Development of Mobile Robot-Based Precision 3D Position Measurement System

Abstract

1. Introduction

1.1. Research Background

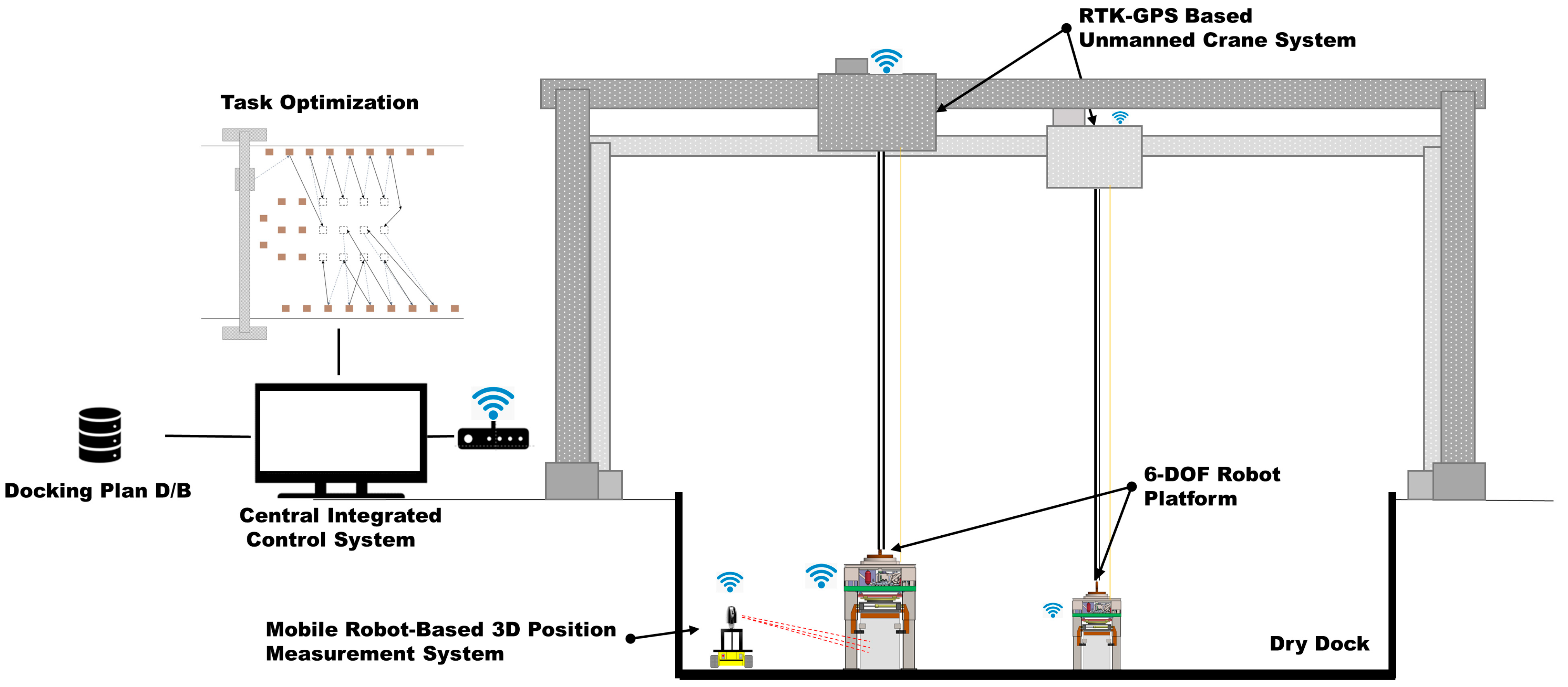

1.2. Dry Dock Automation System and Research Objectives

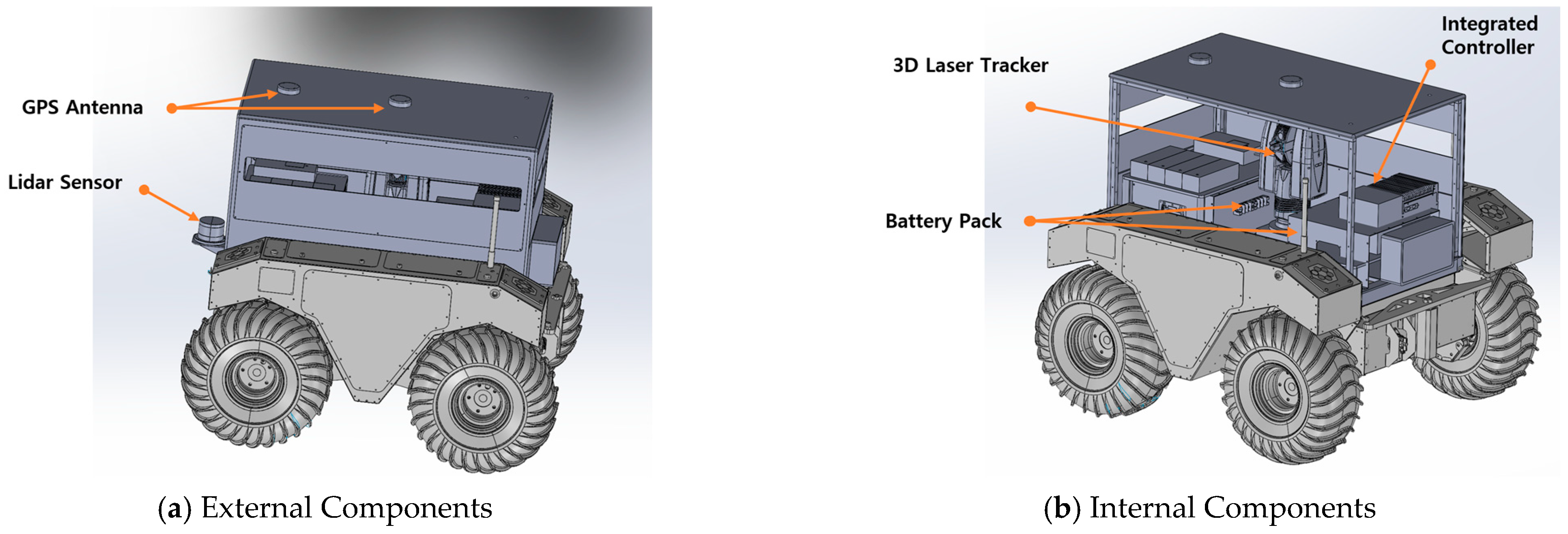

2. Design of Mobile Robot-Based Precision 3D Measurement System

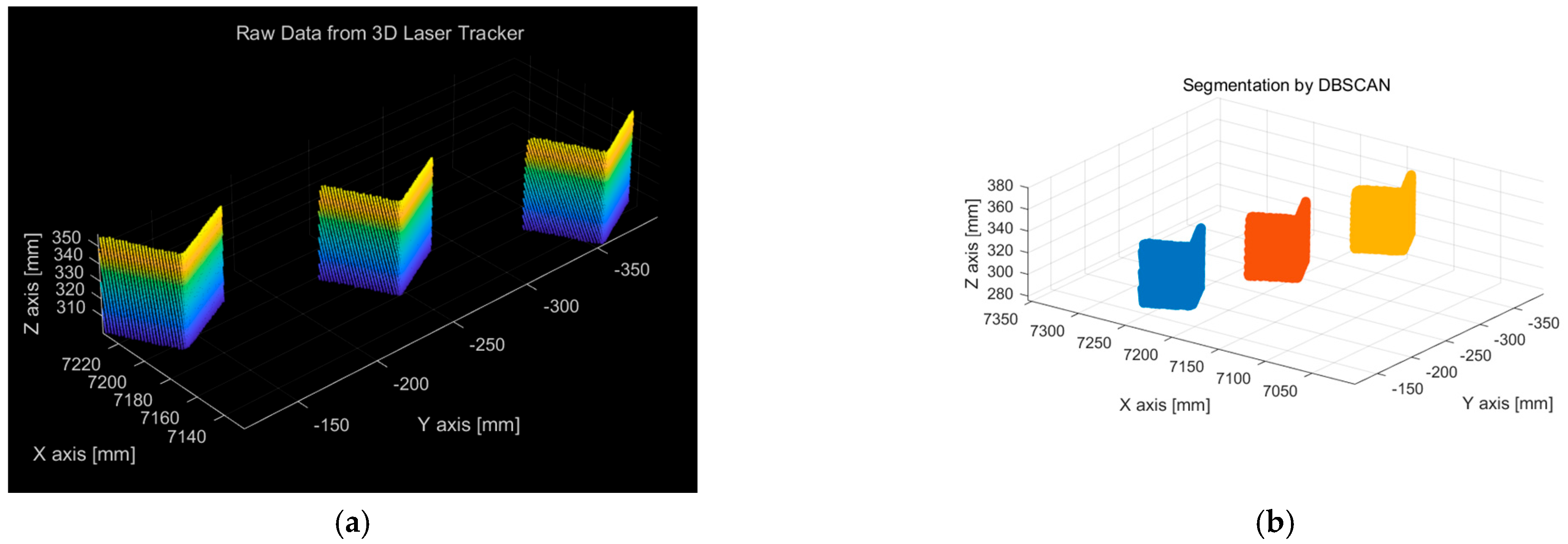

3. Docking Block Position Extraction Algorithm

