Study on Height Measurement for Polyethylene Terephthalate (PET) Materials Based on Residual Networks

Abstract

1. Introduction

2. Methods

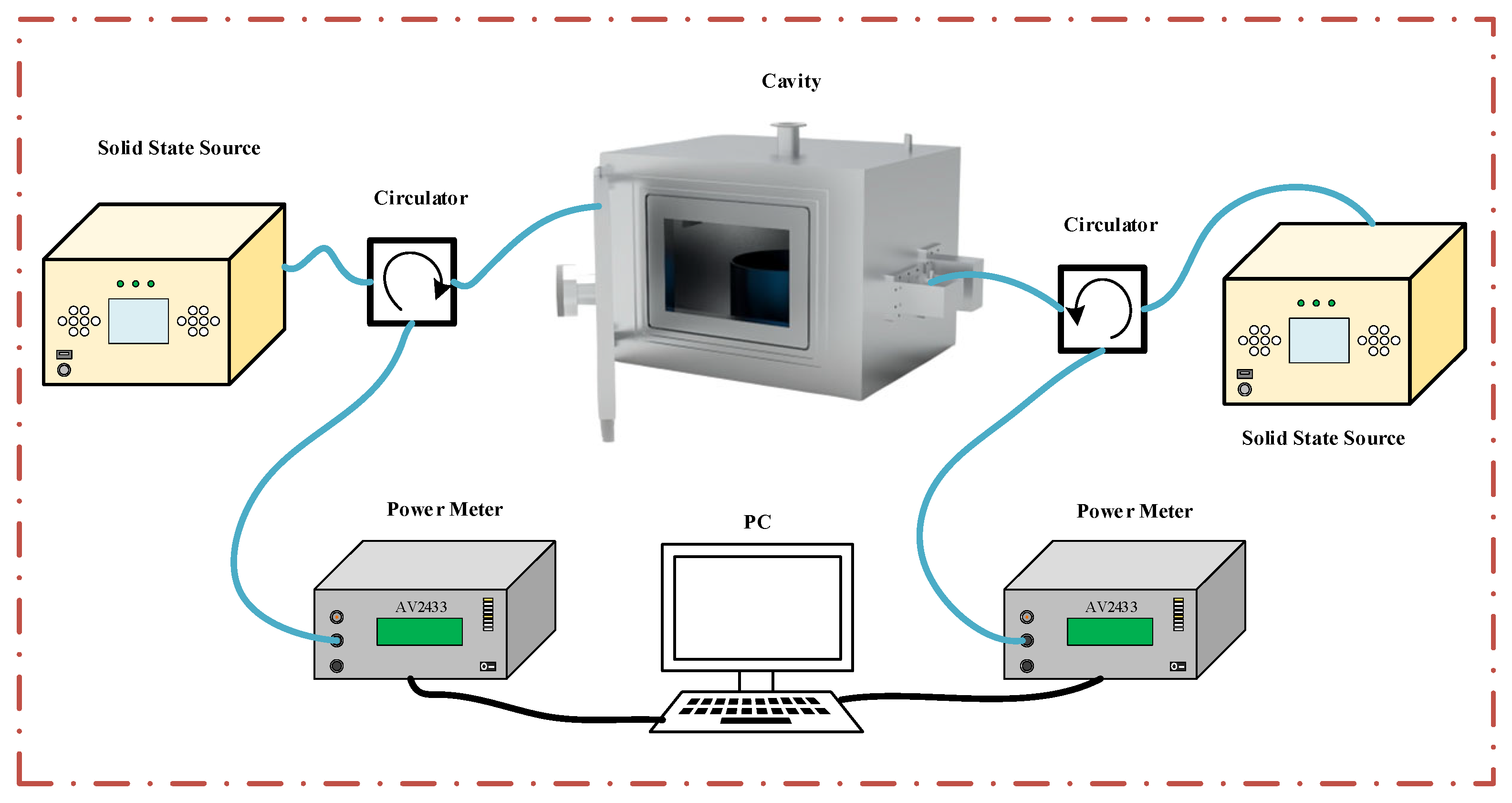

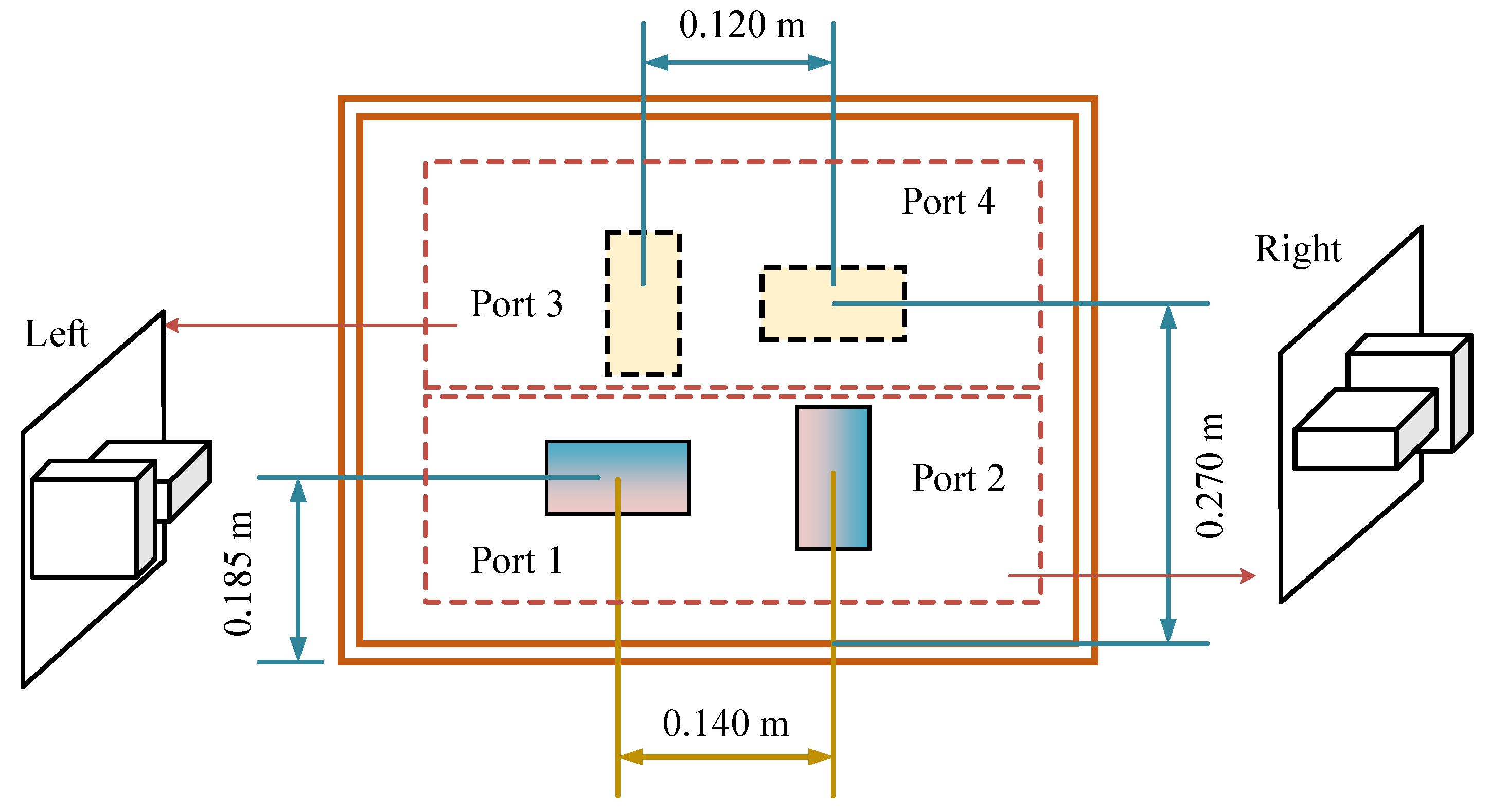

2.1. Reflection Power Measurement System

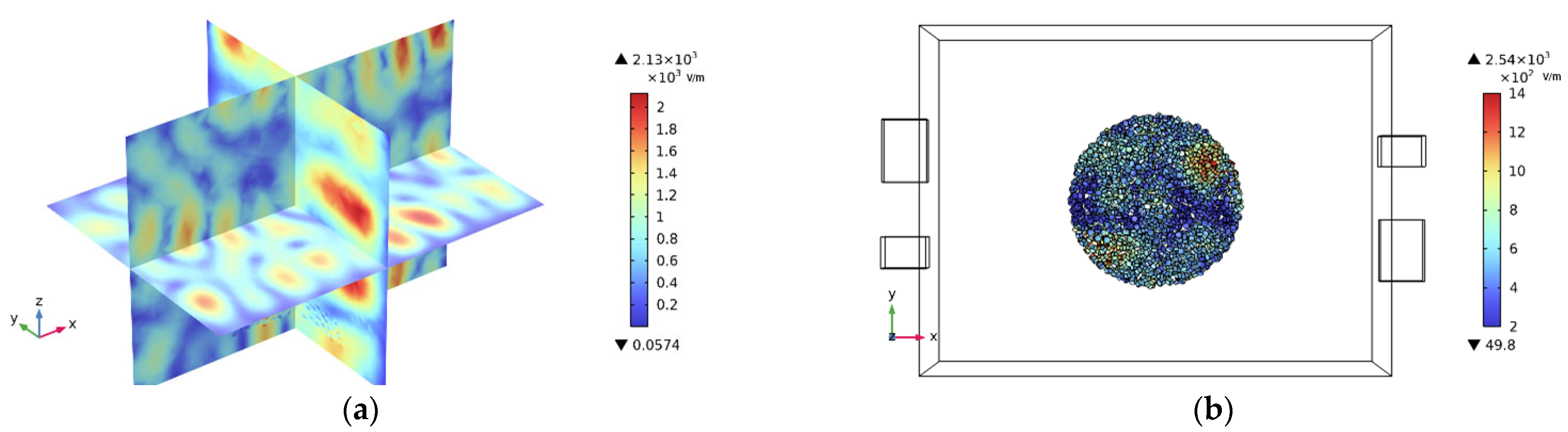

2.2. Microwave Simulation

2.3. Network Theory

3. Results

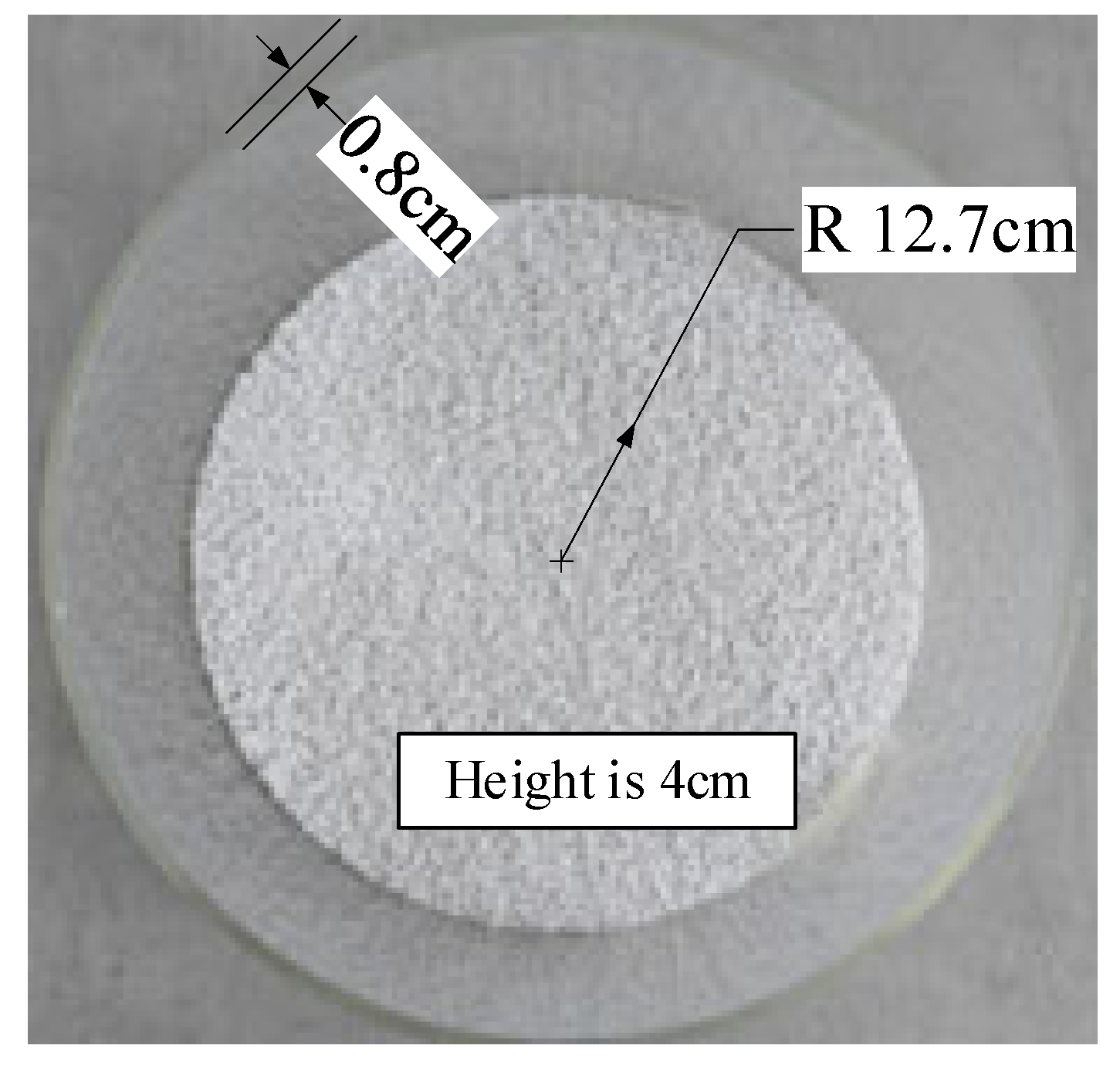

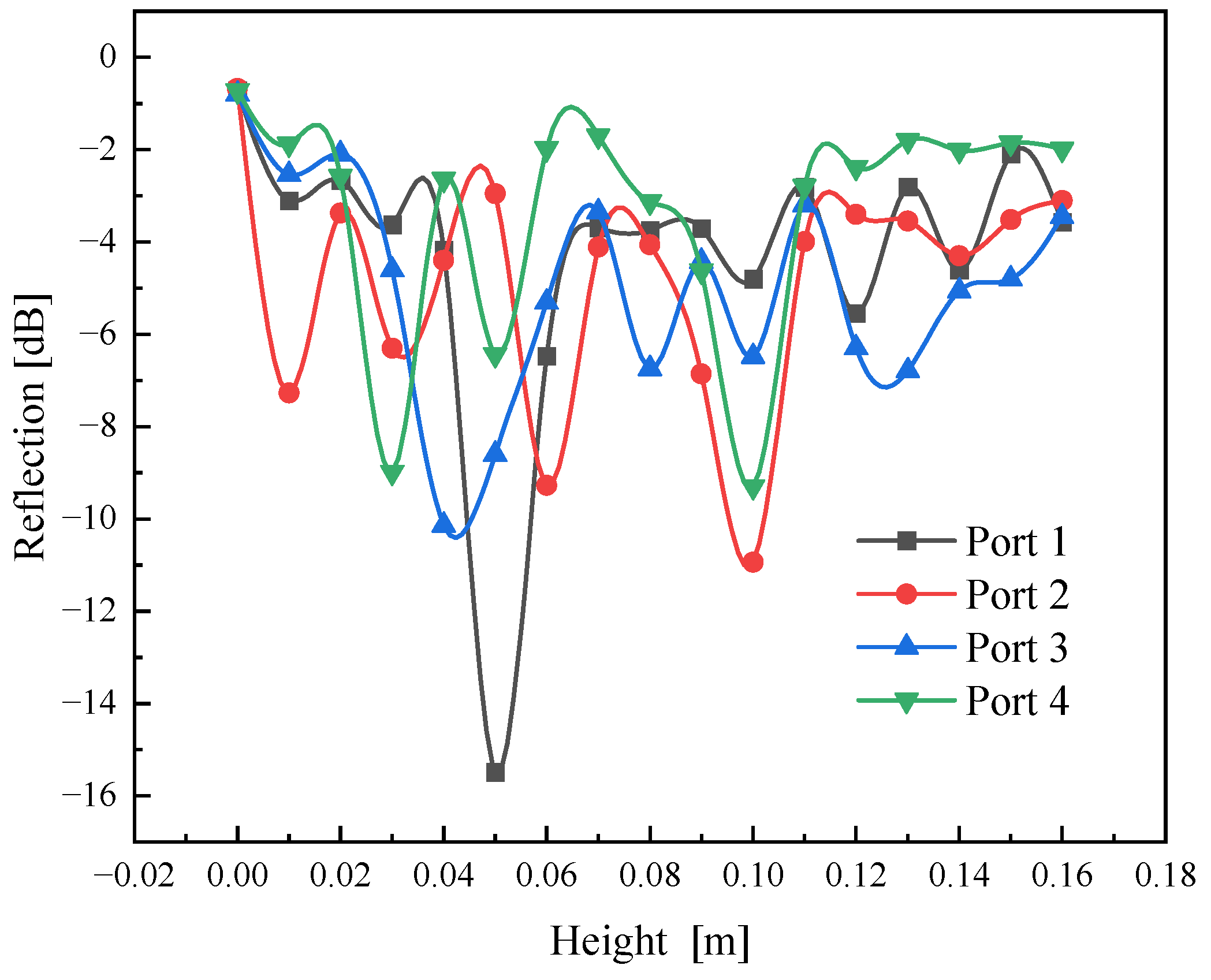

3.1. Reflection Power Measurement

