Optimization of a Coupled Neuron Model Based on Deep Reinforcement Learning and Application of the Model in Bearing Fault Diagnosis

Abstract

1. Introduction

2. Theory

2.1. Coupled Neuron

2.2. DRL Algorithm

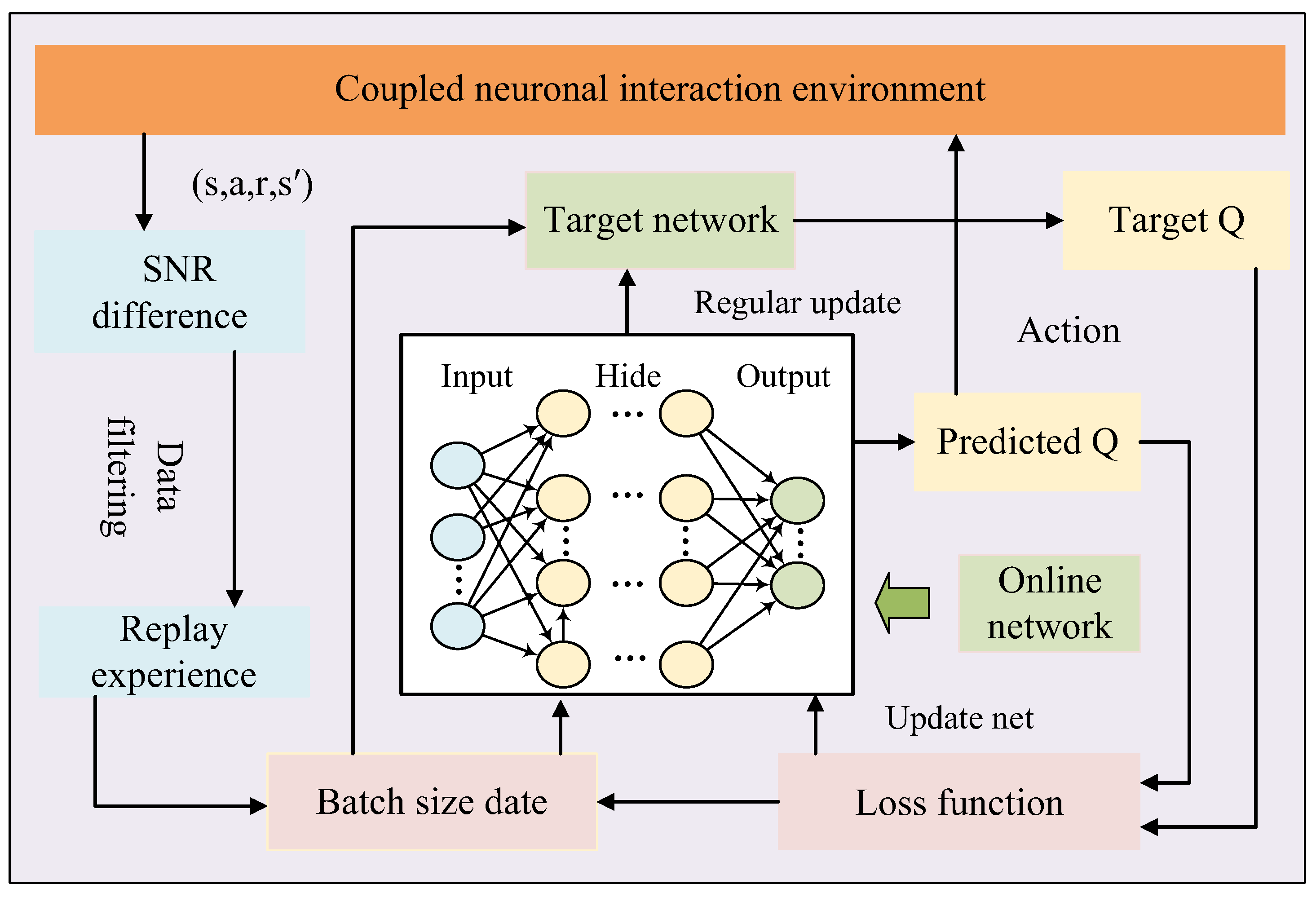

2.3. System Flow Design

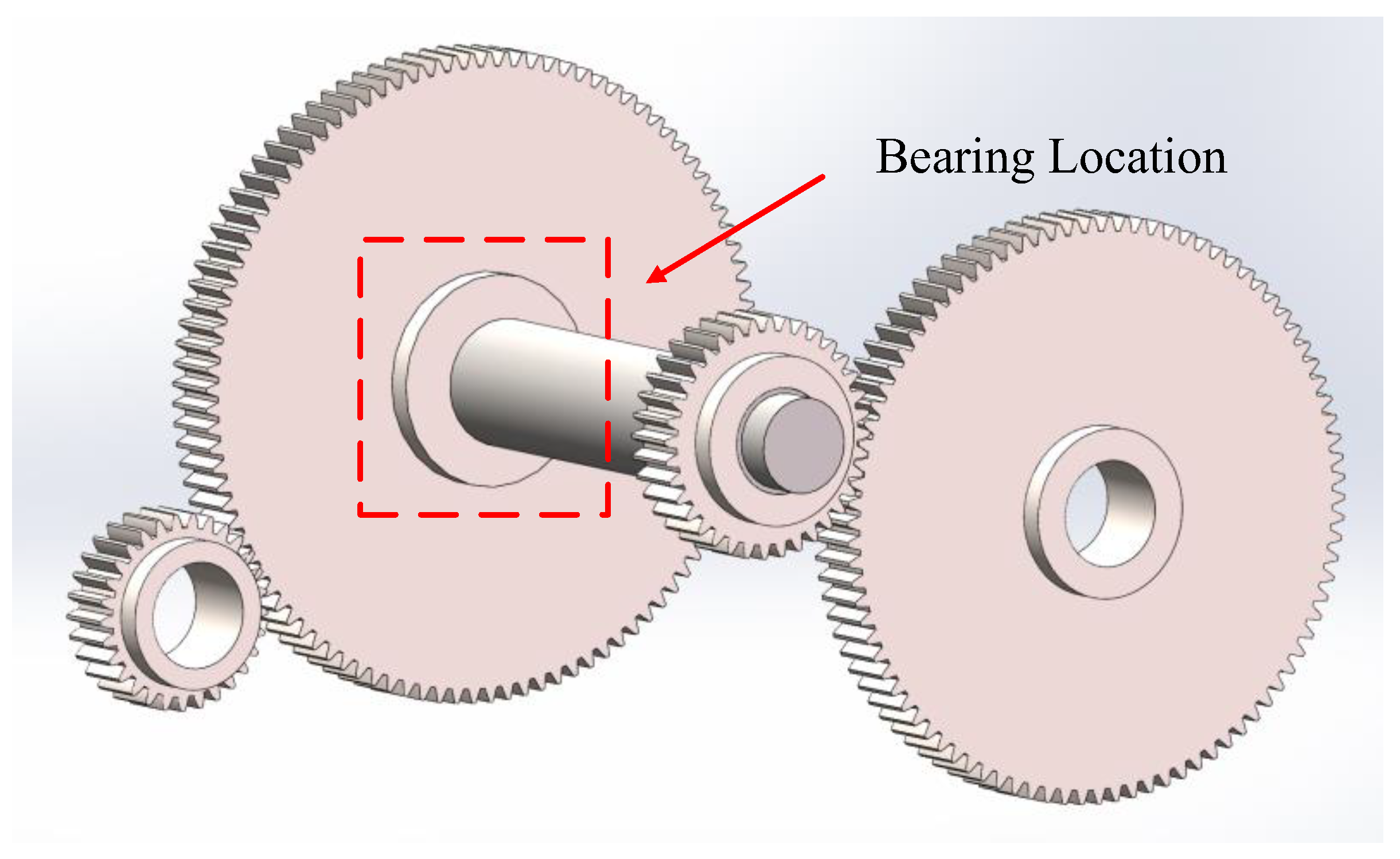

- Information gathering: To address the operational specifics of bearings, sensors are strategically placed at critical locations to record bearing fault signals, ensuring data accuracy and reliability. These signals are subsequently fed into coupled neurons to extract parameter information from the neuron model. Initial training is then conducted, where the collected data is used to initialize the policy network. This initialization accelerates the transition of the initial network to a stable operational state, enabling rapid convergence and robust performance in subsequent training phases.

- Establish an experience playback area: The pre-trained optimal data is utilized as the initial state of the coupled neurons for further optimization. After the agent selects an action, the first training experience comprising the current state, action, reward, and next state is generated. The SNR difference for each state is then calculated. Using the SNR as the evaluation metric, the training experiences are filtered before being stored in the experience replay buffer. The system checks whether the number of accumulated experiences meets the minimum training batch size. If not, the agent continues to select actions and interact with the neurons to collect subsequent training data. This iterative process repeats until the experience replay buffer contains sufficient data to fulfill the minimum batch requirement, ensuring stable and efficient training initialization.

- Train the network to get the optimal parameters: Once the experience replay buffer accumulates sufficient training data, the network training process begins. A mini-batch of data is sampled from the buffer, and the online network computes predicted Q-values for these experiences. The target Q-network is then used to calculate target Q-values. The loss function derived from these values is minimized via backpropagation, and gradient descent is applied to update the weight parameters of the online network. After a predefined number of training iterations, the parameters of the online network are copied to the target Q-network, effectively creating a deep duplicate of the online network at periodic intervals to stabilize training. Finally, the system checks if the predefined number of training iterations is reached. If not, the agent selects the action with the highest Q-value (predicted by the online network) for the current state, continuing the cycle of interaction, experience collection, and network refinement until convergence criteria are met.