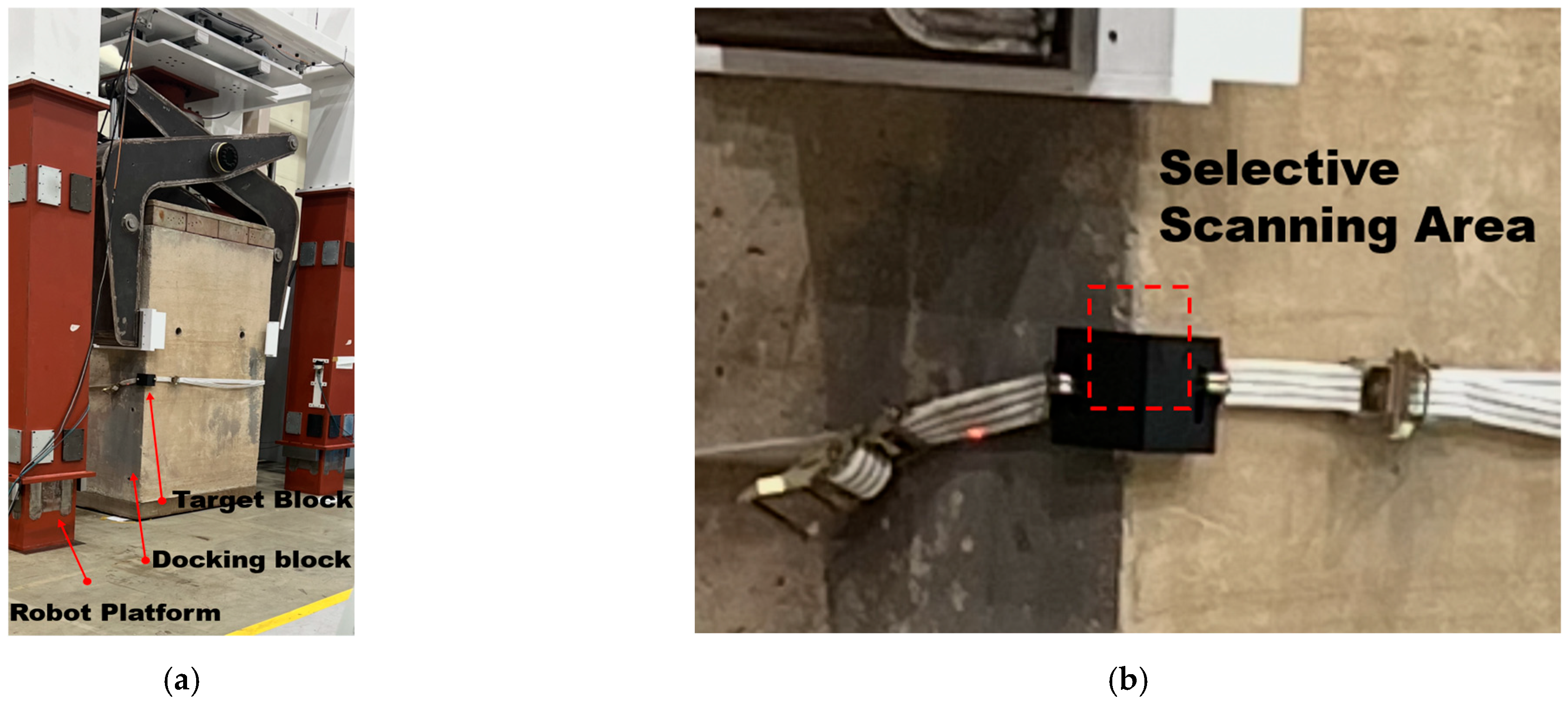

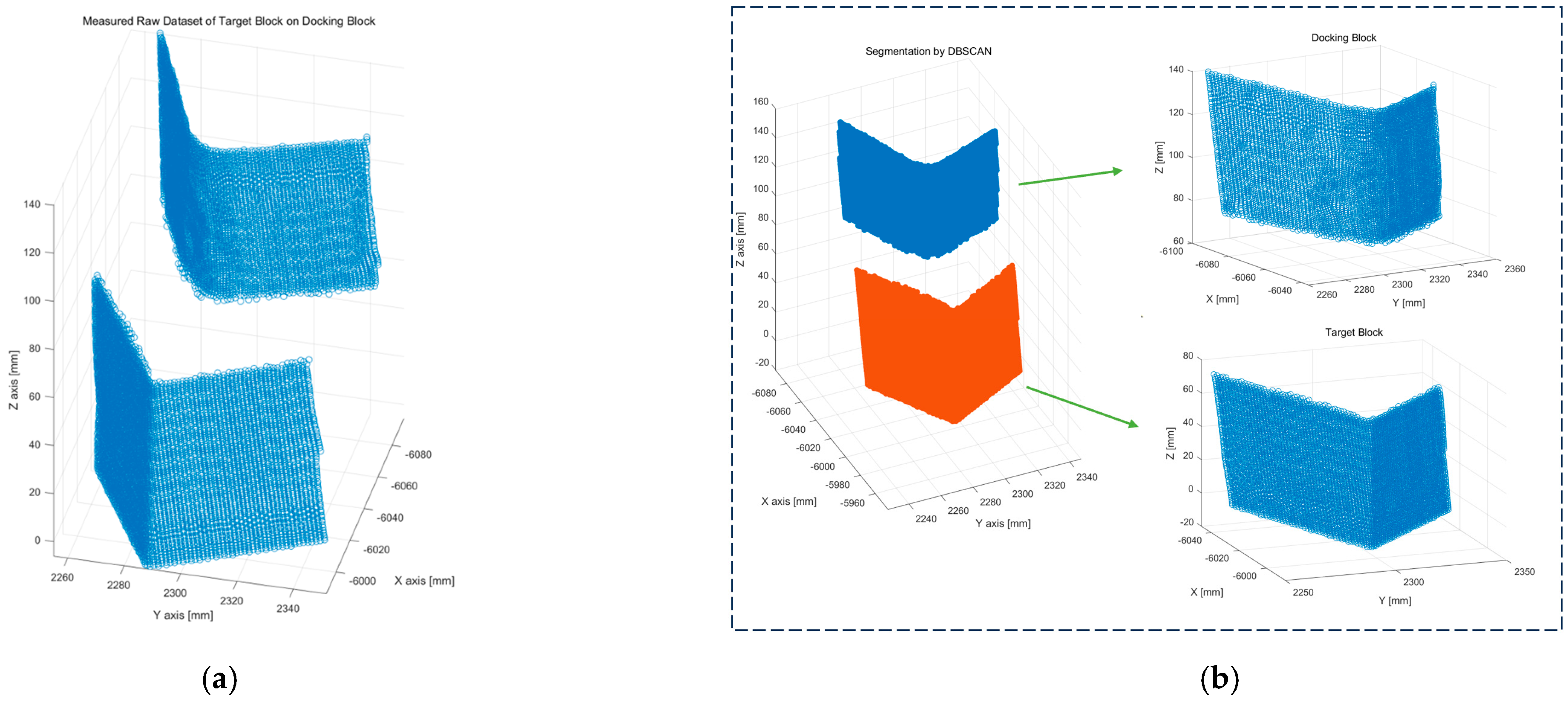

3.1. Environmental Setup

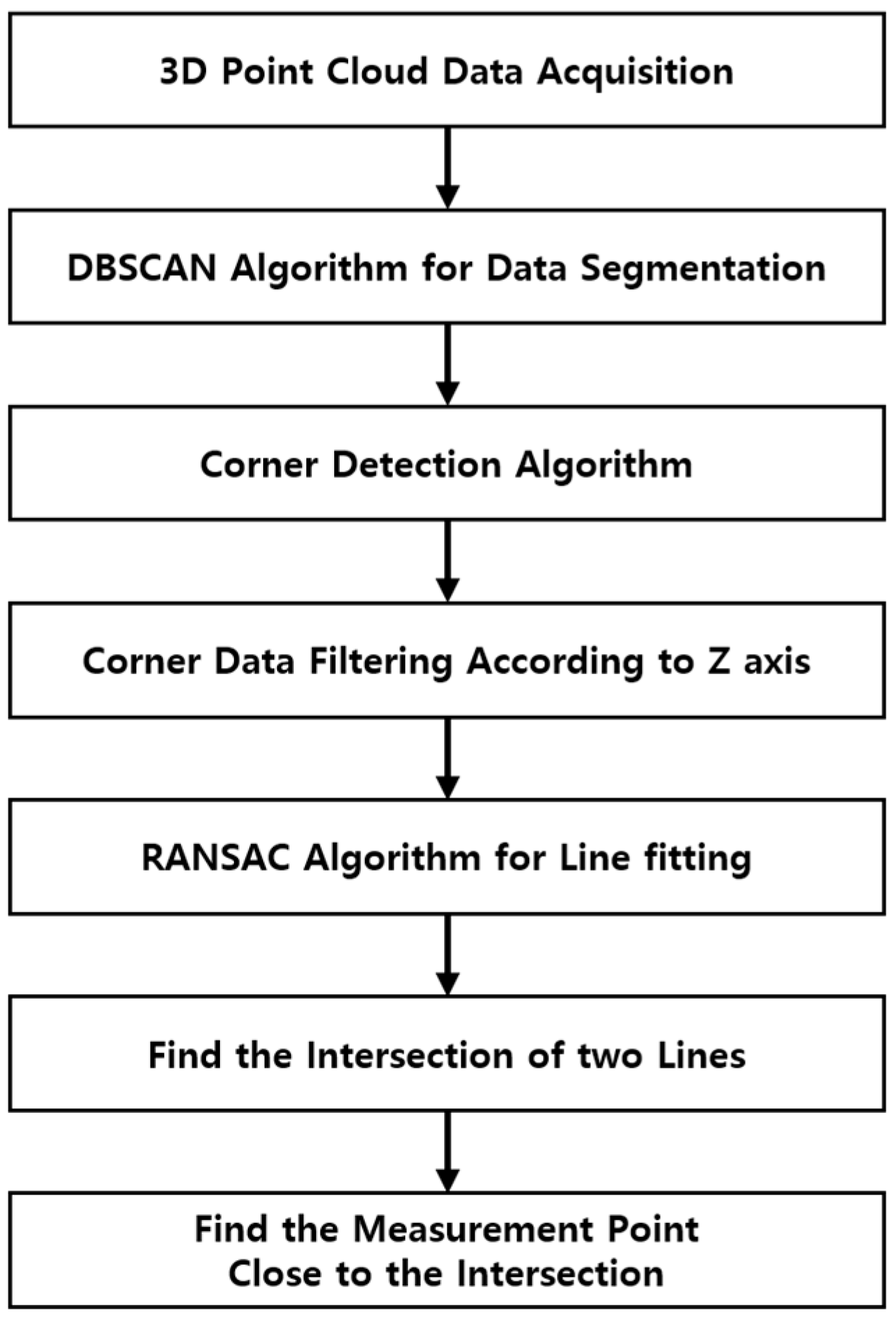

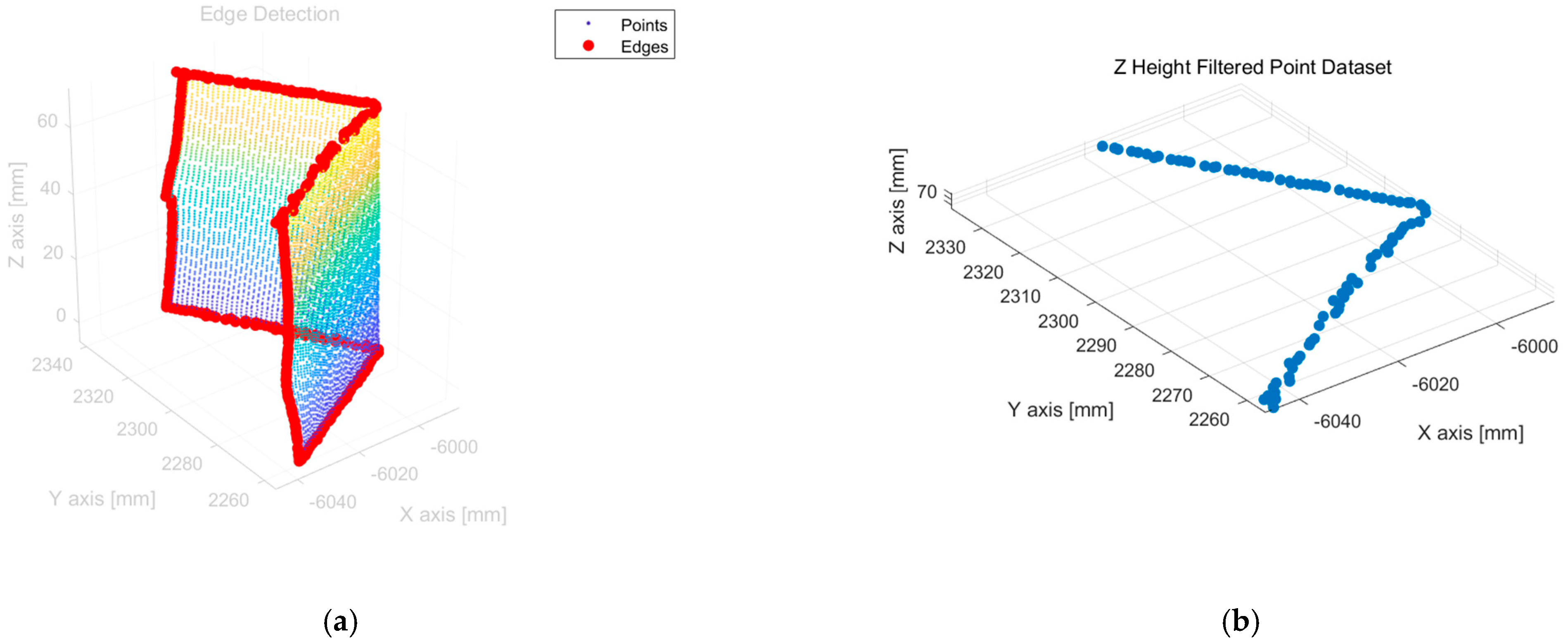

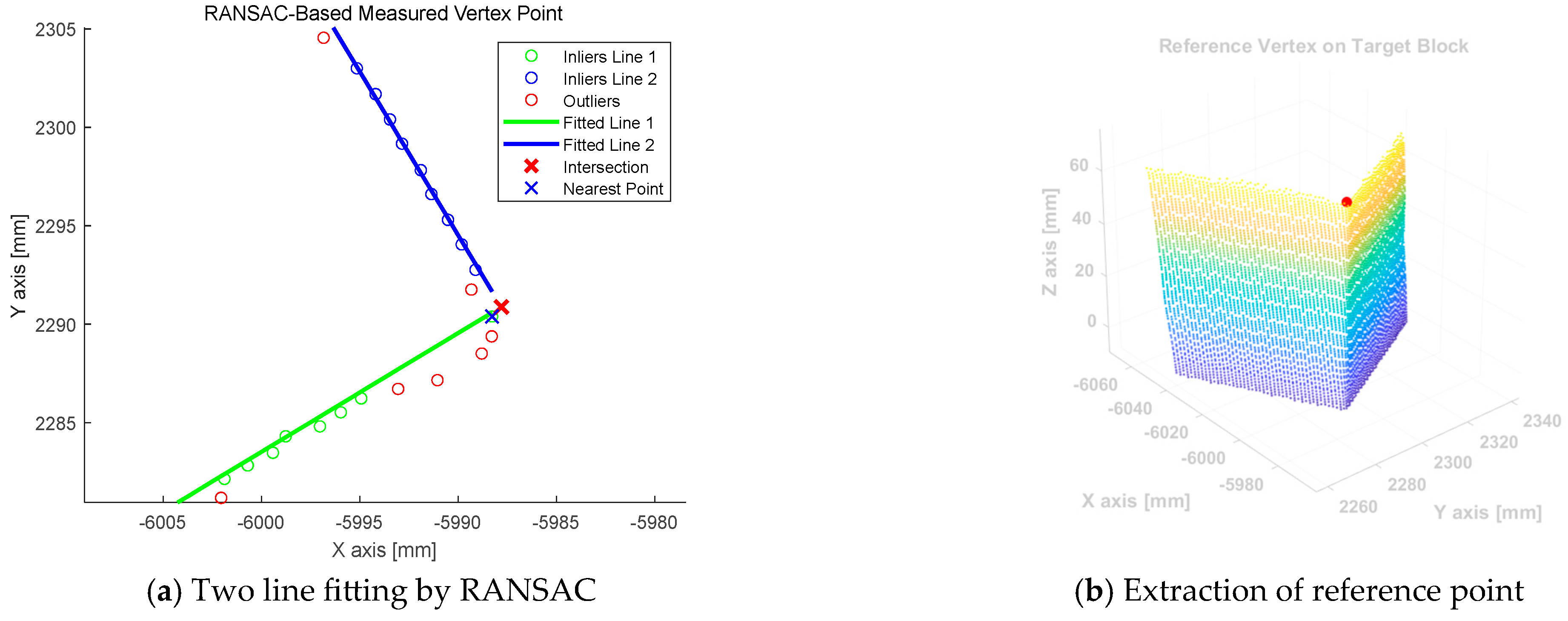

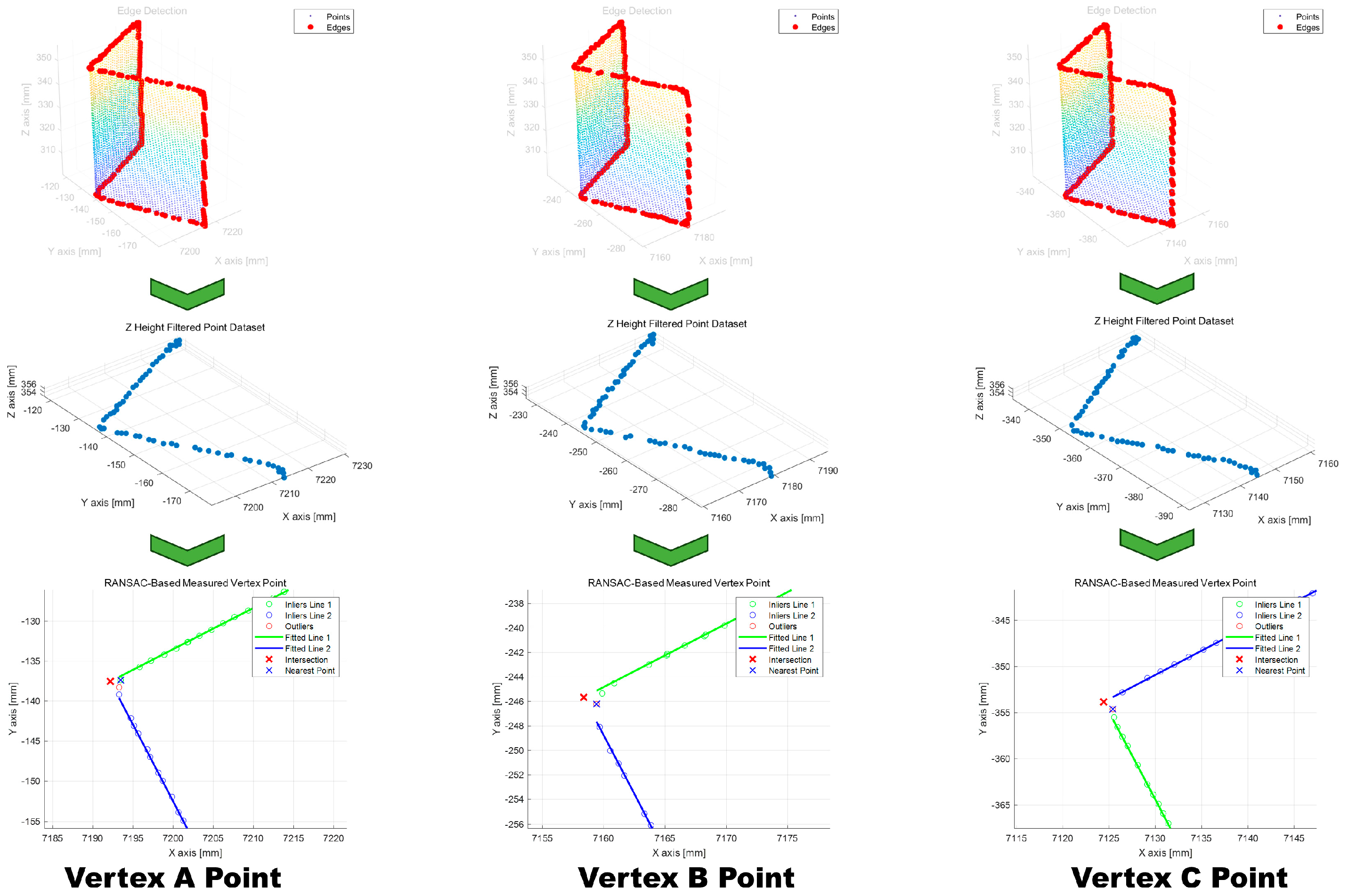

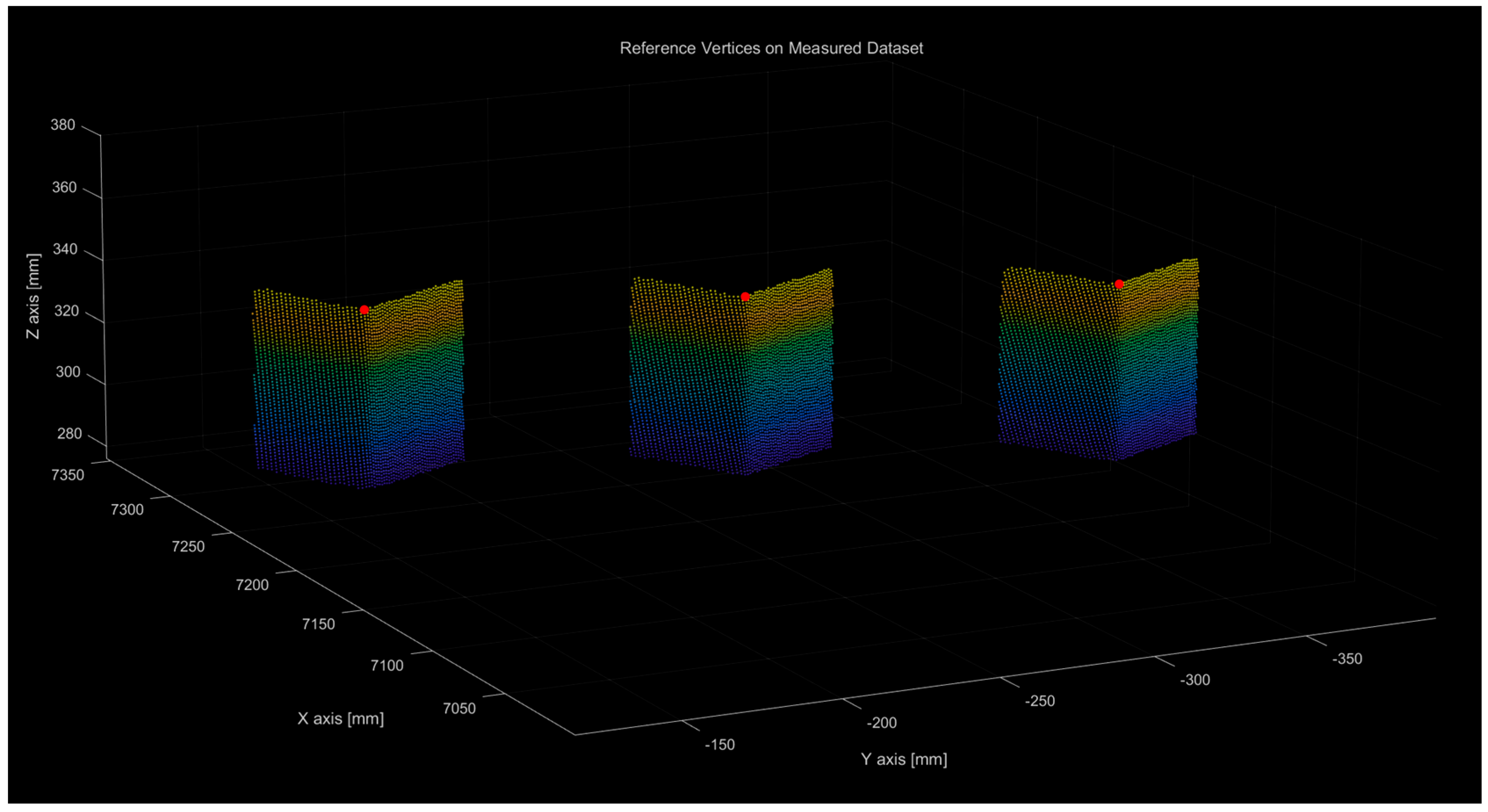

3.2. Reference Point Extraction Algorithm

4. Algorithm Verification and Accuracy Evaluation

