High-Density Tactile Sensor Array for Sub-Millimeter Texture Recognition

Abstract

Highlights

- Development of a high-density tactile sensor array featuring 10 μm pyramid microstructures and a CNT resistive layer, achieving ultra-high sensitivity (8.082 kPa−1) in the 0.2–0.5 kPa range and 500 μm spatial resolution—surpassing human fingertip discrimination thresholds.

- The sensor demonstrates exceptional performance; rapid response (125 ms loading), high stability (>1000 cycles), minimal unit variability (0.634% error), and reliable low-pressure detection (down to 90 Pa), validated through finite element simulations and experimental testing.

- Enables high-fidelity reconstruction of sub-millimeter textures (e.g., 500 μm patterns, Braille dots), advancing applications in prosthetics, robotics, and human–machine interfaces requiring ultra-fine tactile feedback.

- Establishes a scalable manufacturing paradigm using mold-based microstructure replication and solution-processable materials, overcoming traditional sensitivity-resolution trade-offs for future tactile sensing technologies.

Abstract

1. Introduction

2. Materials and Methods

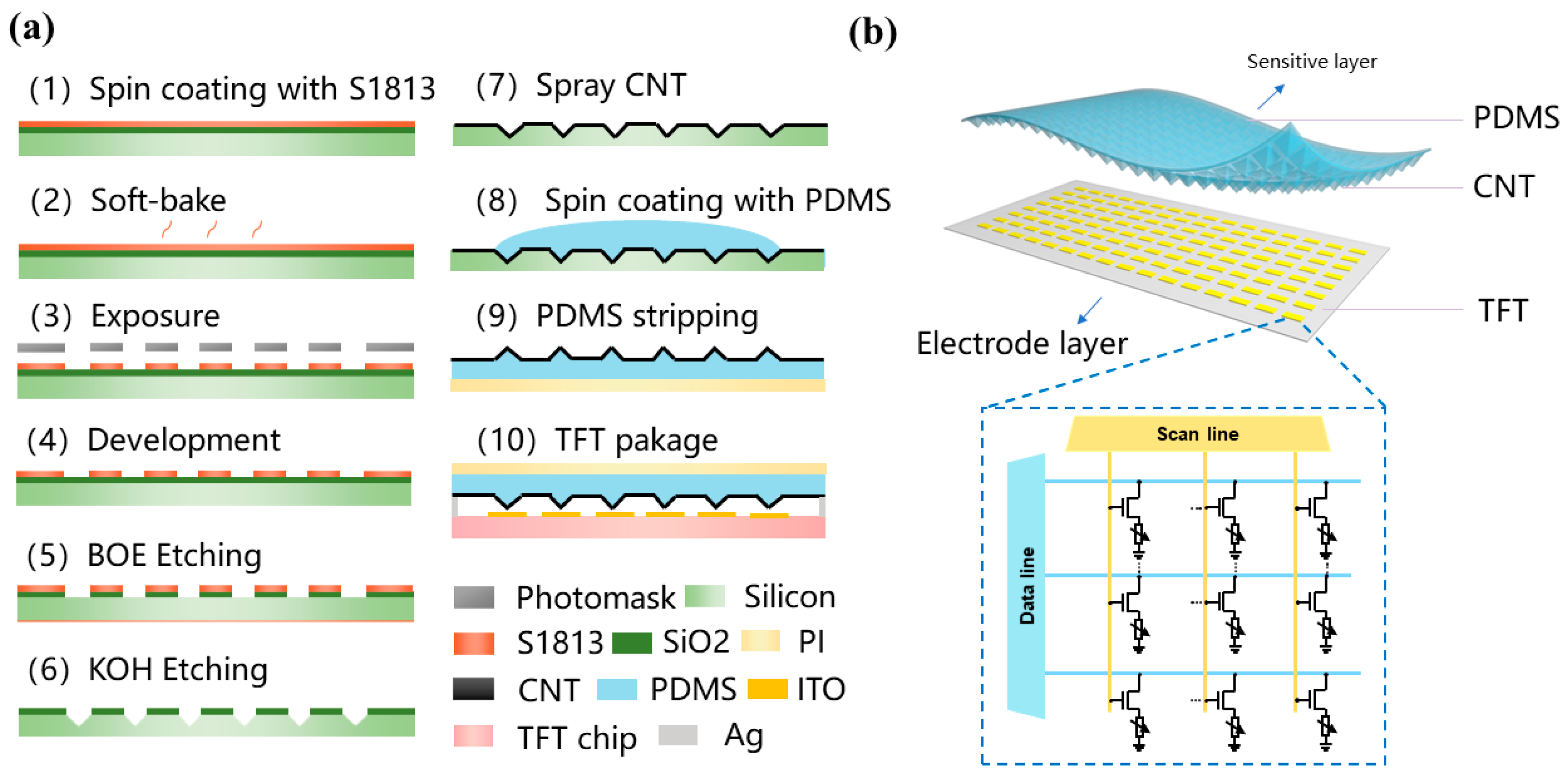

2.1. Fabrication of the Sensor Array

2.2. Characterization and Measurements

2.3. Finite Element Analysis (FEA) for the Micro-Pyramid Array

3. Results

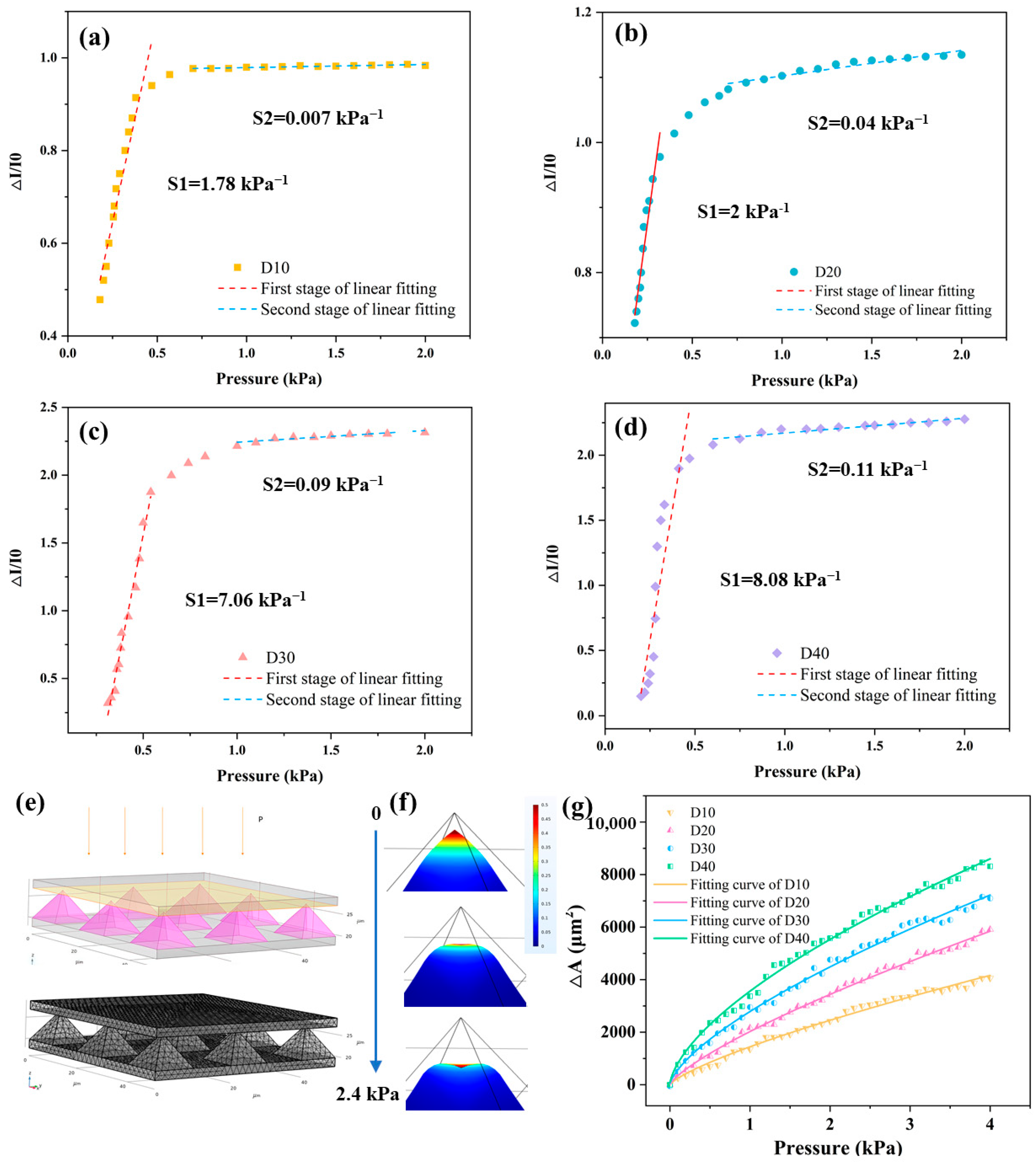

3.1. Characterization of the Sensor Array

3.2. Performance Testing of the Sensor Array

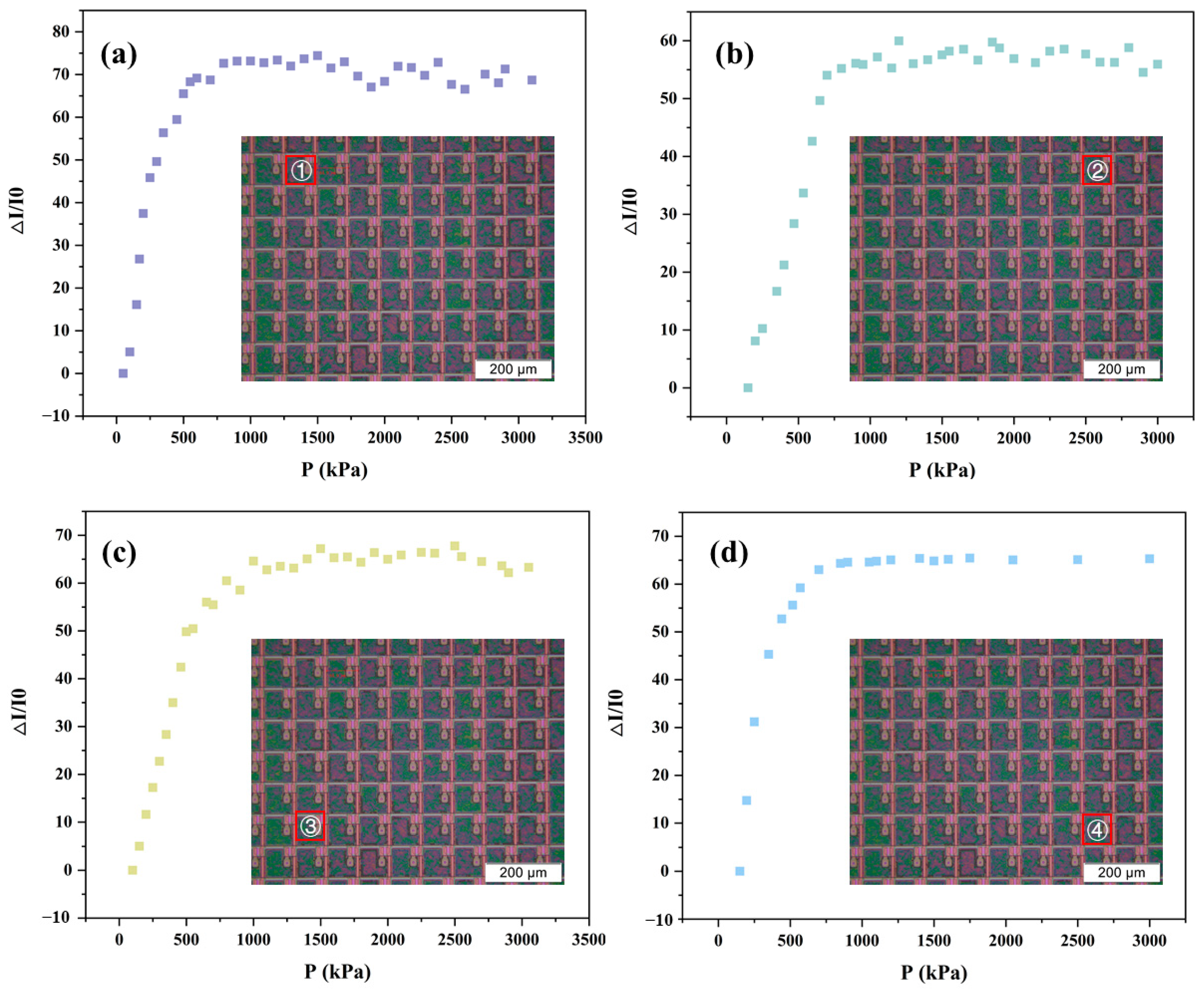

3.3. Performance Testing of Individual Sensor Units

3.4. Texture Recognition of the Sensor Array

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| TFT | Thin-film transistor |

| CNT | Carbon nanotube |

| BOE | Buffered oxide etch |

References

- An, B.W.; Heo, S.; Ji, S.; Bien, F.; Park, J.-U. Transparent and flexible fingerprint sensor array with multiplexed detection of tactile pressure and skin temperature. Nat. Commun. 2018, 9, 2458. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Sun, X.; Wang, Q.; Chen, J. Tactile modeling and rendering image-textures based on electrovibration. Vis. Comput. 2017, 33, 637–646. [Google Scholar] [CrossRef]

