Design and Analysis of a Fluid-Filled RF MEMS Switch

Abstract

:1. Introduction

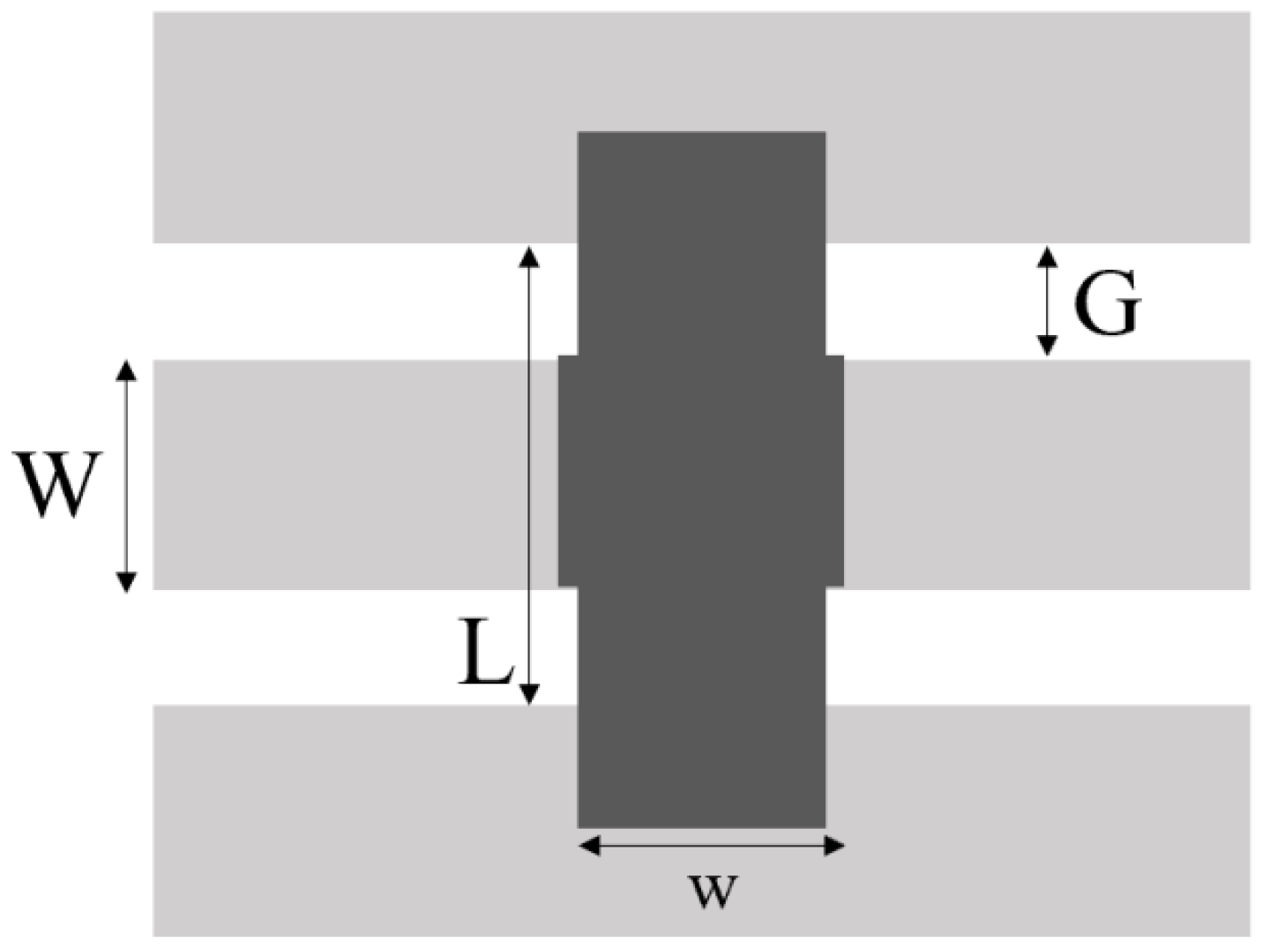

2. Analysis of the Structure and Working Principle of the Switch

2.1. The Working Process of Capacitive RF MEMS Switch

- (1)

