Numerical Investigation on High-Performance Cu-Based Surface Plasmon Resonance Sensor for Biosensing Application

Abstract

:1. Introduction

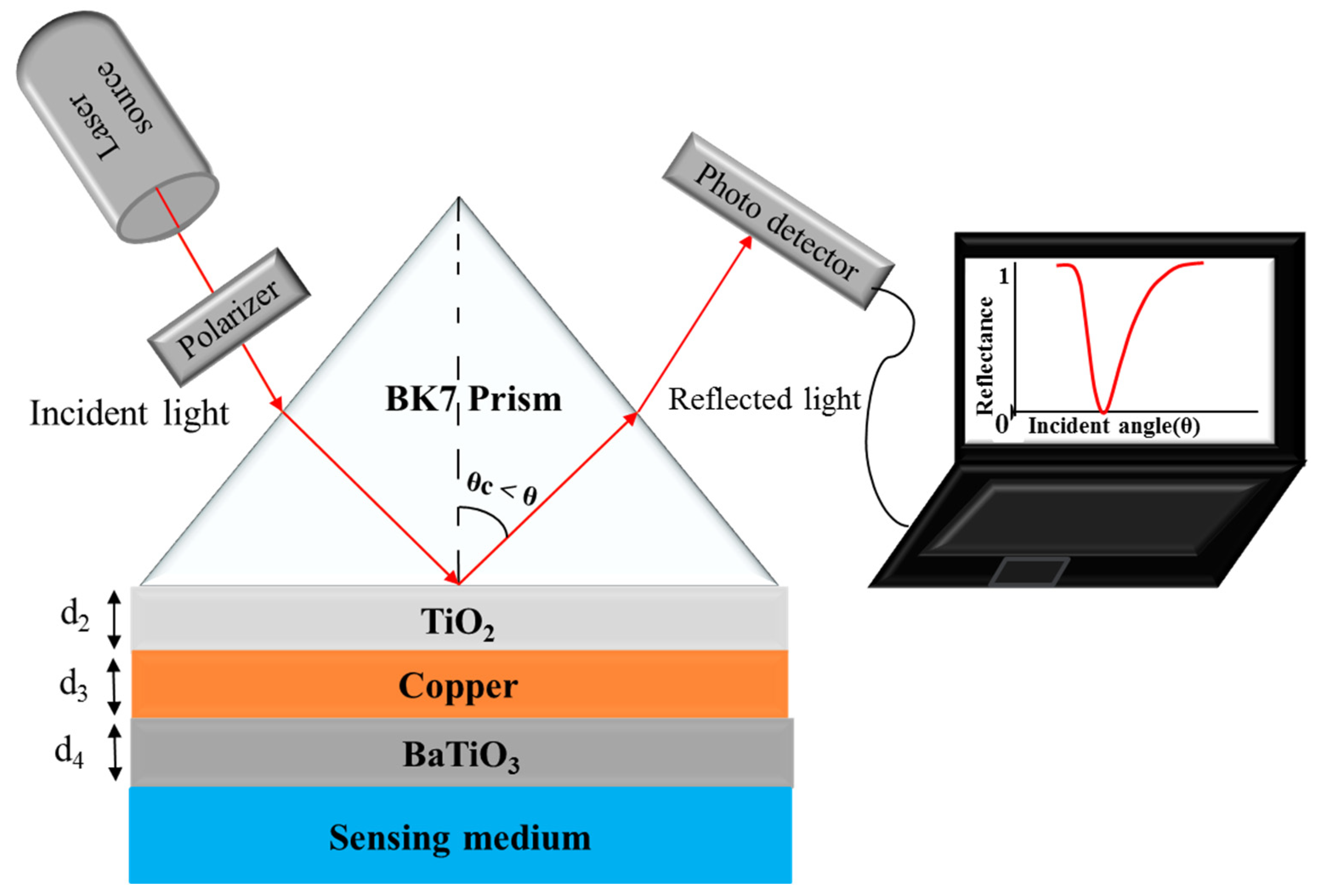

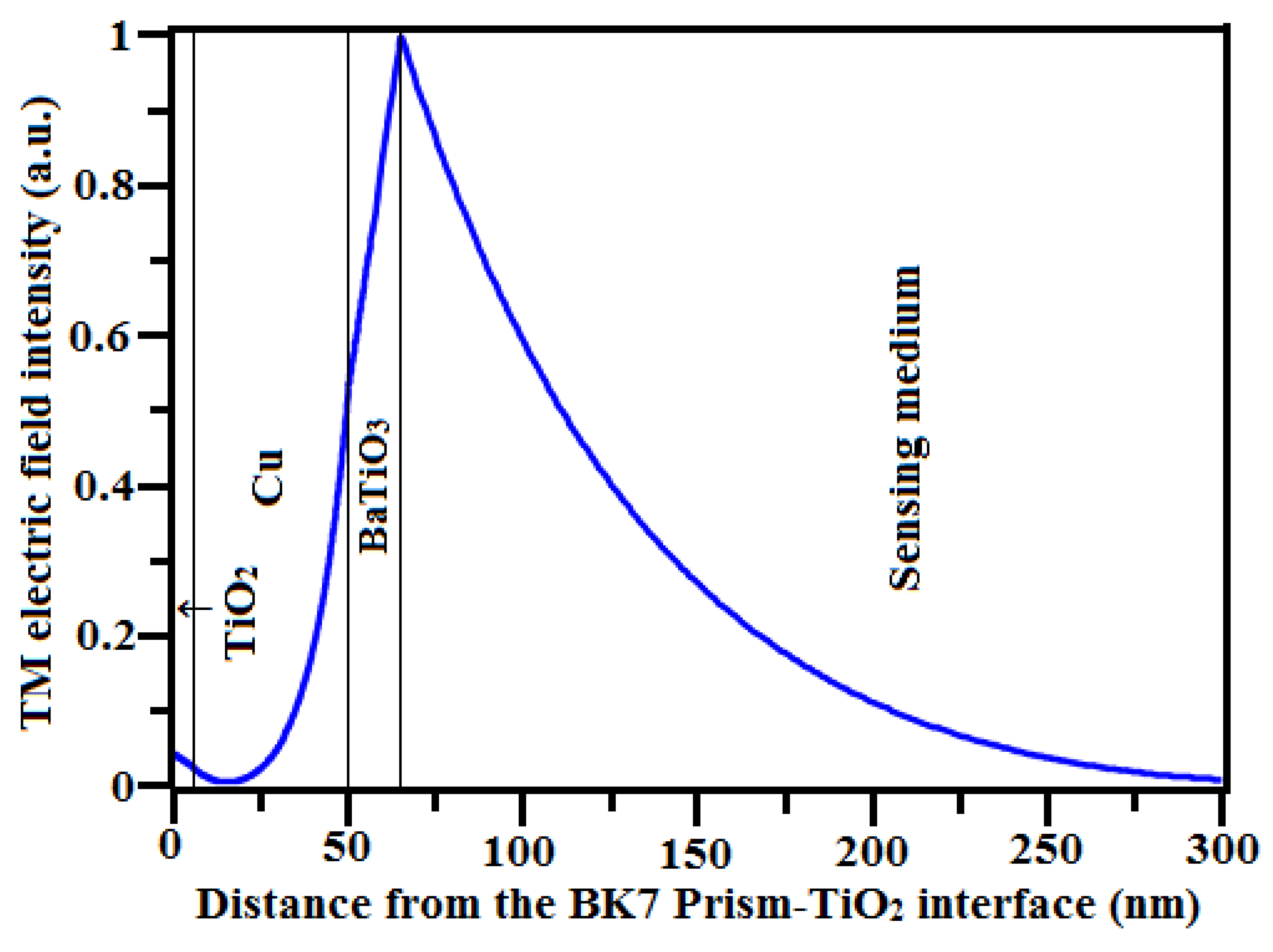

2. Theoretical Model

2.1. Structure Description

2.2. Reflectance

2.3. Performance Parameters

2.3.1. Sensitivity (Sn)

2.3.2. Detection Accuracy (DA) or Signal-to-Noise Ratio (SNR)

2.3.3. Figure of Merit (FOM) or Quality Factor (Q)

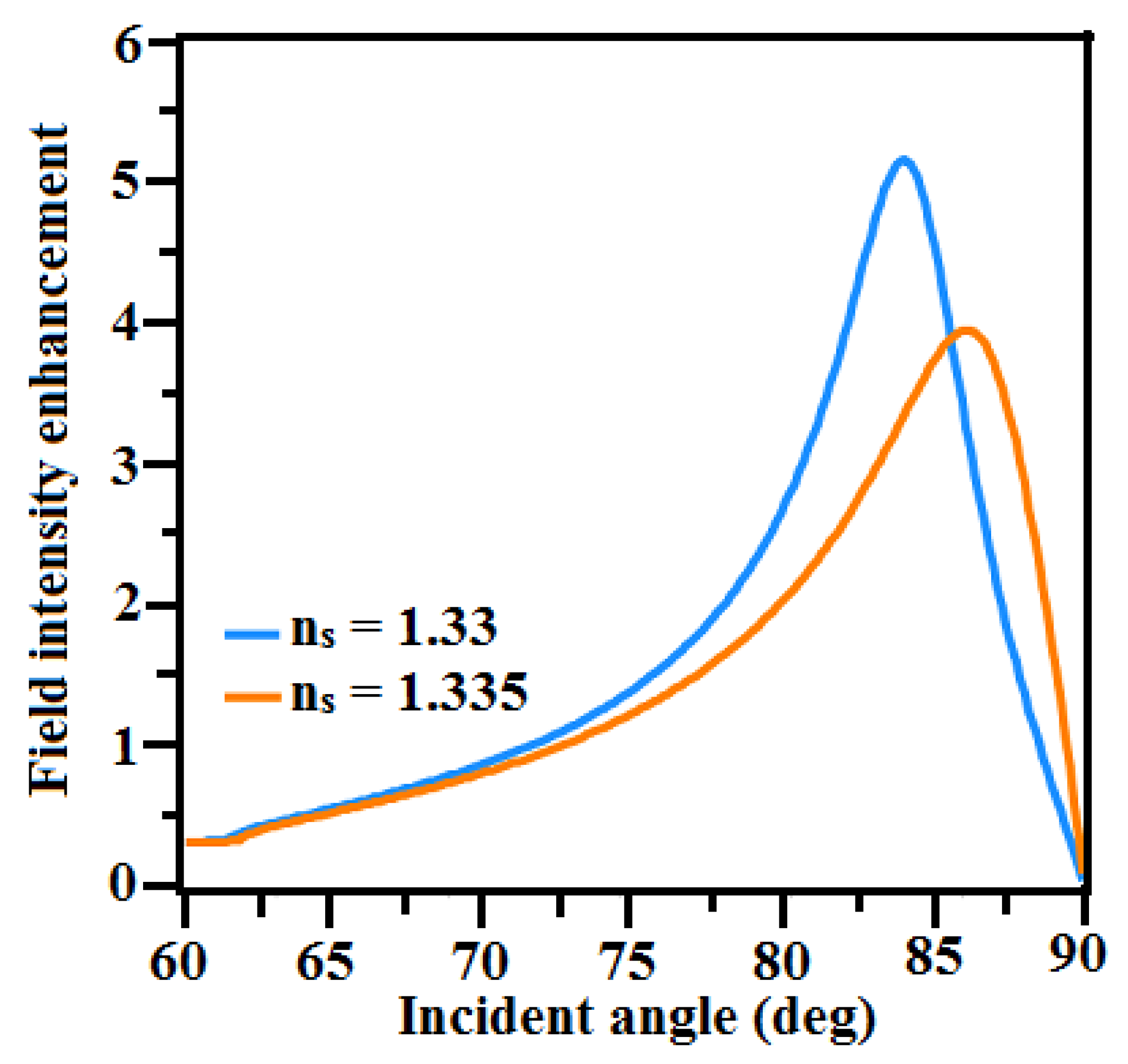

2.3.4. Electric Field Intensity Enhancement Factor (EFIEF)

