A Flexible and Stretchable MXene/Waterborne Polyurethane Composite-Coated Fiber Strain Sensor for Wearable Motion and Healthcare Monitoring

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of MXene Nanosheet Suspension

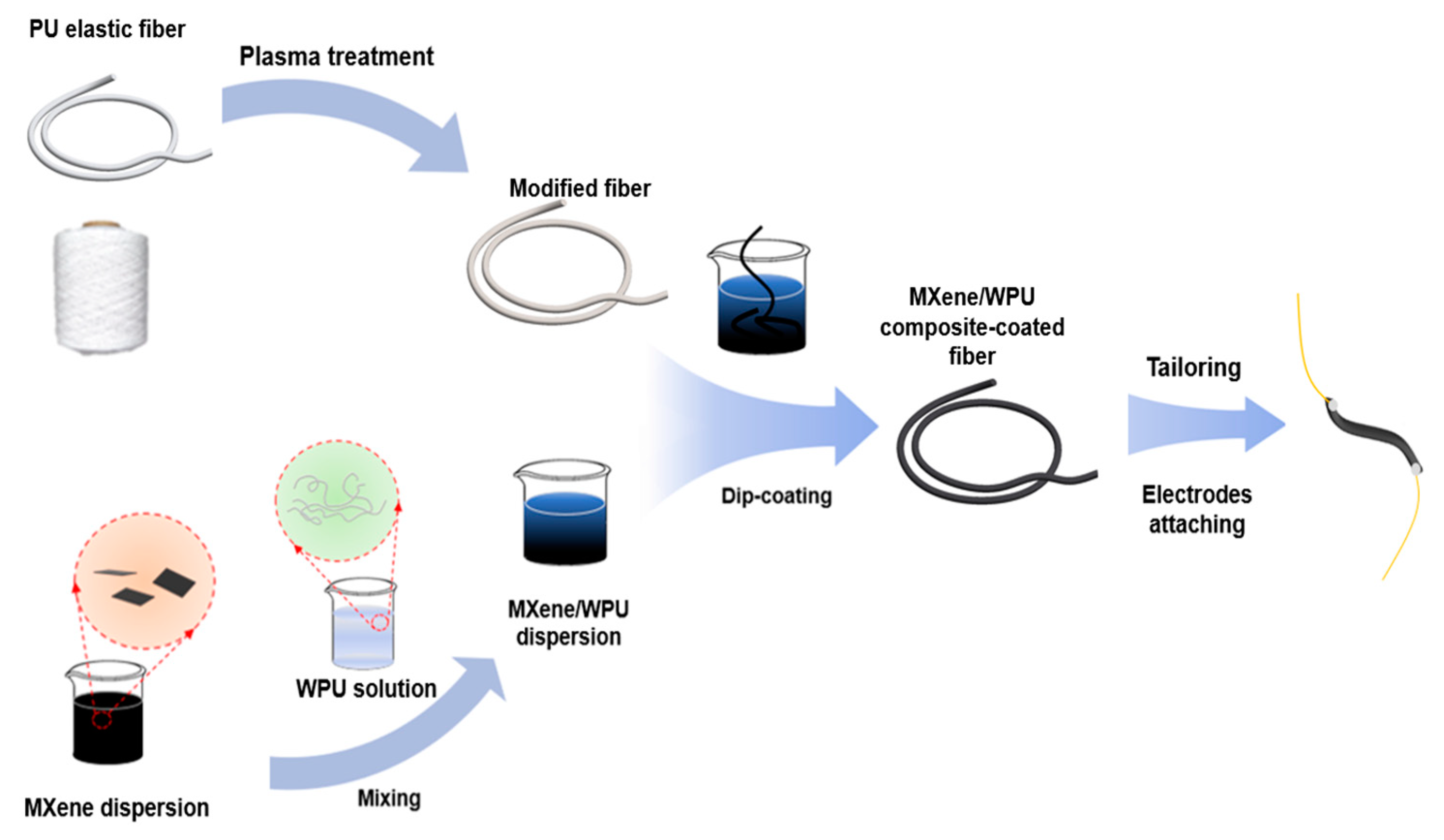

2.3. Preparation of the MXene/WPU Composite-Coated Fiber Sensor

2.4. Characterization

3. Results and Discussion

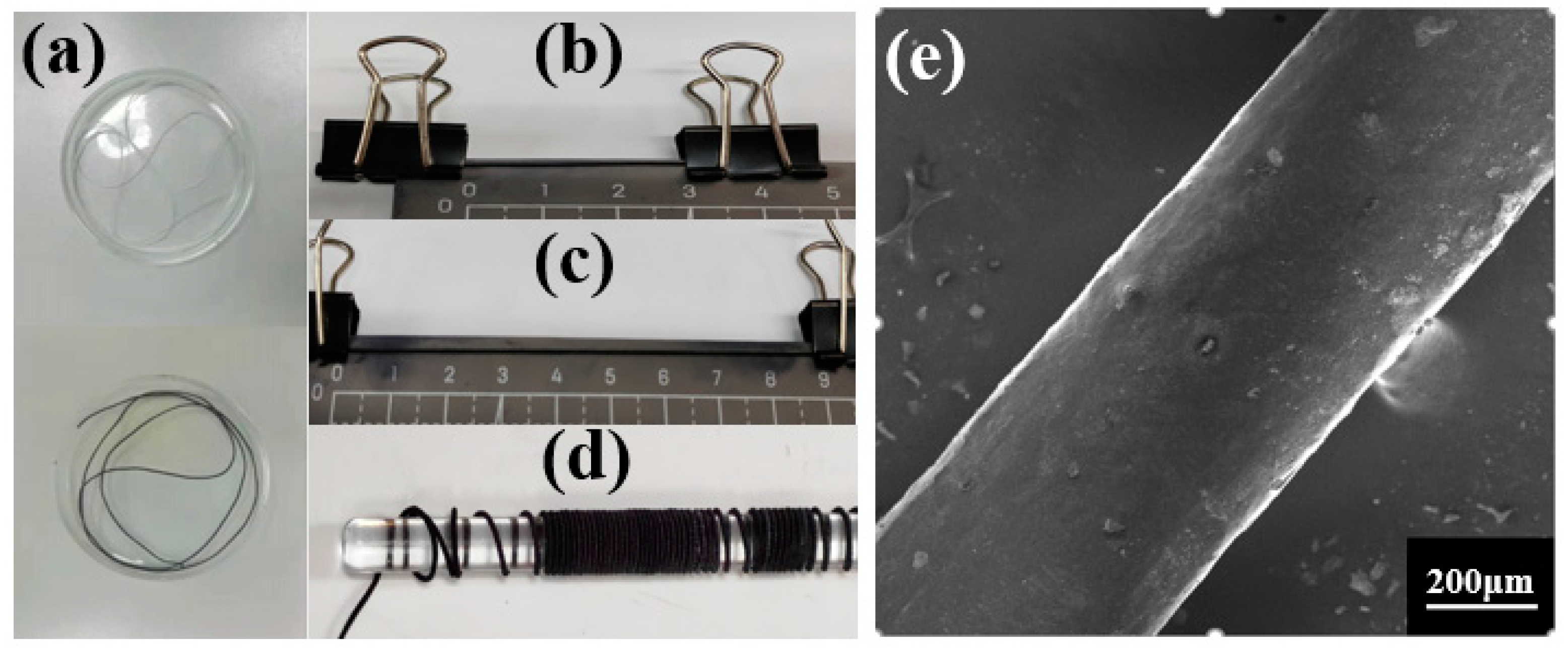

3.1. Morphologies of MXene/WPU Composite-Coated Fiber

3.2. Strain Sensing Performance of MXene/WPU Composite-Coated Fiber

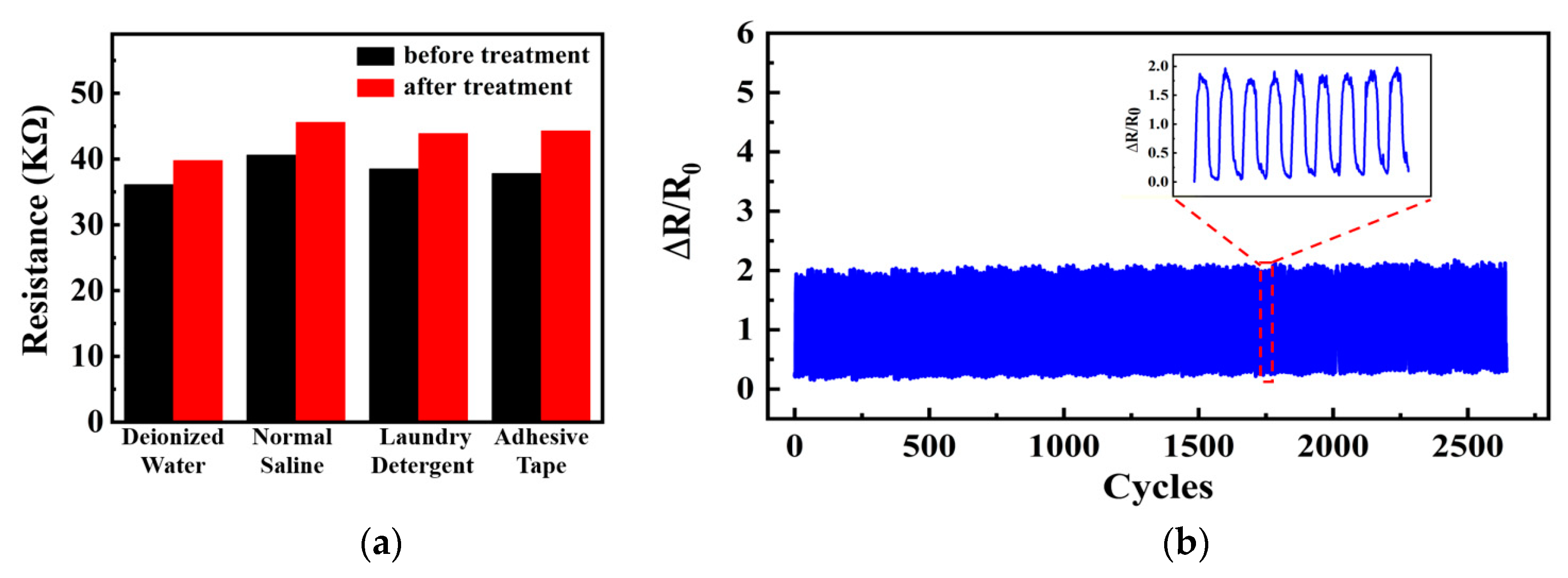

3.3. Robustness and Durability of MXene/WPU Composite-Coated Fiber