- The initial state of the switch (up state), in which no driving voltage is applied, the switch is equivalent to two small capacitors in series, as shown below:In contrast to the classical capacitance equation, is added to calculate the capacitance, making it easier to compare the results of the simulation with the actual calculation afterwards. Where, , , and are the dielectric constants of the air, the insulating dielectric layer, and the filling medium, respectively; is the width of the cantilever beam; is the width of the central conduction strip; is the initial distance between the cantilever beam and the insulating dielectric layer; is the thickness of the insulating dielectric layer; is the dielectric constant of the insulating dielectric layer. is the edge capacitance, which usually accounts for 20–60% of the capacitance value of the parallel plate. In the state, the edge capacitance cannot be ignored. Because is small, the signal of the central guide band can be transmitted almost without attenuation during the transmission process.

- (2)

- When a certain driving voltage is applied to the cantilever beam, the switch is in a pull-down state, and the equivalent capacitance between the insulating dielectric layer and cantilever beam increases rapidly, as the same time, it is necessary to consider the effect of filling medium on capacitance, so the following is introduced:where represents the distance that the cantilever moves towards the insulating dielectric layer, during which the equivalent capacitance increases rapidly in value.

- (3)

- When the switch is pulled down to come in contact with the insulating dielectric layer (down state), the equivalent capacitance of the cantilever beam and the insulating dielectric layer reaches the maximum in this case, it can be equivalent to a large capacitance. Considering the influence of insulating medium on capacitors, the following formula is defined:At this point, corresponds to a large capacitor with respect to , through which the signal is coupled to ground.

- (4)

- After the driving voltage is removed, the electrostatic force on the cantilever beam is reduced, and the switch returns is restored to state through mechanical restoring force. At this point, the mechanical force on the switch is much larger than the viscous force of the insulating medium, so its effect can be ignored.

2.2. Calculation of RF MEMS Switch Pull-Down Voltage

2.3. Calculation of RF MEMS Switching Time

2.4. Capacitance Ratio of RF MEMS Switch

2.5. Loss of RF MEMS Switch

2.6. Isolation of RF MEMS Switch

3. Manufacturing Method of Switch

- Step 1:

- Select silicon with high resistivity as the substrate material and form an oxide layer on the substrate surface by dry-wet-dry thermal oxidation process to make the substrate have good electrical insulation and prevent current leakage. See Figure 4a below.

- Step 2:

- Forming signal lines and bottom electrodes of Cr-Au alloy by RF sputtering with positive adhesive stripping. See Figure 4b below.

- Step 3:

- Sputtering a layer of SiN bilayer dielectric film, covering the CPW central signal line as an insulating layer, the thickness is 150/50 nm. See Figure 4c below.

- Step 4:

- Evaporation of 3 μm thick AI, wet corrosion to obtain the support column. See Figure 4d below.

- Step 5:

- Rotational coating of a layer of polyamide with a thickness of 3 μm, after lithography to obtain a sacrificial layer. See Figure 4e below.

- Step6:

- Electron beam evaporation of a layer of Al for the upper electrode, wet corrosion out of the sacrificial layer release hole (small hole size of 8 × 8 μm). See Figure 4f below.

- Step 7:

- Reactive ion etching to release polyamide sacrificial layer. See Figure 4g below.

- Step 8:

- Standard supercritical dry ice treatment was used and filling medium is added. See Figure 4h below.

