Novel Spatio-Temporal Joint Learning-Based Intelligent Hollowing Detection in Dams for Low-Data Infrared Images

Abstract

1. Introduction

- (1)

- An unsteady partial differential equation for the surface temperature field of the dam was established;

- (2)

- A multi-subnet, physics-informed neural network model was constructed to solve the numerical solution of the partial differential equation with Robin boundary and obtained the surface temperature pattern in the time domain;

- (3)

- An adaptive joint learning method with spatio-temporal features from the mixed infrared data was employed, which can handle the low data issue.

2. Modeling and Analysis of Surface Temperature Field of Dams

2.1. Mathematical Modeling of Surface Temperature Field for Dams

2.2. Infrared Features Extraction in the Time Domain for Dams

2.2.1. Network Structure of MS-PINNs

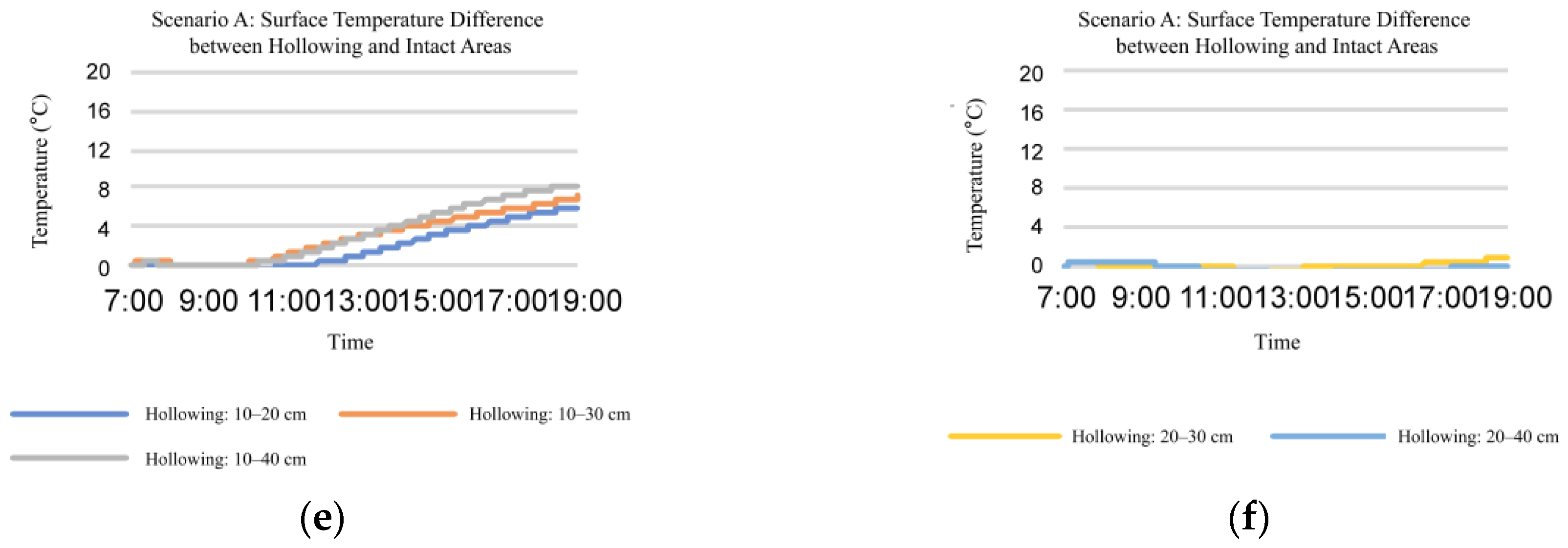

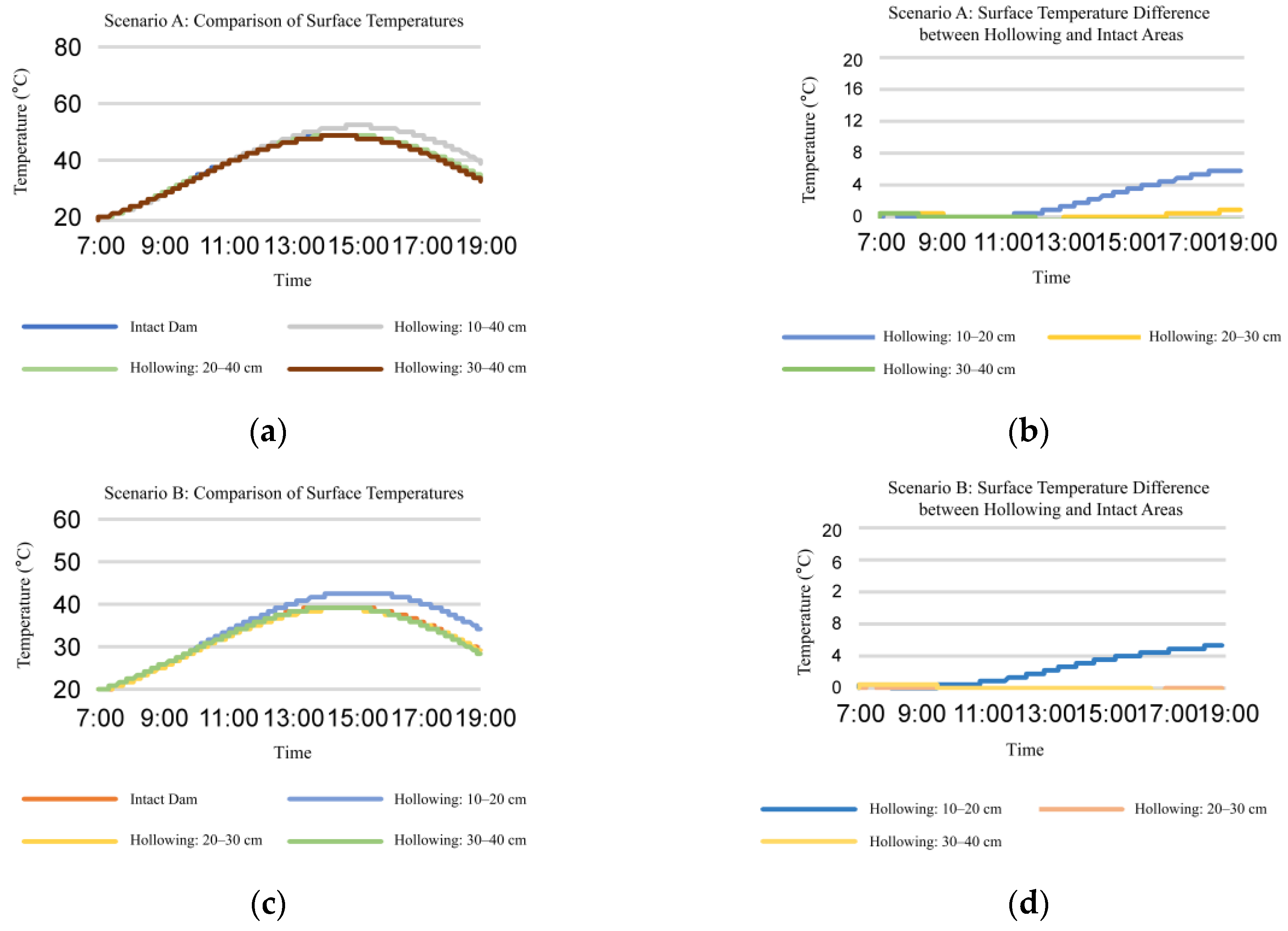

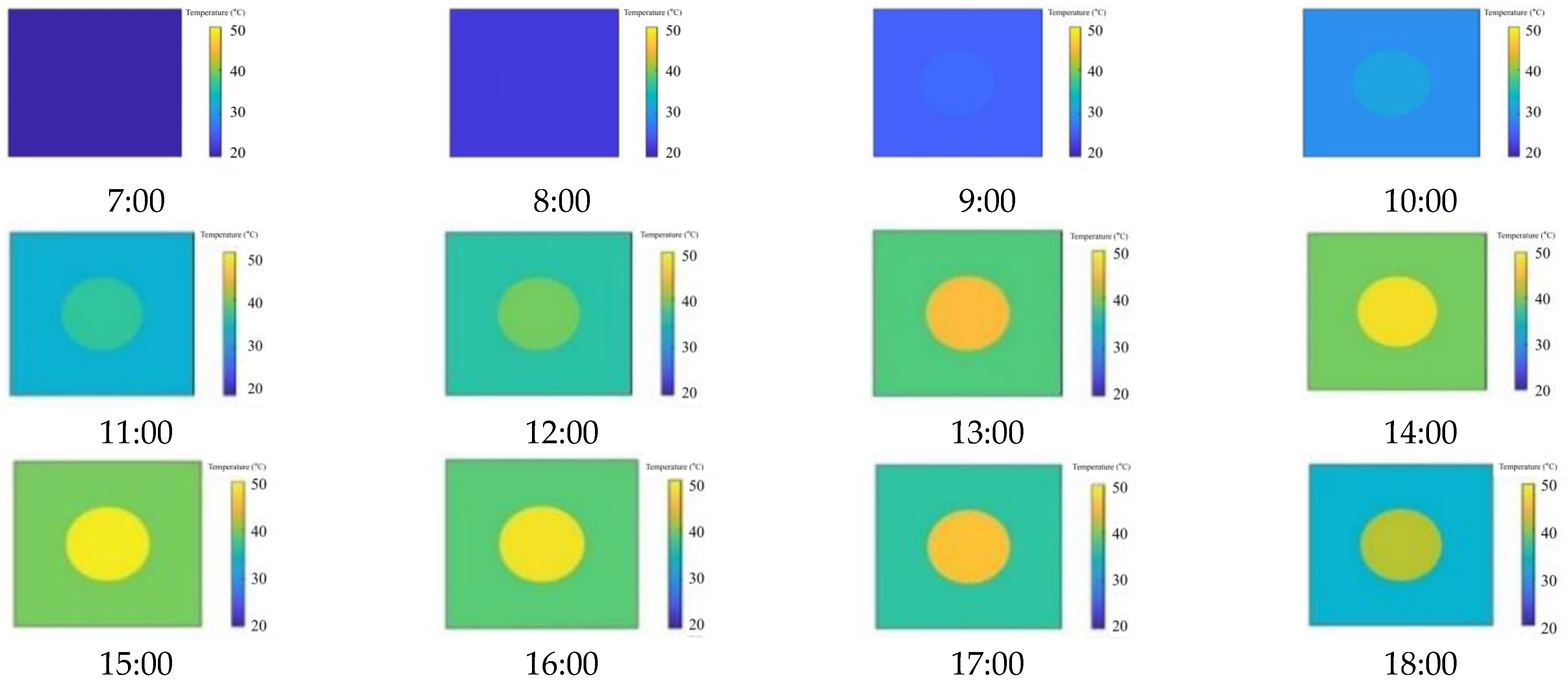

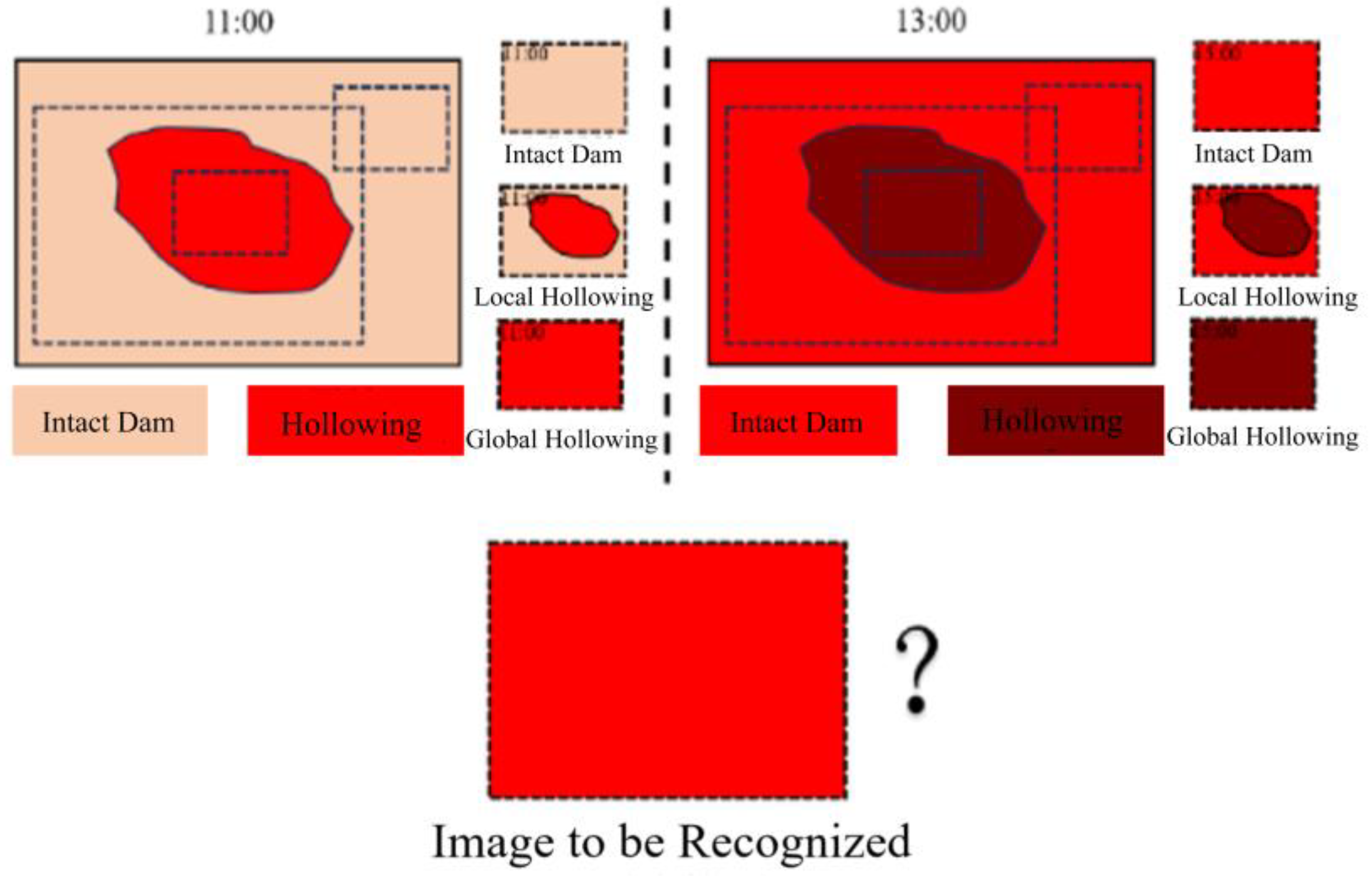

2.2.2. Analysis of Infrared Features in the Time Domain for Dam

3. Low-Data Recognition Method for Hollowings in the Dams