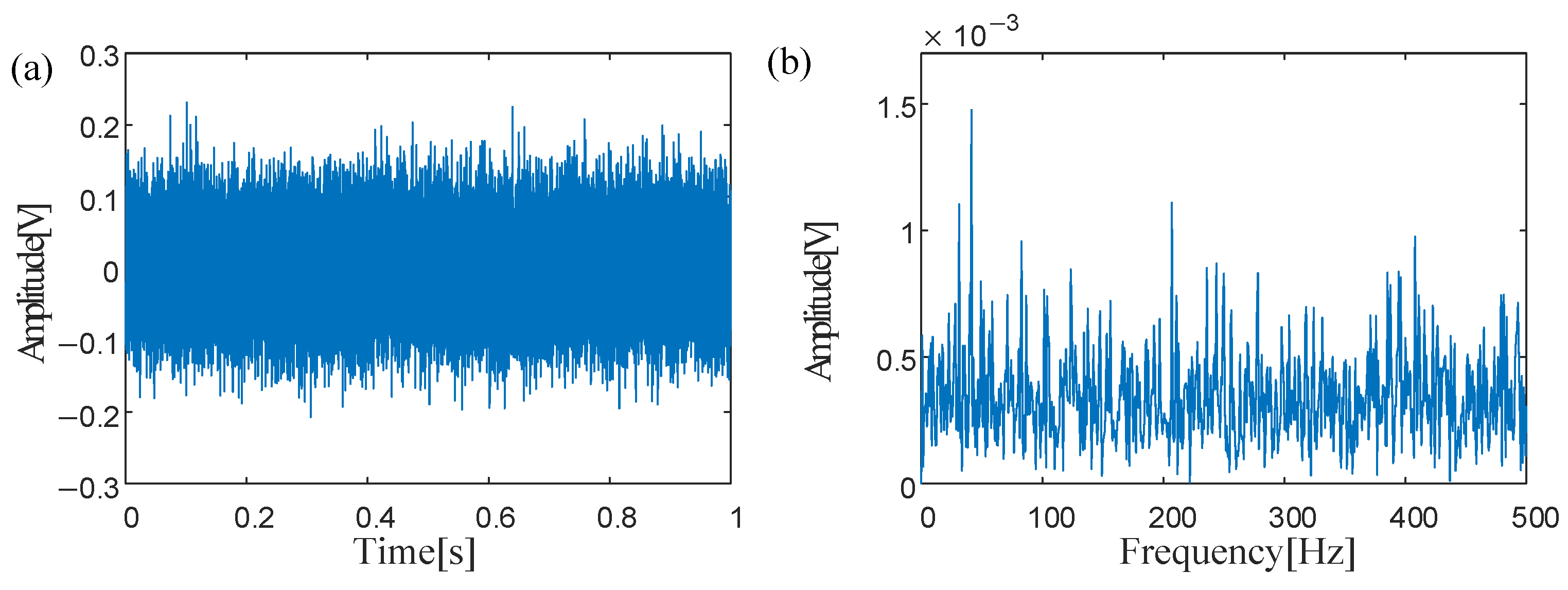

- Parameter output and troubleshooting: If the training iterations meet the predefined target, the optimal parameter set and the highest achievable SNR are output and integrated into the coupled neuron model for fault diagnosis. Subsequently, advanced spectral analysis techniques are applied to deeply extract characteristic frequencies in bearing signals that correlate strongly with fault patterns. This approach not only significantly enhances diagnostic efficiency but also improves the accuracy of fault detection. Furthermore, by enabling early-stage fault identification and intervention, the method drastically reduces equipment downtime. Such capabilities hold immeasurable value for ensuring production continuity and operational efficiency in industrial settings.

