Early Identification of Unbalanced Freight Traffic Loads Based on Wayside Monitoring and Artificial Intelligence

Abstract

1. Introduction

- -

- This automatic AI-based methodology is an improvement regarding the common methods found in literature, based on direct observations and contact force calculations;

- -

- This methodology is based on responses obtained not only from strain gauges but also from accelerometers. The use of accelerometers in WIM systems is not so common but brings some advantages. One is the ease of installation, and another is the possibility of being used in a wider monitoring system to detect other types of vehicle damages;

- -

- The proposed methodology is tested regarding the number and type of sensors showing a very high accuracy even with a reduced number of sensors.

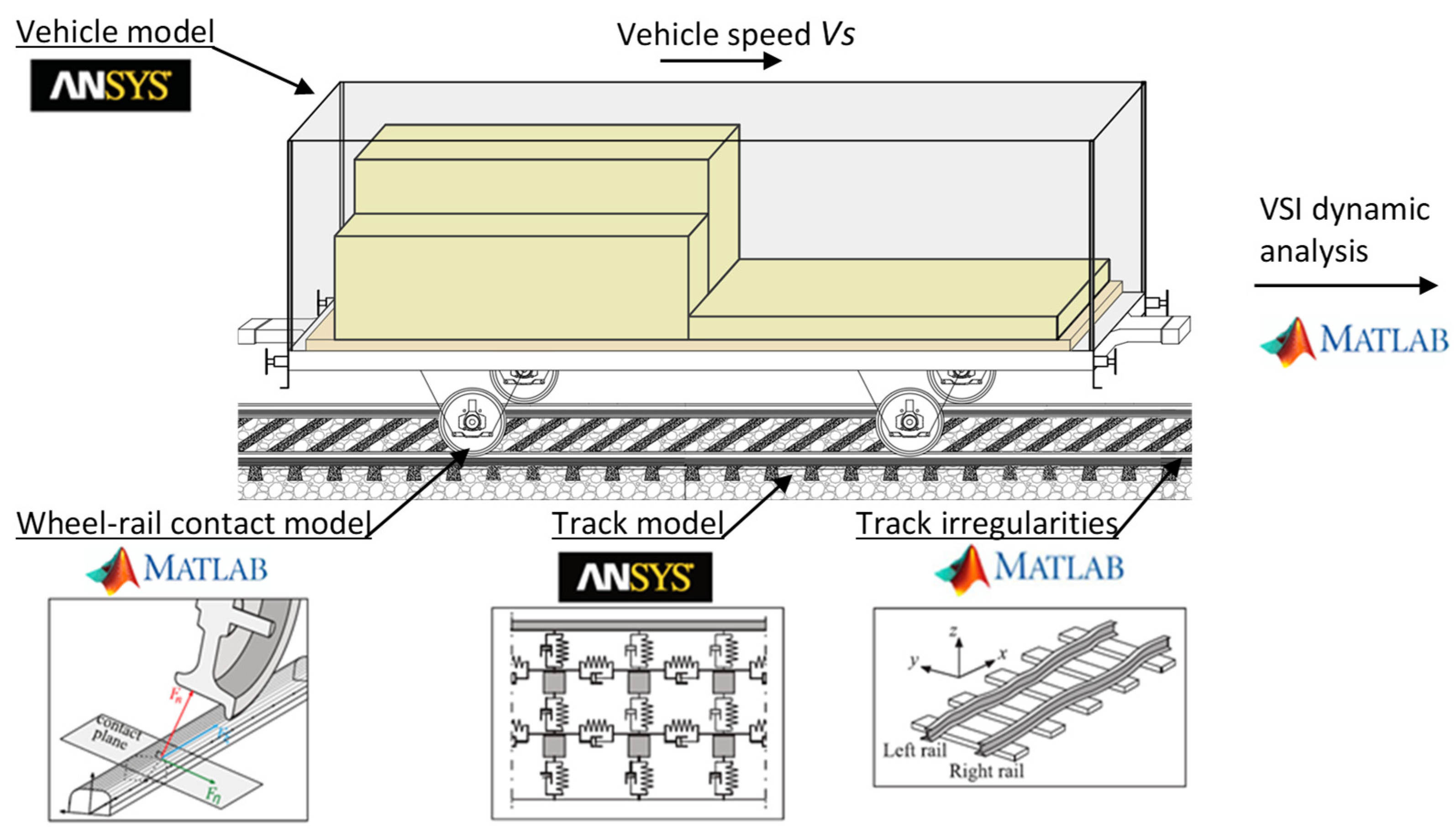

2. Modelling

2.1. Freight Vehicle

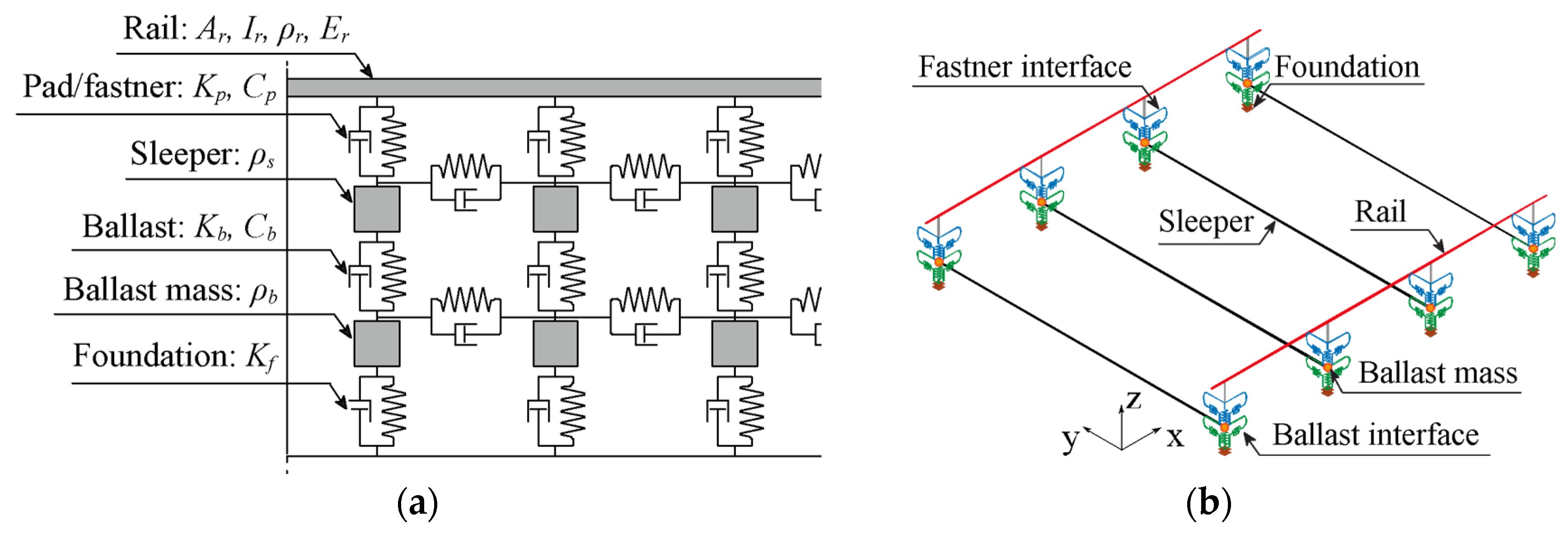

2.2. Track

2.3. Vehicle–Track Interaction

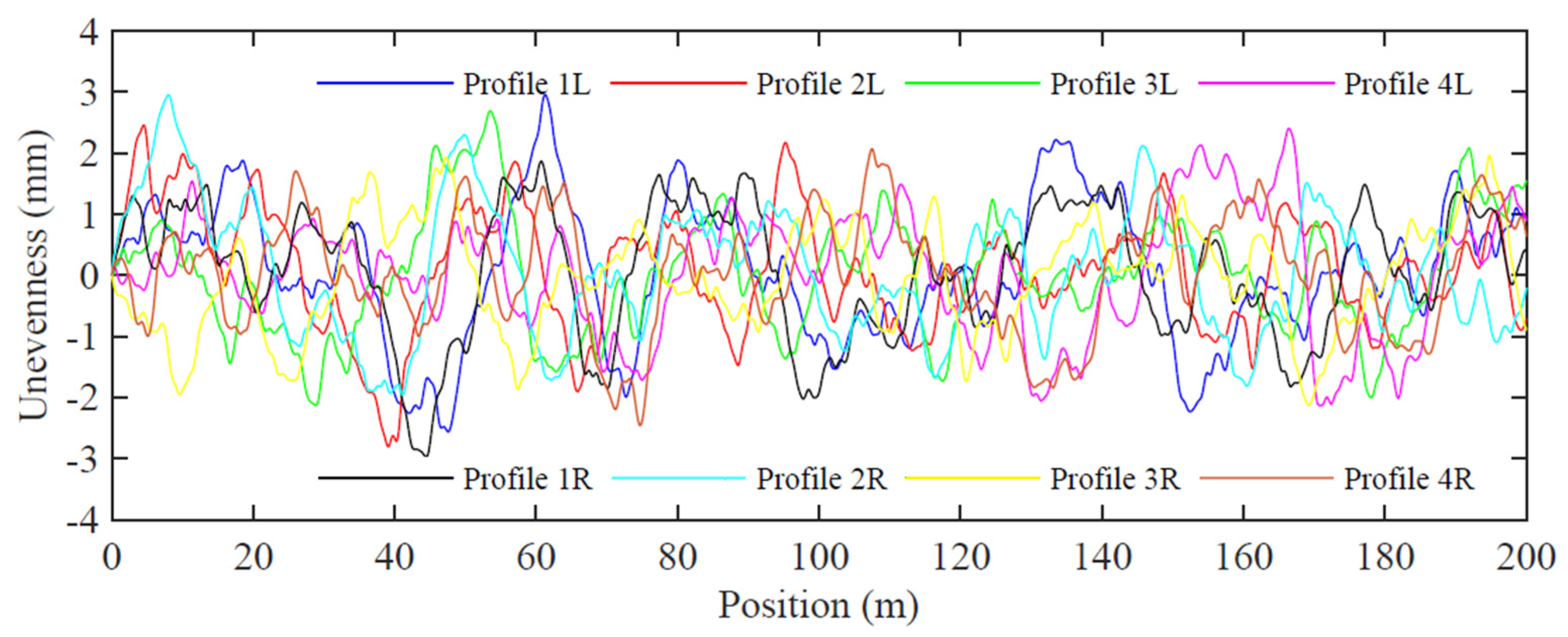

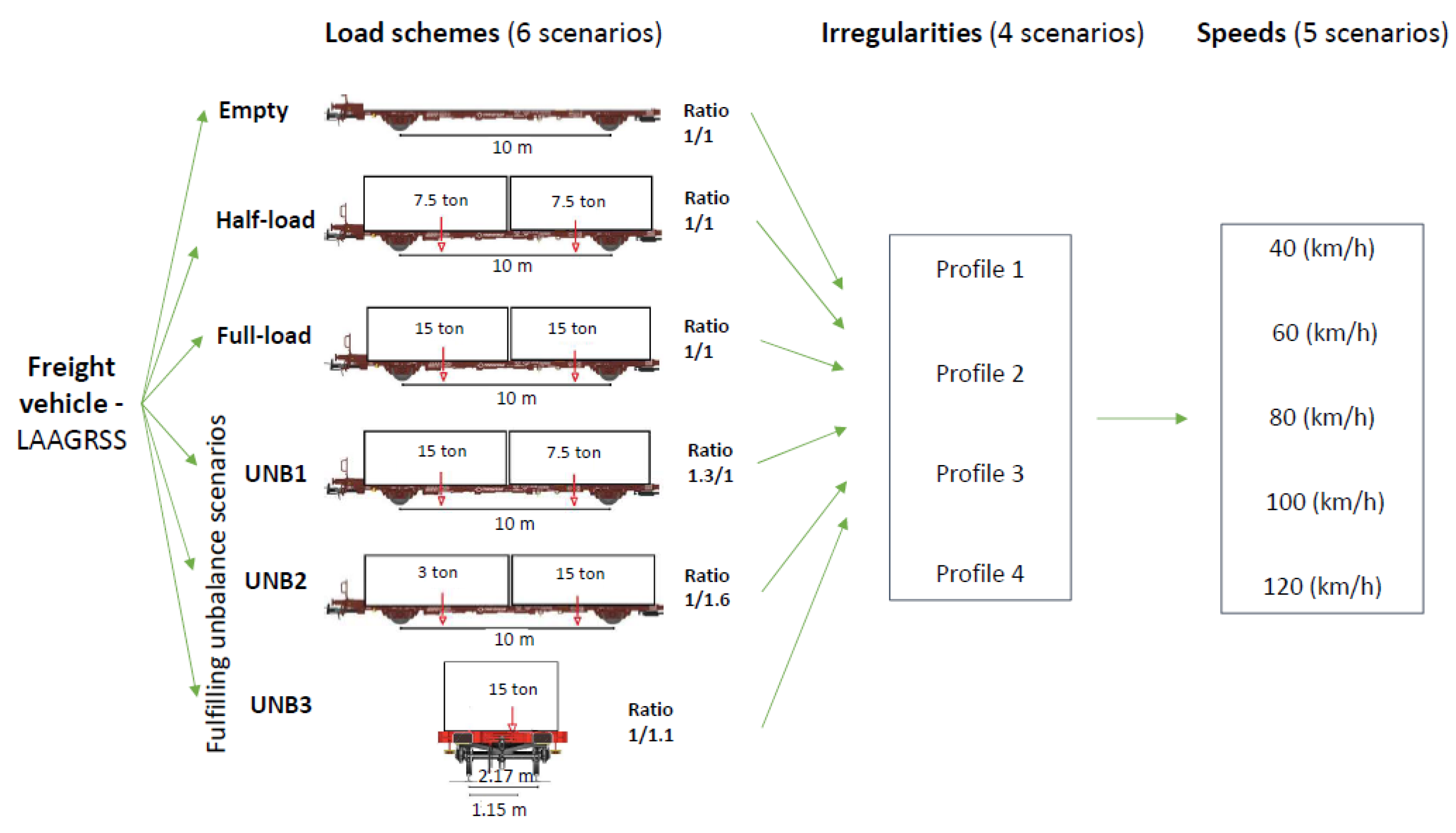

3. Simulation

3.1. Virtual Wayside Monitoring Device

