A Dual-Signal Ratiometric Optical Sensor Based on Natural Pine Wood and Platinum(II) Octaethylporphyrin with High Performance for Oxygen Detection

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the PtOEP/PDMS@Pine Sensor

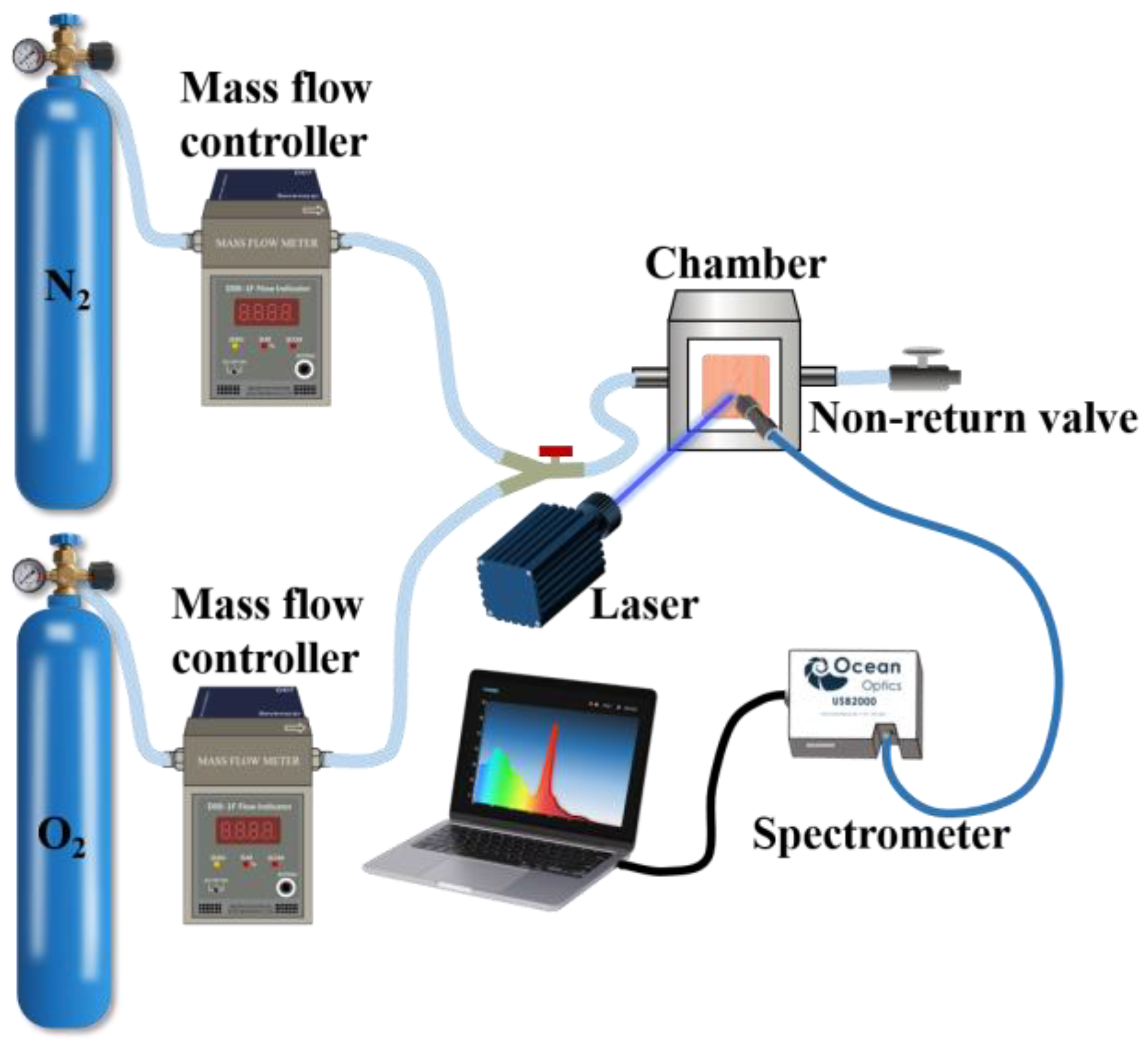

2.3. Instruments and Characterization

3. Results and Discussion

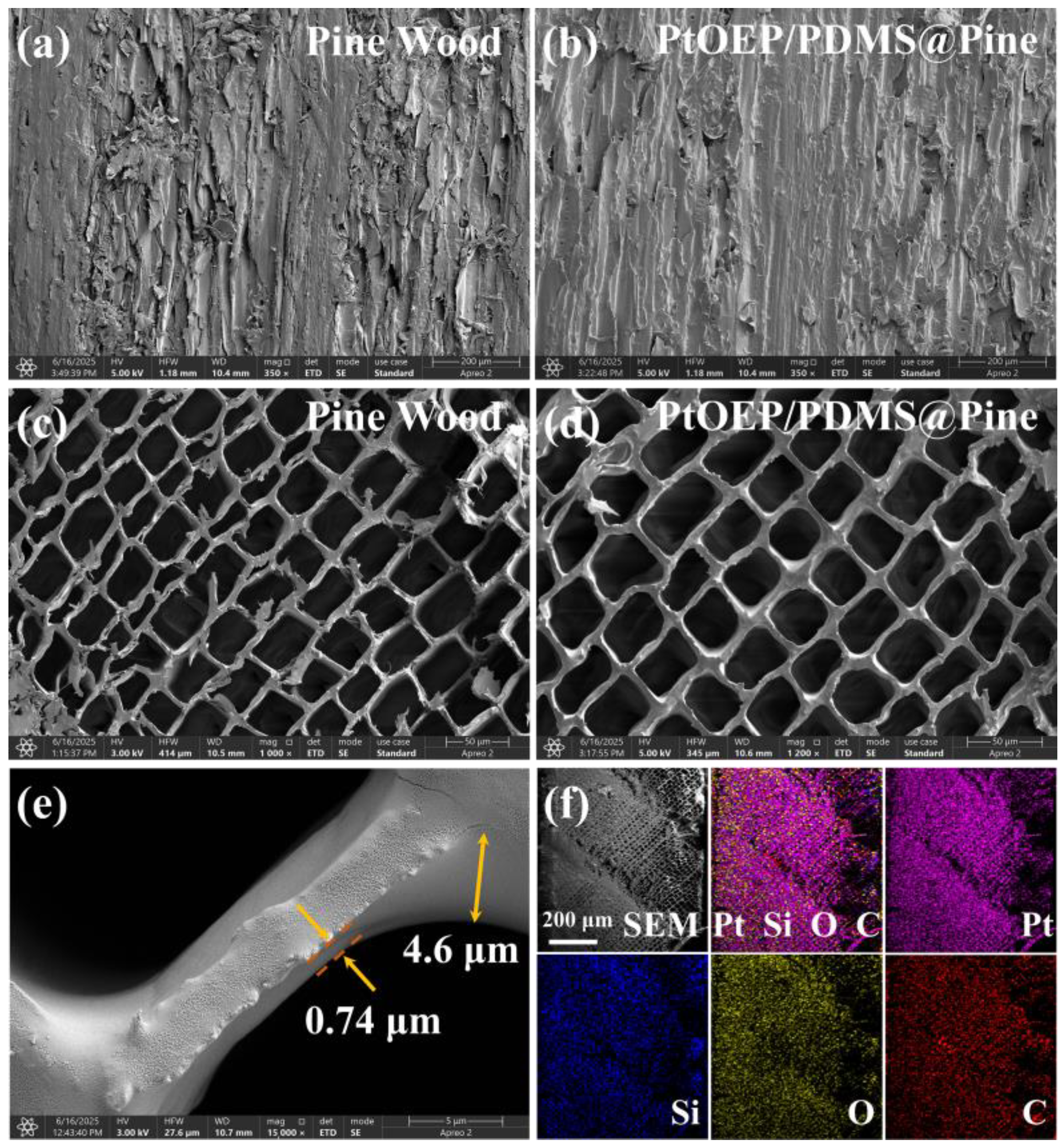

