Research on Rotating Machinery Fault Diagnosis Based on an Improved Eulerian Video Motion Magnification

Abstract

:1. Introduction

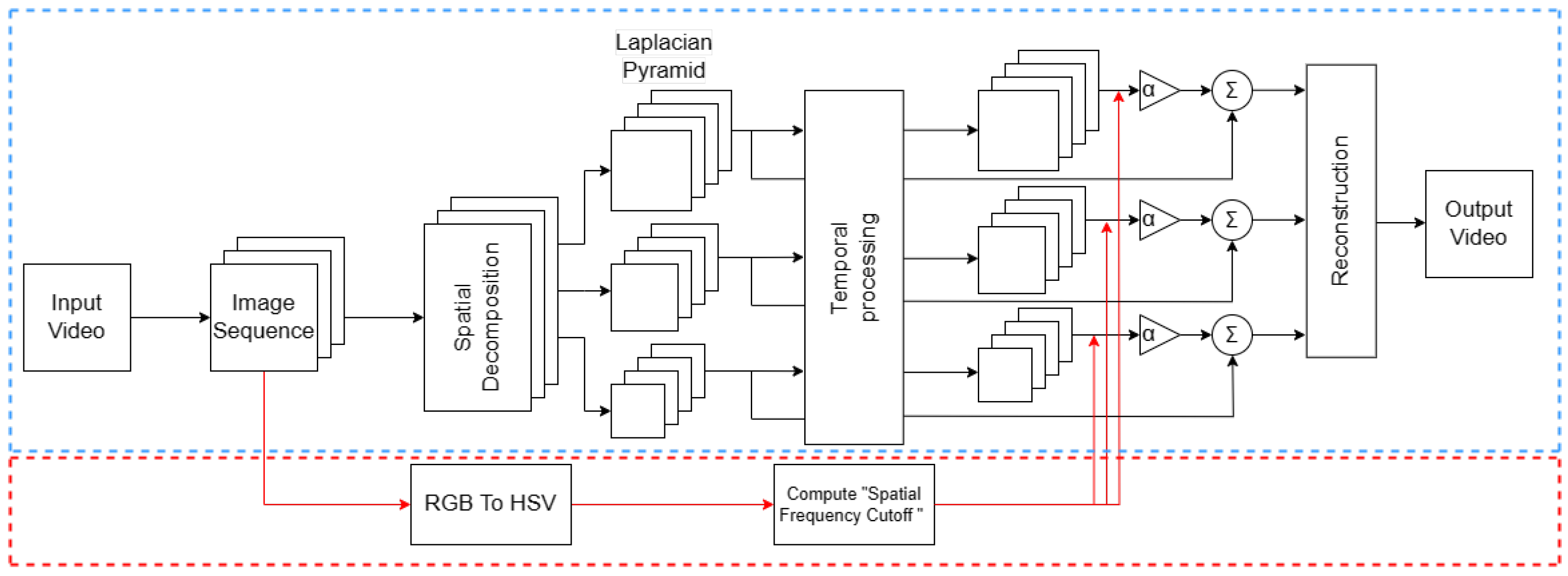

2. Methods

2.1. The Eulerian Motion Magnification Method

2.2. The Automatic Calculation Method for Spatial Cutoff Wavelength

2.3. The Improved Eulerian Video Motion Magnification Method Flow

- Step 1:

- Decompose the input video by frames into image sequences;

- Step 2:

- The image sequences in step (1) are converted from RGB color space to HSV color space, and the spatial cutoff wavelength λc is calculated;

- Step 3:

- The image sequences in step (1) are decomposed into different spatial frequency bands [40] by Laplace pyramid and filtered by butterworth filter to obtain the image signal of the specified frequency band;

- Step 4:

- Using the given amplification factor α and the spatial cutoff wavelength λc calculated in step (2), the motion magnification of each image signal obtained in step (3) is carried out, which is added back to the original signal for reconstruction. Then, the motion magnification video is obtained.