3. Simulation Illustration

4. Applications

5. Conclusions

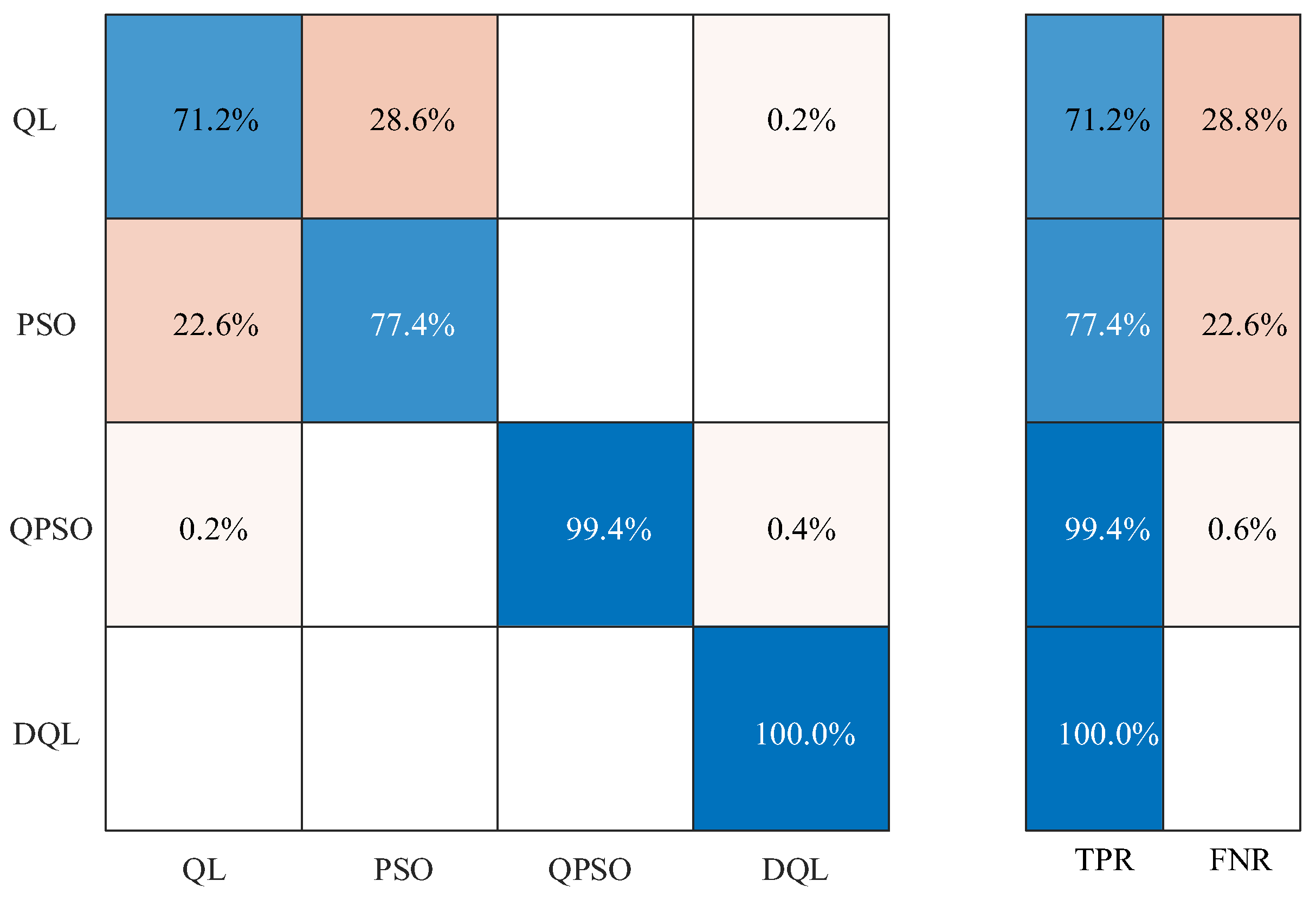

- Aiming at the problem of parameter optimization in coupled neurons, this paper proposes to use a deep reinforcement learning algorithm for optimization, so as to obtain the parameter combination with the best signal-to-noise ratio in coupled neurons, and apply it to bearing fault detection.

- An empirical playback region based on noise processing is introduced into the deep reinforcement learning framework, and the coupled neuron model parameter optimization algorithm driven by deep reinforcement learning is finally formed by filtering the playback region data with the signal-to-noise ratio as the optimization objective.

- Through experimental application of simulation signals and gearbox bearing fault vibration signals collected in a laboratory environment, the experimental results show that when the coupled neuron model is optimized by using the deep reinforcement learning algorithm, the signal-to-noise ratio of the output signal and the bearing fault recognition rate are −13.0407 dB and 100%, respectively, which are the best among the four comparison methods, verifying the effectiveness of the proposed method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xu, F.N.; Ding, N.; Li, N.; Liu, L.; Hou, N.; Xu, N.; Guo, W.M.; Tian, L.N.; Xu, H.X.; Wu, C.M.L.; et al. A review of bearing failure Modes, mechanisms and causes. Eng. Fail. Anal. 2023, 152, 107518. [Google Scholar] [CrossRef]

- Wang, B.X.; Ding, C.C. An Adaptive Signal Denoising Method Based on Reweighted SVD for the Fault Diagnosis of Rolling Bearings. Sensors. 2025, 25, 2470. [Google Scholar] [CrossRef] [PubMed]

- Han, D.F.; Qi, H.Y.; Wang, S.X.; Hou, D.M.; Wang, C.P. Adaptive stepsize forward-backward pursuit and acoustic emission-based health state assessment of high-speed train bearings. Struct. Health Monit.-Int. J. 2024; in press. [Google Scholar] [CrossRef]

