Stretchable Strain Sensor with Small but Sufficient Adhesion to Skin

Abstract

1. Introduction

2. Materials and Methods

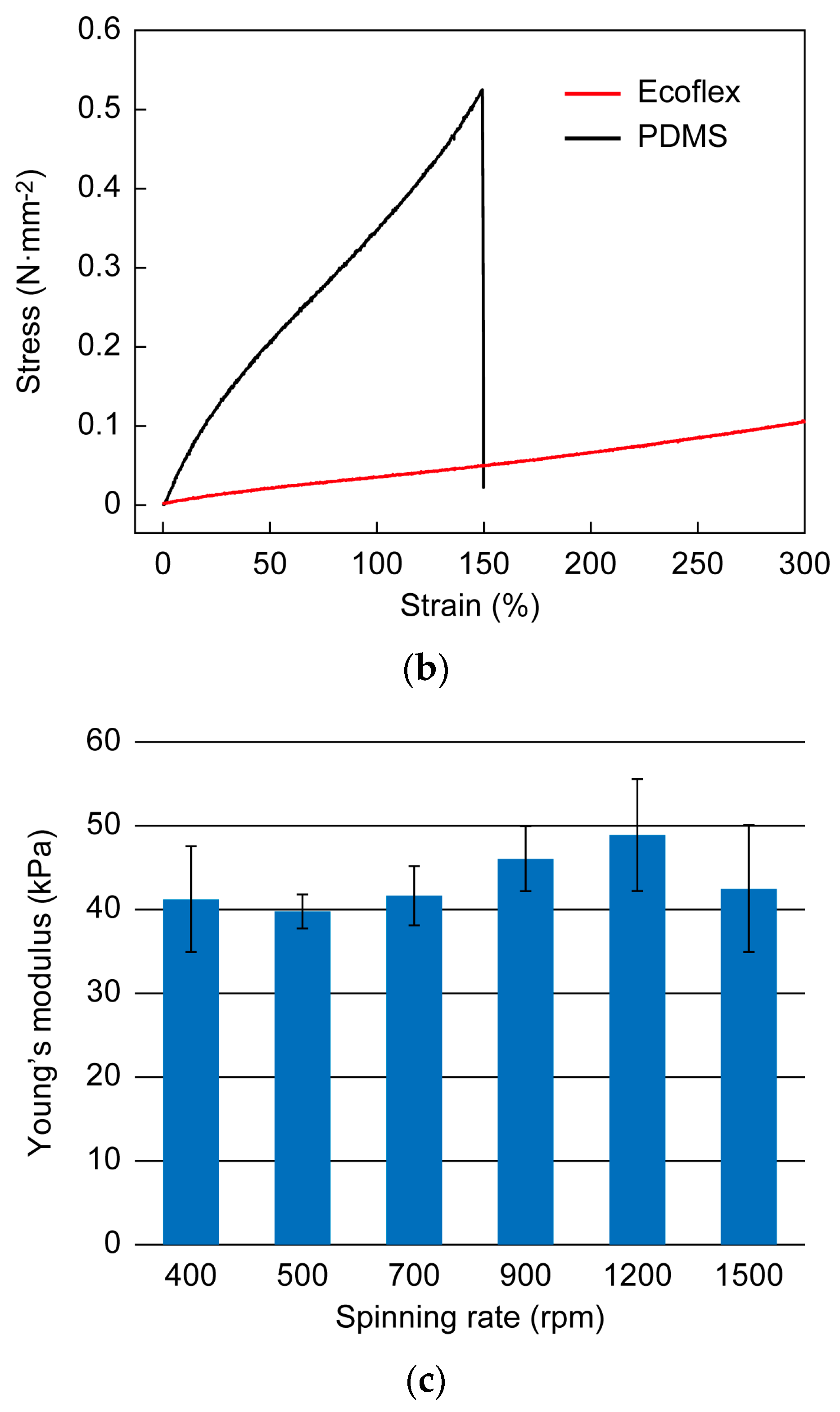

2.1. Material

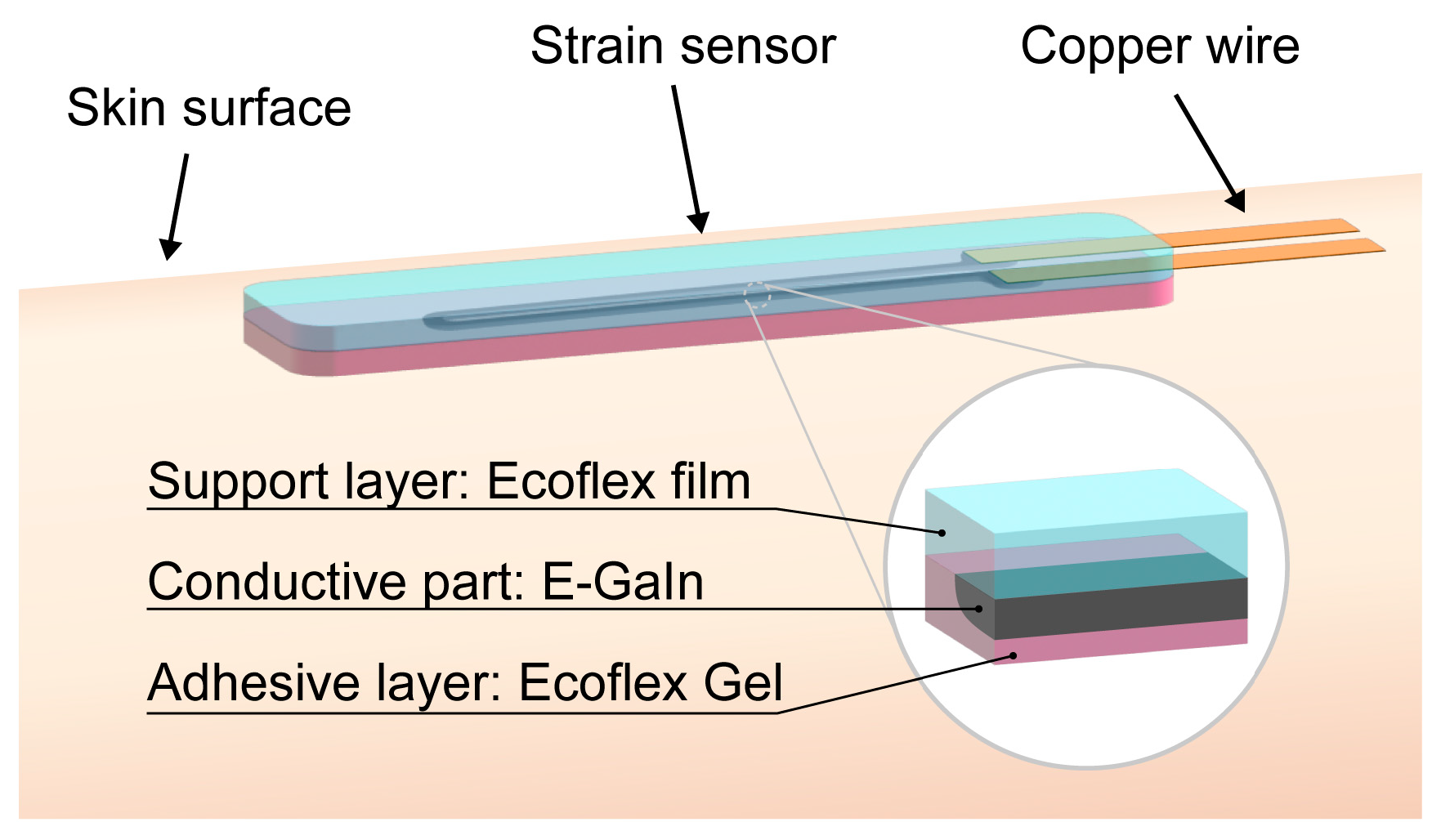

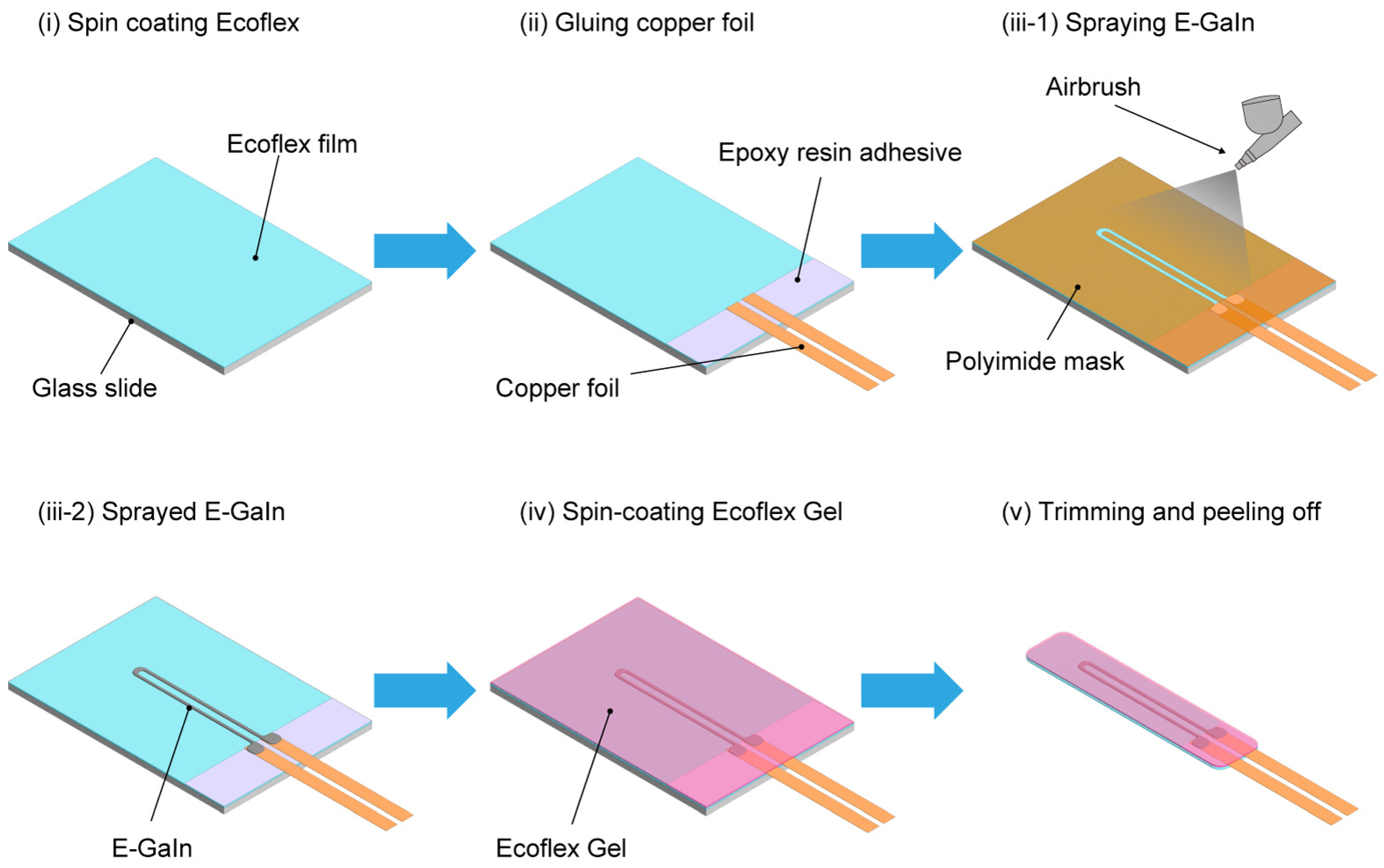

2.2. Fabrication of Stretchable Sensor

2.3. Characterization of Stretchable Sensor

2.3.1. Electrical Properties

2.3.2. Adhesion

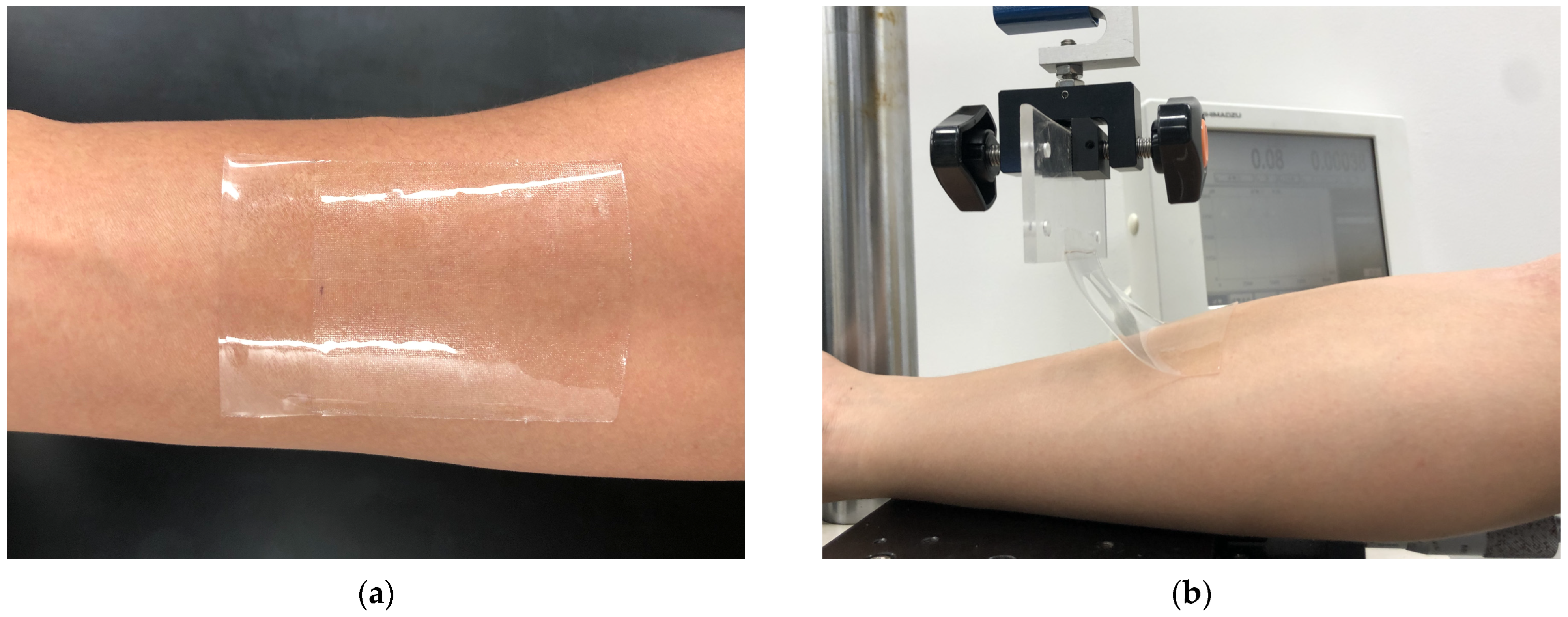

2.4. Demonstration

3. Results and Discussion

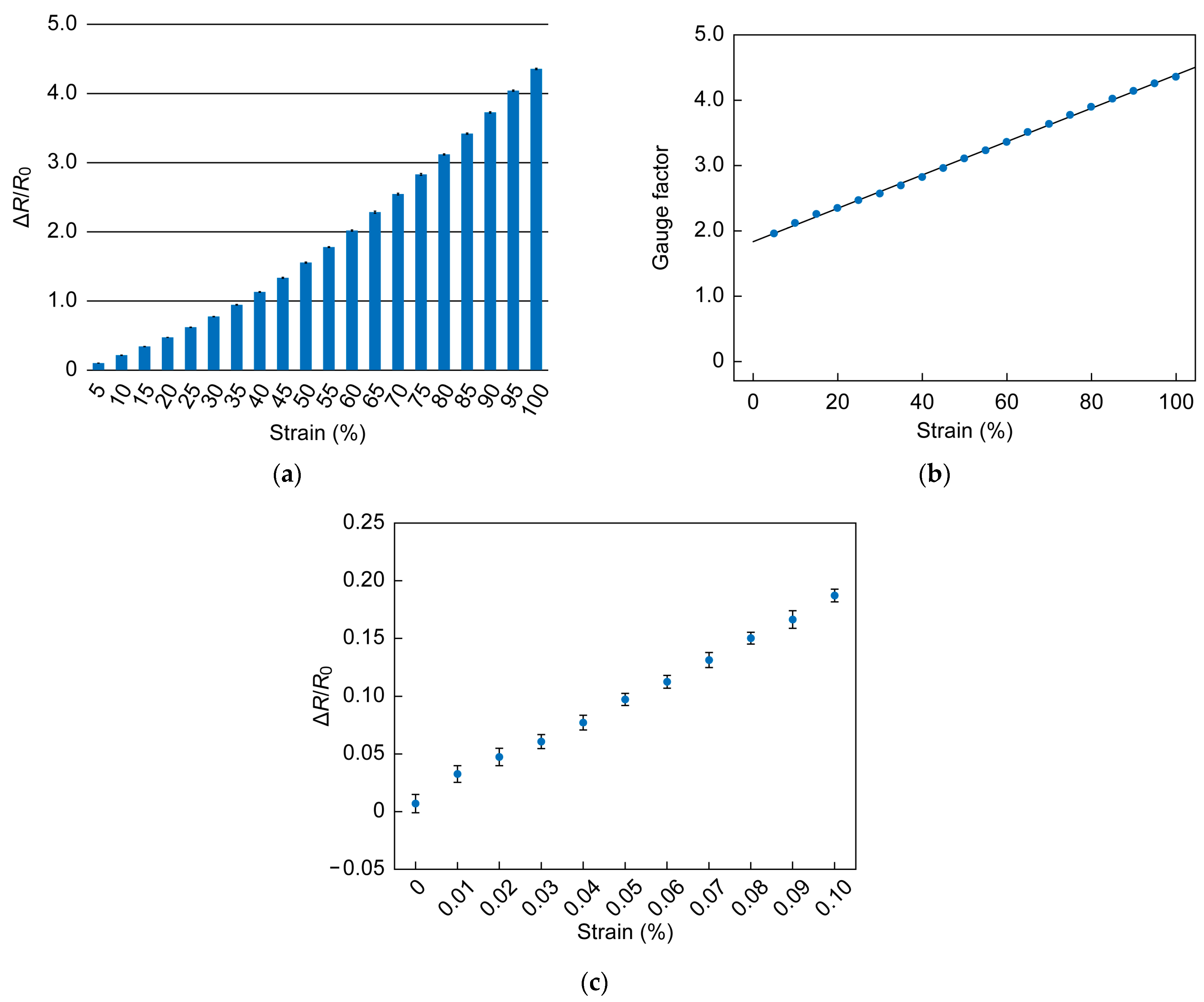

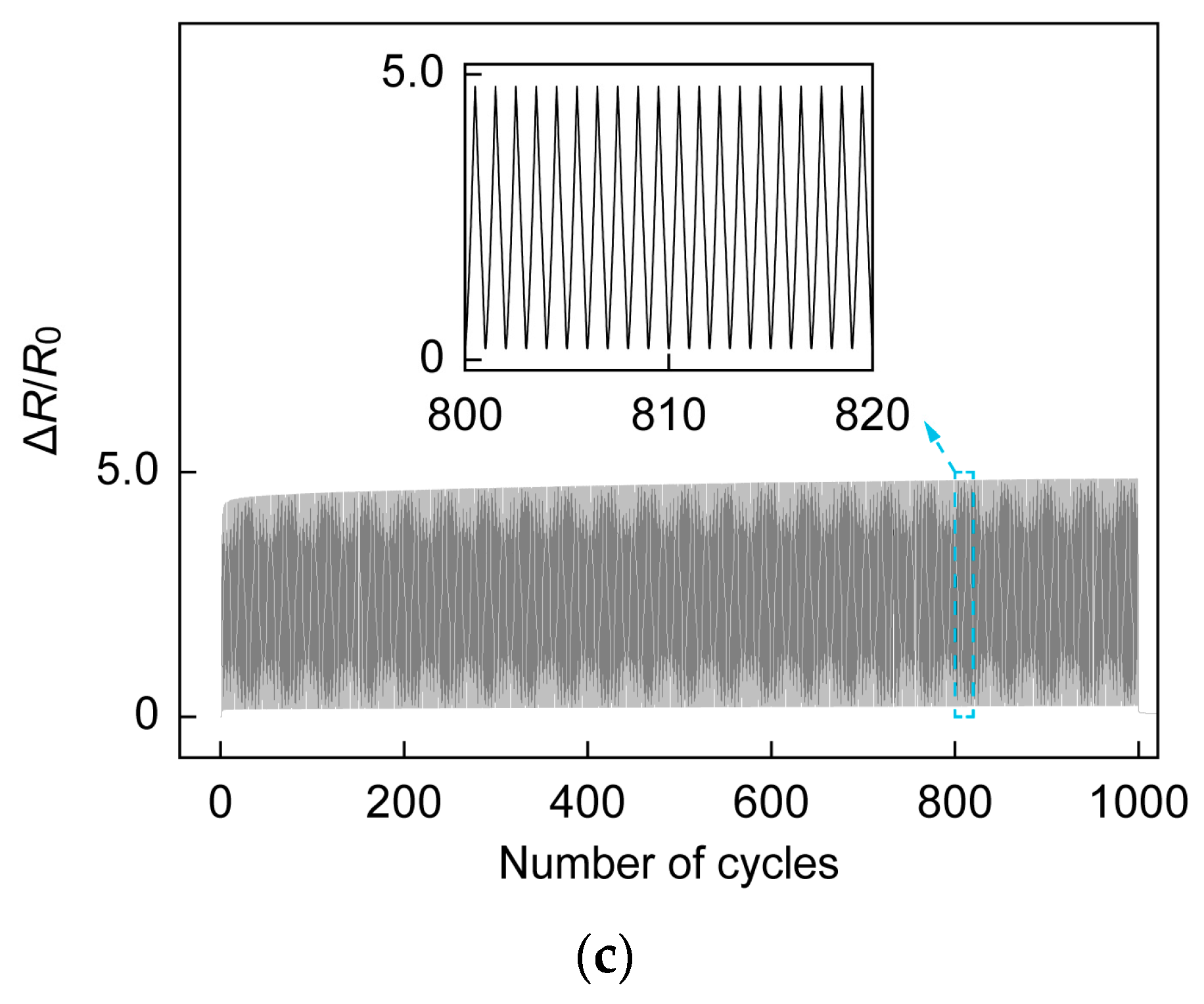

3.1. Mechanical and Electrical Properties of Stretchable Sensor

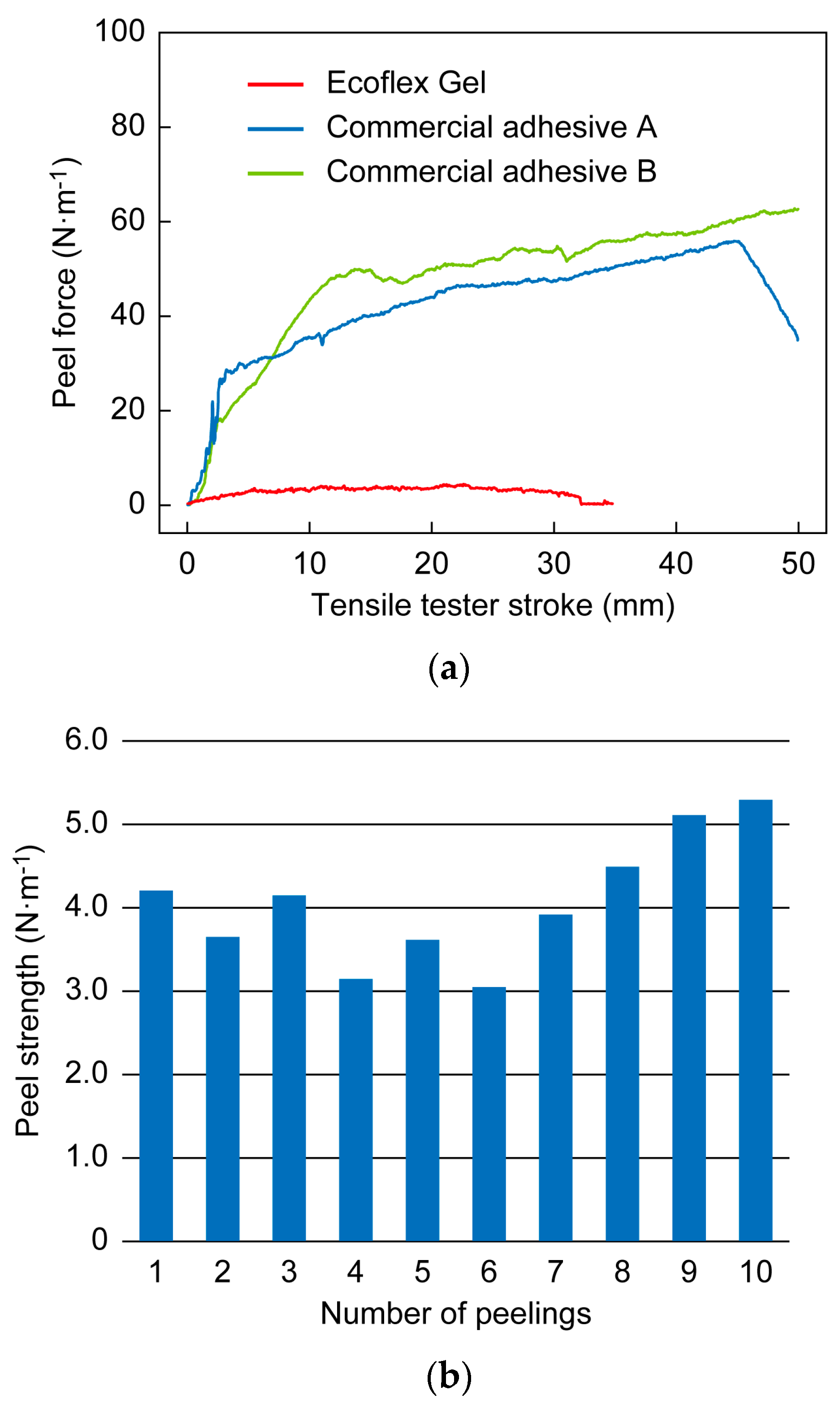

3.2. Adhesion Tests

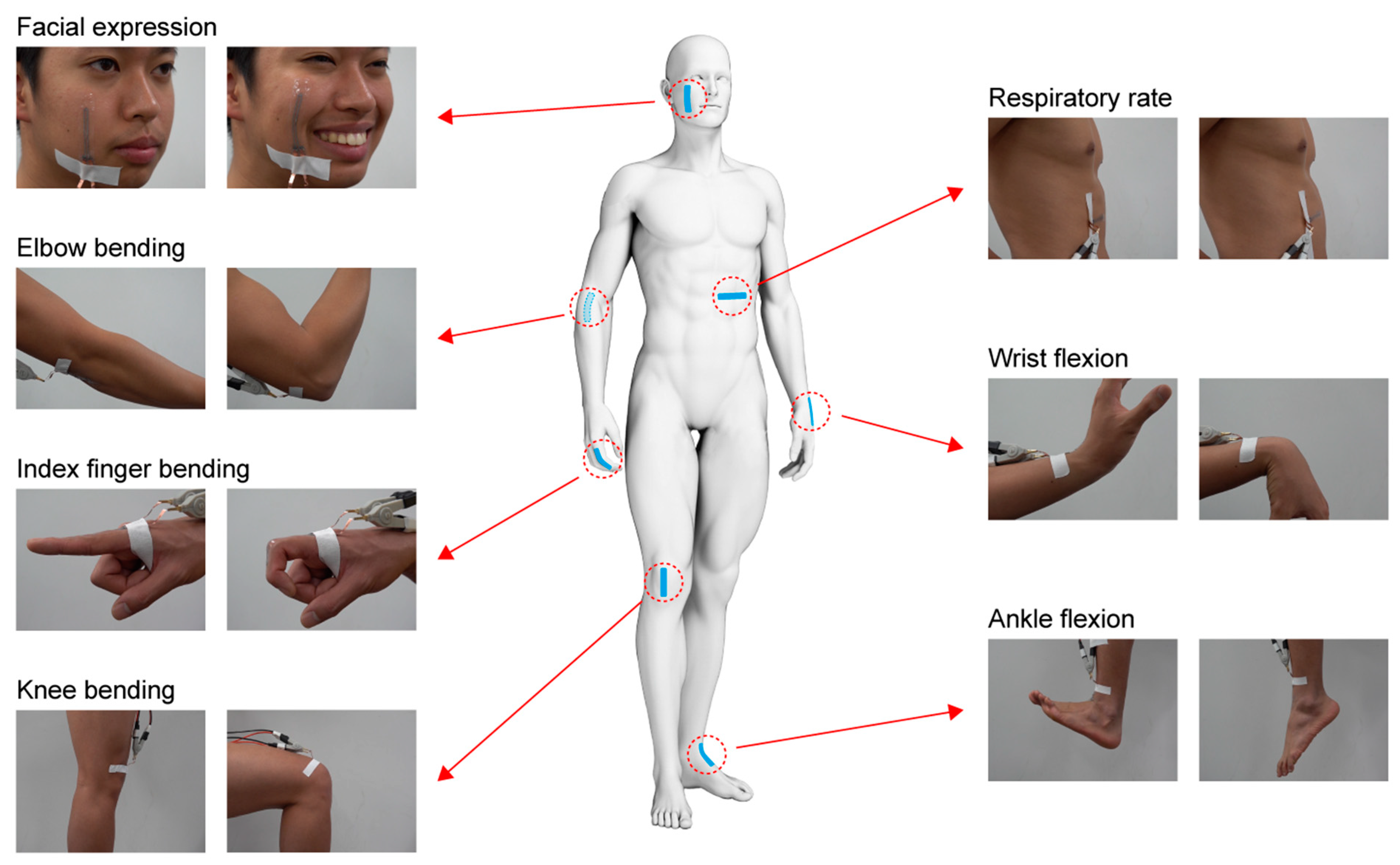

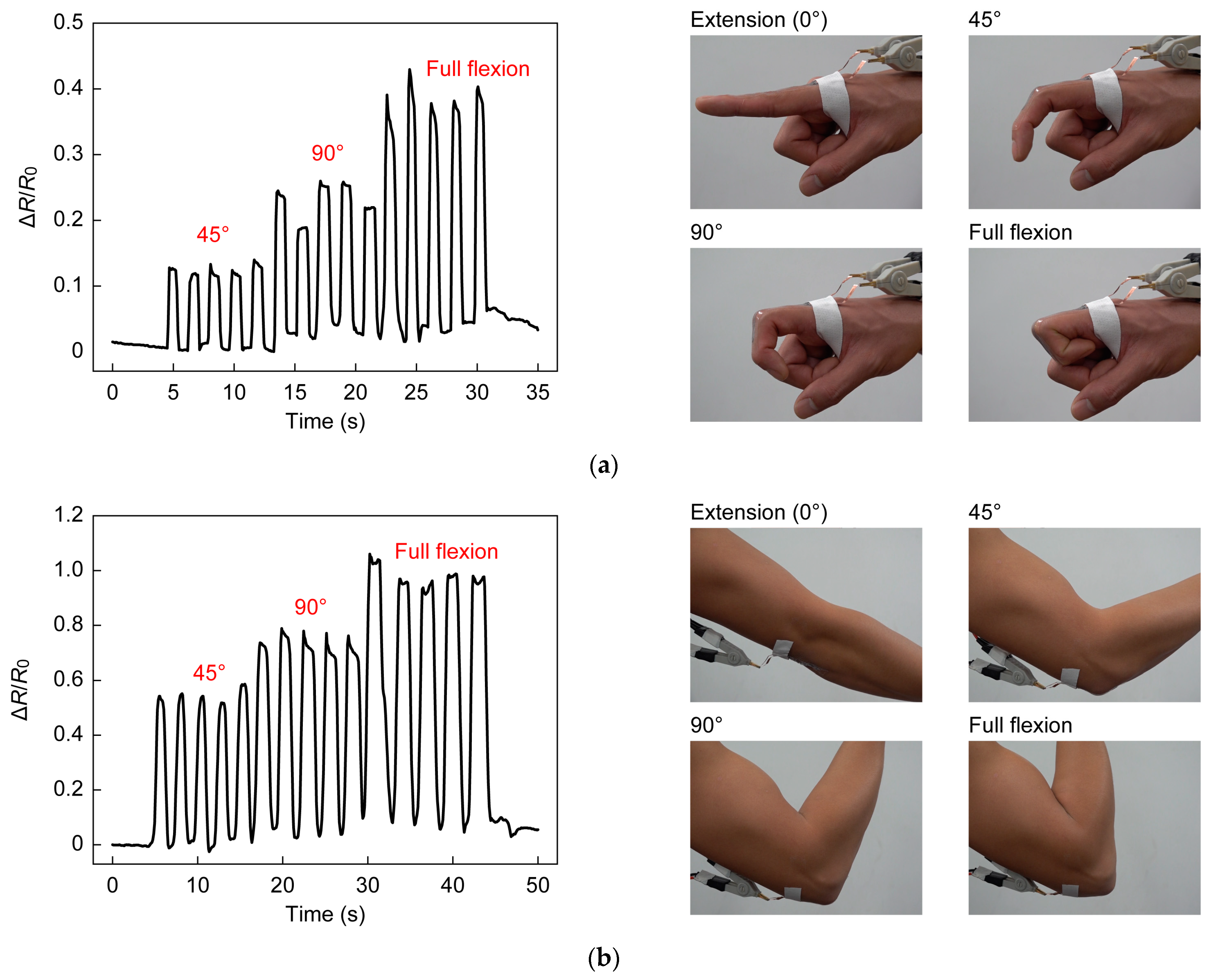