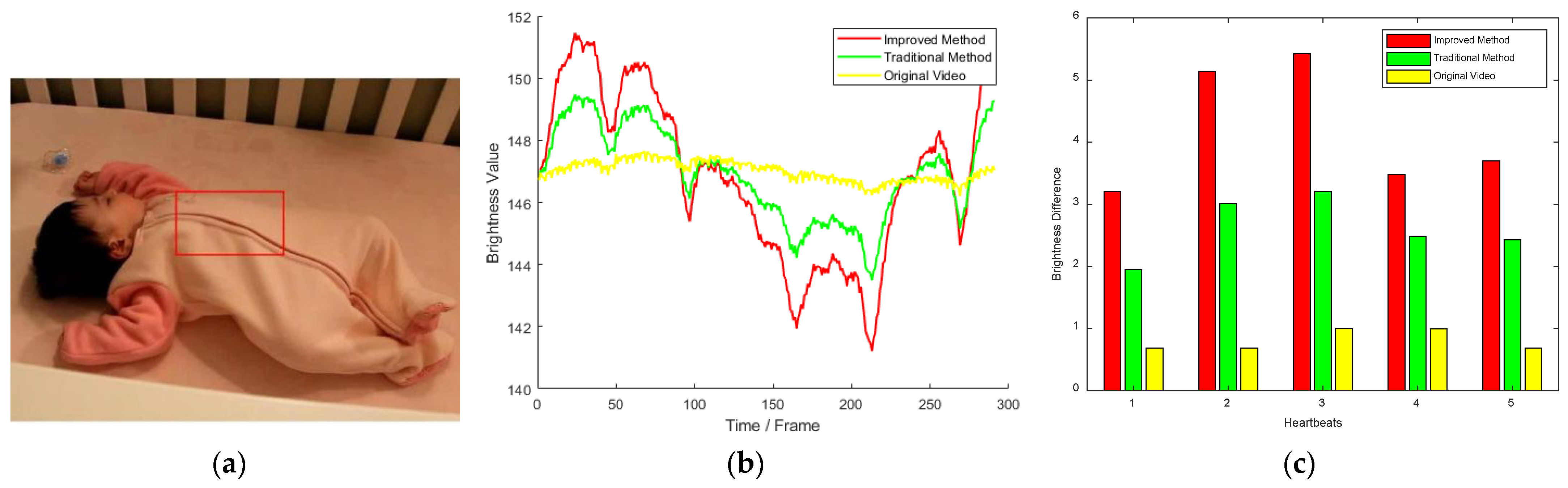

2.4. Simulation Analysis

3. Experiments

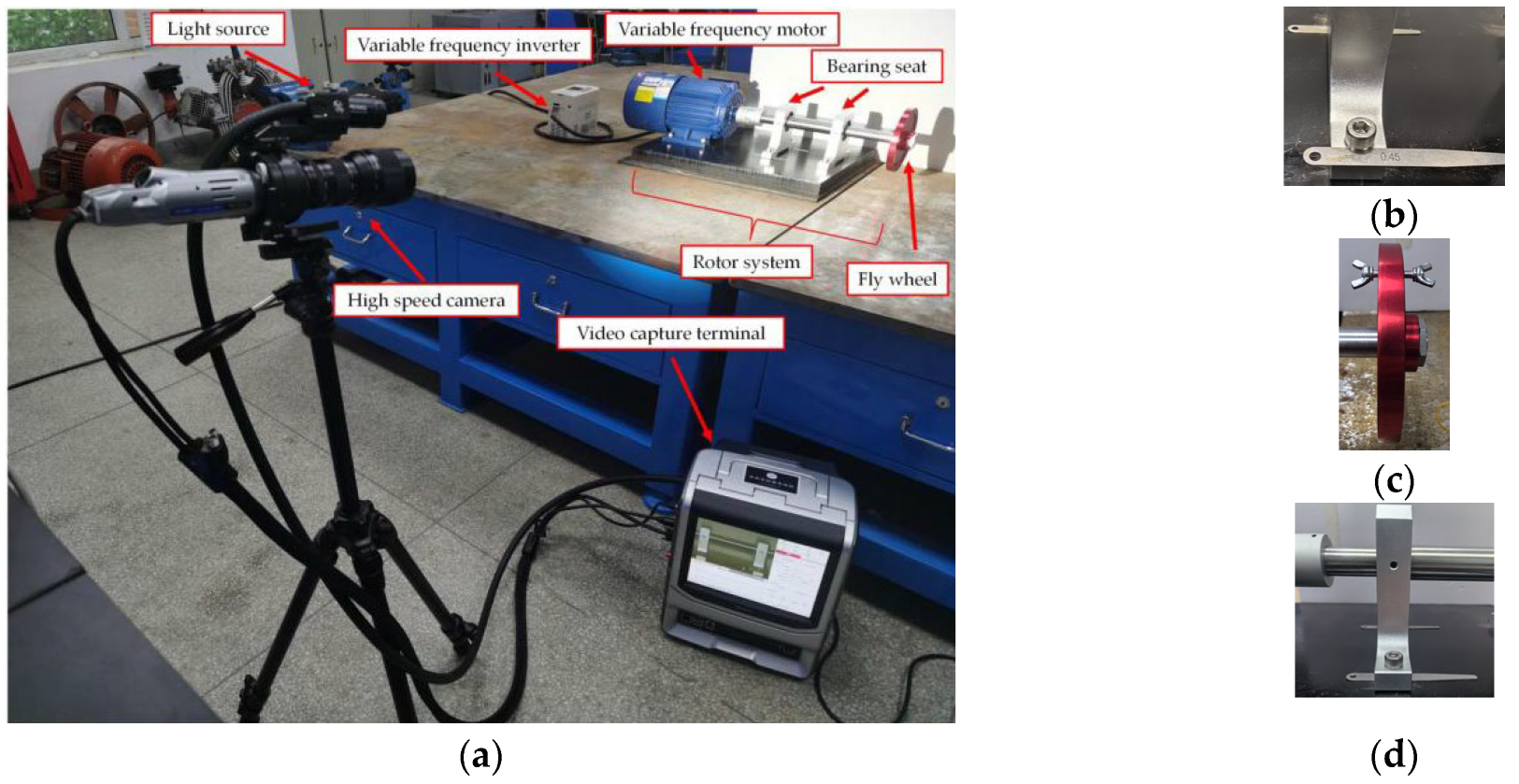

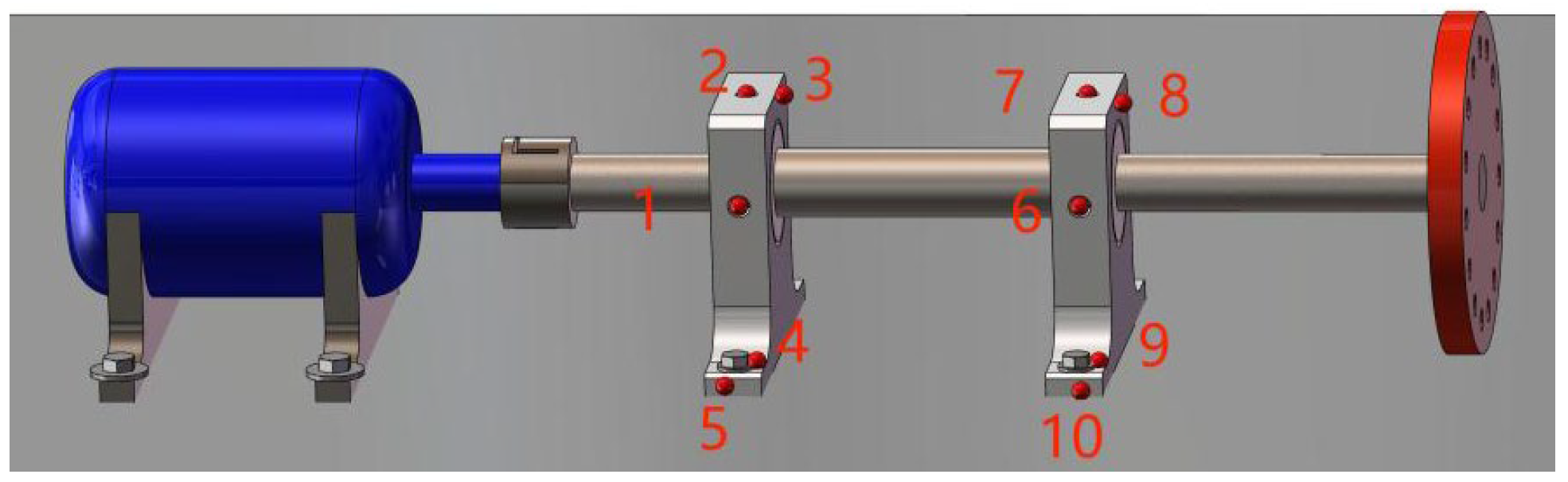

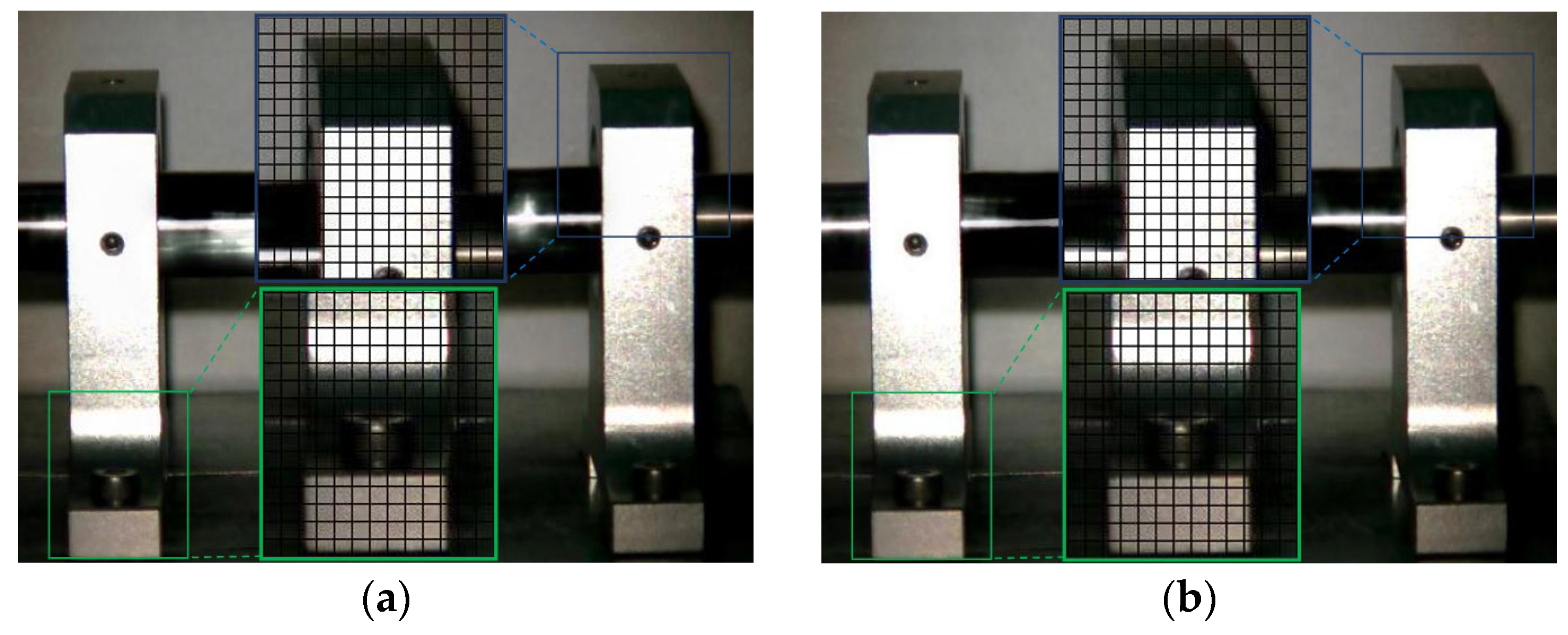

3.1. Experimental Setup