- Chang, Z.; Jia, Q.; Yuan, X.; Chen, Y.L. Main failure mode of oil-air lubricated rolling bearing installed in high speed machining. Tribol. Int. 2017, 112, 68–74. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, H.; Fan, Y.S.; Shangguan, L.J.; Yang, Y. A review of research on wind turbine bearings’ failure analysis and fault diagnosis. Lubricants 2022, 11, 14. [Google Scholar] [CrossRef]

- Wang, C.P.; Qi, H.Y.; Hou, D.M.; Han, D.F. Coupled vibration-acoustic emission model for high-speed train bearings with local defects. Appl. Acoust. 2024, 224, 110142. [Google Scholar] [CrossRef]

- Xu, X.F.; Yang, X.; He, C.B.; Shi, P.M.; Hua, C.C. Adversarial Domain Adaptation Model Based on LDTW for Extreme Partial Transfer Fault Diagnosis of Rotating Machines. IEEE Trans. Instrum. Meas. 2024, 73, 3538811. [Google Scholar] [CrossRef]

- Guo, H.; Duan, H.T.; Lei, J.Z.; Wang, D.F.; Du, S.M.; Zhang, Y.Z.; Ding, Z.Y. Failure analysis of automobile engine pump shaft bearing. Adv. Mech. Eng. 2021, 13, 16878140211009411. [Google Scholar] [CrossRef]

- Qiao, Z.J.; He, Y.B.; Liao, C.R.; Zhu, R.H. Noise-boosted weak signal detection in fractional nonlinear systems enhanced by increasing potential-well width and its application to mechanical fault diagnosis. Chaos Solitons Fractals 2023, 175, 113960. [Google Scholar] [CrossRef]

- Hou, D.M.; Qi, H.Y.; Wang, C.P.; Luo, H.L.; Han, D.F. High-speed train wheel set bearing fault diagnosis and prognostics: Evaluation of signal processing methods under multi-source interference. Struct. Health Monit.-Int. J. 2023, 22, 2280–2304. [Google Scholar] [CrossRef]

- Qiao, Z.J.; Chen, S.; Lai, Z.H.; Zhou, S.T.; Sanjuan, M.A.F. Harmonic-Gaussian double-well potential stochastic resonance with its application to enhance weak fault characteristics of machinery. Nonlinear Dyn. 2023, 111, 7293–7307. [Google Scholar] [CrossRef]

- Liang, J.; Sun, J.; Jiang, Y.H.; Pan, W.F.; Jiao, W.D. Advances and Challenges in the Hunting Instability Diagnosis of High-Speed Trains. Sensors 2024, 24, 5719. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Yu, X.L.; Guo, Y.; Kang, W.; Chen, X. A noise-enhanced feature extraction method combined with tunable Q-factor wavelet transform and its application to planet-bearing fault diagnosis. Appl. Acoust. 2025, 239, 110845. [Google Scholar] [CrossRef]

- Peng, H.; Zhang, H.; Shangguan, L.J.; Fan, Y.S. Review of tribological failure analysis and lubrication technology research of wind power bearings. Polymers 2022, 14, 3041. [Google Scholar] [CrossRef]

- Qiao, Z.J.; Zhang, C.L.; Zhang, C.L.; Ma, X.; Zhu, R.H.; Lai, Z.H.; Zhou, S.T. Stochastic resonance array for designing noise-boosted filter banks to enhance weak multi-harmonic fault characteristics of machinery. Appl. Acoust. 2025, 236, 110710. [Google Scholar] [CrossRef]

- He, Y.B.; Qiao, Z.J.; Zhang, C.L.; Ma, X.; Zhu, R.H.; Lai, Z.H.; Zhou, S.T. Two-stage benefits of internal and external noise to enhance early fault detection of machinery by exciting fractional SR. Chaos Solitons Fractals 2024, 182, 114749. [Google Scholar] [CrossRef]

- Zhang, W.Y.; Shi, P.M.; Li, M.D.; Han, D.Y. A novel stochastic resonance model based on bistable stochastic pooling network and its application. Chaos Solitons Fractals 2021, 145, 110800. [Google Scholar] [CrossRef]

- Yang, C.P.; Qiao, Z.J.; Zhu, R.H.; Xu, X.F.; Lai, Z.H.; Zhou, S.T. An intelligent fault diagnosis method enhanced by noise injection for machinery. IEEE Trans. Instrum. Meas. 2023, 72, 3534011. [Google Scholar] [CrossRef]

- Gruber, H.; Fuchs, A.; Bader, M. Evaluation of a condition monitoring algorithm for early bearing fault detection. Sensors 2024, 24, 2138. [Google Scholar] [CrossRef]