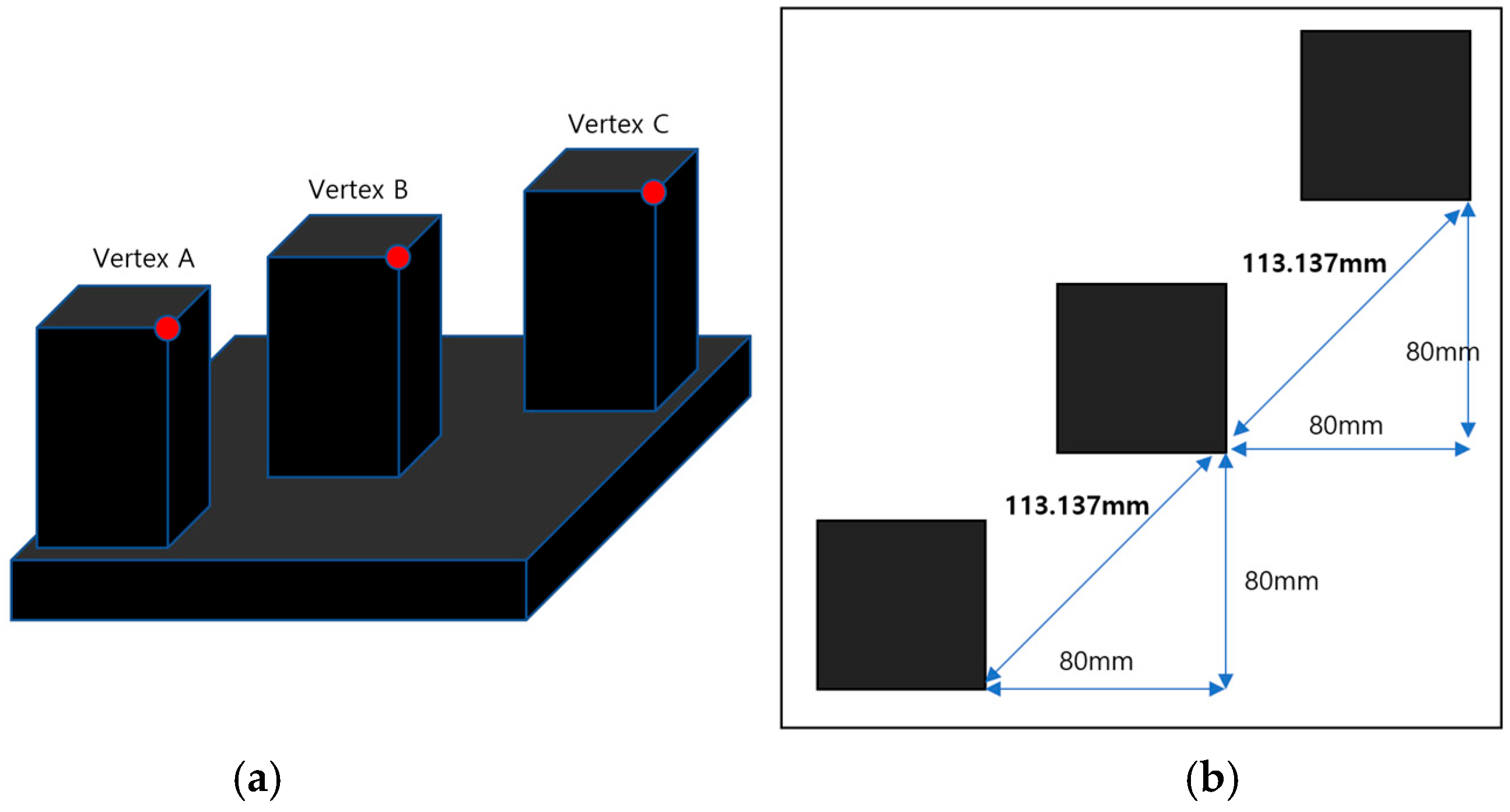

4.1. Design of the Verification Specimen

4.2. Vertex Measurement and Accuracy Evaluation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jia, S.; Li, C.L.; Meng, Q. The dry dock scheduling problem. Transp. Res. Part B Methodol. 2024, 181, 102893. [Google Scholar] [CrossRef]

