1. Introduction

Magnetic field sensors have been ubiquitous in modern technology since the invention of the compass. The current state-of-the-art magnetometers have found applications ranging from biomedical fields, where high sensitivity is the crucial metric, to military sensors, where size, weight, and power (SWaP) are key factors [

1,

2,

3]. Fluxgate magnetometers are one of the most common for naval applications as they are technologically mature, physically robust vector magnetic field sensors with sensitivities in the picoteslas at frequencies from 0.1 Hz to ~10 kHz [

4]. The development of ultra-low-power miniature systems designed to supplant fluxgate magnetometers has found renewed interest in recent years [

1,

5].

Microelectromechanical systems (MEMS) offer an avenue of development to combine low SWaP with high sensitivity for critical systems development [

6,

7,

8,

9]. Magnetoelectric (ME)-based MEMS devices exploit the coupling occurring in artificial ME heterostructure systems by combining a piezoelectric and ferromagnetic material to produce functional devices for a multitude of engineering applications. The giant ME coupling that occurs in resonant multilayer devices has shown promise as magnetic sensors by exploiting a resonance frequency shift in response to an external magnetic field through magnetostrictive stress in the ferromagnetic material [

5,

10].

Magnetoelectric-based magnetometers have garnered much attention as they boast ultra-low-power systems with small form factor and limit of detection in the tens of pT [

5,

10,

11]. Most magnetometers require tens to hundreds of mW (or more) of power to operate, such as the fluxgate, where the soft magnetic material needs to be constantly driven into a saturation state by a current source. ME-MEMS magnetometers, on the other hand, utilize a voltage source connected to a piezoelectric stack with a high impedance to drive the resonator and typically require only μW or less of power to drive the resonator, and when combined with an ultra-low-power operational amplifier for the supplemental electronics, the combined power requirements can still be sub-milliwatt. Within this class of magnetometers, multiple configurations are possible, though most rely on exploiting the mechanically resonant characteristics of a released ME heterostructure device. For example, a cantilever design is often used, which can reliably reach sensitivities in the tens of pT at low frequencies (<100 Hz); yet, when sensing a resonant magnetic field, the sensitivity can reach hundreds of fT and is theoretically only limited by the magnetic noise floor [

12,

13,

14,

15]. However, these cantilever designs are susceptible to vibrational noise, especially at low frequencies (0.1–1000 Hz), and obtaining the lowest limit of detection requires an EM shield and vibration suppression [

13]. Through optimizing the resonant device configuration, it may be possible to circumvent the shortcomings of current designs. To this end, we study a fixed–fixed resonant beam structure, for it is less susceptible to vibration while providing similar characteristics to ME-MEMS cantilever devices.

Alongside the intrinsic properties of the ferromagnetic material capable of responding to an external magnetic field, the fundamental noise characteristics from accompanying electronics contribute to the limit of detection [

16]. Often, the theoretical magnetic noise floor is never reached due to various noise contributions from the excitation voltage source, charge amplifier, voltage amplifier, and demodulation circuits [

12,

16]. Determining the inherent properties of the resonators is essential for a comparison between multiple devices and across multiple designs to decouple the resonant device from the electronics used for measurements. In an ME magnetometer sensor design, some of the most salient parameters to consider are the electric sensitivity S

el =

(

is the admittance slope between resonance and antiresonance peaks,

is the frequency), magnetic sensitivity S

mag =

(

is the bias magnetic field,

is the resonance frequency), as well as the sensor and electronics noise floor [

14]. The intrinsic sensitivity of the resonator is a product of S

mag and S

el, which are measures of the resonant frequency shift per magnetic field and amplitude change per frequency shift, respectively [

17]. S

mag values found in resonators that claim picotesla sensitivity are typically in the 50–100 Hz/mT range, while S

el values can vary widely depending on the specific device design and the harmonic being utilized for detection. Utilizing the fundamental resonance mode is, at times, not the most advantageous operational frequency as higher harmonics can provide larger S

el values and offer a lower noise floor resulting from the 1/

noise contribution. Typically, S

mag values are inherent to a specific resonator and, in some cases, directly related to the released stress state and, therefore, would be considered a fundamental property of the resonator, though this value ultimately can be dependent upon the resonance mode used to determine S

mag. The sensor amplitude sensitivity can thus be defined as S

am = S

mag · S

el, which is the intrinsic sensitivity of the magnetoelectric resonator [

14,

18].