3.1. The Morphology Characteristics of the PtOEP/PDMS@Pine Sensor

3.2. The Hydrophobicity of the PtOEP/PDMS@Pine Sensor

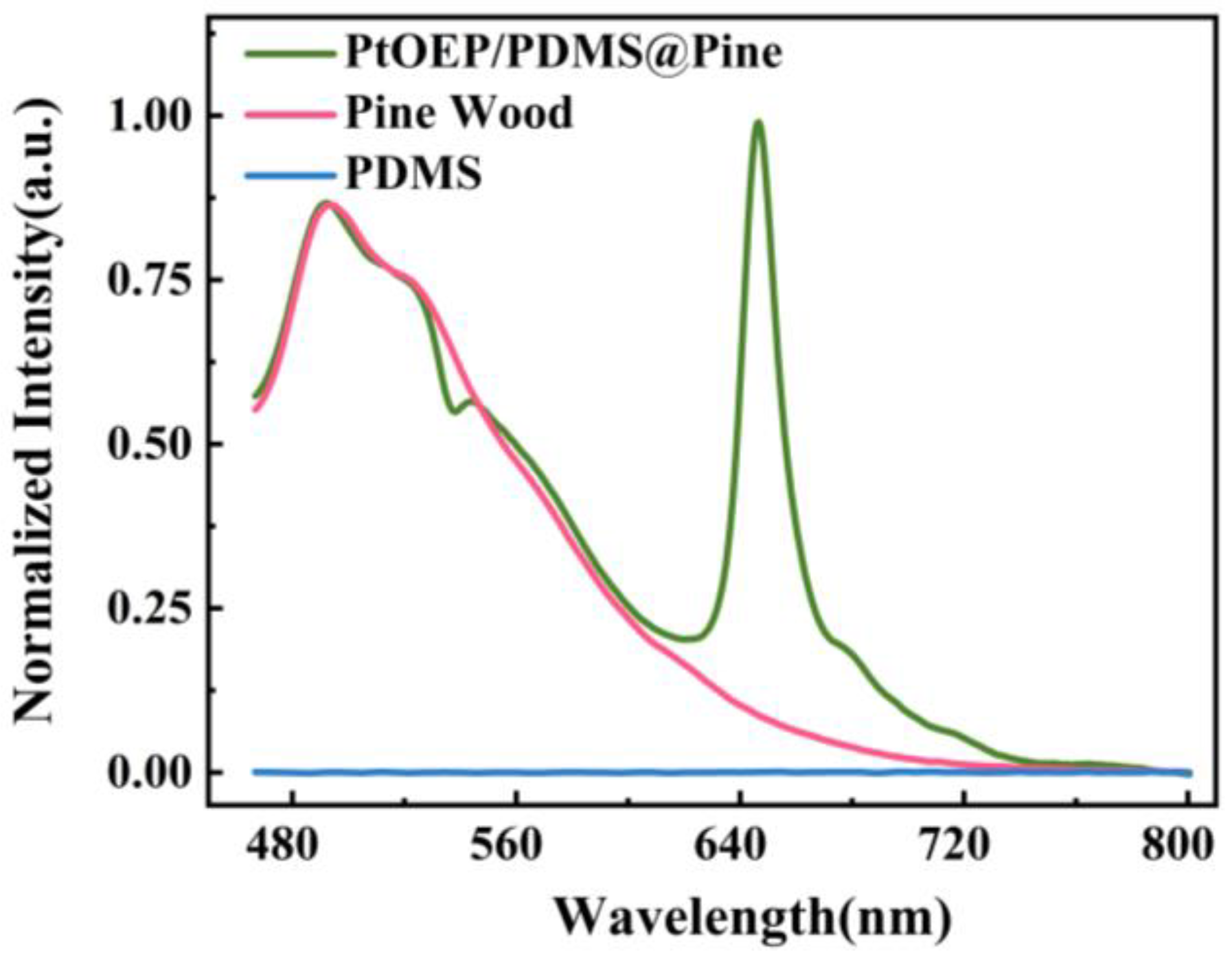

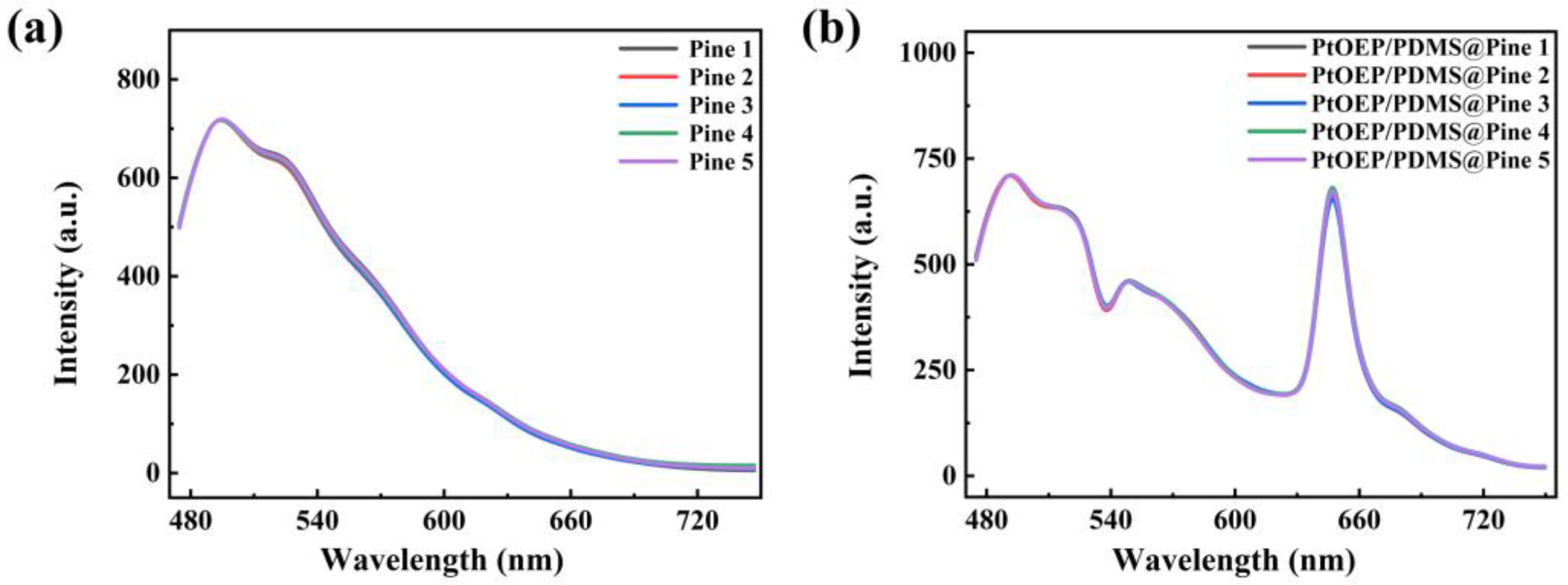

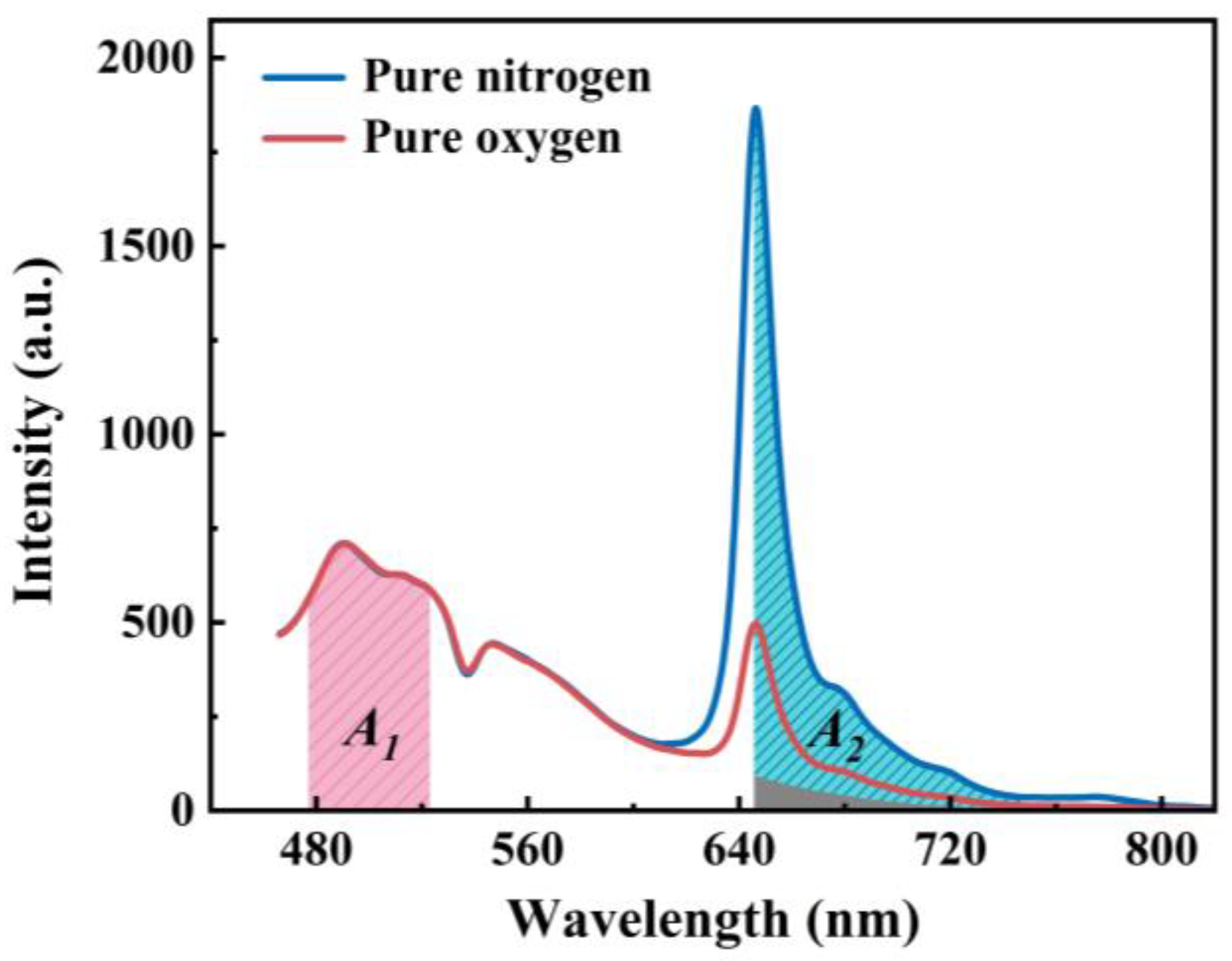

3.3. The Optical Properties of the PtOEP/PDMS@Pine Sensor