3.2. Test Plan

4. Results and Discussion

4.1. Results and Analysis of Vibration Measurements

4.2. Results and Analysis of the High-Speed Camera Measurement

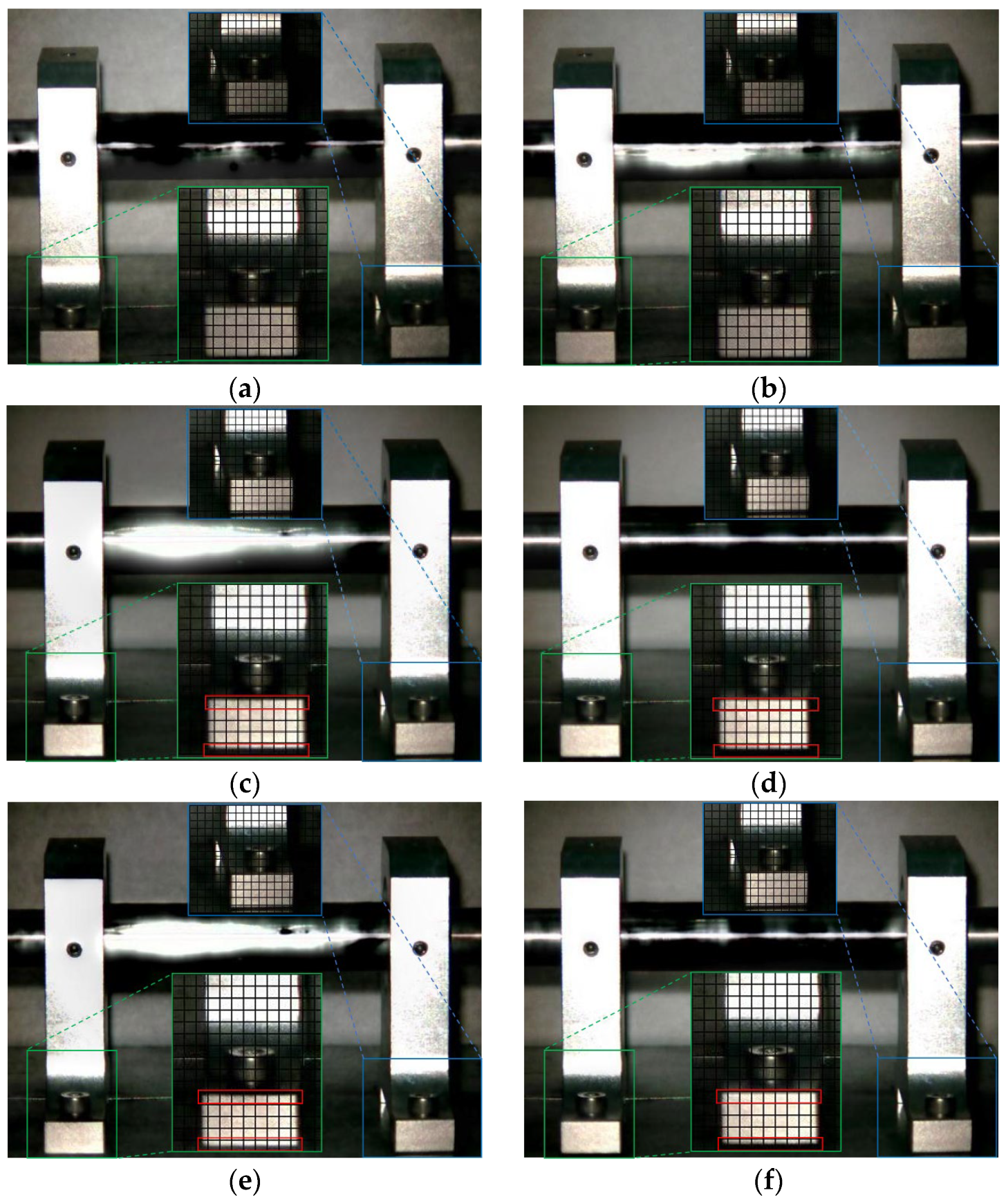

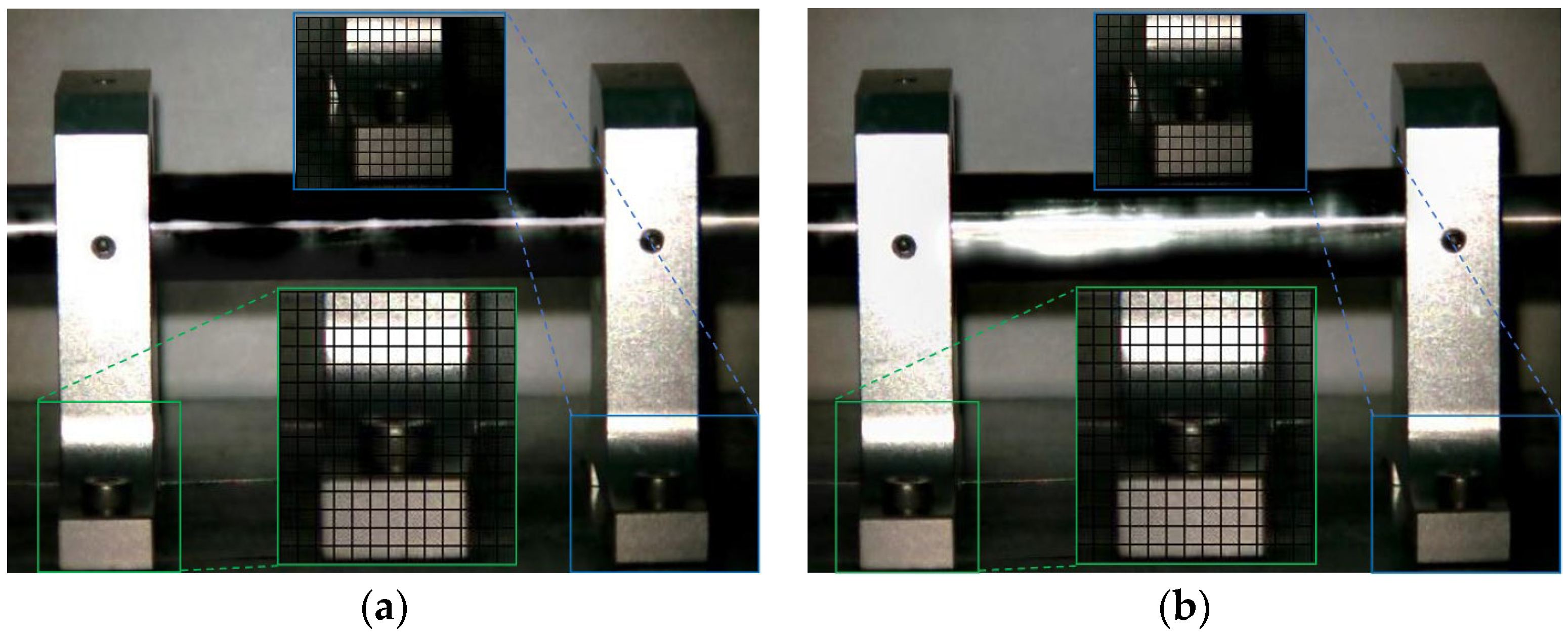