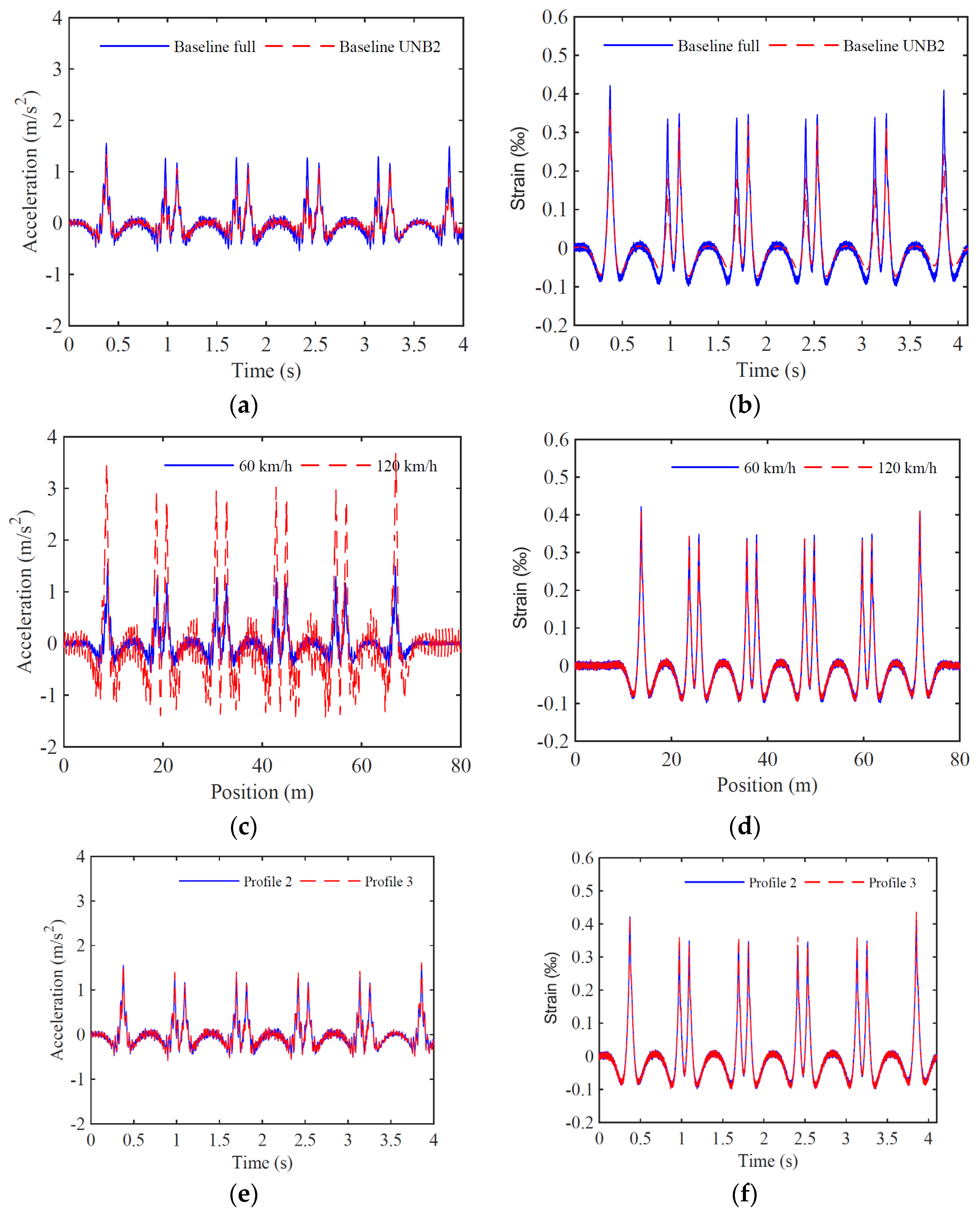

3.2. Baseline

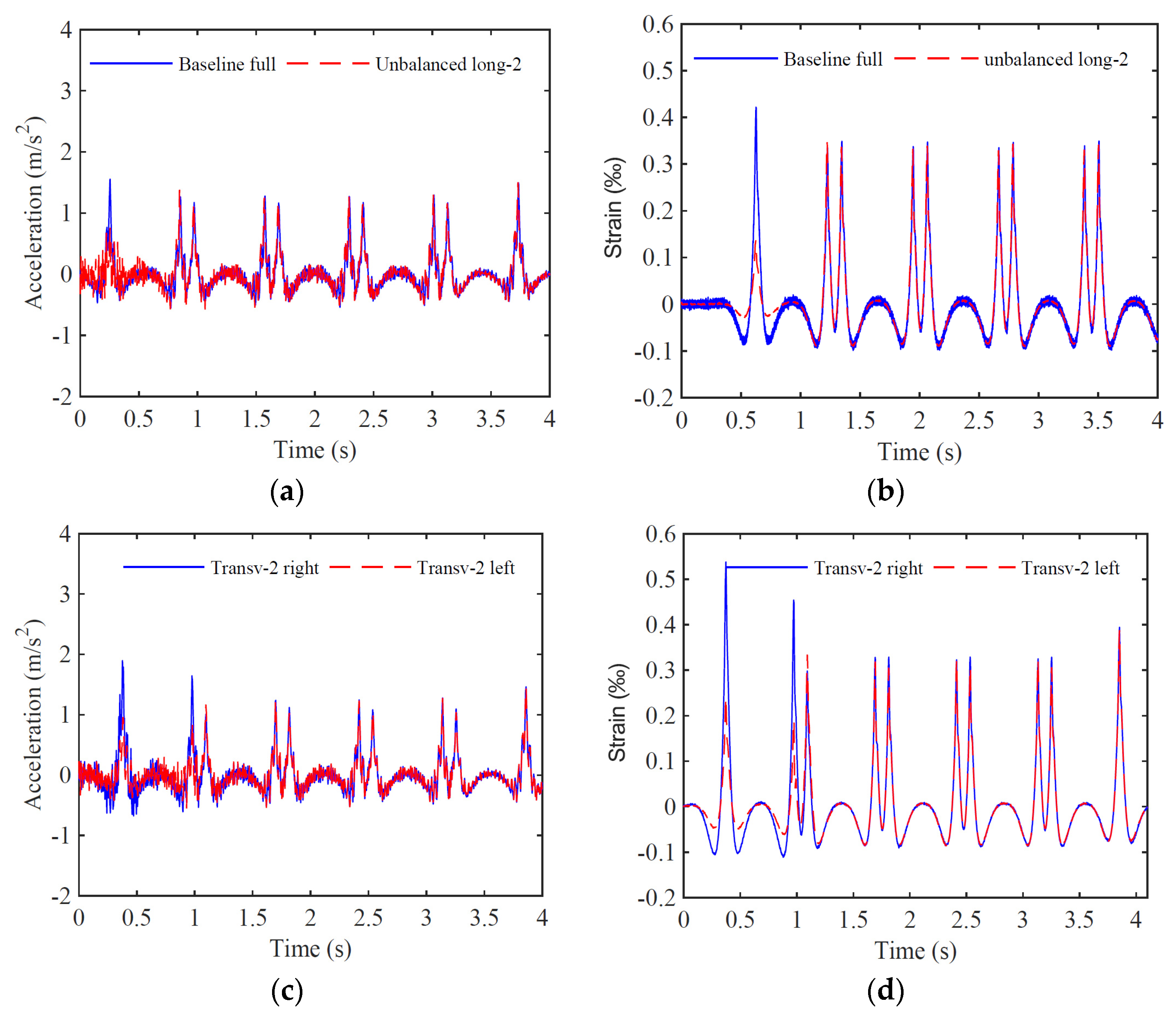

3.3. Unbalanced Scenarios

3.4. Track Dynamic Response

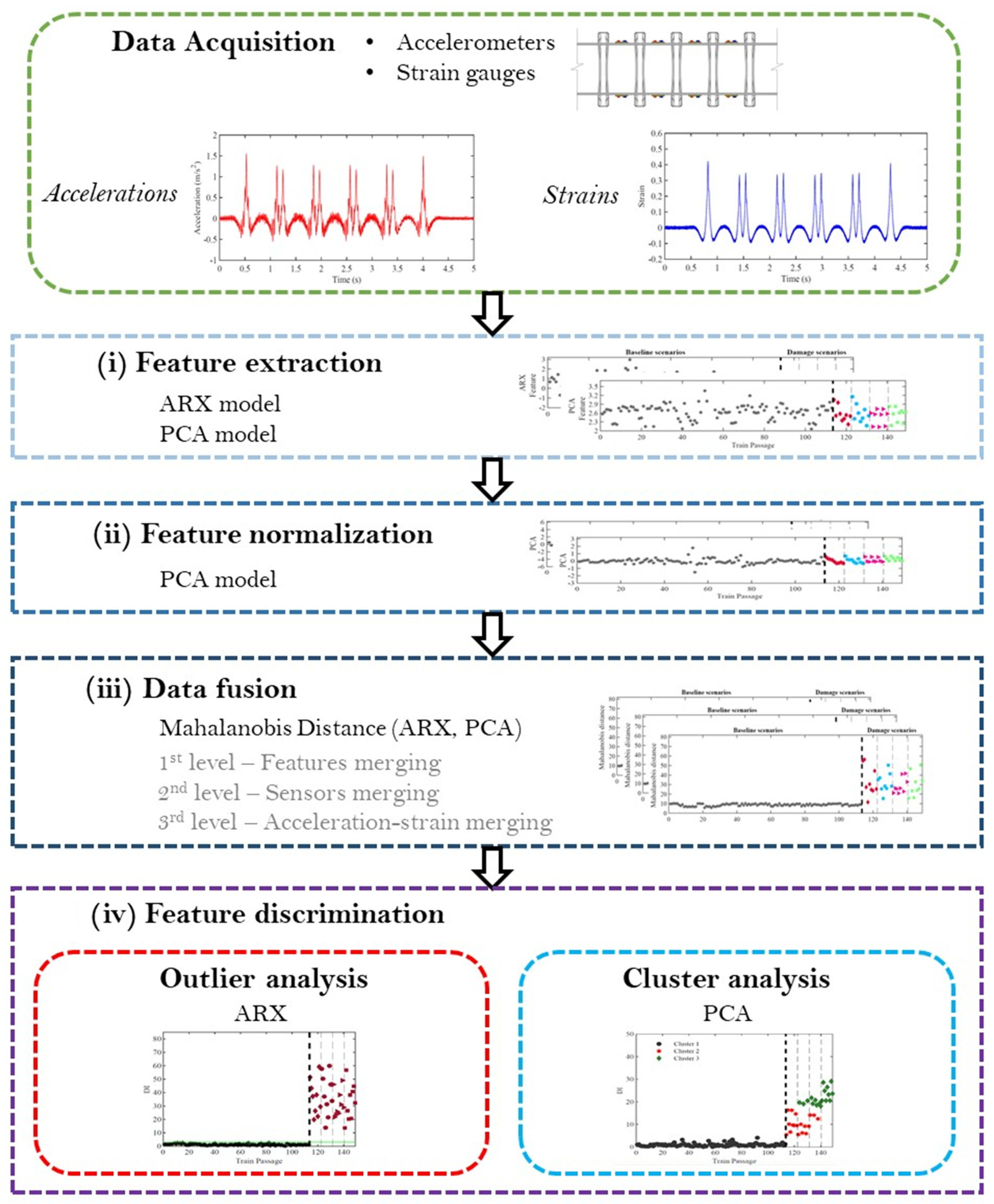

4. Methodology for Unbalanced Loads Detection

4.1. Overview

- (i)

- The feature extraction from the measured data is made by testing two different indicator extraction techniques, namely, ARX models and PCA.

- (ii)

- To remove the effects of operational and environmental variations, the method of latent variables PCA is adopted.

