Material-Enabled Impact Detection and Damage Localisation System Using Shape Memory Alloy Tufted Composites

Abstract

1. Introduction

2. Methodology

2.1. Composite T-Joint Samples

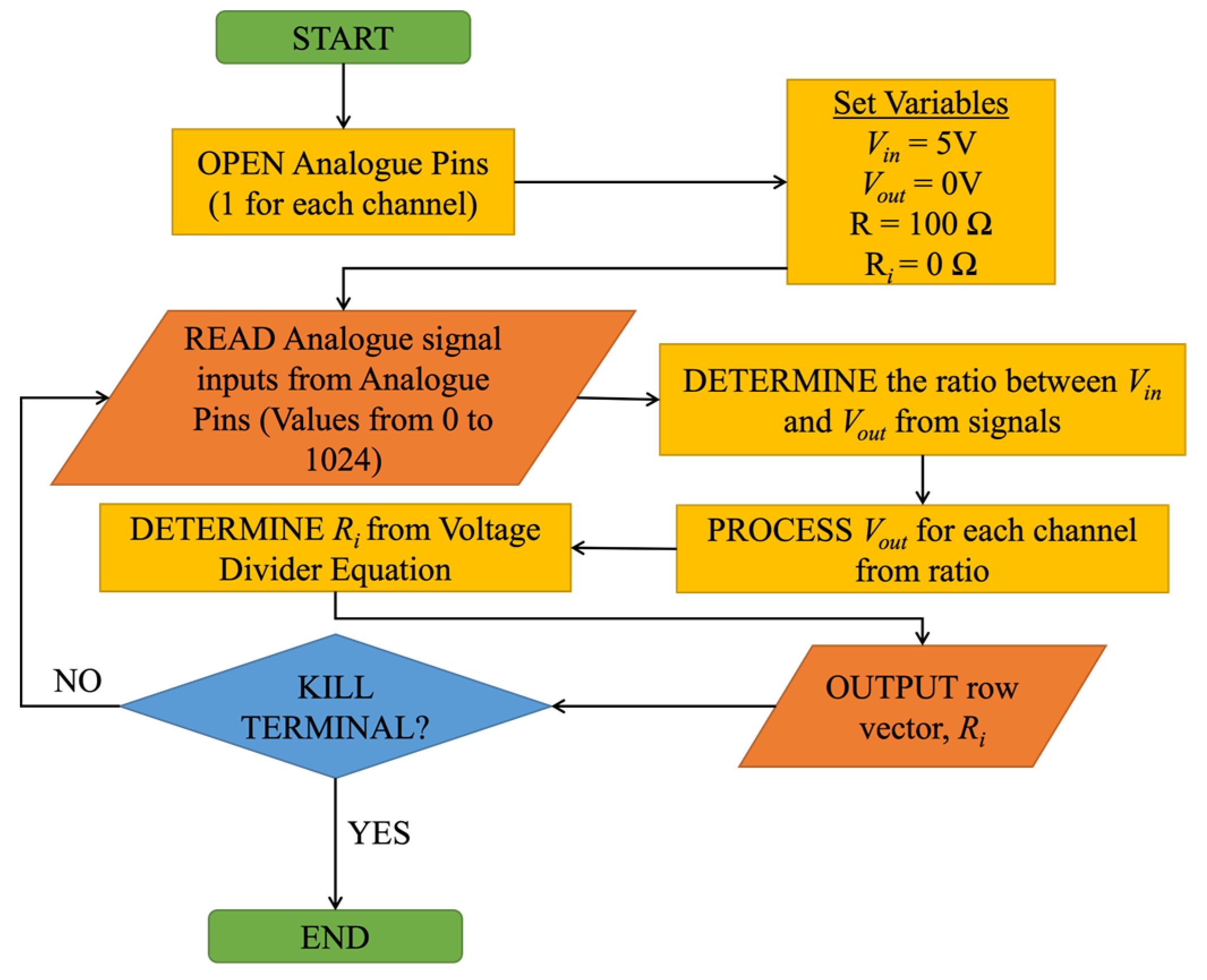

2.2. Multi-Wire Resistance Measurement Using Arduino

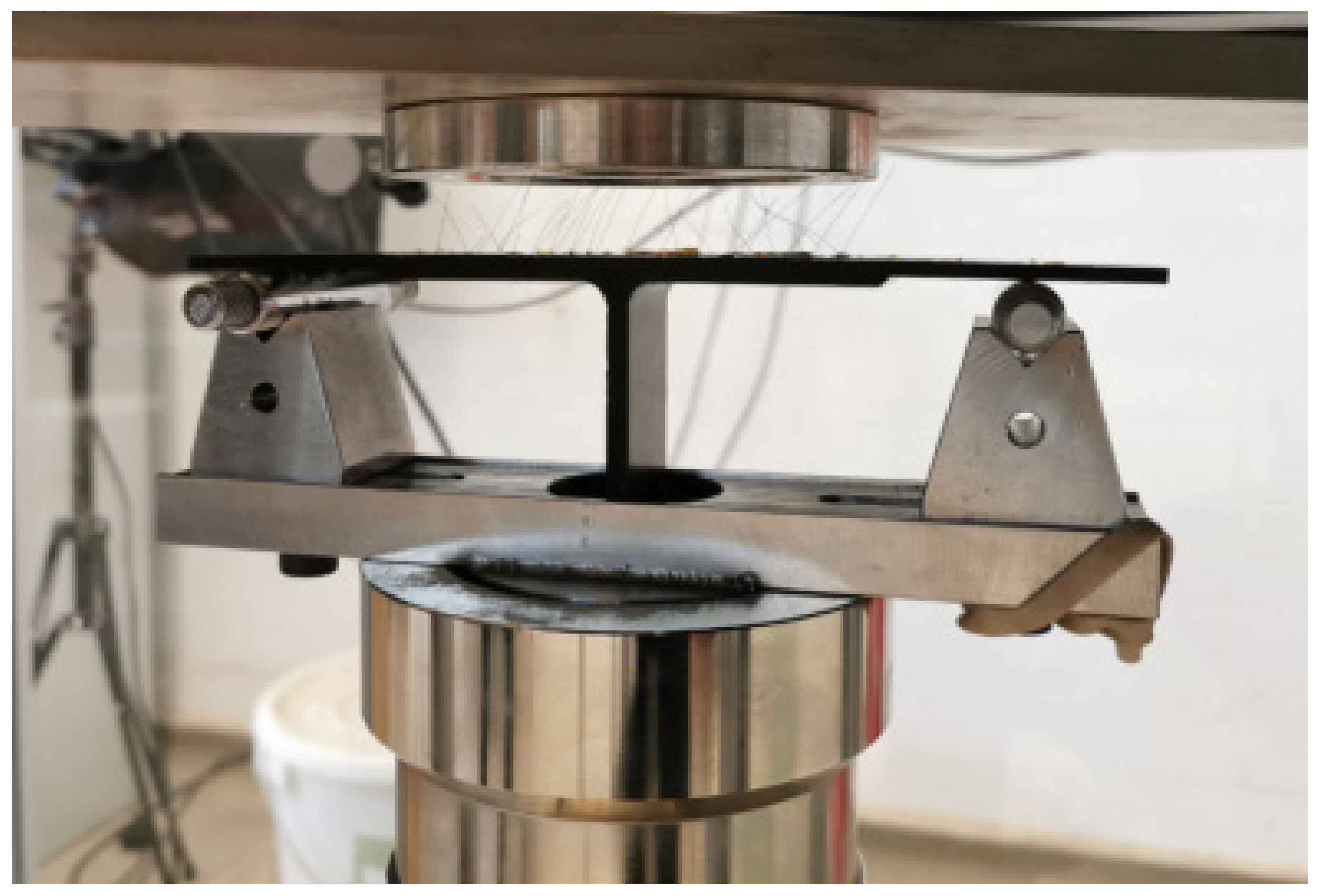

2.3. Impact Testing of T-Joints