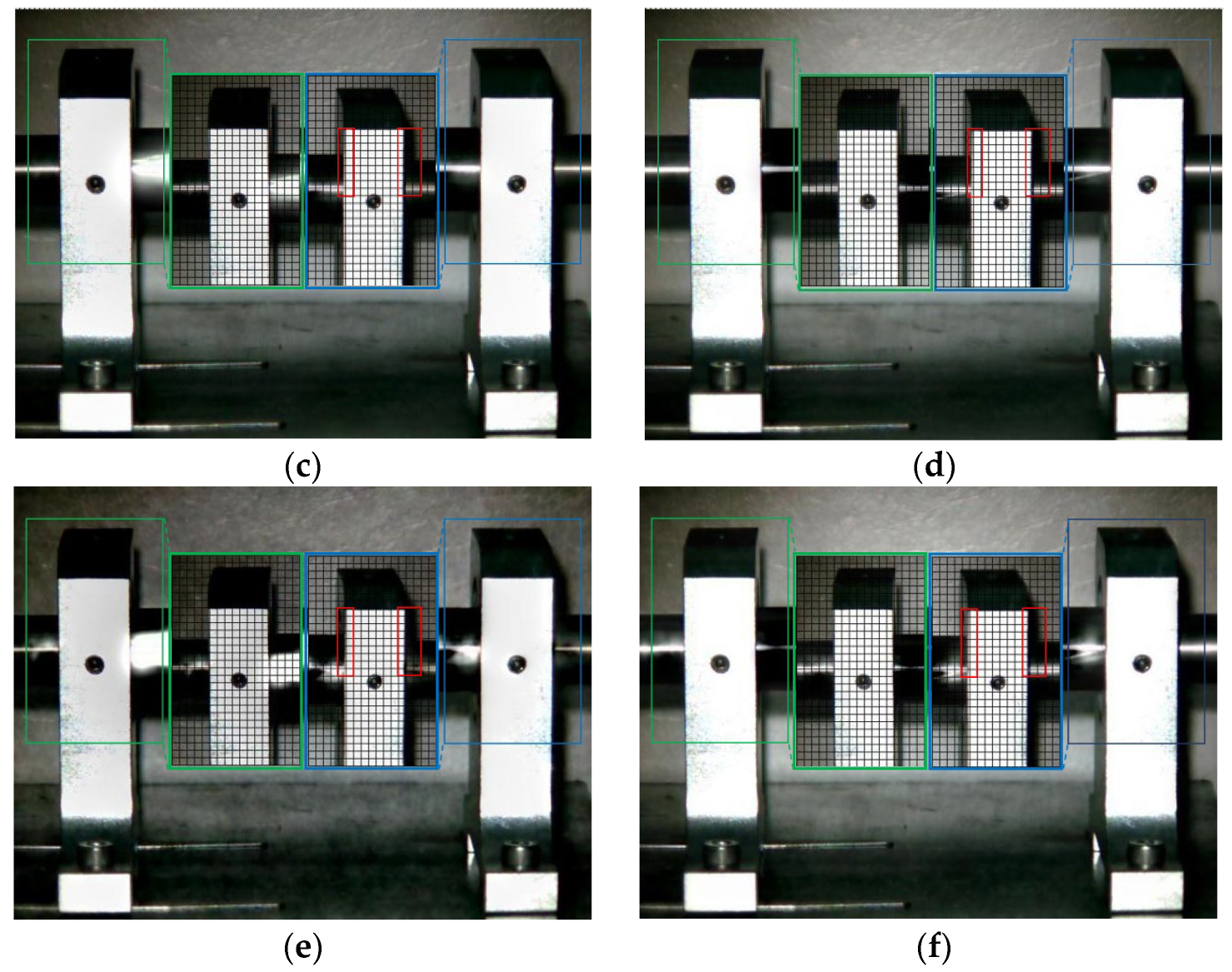

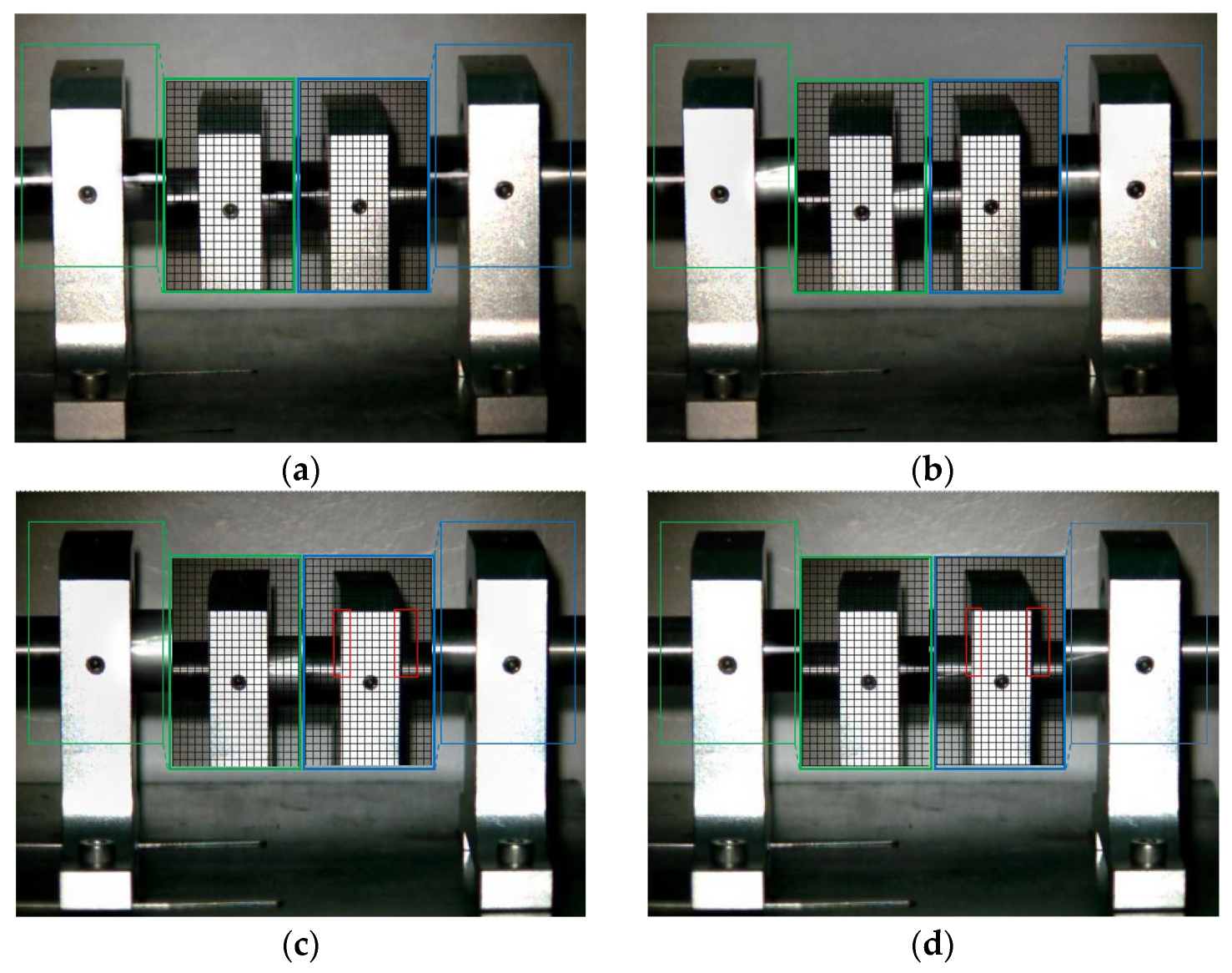

4.2.1. Condition 2

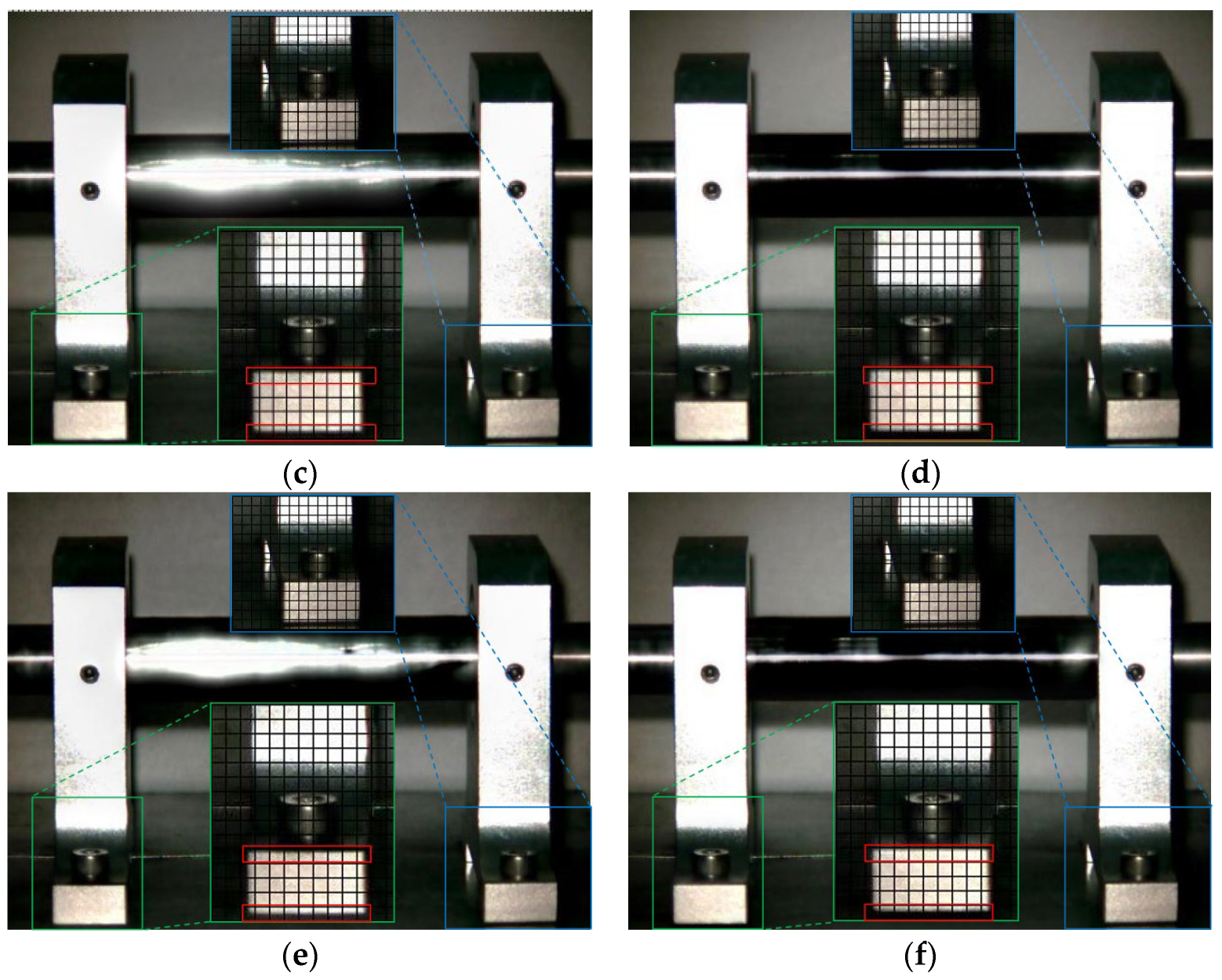

4.2.2. Condition 3

4.2.3. Condition 4

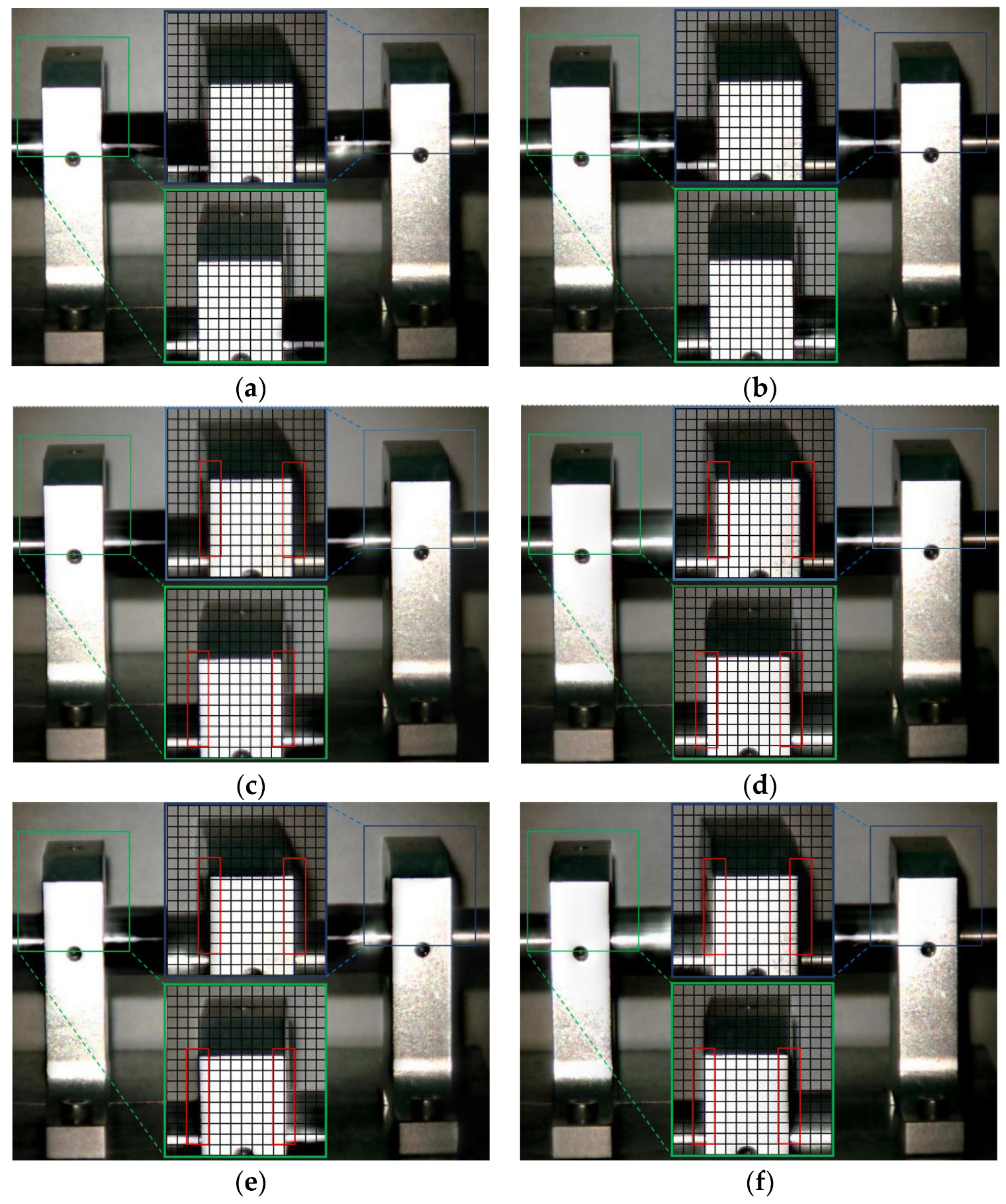