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gupta, V.K.; Choudhary, K.; Kumar, S. 2D Materials-based Plasmonic Sensors for Health Monitoring Systems—A Review. IEEE Sens. J. 2023, 23, 11324–11335. [Google Scholar] [CrossRef]

- Maharana, P.K.; Jha, R.; Padhy, P. On the electric field enhancement and performance of SPR gas sensor based on graphene for visible and near infrared. Sens. Actuators B 2015, 207, 117–122. [Google Scholar] [CrossRef]

- Xu, H.; Wu, L.; Dai, X.; Gao, Y.; Xiang, Y. An ultra-high sensitivity surface plasmon resonance sensor based on graphene-aluminum-graphene sandwich-like structure. J. Appl. Phys. 2016, 120, 053101. [Google Scholar] [CrossRef]

- Yu, X.; Yuan, Y.; Xiao, B.; Li, Z.; Qu, J.; Song, J. Flexible Plasmonic pressure sensor based on layered Two-Dimensional heterostructures. J. Lightwave Technol. 2018, 36, 5678–5684. [Google Scholar] [CrossRef]

- Mollah, M.A.; Islam, S.M.R.; Yousufali, M.; Abdulrazak, L.F.; Hossain, M.B.; Amir, I.S. Plasmonic temperature sensor using D-shaped photonic crystal fiber. Results Phys. 2020, 16, 102966. [Google Scholar] [CrossRef]