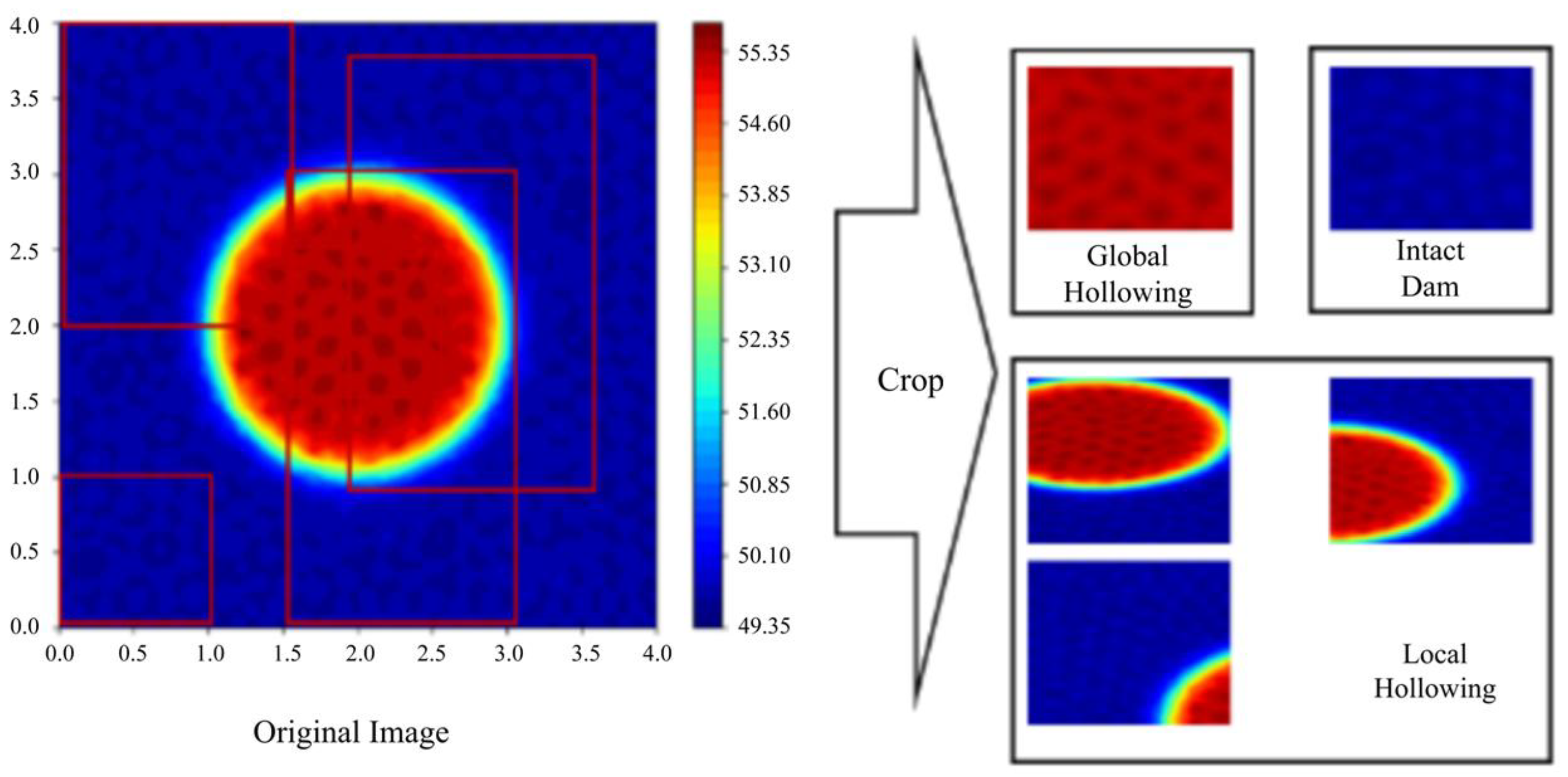

3.1. The Construction of the Mixed Dataset

3.1.1. The Generation of Synthetic Infrared Images with Temperature Diffusion

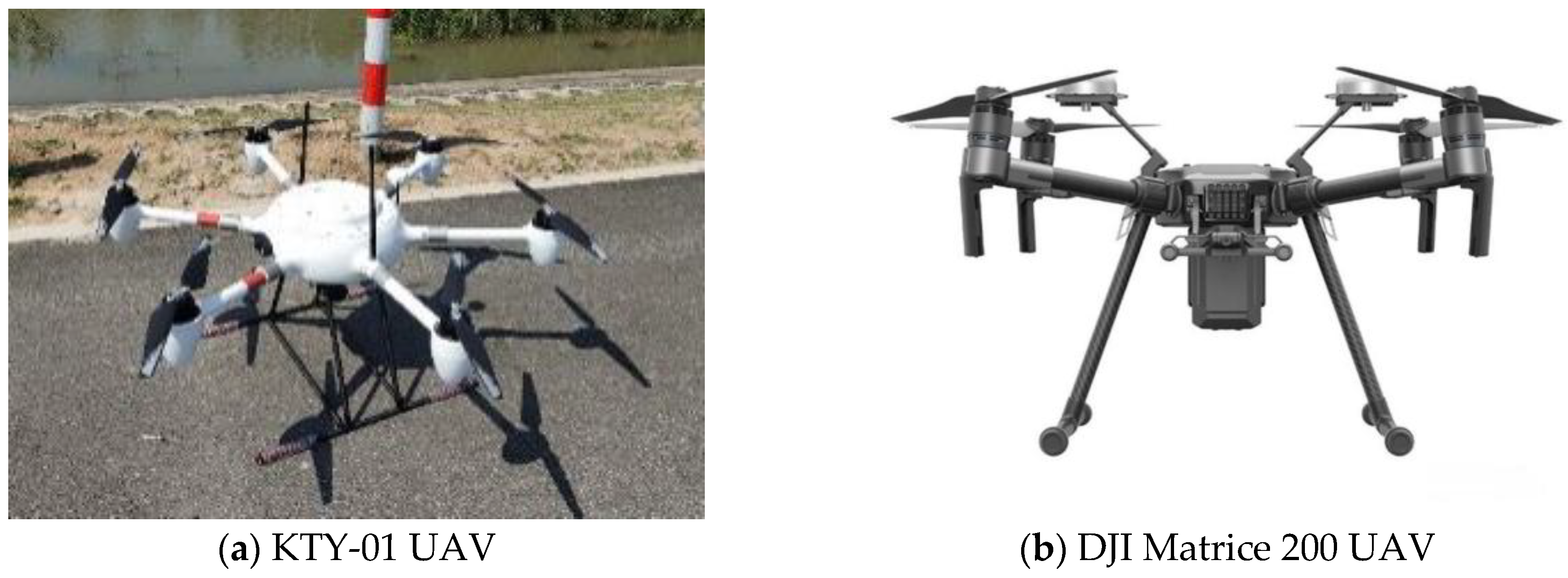

3.1.2. Data Collection

3.1.3. Dataset [19]

3.2. Prior Knowledge Guided Adaptive Joint Learning Hollowing Recognition

| Algorithm 1: Adaptive Joint Learning Semantic Segmentation Based on Prior Knowledge |