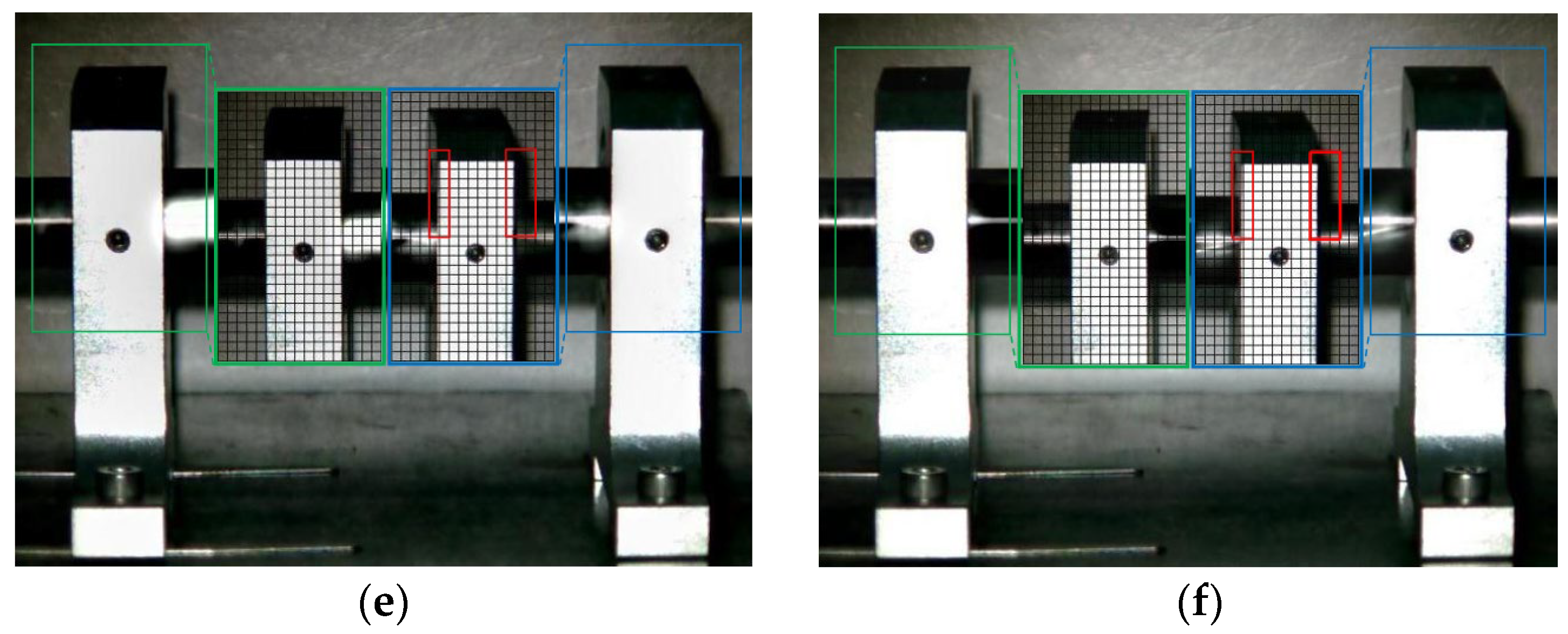

4.2.4. Condition 5

5. Conclusions

- (1)

- Using a sourced publicly available video for the simulation analysis, the proposed automatic calculation method of spatial cutoff wavelength based on HSV color space had strong robustness, and the obtained motion magnification image could better reflect the small motion, which solved the problem of defects arising from the manual parameter adjustment of the current Euler motion magnification method.