- Kawazoe, M.; Kosemura, Y.; Miki, N. Encoding and presentation of surface textures using a mechanotactile display. Sens. Actuators A-Phys. 2017, 261, 30–39. [Google Scholar] [CrossRef]

- Ha, K.-H.; Yoo, J.; Li, S.; Mao, Y.; Xu, S.; Qi, H.; Wu, H.; Fan, C.; Yuan, H.; Kim, J.-T.; et al. Full freedom-of-motion actuators as advanced haptic interfaces. Science 2025, 387, 1383–1390. [Google Scholar] [CrossRef]

- Wang, S.; Fan, X.; Zhang, Z.; Su, Z.; Ding, Y.; Yang, H.; Zhang, X.; Wang, J.; Zhang, J.; Hu, P. A Skin-Inspired High-Performance Tactile Sensor for Accurate Recognition of Object Softness. ACS Nano 2024, 18, 17175–17184. [Google Scholar] [CrossRef]

- Johansson, R.S.; Flanagan, J.R. Coding and use of tactile signals from the fingertips in object manipulation tasks. Nat. Rev. Neurosci. 2009, 10, 345–359. [Google Scholar] [CrossRef]

- Hwang, I.; Yun, S.; Park, J. Perceptual space and adjective rating of 2.5D tactile patterns. Sci. Rep. 2025, 15, 4244. [Google Scholar] [CrossRef]

- Wen, L.; Nie, M.; Fan, J.; Chen, P.; Li, B.; Chen, S.; Xiong, Y.; Zhang, Q.; Yin, K.; Sun, L. Tactile Recognition of Shape and Texture on the Same Substrate. Adv. Intell. Syst. 2023, 5, 2300337. [Google Scholar] [CrossRef]

- Bai, N.; Xue, Y.; Chen, S.; Shi, L.; Shi, J.; Zhang, Y.; Hou, X.; Cheng, Y.; Huang, K.; Wang, W.; et al. A robotic sensory system with high spatiotemporal resolution for texture recognition. Nat. Commun. 2023, 14, 7121. [Google Scholar] [CrossRef]

- Yang, J.-H.; Kim, S.-Y.; Lim, S.-C. Effects of Sensing Tactile Arrays, Shear Force, and Proprioception of Robot on Texture Recognition. Sensors 2023, 23, 3201. [Google Scholar] [CrossRef]

- Zhi, X.; Ma, S.; Xia, Y.; Yang, B.; Zhang, S.; Liu, K.; Li, M.; Li, S.; Peiyuan, W.; Wang, X. Hybrid tactile sensor array for pressure sensing and tactile pattern recognition. Nano Energy 2024, 125, 109532. [Google Scholar] [CrossRef]