| Input: Infrared grayscale image Img; Acquisition time t; Prior threshold |

| Output: Segmentation results Binary_Img |

| Step 1: Read the maximum and minimum temperatures corresponding to the pixel intensity extremes of Img. |

| 1: max (Img) -> T_max; min (Img) -> T_min |

| Step 2: Convert Img to a temperature matrix TI based on T_max and T_min. |

| 2: TI = (Img − min (Img))/(max (Img) − min (Img)) × (T_max − T_min) |

| Step 3: Calculate dam surface temperature threshold Tthreshold and bias Tbias based on t and the prior threshold. |

| Step 4: Calculate the proportion of high-temperature anomalous pixels (Pixel_proportion) in TI exceeding Tthreshold + Tbias. |

| 3: for i = 0 to TI.shape [0] do |

| 4: for j = 0 to TI.shape [1] do |

| 5: if TI [i, j] > Tthreshold+ Tbias do sumTi = sumTi + 1 |

| 6: Pixel_proportion = sumTi/(TI.shape [0] × TI.shape [1]) |

| Step 5: Determine anomaly type. |

| 7: if Pixel_proportion > 99%: global anomaly exists, Binary_Img[:,:] = 255 |

| 8: else if Pixel_proportion < 1%: anomaly-free, Binary_Img[:,:] = 0 |

| 9: else local anomaly exists, do Step 6 |

| Step 6: Remove low-temperature pixel interference. |

| 10: if (Tthreshold − 2 × Tbias) > T_min: TI [TI < (Tthreshold − 2 × Tbias)] = Tthreshold − 2 × Tbias |