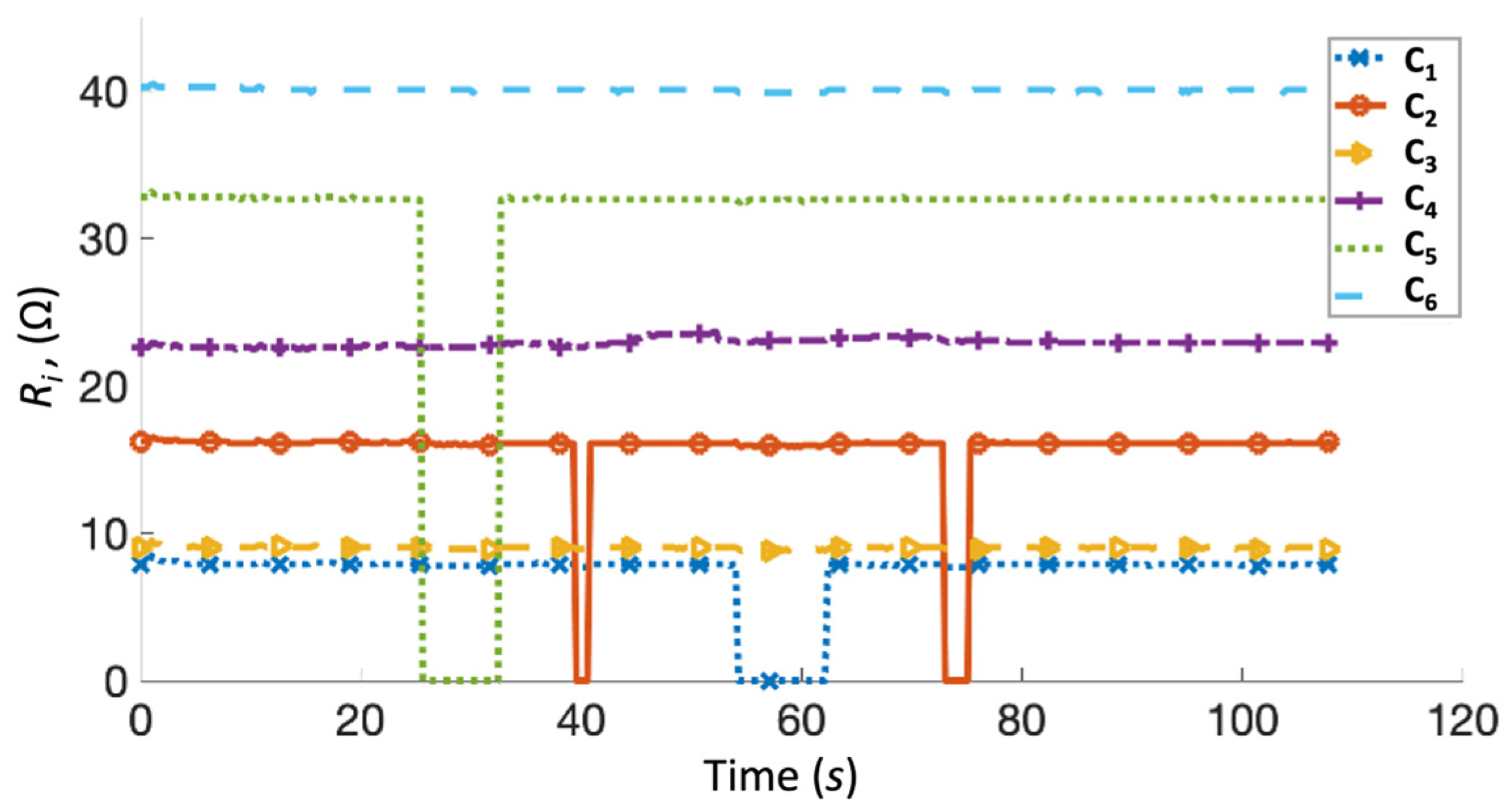

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shekarchi, M.; Farahani, E.M.; Yekrangnia, M.; Ozbakkaloglu, T. Mechanical strength of CFRP and GFRP composites filled with APP fire retardant powder exposed to elevated temperature. Fire Saf. J. 2020, 115, 103178. [Google Scholar] [CrossRef]

- Petersen, M.R.; Chen, A.; Roll, M.; Jung, S.J.; Yossef, M. Mechanical properties of fire-retardant glass fiber-reinforced polymer materials with alumina tri-hydrate filler. Compos. Eng. 2015, 78, 109–121. [Google Scholar] [CrossRef]

- Wang, K.; Young, B.; Smith, S.T. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 2011, 33, 2154–2161. [Google Scholar] [CrossRef]

