Defect Detection of GFRP Composites through Long Pulse Thermography Using an Uncooled Microbolometer Infrared Camera

Abstract

1. Introduction

2. Materials and Methods

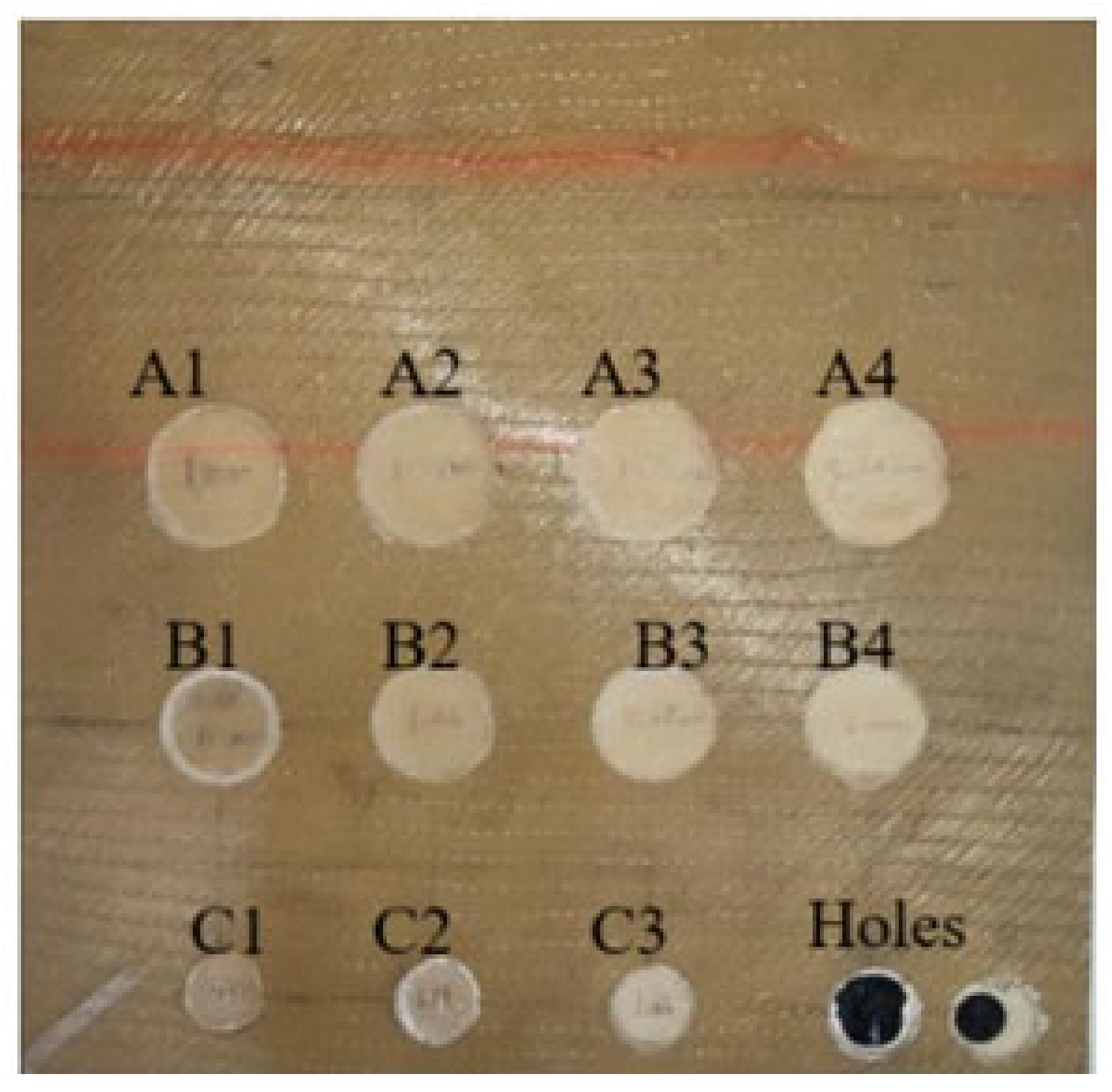

2.1. Test Sample

2.2. Long Pulse Thermography (LPT) Configuration Setup

2.3. Experiment Procedure on Selected Parameters Using LPT Thermography

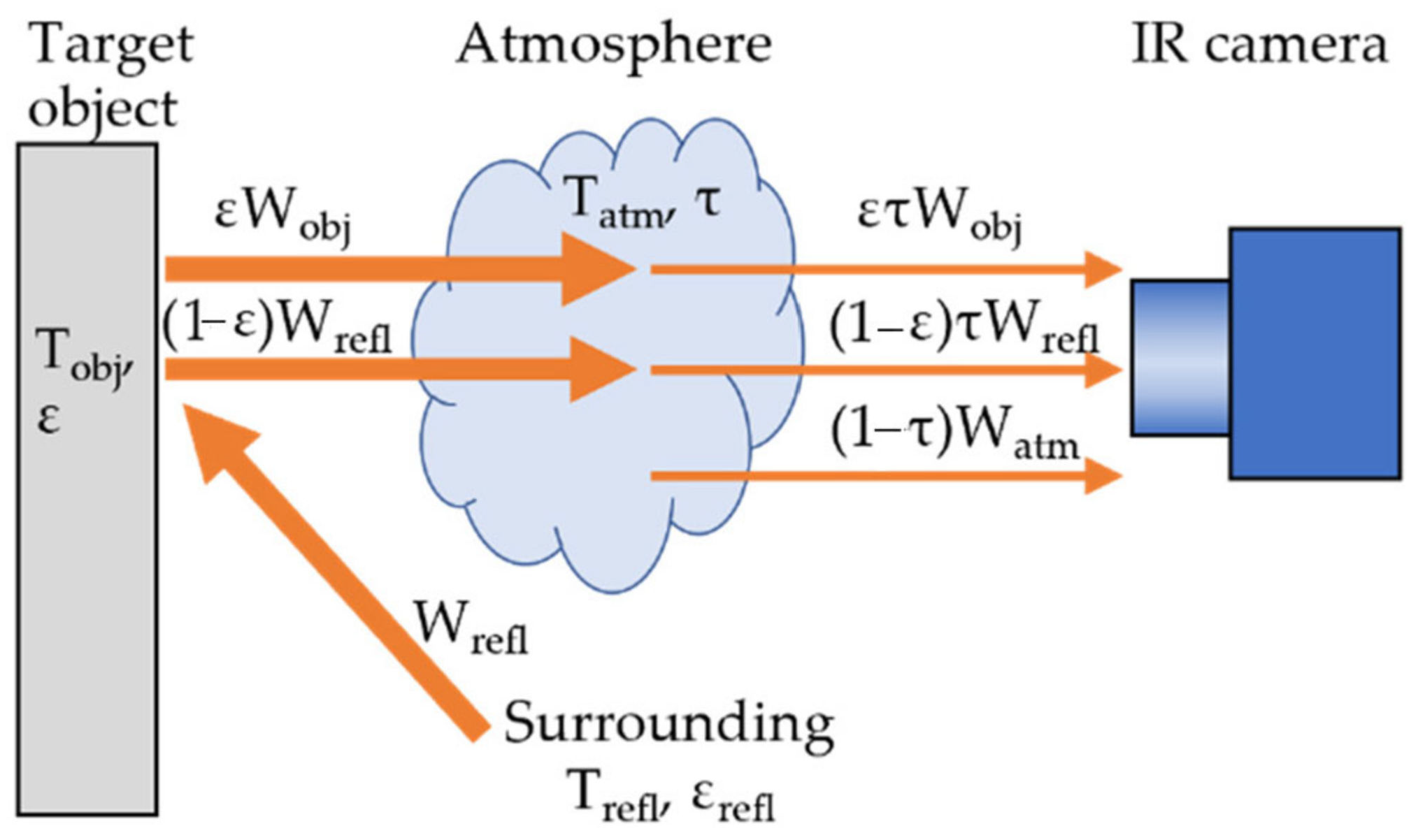

2.3.1. Environment Condition and Surrounding Temperature

2.3.2. Parameter for Internal Enclosure Background Color Reflection

2.3.3. Parameter for Background Reflection

2.3.4. Material Surface Emissivity

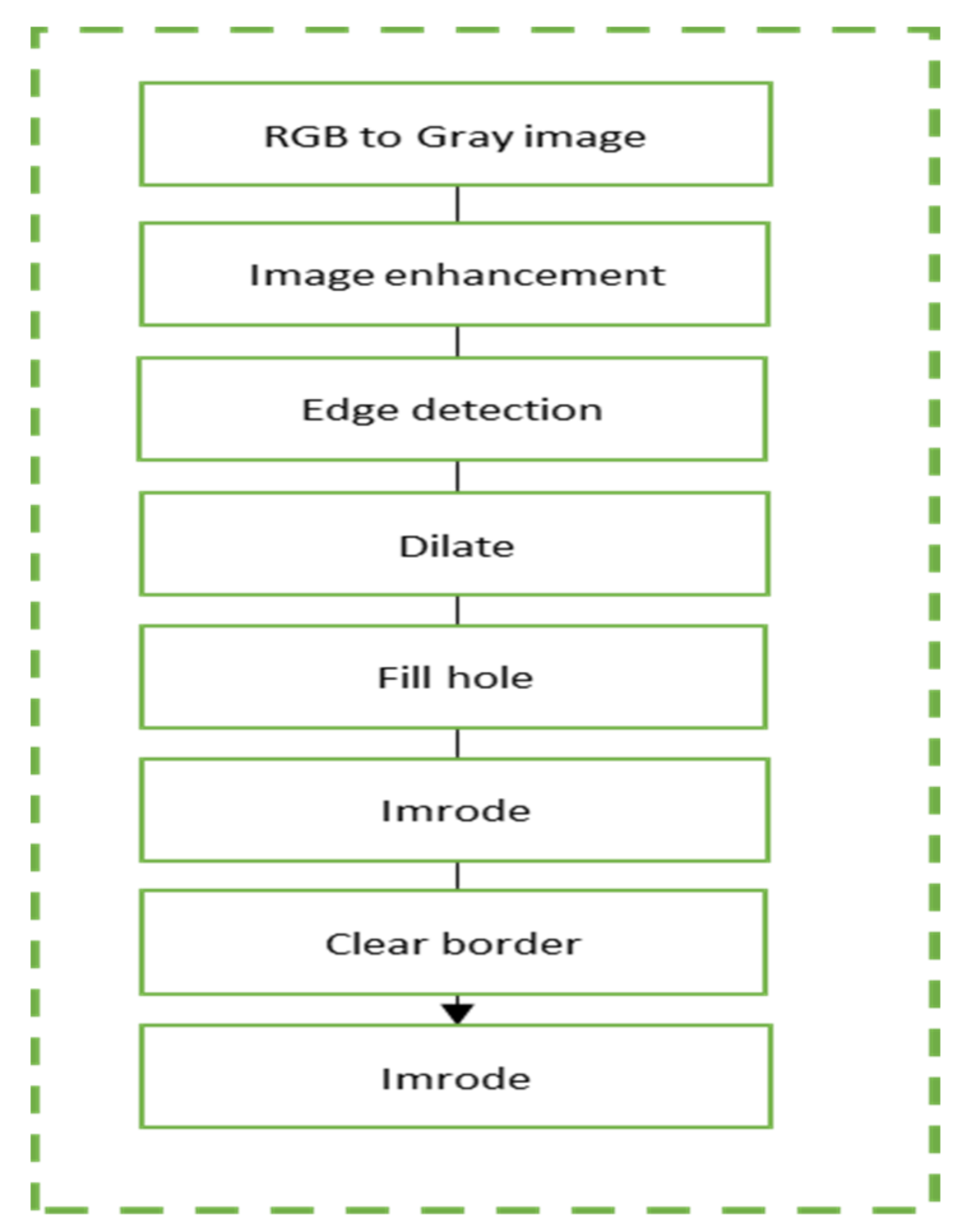

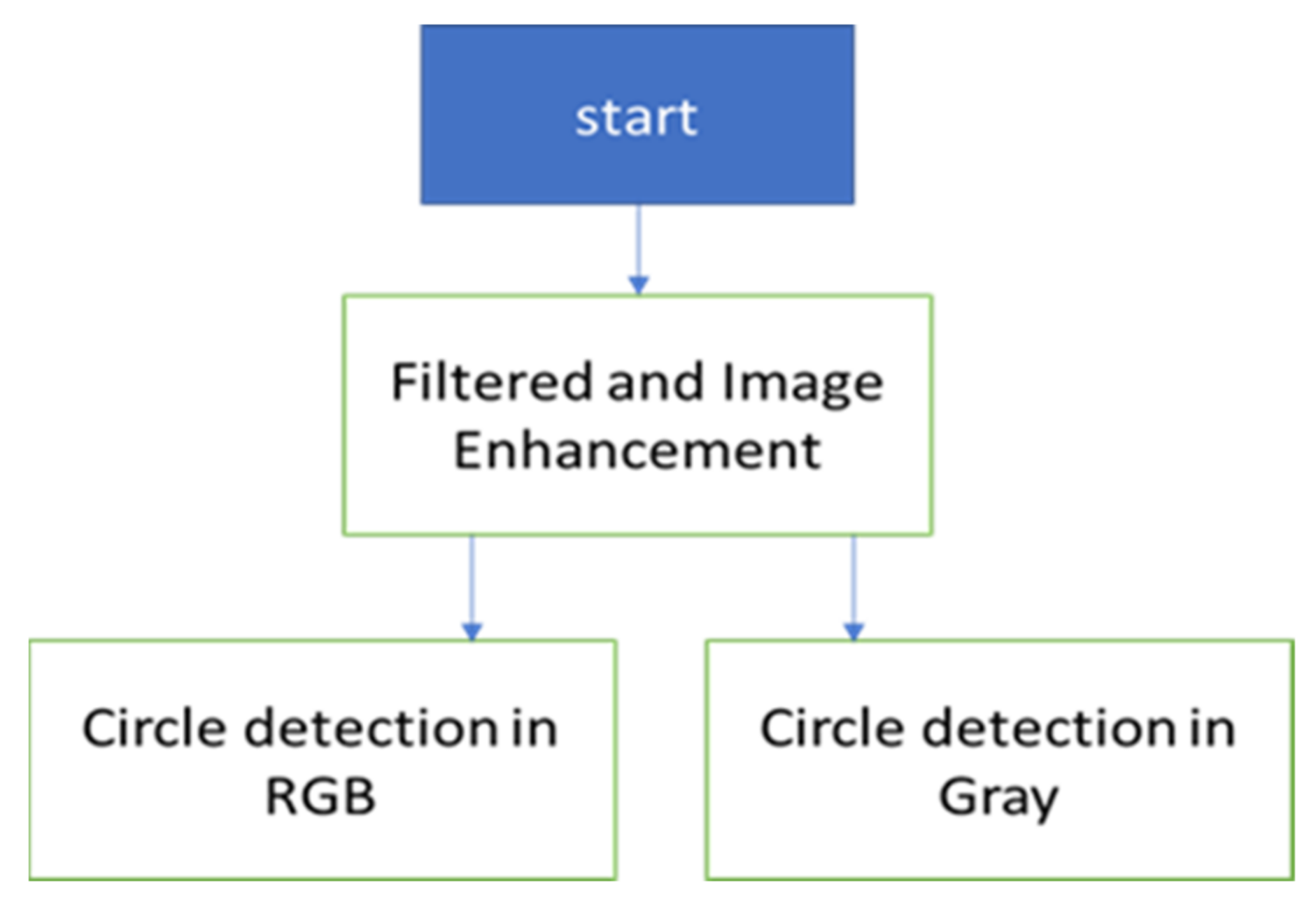