3.4. The Establishment of the Calibration Curve Based on the PtOEP/PDMS@Pine Sensor

3.5. The Impact of PtOEP Concentration and Preparation Methodology on the Performance of the PtOEP/PDMS@Pine Sensor

3.6. The Anti-Interference Capability of the PtOEP/PDMS@Pine Sensor

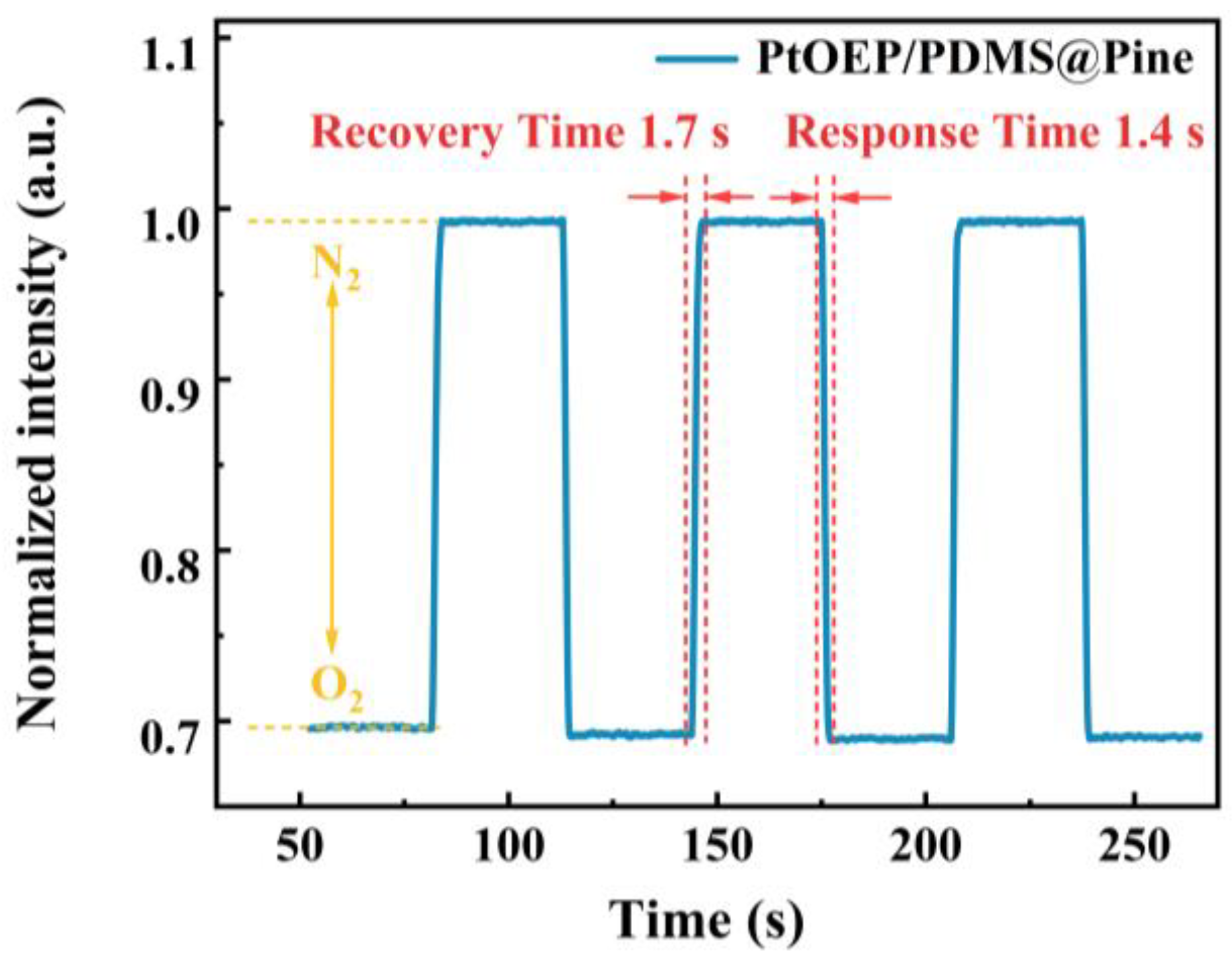

3.7. The Response Time and Recovery Performance of the PtOEP/PDMS@Pine Sensor

