Study and Characterization of Silicon Nitride Optical Waveguide Coupling with a Quartz Tuning Fork for the Development of Integrated Sensing Platforms

Abstract

Highlights

- We successfully coupled a silicon nitride waveguide with a custom-designed, low-frequency, and T-shaped QTF, enabling both Quartz-Enhanced Photoacoustic Spectroscopy (QEPAS) and Light-Induced Thermoelastic Spectroscopy (LITES) techniques for sensing.

- We achieved comparable signal-to-noise ratios with QEPAS and LITES when detecting 1.6% water vapor concentration, with performance limited by the output power illuminating the QTF.

- Demonstrated the feasibility of integrating photonic components with piezoelectric resonators for portable gas-sensing applications.

- Identified on-chip laser-waveguide integration as a key route to compact sensing platforms.

Abstract

1. Introduction

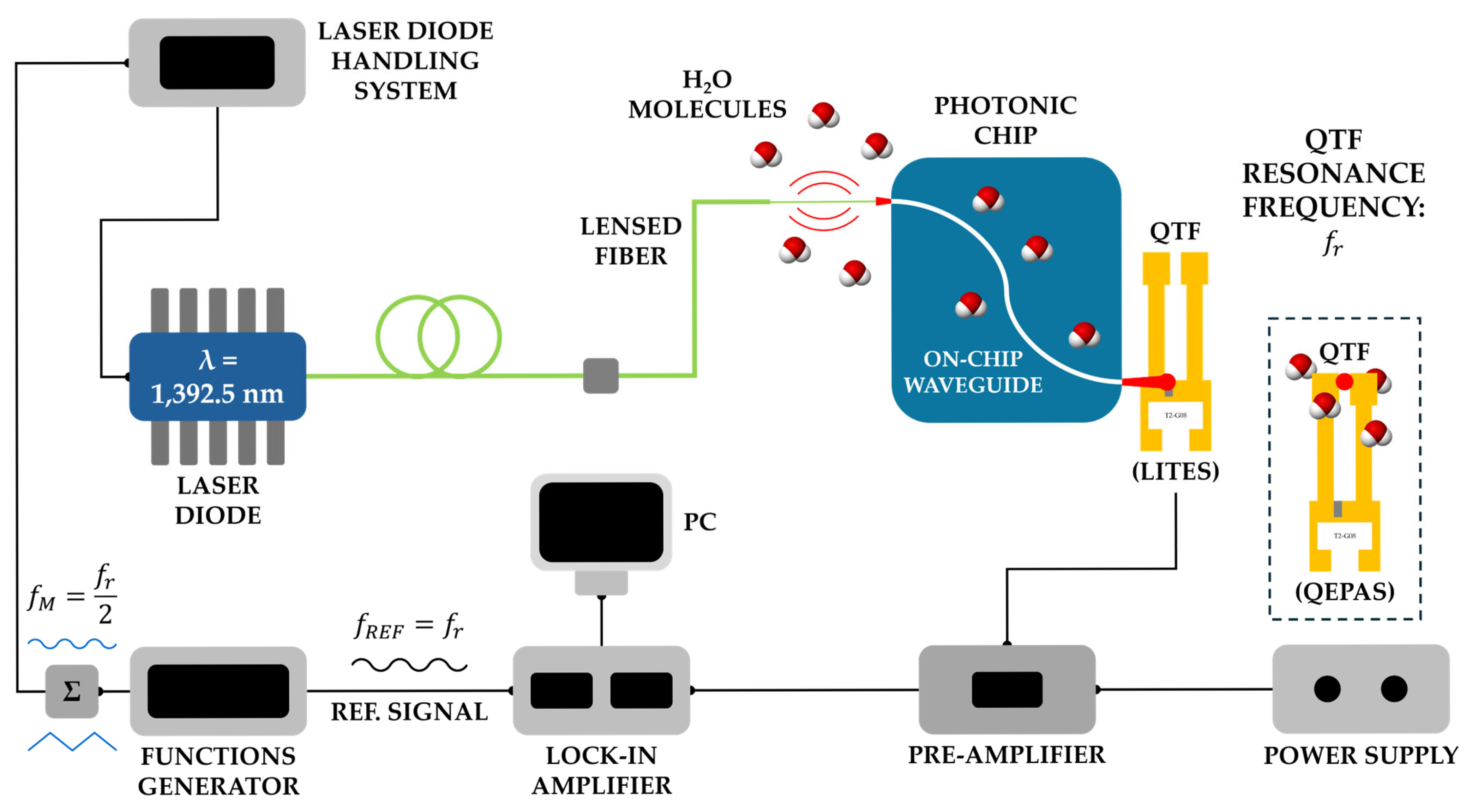

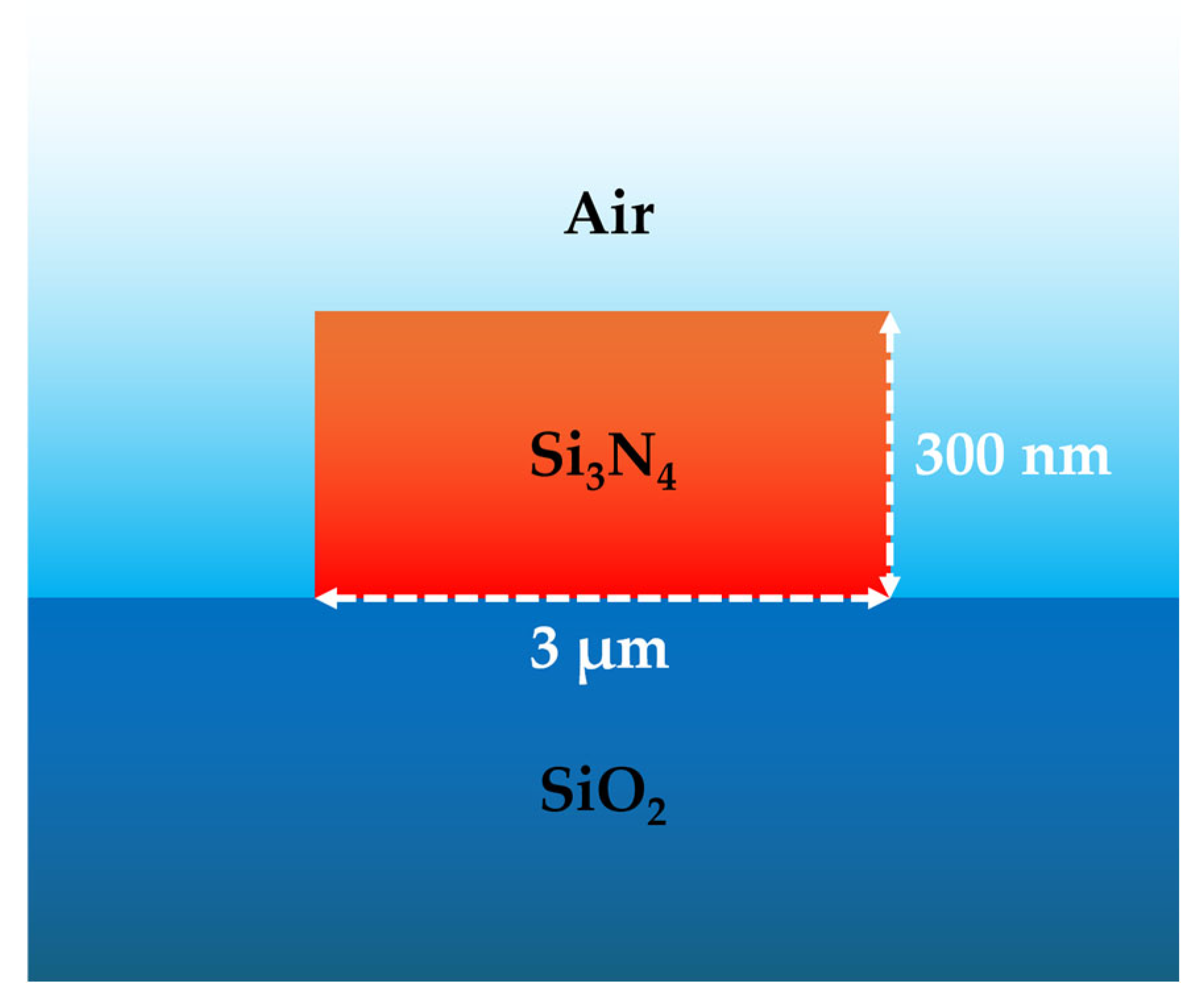

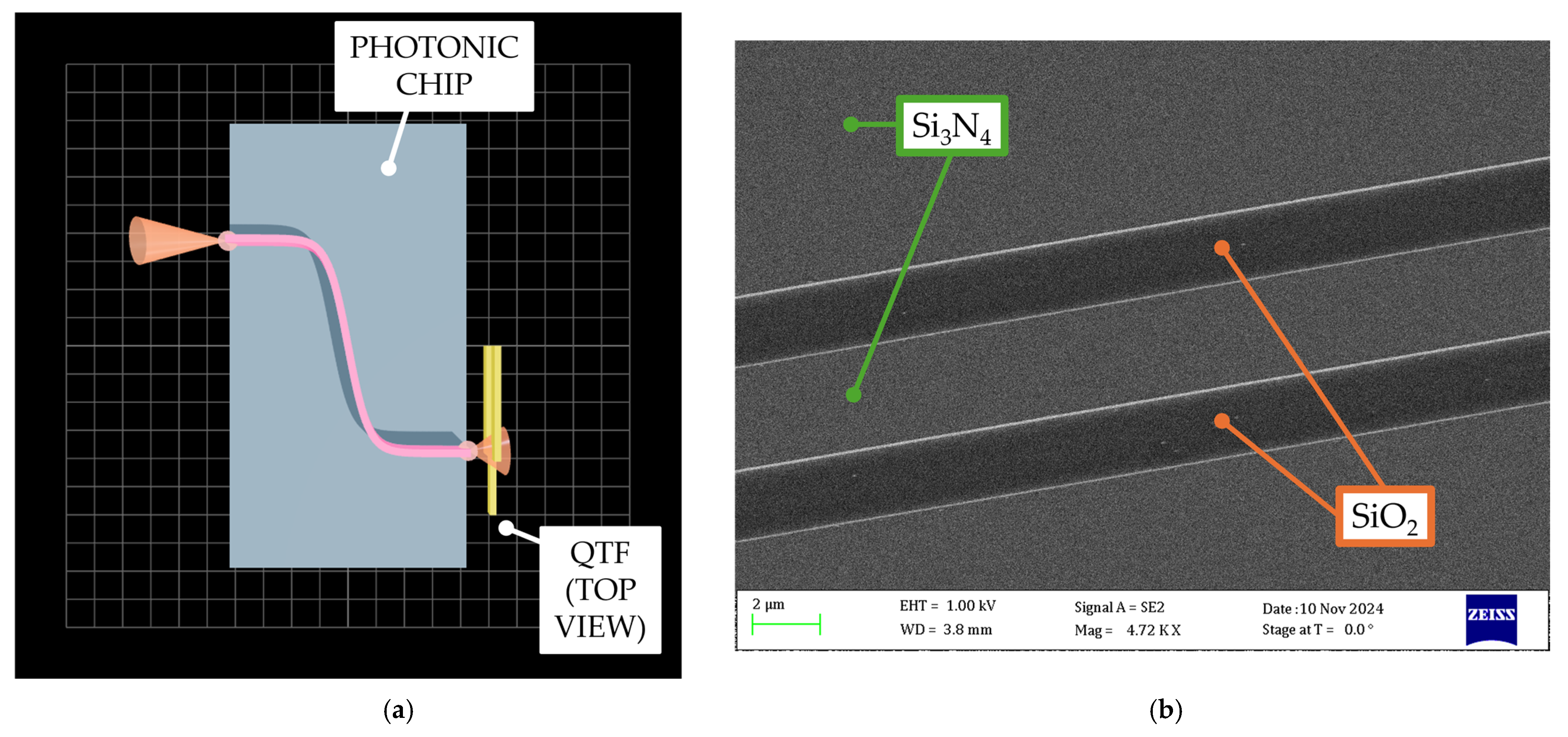

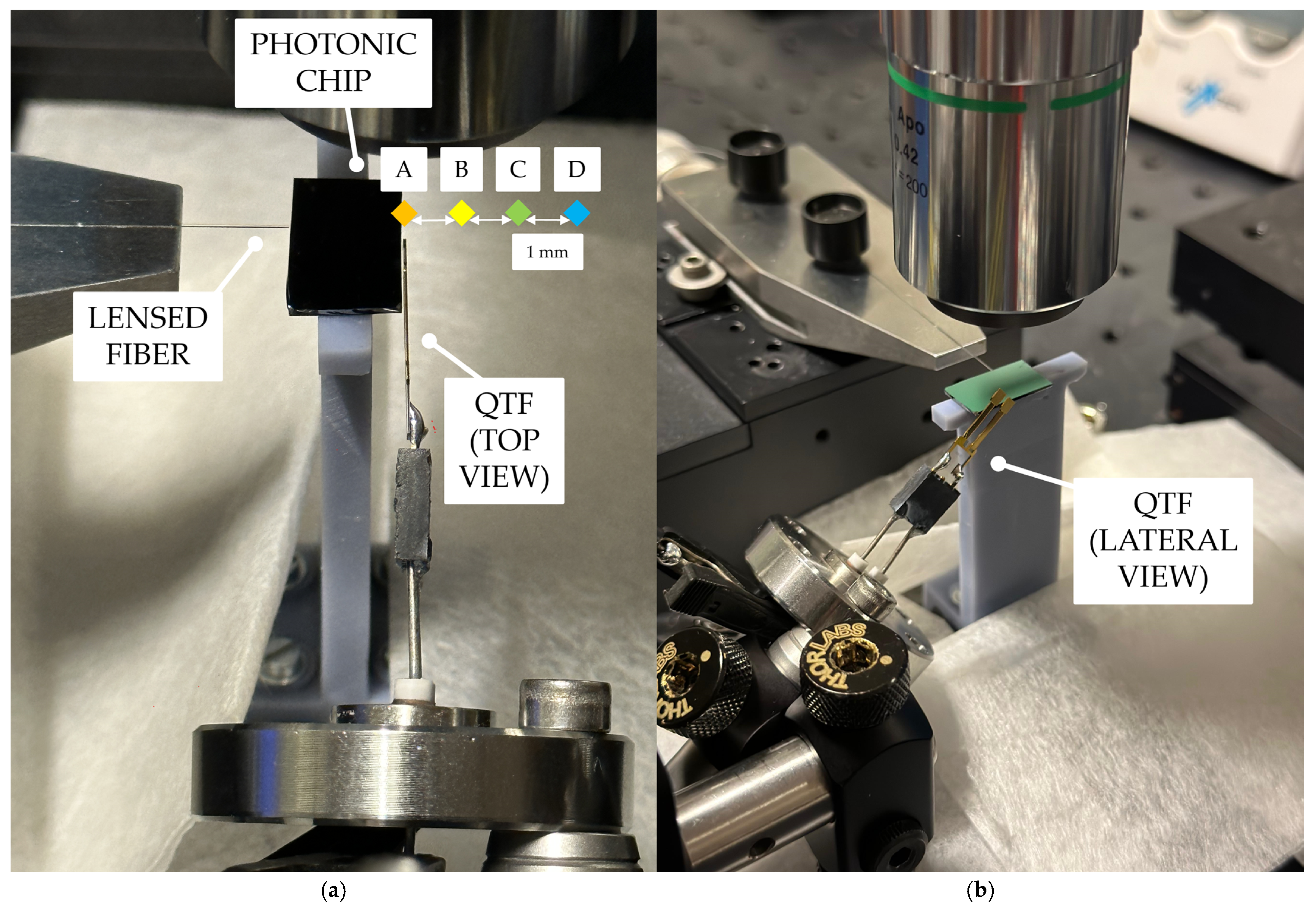

2. Semi-Integrated Sensing Architecture

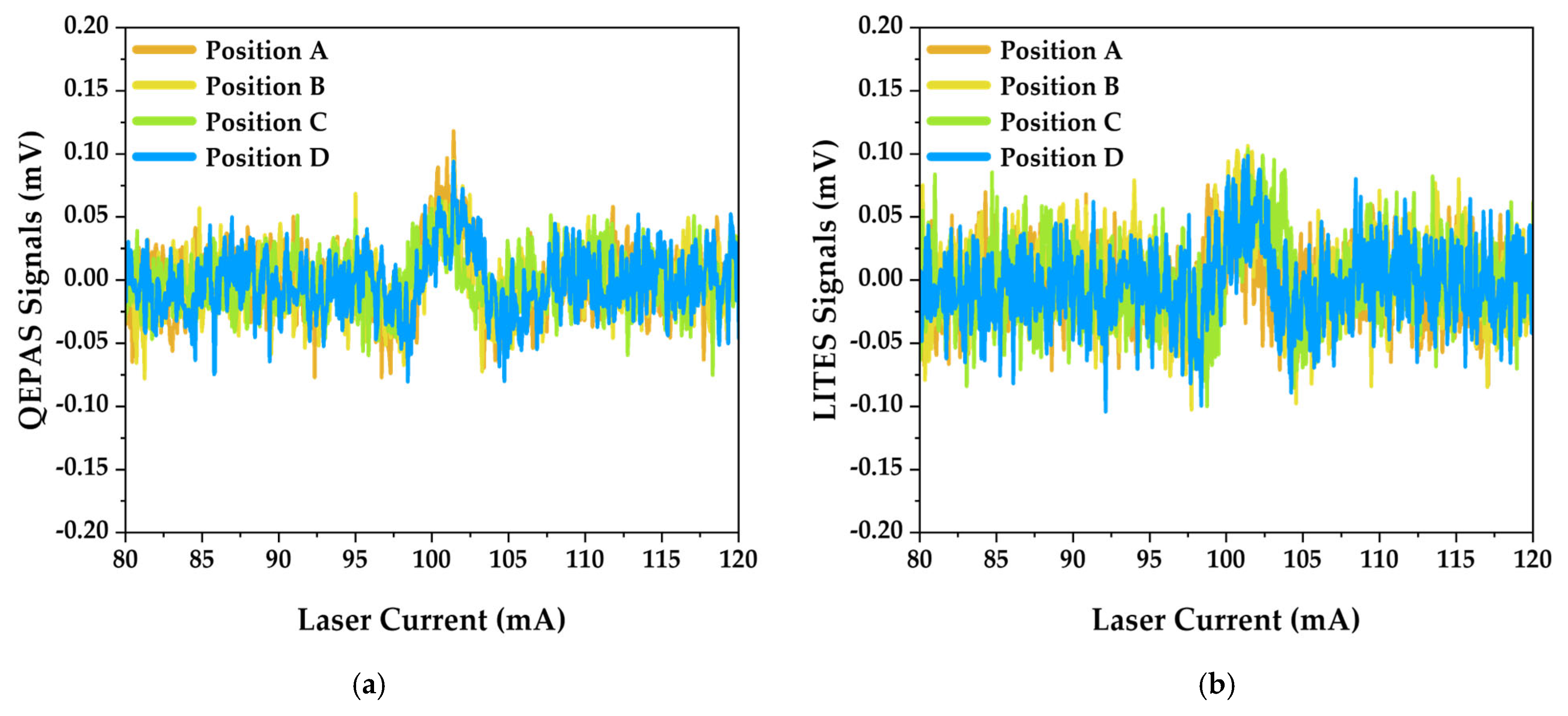

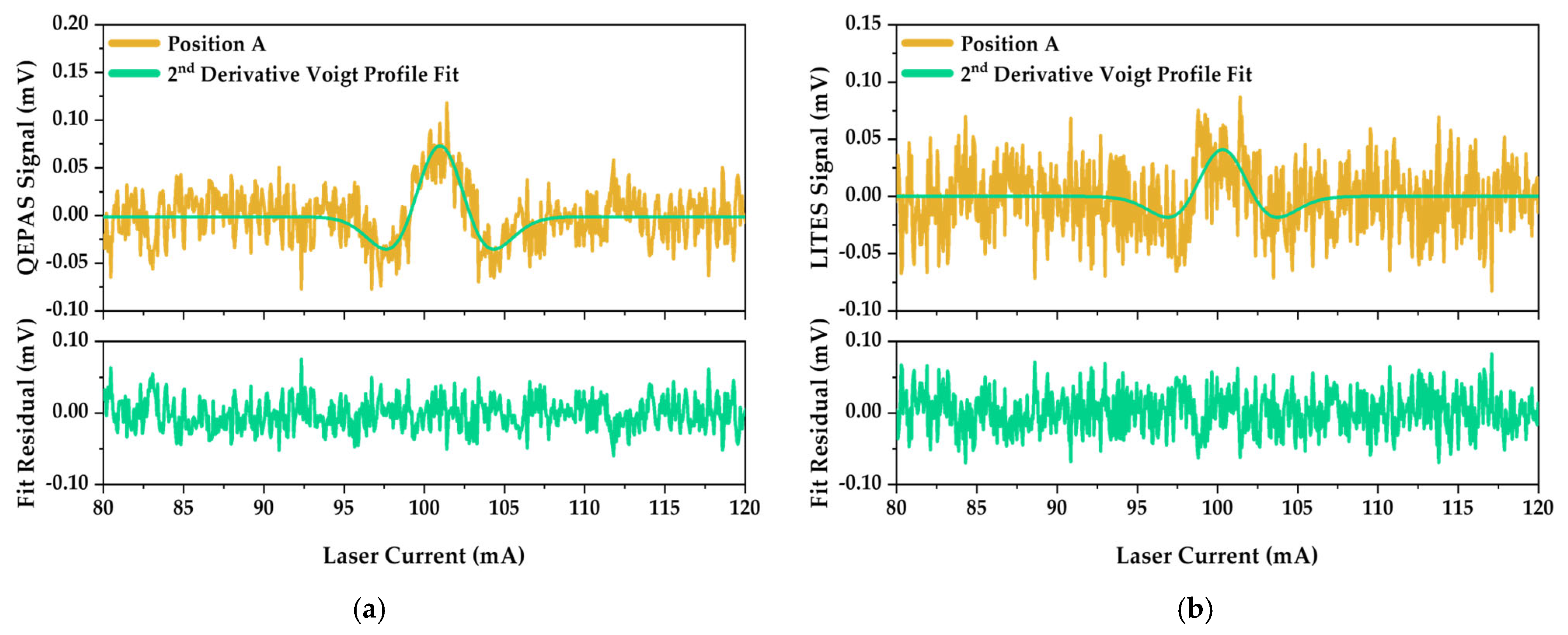

3. QEPAS and LITES Results