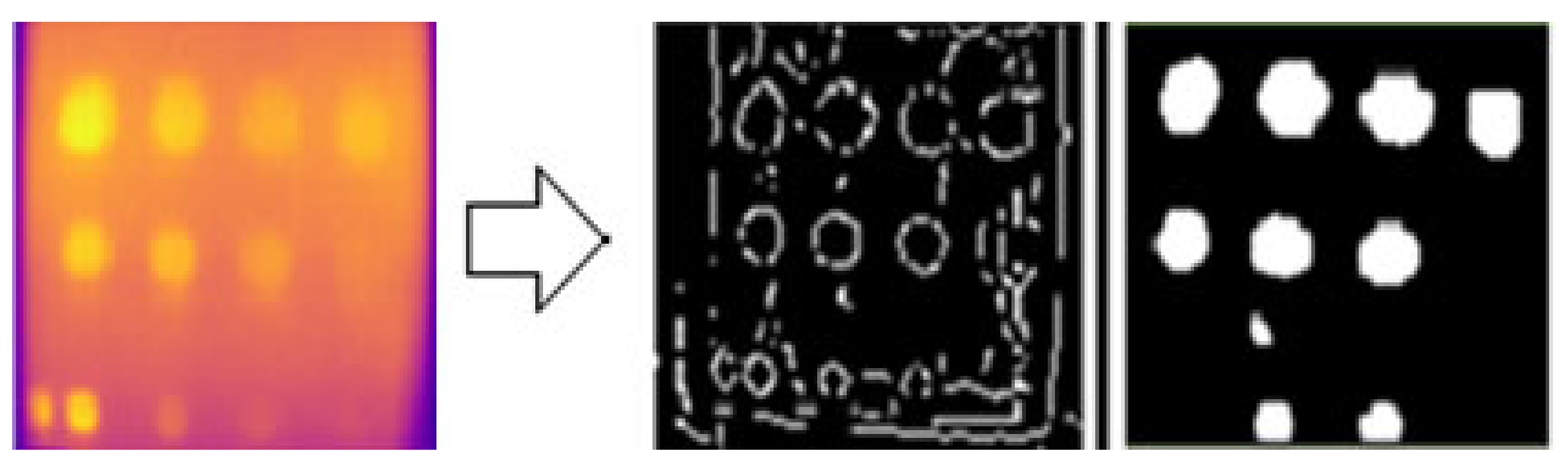

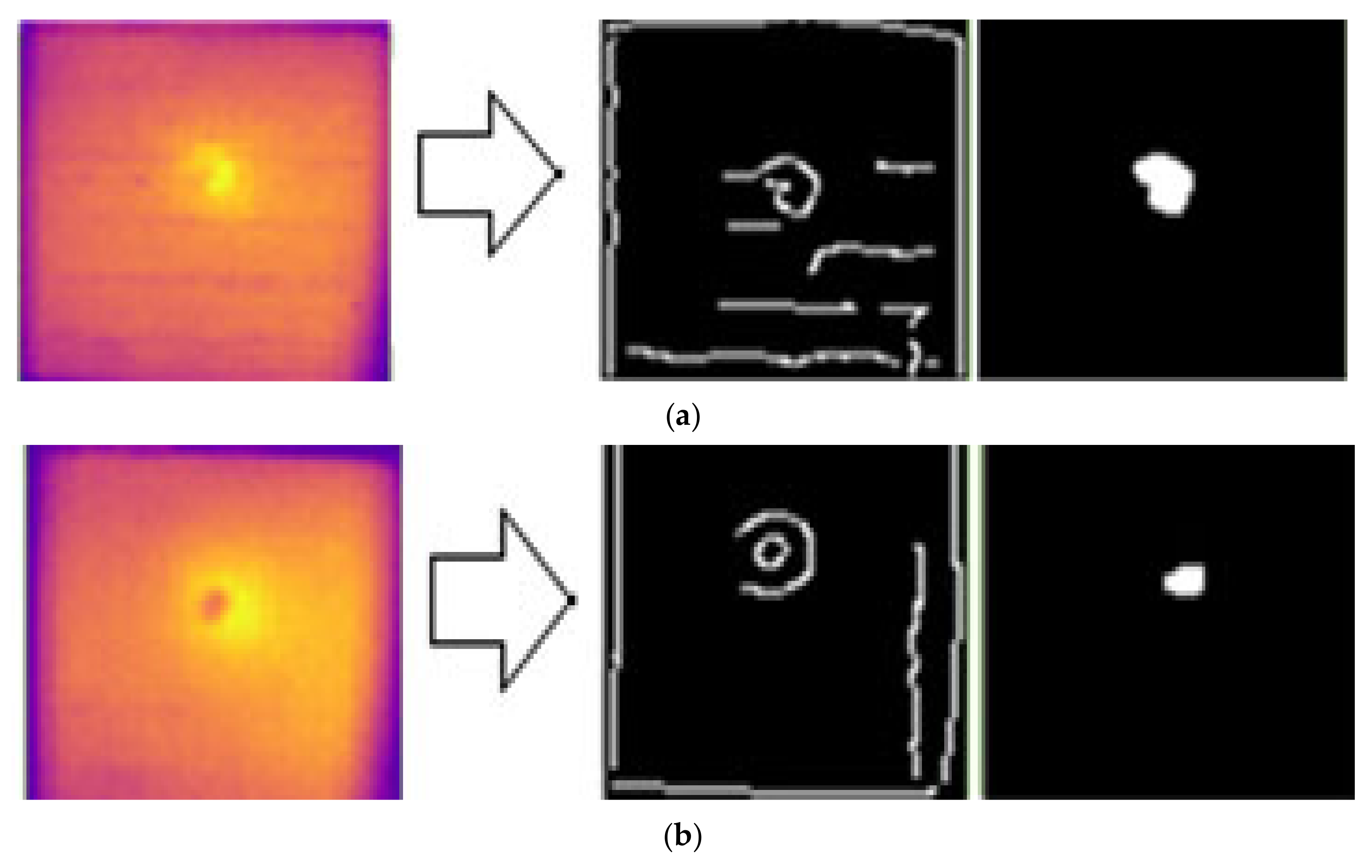

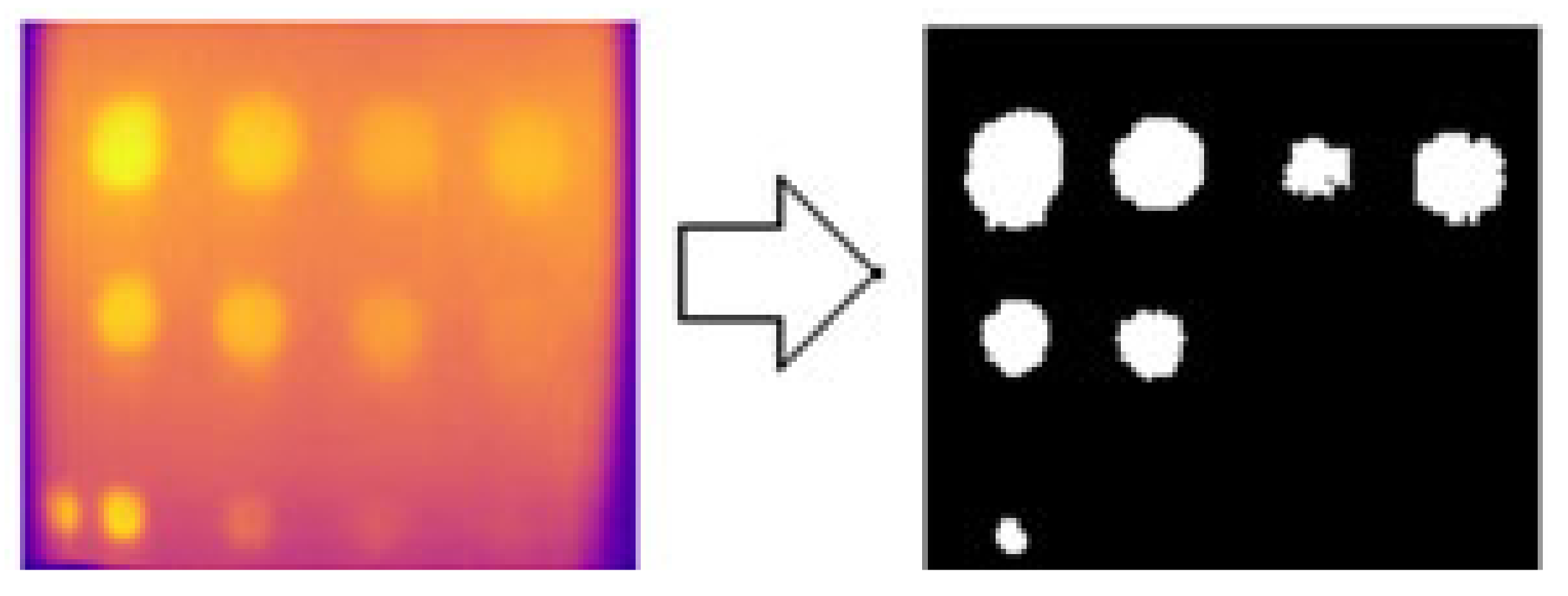

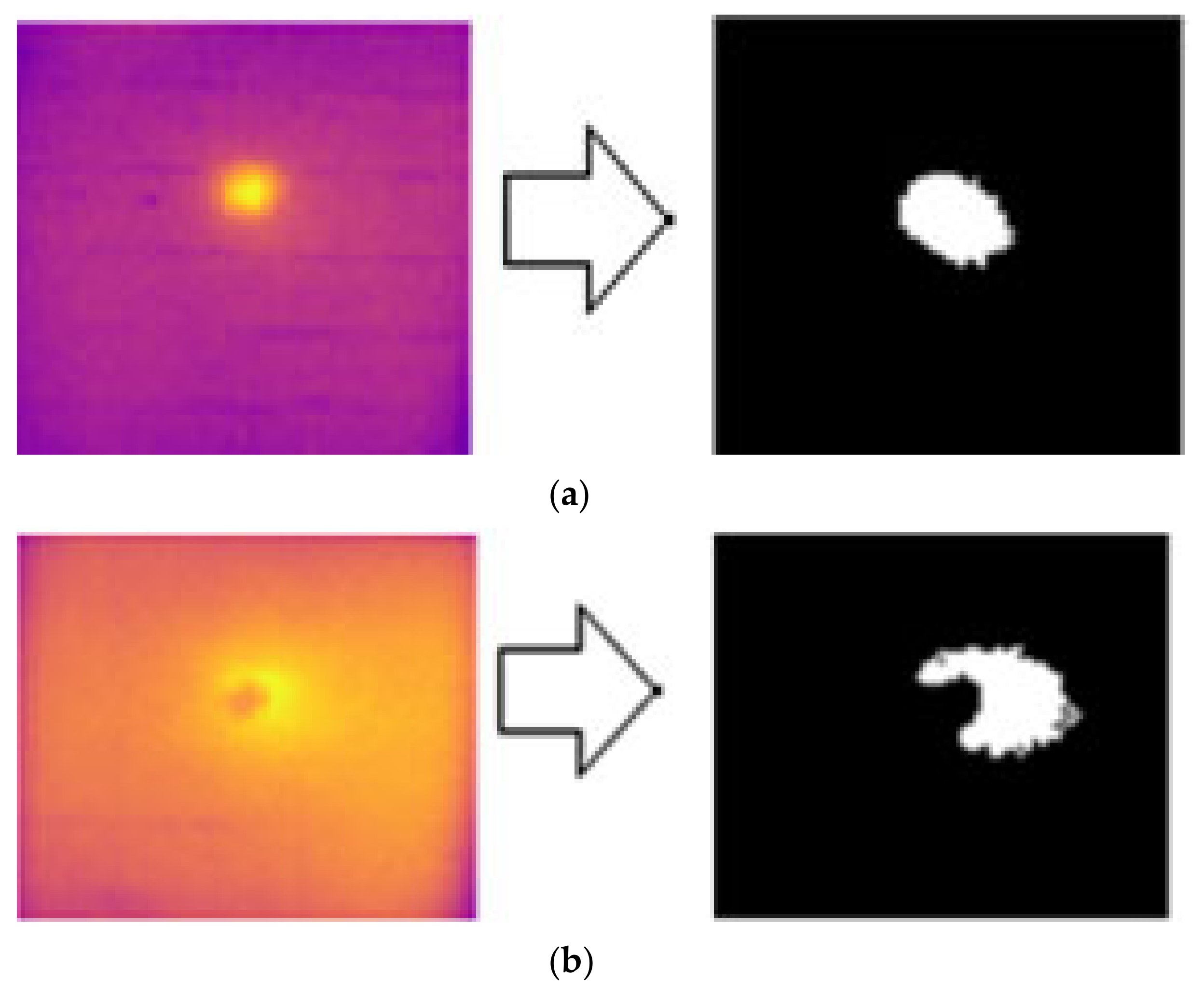

2.4. Automatic Defect Detection Using Image Processing

3. Results

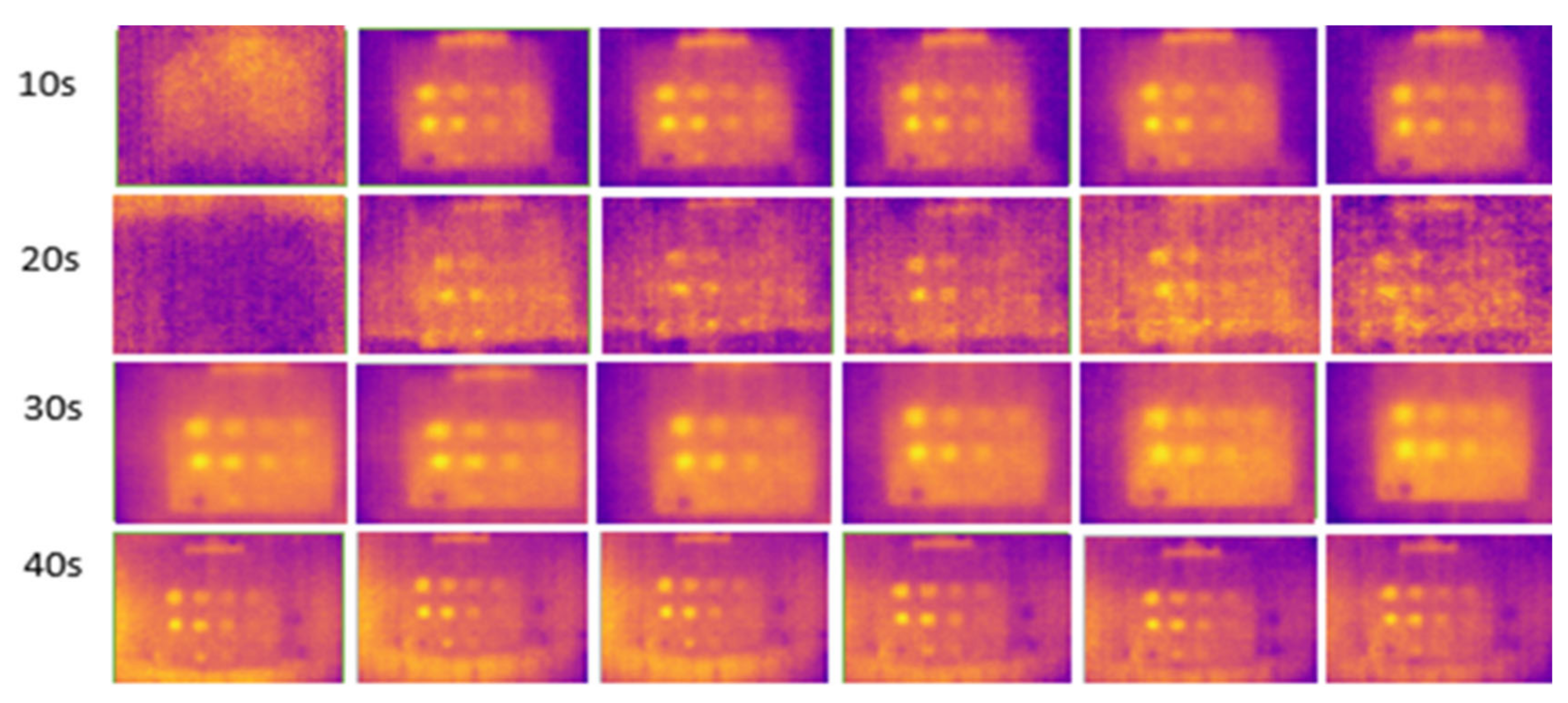

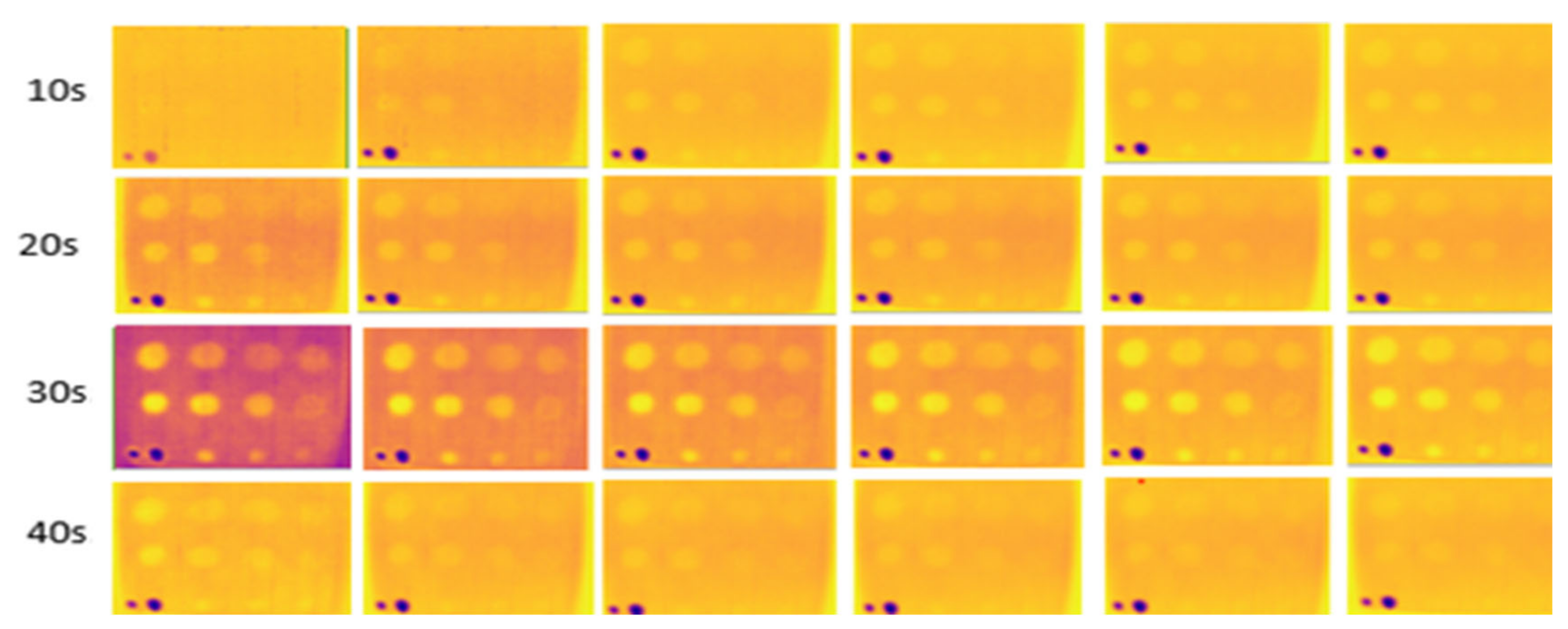

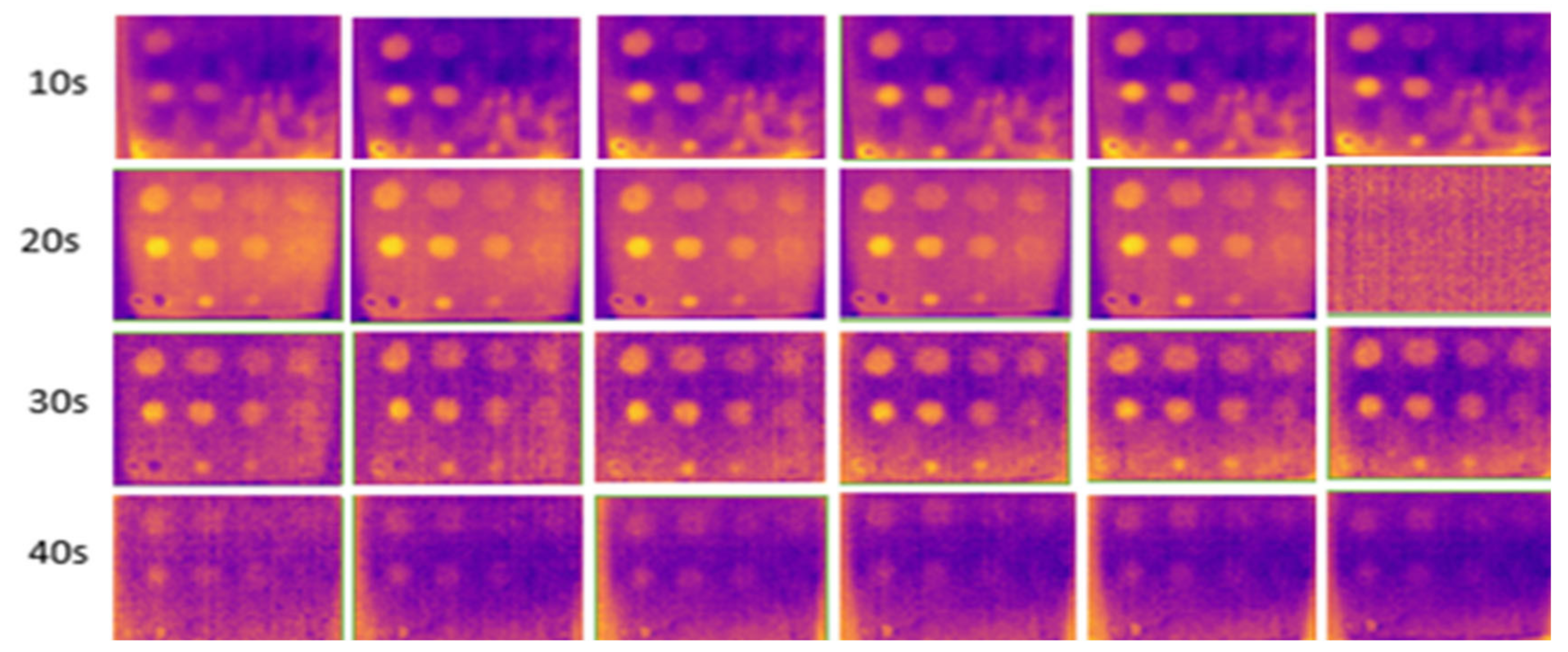

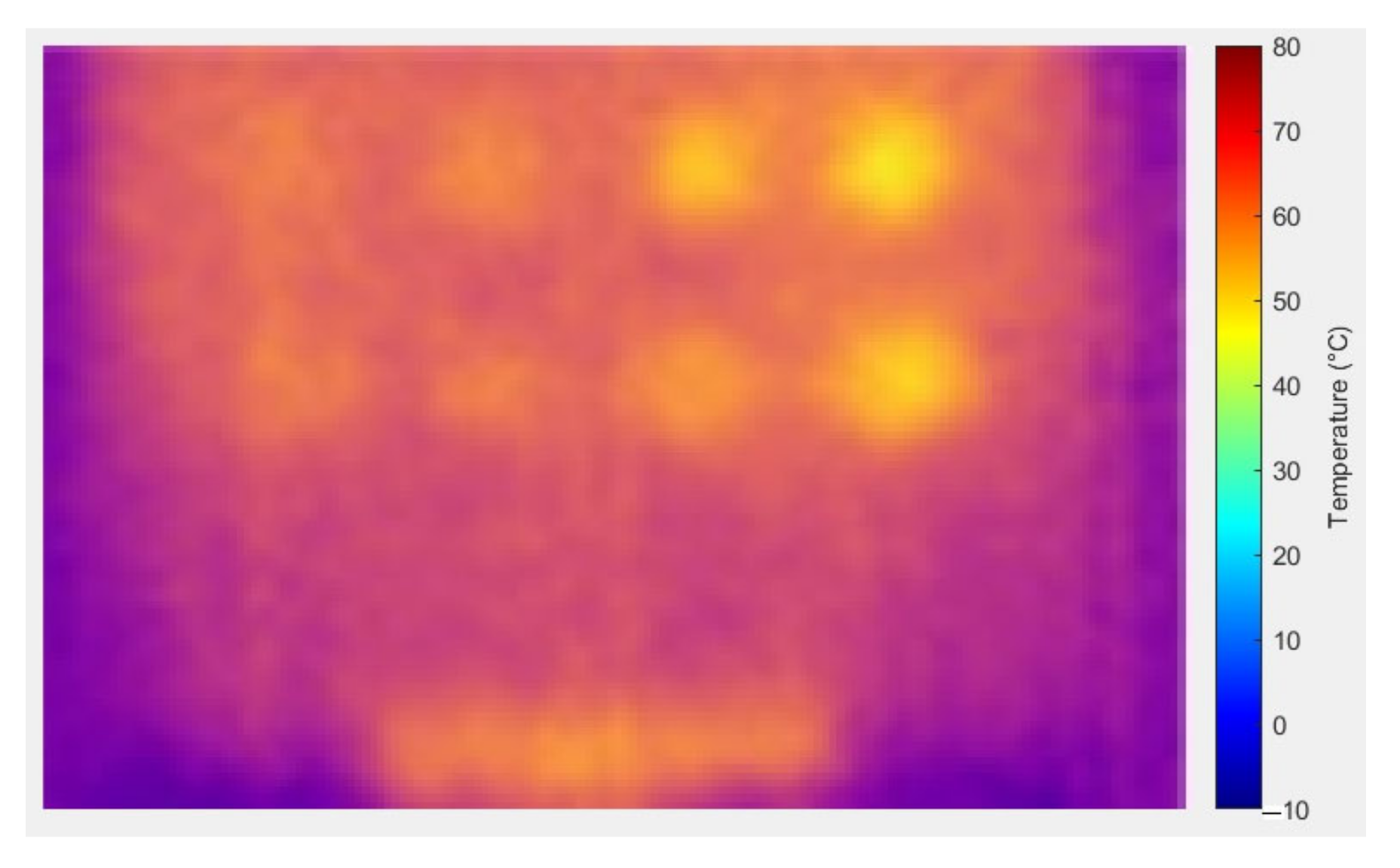

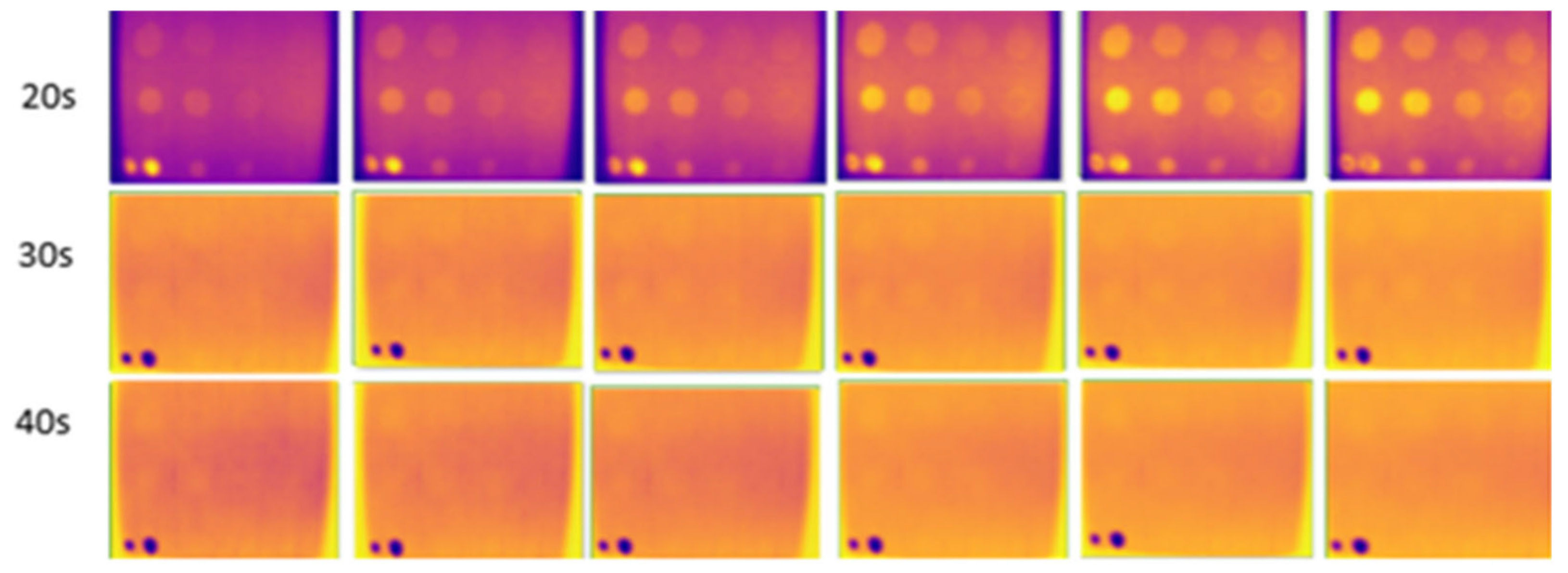

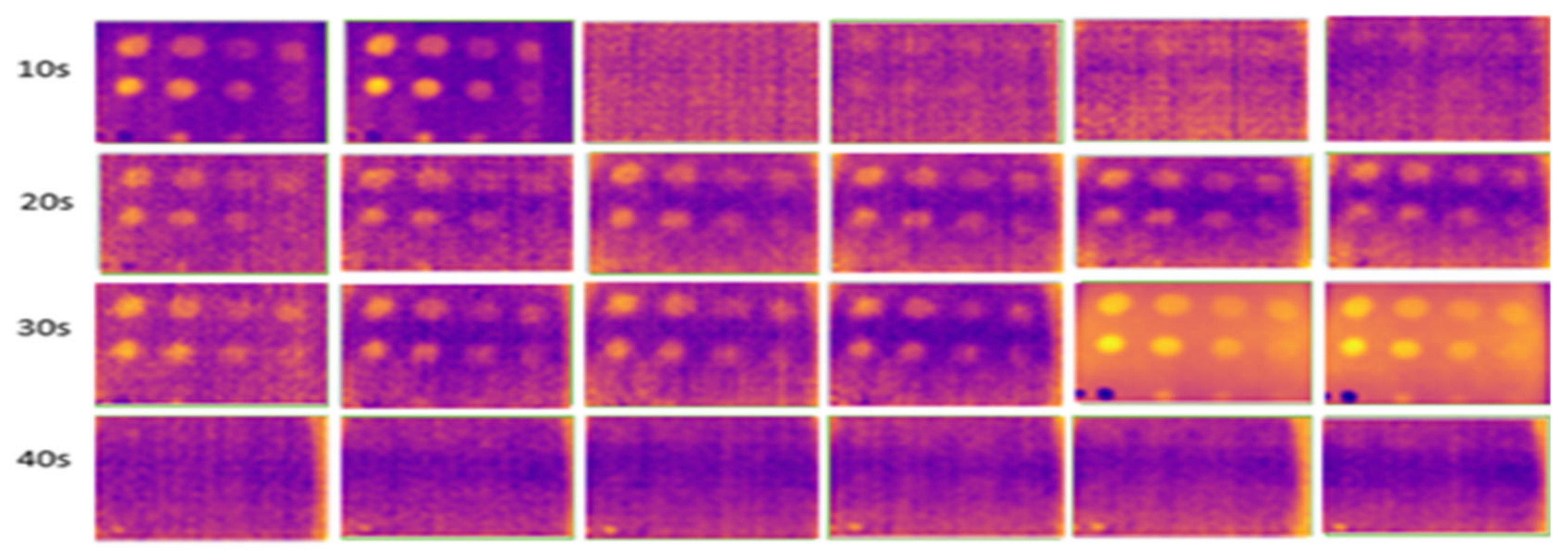

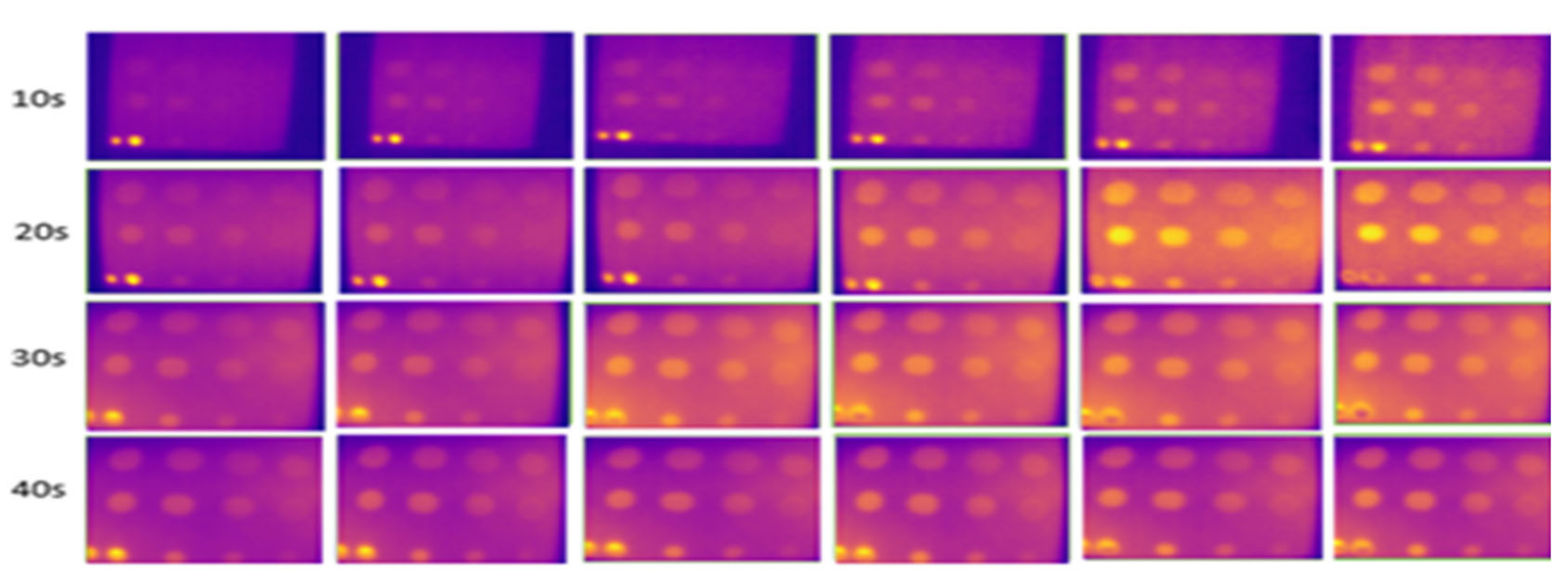

3.1. The Environmental Temperature Indoors and Outdoors

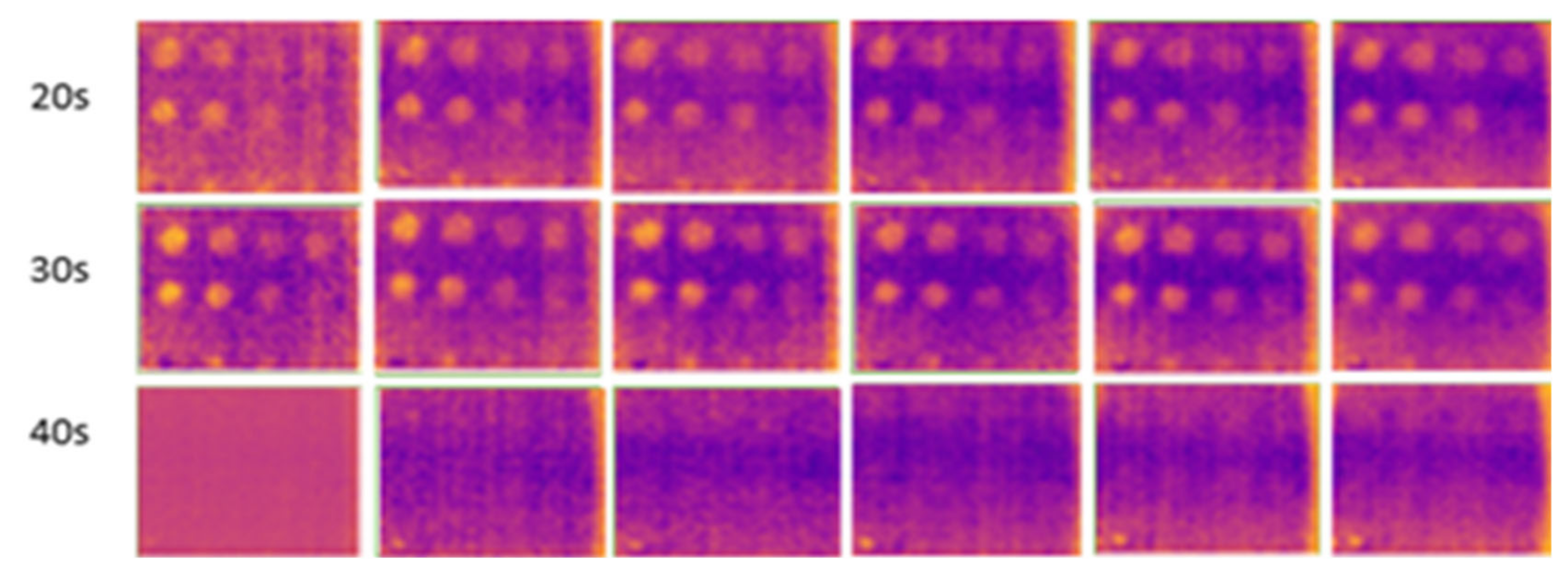

3.2. Internal Enclosure Background Color Reflection

3.3. Background Reflection Parameter