- (iii)

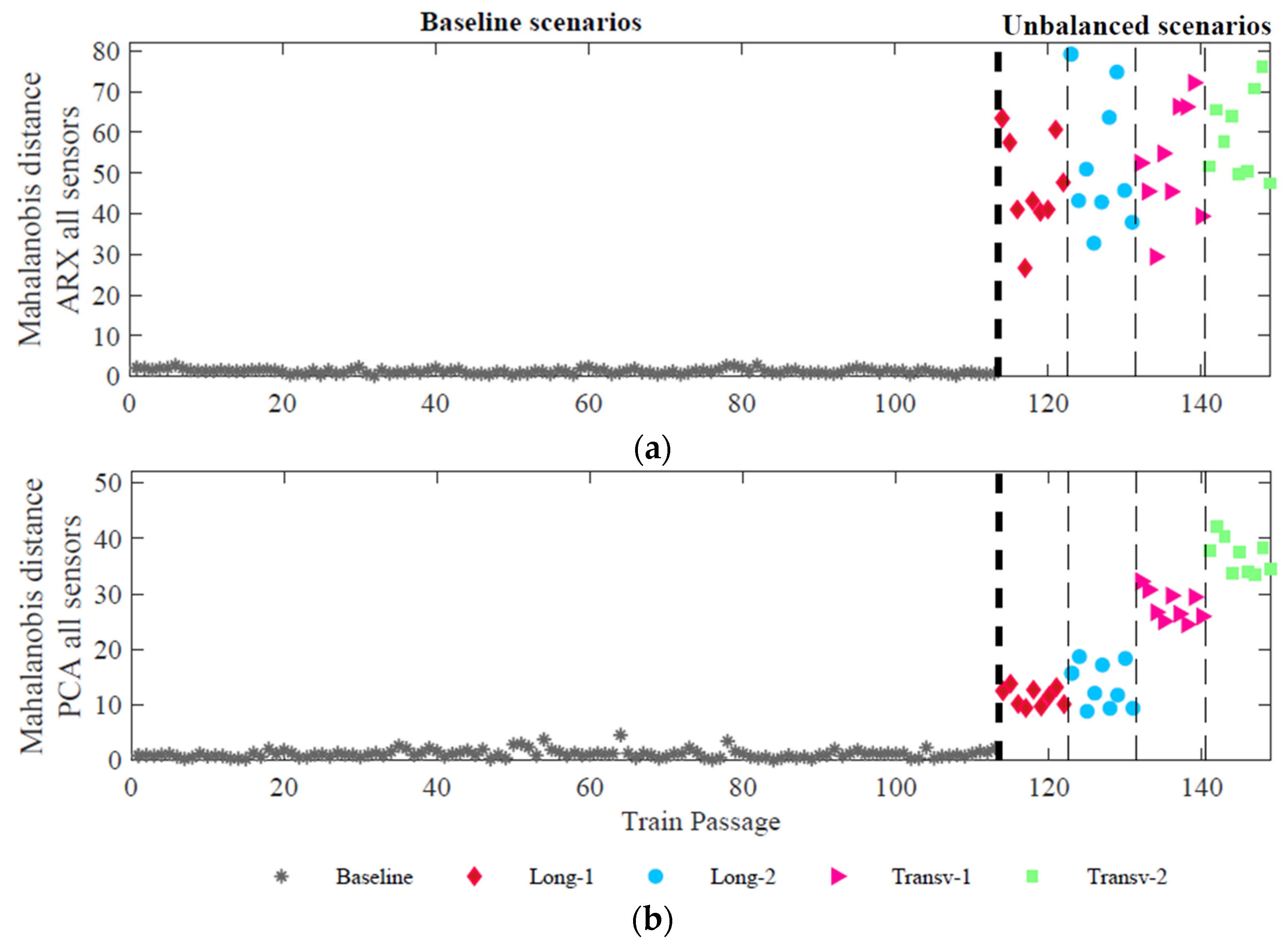

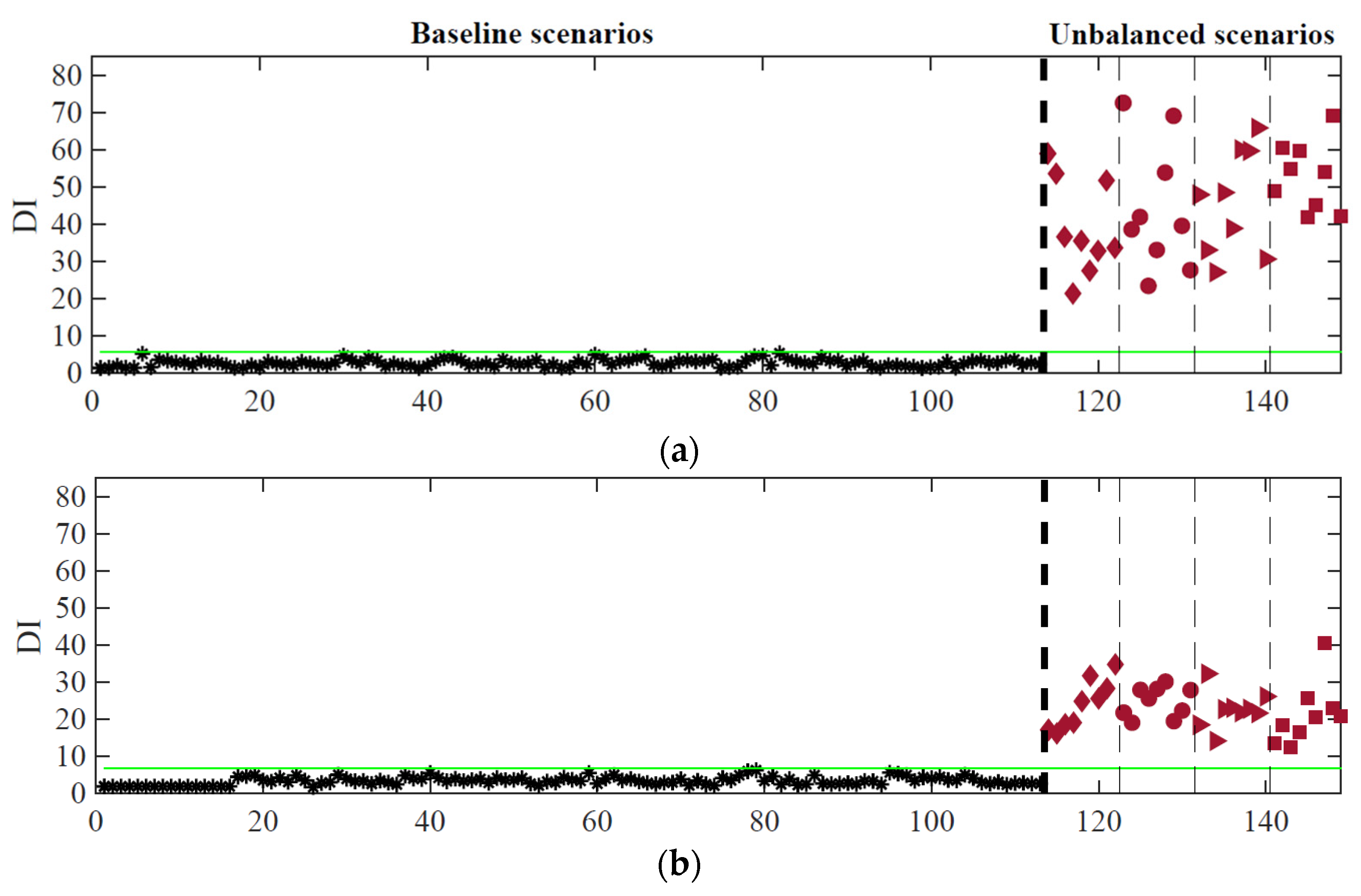

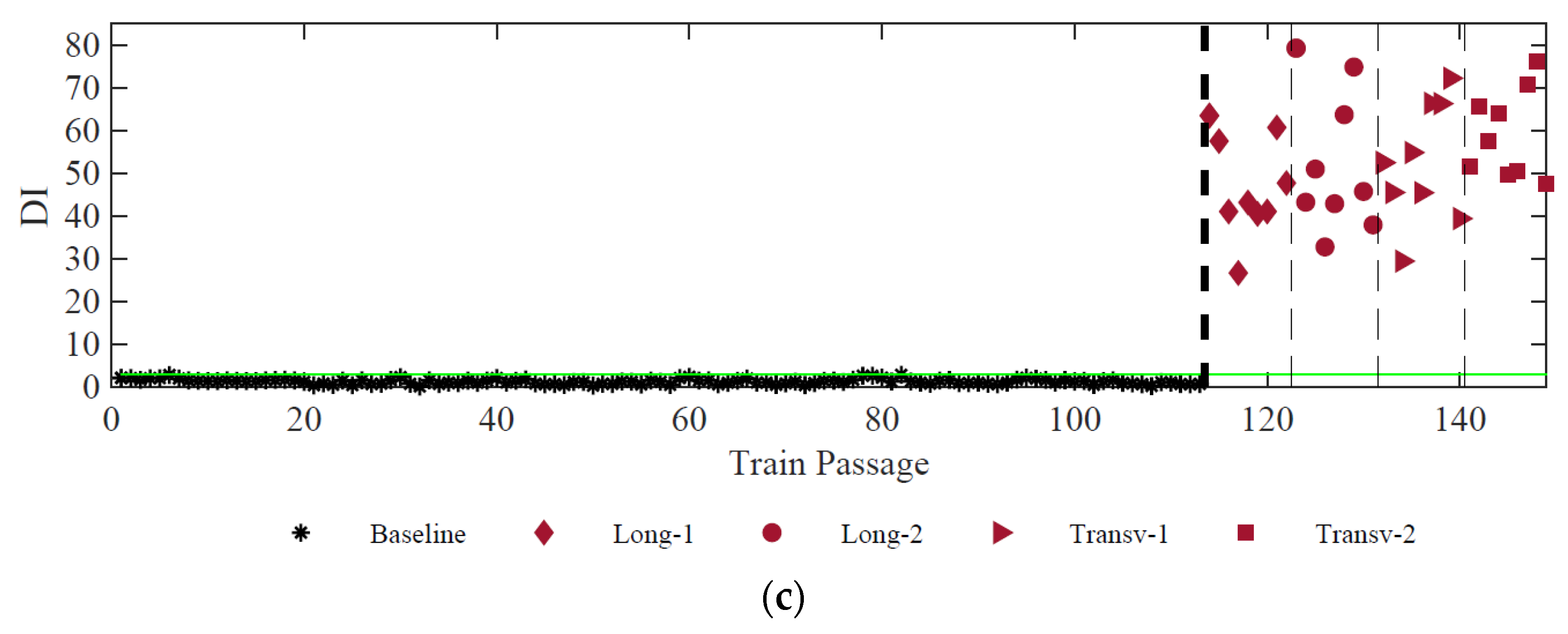

- The Mahalanobis distance is then used for the fusion of all features into one damage index for each simulation but also to combine features from various sources. Thus, in the first level is performed the fusion of all features, in the second level, the fusion of all sensors, and in the third level, the fusion of the different measured quantities, in this case, accelerations and strains.