In this work, we study a new design of double-clamped magnetoelectric MEMS resonators as magnetometers. Initial COMSOL

® modeling reveals the majority of charge generated in a fixed–fixed resonator occurs at the anchor points, leading to a conceptual redesign of the structures we previously reported [

19,

20,

21,

22]. By splitting the top electrode that runs across the surface of the beam, it is now possible to drive on one side and sense on the other. For this, we have designed the electrode to extend out a quarter of the length from both anchor points, which are then coated with a magnetostrictive material, and the remaining area on the surface to place an additional strip of the magnetostrictive material. This provides the benefit of reducing the feedthrough capacitance while maximizing the area covered by the functional magnetostrictive material. In this new design, we have also utilized thin films of a new iron–cobalt–hafnium alloy (Fe

0.5Co

0.5)

0.92Hf

0.08 that provide a low-stress, highly magnetostrictive material with an amorphous crystalline structure and ultra-low magnetocrystalline anisotropy. We have also designed a printed circuit board containing two charge amplifiers for integration of the MEMS chip for testing and evaluation.

2. Materials and Methods

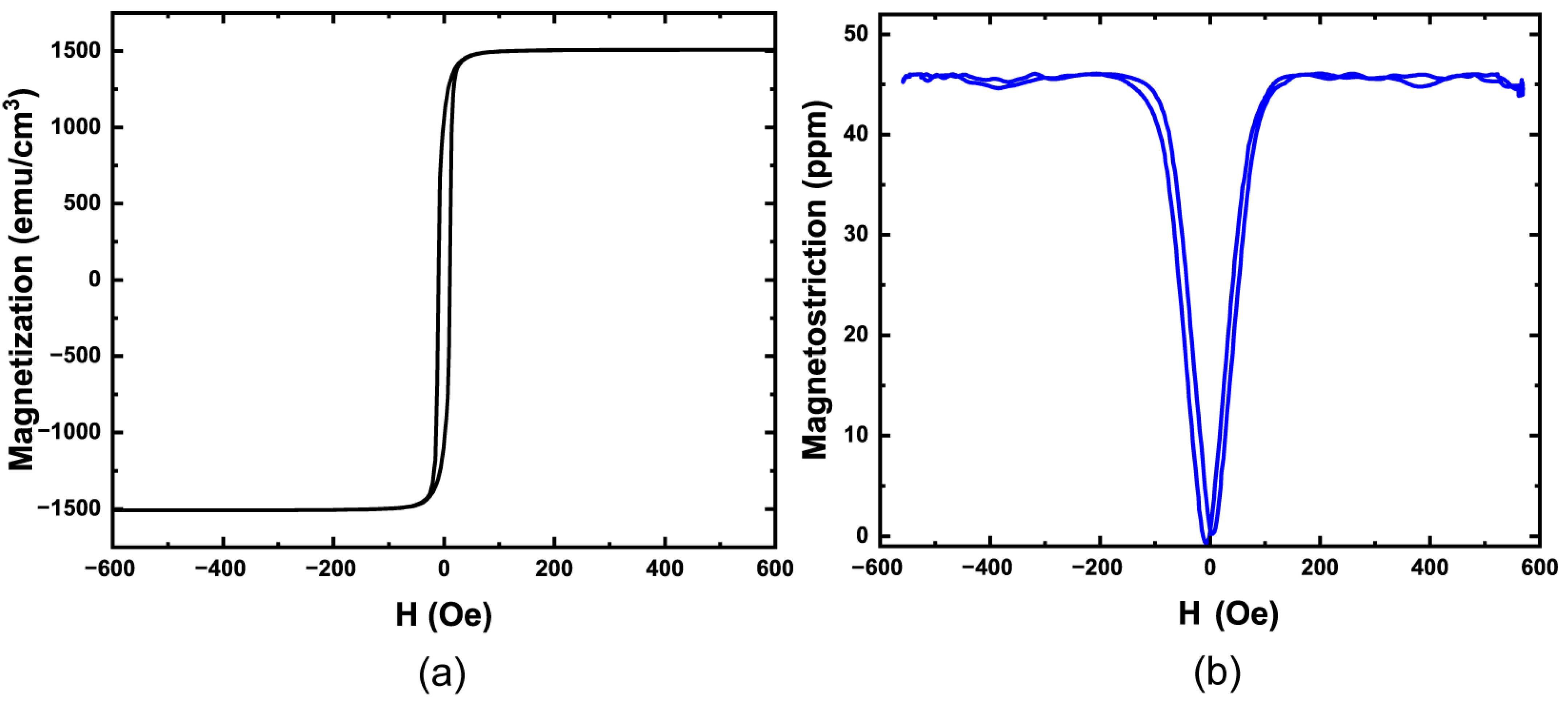

COMSOL Multiphysics was used to evaluate the charge generated in a suspended double-clamped magnetoelectric resonator on which we have previously reported [