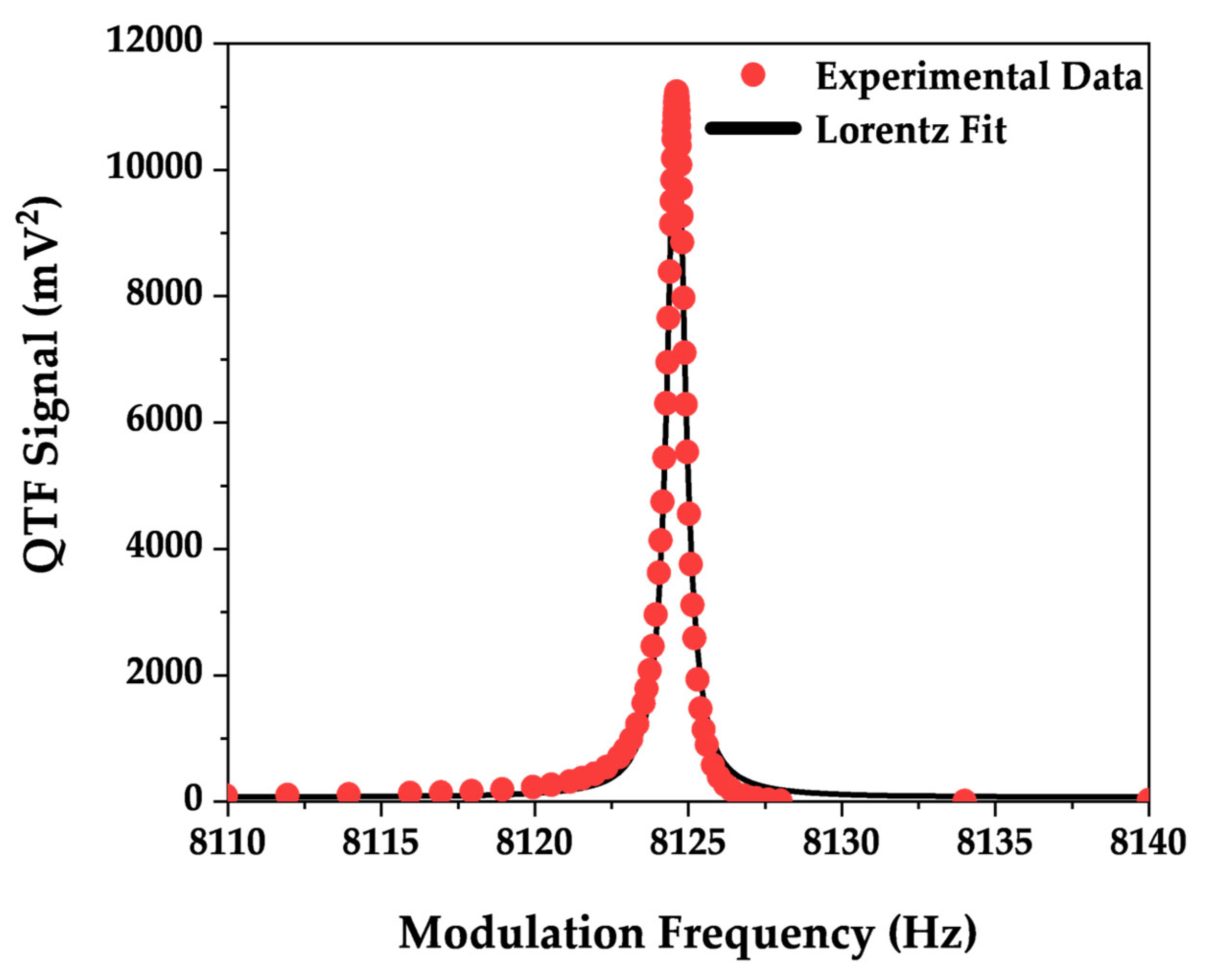

Experimental Data Fitting

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| 2f | Second harmonic |

| CMOS | Complementary Metal-Oxide Semiconductor |

| DAQ | Data acquisition |

| fr | Resonance frequency |

| H2O | Water vapor |

| IR | Infrared |

| LiNTF | Lithium Niobate Tuning Fork |

| LITES | Light-Induced Thermoelastic Spectroscopy |

| MDL | Minimum Detection Limit |

| NIR | Near-IR |

| PC | Personal Computer |

| Q | Quality factor |

| QEPAS | Quartz-Enhanced Photoacoustic Spectroscopy |

| QTF | Quartz Tuning Fork |

| SEM | Scanning Electron Microscope |

| Si3N4 | Silicon nitride |

| SiNOI | Silicon Nitride-On-Insulator |

| SiO2 | Silicon dioxide/silica |

| SNR | Signal-to-noise ratio |

| SWIR | Short-Wavelength IR |

| TDLAS | Tunable Diode Laser Absorption Spectroscopy |

| WMS | Wavelength Modulation Spectroscopy |

References

- Yamazoe, N.; Miura, N. Environmental Gas Sensing. Sens. Actuators B Chem. 1994, 20, 95–102. [Google Scholar] [CrossRef]

- Sharma, J.N.; Al-Omran, A.; Parvathy, S.S. Role of Nitric Oxide in Inflammatory Diseases. Inflammopharmacology 2007, 15, 252–259. [Google Scholar] [CrossRef] [PubMed]