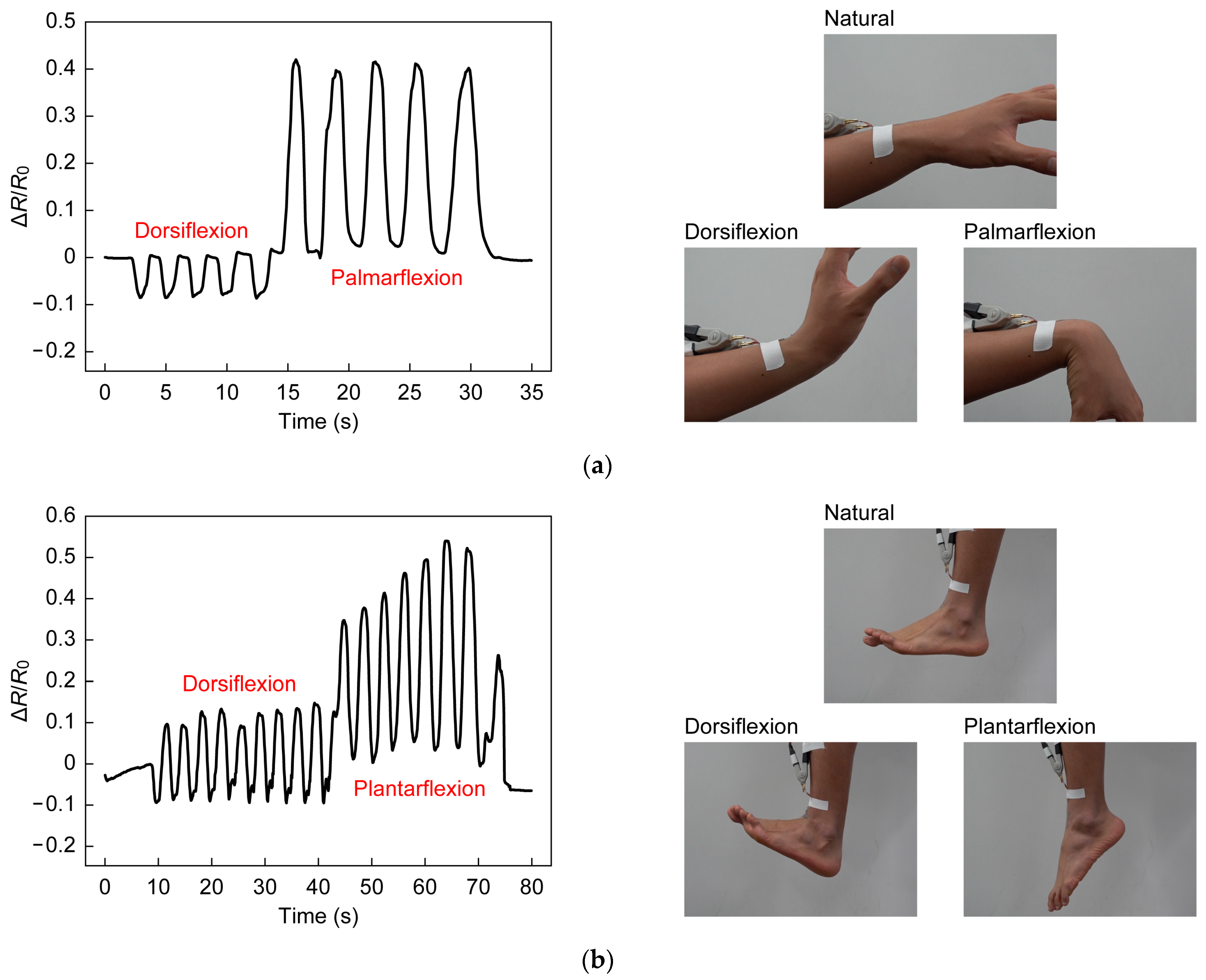

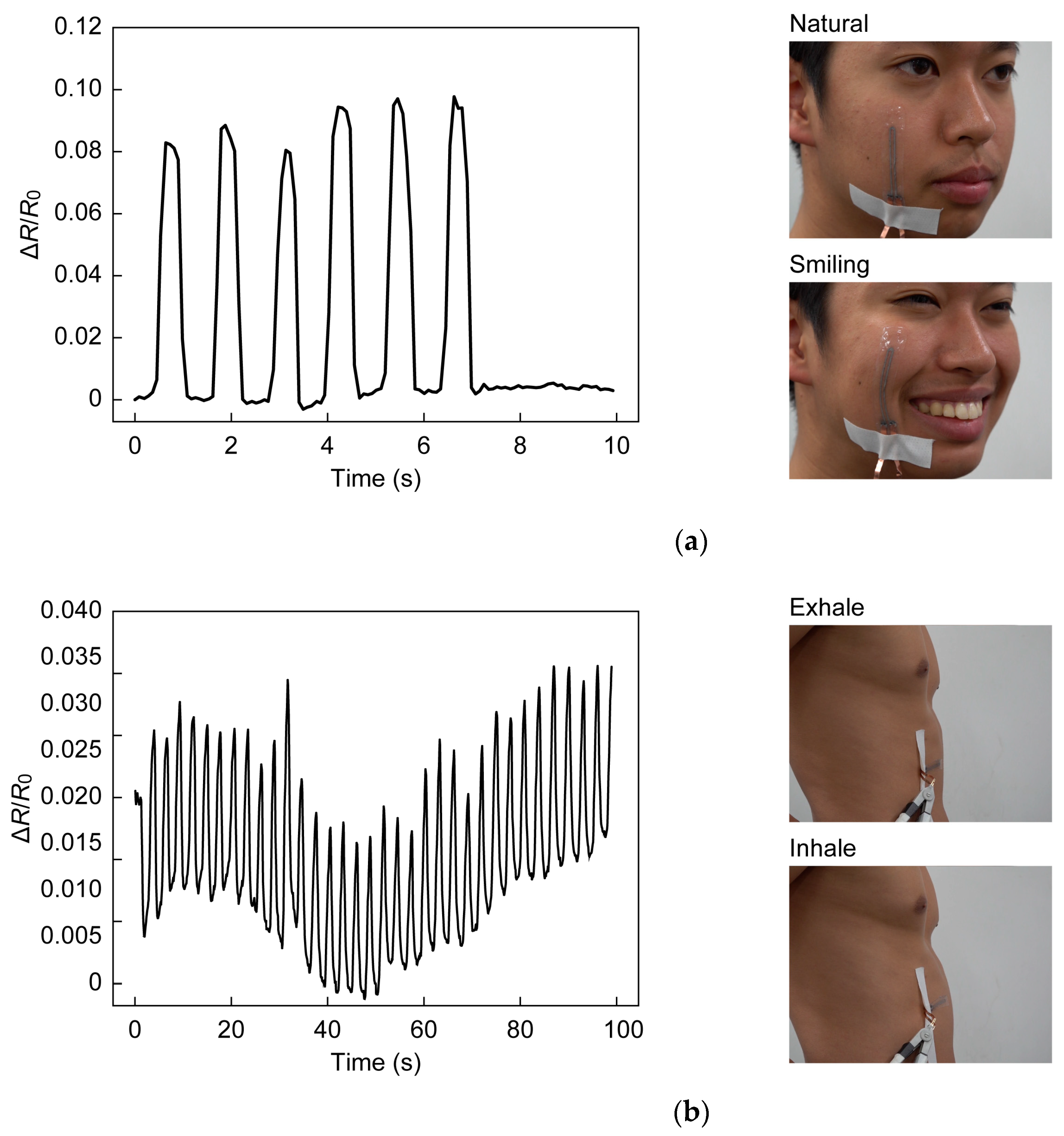

3.3. Demonstration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, Z.; Xu, Y.; Cheng, Y.; Xue, M.; Deng, M.; Jaffrezic-Renault, N.; Guo, Z. Recent Advances in Skin-like Wearable Sensors: Sensor Design, Health Monitoring, and Intelligent Auxiliary. Sens. Diagn. 2022, 1, 686–708. [Google Scholar] [CrossRef]

- Pang, C.; Lee, C.; Suh, K.-Y. Recent Advances in Flexible Sensors for Wearable and Implantable Devices. J. Appl. Polym. Sci. 2013, 130, 1429–1441. [Google Scholar] [CrossRef]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

- Cheng, Y.; Wang, R.; Sun, J.; Gao, L. A Stretchable and Highly Sensitive Graphene-Based Fiber for Sensing Tensile Strain, Bending, and Torsion. Adv. Mater. 2015, 27, 7365–7371. [Google Scholar] [CrossRef]