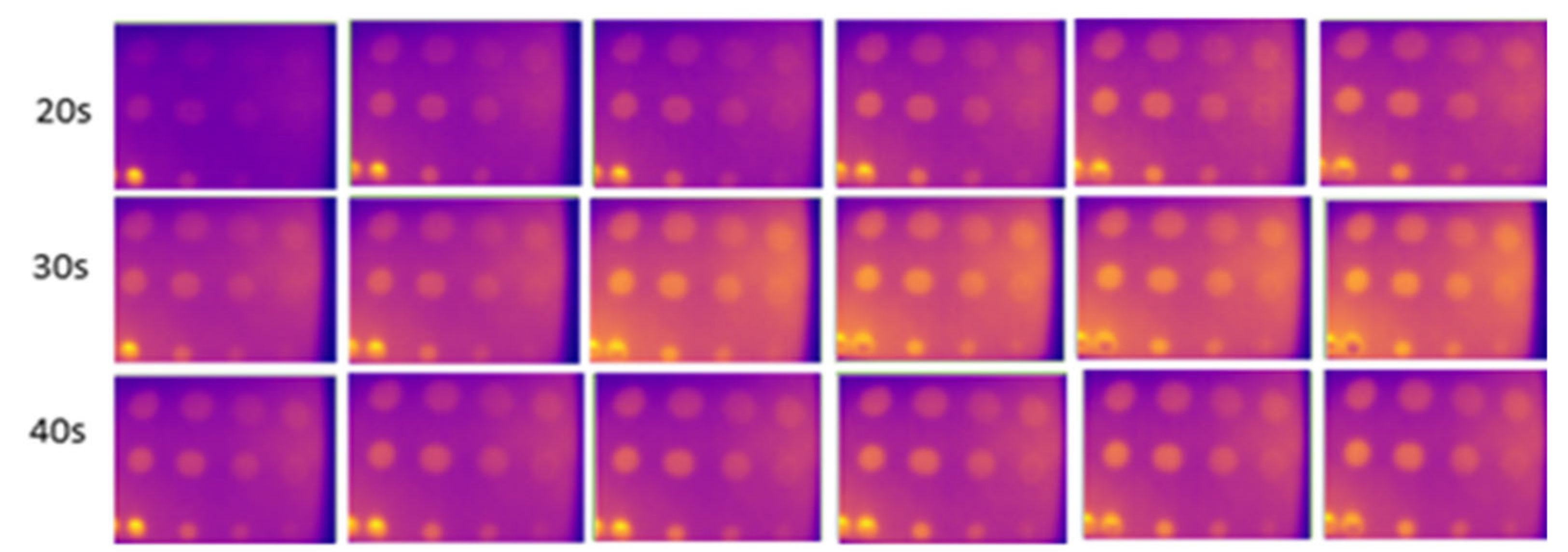

3.4. Surface Emissivity Parameter

3.5. Optimized Parameter

3.6. Image Processing Result

3.7. Tanimoto Criterion Result

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nugraha, A.D.; Nuryanta, M.I.; Sean, L.; Budiman, K.; Kusni, M.; Muflikhun, M.A. Recent Progress on Natural Fibers Mixed with CFRP and GFRP: Properties, Characteristics, and Failure Behaviour. Polymers 2022, 14, 5138. [Google Scholar] [CrossRef] [PubMed]

- Protchenko, K. Residual Fire Resistance Testing of Basalt- and Hybrid-FRP Reinforced Concrete Beams. Materials 2022, 15, 1509. [Google Scholar] [CrossRef] [PubMed]