- Yang, Y.-J.; Cheng, M.-Y.; Chang, W.-Y.; Tsao, L.-C.; Yang, S.-A.; Shih, W.-P.; Chang, F.-Y.; Chang, S.-H.; Fan, K.-C. An integrated flexible temperature and tactile sensing array using PI-copper films. Sens. Actuators A-Phys. 2008, 143, 143–153. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, X.; Mei, D.; Zhu, L.; Chen, J. Flexible tactile sensor array for distributed tactile sensing and slip detection in robotic hand grasping. Sens. Actuators A-Phys. 2019, 297, 11512. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, J.; Mei, D. Flexible Tactile Sensor Array for Slippage and Grooved Surface Recognition in Sliding Movement. Micromachines 2019, 10, 579. [Google Scholar] [CrossRef]

- Hsieh, M.-L.; Yeh, S.-K.; Lee, J.-H.; Cheng, M.-C.; Fang, W. CMOS-MEMS capacitive tactile sensor with vertically integrated sensing electrode array for sensitivity enhancement. Sens. Actuators A-Phys. 2021, 317, 112350. [Google Scholar] [CrossRef]

- Guo, Z.; Lian, Z.; Li, B.; Xuan, F. Scalable and adaptable tactile sensor array with island-bridge-form sensing units for multi-directional stimuli recognition. Measurement 2024, 238, 115382. [Google Scholar] [CrossRef]

- Nan, X.; Xu, Z.; Cao, X.; Hao, J.; Wang, X.; Duan, Q.; Wu, G.; Hu, L.; Zhao, Y.; Yang, Z.; et al. A Review of Epidermal Flexible Pressure Sensing Arrays. Biosens.-Basel 2023, 13, 656. [Google Scholar] [CrossRef]

- Amoli, V.; Kim, J.S.; Jee, E.; Chung, Y.S.; Kim, S.Y.; Koo, J.; Choi, H.; Kim, Y.; Kim, D.H. A bioinspired hydrogen bond-triggered ultrasensitive ionic mechanoreceptor skin. Nat. Commun. 2019, 10, 4019. [Google Scholar] [CrossRef]

- Yu, Z.; Mao, Y.; Wu, Z.; Li, F.; Cao, J.; Zheng, Y.; Zhong, X.; Wang, L.; Zhu, J.; Gao, P.; et al. Fully-Printed Bionic Tactile E-Skin with Coupling Enhancement Effect to Recognize Object Assisted by Machine Learning. Adv. Funct. Mater. 2024, 34, 2307503. [Google Scholar] [CrossRef]

- Choi, E.; Sul, O.; Lee, J.; Seo, H.; Kim, S.; Yeom, S.; Ryu, G.; Yang, H.; Shin, Y.; Lee, S.-B. Biomimetic Tactile Sensors with Bilayer Fingerprint Ridges Demonstrating Texture Recognition. Micromachines 2019, 10, 642. [Google Scholar] [CrossRef] [PubMed]

- Yanwari, M.I.; Okamoto, S. Healing Function for Abraded Fingerprint Ridges in Tactile Texture Sensors. Sensors 2024, 24, 4078. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, L.; Xia, Y.; Qiu, R.; Liu, W.; Wu, M.; Zhu, Y.; Zhu, S.; Jia, C.; Zhu, M.; et al. Flexible High-Resolution Triboelectric Sensor Array Based on Patterned Laser-Induced Graphene for Self-Powered Real-Time Tactile Sensing. Adv. Funct. Mater. 2021, 31, 2100709. [Google Scholar] [CrossRef]

- Takei, K.; Takahashi, T.; Ho, J.C.; Ko, H.; Gillies, A.G.; Leu, P.W.; Fearing, R.S.; Javey, A. Nanowire active-matrix circuitry for low-voltage macroscale artificial skin. Nat. Mater. 2010, 9, 821–826. [Google Scholar] [CrossRef]

- Chun, S.; Choi, I.Y.; Son, W.; Bae, G.Y.; Lee, E.J.; Kwon, H.; Jung, J.; Kim, H.S.; Kim, J.K.; Park, W. A Highly Sensitive Force Sensor with Fast Response Based on Interlocked Arrays of Indium Tin Oxide Nanosprings toward Human Tactile Perception. Adv. Funct. Mater. 2018, 28, 1804132. [Google Scholar] [CrossRef]