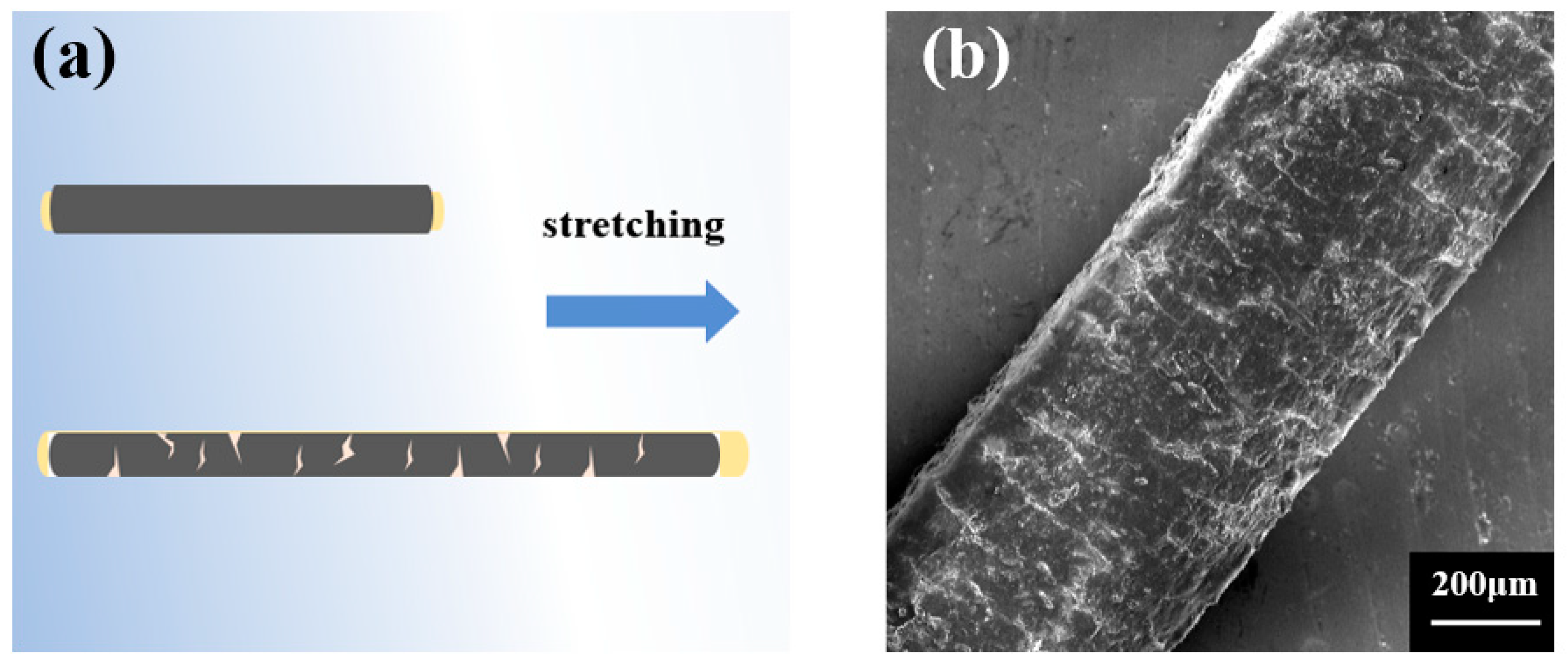

3.4. Strain Sensing Mechanism Analysis

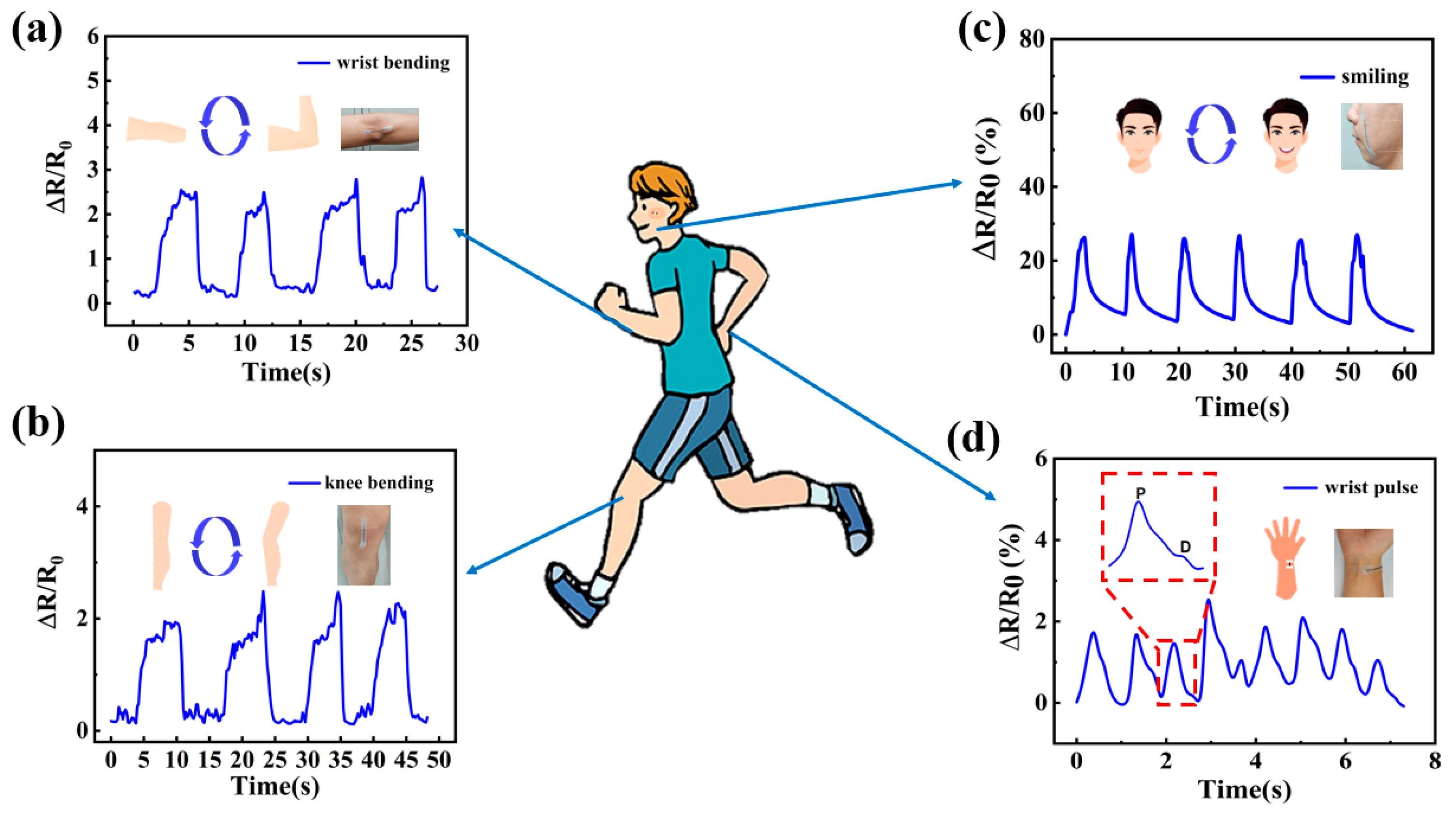

3.5. Full-Scale Human Motion Detection

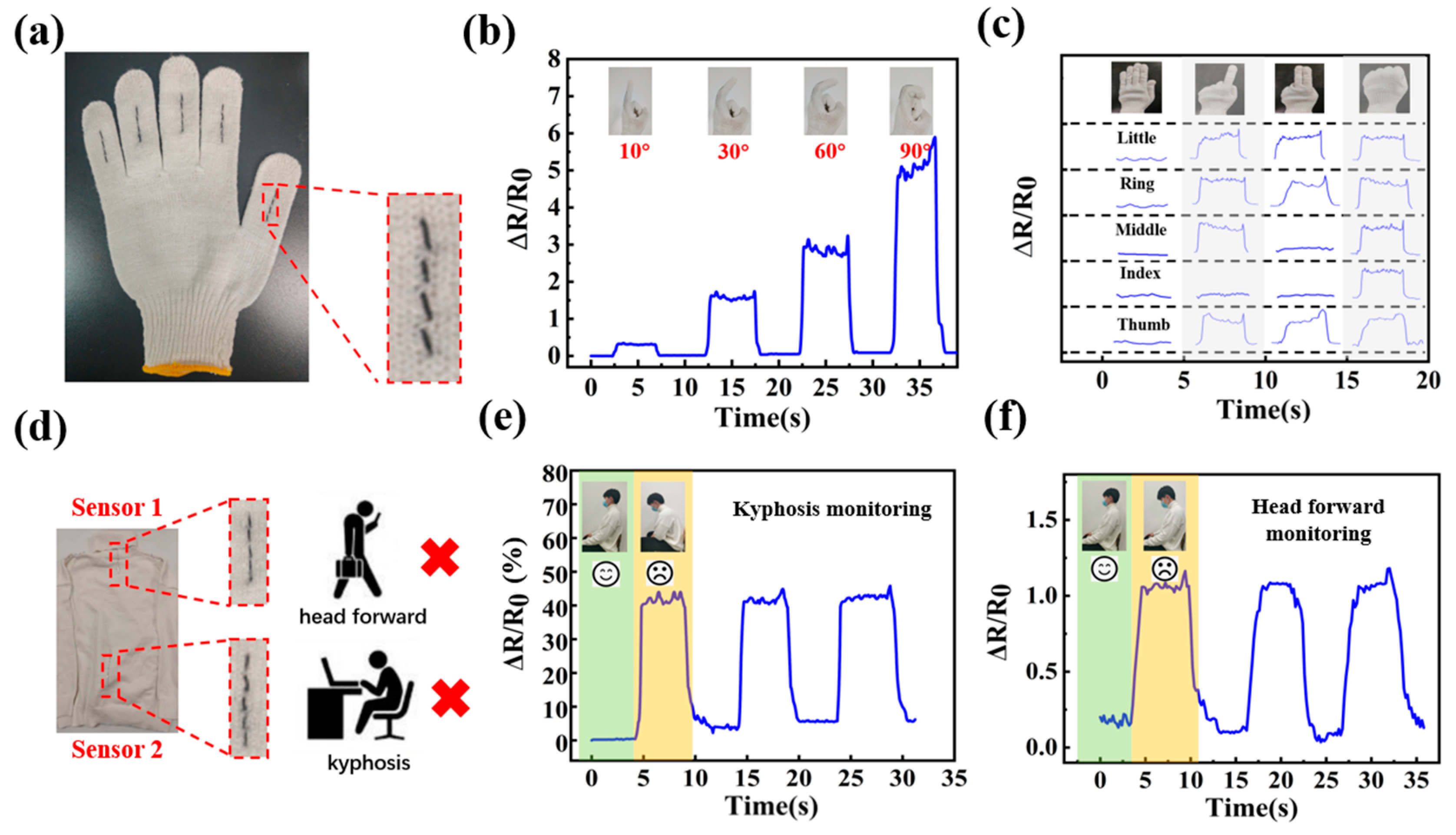

3.6. Applications for Wearable Gesture and Healthcare Monitoring

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lou, Z.; Wang, L.; Jiang, K.; Wei, Z.; Shen, G. Reviews of wearable healthcare systems: Materials, devices and system integration. Mater. Sci. Eng. R Rep. 2020, 140, 100523. [Google Scholar] [CrossRef]

- Huang, S.; Liu, Y.; Zhao, Y.; Ren, Z.; Guo, C.F. Flexible electronics: Stretchable electrodes and their future. Adv. Funct. Mater. 2019, 29, 1805924. [Google Scholar] [CrossRef]