| 11: Img = (TI − T_min)/(T_max − T_min) × (max (Img) − min (Img)) |

| Step 7: Perform Otsu’s thresholding for local hollowing segmentation. |

| Gthreshold, Binary_Img = OTSU(Img) |

| Step 8: Assign semantic labels to high-temperature anomaly pixels. |

| Step 9: Apply morphological operations to refine segmentation. |

| 12: Binary_Img = morphologyEx (Binary_Img, cv2.MORPH_OPEN, (3 × 3)) |

| 13: Binary_Img = morphologyEx (Binary_Img, cv2.MORPH_CLOSE, (3 × 3)) |

| End |

4. Experiment and Analysis

4.1. Model Evaluation

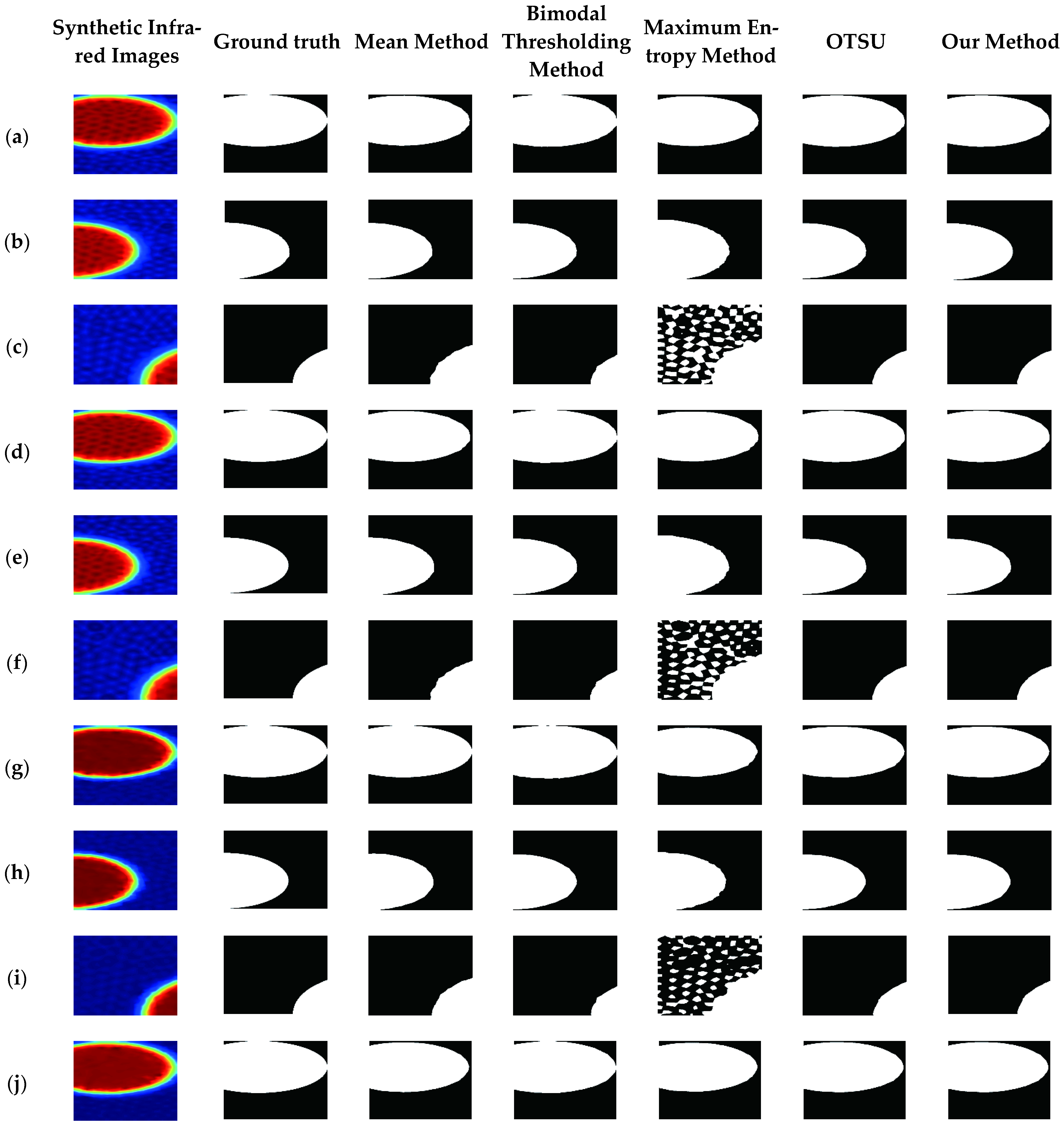

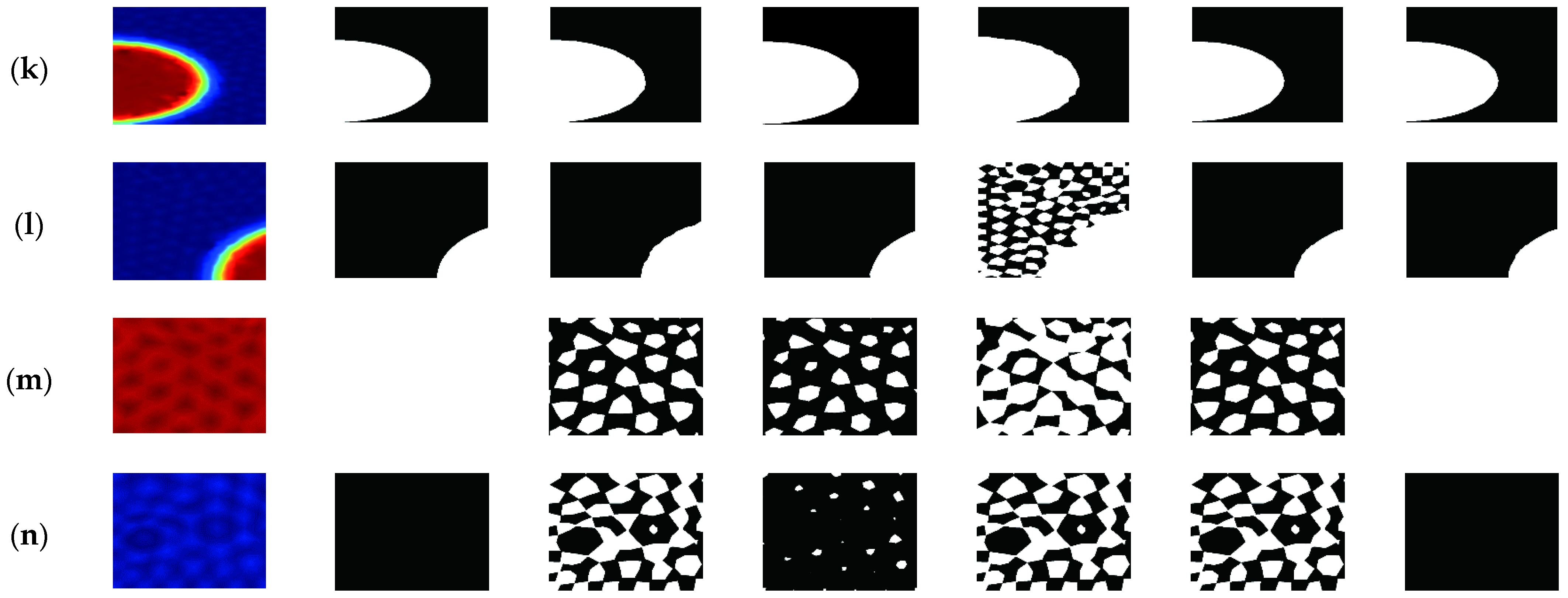

4.2. Analysis of the Recognition Precision on Synthetic Infrared Images

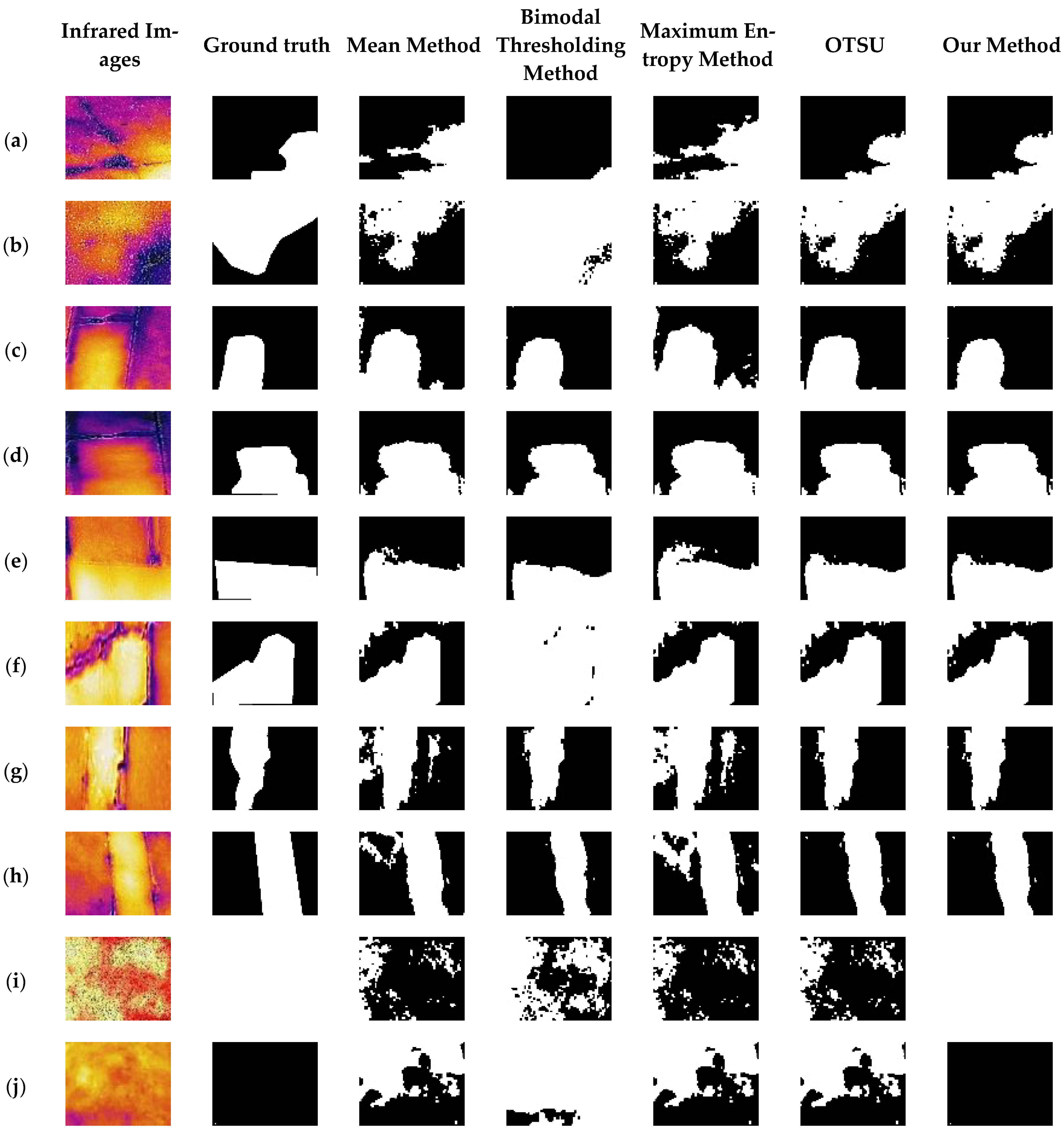

4.3. Experiments on Real Data

4.4. Experiments on of the Cross-Sectional Area for Hollowing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UAV | Unmanned Aerial Vehicle |

| PINNs | Physics-Informed Neural Networks |

| IR | Infrared |

| NDT | Non-Destructive Testing |

| IRT | Infrared Thermography |

| LSM | Level Set Method |

| PIRT | Passive Infrared Thermography |

| PBT | Progressive Background-aware Transformer |

| mAP | Mean Average Precision |

| MS-PINNs | Multi-Subnet Physics-Informed Neural Network |

| AD | Automatic Differentiation |

| PA | Pixel Accuracy |

| IoU | Intersection over Union |

| mIoU | Mean Intersection over Union |

References