- Rodriguez, N.; Lagos, C.; Cabrera, E.; Cañete, L. Extreme learning machine based on stationary wavelet singular values for bearing failure diagnosis. Stud. Inf. Control 2017, 26, 287–294. [Google Scholar] [CrossRef]

- Li, X.; Ma, Z.Q.; Kang, D.; Li, X. Fault diagnosis for rolling bearing based on VMD-FRFT. Measurement 2020, 155, 107554. [Google Scholar] [CrossRef]

- Guo, Y.F.; Lou, X.J.; Dong, Q.; Wang, L.J. Dynamic behavior of periodic potential system driven by cross-correlated non-Gaussian noise and Gaussian white noise. Internat. J. Robust Nonlinear Control 2022, 32, 126–140. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Pan, S.P.; Dong, X.; Zhang, X. Interpretable quadratic convolutional residual neural network for bearing fault diagnosis. J. Braz. Soc. Mech. Sci. Eng. 2025, 47, 158. [Google Scholar] [CrossRef]

- Guo, P.P.; Huang, W.G.; Jia, N.; Ding, C.C.; Huangfu, Y.F.; Jiang, X.X.; Shi, J.J. A novel adaptive gating neurons model with physical features weighted for bearing fault diagnosis under strong noise. Eng. Appl. Artif. Intell. 2025, 149, 110532. [Google Scholar] [CrossRef]

- He, L.F.; Huang, X.X.; Hou, J.C. A Novel High-Dimensional Coupled FHN Neuron Stochastic Resonance Model and its Performance in Faults Recognition. J. Vib. Eng. Technol. 2025, 13, 6. [Google Scholar] [CrossRef]

- Liao, J.X.; Dong, H.C.; Sun, Z.Q.; Sun, J.W.; Zhang, S.P.; Fan, F.L. Attention-embedded quadratic network (qttention) for effective and interpretable bearing fault diagnosis. IEEE Trans. Instrum. Meas. 2023, 72, 1–13. [Google Scholar] [CrossRef]

- Hu, H.X.; Cao, C.C.; Hu, Q.; Zhang, Y.; Lin, Z.Z. A real-time bearing fault diagnosis model based on siamese convolutional autoencoder in industrial internet of things. IEEE Internet Things J. 2023, 11, 3820–3831. [Google Scholar] [CrossRef]

- Hou, J.B.; Wu, Y.X.; Ahmad, A.S.; Gong, H.; Liu, L. A novel rolling bearing fault diagnosis method based on adaptive feature selection and clustering. IEEE Access 2021, 9, 99756–99767. [Google Scholar] [CrossRef]

- Wang, R.X.; Jiang, H.K.; Zhu, K.; Wang, Y.F.; Liu, C.Q. A deep feature enhanced reinforcement learning method for rolling bearing fault diagnosis. Adv. Eng. Inform. 2022, 54, 101750. [Google Scholar] [CrossRef]

- Jiang, L.L.; Shi, C.Z.; Sheng, H.S.; Li, X.J.; Yang, T.G. Lightweight CNN architecture design for rolling bearing fault diagnosis. Meas. Sci. Technol. 2024, 35, 126142. [Google Scholar] [CrossRef]

- Jang, B.; Kim, M.; Harerimana, G.; Kim, J.W. Q-learning algorithms: A comprehensive classification and applications. IEEE Access 2019, 7, 133653–133667. [Google Scholar] [CrossRef]

- Clifton, J.; Laber, E. Q-learning: Theory and applications. Annu. Rev. Stat. Its Appl. 2020, 7, 279–301. [Google Scholar] [CrossRef]

- Dong, Z.L.; Jiang, Y.H.; Jiao, W.D.; Zhang, F.B.; Wang, Z.Y.; Huang, J.F.; Wang, X.; Zhang, K. Double Attention-guided Tree-inspired Grade Decision Network: A Method for Bearing Fault Diagnosis of Unbalanced Samples Under Strong Noise Conditions. Adv. Eng. Inform. 2025, 64, 103004. [Google Scholar] [CrossRef]

- Yan, J.; Cheng, Y.; Zhang, F.; Zhou, N.; Wang, H.; Jin, B.; Wang, M.; Zhang, W. Multi-Modal Imitation Learning for Arc Detection in Complex Railway Environments. IEEE Trans. Instrum. Meas. 2025, 74, 3556896. [Google Scholar] [CrossRef]

- Cheng, Y.; Yan, J.K.; Zhang, F.; Li, M.D.; Zhou, N.; Shi, C.J.; Jin, B.; Zhang, W.H. Surrogate modeling of pantograph-catenary system interactions. Mech. Syst. Signal Process. 2025, 224, 112134. [Google Scholar] [CrossRef]