- Zhang, W.; Gu, G.; Ren, H.; Zhang, Z.; Zhang, Z.; Qin, H.; Zheng, M.; Du, Z.; Cheng, G. A real-time self-powered wireless pressure sensing system based on capacitive triboelectric pressure sensor. Nano Energy 2025, 136, 110729. [Google Scholar] [CrossRef]

- Zhou, H.; Gui, Y.; Gu, G.; Ren, H.; Zhang, W.; Du, Z.; Cheng, G. A plantar pressure detection and gait analysis system based on flexible triboelectric pressure sensor array and deep learning. Small 2025, 21, 2405064. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Ghosh, R.; Song, M.S.; Hwang, Y.; Tchoe, Y.; Saroj, R.K.; Ali, A.; Guha, P.; Kim, B.; Kim, S.-W.; et al. Individually addressable and flexible pressure sensor matrixes with ZnO nanotube arrays on graphene. NPG Asia Mater. 2022, 14, 40. [Google Scholar] [CrossRef]

- Zhang, L.; Mo, Y.; Ma, W.; Wang, R.; Wan, Y.; Bao, R.; Pan, C. High-Resolution Spatial Mapping of Pressure Distribution by a Flexible and Piezotronics Transistor Array. ACS Appl. Electron. Mater. 2023, 5, 5823–5830. [Google Scholar] [CrossRef]

- Han, Z.; Mo, L.; Han, S.; Sun, Z.; Ma, W.; Hu, H.; Geng, M.; Liu, L.; Xin, Z.; Hu, K.; et al. Flexible Sensors with Enhanced Sensitivity and Broadened Detection Range Through Conformal Printing and Space-Confined Design. Small 2025, 21, 2407168. [Google Scholar] [CrossRef]

- Tang, Y.; Li, D.; Wang, Y.; Li, F.; Chen, Y.; Liang, K.; Ren, H.; Song, C.; Wang, H.; Zhu, B. Flexible, Transparent, Active-Matrix Tactile Sensor Interface Enabled by Solution-Processed Oxide TFTs. In Proceedings of the International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2022. [Google Scholar]

| Methods | Sensitivity (kPa−1) | Range (kPa) | Electrode Density | Spatial Resolution (μm) | Reference |

|---|---|---|---|---|---|

| Capacitive | ~1.78 × 10−3 kPa−1(<350 kPa), ~9.65 × 10−5 kPa−1 (>350 kPa) | 35 Pa–330 | 318 DPI | 250 | [1] |

| Piezoresistive | 3.1 (0.1–6 kPa), 15.4 (6–18 kPa) | 6–18 | 36 DPI | 700 | [24] |

| Piezoelectric | 4.4 | 6.6–3000 | 1058 | 20 | [27] |

| Resistive | 29.9 | 50 × 10−3–1.06 | 10 × 10 pixels | 5000 | [30] |

| Piezoelectric | / | / | 181 DPI | / | [28] |

| Piezoresistive | 3987 | 0.6–80 | 80 × 80 pixels | / | [29] |

| This work | 8.082 kPa−1 (0.2–0.5 kPa) | 0.2–2 | 460 DPI | 500 | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, C.; Wang, G.; Liu, Y.; Zhang, M. High-Density Tactile Sensor Array for Sub-Millimeter Texture Recognition. Sensors 2025, 25, 5078. https://doi.org/10.3390/s25165078

Cao C, Wang G, Liu Y, Zhang M. High-Density Tactile Sensor Array for Sub-Millimeter Texture Recognition. Sensors. 2025; 25(16):5078. https://doi.org/10.3390/s25165078

Chicago/Turabian StyleCao, Chengran, Guocheng Wang, Yixin Liu, and Min Zhang. 2025. "High-Density Tactile Sensor Array for Sub-Millimeter Texture Recognition" Sensors 25, no. 16: 5078. https://doi.org/10.3390/s25165078

APA StyleCao, C., Wang, G., Liu, Y., & Zhang, M. (2025). High-Density Tactile Sensor Array for Sub-Millimeter Texture Recognition. Sensors, 25(16), 5078. https://doi.org/10.3390/s25165078