Commercial sensor |

| [196] | Capacitive | 8 × 8 (1 cm × 1 cm) | Standard CMOS | Object to detect |

| [131] | Resistive | 8 × 6 | - | - |

| [9] | Capacitive | 1 × 108, one per disc in the transformer windings | - | Air |

| [3] | Piezoresistive | 10 × 1 | Ag | PAni |

| [124] | Resistive | 16 × 8 | - | - |

| [165] | Capacitive | 450 × 450 | - | - |

| [95] | Resistive | 16 × 16 | Printed Al, Ag | Printed PEN, Al |

| [157] | Capacitive | 8 × 8 | Steel | Fabric |

| [180] | Capacitive | 4 × 1 (10 cm × 4 cm) | Cu | Object to detect |

| [123] | Resistive | From 8 × 8 to 256 × 256 | - | - |

| [64] | Piezoresistive | 4 × 4 (40 × 50 mm2) | Au | Printed PEDOT, Kapton |

| [239] | Transistor | 3 × 3 | Au, Cr | Graphene |

| [90] | Piezoresistive | 2 × 2 | - | PDMS, Si |

| [125] | Resistive | 8 × 6 | - | - |

| [234] | Transistor | 2 × 1 | Au | CNT |

| [202] | Capacitive | 3 × 2 (6 × 9 mm) | Au, Si | - |

| [359] | Hall effect | 8 × 8 | Commercial sensor | Commercial sensor |

| [265] | Piezoelectric | 3 × 2 | Al | PVDF |

| [296] | Piezoelectric | 4 sensors | Cu | PZT |

| [335] | Fiber Optic | 80 × 1 | FBG | FBG |

| [309] | Piezoelectric | 2 × 1 | Au | Si, Quartz, Ni |

| [345] | Fiber Optic | 128 × 1 | Fiber Optic | Fiber Optic |

| [306] | Piezoelectric (heterogeneous) | 18 sensors | - | Quartz, CNT |

| [303] | Piezoelectric | 2 × 2 | Ag | Ag, PZT |

| [294] | Piezoelectric | 3 × 1, 1 × 1 | Cu | PZT |

| [333] | Fiber Optic | 4 × 2, 1 × 4 | FBG | FBG |

| [274] | Piezoelectric | 1 × 4, 3 × 3 | Cu, Pt, Ti, Ag | PZT |

| [332] | Fiber Optic | 4 × 1 | FBG | FBG |

| [308] | Piezoelectric | 2 × 2 | Mo | AlN |

| [291] | Piezoelectric | 2 × 1 | Cu | PZT |

| [122] | Resistive | 8 × 8 | - | - |

| [293] | Piezoelectric | 6 × 1 | Cu, Printed Ag | PZT |

| [270] | Piezoelectric | 3 × 3 | Ag, Al, Au | PZT, Si |

| [128] | Resistive | 4 × 4 | - | - |

| [323] | Triboelectric | 6 × 3 1 cm per cell | Cu, PDMS | PTFE |

| [130] | Resistive | 5 × 3 | - | - |

| [126] | Resistive | From 8 sensors to 449 sensors | - | - |

| [129] | Resistive | 20 × 20 | - | - |

Appendix B

| Study | Wearable or Environmental | Application | Measured Variable | Validation Experiments |

|---|---|---|---|---|

| [183] | Environmental | Pressure | Pressure | Customized object or stamp Motor |

| [337] | Environmental | Temperature | Temperature | Computational simulation |

| [365] | Environmental | Magnetic field detection | Position Angular position | Magnetic machine Computational simulation |

| [251] | Environmental Wearable | Pressure Strain | Pressure Strain | Motor Robot Customized object or stamp Subjects wearing the device |

| [363] | Environmental | Electric system monitoring | Current | Computational simulation Lab experiment |

| [103] | Environmental | Magnetic field detection | Magnetic Field | Magnetic machine |

| [346] | Environmental | Surgery | Position | Motor |

| [331] | Environmental | HMI Walking assessment | Pressure | Subjects interacting externally with the device Computational simulation |

| [102] | Environmental | Organic compounds Airflow applications | Concentration Pressure | Wind machine Computational simulation |