20,

22]. A 1 mm long and 40 um wide beam was modeled comprised of a continuous 1 μm thick aluminum nitride (AlN) piezoelectric layer mechanically coupled to a 1 μm thick layer of magnetostrictive iron cobalt (Fe

0.5Co

0.5) based upon our previous fixed–fixed device designs. We have previously found the fundamental frequency of the released beams is governed by the internal stresses that develop during fabrication processes.

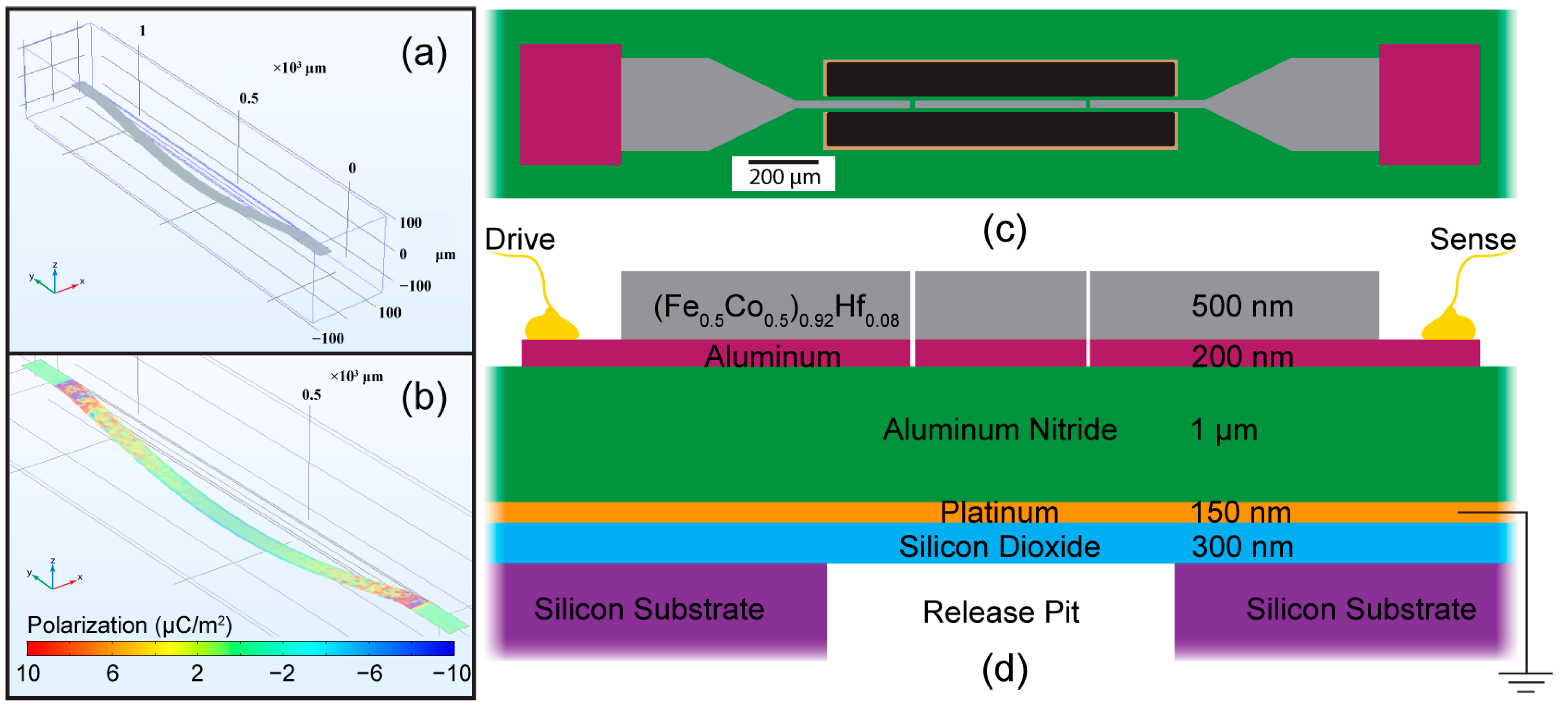

Figure 1a shows the fundamental frequency of the released resonator beam, which ranges from 30 to 40 kHz depending on the residual stresses used as input parameters in the model. Multiple stress configurations were explored during the modeling, and it was concluded that non-uniform stresses or strains applied between the piezoelectric and magnetostrictive layers cause displacements of the beam (buckling) with no applied electric or magnetic field. This results in the buckling of the beam, which is often seen in these types of suspended double-clamped structures that are not released under tension. Due to the clamped restricted boundary conditions, the resonator will buckle in the ±z direction, and when a magnetic field is artificially incorporated into the model (through stress tensor), the fundamental resonance frequency shifts higher due to the decreased buckling and effectively contributes a tensile strain on the beam. It is this shift of the resonance frequency when in the presence of a magnetic field that is the basis of detection for these types of ME sensors.

For this model, an external magnetic field is modeled by an effective change in the magnetostrictive layer, which leads to a shift in the resonant frequency. Fe

0.5Co

0.5 has been shown to have a saturation magnetostriction near 60 ppm; therefore, a value of 6 × 10

−6 was used for the ε

yy parameter in the strain tensor, representing an effective strain resulting from the presence of a saturating magnetic field applied along the long axis of the beam.

Figure 1b plots the piezoelectric polarization (surface charge) that is generated when the beam is subjected to an external magnetic field, resulting in 60 ppm strain. From the COMSOL

® simulations, we can see the majority of charge generated occurs at the anchor points on each end of the beam. The largest charge will always be generated by the section of the beam that is distorted away from the neutral axis within the beam. In this case, it will be at the boundaries of the resonator.

Resonators reported in this study were fabricated using the masking process developed in [

23] and variations summarized in [

24]. The masking steps of Ref. [

23] were utilized to produce a 1 mm long and 40 μm wide suspended beam as depicted in

Figure 1c. A top view of the fabricated resonators is shown in

Figure 1c, where the electrically conductive materials (FeCo-Hf and Al) are sectioned into three portions. The resonator is a fully suspended bridge structure where an XeF

2 etch process is used to release the device from the substrate with the release pit area giving substrate access to the etchant shown in black in

Figure 1c. The film stack is illustrated in

Figure 1d, where a (Fe

0.5Co

0.5)

0.92Hf

0.08 magnetostrictive layer provides the magnetically functional portion of the magnetometer and is deposited at 500 nm thickness. The AlN deposited was chosen to be 1 μm in order to increase piezoelectric motion of the beam, as well as to place the neutral axis of the beam at the interface between the piezoelectric and magnetostrictive material. To reduce feedthrough capacitance, the conductive top portions of the beam were separated into three sections where the drive voltage is applied to one side of the beam and charge is collected on the opposite side with the Pt bottom electrode grounded. The resonator is driven by applying an AC voltage to the AlN between the top electrode (drive) and the ground plane in

Figure 1d. Subsequently, the opposite side (sense) collects the charge generated for direct readout or demodulation techniques.