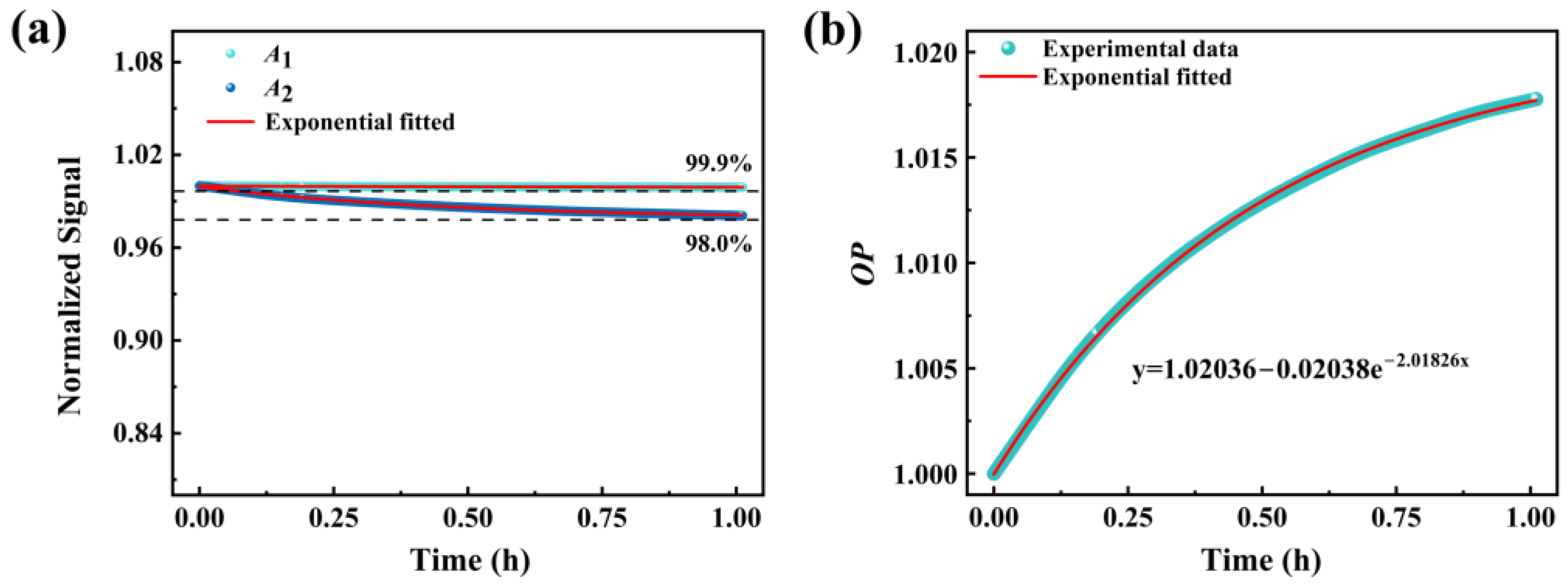

3.8. The Optical Stability of the PtOEP/PDMS@Pine Sensor

3.9. The Long-Term Stability of the PtOEP/PDMS@Pine Sensor

3.10. The Impact of Temperature on the Performance of the PtOEP/PDMS@Pine Sensor

3.11. The Impact of Humidity on the Performance of the PtOEP/PDMS@Pine Sensor

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| PtOEP | Platinum(II) octaethylporphyrin |

| PDMS | Polydimethylsiloxane |

| OP | Optical parameter |

| [O2] | Oxygen concentration |

| OS | Optical signal |

| T | Temperature |

References

- Dissmeyer, N. Oxygen sensing: Protein degradation meets retrograde signaling. Curr. Biol. 2022, 32, R281–R284. [Google Scholar] [CrossRef]