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A Stretchable Carbon Nanotube Strain Sensor for Human-Motion Detection. Nat. Nanotech. 2011, 6, 296–301. [Google Scholar] [CrossRef]

- Lee, J.; Kim, S.; Lee, J.; Yang, D.; Chon Park, B.; Ryu, S.; Park, I. A Stretchable Strain Sensor Based on a Metal Nanoparticle Thin Film for Human Motion Detection. Nanoscale 2014, 6, 11932–11939. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Cao, T.; Wang, T.; Sun, L.; Wang, K.; Fan, X. Antiliquid-Interfering, Antibacteria, and Adhesive Wearable Strain Sensor Based on Superhydrophobic and Conductive Composite Hydrogel. ACS Appl. Mater. Interfaces 2021, 13, 46022–46032. [Google Scholar] [CrossRef]

- Lee, H.; Seong, B.; Moon, H.; Byun, D. Directly Printed Stretchable Strain Sensor Based on Ring and Diamond Shaped Silver Nanowire Electrodes. RSC Adv. 2015, 5, 28379–28384. [Google Scholar] [CrossRef]

- Lee, C.; Jug, L.; Meng, E. High Strain Biocompatible Polydimethylsiloxane-Based Conductive Graphene and Multiwalled Carbon Nanotube Nanocomposite Strain Sensors. Appl. Phys. Lett. 2013, 102, 183511. [Google Scholar] [CrossRef]

- Lu, N.; Lu, C.; Yang, S.; Rogers, J. Highly Sensitive Skin-Mountable Strain Gauges Based Entirely on Elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire–Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Boland, C.S.; Khan, U.; Backes, C.; O’Neill, A.; McCauley, J.; Duane, S.; Shanker, R.; Liu, Y.; Jurewicz, I.; Dalton, A.B.; et al. Sensitive, High-Strain, High-Rate Bodily Motion Sensors Based on Graphene–Rubber Composites. ACS Nano 2014, 8, 8819–8830. [Google Scholar] [CrossRef]