- Step 9:

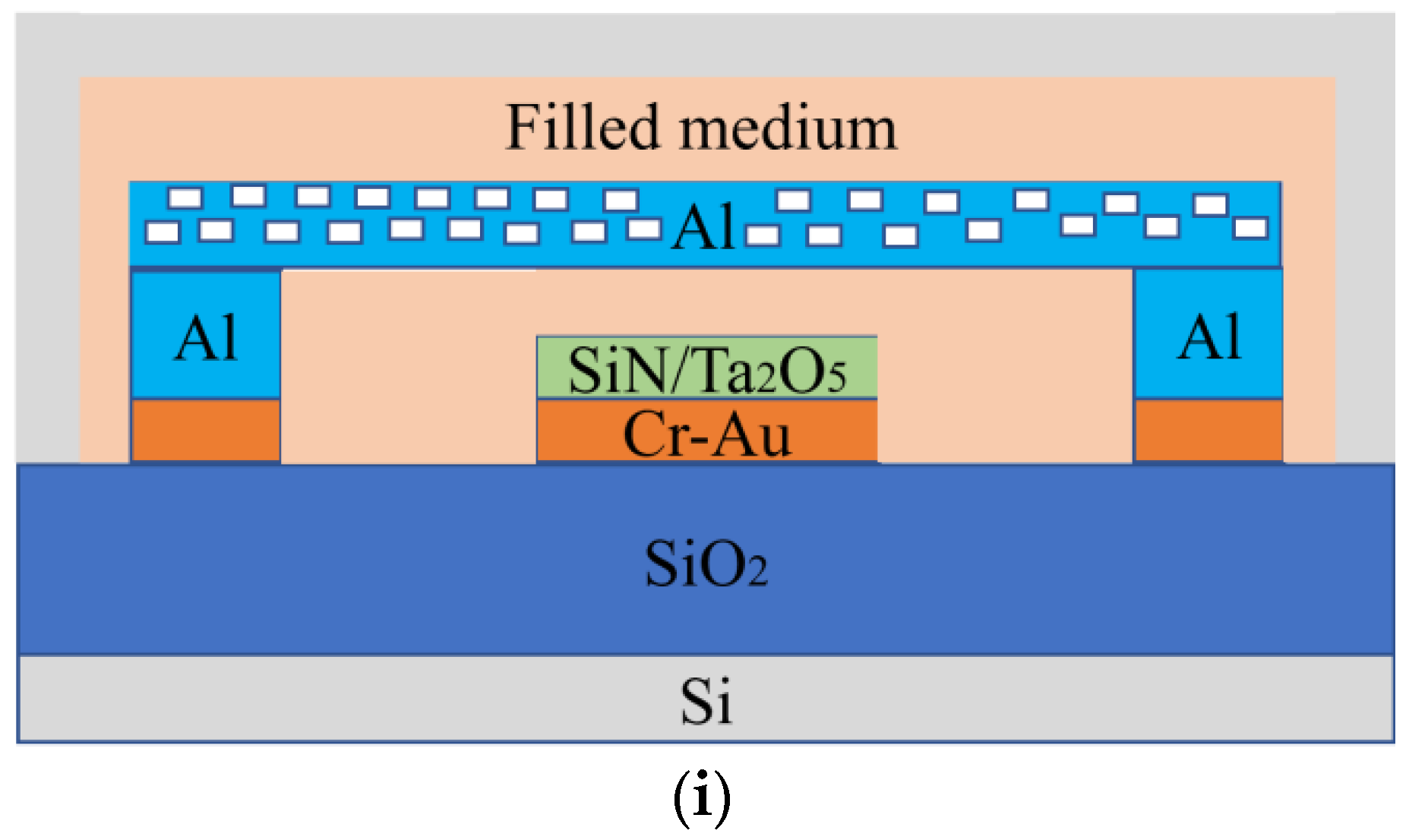

- Finally, a package is formed on a silicon wafer. See Figure 4i below.