- (iv)

- For feature discrimination, automatic detection is achieved by combining ARX-based features and outliers analysis, and for classification, an automatic clustering process based on the k-means technique and PCA-based features is implemented.

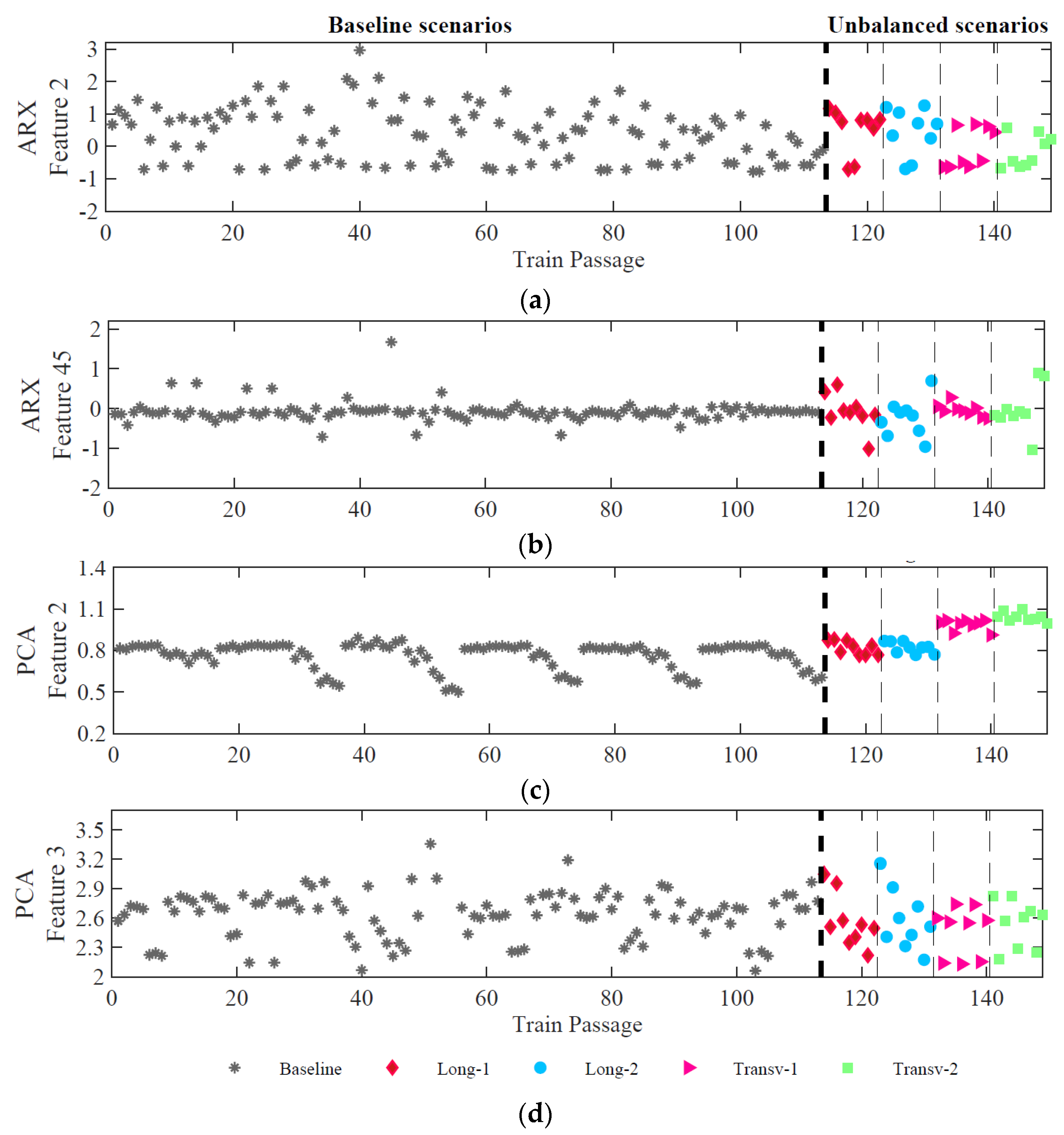

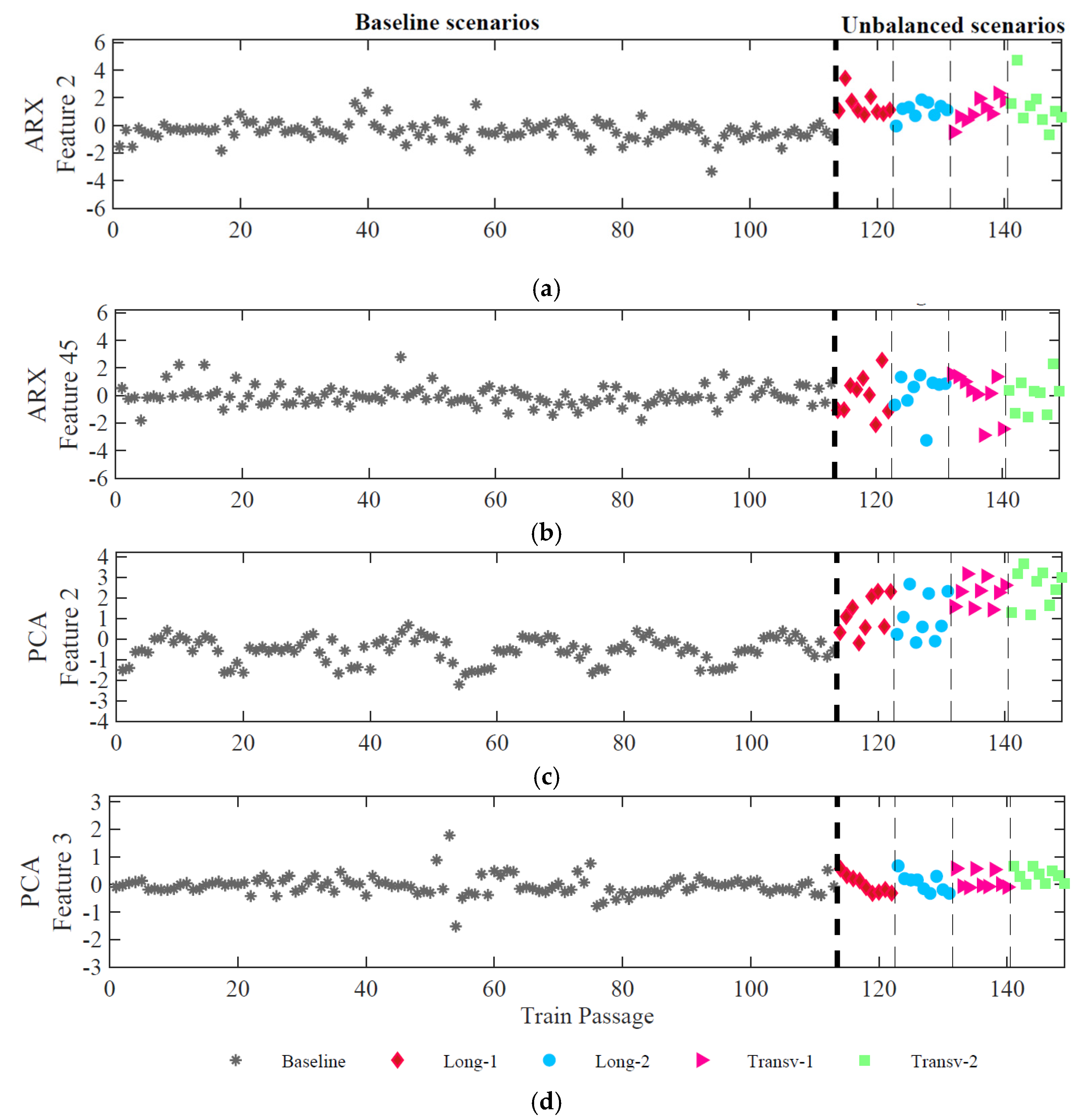

4.2. Feature Extraction—ARX vs. PCA

- -

- Matrix XARX with 149 × 80, ARX features;

- -

- Matrix XPCA with 149 × 4, PCA features.