- (2)

- Using the improved method, the overhung rotor-bearing test device had no obvious displacement change in the passband region covering 1× frequency and 2× frequency under the normal working condition.

- (3)

- By using the improved method, it can be shown that in the passband region covering 1× frequency and 2× frequency of the overhung rotor-bearing test device, the drive-end bearing seat with the loosened anchor bolt fault had an obvious displacement change in the vertical direction, while the bearing seat without the fault had no obvious displacement in each direction. There were obvious axial displacement changes in both bearing seats under the unbalanced condition. Under the compound fault condition, the motion magnification video comprehensively reflected the single fault characteristics of each condition. Under the misalignment fault condition, axial displacement existed in the free-end bearing seat, but no significant displacement existed in the drive-end bearing seat.

- (4)

- The improved Eulerian video motion magnification method could not only visually diagnose the common faults of rotating machinery, but could also determine the fault location, which provides a new method for the non-contact fault diagnosis of rotating machinery.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. London Ser. A Math. Phys. Eng. Sci. 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, R. Oscillatory behavior-based wavelet decomposition for the monitoring of bearing condition in centrifugal pumps. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 757–772. [Google Scholar] [CrossRef]

- Jiang, H.; Li, C.; Li, H. An improved EEMD with multiwavelet packet for rotating machinery multi-fault diagnosis. Mech. Syst. Signal Process. 2013, 36, 225–239. [Google Scholar] [CrossRef]

- Bentley, P.M.; McDonnell, J. Wavelet transforms: An introduction. Electron. Commun. Eng. J. 1994, 6, 175–186. [Google Scholar] [CrossRef]

- Zhao, X.; Patel, T.H.; Zuo, M.J. Multivariate EMD and full spectrum based condition monitoring for rotating machinery. Mech. Syst. Signal Process. 2012, 27, 712–728. [Google Scholar] [CrossRef]

- Bendjama, H.; Bouhouche, S.; Boucherit, M.S. Application of wavelet transform for fault diagnosis in rotating machinery. Int. J. Mach. Learn. Comput. 2012, 2, 82–87. [Google Scholar] [CrossRef]

- Dossing, O. Structural stroboscopy-measurement of operational deflection shapes. Sound Vib. Mag. 1988, 1, 18–24. [Google Scholar]

- Olson, E.J.; Onari, M.M. Solving Structural Vibration Problems Using Operating Deflection Shape (ODS) Analysis. In Proceedings of the 37th Turbomachinery Symposium, Houston, TX, USA, 8–11 September 2008. [Google Scholar]

- Ganeriwala, S.N.; Schwarz, B.; Richardson, M.H. Operating deflection shapes detect unbalance in rotating equipment. Sound Vib. 2009, 43, 11–13. [Google Scholar]

- Rao, K.B.; Reddy, D.M. Fault diagnosis in rotors using adaptive neuro-fuzzy inference systems. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 2714–2728. [Google Scholar]

- Sperber, C.; Weber, W.; Eberhard, P. Finding useful features in vibration signals for fault diagnosis. Proc. Appl. Math. Mech. 2021, 20, e202000023. [Google Scholar] [CrossRef]

- Masrol, S.R.; Madlan, M.; Md Salleh, S.; Ismon, M.B.; Roslan, M.N. Vibration analysis of unbalanced and misaligned rotor system using laser vibrometer. Appl. Mech. Mater. 2013, 315, 681–685. [Google Scholar] [CrossRef]

- Ozbek, M.; Rixen, D.J. Optical measurements and operational modal analysis on a large wind turbine: Lessons learned. In Proceedings of the 29th IMAC, A Conference on Structural Dynamics, Jacksonville, FL, USA, 31 January–3 February 2011; Volume 5, pp. 257–276. [Google Scholar]

- Lucas, B.D.; Kanade, T. An iterative image registration technique with an application to stereo vision. In Proceedings of the IJCAI’81: 7th International Joint Conference on Artificial Intelligence, Vancouver, BC, Canada, 24–28 August 1981; pp. 674–679. [Google Scholar]

- Baker, S.; Matthews, I. Lucas-kanade 20 years on: A unifying framework. Int. J. Comput. Vis. 2004, 56, 221–255. [Google Scholar] [CrossRef]

- Bay, H.; Tuytelaars, T.; Van Gool, L. Surf: Speeded up robust features. In Proceedings of the Computer Vision—ECCV 2006: 9th European Conference on Computer Vision, Graz, Austria, 7–13 May 2006; pp. 404–417. [Google Scholar]

- Chao, S.; Peng, C. Bearing Fault Diagnosis Method Based on Vision Measurement and Convolutional Neural Network. In Proceedings of the Advances in Guidance, Navigation and Control: Proceedings of 2020 International Conference on Guidance, Navigation and Control, ICGNC 2020, Tianjin, China, 23–25 October 2020; pp. 5429–5437. [Google Scholar]

- Zhang, T.; Shi, D.; Wang, Z.; Zhang, P.; Wang, S.; Ding, X. Vibration-based structural damage detection via phase-based motion estimation using convolutional neural networks. Mech. Syst. Signal Process. 2022, 178, 109320. [Google Scholar] [CrossRef]

- Peng, C.; Zeng, C.; Wang, Y. Camera-based micro-vibration measurement for lightweight structure using an improved phase-based motion extraction. IEEE Sens. J. 2019, 20, 2590–2599. [Google Scholar] [CrossRef]

- Inyang, U.I.; Petrunin, I.; Jennions, I. Diagnosis of multiple faults in rotating machinery using ensemble learning. Sensors 2023, 23, 1005. [Google Scholar] [CrossRef]

- Liu, C.; Torralba, A.; Freeman, W.T.; Durand, F.; Adelson, E.H. Motion magnification. ACM Trans. Graph. 2005, 24, 519–526. [Google Scholar] [CrossRef]

- Sushma, M. Time Frequency Analysis for Motion Magnification and Detection. Master’s Thesis, International Institute of Information Technology, Hyderabad, India, 2015. [Google Scholar]

- Fontanari, T.V.; Oliveira, M.M. Simultaneous magnification of subtle motions and color variations in videos using Riesz pyramids. Comput. Graph. 2021, 101, 35–45. [Google Scholar] [CrossRef]

- Siringoringo, D.M.; Wangchuk, S.; Fujino, Y. Noncontact operational modal analysis of light poles by vision-based motion-magnification method. Eng. Struct. 2021, 244, 112728. [Google Scholar] [CrossRef]