- Liu, E.; Cai, Z.; Ye, Y.; Zhou, M.; Liao, H.; Yi, Y. An Overview of Flexible Sensors: Development, Application, and Challenges. Sensors 2023, 23, 817. [Google Scholar] [CrossRef] [PubMed]

- Yin, Y.; Guo, C.; Li, H.; Yang, H.; Xiong, F.; Chen, D. The progress of research into flexible sensors in the field of smart wearables. Sensors 2022, 22, 5089. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhuo, F.; Zhou, J.; Liu, Y.; Zhang, J.; Dong, S.; Liu, X.; Elmarakbi, A.; Duan, H.; Fu, Y. Advances in graphene-based flexible and wearable strain sensors. Chem. Eng. J. 2023, 464, 142576. [Google Scholar] [CrossRef]

- Aftab, S.; Hegazy, H.H.; Kabir, F. Emerging Trends in 2D Flexible Electronics. Adv. Mater. Technol. 2023, 8, 2201897. [Google Scholar] [CrossRef]

- Kim, H.; Lee, Y.J.; Byun, G.; Choi, C.; Yeo, W.H. Advances in Ultrathin Soft Sensors, Integrated Materials, and Manufacturing Technologies for Enhanced Monitoring of Human Physiological Signals. Adv. Electron. Mater. 2023, 9, 2201294. [Google Scholar] [CrossRef]

- Niu, B.; Yang, S.; Tian, X.; Hua, T. Highly sensitive and stretchable fiber strain sensors empowered by synergetic conductive network of silver nanoparticles and carbon nanotubes. Appl. Mater. Today 2021, 25, 101221. [Google Scholar] [CrossRef]

- Sheng, N.; Ji, P.; Zhang, M.; Wu, Z.; Liang, Q.; Chen, S.; Wang, H. High Sensitivity Polyurethane-Based Fiber Strain Sensor with Porous Structure via Incorporation of Bacterial Cellulose Nanofibers. Adv. Electron. Mater. 2021, 7, 2001235. [Google Scholar] [CrossRef]

- Tang, X.; Cheng, D.; Ran, J.; Li, D.; He, C.; Bi, S.; Cai, G.; Wang, X. Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor. Nanotechnol. Rev. 2021, 10, 221–236. [Google Scholar] [CrossRef]

- Nag, A.; Alahi, M.E.E.; Mukhopadhyay, S.C. Recent progress in the fabrication of graphene fibers and their composites for applications of monitoring human activities. Appl. Mater. Today 2021, 22, 100953. [Google Scholar] [CrossRef]