4.3. Feature Normalization—PCA

4.4. Data Fusion—Mahalanobis Distance

4.5. Feature Discrimination

4.5.1. Outlier Analysis

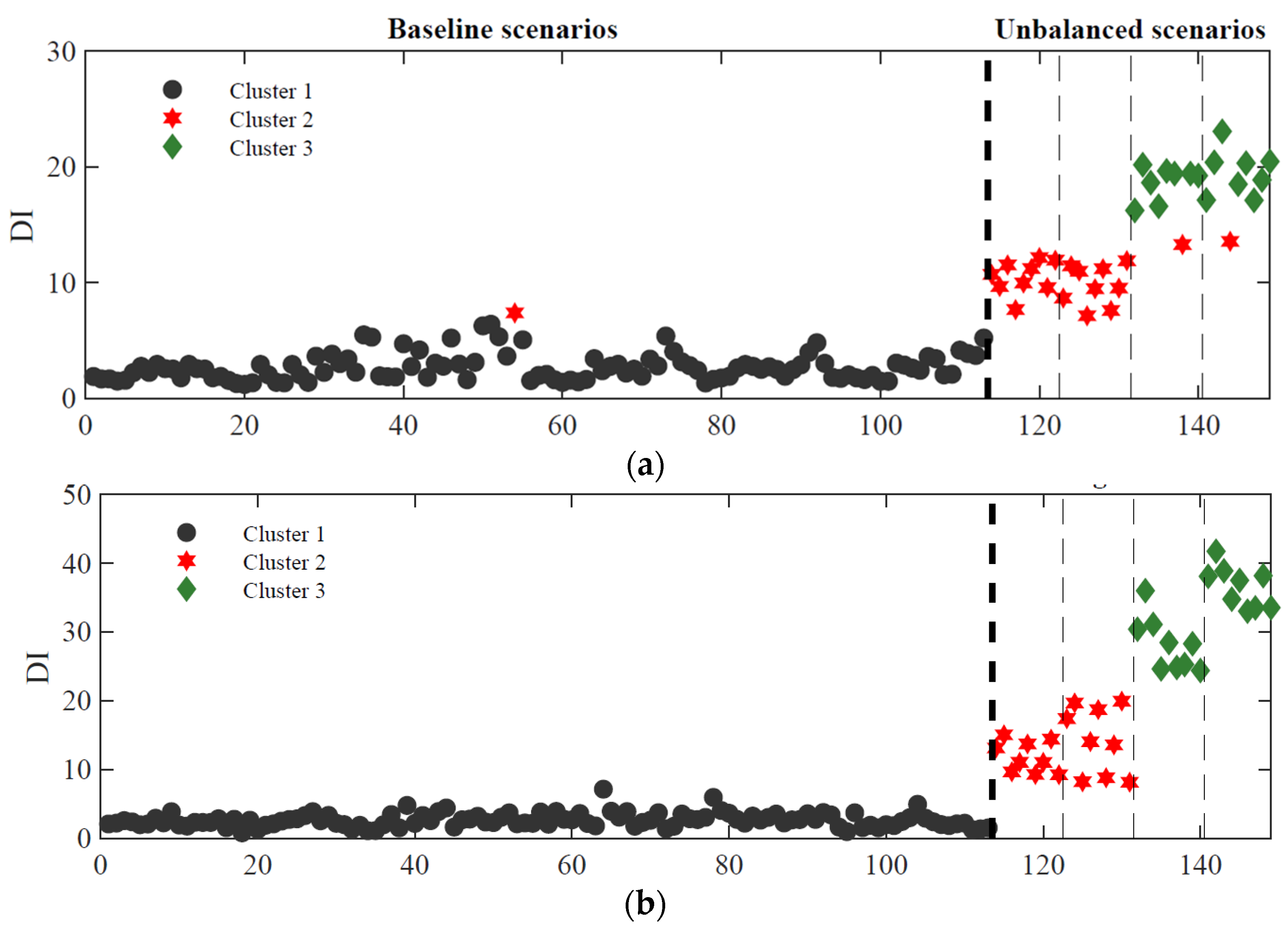

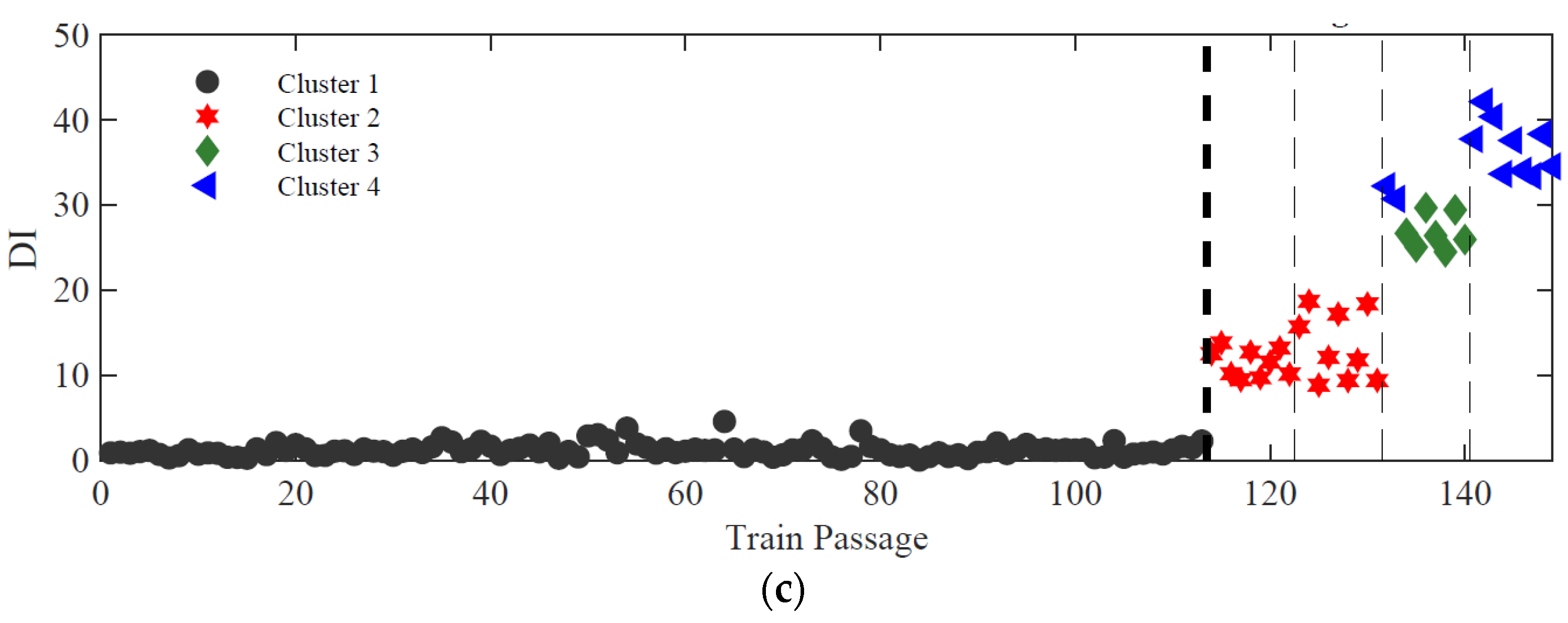

4.5.2. Cluster Analysis

4.5.3. Sensitivity for Different Sensor Layouts

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Montenegro, P.A.; Carvalho, H.; Ribeiro, D.; Calçada, R.; Tokunaga, M.; Tanabe, M.; Zhai, W.M. Assessment of train running safety on bridges: A literature review. Eng. Struct. 2021, 241, 112425. [Google Scholar] [CrossRef]

- Alves, V.; Meixedo, A.; Ribeiro, D.; Calçada, R.; Cury, A. Evaluation of the Performance of Different Damage Indicators in Railway Bridges. Procedia Eng. 2015, 114, 746–753. [Google Scholar] [CrossRef]

- Pintão, B.; Mosleh, A.; Vale, C.; Montenegro, P.; Costa, P. Development and Validation of a Weigh-in-Motion Methodology for Railway Tracks. Sensors 2022, 22, 1976. [Google Scholar] [CrossRef] [PubMed]

- Transportation Technology Center, Inc. General Rules Covering Loading of Carload Shipments of Commodities in Closed Cars; Transportation Technology Center, Inc.: Pueblo, CO, USA, 2010. [Google Scholar]

- Chinese Railway. General Rules Covering Loading and Reinforcement in Railway Freight Wagons; C.R. Press: Beijing, China, 2006. [Google Scholar]

- UIC. Code of Practice for the Loading and Securing of Goods on Railway Wagons; UIC: Paris, France, 2022. [Google Scholar]

- Zhang, D.; Tang, Y.; Peng, Q.; Dong, C.; Ye, Y. Effect of mass distribution on curving performance for a loaded wagon. Nonlinear Dyn. 2021, 104, 2259–2273. [Google Scholar] [CrossRef]

- Zhang, D.; Tang, Y.; Sun, Z.; Peng, Q. Optimising the location of wagon gravity centre to improve the curving performance. Veh. Syst. Dyn. 2022, 60, 1627–1641. [Google Scholar] [CrossRef]

- Jianjun, P.; Weilai, L.; Xin, D. Train overload and unbalanced load detection based on FBG gauge. In Proceedings of the SPIE Fourth Asia Pacific Optical Sensors Conference, Wuhan, China, 15–18 October 2013. [Google Scholar]

- Pagaimo, J.; Magalhães, H.; Costa, J.N.; Ambrósio, J. Derailment study of railway cargo vehicles using a response surface methodology. Veh. Syst. Dyn. 2022, 60, 309–334. [Google Scholar] [CrossRef]

- RAIB. Rail Accident Investigation Branch. 2022. Available online: https://www.gov.uk/government/organisations/rail-accident-investigation-branch (accessed on 26 January 2023).