- Yamazoe, N.; Shimanoe, K. New Perspectives of Gas Sensor Technology. Sens. Actuators B Chem. 2009, 138, 100–107. [Google Scholar] [CrossRef]

- Liu, X.; Cheng, S.; Liu, H.; Hu, S.; Zhang, D.; Ning, H. A Survey on Gas Sensing Technology. Sensors 2012, 12, 9635–9665. [Google Scholar] [CrossRef]

- Mac Dowell, N.; Fennell, P.S.; Shah, N.; Maitland, G.C. The Role of CO2 Capture and Utilization in Mitigating Climate Change. Nat. Clim. Change 2017, 7, 243–249. [Google Scholar] [CrossRef]

- Baranwal, J.; Barse, B.; Gatto, G.; Broncova, G.; Kumar, A. Electrochemical Sensors and Their Applications: A Review. Chemosensors 2022, 10, 363. [Google Scholar] [CrossRef]

- Najafi, P.; Ghaemi, A. Chemiresistor Gas Sensors: Design, Challenges, and Strategies: A Comprehensive Review. Chem. Eng. J. 2024, 498, 154999. [Google Scholar] [CrossRef]

- Popa, D.; Udrea, F. Towards Integrated Mid-Infrared Gas Sensors. Sensors 2019, 19, 2076. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Sun, F.; Dai, Y.; Wang, S.; Bai, Y.; Li, L.; Li, T.; Zhang, T.; Qin, S. “Top-down” and “Bottom-up” Strategies for Wafer-Scaled Miniaturized Gas Sensors Design and Fabrication. Microsyst. Nanoeng. 2020, 6, 31. [Google Scholar] [CrossRef]

- El Shamy, R.S.; Swillam, M.A.; ElRayany, M.M.; Sultan, A.; Li, X. Compact Gas Sensor Using Silicon-on-Insulator Loop-Terminated Mach–Zehnder Interferometer. Photonics 2021, 9, 8. [Google Scholar] [CrossRef]

- Fan, E.; Liu, H.; Wang, C.; Ma, J.; Guan, B.-O. Compact Optical Fiber Photoacoustic Gas Sensor with Integrated Multi-Pass Cell. Photoacoustics 2023, 32, 100524. [Google Scholar] [CrossRef] [PubMed]

- Galli, I.; Bartalini, S.; Ballerini, R.; Barucci, M.; Cancio, P.; De Pas, M.; Giusfredi, G.; Mazzotti, D.; Akikusa, N.; De Natale, P. Spectroscopic Detection of Radiocarbon Dioxide at Parts-per-Quadrillion Sensitivity. Optica 2016, 3, 385. [Google Scholar] [CrossRef]

- Itoh, T.; Miwa, T.; Tsuruta, A.; Akamatsu, T.; Izu, N.; Shin, W.; Park, J.; Hida, T.; Eda, T.; Setoguchi, Y. Development of an Exhaled Breath Monitoring System with Semiconductive Gas Sensors, a Gas Condenser Unit, and Gas Chromatograph Columns. Sensors 2016, 16, 1891. [Google Scholar] [CrossRef]

- Wang, P.; Chen, W.; Wan, F.; Wang, J.; Hu, J. Cavity-Enhanced Raman Spectroscopy with Optical Feedback Frequency-Locking for Gas Sensing. Opt. Express 2019, 27, 33312. [Google Scholar] [CrossRef]

- Boehme, I.; Weimar, U.; Barsan, N. Unraveling the Surface Chemistry of CO Sensing with In2O3 Based Gas Sensors. Sens. Actuators B Chem. 2021, 326, 129004. [Google Scholar] [CrossRef]

- Cristescu, S.M.; Persijn, S.T.; te Lintel Hekkert, S.; Harren, F.J.M. Laser-Based Systems for Trace Gas Detection in Life Sciences. Appl. Phys. B 2008, 92, 343. [Google Scholar] [CrossRef]

- Hodgkinson, J.; Tatam, R.P. Optical Gas Sensing: A Review. Meas. Sci. Technol. 2013, 24, 012004. [Google Scholar] [CrossRef]

- Bogue, R. Detecting Gases with Light: A Review of Optical Gas Sensor Technologies. Sens. Rev. 2015, 35, 133–140. [Google Scholar] [CrossRef]

- Ma, Y. Review of Recent Advances in QEPAS-Based Trace Gas Sensing. Appl. Sci. 2018, 8, 1822. [Google Scholar] [CrossRef]

- Yang, T.; Chen, W.; Wang, P. A Review of All-Optical Photoacoustic Spectroscopy as a Gas Sensing Method. Appl. Spectrosc. Rev. 2021, 56, 143–170. [Google Scholar] [CrossRef]

- Kosterev, A.A.; Bakhirkin, Y.A.; Curl, R.F.; Tittel, F.K. Quartz-Enhanced Photoacoustic Spectroscopy. Opt. Lett. 2002, 27, 1902. [Google Scholar] [CrossRef] [PubMed]

- Patimisco, P.; Scamarcio, G.; Tittel, F.; Spagnolo, V. Quartz-Enhanced Photoacoustic Spectroscopy: A Review. Sensors 2014, 14, 6165–6206. [Google Scholar] [CrossRef] [PubMed]

- West, G.A.; Barrett, J.J.; Siebert, D.R.; Reddy, K.V. Photoacoustic Spectroscopy. Rev. Sci. Instrum. 1983, 54, 797–817. [Google Scholar] [CrossRef]

- Friedt, J.-M.; Carry, É. Introduction to the Quartz Tuning Fork. Am. J. Phys. 2007, 75, 415–422. [Google Scholar] [CrossRef]

- Dong, L.; Kosterev, A.A.; Thomazy, D.; Tittel, F.K. QEPAS Spectrophones: Design, Optimization, and Performance. Appl. Phys. B 2010, 100, 627–635. [Google Scholar] [CrossRef]

- Patimisco, P.; Sampaolo, A.; Zheng, H.; Dong, L.; Tittel, F.K.; Spagnolo, V. Quartz–Enhanced Photoacoustic Spectrophones Exploiting Custom Tuning Forks: A Review. Adv. Phys. X 2017, 2, 169–187. [Google Scholar] [CrossRef]

- Patimisco, P.; Sampaolo, A.; Giglio, M.; dello Russo, S.; Mackowiak, V.; Rossmadl, H.; Cable, A.; Tittel, F.K.; Spagnolo, V. Tuning Forks with Optimized Geometries for Quartz-Enhanced Photoacoustic Spectroscopy. Opt. Express 2019, 27, 1401. [Google Scholar] [CrossRef]

- Lin, H.; Liu, Y.; Lin, L.; Zhu, W.; Zhou, X.; Zhong, Y.; Giglio, M.; Sampaolo, A.; Patimisco, P.; Tittel, F.K.; et al. Application of Standard and Custom Quartz Tuning Forks for Quartz-Enhanced Photoacoustic Spectroscopy Gas Sensing. Appl. Spectrosc. Rev. 2023, 58, 562–584. [Google Scholar] [CrossRef]