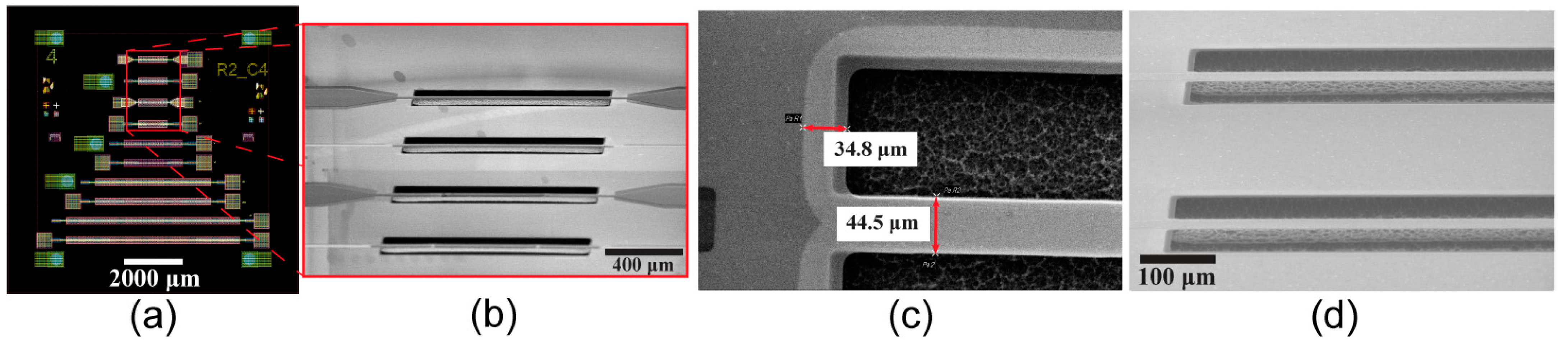

Chips containing multiple beam lengths were fabricated, as seen in the combined mask image of

Figure 2a. In this work, we focused on the top 4 resonators where the released length was 1 mm. A tilted scanning electron microscope SEM image of the released beams is shown in

Figure 2b, where the beams can be seen buckling slightly upward. This is a sign these beams are released in a compressive stress state. To verify the beams are fully released, the undercut caused by the XeF

2 etching process is measured, as can be seen in

Figure 2c, where the light grey areas signify the undercut areas. The penetration of the SEM (30 kV) electrons allows for the contrast to be visible. Here, we can see the etching process causes ~35 μm of undercut into the Si substrate, and there is no residual Si beneath the resonator (dark gray spots), yielding a fully released beam.

Figure 2d is a zoomed image of the beams where released beams show no sign of residual Si protruding beneath the beams. The presence of lingering Si fragments causes nodes in the resonator to affect the resonant properties of the beam (spurious harmonic frequencies) and consistently suppresses the motion.

Once the resonator has been released by the final XeF

2 etch, a suspended beam is functionally complete and ready for implementation, measurement, and evaluation. The functional principle behind this type of magnetometer is a change in the resonance frequency when in the presence of an external magnetic field.