4. Results

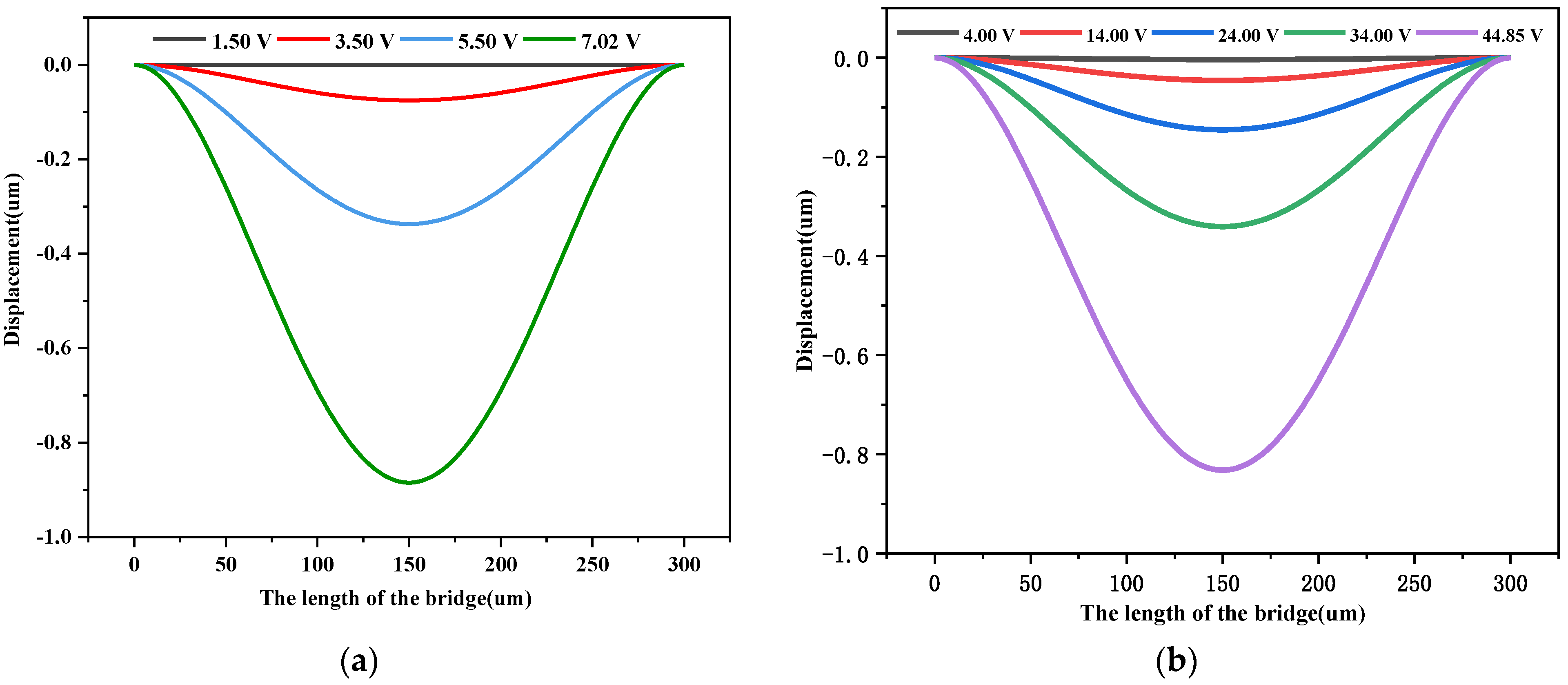

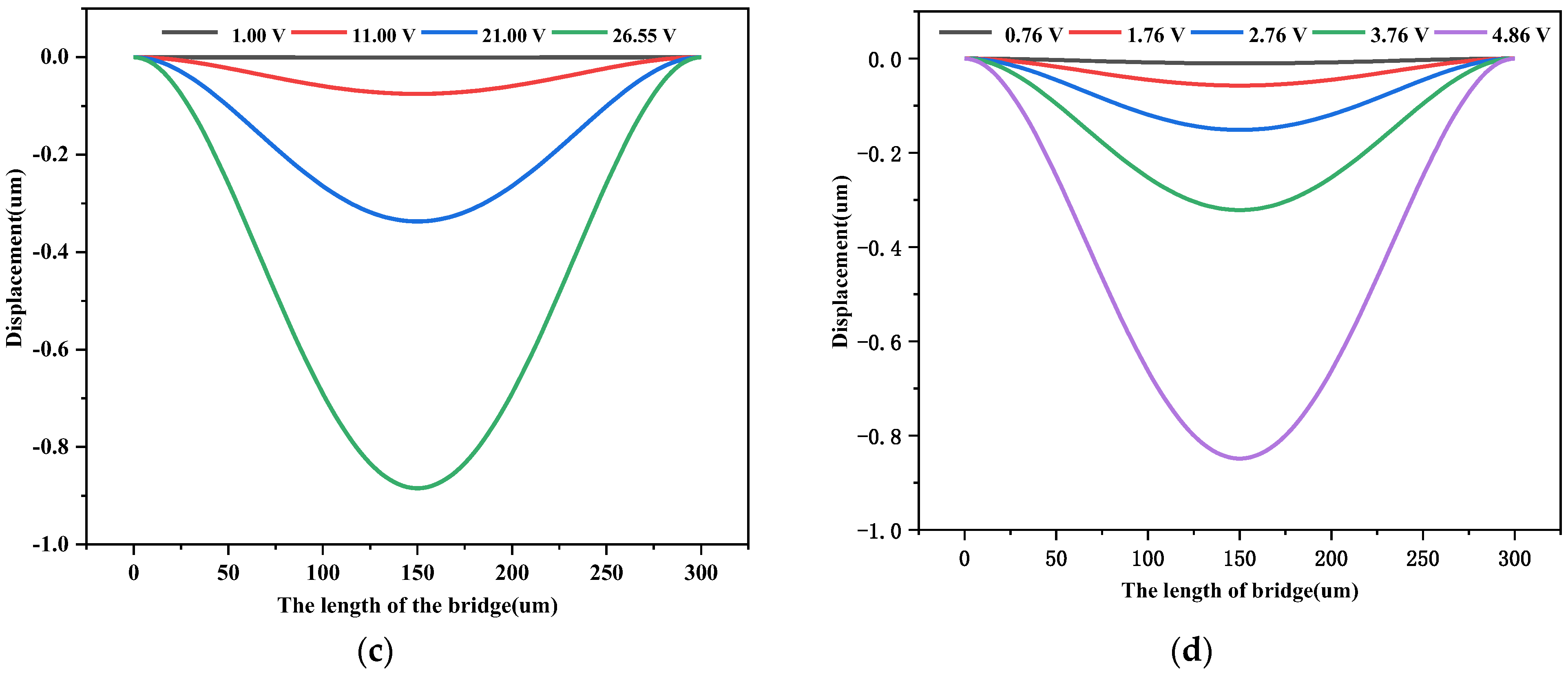

4.1. Effect of Threshold Voltage Change

4.2. Effect of Change of Switch Filling Material on Response Time

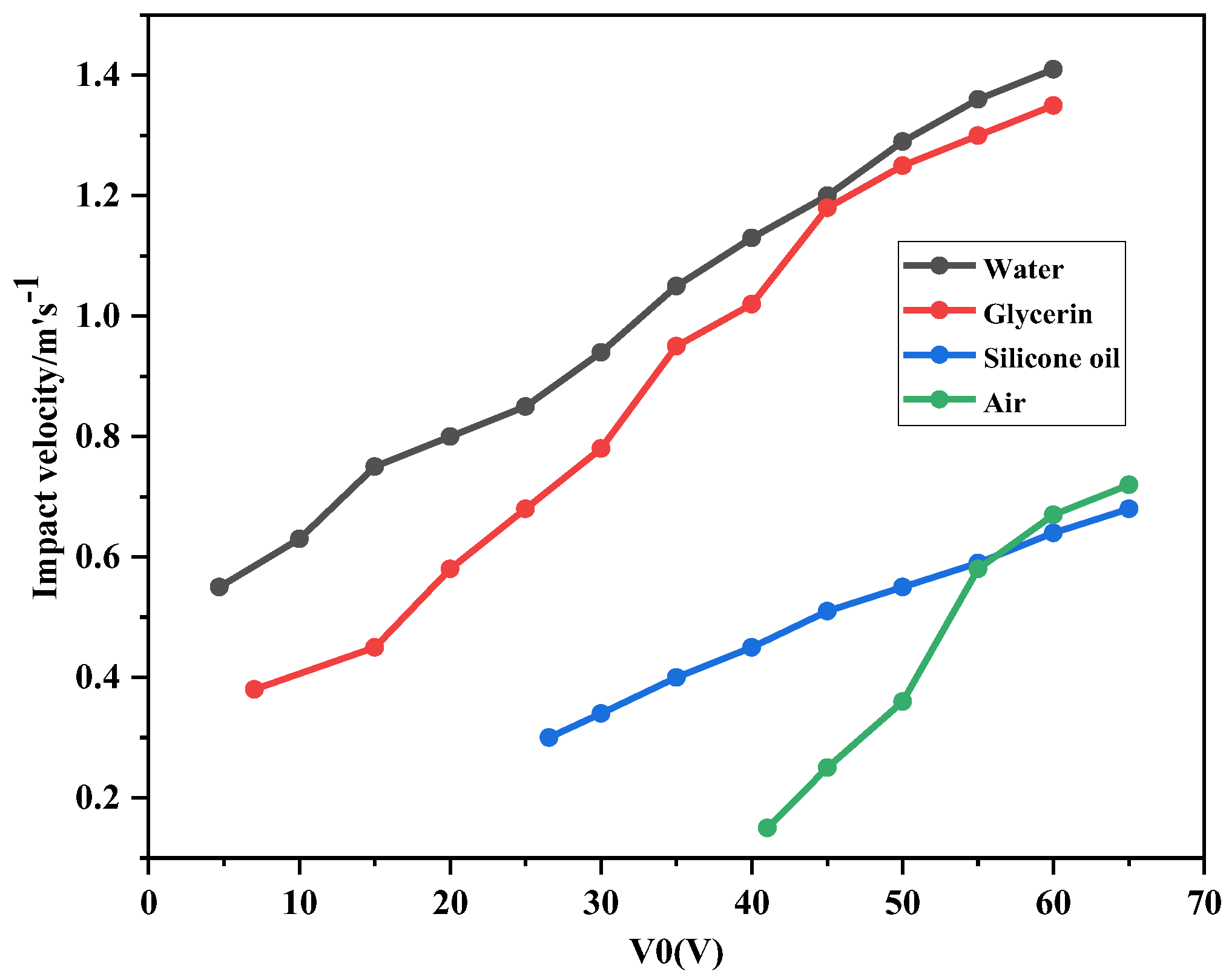

4.3. Effect of Change of Switch Filling Material on Impact Velocity

4.4. Effect of Change of Switch Filling Material on Capacitance

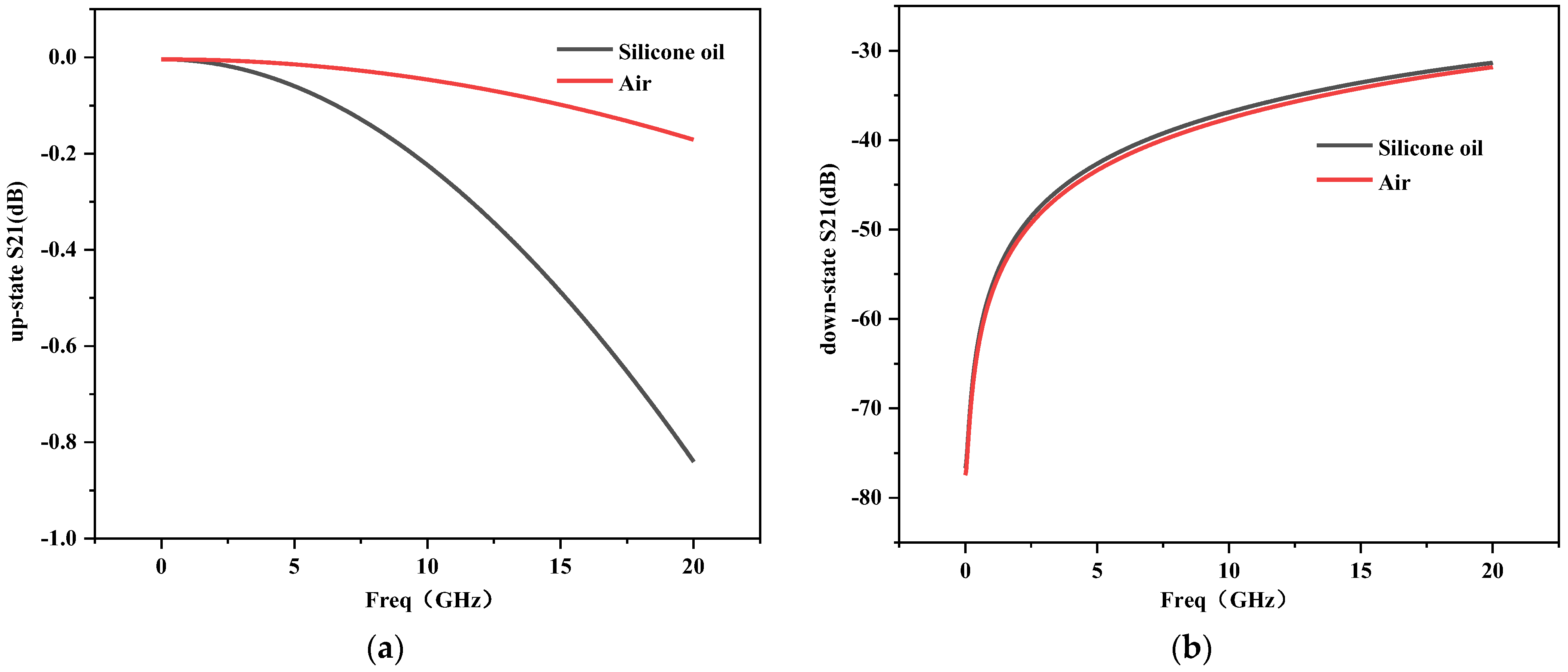

4.5. Effect of Change of Switch Filling Material on Insertion Loss and Isolation