- Tong, R.; Ma, Z.; Gu, P.; Yao, R.; Li, T.; Zeng, M.; Guo, F.; Liu, L.; Xu, J. Stretchable and sensitive sodium alginate ionic hydrogel fibers for flexible strain sensors. Int. J. Biol. Macromol. 2023, 246, 125683. [Google Scholar] [CrossRef] [PubMed]

- Heo, J.S.; Eom, J.; Kim, Y.H.; Park, S.K. Recent Progress of Textile-Based Wearable Electronics: A Comprehensive Review of Materials, Devices, and Applications. Small 2018, 14, 1703034. [Google Scholar] [CrossRef]

- Lee, J.; Jeon, S.; Seo, H.; Lee, J.T.; Park, S. Fiber-Based Sensors and Energy Systems for Wearable Electronics. Appl. Sci. 2021, 11, 531. [Google Scholar] [CrossRef]

- Xu, Y.; Feng, Q.; Zhang, C.; Liu, T. Wet-spinning of ionic liquid@ elastomer coaxial fibers with high stretchability and wide temperature resistance for strain sensors. Compos. Commun. 2021, 25, 100693. [Google Scholar] [CrossRef]

- Seyedin, S.; Razal, J.M.; Innis, P.C.; Jeiranikhameneh, A.; Beirne, S.; Wallace, G.G. Knitted strain sensor textiles of highly conductive all-polymeric fibers. ACS Appl. Mater. Interfaces 2015, 7, 21150–21158. [Google Scholar] [CrossRef]

- Cheng, H.; Zuo, T.; Chen, Y.; Yu, D.; Wang, W. High sensitive, stretchable and weavable fiber-based PVA/WPU/MXene materials prepared by wet spinning for strain sensors. J. Mater. Sci. 2023, 58, 13875–13887. [Google Scholar] [CrossRef]

- Wu, X.; Han, Y.; Zhang, X.; Lu, C. Highly sensitive, stretchable, and wash-durable strain sensor based on ultrathin conductive layer@ polyurethane yarn for tiny motion monitoring. ACS Appl. Mater. Interfaces 2016, 8, 9936–9945. [Google Scholar] [CrossRef]

- Shi, B.; Wang, T.; Shi, L.; Li, J.; Wang, R.; Sun, J. Highly stretchable and strain sensitive fibers based on braid-like structure and sliver nanowires. Appl. Mater. Today 2020, 19, 100610. [Google Scholar] [CrossRef]

- On, S.Y.; Park, S.; Kim, S.S. Preparation and characterization of hybrid structured MWCNT/UHMWPE fiber sensors for strain sensing and load bearing of composite structures. Adv. Mater. Technol. 2019, 4, 1900807. [Google Scholar] [CrossRef]

- Huang, J.; Wei, Q.; Zhao, M. Flexible and Stretchable Poly(styrene-butadiene-styrene)/MXene Nanosheet Composite and Coaxial Fibers for Wearable Strain Sensors. ACS Appl. Nano Mater. 2023, 6, 8743–8751. [Google Scholar] [CrossRef]

- Mi, Q.; Wang, Q.; Zang, S.; Mao, G.; Zhang, J.; Ren, X. RGO-coated elastic fibres as wearable strain sensors for full-scale detection of human motions. Smart Mater Struct. 2018, 27, 015014. [Google Scholar] [CrossRef]

- Zang, S.; Wang, Q.; Wan, J.; Huang, X.; Ren, X. A flexible and skin-mountable elastic fiber-based sensor patch for healthcare monitoring. Biomed. Phys. Eng. Express 2019, 5, 045011. [Google Scholar] [CrossRef]

- Zang, S.; Wang, Q.; Mi, Q.; Zhang, J.; Ren, X. A Facile, Precise Radial Artery Pulse Sensor Based on Stretchable Graphene-Coated Fiber. Sens. Actuator A Phys. 2017, 237, 532–537. [Google Scholar] [CrossRef]

- Huang, X.A.; Wang, Q.; Zang, S.; Wan, J.; Yang, G.; Huang, Y.; Ren, X. Tracing the Motion of Finger Joints for Gesture Recognition via Sewing RGO-Coated Fibers Onto a Textile Glove. IEEE Sens. J. 2019, 19, 9504–9511. [Google Scholar] [CrossRef]

- Tang, J.; Wu, J.; Ma, S.; Yan, T.; Pan, Z. Flexible strain sensor based on CNT/TPU composite nanofiber yarn for smart sports bandage. Compos. B Eng. 2022, 232, 109605. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Tao, X. Enhanced electromechanical resilience and mechanism of the composites-coated fabric sensors with crack-induced conductive network for wearable applications. Smart Mater Struct. 2022, 31, 035032. [Google Scholar] [CrossRef]

- Yang, H.; Shang, J.C.; Wang, W.F.; Yang, Y.F.; Yuan, Y.N.; Lei, H.S.; Fang, D.N. Polyurethane sponges-based ultrasensitive pressure sensor via bioinspired microstructure generated by pre-strain strategy. Compos. Sci. Technol. 2022, 221, 109308. [Google Scholar] [CrossRef]