- Hawkes, L.; Kendall-Bar, J. A deep dive into oxygen sensing. Science 2025, 387, 1256–1257. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Deng, X.J.; Li, J.Y.; Wang, G.M.; Li, X.; Yao, H.H.; Lei, C.H.; Zhang, K.K. Developing robust organic afterglow emulsion for dissolved oxygen sensing. Chem. Eng. J. 2023, 474, 145809. [Google Scholar] [CrossRef]

- Jana, S.; Alayash, A.I. Exploring the Molecular Interplay Between Oxygen Transport, Cellular Oxygen Sensing, and Mitochondrial Respiration. Antioxid. Redox Signal. 2025, 42, 730–750. [Google Scholar] [CrossRef] [PubMed]

- Salaris, N.; Chen, W.Q.; Haigh, P.; Caciolli, L.; Giobbe, G.G.; De Coppi, P.; Papakonstantinou, I.; Tiwari, M.K. Nonwoven fiber meshes for oxygen sensing. Biosens. Bioelectron. 2024, 255, 116198. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Qian, J.J.; Zhao, S.Q.; Lv, Y.B.; Feng, Z.; Wang, S.Y.; He, H.B.; Zhang, S.T.; Liu, H.C.; Yang, B. Highly Sensitive Thianthrene Covalent Trimer Room-Temperature Phosphorescent Materials for Low-Concentration Oxygen Detection. Angew. Chem.-Int. Edit. 2025, 64, e202424669. [Google Scholar] [CrossRef]

- Du, B.S.; Zhang, M.; Ye, J.F.; Wang, D.K.; Han, J.H.; Zhang, T.F. Novel Au Nanoparticle-Modified ZnO Nanorod Arrays for Enhanced Photoluminescence-Based Optical Sensing of Oxygen. Sensors 2023, 23, 2886. [Google Scholar] [CrossRef]

- Lin, F.Y.; Liu, X.L.; Ye, M.; Jin, J.W.; Chen, X. Sensitive and reversible sensing of oxygen based on transition metals doped quasi-2D layered perovskites with 4T1→6A1 luminescence. Sens. Actuator B-Chem. 2025, 430, 137382. [Google Scholar] [CrossRef]

- Yang, L.O.; Zhang, L.C.; Tian, D.J.; Ye, M.; Lin, F.Y.; Liu, X.L.; Wang, Y.R.; Chen, X. Oxygen sensing behavior modulation of tetranuclear copper iodide hybrid materials using ligand engineering. Sens. Actuator B-Chem. 2023, 393, 134310. [Google Scholar] [CrossRef]

- Sun, L.; Romolini, G.; Dieu, B.; Grandjean, D.; Keshavarz, M.; Fron, E.; D’Acapito, F.; Roeffaers, M.B.J.; van der Auweraer, M.; Hofkens, J. Ultrasensitive Luminescence Switching of Zeolite Y Confined Silver Clusters for Dual-Channel Oxygen Sensing. Adv. Opt. Mater. 2024, 12, 2400784. [Google Scholar] [CrossRef]

- Duong, H.D.; Rhee, J.I. Preparation and characterization of dually fluorescent core-shell particles and dual-sensing membranes for simultaneous detection of pH and dissolved oxygen. J. Ind. Eng. Chem. 2024, 133, 515–524. [Google Scholar] [CrossRef]

- Wen, Y.; Zhang, S.D.; Yuan, W.; Feng, W.; Li, F.Y. Afterglow/Fluorescence Dual-Emissive Ratiometric Oxygen Probe for Tumor Hypoxia Imaging. Anal. Chem. 2023, 95, 2478–2486. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.X.; Ding, Q.L.; Wang, H.; Ye, J.D.; Luo, Y.B.; Yu, J.H.; Zhan, R.Z.; Zhang, H.; Tao, K.; Liu, C.; et al. A Humidity-Resistant, Sensitive, and Stretchable Hydrogel-Based Oxygen Sensor for Wireless Health and Environmental Monitoring. Adv. Funct. Mater. 2024, 34, 2308280. [Google Scholar] [CrossRef]

- Liu, H.C.; Pan, G.C.; Yang, Z.Q.; Wen, Y.T.; Zhang, X.Y.; Zhang, S.T.; Li, W.J.; Yang, B. Dual-Emission of Fluorescence and Room-Temperature Phosphorescence for Ratiometric and Colorimetric Oxygen Sensing and Detection Based on Dispersion of Pure Organic Thianthrene Dimer in Polymer Host. Adv. Opt. Mater. 2022, 10, 2102814. [Google Scholar] [CrossRef]

- Wang, Y.D.; Qin, F.; Zhang, H.L.; Kou, M.; Zhang, Z.G. A high-performance optical trace oxygen sensor based on the room-temperature phosphorescence from palladium (II) octaethylporphyrin. Measurement 2023, 206, 112275. [Google Scholar] [CrossRef]

- Yang, J.; Dai, P.L.; Li, M.; Tang, M.; Wu, Q.; Liu, S.J.; Zhao, Q.; Zhang, K.Y. Dual-lifetime luminescent probe for time-resolved ratiometric oxygen sensing and imaging. Dalton Trans. 2022, 51, 6095–6102. [Google Scholar] [CrossRef]