- Okabe, T.; Ishii, K.; Nishikawa, M.; Takeda, N. Prediction of Tensile Strength of Unidirectional CFRP Composites. Adv. Compos. Mater. 2010, 19, 229–241. [Google Scholar] [CrossRef]

- Okabe, T.; Takeda, N. Size effect on tensile strength of unidirectional CFRP composites—Experiment and simulation. Compos. Sci. Technol. 2002, 62, 2053–2064. [Google Scholar] [CrossRef]

- Ji, X.-l.; Zhou, W.; Sun, H.; Liu, J.; Ma, L.-h. Damage evolution behavior of bi-adhesive repaired composites under bending load by acoustic emission and micro-CT. Compos. Struct. 2022, 279, 114742. [Google Scholar] [CrossRef]

- Park, S.-S.; Choe, H.-S.; Kwak, B.-S.; Choi, J.-H.; Kweon, J.-H. Micro-bolt repair for delaminated composite plate under compression. Compos. Struct. 2018, 192, 245–254. [Google Scholar] [CrossRef]

- Cheung, C.H.E.; Lin, K.Y. Numerical Analysis of Fastener Delamination/Disbond Arrest Mechanism in Aircraft Composite Structures. J. Aircr. 2012, 49, 630–635. [Google Scholar] [CrossRef]

- Ueda, M.; Miyake, S.; Hasegawa, H.; Hirano, Y. Instantaneous mechanical fastening of quasi-isotropic CFRP laminates by a self-piercing rivet. Compos. Struct. 2012, 94, 3388–3393. [Google Scholar] [CrossRef]

- Cheung, C.H.; Gray, P.; Lin, K.Y. Fastener as Fail-Safe Disbond/Delamination Arrest for Laminated Composite Structures. In Proceedings of the 18th International Conference on Composite Materials, ICC, Jeju, Republic of Korea, 21–26 August 2011. [Google Scholar]

- Wu, K.-W.; Lee, C.-L.; Chang, Y.-C.; Ong, C.-L. Compressive strength of delaminated and repaired composite plates. Mater. Chem. Phys. 1996, 43, 173–177. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Design considerations in the strengthening of composite lap joints using metal z-pins. Compos. Appl. Sci. Manuf. 2022, 160, 107031. [Google Scholar] [CrossRef]

- Abbasi, S.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Improving the structural properties of composite T-joints by z-weaving of continuous metallic filaments. Compos. Struct. 2021, 260, 113509. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wu, S.; Wang, C.H.; Mouritz, A.P. Improvements to the structural properties of bonded composite joints using z-pins. In Proceedings of the 17th Australian International Aerospace Congress: AIAC 2017, Barton, ACT, Melbourne, Australia, 26 February–2 March 2017; pp. 44–49. [Google Scholar]

- Tsoi, K.A.; Stalmans, R.; Schrooten, J.; Wevers, M.; Mai, Y.-W. Impact damage behaviour of shape memory alloy composites. Mater. Sci. Eng. A 2003, 342, 207–215. [Google Scholar] [CrossRef]

- Midani, M.; Seyam, A.-F.; Saleh, M.N.; Pankow, M. The effect of the through-thickness yarn component on the in- and out-of-plane properties of composites from 3D orthogonal woven preforms. J. Text. Inst. 2019, 110, 317–327. [Google Scholar] [CrossRef]

- Dash, A.K.; Behera, B.K. Role of weave design on the mechanical properties of 3D woven fabrics as reinforcements for structural composites. J. Text. Inst. 2018, 109, 952–960. [Google Scholar] [CrossRef]

- Midani, M.; Seyam, A.-F.; Pankow, M. A generalized analytical model for predicting the tensile behavior of 3D orthogonal woven composites using finite deformation approach. J. Text. Inst. 2018, 109, 1465–1476. [Google Scholar] [CrossRef]

- Huang, T.; Wang, Y.; Wang, G. Review of the Mechanical Properties of a 3D Woven Composite and Its Applications. Polym. -Plast. Technol. Eng. 2018, 57, 740–756. [Google Scholar] [CrossRef]