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Iannacci, J. RF-MEMS technology as an enabler of 5G: Low-loss ohmic switch tested up to 110 GHz. Sens. Actuators A Phys. 2018, 279, 624–629. [Google Scholar] [CrossRef]

- Mousavi, M.; Alzgool, M.; Davaji, B.; Towfighian, S. Event-driven MEMS vibration sensor: Integration of triboelectric nanogenerator and low-frequency switch. Mech. Syst. Signal. Pract. 2023, 187, 109921. [Google Scholar] [CrossRef]

- Sharma, K.; Karmakar, A.; Sharma, M.; Chauhan, A.; Bansal, S.; Hooda, M.; Kumar, S.; Gupta, N.; Singh, A.K. Reconfigurable dual notch band antenna on Si-substrate integrated with RF MEMS SP4T switch for GPS, 3G, 4G, bluetooth, UWB and close range radar applications. AEU-Int. J. Electron. Commun. 2019, 110, 152873. [Google Scholar] [CrossRef]

- He, X.J.; Lv, Z.Q.; Liu, B.; Li, Z.H. High-isolation lateral RF MEMS capacitive switch based on HfO2 dielectric for high frequency applications. Sens. Actuators A Phys. 2012, 188, 342–348. [Google Scholar] [CrossRef]

- Biswas, B.; Karmakar, A. Customary of CPW configuration’s in silicon RF technology targeting monolithic integration for GHz to THz frequency band. Mater. Today: Proc. 2022, 71, 220–226. [Google Scholar] [CrossRef]

- Iannacci, J. Internet of Things (IoT); Internet of Everything (IoE); tactile internet; 5G—A (not so evanescent) unifying vision empowered by EH-MEMS (energy harvesting MEMS) and RF-MEMS (radio frequency MEMS). Sens. Actuators A Phys. 2018, 272, 187–198. [Google Scholar] [CrossRef]