- Fang, T.; Xue, S.S.; Zhu, W.B.; Zhang, Y.Y.; Li, Y.Q.; Chen, Z.K.; Huang, P.; Fu, S.Y. Multifunctional Polyurethane Composite Foam with Outstanding Anti-impact Capacity for Soft Body Armors. ACS Appl. Mater. Interfaces 2022, 14, 13778–13789. [Google Scholar]

- Zhu, W.B.; Xue, S.S.; Zhang, H.; Wang, Y.Y.; Huang, P.; Tang, Z.H.; Li, Y.Q.; Fu, S.Y. Direct ink writing of a graphene/CNT/silicone composite strain sensor with a near-zero temperature coefficient of resistance. J. Mater. Chem. C 2022, 21, 8226–8233. [Google Scholar] [CrossRef]

- Wu, L.; Yuan, X.; Tang, Y.; Wageh, S.; AI-Hartomy, O.A.; AI-Sehemi, A.G.; Yang, J.; Xiang, Y.; Zhang, H.; Qin, Y. MXene sensors based on optical and electrical sensing signals: From biological, chemical, and physical sensing to emerging intelligent and bionic devices. PhotoniX 2023, 4, 15. [Google Scholar] [CrossRef]

- Khalid, M.A.U.; Chang, S.H. Flexible strain sensors for wearable applications fabricated using novel functional nanocomposites: A review. Compos. Struct. 2022, 284, 115214. [Google Scholar] [CrossRef]

- Pu, J.H.; Zhao, X.; Zha, X.J.; Li, W.D.; Ke, K.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Yang, W. A strain localization directed crack control strategy for designing MXene-based customizable sensitivity and sensing range strain sensors for full-range human motion monitoring. Nano Energy 2020, 74, 104814. [Google Scholar] [CrossRef]

- Fu, W.; Wang, Q.; Liu, H.; Cao, J.; Xu, J.; Yuan, X.; Ren, X. Highly stretchable and conductive MXene/polyurethane composite film coated on various flexible substrates for ultrasensitive strain sensors. Mater. Lett. 2022, 320, 132328. [Google Scholar] [CrossRef]

- Bu, Y.; Shen, T.; Yang, W.; Yang, S.; Zhao, Y.; Liu, H.; Zheng, Y.; Liu, C.; Shen, C. Ultrasensitive strain sensor based on superhydrophobic microcracked conductive Ti3C2Tx MXene/paper for human-motion monitoring and E-skin. Sci. Bull. 2021, 66, 1849–1857. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, D.; Byun, J.E.; Ansari, M.Z.; Kim, H.; Cheon, T.; Jang, J.; Cho, Y.R.; Lee, J.W.; Kim, S.H. Layer Engineered MXene Empowered Wearable Pressure Sensors for Non-Invasive Vital Human-Machine Interfacing Healthcare Monitoring. Adv. Mater. Technol. 2023, 8, 2301175. [Google Scholar] [CrossRef]

- Abbasipour, M.; Kateb, P.; Ciroira, F.; Pasini, D. Stretchable kirigami-inspired conductive polymers for strain sensors applications. Flex. Print. Electron. 2023, 8, 024003. [Google Scholar] [CrossRef]

- Liu, L.; Wang, L.; Liu, X.; Yuan, W.; Yuan, M.; Xia, Q.; Hu, Q.; Zhou, A. High-Performance Wearable Strain Sensor Based on MXene @Cotton Fabric with Network Structure. Nanomaterials 2021, 11, 889. [Google Scholar] [CrossRef]

- Kumar, S.; Mondal, A.; Panwar, V.; Shekhawat, R.; Misra, A. Highly Efficient Photo Rechargeable Supercapacitor based on Ambipolar Interface of Graphitic Carbon Nitride and MXene. Batter. Supercaps 2023, e202300393. [Google Scholar] [CrossRef]

- Nasrin, K.; Sudharshan, V.; Subramani, K.; Sathish, M. Insights into 2D/2D MXene Heterostructures for Improved Synergy in Structure toward Next-Generation Supercapacitors: A Review. Adv. Funct. Mater. 2022, 32, 2110267. [Google Scholar] [CrossRef]

- Murali, G.; Reddy Modigunta, J.K.; Park, Y.H.; Lee, J.H.; Rawal, J.; Lee, S.Y.; Park, S.J. A review on MXene synthesis, stability, and photocatalytic applications. ACS Nano 2022, 16, 13370–13429. [Google Scholar] [CrossRef] [PubMed]

- Fu, J.Z.; Sun, Q.Y.; Long, C.; Hu, X.; Wang, N.; Guo, H.M.; Zeng, W.; Xiong, Y.; Wei, N. Enhanced pressure sensors in supercapacitive-piezoelectric mixed mode with jelly-gel as dielectric layer. J. Mater. Sci. 2022, 57, 3553–3564. [Google Scholar] [CrossRef]