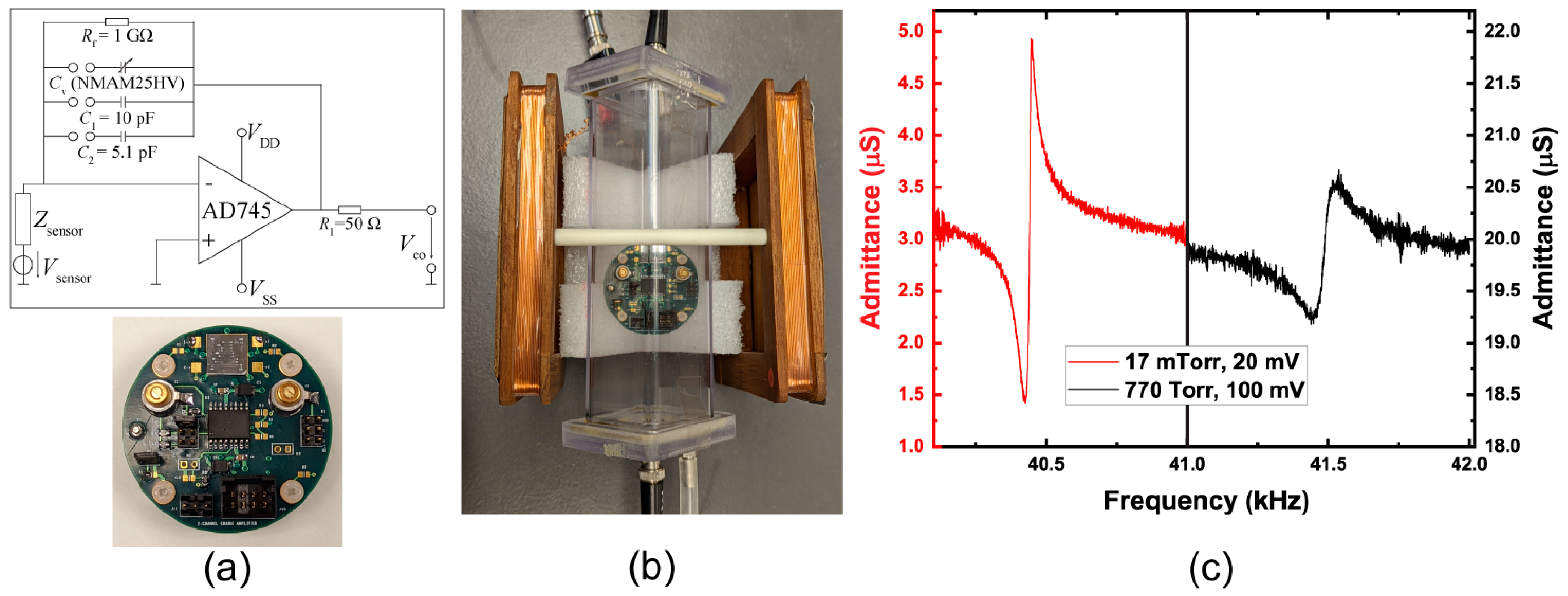

Figure 3a illustrates the initial operation of the resonator, whereby one side of the beam is driven with a voltage source, and the other side senses the charge generated by the piezoelectric layer. Each beam has resonant properties (admittance and phase) associated with the mechanical impedance, as depicted in

Figure 3a (when not in the presence of any magnetic field).