- Bhagwat, P.; Ramachandran, M.; Raichurkar, P. Mechanical properties of hybrid glass/carbon fiber reinforced epoxy composites. Mater. Today Proc. 2017, 4, 7375–7380. [Google Scholar] [CrossRef]

- Sonnenschein, R.; Gajdosova, K.; Holly, I. FRP Composites and their Using in the Construction of Bridges. Procedia Eng. 2016, 161, 477–482. [Google Scholar] [CrossRef]

- Perillo, G.; Jørgensen, J.K. Numerical/Experimental Study of the Impact and Compression after Impact on GFRP Composite for Wind/Marine Applications. Procedia Eng. 2016, 167, 129–137. [Google Scholar] [CrossRef]

- Al-Fatlawi, A.; Jármai, K.; Kovács, G. Optimal Design of a Fiber-Reinforced Plastic Composite Sandwich Structure for the Base Plate of Aircraft Pallets In Order to Reduce Weight. Polymers 2021, 13, 834. [Google Scholar] [CrossRef] [PubMed]

- Dai, Y.; Huang, Y.; He, X.; Hui, D.; Bai, Y. Continuous performance assessment of thin-film flexible photovoltaic cells under mechanical loading for building integration. Sol. Energy 2019, 183, 96–104. [Google Scholar] [CrossRef]

- Torres, M.; Franco-Urquiza, E.A.; Hernández-Moreno, H.; González-Villa, M.A. Mechanical Behavior of a Fuselage Stiffened Carbon-Epoxy Panel under Debonding Load. J. Aeronaut. Aerosp. Eng. 2018, 7, 2–6. [Google Scholar]

- Rahimizadeh, A.; Kalman, J.; Henri, R.; Fayazbakhsh, K.; Lessard, L. Recycled glass fiber composites fromwind turbine waste for 3D printing feedstock: Effects of fiber content and interface on mechanical performance. Materials 2019, 12, 3929. [Google Scholar] [CrossRef] [PubMed]

- Morăraș, C.I.; Goanță, V.; Istrate, B.; Munteanu, C.; Dobrescu, G.S. Structural Testing by Torsion of Scalable Wind Turbine Blades. Polymers 2022, 14, 3937. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Lin, Y.; Zong, Z.; Sun, G.; Li, Q. Lightweight design of carbon twill weave fabric composite body structure for electric vehicle. Compos. Struct. 2013, 97, 231–238. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M. Impact damage in GFRP: New insights with infrared thermography. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1839–1847. [Google Scholar] [CrossRef]