- Yin, J.; Xu, L.; Chen, S.; Wang, S.; Wang, S.; Lin, Y. Development and prospect of geophysical exploration technology in water conservancy projects. Express Water Resour. Hydropower Inf. 2022, 43, 32–39+51. [Google Scholar]

- Xiang, Y.; Sheng, J.; Yuan, H.; Zhou, K. Research on degrading and decommissioning assessment of reservoir in China. Sci. Sin. (Technol.) 2015, 45, 1304–1310. [Google Scholar]

- Yu, F.; Liu, X.; Wang, W.; Yan, Y.; Lei, X.; Wang, Q. Summary of non-destructive detection technology for hidden dangers of dams. Jilin Water Resour. 2021, 472, 15–17+31. [Google Scholar]

- Fu, D.; Wang, L.; Bi, Z.; Li, Y. Application of comprehensive geophysical prospecting method in leakage detection of reservoir dams. Water Resour. Plan. Des. 2023, 237, 96–99+111. [Google Scholar]

- Leng, Y.; Huang, J.; Zhang, Z.; Wang, R.; Zhao, S. Research progress in scatheless detection of hidden troubles in embankments. Prog. Geophys. 2003, 18, 370–379. [Google Scholar]

- Xu, L.; Zhang, G.; Ma, Z. Development of comprehensive geophysical prospecting technology for hidden danger detection of earth rock dams. Prog. Geophys. 2022, 37, 1769–1779. [Google Scholar]

- Sakagami, T.; Kubo, S. Development of a new non-destructive testing technique for quantitative evaluations of delamination defects in concrete structures based on phase delay measurement using lock-in thermography. Infrared Phys. Technol. 2002, 43, 311–316. [Google Scholar] [CrossRef]