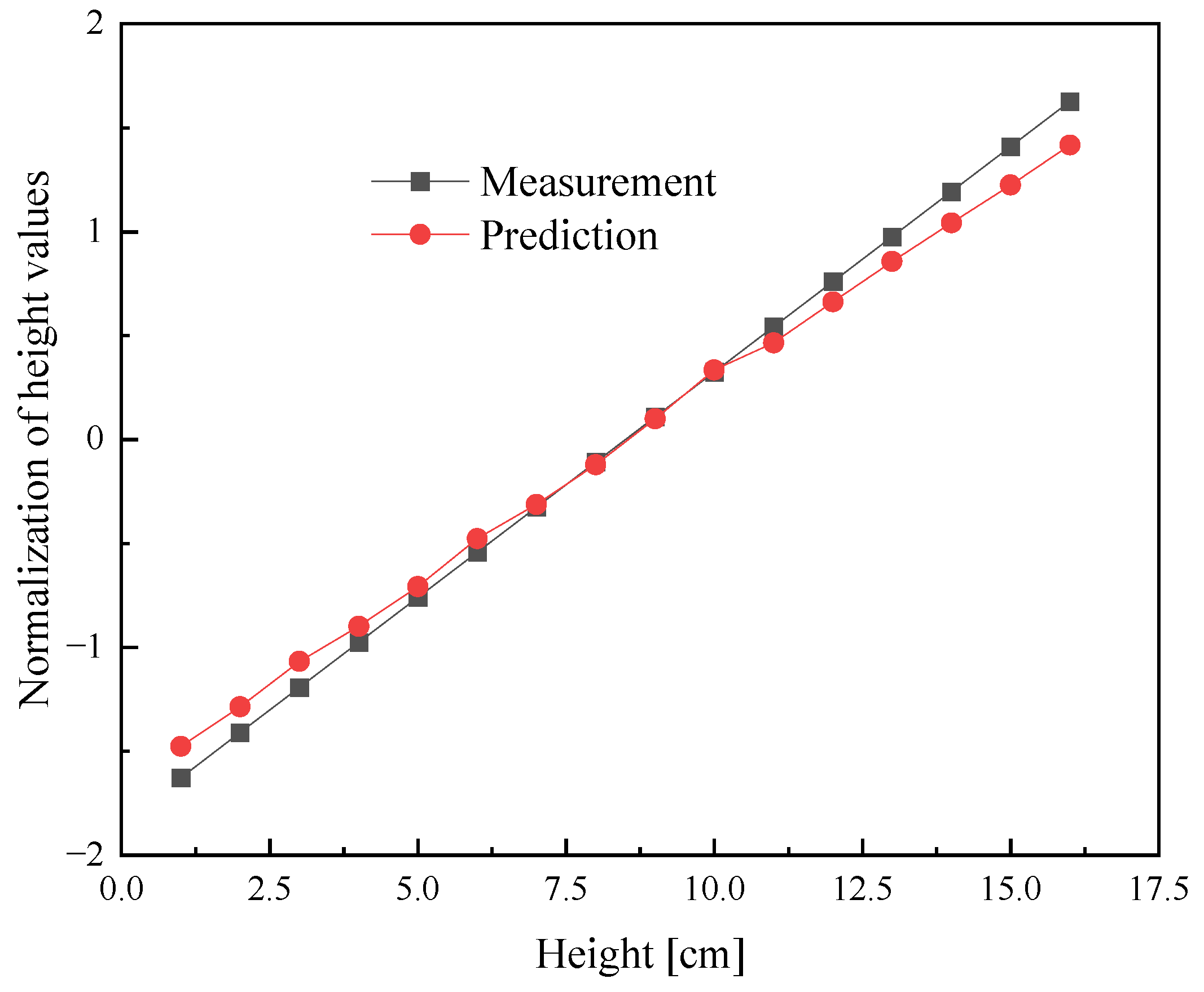

3.2. Network Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| MLP | Multilayer Perceptron |

| PET | Polyethylene Terephthalate |

| VNA | Vector Network Analyzer |

References

- Burgos Pintos, P.; Sanz de León, A.; Molina, S.I. Large format additive manufacturing of polyethylene terephthalate (PET) by material extrusion. Addit. Manuf. 2024, 79, 103908. [Google Scholar] [CrossRef]