- Vo, T.H.; Lam, P.K.; Sheng, Y.J.; Tsao, H.K. Jammed Microgels in Deep Eutectic Solvents as a Green and Low-Cost Ink for 3D Printing of Reliable Auxetic Strain Sensors. ACS Appl. Mater. Interfaces 2023, 15, 33109–33118. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, J.; Zheng, Y.; Shi, B.; Chen, A.; Wang, L.; Shen, G. Biocompatible liquid metal coated stretchable electrospinning film for strain sensors monitoring system. Sci. China Mater. 2022, 65, 2235–2243. [Google Scholar] [CrossRef]

- Carrasco-Saaverdra, S.; Tanguy, N.R.; Garcia-Nieto, I.; Pimentel-Dominguez, R.; Panzer, M.J.; Mota-Morales, J.D. Transient Dual-Response Iontronic Strain Sensor Based on Gelatin and Cellulose Nanocrystals Eutectogel Nanocomposites. Adv. Mater. Interfaces 2023, 00536. [Google Scholar] [CrossRef]

- Zeng, Z.; Chen, M.; Jin, H.; Li, W.; Xue, X.; Zhou, L. Thin and flexible multi-walled carbon nanotube/waterborne polyurethane composites with high-performance electromagnetic interference shielding. Carbon 2016, 96, 768–777. [Google Scholar] [CrossRef]

- Wang, J.; Ye, L. Structure and properties of polyvinyl alcohol/polyurethane blends. Compos. B Eng. 2015, 69, 389–396. [Google Scholar] [CrossRef]

- Jia, Y.; Sun, R.; Pan, Y.; Wang, X.; Zhai, Z.; Min, Z.; Zheng, G.; Liu, C.; Shen, C.; Liu, X. Flexible and thin multifunctional waterborne polyurethane/Ag film for high-efficiency electromagnetic interference shielding, electro-thermal and strain sensing performances. Compos. B Eng. 2021, 210, 108668. [Google Scholar] [CrossRef]

- Luo, J.Q.; Zhao, S.; Zhang, H.B.; Deng, Z.M.; Li, L.L.; Yu, Z.Z. Flexible, stretchable and electrically conductive MXene/natural rubber nanocomposite films for efficient electromagnetic interference shielding. Compos. Sci. Technol. 2019, 182, 107754. [Google Scholar] [CrossRef]

- Pi, M.; Jiang, L.; Wang, Z.; Cui, W.; Shi, L.; Ran, R. Robust and ultrasensitive hydrogel sensors enhanced by MXene/cellulose nanocrystals. J. Mater. Sci. 2021, 56, 8871–8886. [Google Scholar] [CrossRef]

- Alhabeb, M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y. Guidelines for synthesis and processing of two-dimensional titanium carbide (Ti3C2Tx MXene). Chem. Mater. 2017, 29, 7633–7644. [Google Scholar]

- Yang, L.; Chen, J.; Guo, Y. Surface modification of a biomedical polyethylene terephthalate (PET) by air plasma. Appl. Surf. Sci. 2009, 255, 4446–4451. [Google Scholar] [CrossRef]

- Li, Q.; Yin, R.; Zhang, D.; Liu, H.; Chen, X.; Zheng, Y.; Guo, Z.; Liu, C.; Shen, C. Flexible conductive MXene/cellulose nanocrystal coated nonwoven fabrics for tunable wearable strain/pressure sensors. J. Mater. Chem. A 2020, 8, 21131–21141. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, skin-mountable, and wearable strain sensors and their potential applications: A review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and stretchable strain sensors: Materials, sensing mechanisms, and applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, J.; Jiang, Y.; Li, X.; Yuan, X.; Zhang, J.; He, Q.; Ye, F.; Luo, G.; Guo, S.; Zhang, Y.; et al. A Flexible and Stretchable MXene/Waterborne Polyurethane Composite-Coated Fiber Strain Sensor for Wearable Motion and Healthcare Monitoring. Sensors 2024, 24, 271. https://doi.org/10.3390/s24010271

Cao J, Jiang Y, Li X, Yuan X, Zhang J, He Q, Ye F, Luo G, Guo S, Zhang Y, et al. A Flexible and Stretchable MXene/Waterborne Polyurethane Composite-Coated Fiber Strain Sensor for Wearable Motion and Healthcare Monitoring. Sensors. 2024; 24(1):271. https://doi.org/10.3390/s24010271

Chicago/Turabian StyleCao, Junming, Yuanqing Jiang, Xiaoming Li, Xueguang Yuan, Jinnan Zhang, Qi He, Fei Ye, Geng Luo, Shaohua Guo, Yangan Zhang, and et al. 2024. "A Flexible and Stretchable MXene/Waterborne Polyurethane Composite-Coated Fiber Strain Sensor for Wearable Motion and Healthcare Monitoring" Sensors 24, no. 1: 271. https://doi.org/10.3390/s24010271

APA StyleCao, J., Jiang, Y., Li, X., Yuan, X., Zhang, J., He, Q., Ye, F., Luo, G., Guo, S., Zhang, Y., & Wang, Q. (2024). A Flexible and Stretchable MXene/Waterborne Polyurethane Composite-Coated Fiber Strain Sensor for Wearable Motion and Healthcare Monitoring. Sensors, 24(1), 271. https://doi.org/10.3390/s24010271