- Sun, B.; Zifarelli, A.; Wu, H.; Dello Russo, S.; Li, S.; Patimisco, P.; Dong, L.; Spagnolo, V. Mid-Infrared Quartz-Enhanced Photoacoustic Sensor for Ppb-Level CO Detection in a SF6 Gas Matrix Exploiting a T-Grooved Quartz Tuning Fork. Anal. Chem. 2020, 92, 13922–13929. [Google Scholar] [CrossRef]

- Lin, H.; Zheng, H.; Montano, B.A.Z.; Wu, H.; Giglio, M.; Sampaolo, A.; Patimisco, P.; Zhu, W.; Zhong, Y.; Dong, L.; et al. Ppb-Level Gas Detection Using on-Beam Quartz-Enhanced Photoacoustic Spectroscopy Based on a 28 KHz Tuning Fork. Photoacoustics 2022, 25, 100321. [Google Scholar] [CrossRef]

- Li, S.; Lu, J.; Shang, Z.; Zeng, X.; Yuan, Y.; Wu, H.; Pan, Y.; Sampaolo, A.; Patimisco, P.; Spagnolo, V.; et al. Compact Quartz-Enhanced Photoacoustic Sensor for Ppb-Level Ambient NO2 Detection by Use of a High-Power Laser Diode and a Grooved Tuning Fork. Photoacoustics 2022, 25, 100325. [Google Scholar] [CrossRef] [PubMed]

- Quartz-Enhanced Photoacoustic Sensor for Methane. Available online: https://www.thorlabs.com/newgrouppage9.cfm?objectgroup_id=16188 (accessed on 12 May 2025).

- Dello Russo, S.; Zifarelli, A.; Patimisco, P.; Sampaolo, A.; Wei, T.; Wu, H.; Dong, L.; Spagnolo, V. Light-Induced Thermo-Elastic Effect in Quartz Tuning Forks Exploited as a Photodetector in Gas Absorption Spectroscopy. Opt. Express 2020, 28, 19074. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Zhao, J.; Lu, P.; Sima, C.; Liu, D. Recent Advances in Light-Induced Thermoelastic Spectroscopy for Gas Sensing: A Review. Remote Sens. 2022, 15, 69. [Google Scholar] [CrossRef]

- Sun, J.; Chang, J.; Wang, C.; Shao, J. Tunable Diode Laser Absorption Spectroscopy for Detection of Multi-Component Gas: A Review. Appl. Spectrosc. Rev. 2024, 59, 1086–1107. [Google Scholar] [CrossRef]

- Liu, Y.; Qiao, S.; Fang, C.; He, Y.; Sun, H.; Liu, J.; Ma, Y. A Highly Sensitive LITES Sensor Based on a Multi-Pass Cell with Dense Spot Pattern and a Novel Quartz Tuning Fork with Low Frequency. Opto-Electron. Adv. 2024, 7, 230230. [Google Scholar] [CrossRef]

- Ma, Y.; He, Y.; Tong, Y.; Yu, X.; Tittel, F.K. Quartz-Tuning-Fork Enhanced Photothermal Spectroscopy for Ultra-High Sensitive Trace Gas Detection. Opt. Express 2018, 26, 32103. [Google Scholar] [CrossRef]

- He, Y.; Ma, Y.; Tong, Y.; Yu, X.; Tittel, F.K. Ultra-High Sensitive Light-Induced Thermoelastic Spectroscopy Sensor with a High Q-Factor Quartz Tuning Fork and a Multipass Cell. Opt. Lett. 2019, 44, 1904. [Google Scholar] [CrossRef]

- Wei, T.; Zifarelli, A.; Dello Russo, S.; Wu, H.; Menduni, G.; Patimisco, P.; Sampaolo, A.; Spagnolo, V.; Dong, L. High and Flat Spectral Responsivity of Quartz Tuning Fork Used as Infrared Photodetector in Tunable Diode Laser Spectroscopy. Appl. Phys. Rev. 2021, 8, 041409. [Google Scholar] [CrossRef]

- Liang, T.; Qiao, S.; Lang, Z.; Ma, Y. Highly Sensitive Trace Gas Detection Based on In-Plane Single-Quartz-Enhanced Dual Spectroscopy. Sensors 2022, 22, 1035. [Google Scholar] [CrossRef]

- Wu, Q.; Lv, H.; Li, J.; Yang, Z.; Kan, R.; Giglio, M.; Zhu, W.; Zhong, Y.; Sampaolo, A.; Patimisco, P.; et al. Side-Excitation Light-Induced Thermoelastic Spectroscopy. Opt. Lett. 2023, 48, 562. [Google Scholar] [CrossRef]

- Qin, L.; Bi, S.; Chen, R.; Zhao, Y.; Shi, J.; Zhang, H.; Wang, Z. Two-Component Gas Sensor of Time-Division Multiplexing Technique Based on QEPAS and LITES. IEEE Photonics Technol. Lett. 2024, 36, 1085–1088. [Google Scholar] [CrossRef]

- Ma, Y.; Qiao, S.; Wang, R.; He, Y.; Fang, C.; Liang, T. A Novel Tapered Quartz Tuning Fork-Based Laser Spectroscopy Sensing. Appl. Phys. Rev. 2024, 11, 041412. [Google Scholar] [CrossRef]

- Melchiorri, M.; Daldosso, N.; Sbrana, F.; Pavesi, L.; Pucker, G.; Kompocholis, C.; Bellutti, P.; Lui, A. Propagation Losses of Silicon Nitride Waveguides in the Near-Infrared Range. Appl. Phys. Lett. 2005, 86, 121111. [Google Scholar] [CrossRef]

- Khan, S.; Chiles, J.; Ma, J.; Fathpour, S. Silicon-on-Nitride Waveguides for Mid- and near-Infrared Integrated Photonics. Appl. Phys. Lett. 2013, 102, 121104. [Google Scholar] [CrossRef]

- Muñoz, P.; Micó, G.; Bru, L.; Pastor, D.; Pérez, D.; Doménech, J.; Fernández, J.; Baños, R.; Gargallo, B.; Alemany, R.; et al. Silicon Nitride Photonic Integration Platforms for Visible, Near-Infrared and Mid-Infrared Applications. Sensors 2017, 17, 2088. [Google Scholar] [CrossRef]

- Bucio, T.D.; Lacava, C.; Clementi, M.; Faneca, J.; Skandalos, I.; Baldycheva, A.; Galli, M.; Debnath, K.; Petropoulos, P.; Gardes, F. Silicon Nitride Photonics for the Near-Infrared. IEEE J. Sel. Top. Quantum Electron. 2020, 26, 1–13. [Google Scholar] [CrossRef]

- Lin, H.; Luo, Z.; Gu, T.; Kimerling, L.C.; Wada, K.; Agarwal, A.; Hu, J. Mid-Infrared Integrated Photonics on Silicon: A Perspective. Nanophotonics 2017, 7, 393–420. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Y.; Qiu, C.; Guo, X.; Sun, L. Silicon Photonic Platform for Passive Waveguide Devices: Materials, Fabrication, and Applications. Adv. Mater. Technol. 2020, 5, 1901153. [Google Scholar] [CrossRef]