- Han, D.F.; Qi, H.Y.; Wang, S.X.; Hou, D.M.; Kong, J.Z.; Wang, C.P. Adaptive maximum generalized Gaussian cyclostationarity blind deconvolution for the early fault diagnosis of high-speed train bearings under non-Gaussian noise. Adv. Eng. Inform. 2024, 62, 102731. [Google Scholar] [CrossRef]

- Kiakojouri, A.; Wang, L.C. A Generalized Convolutional Neural Network Model Trained on Simulated Data for Fault Diagnosis in a Wide Range of Bearing Designs. Sensors 2025, 25, 2378. [Google Scholar] [CrossRef]

- Guo, H.J.; Ping, D.Z.; Wang, L.J.; Zhang, W.J.; Wu, J.F.; Ma, X.; Xu, Q.; Lu, Z.Y. Fault Diagnosis Method of Rolling Bearing Based on 1D Multi-Channel Improved Convolutional Neural Network in Noisy Environment. Sensors 2025, 25, 2286. [Google Scholar] [CrossRef]

- Le, N.; Rathour, V.S.; Yamazaki, K.; Luu, K.; Savvides, M. Deep reinforcement learning in computer vision: A comprehensive survey. Artif. Intell. Rev. 2022, 55, 2733–2819. [Google Scholar] [CrossRef]

- Chen, C.; Yu, J.T.; Qian, S.R. An Enhanced Deep Q Network Algorithm for Localized Obstacle Avoidance in Indoor Robot Path Planning. Appl. Sci. 2024, 14, 11195. [Google Scholar] [CrossRef]

- Kang, Y.X.; Chen, G.; Wang, H.; Pan, W.P.; Wei, X.K. Dual-input anomaly detection method based on deep reinforcement learning. Struct. Health Monit. 2024, 23, 1578–1591. [Google Scholar] [CrossRef]

- Li, C.; Yue, X.; Liu, Z.Y.; Ma, G.Y.; Zhang, H.B.; Zhou, Y.; Zhu, Y. A modified dueling DQL algorithm for robot path planning incorporating priority experience replay and artificial potential fields. Appl. Intell. 2025, 55, 366. [Google Scholar] [CrossRef]

- Ren, Z.P.; Dong, D.Y.; Li, H.X.; Chen, C.L. Self-paced prioritized curriculum learning with coverage penalty in deep reinforcement learning. IEEE Trans. Neural Netw. Learn. Syst. 2018, 29, 2216–2226. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, Y.; Wang, X.Q.; Hu, R.Z.; Xu, H.H. Aper-ddqn: Uav precise airdrop method based on deep reinforcement learning. IEEE Access 2022, 10, 50878–50891. [Google Scholar] [CrossRef]

- Qiao, Z.J.; Shu, X.D. Coupled neurons with multi-objective optimization benefit incipient fault identification of machinery. Chaos Solitons Fractals 2021, 145, 110813. [Google Scholar] [CrossRef]

- Rulkov, N.F. Modeling of spiking-bursting neural behavior using two-dimensional map. Phys. Rev. E 2002, 65, 041922. [Google Scholar] [CrossRef] [PubMed]

- Ghrib, M.; Rébillat, M.; des Roches, G.V.; Mechbal, N. Automatic damage type classification and severity quantification using signal based and nonlinear model based damage sensitive features. J. Process Control 2019, 83, 136–146. [Google Scholar] [CrossRef]

- Lewis, F.L.; Vrabie, D. Reinforcement learning and adaptive dynamic programming for feedback control. IEEE Circuits Syst. Mag. 2009, 9, 32–50. [Google Scholar] [CrossRef]

- Shakya, A.K.; Pillai, G.; Chakrabarty, S. Deep reinforcement learning: A brief survey. IEEE Signal Process. Mag. 2017, 34, 26–38. [Google Scholar]

- Chu, T.S.; Wang, J.; Codecà, L.; Li, Z.J. Multi-agent deep reinforcement learning for large-scale traffic signal control. IEEE Trans. Intell. Transp. Syst. 2019, 21, 1086–1095. [Google Scholar] [CrossRef]

- Lee, D.; Hu, J.H.; He, N. A discrete-time switching system analysis of Q-learning. SIAM J. Control Optim. 2023, 61, 1861–1880. [Google Scholar] [CrossRef]

- Varghese, N.V.; Mahmoud, Q.H. A survey of multi-task deep reinforcement learning. Electronics 2020, 9, 1363. [Google Scholar] [CrossRef]

- Fotouhi, A.; Ding, M.; Hassan, M. Deep Q-Learning for Two-Hop Communications of Drone Base Stations. Sensors 2021, 21, 1960. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, J.M.; Yin, J.T.; Chen, Y.L.; Wu, B.G. Optimization of the Stand Structure in Secondary Forests of Pinus yunnanensis Based on Deep Reinforcement Learning. Forests 2024, 15, 2181. [Google Scholar] [CrossRef]