- Little, H.A.; Tanikella, N.G.; Reich, M.J.; Fiedler, M.J.; Snabes, S.L.; Pearce, J.M. Towards Distributed Recycling with Additive Manufacturing of PET Flake Feedstocks. Materials 2020, 13, 4273. [Google Scholar] [CrossRef] [PubMed]

- Bian, X.; Xia, G.; Xin, J.H.; Jiang, S.; Ma, K. Applications of waste polyethylene terephthalate (PET) based nanostructured materials: A review. Chemosphere 2024, 350, 141076. [Google Scholar] [CrossRef]

- Pinter, E.; Welle, F.; Mayrhofer, E.; Pechhacker, A.; Motloch, L.; Lahme, V.; Grant, A.; Tacker, M. Circularity Study on PET Bottle-To-Bottle Recycling. Sustainability 2021, 13, 7370. [Google Scholar] [CrossRef]

- Najmi, S.; Vance, B.C.; Selvam, E.; Huang, D.; Vlachos, D.G. Controlling PET oligomers vs monomers via microwave-induced heating and swelling. Chem. Eng. J. 2023, 471, 144712. [Google Scholar] [CrossRef]

- Tang, Q.; Hu, Z.; Tao, Z.; Ye, D.; Tang, J. Research on the rapid combustion process of butane under microwave discharge. Sci. Rep. 2022, 12, 10. [Google Scholar] [CrossRef]