- Hughes, S.; Ramunno, L.; Young, J.F.; Sipe, J.E. Extrinsic Optical Scattering Loss in Photonic Crystal Waveguides: Role of Fabrication Disorder and Photon Group Velocity. Phys. Rev. Lett. 2005, 94, 033903. [Google Scholar] [CrossRef]

- Li, J.; O’Faolain, L.; Schulz, S.A.; Krauss, T.F. Low Loss Propagation in Slow Light Photonic Crystal Waveguides at Group Indices up to 60. Photonics Nanostruct. 2012, 10, 589–593. [Google Scholar] [CrossRef]

- Tombez, L.; Zhang, E.J.; Orcutt, J.S.; Kamlapurkar, S.; Green, W.M.J. Methane Absorption Spectroscopy on a Silicon Photonic Chip. Optica 2017, 4, 1322. [Google Scholar] [CrossRef]

- Yallew, H.D.; Vlk, M.; Datta, A.; Alberti, S.; Zakoldaev, R.A.; Høvik, J.; Aksnes, A.; Jágerská, J. Sub-Ppm Methane Detection with Mid-Infrared Slot Waveguides. ACS Photonics 2023, 10, 4282–4289. [Google Scholar] [CrossRef] [PubMed]

- Luke, K.; Okawachi, Y.; Lamont, M.R.E.; Gaeta, A.L.; Lipson, M. Broadband Mid-Infrared Frequency Comb Generation in a Si_3N_4 Microresonator. Opt. Lett. 2015, 40, 4823. [Google Scholar] [CrossRef]

- Moss, D.J.; Morandotti, R.; Gaeta, A.L.; Lipson, M. New CMOS-Compatible Platforms Based on Silicon Nitride and Hydex for Nonlinear Optics. Nat. Photonics 2013, 7, 597–607. [Google Scholar] [CrossRef]

- Romero-García, S.; Merget, F.; Zhong, F.; Finkelstein, H.; Witzens, J. Silicon Nitride CMOS-Compatible Platform for Integrated Photonics Applications at Visible Wavelengths. Opt. Express 2013, 21, 14036. [Google Scholar] [CrossRef]

- Blumenthal, D.J.; Heideman, R.; Geuzebroek, D.; Leinse, A.; Roeloffzen, C. Silicon Nitride in Silicon Photonics. Proc. IEEE 2018, 106, 2209–2231. [Google Scholar] [CrossRef]

- Sharma, T.; Wang, J.; Kaushik, B.K.; Cheng, Z.; Kumar, R.; Wei, Z.; Li, X. Review of Recent Progress on Silicon Nitride-Based Photonic Integrated Circuits. IEEE Access 2020, 8, 195436–195446. [Google Scholar] [CrossRef]

- Xiang, C.; Jin, W.; Bowers, J.E. Silicon Nitride Passive and Active Photonic Integrated Circuits: Trends and Prospects. Photonics Res. 2022, 10, A82. [Google Scholar] [CrossRef]

- Debrégeas-Sillard, H.; Kazmierski, C. Challenges and Advances of Photonic Integrated Circuits. Comptes Rendus Phys. 2008, 9, 1055–1066. [Google Scholar] [CrossRef]

- Maire, G.; Vivien, L.; Sattler, G.; Kazmierczak, A.; Sanchez, B.; Gylfason, K.B.; Griol, A.; Marris-Morini, D.; Cassan, E.; Giannone, D.; et al. High Efficiency Silicon Nitride Surface Grating Couplers. Opt. Express 2008, 16, 328. [Google Scholar] [CrossRef]

- Hong, J.; Spring, A.M.; Qiu, F.; Yokoyama, S. A High Efficiency Silicon Nitride Waveguide Grating Coupler with a Multilayer Bottom Reflector. Sci. Rep. 2019, 9, 12988. [Google Scholar] [CrossRef] [PubMed]

- Yoo, K.M.; Midkiff, J.; Rostamian, A.; Chung, C.; Dalir, H.; Chen, R.T. InGaAs Membrane Waveguide: A Promising Platform for Monolithic Integrated Mid-Infrared Optical Gas Sensor. ACS Sens. 2020, 5, 861–869. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Li, B.; Zhang, H.; Li, M.; Li, Q.; He, J.-J. Silicon Waveguide Sensors for Carbon Dioxide Gas Sensing in the Mid-Infrared Region. Photonics 2023, 10, 120. [Google Scholar] [CrossRef]

- Yan, Y.; Feng, H.; Wang, C.; Ren, W. On-Chip Photothermal Gas Sensor Based on a Lithium Niobate Rib Waveguide. Sens. Actuators B Chem. 2024, 405, 135392. [Google Scholar] [CrossRef]

- Cantatore, A.F.P.; Menduni, G.; Zifarelli, A.; Patimisco, P.; Gonzalez, M.; Seren, H.R.; Spagnolo, V.; Sampaolo, A. Lithium Niobate—Enhanced Photoacoustic Spectroscopy. Photoacoustics 2024, 35, 100577. [Google Scholar] [CrossRef]

- Ma, Y. Recent Advances in QEPAS and QEPTS Based Trace Gas Sensing: A Review. Front. Phys. 2020, 8, 268. [Google Scholar] [CrossRef]

- Zifarelli, A.; De Palo, R.; Venck, S.; Joulain, F.; Cozic, S.; Weih, R.; Sampaolo, A.; Patimisco, P.; Spagnolo, V. All-Fiber-Coupled Mid-Infrared Quartz-Enhanced Photoacoustic Sensors. Opt. Laser Technol. 2024, 176, 110926. [Google Scholar] [CrossRef]

- Yang, X.; Xiao, Y.; Ma, Y.; He, Y.; Tittel, F. A Miniaturized QEPAS Trace Gas Sensor with a 3D-Printed Acoustic Detection Module. Sensors 2017, 17, 1750. [Google Scholar] [CrossRef]

- Passaro, V.; Tullio, C.; Troia, B.; Notte, M.; Giannoccaro, G.; Leonardis, F. Recent Advances in Integrated Photonic Sensors. Sensors 2012, 12, 15558–15598. [Google Scholar] [CrossRef]

- De Carlo, M.; Menduni, G.; Sampaolo, A.; De Leonardis, F.; Spagnolo, V.; Passaro, V.M.N. Modeling and Design of a Semi-Integrated QEPAS Sensor. J. Light. Technol. 2021, 39, 646–653. [Google Scholar] [CrossRef]

- Marcuse, D. Length Optimization of an S-Shaped Transition between Offset Optical Waveguides. Appl. Opt. 1978, 17, 763. [Google Scholar] [CrossRef] [PubMed]

- Gordon, I.E.; Rothman, L.S.; Hargreaves, R.J.; Hashemi, R.; Karlovets, E.V.; Skinner, F.M.; Conway, E.K.; Hill, C.; Kochanov, R.V.; Tan, Y.; et al. The HITRAN2020 Molecular Spectroscopic Database. J. Quant. Spectrosc. Radiat. Transf. 2022, 277, 107949. [Google Scholar] [CrossRef]