- Zakharenko, M.; Frøseth, G.; Rönnquist, A. Train Classification Using a Weigh-in-Motion System and Associated Algorithms to Determine Fatigue Loads. Sensors 2022, 22, 1772. [Google Scholar] [CrossRef]

- Mosleh, A.; Costa, P.; Calçada, R. A new strategy to estimate static loads for the dynamic weighing in motion of railway vehicles. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 234, 183–200. [Google Scholar] [CrossRef]

- Zhou, W.; Abdulhakeem, S.; Fang, C.; Han, T.; Li, G.; Wu, Y.; Faisal, Y. A new wayside method for measuring and evaluating wheel-rail contact forces and positions. Measurement 2020, 166, 108244. [Google Scholar] [CrossRef]

- ARGOS. 2022. Available online: https://www.argos-systems.at/en/ (accessed on 26 January 2023).

- Onat, A.; Kayaalp, B. A Novel Methodology for Dynamic Weigh in Motion System for Railway Vehicles With Traction. IEEE Trans. Veh. Technol. 2019, 68, 10545–10558. [Google Scholar] [CrossRef]

- Costa, B.J.A.; Martins, R.; Santos, M.; Felgueiras, C.; Calçada, R. Weighing-in-motion wireless system for sustainable railway transport. Energy Procedia 2017, 136, 408–413. [Google Scholar] [CrossRef]

- Mosleh, A.; Montenegro, P.A.; Costa, P.A.; Calçada, R. 10—Approaches for Weigh-In-Motion and Wheel Defect Detection of Railway Vehicles, in Rail Infrastructure Resilience; Calçada, R., Kaewunruen, S., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 183–207. [Google Scholar]

- Sekuła, K.; Kołakowski, P. Piezo-based weigh-in-motion system for the railway transport. Struct. Control. Health Monit. 2012, 19, 199–215. [Google Scholar] [CrossRef]

- Jian, S.; Xiugang, W.; Rong, C.; Guan, X.; Zongju, T. Design and research on monitoring system of overload and unbalanced load of freight cars. In Proceedings of the World Automation Congress, Puerto Vallarta, Mexico, 24–28 June 2012. [Google Scholar]

- Maraini, D.; Shahidi, P.; Hopkins, B.; Seidel, A. Development of a Bogie-Mounted Vehicle On-Board Weighing System. In Proceedings of the ASME 2014 Joint Rail Conference, Colorado Springs, CO, USA, 2–4 April 2014. [Google Scholar]

- Tanaka, T.; Sugiyama, H. Prediction of railway wheel load unbalance induced by air suspension leveling valves using quasi-steady curve negotiation analysis procedure. Proc. Inst. Mech. Eng. Part K: J. Multi-Body Dyn. 2019, 234, 19–37. [Google Scholar] [CrossRef]

- Allotta, B.; Gaburri, G.; Innocenti, A.; Marini, L.; Meli, E.; Pugi, L.; D’Adamio, P. An innovative high speed Weigh in Motion system for railway vehicles. In Proceedings of the 2014 IEEE/ASME 10th International Conference on Mechatronic and Embedded Systems and Applications (MESA), Senigallia, Italy, 10–12 September 2014. [Google Scholar]

- Ding, Y.; Cheng, L. High Speed Overload and Imbalance Load System in China. In Proceedings of the 2018 Joint Rail Conference, Pittsburgh, PA, USA, 18–20 April 2018. [Google Scholar]

- Qing, C.; Mei, H. Study on a combined method of Butterworth high-pass filter and Canny edge detector in the application of detecting cargo loading position on railway vehicles. In Proceedings of the 2011 International Conference on Computer Science and Network Technology, Harbin, China, 24–26 December 2011. [Google Scholar]

- Mosleh, A.; Montenegro, P.; Costa, P.A.; Calçada, R. An approach for wheel flat detection of railway train wheels using envelope spectrum analysis. Struct. Infrastruct. Eng. 2021, 17, 1710–1729. [Google Scholar] [CrossRef]

- Mosleh, A.; Meixedo, A.; Ribeiro, D.; Montenegro, P.; Calçada, R. Early wheel flat detection: An automatic data-driven wavelet-based approach for railways. Veh. Syst. Dyn. 2022, 1–30. [Google Scholar] [CrossRef]

- Krummenacher, G.; Ong, C.; Koller, S.; Kobayashi, S.; Buhmann, J. Wheel Defect Detection With Machine Learning. IEEE Trans. Intell. Transp. Syst. 2018, 19, 1176–1187. [Google Scholar] [CrossRef]

- Li, Y.; Zuo, M.; Lin, J.; Liu, J. Fault detection method for railway wheel flat using an adaptive multiscale morphological filter. Mech. Syst. Signal Process. 2017, 84, 642–658. [Google Scholar] [CrossRef]

- Liang, B.; Iwnicki, S.D.; Zhao, Y.; Crosbee, D. Railway wheel-flat and rail surface defect modelling and analysis by time–frequency techniques. Veh. Syst. Dyn. 2013, 51, 1403–1421. [Google Scholar] [CrossRef]

- Mosleh, A.; Montenegro, P.A.; Costa, P.A.; Calçada, R. Railway Vehicle Wheel Flat Detection with Multiple Records Using Spectral Kurtosis Analysis. Appl. Sci. 2021, 11, 4002. [Google Scholar] [CrossRef]

- Ni, Y.-Q.; Zhang, Q.-H. A Bayesian machine learning approach for online detection of railway wheel defects using track-side monitoring. Struct. Health Monit. 2020, 20, 1536–1550. [Google Scholar] [CrossRef]

- Wei, X.; Yin, X.; Hu, Y.; He, Y.; Jia, L. Squats and corrugation detection of railway track based on time-frequency analysis by using bogie acceleration measurements. Veh. Syst. Dyn. 2020, 58, 1167–1188. [Google Scholar] [CrossRef]

- Meixedo, A.; Santos, J.; Ribeiro, D.; Calçada, R.; Todd, M. Damage detection in railway bridges using traffic-induced dynamic responses. Eng. Struct. 2021, 238, 112189. [Google Scholar] [CrossRef]

- Meixedo, A.; Santos, J.; Ribeiro, D.; Calçada, R.; Todd, M. Online unsupervised detection of structural changes using train–induced dynamic responses. Mech. Syst. Signal Process. 2022, 165, 108268. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Chen, Z.; Yan, Y.; Geng, C.; Zuo, M. Time-frequency ridge estimation: An effective tool for gear and bearing fault diagnosis at time-varying speeds. Mech. Syst. Signal Process. 2023, 189, 110108. [Google Scholar] [CrossRef]

- Meixedo, A.; Ribeiro, D.; Santos, J.; Calçada, R.; Todd, M. Real-Time Unsupervised Detection of Early Damage in Railway Bridges Using Traffic-Induced Responses, in Structural Health Monitoring Based on Data Science Techniques; Cury, A., et al., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 117–142. [Google Scholar]

- Shin, S.W.; Yun, C.B.; Futura, H.; Popovics, J.S. Nondestructive Evaluation of Crack Depth in Concrete Using PCA-compressed Wave Transmission Function and Neural Networks. Exp. Mech. 2008, 48, 225–231. [Google Scholar] [CrossRef]

- Meixedo, A.; Ribeiro, D.; Santos, J.; Calçada, R.; Todd, M. 18—Structural Health Monitoring Strategy for Damage Detection in Railway Bridges Using Traffic Induced Dynamic Responses, in Rail Infrastructure Resilience; Calçada, R., Kaewunruen, S., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 389–408. [Google Scholar]

- Mosleh, A.; Meixedo, A.; Ribeiro, D.; Montenegro, P.; Calçada, R. Automatic clustering-based approach for train wheels condition monitoring. Int. J. Rail Transp. 2022, 1–26. [Google Scholar] [CrossRef]