- Muringayil Joseph, T.; Azat, S.; Ahmadi, Z.; Moini Jazani, O.; Esmaeili, A.; Kianfar, E.; Haponiuk, J.; Thomas, S. Polyethylene terephthalate (PET) recycling: A review. Case Stud. Chem. Environ. Eng. 2024, 9, 100673. [Google Scholar] [CrossRef]

- Tang, Q.; Hu, Z.; Cui, X.; Tao, Z.; Tang, J. A Simple and Stable Atmospheric Pressure Electrodeless Water Vapor Microwave Plasma Torch. Appl. Sci. 2022, 12, 6813. [Google Scholar] [CrossRef]

- Schütz, S.; Di Domenico, M.; Poretti, S.; Monleone, R. A microwave cavity design and optimisation for a homogeneous and faster drying process inside an industrial Agitated Nutsche Filter. Open Res. Eur. 2023, 3, 63. [Google Scholar] [CrossRef]

- Ding, G.-A.; Qu, J.-J.; Liu, F.; Yuan, C.-L.; Liu, X.; Meng, L.-F.; Chen, G.-H.; Su, Q. Effect of PTFE, PET, and PFA on the microwave dielectric properties of H3BO3 ceramics. Mater. Chem. Phys. 2022, 277, 125566. [Google Scholar] [CrossRef]