- Pajares, G. Overview and Current Status of Remote Sensing Applications Based on Unmanned Aerial Vehicles (UAVs). Photogramm. Eng. Remote Sens. 2015, 81, 281–330. [Google Scholar] [CrossRef]

- Duangsuwan, S.; Jamjareekulgarn, P. Development of Drone Real-Time Air Pollution Monitoring for Mobile Smart Sensing in Areas with Poor Accessibility. Sens. Mater. 2020, 32, 511–520. [Google Scholar] [CrossRef]

- Remis, A.; Monge-Bartolome, L.; Paparella, M.; Gilbert, A.; Boissier, G.; Grande, M.; Blake, A.; O’Faolain, L.; Cerutti, L.; Rodriguez, J.-B.; et al. Unlocking the Monolithic Integration Scenario: Optical Coupling between GaSb Diode Lasers Epitaxially Grown on Patterned Si Substrates and Passive SiN Waveguides. Light Sci. Appl. 2023, 12, 150. [Google Scholar] [CrossRef]

- Ji, X.; Okawachi, Y.; Gil-Molina, A.; Corato-Zanarella, M.; Roberts, S.; Gaeta, A.L.; Lipson, M. Ultra-Low-Loss Silicon Nitride Photonics Based on Deposited Films Compatible with Foundries. Laser Photonics Rev. 2023, 17, 202200544. [Google Scholar] [CrossRef]

- Thottoli, A.; Vorobev, A.S.; Biagi, G.; Iadanza, S.; Giglio, M.; Magno, G.; Grande, M.; O’Faolain, L. Compact Angled Multimode Interference Duplexers for Multi-Gas Sensing Applications. Opt. Express 2024, 32, 3451. [Google Scholar] [CrossRef]

- Fang, Q.; Liow, T.-Y.; Song, J.F.; Tan, C.W.; Yu, M.B.; Lo, G.Q.; Kwong, D.-L. Suspended Optical Fiber-to-Waveguide Mode Size Converter for Silicon Photonics. Opt. Express 2010, 18, 7763–7769. [Google Scholar] [CrossRef]

- Almeida, V.R.; Panepucci, R.R.; Lipson, M. Nanotaper for Compact Mode Conversion. Opt. Lett. 2003, 28, 1302. [Google Scholar] [CrossRef]

- McNab, S.; Moll, N.; Vlasov, Y. Ultra-Low Loss Photonic Integrated Circuit with Membrane-Type Photonic Crystal Waveguides. Opt. Express 2003, 11, 2927. [Google Scholar] [CrossRef]

- Olivieri, M.; Zifarelli, A.; Menduni, G.; Di Gioia, M.; Marzocca, C.; Passaro, V.M.N.; Sampaolo, A.; Giglio, M.; Spagnolo, V.; Patimisco, P. Influence of Air Pressure on the Resonance Properties of a T-Shaped Quartz Tuning Fork Coupled with Resonator Tubes. Appl. Sci. 2021, 11, 7974. [Google Scholar] [CrossRef]

- Zheng, H.; Lin, H.; Dong, L.; Liu, Y.; Patimisco, P.; Zweck, J.; Mozumder, A.; Sampaolo, A.; Spagnolo, V.; Huang, B.; et al. Influence of Tuning Fork Resonance Properties on Quartz-Enhanced Photoacoustic Spectroscopy Performance. Sensors 2019, 19, 3825. [Google Scholar] [CrossRef] [PubMed]

- Reid, J.; Labrie, D. Second-Harmonic Detection with Tunable Diode Lasers? Comparison of Experiment and Theory. Appl. Phys. B Photophysics Laser Chem. 1981, 26, 203–210. [Google Scholar] [CrossRef]

- Xu, L.; Li, J.; Liu, N.; Zhou, S. Quartz Crystal Tuning Fork Based 2f/1f Wavelength Modulation Spectroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2022, 267, 120608. [Google Scholar] [CrossRef]

- Zhou, Z.; Ou, X.; Fang, Y.; Alkhazraji, E.; Xu, R.; Wan, Y.; Bowers, J.E. Prospects and Applications of On-Chip Lasers. eLight 2023, 3, 1. [Google Scholar] [CrossRef]

- Dietrich, P.-I.; Blaicher, M.; Reuter, I.; Billah, M.; Hoose, T.; Hofmann, A.; Caer, C.; Dangel, R.; Offrein, B.; Troppenz, U.; et al. In Situ 3D Nanoprinting of Free-Form Coupling Elements for Hybrid Photonic Integration. Nat. Photonics 2018, 12, 241–247. [Google Scholar] [CrossRef]

- Dai, D. Silicon Nanophotonic Integrated Devices for On-Chip Multiplexing and Switching. J. Light. Technol. 2017, 35, 572–587. [Google Scholar] [CrossRef]

| Techniques | QTF Positions | |||

|---|---|---|---|---|

| A | B | C | D | |

| QEPAS | 0.023 mV | 0.019 mV | 0.022 mV | 0.019 mV |

| LITES | 0.026 mV | 0.027 mV | 0.026 mV | 0.028 mV |

| Techniques | QTF Positions | |||

|---|---|---|---|---|

| A | B | C | D | |

| QEPAS | 3.2 | 2.7 | 1.9 | 2.9 |

| LITES | 1.6 | 2.8 | 2.5 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melchiorre, L.; Thottoli, A.; Vorobev, A.S.; Menduni, G.; Sampaolo, A.; Magno, G.; O’Faolain, L.; Spagnolo, V. Study and Characterization of Silicon Nitride Optical Waveguide Coupling with a Quartz Tuning Fork for the Development of Integrated Sensing Platforms. Sensors 2025, 25, 3663. https://doi.org/10.3390/s25123663

Melchiorre L, Thottoli A, Vorobev AS, Menduni G, Sampaolo A, Magno G, O’Faolain L, Spagnolo V. Study and Characterization of Silicon Nitride Optical Waveguide Coupling with a Quartz Tuning Fork for the Development of Integrated Sensing Platforms. Sensors. 2025; 25(12):3663. https://doi.org/10.3390/s25123663

Chicago/Turabian StyleMelchiorre, Luigi, Ajmal Thottoli, Artem S. Vorobev, Giansergio Menduni, Angelo Sampaolo, Giovanni Magno, Liam O’Faolain, and Vincenzo Spagnolo. 2025. "Study and Characterization of Silicon Nitride Optical Waveguide Coupling with a Quartz Tuning Fork for the Development of Integrated Sensing Platforms" Sensors 25, no. 12: 3663. https://doi.org/10.3390/s25123663

APA StyleMelchiorre, L., Thottoli, A., Vorobev, A. S., Menduni, G., Sampaolo, A., Magno, G., O’Faolain, L., & Spagnolo, V. (2025). Study and Characterization of Silicon Nitride Optical Waveguide Coupling with a Quartz Tuning Fork for the Development of Integrated Sensing Platforms. Sensors, 25(12), 3663. https://doi.org/10.3390/s25123663