- Guan, H.; Wang, M.; Meng, Q. Syncrolift Dry Dock Scheduling with a Capacitated Ship Transfer System. Comput. Oper. Res. 2025, 182, 107138. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, J. GPS RTK performance characteristics and analysis. Positioning 2008, 1, 1–8. [Google Scholar] [CrossRef]

- Famiglietti, N.A.; Cecere, G.; Grasso, C.; Memmolo, A.; Vicari, A. A test on the potential of a low cost unmanned aerial vehicle RTK/PPK solution for precision positioning. Sensors 2021, 21, 3882. [Google Scholar] [CrossRef] [PubMed]

- Takasu, T.; Yasuda, A. Evaluation of RTK-GPS performance with low-cost single-frequency GPS receivers. In Proceedings of the International Symposium on GPS/GNSS, Tokyo, Japan, 11–14 November 2008; pp. 852–861. [Google Scholar]

- Alarifi, A.; Al-Salman, A.; Alsaleh, M.; Alnafessah, A.; Al-Hadhrami, S.; Al-Ammar, M.A.; Al-Khalifa, H.S. Ultra wideband indoor positioning technologies: Analysis and recent advances. Sensors 2016, 16, 707. [Google Scholar] [CrossRef] [PubMed]

- Kunhoth, J.; Karkar, A.; Al-Maadeed, S.; Al-Ali, A. Indoor positioning and wayfinding systems: A survey. Hum.-Centric Comput. Inf. Sci. 2020, 10, 18. [Google Scholar] [CrossRef]

- Huang, L. Review on LiDAR-based SLAM techniques. In Proceedings of the 2021 International Conference on Signal Processing and Machine Learning (CONF-SPML), Stanford, CA, USA, 14 November 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 163–168. [Google Scholar]

- Szybicki, D.; Obal, P.; Penar, P.; Kurc, K.; Muszyńska, M.; Burghardt, A. Development of a Dedicated Application for Robots to Communicate with a Laser Tracker. Electronics 2022, 11, 3405. [Google Scholar] [CrossRef]