- Eitner, M.; Miller, B.; Sirohi, J.; Tinney, C. Effect of broad-band phase-based motion magnification on modal parameter estimation. Mech. Syst. Signal Process. 2021, 146, 106995. [Google Scholar] [CrossRef]

- Luo, K.; Kong, X.; Wang, X.; Jiang, T.; Frøseth, G.T.; Rønnquist, A. Cable vibration measurement based on broad-band phase-based motion magnification and line tracking algorithm. Mech. Syst. Signal Process. 2023, 200, 110575. [Google Scholar] [CrossRef]

- Sarrafi, A.; Mao, Z.; Niezrecki, C.; Poozesh, P. Vibration-based damage detection in wind turbine blades using Phase-based Motion Estimation and motion magnification. J. Sound Vib. 2018, 421, 300–318. [Google Scholar] [CrossRef]

- Liu, P.; Ma, Z.; Jang, J.; Sohn, H. Motion magnification-based nonlinear ultrasonic signal enhancement and its application to remaining fatigue life estimation of a steel padeye. Mech. Syst. Signal Process. 2023, 200, 110525. [Google Scholar] [CrossRef]

- Fioriti, V.; Roselli, I.; Cataldo, A.; Forliti, S.; Colucci, A.; Baldini, M.; Picca, A. Motion Magnification Applications for the Protection of Italian Cultural Heritage Assets. Sensors 2022, 22, 9988. [Google Scholar] [CrossRef] [PubMed]

- Śmieja, M.; Mamala, J.; Prażnowski, K.; Ciepliński, T.; Szumilas, Ł. Motion Magnification of Vibration Image in Estimation of Technical Object Condition-Review. Sensors 2021, 21, 6572. [Google Scholar] [CrossRef] [PubMed]

- Cataldo, A.; Roselli, I.; Fioriti, V.; Saitta, F.; Colucci, A.; Tatì, A.; Ponzo, F.C.; Ditommaso, R.; Mennuti, C.; Marzani, A. Advanced Video-Based Processing for Low-Cost Damage Assessment of Buildings under Seismic Loading in Shaking Table Tests. Sensors 2023, 23, 5303. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.-Y.; Rubinstein, M.; Shih, E.; Guttag, J.; Durand, F.; Freeman, W. Eulerian video magnification for revealing subtle changes in the world. ACM Trans. Graph. 2012, 31, 1–8. [Google Scholar] [CrossRef]

- Horn, B.K.; Schunck, B.G. Determining optical flow. Artif. Intell. 1981, 17, 185–203. [Google Scholar] [CrossRef]

- Wadhwa, N.; Wu, H.-Y.; Davis, A.; Rubinstein, M.; Shih, E.; Mysore, G.J.; Chen, J.G.; Buyukozturk, O.; Guttag, J.V.; Freeman, W.T. Eulerian video magnification and analysis. Commun. ACM 2016, 60, 87–95. [Google Scholar] [CrossRef]

- Kumar, T.; Verma, K. A Theory Based on Conversion of RGB image to Gray image. Int. J. Comput. Appl. 2010, 7, 7–10. [Google Scholar] [CrossRef]

- Shaik, K.B.; Ganesan, P.; Kalist, V.; Sathish, B.; Jenitha, J.M.M. Comparative study of skin color detection and segmentation in HSV and YCbCr color space. Procedia Comput. Sci. 2015, 57, 41–48. [Google Scholar] [CrossRef]

- Hassan, M.R.; Ema, R.R.; Islam, T. Color image segmentation using automated K-means clustering with RGB and HSV color spaces. Glob. J. Comput. Sci. Technol. 2017, 17, 25–33. [Google Scholar]

- Saravanan, G.; Yamuna, G.; Nandhini, S. Real time implementation of RGB to HSV/HSI/HSL and its reverse color space models. In Proceedings of the 2016 International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 6–8 April 2016; pp. 0462–0466. [Google Scholar]

- Li, S.; Yang, B. Multifocus image fusion using region segmentation and spatial frequency. Image Vis. Comput. 2008, 26, 971–979. [Google Scholar] [CrossRef]

- Wu, X.; Yang, X.; Jin, J.; Yang, Z. Amplitude-based filtering for video magnification in presence of large motion. Sensors 2018, 18, 2312. [Google Scholar] [CrossRef] [PubMed]

| Name | Descriptions |

|---|---|

| Condition 1 | Normal. |

| Condition 2 | Loosen one of the anchor bolts of the drive-end bearing seat. |

| Condition 3 | Fix 13 g bolts at the fly wheel. |

| Condition 4 | Set to the compound fault of condition 2 and condition 3. |

| Condition 5 | A 0.5 mm thickness gasket is arranged under the drive-end bearing seat. |

| Mesurement Point | Condition 1 | Condition 2 | Condition 3 | Condition 4 | Condition 5 |

|---|---|---|---|---|---|

| 1 | 0.24 | 2.04 | 1.86 | 3.23 | 0.77 |

| 2 | 0.35 | 1.26 | 0.34 | 1.12 | 0.3 |

| 3 | 0.70 | 1.22 | 1.71 | 1.50 | 1.28 |

| 4 | 0.22 | 3.6 | 0.42 | 2.48 | 0.21 |

| 5 | 0.27 | 0.16 | 0.26 | 0.23 | 0.2 |

| 6 | 0.35 | 0.29 | 0.52 | 0.48 | 0.54 |

| 7 | 0.23 | 0.24 | 1.9 | 2.0 | 0.61 |

| 8 | 1.04 | 0.67 | 1.71 | 1.12 | 2.94 |

| 9 | 0.26 | 0.27 | 0.41 | 0.5 | 0.36 |

| 10 | 0.29 | 0.24 | 0.46 | 0.4 | 0.33 |

| Condition | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| λc | 51.28 | 51.48 | 56.20 | 58.54 | 51.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, H.; Zhang, X.; Jiang, D.; Gu, J. Research on Rotating Machinery Fault Diagnosis Based on an Improved Eulerian Video Motion Magnification. Sensors 2023, 23, 9582. https://doi.org/10.3390/s23239582

Zhao H, Zhang X, Jiang D, Gu J. Research on Rotating Machinery Fault Diagnosis Based on an Improved Eulerian Video Motion Magnification. Sensors. 2023; 23(23):9582. https://doi.org/10.3390/s23239582

Chicago/Turabian StyleZhao, Haifeng, Xiaorui Zhang, Dengpan Jiang, and Jin Gu. 2023. "Research on Rotating Machinery Fault Diagnosis Based on an Improved Eulerian Video Motion Magnification" Sensors 23, no. 23: 9582. https://doi.org/10.3390/s23239582

APA StyleZhao, H., Zhang, X., Jiang, D., & Gu, J. (2023). Research on Rotating Machinery Fault Diagnosis Based on an Improved Eulerian Video Motion Magnification. Sensors, 23(23), 9582. https://doi.org/10.3390/s23239582