- Asokkumar, A.; Jasiūnienė, E.; Raišutis, R.; Kažys, R.J. Comparison of Ultrasonic Non-contact Air-coupled Techniques for Characterization of Impact-type Defects in Pultruded Gfrp Composites. Materials 2021, 14, 1058. [Google Scholar] [CrossRef]

- Ryu, C.-H.; Park, S.-H.; Kim, D.-H.; Jhang, K.-Y.; Kim, H.-S. Nondestructive evaluation of hidden multi-delamination in a glass-fiber-reinforced plastic composite using terahertz spectroscopy. Compos. Struct. 2016, 156, 338–347. [Google Scholar] [CrossRef]

- Meola, C.; Carlomagno, G.M. Infrared thermography to evaluate impact damage in glass/epoxy with manufacturing defects. Int. J. Impact Eng. 2014, 67, 1–11. [Google Scholar] [CrossRef]

- Raišutis, R.; Tumšys, O. Application of dual focused ultrasonic phased array transducer in two orthogonal cross-sections for inspection of multi-layered composite components of the aircraft fuselage. Materials 2020, 13, 1689. [Google Scholar] [CrossRef] [PubMed]

- Han, Z.; Jang, J.; Lee, S.G.; Lee, D.; Oh, D. Error Analysis of Non-Destructive Ultrasonic Testing of Glass Fiber-Reinforced Polymer Hull Plates. J. Compos. Sci. 2021, 5, 238. [Google Scholar] [CrossRef]

- Jensen, F.; Terlau, M.; Sorg, M.; Fischer, A. Active Thermography for the Detection of Sub-Surface Defects on a Curved and Coated GFRP-Structure. Appl. Sci. 2021, 11, 9545. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; Molleda, J.; Bulnes, F.G. Infrared Thermography for Temperature Measurement and Non-Destructive Testing. Sensors 2014, 14, 12305–12348. [Google Scholar] [CrossRef] [PubMed]

- Qu, Z.; Jiang, P.; Zhang, W. Development and Application of Infrared Thermography Non-Destructive Testing Techniques. Sensors 2020, 20, 3851. [Google Scholar] [CrossRef] [PubMed]

- Farmaki, S.; Exarchos, D.A.; Tragazikis, I.K.; Matikas, T.E.; Dassios, K.G. A Novel Infrared Thermography Sensing Approach for Rapid, Quantitative Assessment of Damage in Aircraft Composites. Sensors 2020, 20, 4113. [Google Scholar] [CrossRef] [PubMed]

- Zalameda, J.; Winfree, W. Detection and Characterization of Damage in Quasi-Static Loaded Composite Structures Using Passive Thermography. Sensors 2018, 18, 3562. [Google Scholar] [CrossRef] [PubMed]

- Pickering, S.G.; Chatterjee, K.; Almond, D.P.; Tuli, S. LED Optical Excitation for the Long Pulse and Lock-in Thermographic Techniques. NDT E Int. 2013, 58, 72–77. [Google Scholar] [CrossRef]

- Wei, Y.; Zhang, S.; Luo, Y.; Ding, L.; Zhang, D. Accurate Depth Determination of Defects in Composite Materials Using Pulsed Thermography. Compos. Struct. 2021, 267, 113846. [Google Scholar] [CrossRef]

- Alhammad, M.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Torbali, M.E.; Genest, M.; Zhang, H.; Zolotas, A.; Maldgue, X.P.V. Automated Impact Damage Detection Technique for Composites Based on Thermographic Image Processing and Machine Learning Classification. Sensors 2022, 22, 9031. [Google Scholar] [CrossRef]

- Zhang, H.; Avdelidis, N.P.; Osman, A.; Ibarra-Castanedo, C.; Sfarra, S.; Fernandes, H.; Matikas, T.E.; Maldague, X.P.V. Enhanced Infrared Image Processing for Impacted Carbon/Glass Fiber-Reinforced Composite Evaluation. Sensors 2017, 18, 45. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Duan, Y.; Liu, S.; Yan, Y.; Tao, N.; Osman, A.; Ibarra-Castanedo, C.; Sfarra, S.; Chen, D.; Zhang, C. LSTM-RNN-Based Defect Classification in Honeycomb Structures Using Infrared Thermography. Infrared Phys. Technol. 2019, 102, 103032. [Google Scholar] [CrossRef]

- Saeed, N.; King, N.; Said, Z.; Omar, M.A. Automatic Defects Detection in CFRP Thermograms, Using Convolutional Neural Networks and Transfer Learning. Infrared Phys. Technol. 2019, 102, 103048. [Google Scholar] [CrossRef]

- Fang, Q.; Ibarra-Castanedo, C.; Maldague, X. Automatic Defects Segmentation and Identification by Deep Learning Algorithm with Pulsed Thermography: Synthetic and Experimental Data. Big Data Cogn. Comput. 2021, 5, 9. [Google Scholar] [CrossRef]

- Sundaram, R.; Kamath, G.M.; Gupta, N. Structural Health Monitoring of Composite Structures-Issues and Challenges. Int. J. Veh. Struct. Syst. 2012, 4, 74. [Google Scholar] [CrossRef]

- Heredia Rivera, U.; Kadian, S.; Nejati, S.; White, J.; Sedaghat, S.; Mutlu, Z.; Rahimi, R. Printed Low-Cost PEDOT: PSS/PVA Polymer Composite for Radiation Sterilization Monitoring. ACS Sens. 2022, 7, 960–971. [Google Scholar] [CrossRef] [PubMed]

- Tashan, J.; Al-mahaidi, R. Investigation of the Parameters That Influence the Accuracy of Bond Defect Detection in CFRP Bonded Specimens Using IR Thermography. Compos. Struct. 2012, 94, 519–531. [Google Scholar] [CrossRef]

- Deane, S.; Avdelidis, N.P.; Ibarra-Castanedo, C.; Zhang, H.; Nezhad, H.Y.; Williamson, A.A.; Nooralishahi, P. Comparison of Cooled and Uncooled IR Sensors by Means of Signal-to-Noise Ratio for NDT Diagnostics of Aerospace Grade Composites. Sensors 2020, 20, 3381. [Google Scholar] [CrossRef] [PubMed]

- Lo, T.Y.; Choi, K.T.W. Building defects diagnosis by infrared thermography. Struct. Surv. 2004, 22, 259–263. [Google Scholar] [CrossRef]

- Tomita, K.; Chew, M.Y.L. A Review of Infrared Thermography for Delamination Detection on Infrastructures and Buildings. Sensors 2022, 22, 423. [Google Scholar] [CrossRef] [PubMed]

- Lucchi, E. Applications of Infrared Thermography in the Energy Audit of Buildings: A Review. Renew. Sustain. Energy Rev. 2018, 82, 3077–3090. [Google Scholar] [CrossRef]

- Edis, E.; Flores-Colen, I.; de Brito, J. Passive thermographic inspection of adhered ceramic claddings: Limitation and conditioning factors. J. Perform. Constr. Facil. 2013, 27, 737–747. [Google Scholar] [CrossRef]

- Vavilov, V.; Burleigh, D. Infrared Thermography and Thermal Nondestructive Testing; Springer International Publishing: New York, NY, USA, 2020. [Google Scholar]

- Suzuki, S.; Ogasawara, N. Infrared thermographic test for removing background reflection based on polarization theory. NDT E Int. 2019, 103, 19–25. [Google Scholar] [CrossRef]

- Meng, X.; Wang, F.; Liang, Z.; Zhang, X.; Weng, J.; Li, Z.; Yue, H. Research on the detection of silica/phenolic composite surface cracks using instantaneous high-power xenon lamp-induced chirp-pulsed radar thermography. Measurement 2023, 209, 112494. [Google Scholar] [CrossRef]

- Liu, L.; Mei, H.; Guo, C.; Tu, Y.; Wang, L.; Liu, J. Remote optical thermography detection method and system for silicone polymer insulating materials used in power industry. IEEE Trans. Instrum. Meas. 2019, 69, 5782–5790. [Google Scholar] [CrossRef]

- Saeed, N.; Omar, M.A.; Abdulrahman, Y.; Salem, S.; Mayyas, A.; Omar, M.A. IR Thermographic Analysis of 3D Printed CFRP Reference Samples with Back-Drilled and Embedded Defects. J. Nondestruct. Eval. 2018, 36, 59. [Google Scholar] [CrossRef]

- Usamentiaga, R.; Venegas, P.; Guerediaga, J.; Vega, L.; López, I. Automatic detection of impact damage in carbon fiber composites using active thermography. Infrared Phys. Technol. 2013, 58, 36–46. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, G.; Meo, M.; Ciampa, F. Image processing based quantitative damage evaluation in composites with long pulse thermography. NDT E Int. 2018, 99, 93–104. [Google Scholar] [CrossRef]

- Tran, Q.H.; Han, D.; Kang, C.; Haldar, A.; Huh, J. Effects of ambient temperature and relative humidity on subsurface defect detection in concrete structures by active thermal imaging. Sensors 2017, 17, 1718. [Google Scholar] [CrossRef] [PubMed]

- Milovanović, B.; Pečur, I.B. Review of active IR thermography for detection and characterization of defects in reinforced concrete. J. Imaging 2016, 2, 11. [Google Scholar] [CrossRef]

- Razani, M.; Parkhimchyk, A.; Tabatabaei, N. Lock-in thermography using a cellphone attachment infrared camera. AIP Adv. 2018, 8, 035305. [Google Scholar] [CrossRef]

- Olafsson, G.; Tighe, R.C.; Boyd, S.W.; Dulieu-Barton, J.M. Lock-in thermography using miniature infra-red cameras and integrated actuators for defect identification in composite materials. Opt. Laser Technol. 2022, 147, 107629. [Google Scholar] [CrossRef]

- Tepegoz, M.; Kucukkomurler, A.; Tankut, F.; Eminoglu, S.; Akin, T. A miniature low-cost LWIR camera with a 160×120 microbolometer FPA. Infrared Technol. Appl. XL 2014, 9070, 90701O. [Google Scholar]