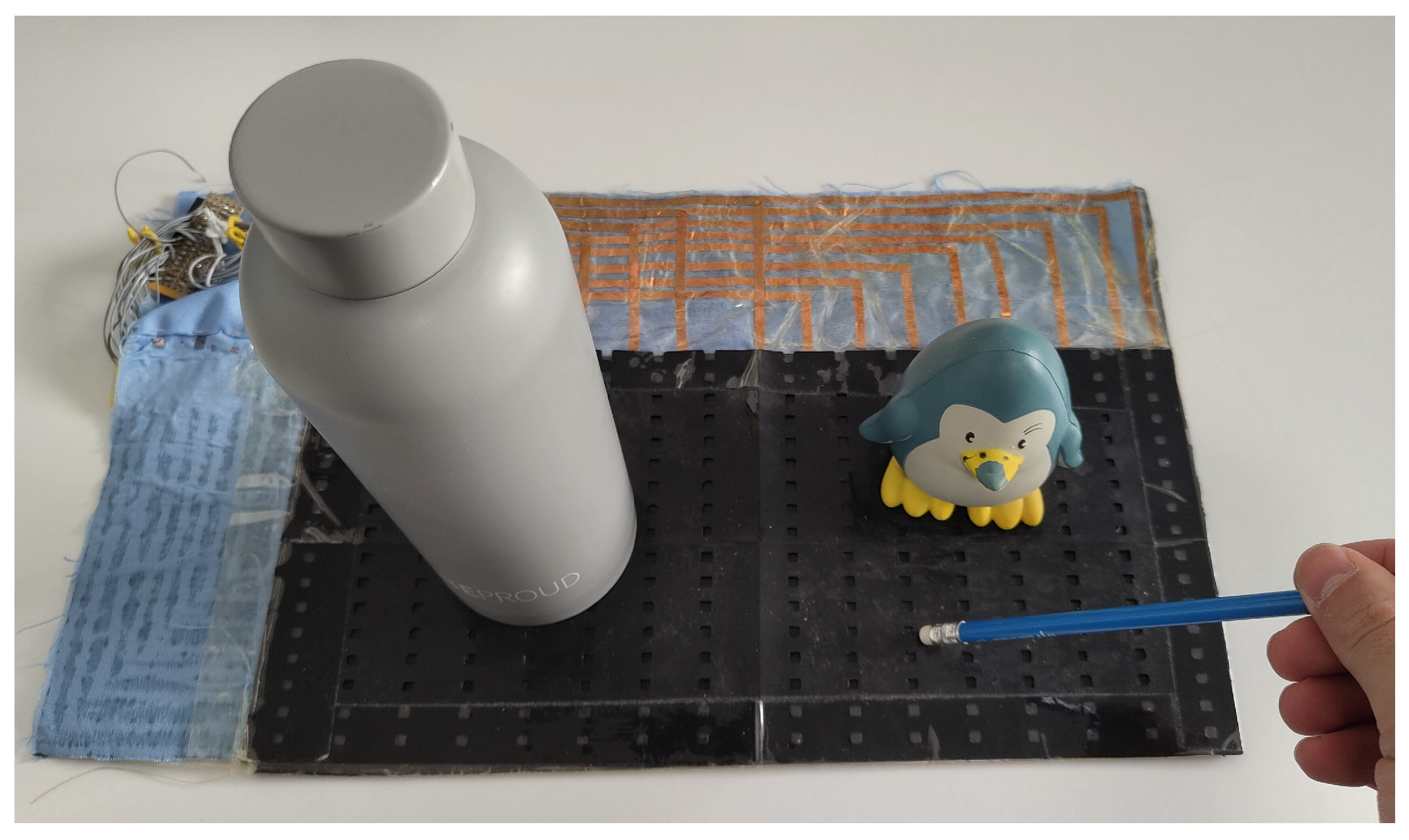

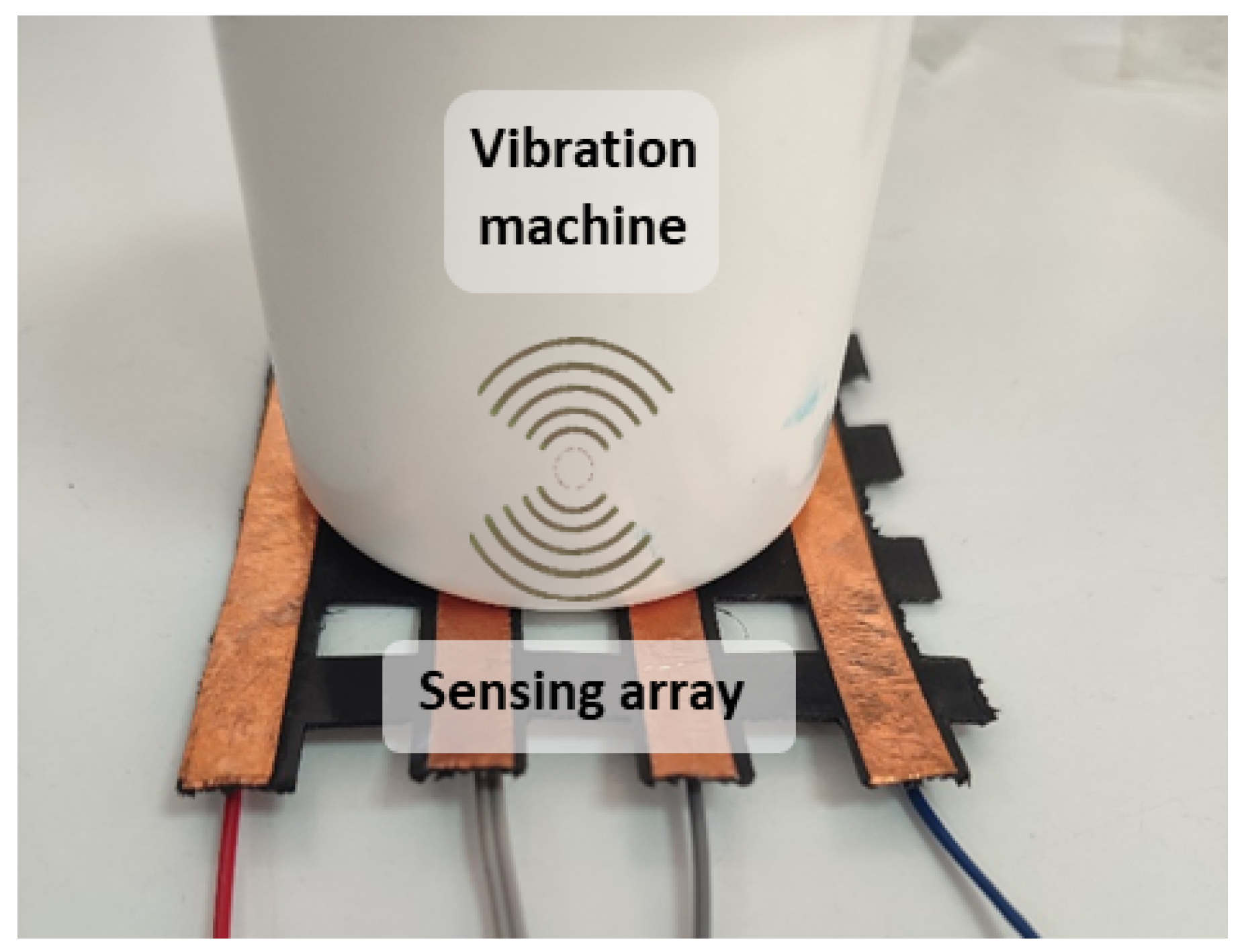

| [330] | Environmental | Skin health | Force | Vibration machine Subjects interacting externally with the device |

| [248] | Environmental Wearable | Pressure Plantar pressure | Pressure | Motor Force gauge Subjects wearing the device |

| [329] | Wearable | Gesture recognition Sport activities Heart monitoring Electronic skin | Force | Force gauge Motor Subjects wearing the device |

| [93] | Environmental | Improve readout accuracy | Force | Force gauge Customized object or stamp |

| [328] | Wearable | HMI | Pressure | Force gauge Customized object or stamp Subjects interacting externally with the device Motor Robot |

| [242] | Environmental | Marine applications | Pressure | Motor Lab experiment Computational simulation |

| [301] | Environmental | SHM | Sound | Computational simulation Lab experiment |

| [107] | Environmental | Improve readout accuracy | Resistance | Computational simulation |

| [163] | Wearable | HMI | Pressure | Customized object or stamp Force gauge Computational simulation |

| [255] | Wearable | Walking assessment | Pressure | Subjects wearing the device |

| [319] | Environmental | HMI | Pressure | Subjects interacting externally with the device Motor |

| [285] | Wearable | Heart monitoring | Force | Motor Subjects interacting externally with the device |

| [87] | Wearable | Heart monitoring Speech detection Sport activities Walking assessment Electronic skin | Pressure | Customized object or stamp Subjects interacting externally with the device Subjects wearing the device Motor |

| [149] | Environmental | Pressure | Pressure | Customized object or stamp Motor Subjects interacting externally with the device |

| [86] | Wearable | Posture assessment | Pressure | Customized object or stamp Motor |

| [280] | Environmental | SHM | Sound | Lab experiment |

| [85] | Wearable | Electronic skin | Pressure | Customized object or stamp Motor Robot |