- Henao, A.; Guzmán de Villoria, R.; Cuartero, J.; Carrera, M.; Picón, J.; Miravete, A. Enhanced Impact Energy Absorption Characteristics of Sandwich Composites through Tufting. Mech. Adv. Mater. Struct. 2015, 22, 1016–1023. [Google Scholar] [CrossRef]

- Khor, W.; Ravindran, A.R.; Ciampa, F.; Ladani, R.B.; Limprapuwiwattana, M.; Whitton, P.; Foreman, A.D.; Meeks, C.; Steele, A.; Cooper, T.; et al. Improving the damage tolerance of composite T-joints using shape memory alloy tufts. Compos. Appl. Sci. Manuf. 2023, 168, 107474. [Google Scholar] [CrossRef]

- Ciampa, F.; Ladani, R.; Knott, G.; Buns, T.; Foreman, A.D.; Meeks, C.; Steele, A.; Cooper, T.; Phillips, A.; Mouritz, A.P. Shape Memory Alloy Tufted Composites Combining High Delamination Resistant And Crack Closure Properties. Compos. Appl. Sci. Manuf. 2021, 147, 106455. [Google Scholar] [CrossRef]

- Ladani, R.B.; Ravindran, A.R.; Wu, S.; Pingkarawat, K.; Kinloch, A.J.; Mouritz, A.P.; Ritchie, R.O.; Wang, C.H. Multi-scale toughening of fibre composites using carbon nanofibres and z-pins. Compos. Sci. Technol. 2016, 131, 98–109. [Google Scholar] [CrossRef]

- Kravchenko, S.G.; Kravchenko, O.G.; Carlsson, L.A.; Pipes, R.B. Influence of through-thickness reinforcement aspect ratio on mode I delamination fracture resistance. Compos. Struct. 2015, 125, 13–22. [Google Scholar] [CrossRef]

- Xue, Y.-J.; Wang, W.-W.; Tan, X.; Hui, Y.-X.; Tian, J.; Zhu, Z.-F. Mechanical behavior and recoverable properties of CFRP shape memory alloy composite under different prestrains. Constr. Build. Mater. 2022, 333, 127186. [Google Scholar] [CrossRef]

- Gnaba, I.; Soulat, D.; Legrand, X.; Wang, P. Investigation of the formability behaviour during stamping of tufted and un-tufted carbon preforms: Towards localized reinforcement technologies. Int. J. Mater. Form. 2021, 14, 1337–1354. [Google Scholar] [CrossRef]

- Shen, H.; Wang, P.; Legrand, X.; Liu, L.; Soulat, D. Influence of the tufting pattern on the formability of tufted multi-layered preforms. Compos. Struct. 2019, 228, 111356. [Google Scholar] [CrossRef]

- Dell’Anno, G.; Treiber, J.W.G.; Partridge, I.K. Manufacturing of composite parts reinforced through-thickness by tufting. Robot. Comput.-Integr. Manuf. 2016, 37, 262–272. [Google Scholar] [CrossRef]

- Nagai, H.; Oishi, R. Shape memory alloys as strain sensors in composites. Smart Mater. Struct. 2006, 15, 493–498. [Google Scholar] [CrossRef]

- Riccio, A.; Sellitto, A.; Ameduri, S.; Concilio, A.; Arena, M. Chapter 24—Shape memory alloys (SMA) for automotive applications and challenges. In Shape Memory Alloy Engineering, 2nd ed.; Concilio, A., Antonucci, V., Auricchio, F., Lecce, L., Sacco, E., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2021; pp. 785–808. [Google Scholar]

- Hu, K.; Rabenorosoa, K.; Ouisse, M. A Review of SMA-Based Actuators for Bidirectional Rotational Motion: Application to Origami Robots. Front. Robot. AI 2021, 8, 678486. [Google Scholar] [CrossRef]

- Auricchio, F.; Boatti, E.; Conti, M.; Marconi, S. Chapter 19—SMA biomedical applications. In Shape Memory Alloy Engineering, 2nd ed.; Concilio, A., Antonucci, V., Auricchio, F., Lecce, L., Sacco, E., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2021; pp. 627–658. [Google Scholar]

- Pushin, V.; Kuranova, N.; Marchenkova, E.; Pushin, A. Design and Development of Ti–Ni, Ni–Mn–Ga and Cu–Al–Ni-based Alloys with High and Low Temperature Shape Memory Effects. Materials 2019, 12, 2616. [Google Scholar] [CrossRef]