- Dattoma, V.; Nobile, R.; Panella, F.W.; Saponaro, A. NDT thermographic techniques on CFRP structural components for aeronautical application. Proc. Struct. Integr. 2018, 8, 452–461. [Google Scholar] [CrossRef]

- Wu, S.; Gao, B.; Yang, Y.; Zhu, Y.; Burrascano, P.; Laureti, S.; Ricci, M.; Wang, Y. Halogen optical referred pulse-compression thermography for defect detection of CFRP. Infrared Phys. Technol. 2019, 102, 103006. [Google Scholar] [CrossRef]

- Almond, D.P.; Angioni, S.L.; Pickering, S.G. Long pulse excitation thermographic non-destructive evaluation. NDT E Int. 2017, 87, 7–14. [Google Scholar] [CrossRef]

- Kalyanavalli, V.; Ramadhas, T.A.; Sastikumar, D. Long pulse thermography investigations of basalt fiber reinforced composite. NDT E Int. 2018, 100, 84–91. [Google Scholar] [CrossRef]

- Kamińska, P.; Ziemkiewicz, J.; Synaszko, P.; Dragan, K. Comparison of pulse thermography (pt) and step heating (sh) thermography in non-destructive testing of unidirectional gfrp composites. Fatigue Aircr. Struct. 2019, 11, 87–102. [Google Scholar] [CrossRef]

- Panella, F.W.; Pirinu, A.; Dattoma, V. A Brief Review and Advances of Thermographic Image-Processing Methods for IRT Inspection: A Case of Study on GFRP Plate. Exp. Tech. 2021, 45, 429–443. [Google Scholar] [CrossRef]

- Moran, J.; Rajic, N. Remote Line Scan Thermography for the Rapid Inspection of Composite Impact Damage. Compos. Struct. 2019, 208, 442–453. [Google Scholar] [CrossRef]

- Yang, R.; He, Y. Optically and Non-Optically Excited Thermography for Composites: A Review. Infrared Phys. Technol. 2016, 75, 26–50. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G.M. Infrared Thermography in the Evaluation of Aerospace Composite Materials: Infrared Thermography to Composites; Woodhead Publishing: Cambridge, UK, 2016. [Google Scholar]

- Manes, A.; Nunes, S.; Jiménez, A.; Amico, S.; Giglio, M. Comparison of Non-Destructive Techniques for Impact Damage Area Assessment in Aramid/Epoxy Composites. Proceedings 2018, 2, 437. [Google Scholar] [CrossRef]

- Galleguillos, C.; Zorrilla, A.; Jimenez, A.; Diaz, L.; Montiano, Á.L.; Barroso, M.; Lasagni, F. Thermographic Non-Destructive Inspection of Wind Turbine Blades Using Unmanned Aerial Systems. Plast. Rubber Compos. 2015, 44, 98–103. [Google Scholar] [CrossRef]

- Barden, T.J.; Almond, D.P.; Pickering, S.G.; Morbidini, M.; Cawley, P. Detection of Impact Damage in CFRP Composites by Thermosonics. Nondestruct. Test. Eval. 2007, 22, 71–82. [Google Scholar] [CrossRef]

- Bendada, A.; Sfarra, S.; Ibarra-Castanedo, C.; Akhloufi, M.; Caumes, J.P.; Pradere, C.; Maldague, X. Subsurface Imaging for Panel Paintings Inspection: A Comparative Study of the Ultraviolet, the Visible, the Infrared, and the Terahertz Spectra. Opto-Electron. Rev. 2015, 23, 90–101. [Google Scholar] [CrossRef]

- Ogasawara, N.; Kobayashi, C.; Yamada, H. Image Processing for Reduction of Background Reflection from Thermal Image. Adv. Exp. Mech. 2018, 3, 173–179. [Google Scholar]

- Idzkowski, A.; Walendziuk, W.; Sawicki, A. Experimental Determination of the Emissivity Coefficient of Selected Materials. Photonics Appl. Astron. Commun. Ind. High-Energy Phys. Exp. 2016, 2016, 468–477. [Google Scholar]

- Zhao, Y.; Jiang, X.; Zhang, Q.; Wang, Q. Numerical Simulation of Thermal Performance of Glass-Fibre-Reinforced Polymer. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 022016. [Google Scholar] [CrossRef]

- Ren, J.; Ren, R.; Green, M.; Huang, X. Defect Detection from X-Ray Images Using a Three-Stage Deep Learning Algorithm. In Proceedings of the 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 5–8 May 2019; pp. 1–4. [Google Scholar]

- Wang, G.; Peter, W.T.; Yuan, M. Automatic Internal Crack Detection from a Sequence of Infrared Images with a Triple-Threshold Canny Edge Detector. Meas. Sci. Technol. 2018, 29, 025403. [Google Scholar] [CrossRef]

- Xu, Z.; Ji, X.; Wang, M.; Sun, X. Edge Detection Algorithm of Medical Image Based on Canny Operator. J. Phys. Conf. Ser. 2021, 1955, 012080. [Google Scholar] [CrossRef]

- Sudharani, K.; Sarma, T.C.; Prasad, K.S. Histogram Related Threshold Techniques for Region Based Automatic Brain Tumor Detection. Indian J. Sci. Technol. 2016, 9, 48. [Google Scholar] [CrossRef]

- Chulkov, A.O.; Sommier, A.; Pradere, C.; Vavilov, V.P.; Siddiqui, A.O.; Prasad, Y.L.V.D. Analyzing Efficiency of Optical and THz Infrared Thermography in Nondestructive Testing of GFRPs by Using the Tanimoto Criterion. NDT E Int. 2021, 117, 102383. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Bison, P.G.; Burleigh, D.D. Ermanno Grinzato’s Contribution to Infrared Diagnostics and Non-Destructive Testing: In Memory of an Outstanding Researcher. Quant. InfraRed Thermogr. J. 2023, 1–14. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, W.; Wu, C.; Xie, J.; Yin, X.; Chen, G. An improved method of eddy current pulsed thermography to detect subsurface defects in glass fiber reinforced polymer composites. Compos. Struct. 2020, 242, 112145. [Google Scholar] [CrossRef]

| No. of Defects | Defect | Diameter (mm) | Depth (mm) |

|---|---|---|---|

| 1 | A1 | 26 | 1.96 |

| 2 | A2 | 26 | 2.00 |

| 3 | A3 | 26 | 1.18 |

| 4 | A4 | 26 | 1.92 |

| 5 | B1 | 21 | 2.88 |

| 6 | B2 | 21 | 1.88 |

| 7 | B3 | 21 | 1.00 |

| 8 | B4 | 21 | 0.96 |

| 9 | C1 | 14 | 2.88 |

| 10 | C2 | 14 | 2.80 |

| 11 | C3 | 14 | 1.88 |

| Parameter Testing |

|---|

| Environment condition and surrounding temperature |

| Internal enclosure color background reflection |

| Background reflection Material surface emissivity |

| Parameter | Optimized Value and Condition |

|---|---|

| Environment and temperature | Indoors at a low temperature (16 °C) |

| Surface emissivity | Black tape on material |

| Closed or open setup | Closes setup |

| Background color | Black |

| Image | Surface Emissivity | Indoor/Outdoor | Enclosure | Internal Color Enclosure | Temperature | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TC | Black | No Tape | White | Indoor | Outdoors | Yes | No | Y | W | B | 16–18 °C | 23–25 °C | |

| 0.43 | Blurry | x | x | x | |||||||||

| 0.91 | Blurry | x | x | x | x | x | |||||||

| 0.81 | Burry, | x | x | x | x | ||||||||

| 0.70 | Burry, | x | x | x | x | x | |||||||

| 0.50 | Blurry | x | x | x | x | x | |||||||

| 0.50 | Blurry | x | x | x | x | x | |||||||

| 0.90 | Blurry | x | x | x | x | ||||||||

| 0.91 | Clear, less noise | x | x | x | x | x | |||||||

| 0.91 | Clear, less noise | x | x | x | x | x | |||||||

| Edge Detection (Sobel) | Edge Detection (Canny) | Histogram Threshold | Circle Detection (RGB) | Circle Using (Grayscale) | |

|---|---|---|---|---|---|

| No. of right detected | 11 | 9 | 6 | 11 | 11 |

| No. of mis detected | 3 | 2 | 5 | 2 | 1 |

| No. of false detected | 1 | 1 | 0 | 0 | 0 |

| TC | 0.64 | 0.91 | 0.17 | 0.82 | 0.91 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwar, M.; Mustapha, F.; Abdullah, M.N.; Mustapha, M.; Sallih, N.; Ahmad, A.; Mat Daud, S.Z. Defect Detection of GFRP Composites through Long Pulse Thermography Using an Uncooled Microbolometer Infrared Camera. Sensors 2024, 24, 5225. https://doi.org/10.3390/s24165225

Anwar M, Mustapha F, Abdullah MN, Mustapha M, Sallih N, Ahmad A, Mat Daud SZ. Defect Detection of GFRP Composites through Long Pulse Thermography Using an Uncooled Microbolometer Infrared Camera. Sensors. 2024; 24(16):5225. https://doi.org/10.3390/s24165225

Chicago/Turabian StyleAnwar, Murniwati, Faizal Mustapha, Mohd Na’im Abdullah, Mazli Mustapha, Nabihah Sallih, Azlan Ahmad, and Siti Zubaidah Mat Daud. 2024. "Defect Detection of GFRP Composites through Long Pulse Thermography Using an Uncooled Microbolometer Infrared Camera" Sensors 24, no. 16: 5225. https://doi.org/10.3390/s24165225

APA StyleAnwar, M., Mustapha, F., Abdullah, M. N., Mustapha, M., Sallih, N., Ahmad, A., & Mat Daud, S. Z. (2024). Defect Detection of GFRP Composites through Long Pulse Thermography Using an Uncooled Microbolometer Infrared Camera. Sensors, 24(16), 5225. https://doi.org/10.3390/s24165225