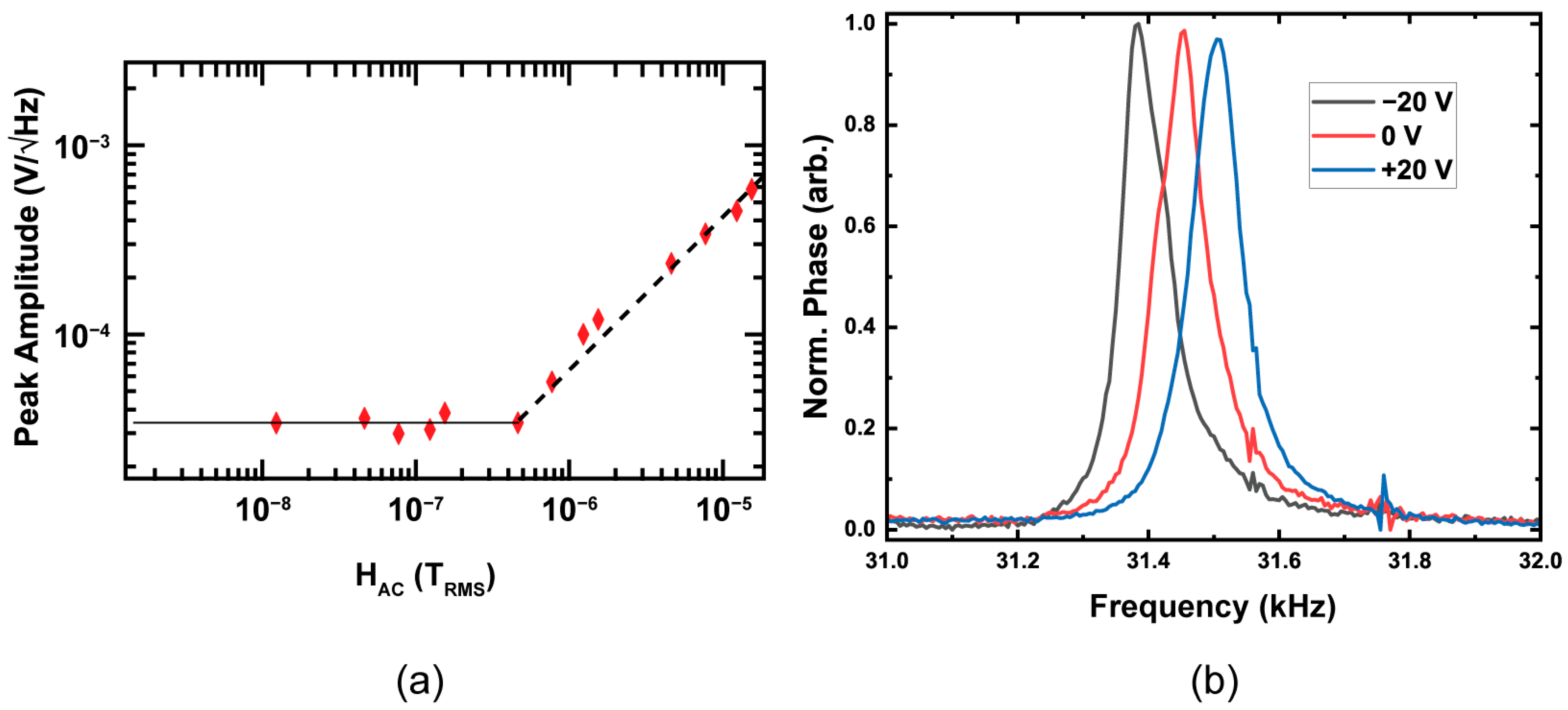

Figure 3b shows the beam when a magnetic field is in the vicinity of the resonator, and depicted beneath is a plot of the shifting resonance frequency (phase) when subjected to an increasing magnetic field. As the magnetic field affects the magnetostrictive layer of the heterostructure, the beam expands slightly increasing the inherent buckling, thereby increasing the stress of the beam and thus shifting the resonance frequency.

The charge generated from the piezoelectric AlN element requires conditioning in order to operate as a functional sensor with a voltage output. A custom 2-channel charge amplifier board was constructed to convert the output terminals from the beams using two AD745 operational amplifiers; Analog Devices, Norwood, MA, USA. The AD745 boasts ultra-low noise performance specs of 2.9 nV/√Hz at 10 kHz, 380 nV

p-p for 0.1–10 Hz, and 6.9 fA/√Hz, making it a favorable operational amplifier for ME-MEMS sensors. The circuit diagram and an image of the complete charge amplifier board are shown in

Figure 4a, with a magnetoelectric sensor chip mounted on the upper section of the board. The second operational amplifier is located on the underside of the PCB. When developing the charge amplifier board, we envisioned including a feedback capacitor option where a variable capacitor, C

V, and two stable capacitors, C

1 and C

2, are available for selection via a jumper bank, as shown in

Figure 4a, in order to adjust the gain. We ultimately believe this decision contributed to the majority source of noise, contributing to the relatively poor detection limit.

MEMS resonators physically vibrate, displacing air, and are thereby susceptible to damping by the ambient air. To reduce the damping when the resonators are placed in operation, they can be packaged under vacuum and encased in a small microchamber with a getter material to maintain a relatively low vacuum (mTorr). By operating the beam under vacuum, it becomes possible to increase the sensitivity of the magnetometer by significantly reducing the air damping [