- Balaras, C.; Argiriou, A. Infrared thermography for building diagnostics. Energy Build. 2022, 34, 171–183. [Google Scholar] [CrossRef]

- Cheng, C.; Cheng, T.; Chiang, C. Defect detection of concrete structures using both infrared thermography and elastic waves. Autom. Constr. 2008, 18, 87–92. [Google Scholar] [CrossRef]

- Keo, S.; Brachelet, F.; Breaban, F.; Defer, D. Steel detection in reinforced concrete wall by microwave infrared thermography. NDT&E Int. 2014, 62, 172–177. [Google Scholar]

- Luo, G.; Pan, J.; Wang, J. Infrared thermal imaging technique-based method for detecting defect of insulation layer of concrete dam. Water Resour. Hydropower Eng. 2020, 51, 71–77. [Google Scholar]

- Cheng, C.; Shen, Z. The application of gray-scale level-set method in segmentation of concrete deck delamination using infrared images. Constr. Build. Mater. 2020, 240, 117974. [Google Scholar] [CrossRef]

- Zou, L.; Jin, H. Research on Infrared Nondestructive Testing of Hidden Defects in Concrete Bridges. Mach. Des. Manuf. 2023, 391, 212–216+220. [Google Scholar]

- Wang, Y.; Tang, L.; Qian, S. Early unsteady leakage detection system of small reservoir dam based on UAV and infrared thermal image. Nondestruct. Test. 2020, 42, 61–65. [Google Scholar]

- Huang, S.; Rao, X.; Li, H. Lightweight Infrared Ship Detection Algorithm Based on Multi-Scale Feature Fusion. Meas. Control Technol. 2025, 44, 16–24. [Google Scholar]

- Yang, H.; Mu, T.; Dong, Z.; Zhang, Z.; Wang, B.; Ke, W.; Yang, Q.; He, Z. PBT: Progressive Background-Aware Transformer for Infrared Small Target Detection. IEEE Trans. Geosci. Remote Sens. 2024, 62, 1–13. [Google Scholar] [CrossRef]

- He, H. Based on Infrared Thermal Imaging Technique in Study on Retaining Engineering Structures Application in Non-Destructive Detection; Chongqing University: Chongqing, China, 2012. [Google Scholar]

- Xu, X.; Wang, Z.; Zhu, A.; Xia, S. Analysis of the Influence of Environmental Factors on the Temperature of Asphalt Concrete Facing on Reservoir Dam. J. Water Resour. Architect. Eng. 2023, 21, 15–20+29. [Google Scholar]

- An infrared Image Dataset of Hollowing [Dataset]. GitHub. Available online: https://github.com/WangYibo228/an_infrared_image_dataset_of_hollowing.git (accessed on 7 May 2025).

| PA 1/% | IoU 2/% | mIoU 3/% | Time 4/ms | |

|---|---|---|---|---|

| Mean Method | 92.7 | 84.6 | 87.5 | <0.1 |

| Bimodal Thresholding Method | 92.8 | 83.8 | 87.2 | 626.9 |

| Maximum Entropy Method | 82.6 | 66.5 | 70.2 | 583.5 |

| OTSU | 93.6 | 91.0 | 90.4 | 0.2 |

| Our Method | 98.6 | 96.0 | 96.7 | 0.2 |

| PA/% | IoU/% | mIoU/% | Time/ms | |

|---|---|---|---|---|

| Mean Method | 81.1 | 65.4 | 67.4 | <0.1 |

| Bimodal Thresholding Method | 78.6 | 60.6 | 61.6 | 533.5 |

| Maximum Entropy Method | 76.8 | 58.6 | 63.5 | 551.8 |

| OTSU | 88.9 | 78.1 | 80.8 | 3.0 |

| Our Method | 94.7 | 84.1 | 86.7 | 3.1 |

| Relative Error in Area/% | |

|---|---|

| Mean Method | 70.3 |

| Bimodal Thresholding Method | 81.4 |

| Maximum Entropy Method | 80.2 |

| OTSU | 17.1 |

| Our Method | 9.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Jin, Z.; Wang, Y.; Wang, Z.; Duan, Z.; Qi, T.; Shi, R. Novel Spatio-Temporal Joint Learning-Based Intelligent Hollowing Detection in Dams for Low-Data Infrared Images. Sensors 2025, 25, 3199. https://doi.org/10.3390/s25103199

Zhang L, Jin Z, Wang Y, Wang Z, Duan Z, Qi T, Shi R. Novel Spatio-Temporal Joint Learning-Based Intelligent Hollowing Detection in Dams for Low-Data Infrared Images. Sensors. 2025; 25(10):3199. https://doi.org/10.3390/s25103199

Chicago/Turabian StyleZhang, Lili, Zihan Jin, Yibo Wang, Ziyi Wang, Zeyu Duan, Taoran Qi, and Rui Shi. 2025. "Novel Spatio-Temporal Joint Learning-Based Intelligent Hollowing Detection in Dams for Low-Data Infrared Images" Sensors 25, no. 10: 3199. https://doi.org/10.3390/s25103199

APA StyleZhang, L., Jin, Z., Wang, Y., Wang, Z., Duan, Z., Qi, T., & Shi, R. (2025). Novel Spatio-Temporal Joint Learning-Based Intelligent Hollowing Detection in Dams for Low-Data Infrared Images. Sensors, 25(10), 3199. https://doi.org/10.3390/s25103199