- Kiran, B.R.; Sobh, I.; Talpaert, V.; Mannion, P.; Al Sallab, A.A.; Yogamani, S.; Pérez, P. Deep reinforcement learning for autonomous driving: A survey. IEEE Trans. Intell. Transp. Syst. 2021, 23, 4909–4926. [Google Scholar] [CrossRef]

- Gholizadeh, N.; Kazemi, N.; Musilek, P. A comparative study of reinforcement learning algorithms for distribution network reconfiguration with deep Q-learning-based action sampling. IEEE Access 2023, 11, 13714–13723. [Google Scholar] [CrossRef]

- Feng, C.B.; Tong, X.; Zhu, M.L.; Qu, F. VR Scene Detail Enhancement Method Based on Depth Reinforcement Learning Algorithm. Int. J. Comput. Intell. Syst. 2024, 17, 148. [Google Scholar] [CrossRef]

- Cheng, Y.; Su, J.J.; Xiu, C.B.; Liu, J.X. Adaptive Clutter Intelligent Suppression Method Based on Deep Reinforcement Learning. Appl. Sci. 2024, 14, 7843. [Google Scholar] [CrossRef]

- Lu, S.L.; Yan, R.Q.; Liu, Y.B.; Wang, Q.J. Tacholess speed estimation in order tracking: A review with application to rotating machine fault diagnosis. IEEE Trans. Instrum. Meas. 2019, 68, 2315–2332. [Google Scholar] [CrossRef]

- Bonello, P. The extraction of campbell diagrams from the dynamical system representation of a foil-air bearing rotor model. Mech. Syst. Signal Pr. 2019, 129, 502–530. [Google Scholar] [CrossRef]

- Lu, Z. Dynamics Modeling and Nonlinear Vibration Study of Aircraft Engine Rotor System. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2017. [Google Scholar]

- Wang, Z.; Yang, Z.; He, H.; Ming, A.; Zhang, W. Dynamic modeling simulation of irregular bearing faults Beijing. J. Univ. Aeronaut. Astronaut. 2021, 47, 1580–1593. [Google Scholar]

- Cui, Y.; Huang, Y.X.; Yang, G.G.; Zhao, G. Cusp modelling of oil-film instability for a rotor-bearing system based on dynamic response. Mech. Syst. Signal Pr. 2024, 212, 111289. [Google Scholar] [CrossRef]

- Tian, J.Y.; Zhang, C.; Wang, Z.J.; Su, H.; Wang, D.F.; Guo, D. Radial load analysis of matched angular contact ball bearings in bearing-rotor system. Mech. Syst. Signal Pr. 2024, 211, 111188. [Google Scholar] [CrossRef]

- Qin, L.T. Rolling Bearing Fault Detection Using Domain Adaptation-Based Anomaly Detection. Int. J. Artif. Intell. Tools 2024, 33, 2440003. [Google Scholar] [CrossRef]

- Ozcan, I.H.; Devecioglu, O.C.; Ince, T.; Eren, L.; Askar, M. Enhanced bearing fault detection using multichannel, multilevel 1D CNN classifier. Electr. Eng. 2022, 104, 435–447. [Google Scholar] [CrossRef]

- Wang, D.; Miao, Q.; Fan, X.F.; Huang, H.Z. Rolling element bearing fault detection using an improved combination of Hilbert and wavelet transforms. J. Mech. Sci. Technol. 2009, 23, 3292–3301. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Li, J.; Xu, X.; Wu, R.; Qiu, Y.; Chen, X.; Qiao, Z. Optimization of a Coupled Neuron Model Based on Deep Reinforcement Learning and Application of the Model in Bearing Fault Diagnosis. Sensors 2025, 25, 3654. https://doi.org/10.3390/s25123654

Wang S, Li J, Xu X, Wu R, Qiu Y, Chen X, Qiao Z. Optimization of a Coupled Neuron Model Based on Deep Reinforcement Learning and Application of the Model in Bearing Fault Diagnosis. Sensors. 2025; 25(12):3654. https://doi.org/10.3390/s25123654

Chicago/Turabian StyleWang, Shan, Jiaxiang Li, Xinsheng Xu, Ruiqi Wu, Yuhang Qiu, Xuwen Chen, and Zijian Qiao. 2025. "Optimization of a Coupled Neuron Model Based on Deep Reinforcement Learning and Application of the Model in Bearing Fault Diagnosis" Sensors 25, no. 12: 3654. https://doi.org/10.3390/s25123654

APA StyleWang, S., Li, J., Xu, X., Wu, R., Qiu, Y., Chen, X., & Qiao, Z. (2025). Optimization of a Coupled Neuron Model Based on Deep Reinforcement Learning and Application of the Model in Bearing Fault Diagnosis. Sensors, 25(12), 3654. https://doi.org/10.3390/s25123654