25], thereby increasing the quality factor and S

el value. An image of the charge amplifier board situated within a low-pressure vacuum chamber (without any wiring attached) is shown in

Figure 4b. Admittance measurements of the fundamental resonance mode using a Keysight E4990A impedance analyzer (Keysight Technologies, Santa Rosa, CA, USA) of a released beam are shown in

Figure 4c under atmosphere (770 Torr) and vacuum (17 mTorr). Linear fit of the slope between the series and parallel resonance peaks of the 17 mTorr scan yields a value of 2.17 × 10

−7 S/Hz, and for 770 Torr, a value of 2.81 × 10

−8 S/Hz represents an increase in S

el of 7.72-fold, with a reduction in the noise by ~1/3. The S

el value obtained under vacuum is similar to those found in other ME-MEMS cantilever systems in atmosphere, which tend to have much higher Q values due to the differing boundary conditions [

14]. Q values of the fundamental resonance recorded in our 1 mm long devices are typically found to be ~450 in atmosphere (770 Torr), whereas under a vacuum of ~10 mTorr, the Q increases to ~1400.

4. Discussion

We have demonstrated the development of a high isolation magnetoelectric MEMS resonator requiring only ~800 nW of power with an extremely small footprint capable of sensing magnetic field variations <500 nT. For these experiments, we chose an AD745 operational amplifier since it is commonly used for magnetoelectric magnetometer sensors research; it does require operation at 15 V with a quiescent current of 8 mA. This choice of operational amplifier, therefore, pulls ~120 mW of power, but other operational amplifiers are suitable replacements, such as the Analog Devices LTC6258, which only requires 105 μW, or Texas Instruments LP358 and LP2904 with a power draw of 162 μW. In this respect, we believe the potential for an ultra-low-power magnetometer is ultimately predicated on optimizing the performance of the resonator where the supplemental electronic specifications can be tailored to individual applications.