- Pushin, V.G.; Kuranova, N.N.; Marchenkova, E.B.; Belosludtseva, E.S.; Kourov, N.I.; Kuntsevich, T.E.; Pushin, A.V.; Uksusnikov, A.N. Thermoelastic Martensitic Transitions and Shape Memory Effects: Classification, Crystal and Structural Mechanisms of Transformations, Properties, Production and Application of Promising Alloys. Mater. Sci. Found. 2015, 81–82, 174–206. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. (1980–2015) 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Chemisky, Y.; Duval, A.; Piotrowski, B.; Ben Zineb, T.; Tahiri, V.; Patoor, E. Numerical tool for SMA material simulation: Application to composite structure design. Smart Mater. Struct. 2009, 18, 104012. [Google Scholar] [CrossRef][Green Version]

- Pushin, V.G.; Valiev, R.Z.; Zhu, Y.T.; Gunderov, D.V.; Kourov, N.I.; Kuntsevich, T.E.; Uksusnikov, A.N.; Yurchenko, L.I. Effect of Severe Plastic Deformation on the Behavior of Ti–Ni Shape Memory Alloys. Mater. Trans. 2006, 47, 694–697. [Google Scholar] [CrossRef]

- Pinto, F.; Ciampa, F.; Meo, M.; Polimeno, U. Multifunctional SMArt composite material for in situ NDT/SHM and de-icing. Smart Mater. Struct. 2012, 21, 105010. [Google Scholar] [CrossRef]

- Ashrafi, M.; Devasia, S.; Tuttle, M.E. Resistive embedded heating for homogeneous curing of adhesively bonded joints. Int. J. Adhes. Adhes. 2015, 57, 34–39. [Google Scholar] [CrossRef]

- Mawardi, A.; Pitchumani, R. Optimal Temperature and Current Cycles for Curing of Composites Using Embedded Resistive Heating Elements. J. Heat Transf. 2003, 125, 126–136. [Google Scholar] [CrossRef]

- Zhu, L.; Pitchumani, R. Analysis of a process for curing composites by the use of embedded resistive heating elements. Compos. Sci. Technol. 2000, 60, 2699–2712. [Google Scholar] [CrossRef]

- Khor, W.; Ravindran, A.R.; Ladani, R.B.; Limprapuwiwattana, M.; Whitton, P.; Meeks, C.; Foreman, A.; Ciampa, F. Material-enabled damage inspection of multifunctional shape memory alloy tufted composite T-joints. NDTE Int. 2023. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Z.; Zhu, J.; Ciampa, F. Enhanced pre-processing of thermal data in long pulse thermography using the Levenberg-Marquardt algorithm. Infrared Phys. Technol. 2019, 99, 158–166. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, J.; Tian, G.; Ciampa, F. Comparative analysis of eddy current pulsed thermography and long pulse thermography for damage detection in metals and composites. NDT E Int. 2019, 107, 102155. [Google Scholar] [CrossRef]

- Grammatikos, S.A.; Kordatos, E.Z.; Matikas, T.E.; David, C.; Paipetis, A.S. Current injection phase thermography for low-velocity impact damage identification in composite laminates. Mater. Des. 2014, 55, 429–441. [Google Scholar] [CrossRef]

- Wang, Z.; Tian, G.; Meo, M.; Ciampa, F. Image processing based quantitative damage evaluation in composites with long pulse thermography. NDT E Int. 2018, 99, 93–104. [Google Scholar] [CrossRef]

- Droździel, M.; Podolak, P.; Czapski, P.; Zgórniak, P.; Jakubczak, P. Failure analysis of GFRP columns subjected to axial compression manufactured under various curing-process conditions. Compos. Struct. 2021, 262, 113342. [Google Scholar] [CrossRef]

- Blanco, N.; Trias, D.; Pinho, S.T.; Robinson, P. Intralaminar fracture toughness characterisation of woven composite laminates. Part II: Experimental characterisation. Eng. Fract. Mech. 2014, 131, 361–370. [Google Scholar] [CrossRef]