- Muralikrishnan, B.; Phillips, S.; Sawyer, D. Laser trackers for large-scale dimensional metrology: A review. Precis. Eng. 2016, 44, 13–28. [Google Scholar] [CrossRef]

- Jang, Y.-S.; KIM, S.-W. Distance measurements using mode-locked lasers: A review. Nanomanufacturing Metrol. 2018, 1, 131–147. [Google Scholar] [CrossRef]

- Vikas; Sahu, R.K. A review on application of laser tracker in precision positioning metrology of particle accelerators. Precis. Eng. 2021, 71, 232–249. [Google Scholar] [CrossRef]

- Suzuki, T.; Kitamura, M.; Amano, Y.; Kubo, N. Autonomous navigation of a mobile robot based on GNSS/DR integration in outdoor environments. J. Robot. Mechatron. 2014, 26, 214–224. [Google Scholar] [CrossRef]

- Patoliya, J.; Mewada, H.; Hassaballah, M.; Khan, M.A.; Kadry, S. A robust autonomous navigation and mapping system based on GPS and LiDAR data for unconstraint environment. Earth Sci. Inform. 2022, 15, 2703–2715. [Google Scholar] [CrossRef]

- Zhang, H.-Y.; Lin, W.-M.; Chen, A.-X. Path planning for the mobile robot: A review. Symmetry 2018, 10, 450. [Google Scholar] [CrossRef]

- Liu, L.; Wang, X.; Yang, X.; Liu, H.; Li, J.; Wang, P. Path planning techniques for mobile robots: Review and prospect. Expert Syst. Appl. 2023, 227, 120254. [Google Scholar] [CrossRef]

- Sariff, N.; Buniyamin, N. An overview of autonomous mobile robot path planning algorithms. In Proceedings of the 2006 4th Student Conference on Research and Development, Shah Alam, Malaysia, 27–28 June 2006; IEEE: Piscataway, NJ, USA, 2006; pp. 183–188. [Google Scholar]

- Khan, K.; Rehman, S.U.; Aziz, K.; Fong, S.; Sarasvady, S. DBSCAN: Past, present and future. In Proceedings of the Fifth International Conference on the Applications of Digital Information and Web Technologies (ICADIWT 2014), Chennai, India, 17–19 February 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 232–238. [Google Scholar]

- Deng, D. DBSCAN clustering algorithm based on density. In Proceedings of the 2020 7th International Forum on Electrical Engineering and Automation (IFEEA), Hefei, China, 25–27 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 949–953. [Google Scholar]

- Smiti, A.; Elouedi, Z. Dbscan-gm: An improved clustering method based on gaussian means and dbscan techniques. In Proceedings of the 2012 IEEE 16th International Conference on Intelligent Engineering Systems (INES), Lisbon, Portugal, 13–15 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 573–578. [Google Scholar]

- Klokov, R.; Lempitsky, V. Escape from cells: Deep kd-networks for the recognition of 3D point cloud models. In Proceedings of the IEEE International Conference on Computer Vision, Venice, Italy, 22–29 October 2017; pp. 863–872. [Google Scholar]

- Oviedo-de la Fuente, M.; Cabo, C.; Ordóñez, C.; Roca-Pardiñas, J. A Distance Correlation Approach for Optimum Multiscale Selection in 3D Point Cloud Classification. Mathematics 2021, 9, 1328. [Google Scholar] [CrossRef]

- Xie, Y.; Tian, J.; Zhu, X.X. Linking points with labels in 3D: A review of point cloud semantic segmentation. IEEE Geosci. Remote Sens. Mag. 2020, 8, 38–59. [Google Scholar] [CrossRef]

- Bolles, R.C.; Fischler, M.A. A RANSAC-based approach to model fitting and its application to finding cylinders in range data. In Proceedings of the International Joint Conference on Artificial Intelligence, Vancouver, BC, Canada, 24–28 August 1981; pp. 637–643. [Google Scholar]

- Zeineldin, R.A.; El-Fishawy, N.A. A survey of RANSAC enhancements for plane detection in 3D point clouds. Menoufia J. Electron. Eng. Res. 2017, 26, 519–537. [Google Scholar] [CrossRef]

- Schnabel, R.; Wahl, R.; Klein, R. Efficient RANSAC for point-cloud shape detection. In Computer Graphics Forum; Blackwell Publishing Ltd.: Oxford, UK, 2007; pp. 214–226. [Google Scholar]

| Points | X | Y | Z |

|---|---|---|---|

| Vertex A (mm) | 7193.2747 | −138.2841 | 355.2094 |

| Vertex B (mm) | 7159.4135 | −246.2145 | 355.1761 |

| Vertex C (mm) | 7125.4157 | −354.6206 | 355.1235 |

| Points | A–B | B–C |

|---|---|---|

| Reference Distance (mm) | 113.1370 | 113.1370 |

| Measured Value Distance (mm) | 113.1174 | 113.6122 |

| Error Value (mm) | 0.0196 | 0.4752 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, P.; Kim, J.-O.; Kim, M.; Kim, K. Development of Mobile Robot-Based Precision 3D Position Measurement System. Sensors 2025, 25, 3261. https://doi.org/10.3390/s25113261

Choi P, Kim J-O, Kim M, Kim K. Development of Mobile Robot-Based Precision 3D Position Measurement System. Sensors. 2025; 25(11):3261. https://doi.org/10.3390/s25113261

Chicago/Turabian StyleChoi, Pilgong, Jeng-O Kim, Myeongjun Kim, and Kyunghan Kim. 2025. "Development of Mobile Robot-Based Precision 3D Position Measurement System" Sensors 25, no. 11: 3261. https://doi.org/10.3390/s25113261

APA StyleChoi, P., Kim, J.-O., Kim, M., & Kim, K. (2025). Development of Mobile Robot-Based Precision 3D Position Measurement System. Sensors, 25(11), 3261. https://doi.org/10.3390/s25113261