- Tadakaluru, S.; Thongsuwan, W.; Singjai, P. Stretchable and Flexible High-Strain Sensors Made Using Carbon Nanotubes and Graphite Films on Natural Rubber. Sensors 2014, 14, 868–876. [Google Scholar] [CrossRef] [PubMed]

- Gong, S.; Lai, D.T.H.; Wang, Y.; Yap, L.W.; Si, K.J.; Shi, Q.; Jason, N.N.; Sridhar, T.; Uddin, H.; Cheng, W. Tattoolike Polyaniline Microparticle-Doped Gold Nanowire Patches as Highly Durable Wearable Sensors. ACS Appl. Mater. Interfaces 2015, 7, 19700–19708. [Google Scholar] [CrossRef] [PubMed]

- Lin, L.; Liu, S.; Zhang, Q.; Li, X.; Ji, M.; Deng, H.; Fu, Q. Towards Tunable Sensitivity of Electrical Property to Strain for Conductive Polymer Composites Based on Thermoplastic Elastomer. ACS Appl. Mater. Interfaces 2013, 5, 5815–5824. [Google Scholar] [CrossRef]

- Kang, D.; Pikhitsa, P.V.; Choi, Y.W.; Lee, C.; Shin, S.S.; Piao, L.; Park, B.; Suh, K.-Y.; Kim, T.; Choi, M. Ultrasensitive Mechanical Crack-Based Sensor Inspired by the Spider Sensory System. Nature 2014, 516, 222–226. [Google Scholar] [CrossRef]

- Wang, S.; Fang, Y.; He, H.; Zhang, L.; Li, C.; Ouyang, J. Wearable Stretchable Dry and Self-Adhesive Strain Sensors with Conformal Contact to Skin for High-Quality Motion Monitoring. Adv. Funct. Mater. 2021, 31, 2007495. [Google Scholar] [CrossRef]

- Shen, Z.; Zhang, Z.; Zhang, N.; Li, J.; Zhou, P.; Hu, F.; Rong, Y.; Lu, B.; Gu, G. High-Stretchability, Ultralow-Hysteresis ConductingPolymer Hydrogel Strain Sensors for Soft Machines. Adv. Mater. 2022, 34, 2203650. [Google Scholar] [CrossRef]

- Deng, H.; Ji, M.; Yan, D.; Fu, S.; Duan, L.; Zhang, M.; Fu, Q. Towards Tunable Resistivity–Strain Behavior through Construction of Oriented and Selectively Distributed Conductive Networks in Conductive Polymer Composites. J. Mater. Chem. A 2014, 2, 10048–10058. [Google Scholar] [CrossRef]

- Liu, Z.F.; Fang, S.; Moura, F.A.; Ding, J.N.; Jiang, N.; Di, J.; Zhang, M.; Lepró, X.; Galvão, D.S.; Haines, C.S.; et al. Hierarchically Buckled Sheath-Core Fibers for Superelastic Electronics, Sensors, and Muscles. Science 2015, 349, 400–404. [Google Scholar] [CrossRef] [PubMed]

- McEvoy, M.A.; Correll, N. Materials That Couple Sensing, Actuation, Computation, and Communication. Science 2015, 347, 1261689. [Google Scholar] [CrossRef] [PubMed]