- Andreades, C.; Meo, M.; Ciampa, F. Tensile and fatigue testing of impacted smart CFRP composites with embedded PZT transducers for nonlinear ultrasonic monitoring of damage evolution. Smart Mater. Struct. 2020, 29, 055034. [Google Scholar] [CrossRef]

- Andreades, C.; Mahmoodi, P.; Ciampa, F. Characterisation of smart CFRP composites with embedded PZT transducers for nonlinear ultrasonic applications. Compos. Struct. 2018, 206, 456–466. [Google Scholar] [CrossRef]

- Bosowski, P.; Hoerr, M.; Mecnika, V.; Gries, T.; Jockenhövel, S. 4-Design and manufacture of textile-based sensors. In Electronic Textiles; Dias, T., Ed.; Woodhead Publishing: Oxford, UK, 2015; pp. 75–107. [Google Scholar]

- Solaz, J.S.; Belda-Lois, J.M.; Garcia, A.C.; Barberà, R.; Dura, J.V.; Gomez, J.A.; Soler, C.; Prat, J.M. 20-Intelligent textiles for medical and monitoring applications. In Intelligent Textiles and Clothing; Mattila, H.R., Ed.; Woodhead Publishing: Oxford, UK, 2006; pp. 369–398. [Google Scholar]

- Takeda, N.; Okabe, Y.; Kuwahara, J.; Kojima, S.; Ogisu, T. Development of smart composite structures with small-diameter fiber Bragg grating sensors for damage detection: Quantitative evaluation of delamination length in CFRP laminates using Lamb wave sensing. Compos. Sci. Technol. 2005, 65, 2575–2587. [Google Scholar] [CrossRef]

- Amano, M.; Okabe, Y.; Takeda, N. Evaluation of Crack Suppression Effect of TiNi SMA Foil Embedded in CFRP Cross-Ply Laminates with Embedded Small-Diameter FBG Sensor. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2005, 48, 443–450. [Google Scholar] [CrossRef][Green Version]

- Malyarenko, E.V.; Hinders, M.K. Ultrasonic Lamb wave diffraction tomography. Ultrasonics 2001, 39, 269–281. [Google Scholar] [CrossRef] [PubMed]

- Doyle, C.; Martin, A.; Liu, T.; Wu, M.; Hayes, S.; Crosby, P.A.; Powell, G.R.; Brooks, D.; Fernando, G.F. In-situprocess and condition monitoring of advanced fibre-reinforced composite materials using optical fibre sensors. Smart Mater. Struct. 1998, 7, 145–158. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Han, B.; Wan, B.; Cai, G.; Chang, R. In Situ Strain and Damage Monitoring of GFRP Laminates Incorporating Carbon Nanofibers under Tension. Polymers 2018, 10, 777. [Google Scholar] [CrossRef] [PubMed]

- Bielefeldt, B.R.; Hochhalter, J.D.; Hartl, D.J. Shape memory alloy sensory particles for damage detection: Experiments, analysis, and design studies. Struct. Health Monit. 2017, 17, 777–814. [Google Scholar] [CrossRef]

- Wen, J.; Xia, Z.; Choy, F. Damage detection of carbon fiber reinforced polymer composites via electrical resistance measurement. Compos. Eng. 2011, 42, 77–86. [Google Scholar] [CrossRef]

- De Baere, I.; Van Paepegem, W.; Degrieck, J. Electrical resistance measurement for in situ monitoring of fatigue of carbon fabric composites. Int. J. Fatigue 2010, 32, 197–207. [Google Scholar] [CrossRef]

- Wang, S.; Wang, D.; Chung, D.D.L.; Chung, J.H. Method of sensing impact damage in carbon fiber polymer-matrix composite by electrical resistance measurement. J. Mater. Sci. 2006, 41, 2281–2289. [Google Scholar] [CrossRef]

- Todoroki, A.; Ueda, M.; Hirano, Y. Strain and Damage Monitoring of CFRP Laminates by Means of Electrical Resistance Measurement. J. Solid Mech. Mater. Eng. 2007, 1, 947–974. [Google Scholar] [CrossRef]

- Abry, J.C.; Choi, Y.K.; Chateauminois, A.; Dalloz, B.; Giraud, G.; Salvia, M. In-situ monitoring of damage in CFRP laminates by means of AC and DC measurements. Compos. Sci. Technol. 2001, 61, 855–864. [Google Scholar] [CrossRef]