- Liao, C.; He, Z.; Tang, R.; Zhang, W.; Liu, C.; Wang, C. The Research on Microwave Drying Characteristics of Polyethylene Terephthalate Materials Based on Frequency and Power Tuning Technology. Processes 2024, 12, 1488. [Google Scholar] [CrossRef]

- Bustos Seibert, M.; Mazzei Capote, G.A.; Gruber, M.; Volk, W.; Osswald, T.A. Manufacturing of a PET Filament from Recycled Material for Material Extrusion (MEX). Recycling 2022, 7, 69. [Google Scholar] [CrossRef]

- Kusuma, H.S.; Lantip, G.I.A.; Mutiara, X.; Lestari, F.W.; Jaya, D.E.C.; Illiyanasafa, N.; Nida, R.A.; Sari, T.A.; Diwiyanto, Y.M.; Listiawati, V.; et al. Experimental investigation in the drying process of moringa leaves using microwave drying: Drying kinetics, energy consumption, and CO2 emission. Appl. Food Res. 2024, 4, 100401. [Google Scholar] [CrossRef]

- An, N.-N.; Li, D.; Wang, L.-J.; Wang, Y. Factors affecting energy efficiency of microwave drying of foods: An updated understanding. Crit. Rev. Food Sci. Nutr. 2024, 64, 2618–2633. [Google Scholar] [CrossRef]

- Anjos, C.A.R.; Faria, J.A.F.; Marsaioli, A. Continuous Microwave Drying of Polyethylene Terephthalate (PET). In Developments in Food Engineering: Proceedings of the 6th International Congress on Engineering and Food, Tokyo, Japan, 23–27 May 1994; Springer: Boston, MA, USA, 1994. [Google Scholar] [CrossRef]

- Sander, A.; Kardum, J.P. Experimental Validation of Thin-layer Drying Models. Chem. Eng. Technol. 2009, 32, 590–599. [Google Scholar] [CrossRef]

- Kast, O.; Schaible, T.; Bonten, C. Interdependence of Hygroscopic Polymer Characteristics and Drying Kinetics during Desiccant Drying and Microwave Supported Drying. Int. Polym. Process. 2020, 35, 376–384. [Google Scholar] [CrossRef]

- Veronesi, P.; Colombini, E.; Salvatori, D.; Catauro, M.; Leonelli, C. Microwave Processing of PET Using Solid-State Microwave Generators. Macromol. Symp. 2021, 395, 2000204. [Google Scholar] [CrossRef]

- Zamorano romero, C.; Palacios alquisira, J. Secado de PET contrastando hornos de microondas y eléctrico. Educ. Química 2023, 34, 212–223. [Google Scholar] [CrossRef]

- Šarolić, A.; Matković, A. Dielectric Permittivity Measurement Using Open-Ended Coaxial Probe—Modeling and Simulation Based on the Simple Capacitive-Load Model. Sensors 2022, 22, 6024. [Google Scholar] [CrossRef]

- Grunwald, S.; Murad, M.O.; Farrington, S.; Wallace, W.; Rooney, D. Multi-Sensor Soil Probe and Machine Learning Modeling for Predicting Soil Properties. Sensors 2024, 24, 6855. [Google Scholar] [CrossRef]

- Li, Z.; Tian, S.; Tang, J.; Yang, W.; Hong, T.; Zhu, H. High-Sensitivity Differential Sensor for Characterizing Complex Permittivity of Liquids Based on LC Resonators. Sensors 2024, 24, 4877. [Google Scholar] [CrossRef]

- Prokhorova, A.; Helbig, M. Experimental Validation of Realistic Measurement Setup for Quantitative UWB-Guided Hyperthermia Temperature Monitoring. Sensors 2024, 24, 5902. [Google Scholar] [CrossRef] [PubMed]

- Xiong, R.; Hu, Y.; Xia, A.; Huang, K.; Yan, L.; Chen, Q. A High-Temperature and Wide-Permittivity Range Measurement System Based on Ridge Waveguide. Sensors 2025, 25, 541. [Google Scholar] [CrossRef]