- Goldsmith, C.; Ehmke, J.; Malczewski, A.; Pillans, B.; Eshelman, S.; Yao, Z.; Brank, J.; Eberly, M. Lifetime characterization of capacitive RF MEMS switches. In Proceedings of the 2001 IEEE MTT-S International Microwave Sympsoium Digest (Cat. No. 01CH37157), Phoenix, AZ, USA, 20–24 May 2001; pp. 227–230. [Google Scholar] [CrossRef]

- Sakata, M.; Komura, Y.; Seki, T.; Kobayashi, K.; Sano, K.; Horiike, S. Micromachined relay which utilizes single crystal silicon electrostatic actuator. In Proceedings of the Technical Digest, IEEE International MEMS 99 Conference, Twelfth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No. 99CH36291), Orlando, FL, USA, 21–21 January 1999; pp. 21–24. [Google Scholar] [CrossRef]

- Ke, F.; Miao, J.; Tan, C.W. Reduction of squeeze-film damping in a wafer-level encapsulated RF MEMS DC shunt switch. Sens. Actuators A: Phys. 2011, 171, 118–125. [Google Scholar] [CrossRef]

- Sravani, K.G.; Rao, K.S.; Guha, K. New pull-in voltage modelling of step structure RF MEMS switch. Microelectron. J. 2021, 117, 105264. [Google Scholar] [CrossRef]

- Riverola, M.; Uranga, A.; Torres, F.; Barniol, N.; Marigo, E.; Soundara-Pandian, M. A reliable fast miniaturized RF MEMS-on-CMOS switched capacitor with zero-level vacuum package. In Proceedings of the 2017 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Pavia, Italy, 20–22 September 2017; pp. 1–3. [Google Scholar] [CrossRef]

- Zhen, P.; Palego, C.; Hwang, J.C.M.; Forehand, D.I.; Goldsmith, C.L.; Moody, C.; Malczewski, A.; Pillans, B.W.; Daigler, R.; Papapolymerou, J. Impact of Humidity on Dielectric Charging in RF MEMS Capacitive Switches. IEEE Microw. Wirel. Compon. 2009, 19, 299–301. [Google Scholar] [CrossRef]

- Hirt, C.W.; Nichols, B.D. Volume of fluid (VOF) method for the dynamics of free boundaries. J. Comput. Phys. 1981, 39, 201–225. [Google Scholar] [CrossRef]

| Materials | Youngs Modulus | Poisson Ratio | Density | Length | Width | Height |

|---|---|---|---|---|---|---|

| Al | 69 GPa | 0.35 | 2.7 g/cm3 | 300 μm | 60 μm | 2 μm |

| Air | Glycerol | Water | Silicone Oil | |

|---|---|---|---|---|

| CL(fF) | 37.2 | 1653 | 3868 | 83.2 |

| Cs(fF) | 2794 | 4720 | 7897 | 3568 |

| C(fF) | 36.8 | 1180 | 3652 | 78.9 |

| ratio | 75.9 | 4.0 | 2.1 | 42.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Cui, W.; Li, Y.; Song, M. Design and Analysis of a Fluid-Filled RF MEMS Switch. Sensors 2023, 23, 2692. https://doi.org/10.3390/s23052692

Zhu H, Cui W, Li Y, Song M. Design and Analysis of a Fluid-Filled RF MEMS Switch. Sensors. 2023; 23(5):2692. https://doi.org/10.3390/s23052692

Chicago/Turabian StyleZhu, Hongyu, Wenhao Cui, Yanzhang Li, and Mingxin Song. 2023. "Design and Analysis of a Fluid-Filled RF MEMS Switch" Sensors 23, no. 5: 2692. https://doi.org/10.3390/s23052692

APA StyleZhu, H., Cui, W., Li, Y., & Song, M. (2023). Design and Analysis of a Fluid-Filled RF MEMS Switch. Sensors, 23(5), 2692. https://doi.org/10.3390/s23052692