- Abry, J.C.; Bochard, S.; Chateauminois, A.; Salvia, M.; Giraud, G. In situ detection of damage in CFRP laminates by electrical resistance measurements. Compos. Sci. Technol. 1999, 59, 925–935. [Google Scholar] [CrossRef]

- Plonus, M. 1-Circuit Fundamentals. In Electronics and Communications for Scientists and Engineers, 2nd ed.; Plonus, M., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2020; pp. 1–78. [Google Scholar]

- Freescale Semiconductor, Inc. How to Increase the Analog-to-Digital Converter Accuracy in an Application; Freescale Semiconductor, Inc.: Austin, TX, USA, 2016. [Google Scholar]

- Ariawan, K.U.; Santyadiputra, G.S.; Sutaya, I.W. Design of Hexapod Robot Movement Based on Arduino Mega 2560. J. Phys. Conf. Ser. 2019, 1165, 012011. [Google Scholar] [CrossRef]

- Alshamsi, H.; Këpuska, V.; Alshamsi, H. Real Time Vehicle Tracking Using Arduino Mega. Int. J. Adhes. Adhes. 2016, 5, 624–627. [Google Scholar]

- Zeyrek, B.Y.; Aydogan, B.; Dilekcan, E.; Ozturk, F. Review of Thermoplastic Composites in Aerospace Industry. Int. J. Eng. Technol. Inform. 2022, 3, 1–6. [Google Scholar]

- Kumar, S.; Padture, N.P. Materials in the Aircraft Industry. In Metallurgical Design and Industry: Prehistory to the Space Age; Kaufman, B., Briant, C.L., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 271–346. [Google Scholar]

- Boyer, R.R.; Cotton, J.D.; Mohaghegh, M.; Schafrik, R.E. Materials considerations for aerospace applications. MRS Bull. 2015, 40, 1055–1066. [Google Scholar] [CrossRef]

- Stolar, L. Assessment of Airplane Design, Fabrication, and Repair. Doctoral Dissertation, Massachusetts Institute of Technology: Cambridge, MA, USA, 2009. [Google Scholar]

- Georgiadis, S.; Gunnion, A.J.; Thomson, R.S.; Cartwright, B.K. Bird-strike simulation for certification of the Boeing 787 composite moveable trailing edge. Compos. Struct. 2008, 86, 258–268. [Google Scholar] [CrossRef]

| Layer | NCF Material | Areal Weight (g/m2) |

|---|---|---|

| Powder Binder | Solvay Cycom 7720 | 10 |

| Toughening Veil | TA1903 | 4 |

| Fibre | Tenax-E ITS55 E23 24K 1600tex, 90° | 268 |

| Toughening Veil | TA1903 | 4 |

| Fibre | Tenax-E ITS55 E23 24K 1600tex, 0° | 268 |

| Parameter | Value |

|---|---|

| Number of channels, N | 10 |

| Total input voltage, Vin | 5 V |

| Maximum resistance measurement on Ri | 200 Ω |

| Fixed resistance, R | 100 Ω |

| Maximum power per channel at R2 | 83.3 mW |

| Maximum total power of system | 833 mW |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adeyemi, W.; Khor, W.; Ciampa, F. Material-Enabled Impact Detection and Damage Localisation System Using Shape Memory Alloy Tufted Composites. Sensors 2023, 23, 9565. https://doi.org/10.3390/s23239565

Adeyemi W, Khor W, Ciampa F. Material-Enabled Impact Detection and Damage Localisation System Using Shape Memory Alloy Tufted Composites. Sensors. 2023; 23(23):9565. https://doi.org/10.3390/s23239565

Chicago/Turabian StyleAdeyemi, Williams, WeeLiam Khor, and Francesco Ciampa. 2023. "Material-Enabled Impact Detection and Damage Localisation System Using Shape Memory Alloy Tufted Composites" Sensors 23, no. 23: 9565. https://doi.org/10.3390/s23239565

APA StyleAdeyemi, W., Khor, W., & Ciampa, F. (2023). Material-Enabled Impact Detection and Damage Localisation System Using Shape Memory Alloy Tufted Composites. Sensors, 23(23), 9565. https://doi.org/10.3390/s23239565