- Alahnomi, R.A.; Zakaria, Z.; Yussof, Z.M.; Althuwayb, A.A.; Alhegazi, A.; Alsariera, H.; Rahman, N.A. Review of Recent Microwave Planar Resonator-Based Sensors: Techniques of Complex Permittivity Extraction, Applications, Open Challenges and Future Research Directions. Sensors 2021, 21, 2267. [Google Scholar] [CrossRef] [PubMed]

- Lebaudy, P.; Estel, L.; Ledoux, A. Microwave heating of poly(ethylene terephthalate) bottle preforms used in the thermoforming process. J. Appl. Polym. Sci. 2008, 108, 2408–2414. [Google Scholar] [CrossRef]

- Frost, N.E.; McGrath, P.B.; Burns, C.W. Effect of fillers on the dielectric properties of polymers. In Proceedings of the Conference Record of the 1996 IEEE International Symposium on Electrical Insulation, Montreal, QC, Canada, 16–19 June 1996; Volume 1, pp. 300–303. [Google Scholar] [CrossRef]

- Hu, S.; Zheng, T.; Bian, C.; Yang, X.; Sun, X.; Zhu, Z.; Gou, Y.; Meng, Y.; Zhang, J.; Ge, J.; et al. FPGA Implementation for 24.576-Gbit/s Optical PAM4 Signal Transmission with MLP-Based Digital Pre-Distortion. Sensors 2024, 24, 7872. [Google Scholar] [CrossRef]

- Dai, G.; Luo, S.; Chen, H.; Ji, Y. Efficient Method for Photovoltaic Power Generation Forecasting Based on State Space Modeling and BiTCN. Sensors 2024, 24, 6590. [Google Scholar] [CrossRef]

- Miyoshi, T.; Koshino, M.; Nambo, H. Applying MLP-Mixer and gMLP to Human Activity Recognition. Sensors 2025, 25, 311. [Google Scholar] [CrossRef]

- Peng, C.; Li, B.; Zou, K.; Zhang, B.; Dai, G.; Tsoi, A.C. An Innovative Neighbor Attention Mechanism Based on Coordinates for the Recognition of Facial Expressions. Sensors 2024, 24, 7404. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, G.; Wei, Z.; Li, S.; Zayier, Y.; Cheng, Y. Machine Learning-Based Prediction of Well Logs Guided by Rock Physics and Its Interpretation. Sensors 2025, 25, 836. [Google Scholar] [CrossRef]

- Zhou, S.; Yang, C.; Cheng, Y.; Jiao, J. An Airborne Gravity Gradient Compensation Method Based on Convolutional and Long Short-Term Memory Neural Networks. Sensors 2025, 25, 421. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, Y.; Tian, Y.; Li, W. A Novel Non-Contact Multi-User Online Indoor Positioning Strategy Based on Channel State Information. Sensors 2024, 24, 6896. [Google Scholar] [CrossRef] [PubMed]

- Shafiq, M.; Gu, Z. Deep Residual Learning for Image Recognition: A Survey. Appl. Sci. 2022, 12, 8972. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, C.; Zhang, W.; Peng, Y.; Liu, C. Study on Height Measurement for Polyethylene Terephthalate (PET) Materials Based on Residual Networks. Sensors 2025, 25, 4030. https://doi.org/10.3390/s25134030

Liao C, Zhang W, Peng Y, Liu C. Study on Height Measurement for Polyethylene Terephthalate (PET) Materials Based on Residual Networks. Sensors. 2025; 25(13):4030. https://doi.org/10.3390/s25134030

Chicago/Turabian StyleLiao, Chongwei, Weixin Zhang, Yujie Peng, and Changjun Liu. 2025. "Study on Height Measurement for Polyethylene Terephthalate (PET) Materials Based on Residual Networks" Sensors 25, no. 13: 4030. https://doi.org/10.3390/s25134030

APA StyleLiao, C., Zhang, W., Peng, Y., & Liu, C. (2025). Study on Height Measurement for Polyethylene Terephthalate (PET) Materials Based on Residual Networks. Sensors, 25(13), 4030. https://doi.org/10.3390/s25134030