- Asghar, U.; Karimov, K.S.; Ibrahim, M.A.; Fatima, N. Multifunctional Organic Shockproof Flexible Sensors Based on a Composite of Nickel Phthalocyanine Colourant, Carbon Nanotubes and Rubber Created with Rubbing-in Technology. Color. Technol. 2022, 138, 176–183. [Google Scholar] [CrossRef]

- Wu, W.; Wang, L.; Shen, G. Flexible Photoplethysmographic Sensing Devices for Intelligent Medical Treatment. J. Mater. Chem. C 2022, 11, 97–112. [Google Scholar] [CrossRef]

- Gao, Y.; Ota, H.; Schaler, E.W.; Chen, K.; Zhao, A.; Gao, W.; Fahad, H.M.; Leng, Y.; Zheng, A.; Xiong, F.; et al. Wearable Microfluidic Diaphragm Pressure Sensor for Health and Tactile Touch Monitoring. Adv. Mater. 2017, 29, 1701985. [Google Scholar] [CrossRef]

- Kim, S.; Yoo, B.; Miller, M.; Bowen, D.; Pines, D.J.; Daniels, K.M. EGaIn-Silicone-Based Highly Stretchable and Flexible Strain Sensor for Real-Time Two Joint Robotic Motion Monitoring. Sens. Actuators A Phys. 2022, 342, 113659. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Luo, Z.; Zhang, J.; Li, L.; Su, Y.; Gao, X.; Li, Y.; Tang, W.; Cao, C.; et al. Superelastic, Sensitive, and Low Hysteresis Flexible Strain Sensor Based on Wave-Patterned Liquid Metal for Human Activity Monitoring. ACS Appl. Mater. Interfaces 2020, 12, 22200–22211. [Google Scholar] [CrossRef]

- Zhang, Y.; Tao, T.H. Skin-Friendly Electronics for Acquiring Human Physiological Signatures. Adv. Mater. 2019, 31, 1905767. [Google Scholar] [CrossRef]

- Laulicht, B.; Langer, R.; Karp, J.M. Quick-Release Medical Tape. Proc. Natl. Acad. Sci. USA 2012, 109, 18803–18808. [Google Scholar] [CrossRef]

- Martin-Monier, L.; Piveteau, P.-L.; Sorin, F. Novel Insights into the Design of Stretchable Electrical Systems. Sci. Adv. 2021, 7, eabf7558. [Google Scholar] [CrossRef]

- Daalkhaijav, U.; Yirmibesoglu, O.D.; Walker, S.; Mengüç, Y. Rheological Modification of Liquid Metal for Additive Manufacturing of Stretchable Electronics. Adv. Mater. Technol. 2018, 3, 1700351. [Google Scholar] [CrossRef]

- Kumar Sarkar, S.; Parameswaran, C.; Maji, D.; Gupta, D. Stencil Printed Liquid Metal Based Micron-Sized Interconnects for Stretchable Electronics. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Wang, A.; Gan, Y.; Yu, H.; Liu, Y.; Zhang, M.; Cheng, B.; Wang, F.; Wang, H.; Yan, J. Improvement of the Cytocompatibility of Electrospun Poly[(R)-3-Hydroxybutyrate-Co-(R)-3-Hydroxyvalerate] Mats by Ecoflex. J. Biomed. Mater. Res. Part A 2012, 100A, 1505–1511. [Google Scholar] [CrossRef]

- Qi, D.; Zhang, K.; Tian, G.; Jiang, B.; Huang, Y. Stretchable Electronics Based on PDMS Substrates. Adv. Mater. 2021, 33, 2003155. [Google Scholar] [CrossRef] [PubMed]

- Obropta, E.W.; Newman, D.J. A Comparison of Human Skin Strain Fields of the Elbow Joint for Mechanical Counter Pressure Space Suit Development. In Proceedings of the 2015 IEEE Aerospace Conference, Big Sky, MT, USA, 7–14 March 2015; pp. 1–9. [Google Scholar]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-Stretchable and Skin-Mountable Strain Sensors Using Carbon Nanotubes–Ecoflex Nanocomposites. Nanotechnology 2015, 26, 375501. [Google Scholar] [CrossRef]

- Kalra, A.; Lowe, A.; Al-Jumaily, A.M. Mechanical Behaviour of Skin: A Review. J. Mater. Sci. Eng 2016, 5, 1000254. [Google Scholar]

- Koschwanez, J.H.; Carlson, R.H.; Meldrum, D.R. Thin PDMS Films Using Long Spin Times or Tert-Butyl Alcohol as a Solvent. PLoS ONE 2009, 4, e4572. [Google Scholar] [CrossRef]

- Emslie, A.G.; Bonner, F.T.; Peck, L.G. Flow of a Viscous Liquid on a Rotating Disk. J. Appl. Phys. 1958, 29, 858–862. [Google Scholar] [CrossRef]

- Liu, M.; Sun, J.; Sun, Y.; Bock, C.; Chen, Q. Thickness-Dependent Mechanical Properties of Polydimethylsiloxane Membranes. J. Micromech. Microeng. 2009, 19, 035028. [Google Scholar] [CrossRef]

- Ahmad, D.; Sahu, S.K.; Patra, K. Fracture Toughness, Hysteresis and Stretchability of Dielectric Elastomers under Equibiaxial and Biaxial Loading. Polym. Test. 2019, 79, 106038. [Google Scholar] [CrossRef]

- Yan, B.; Ding, H.; Zhang, Y.; Lin, P.; Wu, D.; Shi, Z.; Chen, X.; Tian, Y.; Li, X. Skin-Attachable and Flexible MWCNT Grid/Ecoflex Strain Sensors with Fast Equilibrium of Response for Detection of Sound Vibrations and Human Motions. J. Mater. Sci. Mater. Electron. 2021, 32, 26439–26448. [Google Scholar] [CrossRef]

- Kendall, K. Thin-Film Peeling-the Elastic Term. J. Phys. D Appl. Phys. 1975, 8, 1449–1452. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nishikawa, T.; Yamane, H.; Matsuhisa, N.; Miki, N. Stretchable Strain Sensor with Small but Sufficient Adhesion to Skin. Sensors 2023, 23, 1774. https://doi.org/10.3390/s23041774

Nishikawa T, Yamane H, Matsuhisa N, Miki N. Stretchable Strain Sensor with Small but Sufficient Adhesion to Skin. Sensors. 2023; 23(4):1774. https://doi.org/10.3390/s23041774

Chicago/Turabian StyleNishikawa, Takaaki, Hisaya Yamane, Naoji Matsuhisa, and Norihisa Miki. 2023. "Stretchable Strain Sensor with Small but Sufficient Adhesion to Skin" Sensors 23, no. 4: 1774. https://doi.org/10.3390/s23041774

APA StyleNishikawa, T., Yamane, H., Matsuhisa, N., & Miki, N. (2023). Stretchable Strain Sensor with Small but Sufficient Adhesion to Skin. Sensors, 23(4), 1774. https://doi.org/10.3390/s23041774