| [281] | Environmental | Electric system monitoring | Vibration | Computational simulation Lab experiment |

| [84] | Environmental | Electronic skin | Pressure | Computational simulation |

| [83] | Environmental | Pressure | Pressure | Customized object or stamp Force gauge |

| [82] | Environmental | Posture assessment | Pressure | Force gauge Subjects interacting externally with the device |

| [81] | Environmental | Posture assessment | Pressure | Customized object or stamp Subjects interacting externally with the device |

| [80] | Wearable | Posture assessment | Strain | Force gauge Subjects wearing the device |

| [141] | Environmental | Improve readout accuracy | Resistance | Computational simulation |

| [108] | Environmental | Walking assessment | Resistance | Computational simulation Subjects interacting externally with the device |

| [101] | Environmental | Inorganic compounds | Concentration | Chemical testing |

| [79] | Environmental | Improve readout accuracy | Pressure | Computational simulation Lab experiment Subjects interacting externally with the device |

| [138] | Environmental | Improve readout accuracy | Resistance | Computational simulation Lab experiment |

| [340] | Environmental | Sound | Sound | Acoustic machine |

| [189] | Environmental | Imaging | Presence | Computational simulation Lab experiment |

| [193] | Environmental | Organic compounds | Concentration | Chemical testing |

| [186] | Environmental | Gesture recognition | Force | Motor Subjects interacting externally with the device |

| [344] | Environmental | Electric system monitoring | Sound | Lab experiment |

| [342] | Environmental | Sound | Sound | Computational simulation Motor |

| [238] | Environmental | Organic compounds | Concentration | Chemical testing |

| [224] | Wearable Environmental | Heart monitoring | Pressure | Customized object or stamp Motor Force gauge Subjects interacting externally with the device |

| [237] | Environmental | Organic compounds | Concentration | Chemical testing |

| [236] | Environmental | Organic compounds | Concentration | Chemical testing |

| [52] | Environmental | Electronic skin | Pressure Temperature | Temperature machine Motor Subjects interacting externally with the device Customized object or stamp |

| [240] | Environmental | Dopamine | Concentration | Chemical testing |

| [215] | Environmental | SHM | Impedance | Lab experiment |

| [214] | Wearable | Gesture recognition | Impedance | Subjects wearing the device Subjects interacting externally with the device |

| [212] | Environmental | Pressure | Pressure | Subjects interacting externally with the device |

| [194] | Environmental | Inorganic compounds | Concentration | Computational simulation Lab experiment |

| [336] | Environmental | Sound | Sound Pressure | Lab experiment |

| [146] | Environmental | Electronic skin | Force | Subjects interacting externally with the device Motor Robot |

| [245] | Wearable Environmental | Posture assessment Walking assessment Speech detection | Pressure | Vibration machine Force gauge Subjects interacting externally with the device Subjects wearing the device Daily life objects Customized object or stamp Computational simulation |

| [243] | Wearable | Eye tracking | Pressure | Subjects wearing the device Motor |

| [77] | Environmental | Posture assessment | Pressure | Subjects interacting externally with the device |

| [100] | Environmental | Organic compounds | Concentration | Chemical testing |

| [190] | Environmental | Imaging Electronic skin | Presence | Robot |

| [358] | Environmental | Surgery | Position | Motor |

| [244] | Environmental | Heart monitoring | Pressure | Subjects interacting externally with the device Motor Force gauge |

| [144] | Environmental | Plantar pressure | Pressure | Subjects interacting externally with the device Motor |

| [147] | Environmental | Pressure Imaging | Pressure | Computational simulation Motor Customized object or stamp Subjects interacting externally with the device |

| [185] | Wearable | HMI Electronic skin | Pressure | Subjects interacting externally with the device Computational simulations Daily life objects Customized object or stamp Force gauge |

| [184] | Environmental | Electronic skin | Force Presence | Robot |

| [182] | Environmental | HMI | Presence | Subjects interacting externally with the device |

| [235] | Environmental | Organic compounds Inorganic compounds | Concentration | Chemical testing |

| [229] | Environmental | Imaging | Light | Computational simulation, Lab experiment, Light machine |

| [353] | Environmental | Radiation | Light | Lab experiment |

| [169] | Wearable | HMI | Strain | Force gauge |

| [213] | Environmental | Gesture recognition | Presence | Subjects interacting externally with the device |

| [199] | Environmental | DNA | Concentration | Computational simulation Chemical testing |

| [209] | Environmental | HMI | Force | Force gauge |