- Javed, K.; Gouriveau, R.; Zerhouni, N.; Nectoux, P. Enabling Health Monitoring Approach Based on Vibration Data for Accurate Prognostics. IEEE Trans. Ind. Electron. 2015, 62, 647–656. [Google Scholar] [CrossRef]

- Cavadas, F.; Smith, I.F.C.; Figueiras, J. Damage detection using data-driven methods applied to moving-load responses. Mech. Syst. Signal Process. 2013, 39, 409–425. [Google Scholar] [CrossRef]

- Wang, J.J.X.; Zhao, R.; Zhang, L.; Duan, L. Multisensory fusion based virtual tool wear sensing for ubiquitous manufacturing. Robot. Comput.-Integr. Manuf. 2017, 45, 47–58. [Google Scholar] [CrossRef]

- Kontolati, K.; Loukrezis, D.; Santos, K.R.M.d.; Giovanis, D.; Shields, M. Manifold learning-based polynomial chaos expansions for high-dimensional surrogate models. Int. J. Uncertain. Quantif. 2021, 12, 39–64. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, Y.; Mu, F.; Cheng, J.; Li, C.; Chen, C. Multimodal MRI Volumetric Data Fusion With Convolutional Neural Networks. IEEE Trans. Instrum. Meas. 2022, 71, 1–15. [Google Scholar] [CrossRef]

- Qian, L.; Zhang, L.; Bao, X.; Li, F.; Yang, J. Supervised sparse neighbourhood preserving embedding. IET Image Process. 2017, 11, 190–199. [Google Scholar] [CrossRef]

- William Nick, K.A.; Bullock, G.; Esterline, A.; Sundaresan, M. A Study of Machine Learning Techniques for Detecting and Classifying Structural Damage. Int. J. Mach. Learn. Comput. 2015, 5, 313–318. [Google Scholar] [CrossRef]

- Addin, O.; Sapuan, S.M.; Mahdi, E.; Othman, M. A Naïve-Bayes classifier for damage detection in engineering materials. Mater. Des. 2007, 28, 2379–2386. [Google Scholar] [CrossRef]

- Vitola, J.; Pozo, F.; Tibaduiza, D.A.; Anaya, M. Distributed Piezoelectric Sensor System for Damage Identification in Structures Subjected to Temperature Changes. Sensors 2017, 17, 1252. [Google Scholar] [CrossRef] [PubMed]

- Bragança, C.; Neto, J.; Pinto, N.; Montenegro, P.; Ribeiro, D.; Carvalho, H.; Calçada, R. Calibration and validation of a freight wagon dynamic model in operating conditions based on limited experimental data. Veh. Syst. Dyn. 2022, 60, 3024–3050. [Google Scholar] [CrossRef]

- ANSYS®, Academic Research, Release 19.2; Ansys Academic: Canonsburg, PA, USA, 2018.

- MATLAB®, Version R2018a; Matlab: Natick, MA, USA, 2018.

- 13848-2:2006; Railway Applications—Track—Track Geometry Quality—Part 2: Measuring Systems—Track Recording Vehicles, CEN/TC 256. European Standards: Brussels, Belgium, 2006.

- Montenegro, P.A.; Neves, S.G.M.; Calçada, R.; Tanabe, M.; Sogabe, M. Wheel–rail contact formulation for analyzing the lateral train–structure dynamic interaction. Comput. Struct. 2015, 152, 200–214. [Google Scholar] [CrossRef]

- Montenegro, P.A.; Heleno, R.; Carvalho, H.; Calçada, R.; Baker, C.J. A comparative study on the running safety of trains subjected to crosswinds simulated with different wind models. J. Wind. Eng. Ind. Aerodyn. 2020, 207, 104398. [Google Scholar] [CrossRef]

- Neto, J.; Montenegro, P.A.; Vale, C.; Calçada, R. Evaluation of the train running safety under crosswinds—A numerical study on the influence of the wind speed and orientation considering the normative Chinese Hat Model. Int. J. Rail Transp. 2021, 9, 204–231. [Google Scholar] [CrossRef]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Für Die Reine Und Angew. Math. 1882, 92, 156–171. [Google Scholar]

- Kalker, J. Book of Tables for the Hertzian Creep-Force Law; Delft University of Technology, Faculty of Technical Mathematics and Informatics: Budapest, Hungary, 1996. [Google Scholar]

- Figueiredo, E.; Park, G.; Farrar, C.R.; Worden, K.; Figueiras, J. Machine learning algorithms for damage detection under operational and environmental variability. Struct. Health Monit. 2010, 10, 559–572. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, Y.; Li, Z.; Gardoni, P. Machine learning approaches to estimate suspension parameters for performance degradation assessment using accurate dynamic simulations. Reliab. Eng. Syst. Saf. 2023, 230, 108950. [Google Scholar] [CrossRef]

- Sousa Tomé, E.; Pimentel, M.; Figueiras, J. Damage detection under environmental and operational effects using cointegration analysis—Application to experimental data from a cable-stayed bridge. Mech. Syst. Signal Process. 2020, 135, 106386. [Google Scholar] [CrossRef]

| Carbody | Wheelset | Suspensions | |||

|---|---|---|---|---|---|

| Parameter | Value | Parameter | Value | Parameter | Value |

| Mass | 13.5 | Mass | 1247 | Longitudinal stiffness | 44,981 |

| Roll moment of inertia, | 49 | Roll moment of inertia | 312 | Lateral stiffness | 30,948 |

| Pitch moment of inertia, | 673 | Yaw moment of inertia | 312 | Vertical stiffness | 1860 |

| Yaw moment of inertia | 665 | Vertical damping | 16.7 | ||

| Length | 10 | ||||

| Height | 2.17 | ||||

| Width | 2.297 | ||||

| Parameter | Value | |

|---|---|---|

| Rail | Ar (m2) | 7.67 × 10−4 |

| ρr (kg.m3) | 7850 | |

| Ir (m4) | 30.38 × 10−6 | |

| Er (N/m2) | 210 × 109 | |

| Rail pad | Kp (N/m) (Kx/Ky Kz) | 20 × 106/20 × 106/500 × 106 |

| Cp (N.s/m) (Cx/Cy Cz) | 50 × 103/50 × 103/200 × 103 | |

| Sleeper | ρs (N/m) | 2590 |

| Ballast | Kb (N/m) (Kx/Ky Kz) | 900 × 103/2250 × 103/30 × 106 |

| Cb (N/m) (Cx/Cy Cz) | 15 × 103/15 × 103/15 × 103 | |

| Foundation | Kf (N/m) (Kx/Ky Kz) | 20 × 106/20 × 106/20 × 106 |

| Sensors (Accelerometers + Strain Gauges) | Detection | Classification | |||

|---|---|---|---|---|---|

| False Positives | False Negatives | Cluster | Groups | False Classifications | |

| 16 (8 + 8) | 0% (0/113) | 0% (0/36) | 3 | (Long 1-2) (Transv1) (Transv2) | 6% (2/36) |

| 12 (6 + 6) | 0% (0/113) | 0% (0/36) | 2 | (Long 1-2) (Transv 1-2) | 6% (2/36) |

| 8 (4 + 4) | 0% (0/113) | 0% (0/36) | 2 | (Long 1-2) (Transv 1-2) | 8% (3/36) |

| 4 (2 + 2) | 2% (2/113) | 0% (0/36) | 2 | (Long 1-2) (Transv 1-2) | 25% (9/36) |

| 2 (2 + 0) | 1% (1/113) | 0% (0/36) | 2 | (Long 1-2) (Transv 1-2) | 28% (10/36) |

| 2 (0 + 2) | 1% (1/113) | 0% (0/36) | 2 | (Long 1-2) (Transv 1-2) | 39% (14/36) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, R.; Guedes, A.; Ribeiro, D.; Vale, C.; Meixedo, A.; Mosleh, A.; Montenegro, P. Early Identification of Unbalanced Freight Traffic Loads Based on Wayside Monitoring and Artificial Intelligence. Sensors 2023, 23, 1544. https://doi.org/10.3390/s23031544

Silva R, Guedes A, Ribeiro D, Vale C, Meixedo A, Mosleh A, Montenegro P. Early Identification of Unbalanced Freight Traffic Loads Based on Wayside Monitoring and Artificial Intelligence. Sensors. 2023; 23(3):1544. https://doi.org/10.3390/s23031544

Chicago/Turabian StyleSilva, R., A. Guedes, D. Ribeiro, C. Vale, A. Meixedo, A. Mosleh, and P. Montenegro. 2023. "Early Identification of Unbalanced Freight Traffic Loads Based on Wayside Monitoring and Artificial Intelligence" Sensors 23, no. 3: 1544. https://doi.org/10.3390/s23031544

APA StyleSilva, R., Guedes, A., Ribeiro, D., Vale, C., Meixedo, A., Mosleh, A., & Montenegro, P. (2023). Early Identification of Unbalanced Freight Traffic Loads Based on Wayside Monitoring and Artificial Intelligence. Sensors, 23(3), 1544. https://doi.org/10.3390/s23031544