Though the ultimate limit of detection measured here is not particularly impressive, it is important to evaluate the resonator independently from the electronics and environmental noise, which are likely the main contributors to the high noise floor. Utilizing the experimental findings reported here, a comparison of detection limits is possible based on the resonator characteristics and theoretical noise floor for individual components versus the as-measured detection limits. For approximating the achievable detection limits, we will presume a resonator with the properties measured in the results section is operated under a vacuum with minimal noise contribution from the electronics. We have shown that, when under a vacuum, an increase in S

el of ~8× (we will define here as S

vac) is possible and will use the measured S

mag of 125 Hz/mT for the calculations. Theoretical amplitude sensitivities, S

am, of these resonators can thus be calculated from S

tot = S

el · S

vac, yielding a value of ~27.5 μS/mT, which is consistent with other cantilever-based MEMS magnetometers [

14,

16,

26]. Based on the noise performance of the AD745 operational amplifier when vacuum-packaged and under optimal conditions, it is possible for the resonator to reach a sensitivity of 7.2 pT when measured using current. If the resonator is measured using the voltage output generated from the charge amplifier with low-frequency demodulation, a detection limit would reach 1.66 nT and, if measured on resonance, could reach 14.7 pT. All of the theoretical limits are based solely on the noise floor of the AD745 operational amplifier, which does not consider the drive voltage noise or additional electronic as well as environmental contributions. Though these calculated detection limits may be overly optimistic, we can also estimate the detection limits of the magnetic noise and the resonator individually based on the results obtained in

Section 3.

Typically, magnetometers utilizing a magnetic material and exploiting the micromagnetic structure (and subsequently domain motion) are ultimately found to have the highest sensitivity perpendicular to the magnetic easy axis. This would, therefore, suggest the highest sensitivity would occur perpendicular to the long axis of the beam and, therefore, the highest S

mag values. In the case of our sensors, we have found the highest S

mag values occur when the H-field is parallel to the long axis of the beam, which one would assume to be the easy axis of the magnetic structure. The compressive released stress state of a positively magnetostrictive material actually promotes the formation of domains to align perpendicular to the long axis of the beam. When an applied magnetic field along the long axis occurs, the domains grow and rotate nearly 90°, thus causing a large change in the resonance frequency, whereas when the field is applied perpendicularly, the domains grow but do not rotate much, resulting in a lower S

mag value. We measured the S

mag with an H-field perpendicular to the beam, which showed a significantly lower value of 26 Hz/mT. The magnetic physics of a compressively released double-clamped ME-MEMS resonator was previously analyzed and discussed in Ref. [

22] as the basis for utilizing these types of resonators as vector magnetometers.

The magnetic noise of the resonator beam alone can be estimated by the intrinsic magnetic noise present and is provided by

where

is the permeability of free space,

is 1/S

mag,

is the Boltzmann constant,

is absolute temperature,

is the resonance frequency,

is the mechanical quality factor,

is the resonator volume and

is the released stress value which we can approximate to be ~50 MPa from simulation models. This would result in an intrinsic magnetic noise floor of ~9 pT/√Hz for the resonator alone and represents a magnetic noise floor far below the detection limit determined in

Section 3.3. Subsequently, the only condition in which the magnetic noise floor of the resonator would become a significant factor is when the resonator is vacuum-packaged, and the accompanying electronics provide a noise floor near that of the operational amplifier specifications. Additionally, one must consider the intrinsic phase noise resulting from the compressive released double-clamped resonator. As there is an inherent correlation of the phase noise to the released stress state, maximum S

mag, transfer function, and piezomotion, it is possible the highest values of S

mag contribute to a larger phase noise at the optimal bias field.

To calculate the intrinsic limit of detection achievable by the resonator using the measured values in

Section 3. We can possibly utilize the calculation of voltage sensitivity from Ref. [

14]. From these calculations, we find that under vacuum, with a 10 GΩ feedback capacitor in the charge amplifier, we can obtain a detection limit of ~780 pT. When calculating this limit of detection, we assume a noise level of 1 μV, which is a realistic noise level stemming from all the charge amplifier components. Ultimately, we believe the true limit of detection for these resonators to be in the 500 pT to 1 nT regime with an improved charge amplifier and accompanying electronics.

Future measurements intended to extract the lowest noise floor possible will include performing the experiments in a shielded environment with an ultra-low noise excitation voltage source with a voltage subtraction circuit included. Additionally, the resonators will be incorporated into a vacuum-packaged device with the presence of larger flux concentrators applied parallel to the beam length for additional sensitivity.