- Zhang, H.L.; Zhang, Z.G. Ratiometric Sensor Based on PtOEP-C6/Poly (St-TFEMA) Film for Automatic Dissolved Oxygen Content Detection. Sensors 2020, 20, 6175. [Google Scholar] [CrossRef]

- Duong, H.D.; Sohn, O.J.; Rhee, J.I. Development of a Ratiometric Fluorescent Glucose Sensor Using an Oxygen-Sensing Membrane Immobilized with Glucose Oxidase for the Detection of Glucose in Tears. Biosensors 2020, 10, 86. [Google Scholar] [CrossRef]

- Kostov, Y.; Rao, G. Ratio measurements in oxygen determinations: Wavelength ratiometry, lifetime discrimination, and polarization detection. Sens. Actuator B-Chem. 2003, 90, 139–142. [Google Scholar] [CrossRef]

- Li, Z.; Wang, X.H.; Fu, X.L.; Liu, J.H.; Liu, Y.A.; Zhang, H.X. Ratiometric fluorescent capillary sensor for real-time dual-monitoring of pH and O2 fluctuation. Spectroc. Acta Part A-Mol. Biomol. Spectrosc. 2025, 327, 125388. [Google Scholar] [CrossRef]

- Zhang, H.L.; Liu, T.; Zhang, X.Y.; Zhao, H.; Zheng, Y.D.; Qin, F.; Zhang, Z.G.; Sheng, T.Q.; Tian, Y. An effective oxygen content detection in phosphorescence of PtOEP-C6/Poly (St-co-TFEMA). Spectroc. Acta Part A-Mol. Biomol. Spectrosc. 2021, 257, 119786. [Google Scholar] [CrossRef] [PubMed]

- Di, L.; Xia, Z.Q.; Wang, H.H.; Xing, Y.; Yang, Z.X. Switchable and adjustable AIE activity of Pt(II) complexes achieving swift-responding and highly sensitive oxygen sensing. Sens. Actuator B-Chem. 2021, 326, 128987. [Google Scholar] [CrossRef]

- do Nascimento, J.P.C.; do Carmo, F.F.; Sales, A.J.M.; Maia, S.M.; Frutuoso, R.L.; Cavalcante, T.D.; Cavalcante, C.; Vieira, J.D.S.; de Carvalho, C.R.R.; Sombra, A.S.B. A novel wireless oxygen gas sensor based on silver film loaded on a patch antenna. Mater. Chem. Phys. 2023, 299, 127513. [Google Scholar] [CrossRef]

- Wei, Y.; Guoping, L.; Li-li, J.; Zaidao, Y. Luminescent oxygen-sensing film based on Eu (III)-doped yttrium hydroxide nanosheets. Opt. Commun. 2022, 524, 128748. [Google Scholar]

- Yang, D.; Qu, Z.; Li, F.; Lu, S.Y. Enhancing Oxygen Sensing Properties of Plasticized PVC Films by Blending Poly (Vinylidene Fluoride-Co-Hexafluoropropylene). IEEE Sens. J. 2024, 24, 27168–27182. [Google Scholar] [CrossRef]

- Zhang, L.S.; Gu, F.; Jiang, P.; Ma, X. Visualization of Solvent Effect and Oxygen Content via a Red Room-Temperature Phosphorescent Material. ACS Appl. Mater. Interfaces 2024, 16, 42794–42801. [Google Scholar] [CrossRef]

- Chen, Y.T.; Sun, C.S.; Ren, Z.R.; Na, B. Review of the Current State of Application of Wood Defect Recognition Technology. Bioresources 2023, 18, 49. [Google Scholar] [CrossRef]

- Mai, C.; Schmitt, U.; Niemz, P. A brief overview on the development of wood research. Holzforschung 2022, 76, 102–119. [Google Scholar] [CrossRef]

- Mascarenhas, F.J.R.; Dias, A.; Christoforo, A.L.; Simoes, R.M.D.; Cunha, A.E.P.; Carneiro, L.C.P.; Dias, A.M.A. Analysis of the Treatability, Water Repellency Efficiency, and Dimensional Stability of Maritime Pine after Microwave Drying. Bioresources 2024, 19, 4292–4312. [Google Scholar] [CrossRef]

- Ermeydan, M.A.; Babacan, M.; Tomak, E.D. Poly(ε-caprolactone) grafting into Scots pine wood: Improvement on the dimensional stability, weathering and decay resistance. Cellulose 2021, 28, 5827–5841. [Google Scholar] [CrossRef]

- Acosta, A.P.; Barbosa, K.T.; Amico, S.C.; Missio, A.L.; Delucis, R.D.; Gatto, D.A. Improvement in mechanical, physical and biological properties of eucalyptus and pine woods by raw pine resin in situ polymerization. Ind. Crop. Prod. 2021, 166, 113495. [Google Scholar] [CrossRef]

- Baranski, J.; Suchta, A.; Baranska, S.; Klement, I.; Vilkovska, T.; Vilkovsky, P. Wood Moisture-Content Measurement Accuracy of Impregnated and Nonimpregnated Wood. Sensors 2021, 21, 7033. [Google Scholar] [CrossRef] [PubMed]

- Kulak, P.; Lachowicz, H.; Moskalik, T.; Pietka, J.; Aniszewska, M.; Gendek, A. The Structural, Physical, and Mechanical Properties of Wood from Scots Pine (Pinus sylvestris L.) Affected by Scots Pine Blister Rust. Forests 2023, 14, 2161. [Google Scholar] [CrossRef]

- Saltik, B. The Effects of Microwave and Microwave plus Infrared Drying Treatments of Pinus brutia and Picea orientalis on Water Absorption and Physical Properties. Bioresources 2024, 19, 9249–9258. [Google Scholar] [CrossRef]

- Sosins, G.; Grinins, J.; Brazdausks, P.; Zicans, J. Water-Related Properties of Wood after Thermal Modification in Closed Process under Pressure in Nitrogen. Forests 2024, 15, 140. [Google Scholar] [CrossRef]

- Chou, N.; Moon, H.; Park, J.; Kim, S. Interfacial and surface analysis of parylene C-modified PDMS substrates for soft bioelectronics. Prog. Org. Coat. 2021, 157, 106309. [Google Scholar] [CrossRef]

- Maparu, A.K.; Singh, P.; Rai, B.; Sharma, A.; Sivakumar, S. PDMS nanoparticles-decorated PDMS substrate promotes adhesion, proliferation and differentiation of skin cells. J. Colloid Interface Sci. 2024, 659, 629–638. [Google Scholar] [CrossRef]

- Tony, A.; Badea, I.; Yang, C.; Liu, Y.Y.; Wang, K.M.; Yang, S.M.; Zhang, W.J. A Preliminary Experimental Study of Polydimethylsiloxane (PDMS)-To-PDMS Bonding Using Oxygen Plasma Treatment Incorporating Isopropyl Alcohol. Polymers 2023, 15, 1006. [Google Scholar] [CrossRef]

- Zimmermann, C.A.; Amouzou, K.N.; Ung, B. Recent Advances in PDMS Optical Waveguides: Properties, Fabrication, and Applications. Adv. Opt. Mater. 2025, 13, 2401975. [Google Scholar] [CrossRef]

- Chen, S.; Ren, Q.; Zhang, K.; Sha, W.E.; Hao, T.T.; Xu, H.B.; Zhao, J.P.; Li, Y. A highly sensitive and flexible photonic crystal oxygen sensor. Sens. Actuator B-Chem. 2022, 355, 131326. [Google Scholar] [CrossRef]

- Penso, C.M.; Rocha, J.L.; Martins, M.S.; Sousa, P.J.; Pinto, V.C.; Minas, G.; Silva, M.M.; Goncalves, L.M. PtOEP-PDMS-Based Optical Oxygen Sensor. Sensors 2021, 21, 5645. [Google Scholar] [CrossRef] [PubMed]

- Niu, Y.J.; Wang, Y.D.; Li, L.; Zhang, X.Y.; Liu, T. Development of Automatic Method for Glucose Detection Based on Platinum Octaethylporphyrin Sol-Gel Film with Long-Term Stability. Sensors 2025, 25, 186. [Google Scholar] [CrossRef] [PubMed]

- Ye, Y.X.; Liu, H.M.; Li, Y.S.; Zhuang, Q.X.; Liu, P.F.; Gu, J.L. One-pot doping platinum porphyrin recognition centers in Zr-based MOFs for ratiometric luminescent monitoring of nitric oxide in living cells. Talanta 2019, 200, 472–479. [Google Scholar] [CrossRef]

- Smith, A.D.; Elgammal, K.; Niklaus, F.; Delin, A.; Fischer, A.C.; Vaziri, S.; Forsberg, F.; Råsander, M.; Hugosson, H.; Bergqvist, L.; et al. Resistive graphene humidity sensors with rapid and direct electrical readout. Nanoscale 2015, 7, 19099–19109. [Google Scholar] [CrossRef] [PubMed]

- Demchenko, A.P. Photobleaching of organic fluorophores: Quantitative characterization, mechanisms, protection. Methods Appl. Fluoresc. 2020, 8, 022001. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Niu, Y.; Mu, H.; Li, J.; Wang, J.; Liu, T. A Dual-Signal Ratiometric Optical Sensor Based on Natural Pine Wood and Platinum(II) Octaethylporphyrin with High Performance for Oxygen Detection. Sensors 2025, 25, 3967. https://doi.org/10.3390/s25133967

Zhang Z, Niu Y, Mu H, Li J, Wang J, Liu T. A Dual-Signal Ratiometric Optical Sensor Based on Natural Pine Wood and Platinum(II) Octaethylporphyrin with High Performance for Oxygen Detection. Sensors. 2025; 25(13):3967. https://doi.org/10.3390/s25133967

Chicago/Turabian StyleZhang, Zhongxing, Yujie Niu, Hongbo Mu, Jingkui Li, Jinxin Wang, and Ting Liu. 2025. "A Dual-Signal Ratiometric Optical Sensor Based on Natural Pine Wood and Platinum(II) Octaethylporphyrin with High Performance for Oxygen Detection" Sensors 25, no. 13: 3967. https://doi.org/10.3390/s25133967

APA StyleZhang, Z., Niu, Y., Mu, H., Li, J., Wang, J., & Liu, T. (2025). A Dual-Signal Ratiometric Optical Sensor Based on Natural Pine Wood and Platinum(II) Octaethylporphyrin with High Performance for Oxygen Detection. Sensors, 25(13), 3967. https://doi.org/10.3390/s25133967