- Yupapin, P.; Trabelsi, Y.; Vigneswaran, D.; Taya, S.A.; Daher, M.G.; Colak, I. Ultra-high-sensitive sensor based on surface plasmon resonance structure having Si and graphene layers for the detection of chikungunya virus. Plasmonics 2022, 17, 1315–1321. [Google Scholar] [CrossRef]

- Tong, J.; Jiang, L.; Chen, H.; Wang, Y.; Yon, K.T.; Forsberg, E.; He, S. Graphene–bimetal plasmonic platform for ultra-sensitive biosensing. Opt. Commun. 2018, 410, 817–823. [Google Scholar] [CrossRef]

- Hasib, M.H.H.; Nur, J.N.; Shushama, K.N.; Rahaman, I.; Rana, M.M.; Mahfuz, M.A. Enhancement of sensitivity for surface plasmon resonance biosensor with higher detection accuracy and quality Factor. In Proceedings of the 1st International Conference on Advances in Science, Engineering and Robotics Technology (ICASERT) IEEE, Dhaka, Bangladesh, 3–5 May 2019. [Google Scholar]

- Karki, B.; Ramya, K.C.; Devi, R.S.S.; Srivastava, V.; Pal, A. Titanium dioxide, black phosphorus and bimetallic layer-based surface plasmon biosensor for formalin detection: Numerical analysis. Opt. Quant. Electron. 2022, 54, 451. [Google Scholar] [CrossRef]

- Suvarnaphaet, P.; Pechprasarn, S. Graphene-based materials for biosensors: A review. Sensors 2017, 17, 2161. [Google Scholar] [CrossRef]

- Kretschmann, E.; Raether, H. Notizen: Radiative decay of non radiative surface plasmons excited by light. Z. Naturf. A 1968, 23, 2135–2136. [Google Scholar] [CrossRef]

- Raj, S.; Alotaibi, M.F.; Al-Hadeethi, Y.; Lohia, P.; Singh, S.; Dwivedi, D.K.; Umar, A.; Alzayed, H.M.; Algadi, H.; Baskoutas, S. Numerical study to enhance the sensitivity of a surface plasmon resonance sensor with BlueP/WS2-covered Al2O3-Nickel Nanofilms. Nanomaterials 2022, 12, 2205. [Google Scholar]

- Maharana, P.K.; Jha, R. Chalcogenide prism and graphene multilayer based surface plasmon resonance affinity biosensor for high performance. Sens. Actuators B Chem. 2012, 169, 161–166. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, Y.L.; Byun, K.M. Graphene-on-silver substrates for sensitive surface plasmon resonance imaging biosensors. Opt. Express 2011, 19, 458–466. [Google Scholar] [CrossRef]

- Saada, Y.; Selmib, M.; Gazzaha, M.H.; Bajahzard, A.; Belmabrouk, H. Performance enhancement of a copper-based optical fiber SPR sensor by the addition of an oxide layer. Optik 2019, 190, 1–9. [Google Scholar] [CrossRef]

- Singh, S.; Mishra, S.K.; Gupta, B.D. Sensitivity enhancement of a surface plasmon resonance based fiber optic refractive index sensor utilizing an additional layer of oxides. Sens. Actuators A Phys. 2013, 193, 136–140. [Google Scholar] [CrossRef]

- Ahmed, S.; Kabir, S. Copper-Germanium-Graphene based highly sensitive plasmonic biosensor for protein detection. In Proceedings of the IEEE International Conference on Computer, Communication, Chemical, Material and Electronic Engineering (IC4ME2), Rajshahi, Bangladesh, 8–9 February 2018. [Google Scholar]

- Singh, M.K.; Pal, S.; Verma, A.; Mishra, V.; Prajapati, Y.K. Sensitivity enhancement using anisotropic black phosphorus and antimonene in bi-metal layer-based surface plasmon resonance biosensor. Superlattices Microstruct. 2021, 156, 106969. [Google Scholar] [CrossRef]

- Wang, S.; Liu, N.; Cheng, Q.; Pang, B.; Lv, J. Surface plasmon resonance on the Antimonene–Fe2O3–Copper layer for optical attenuated total reflection spectroscopic application. Plasmonics 2021, 16, 559–566. [Google Scholar] [CrossRef]

- Verma, V.K.; Pal, S.; Rizal, C.; Prajapati, Y.K. Tunable and sensitive detection of cortisol using Anisotropic Phosphorene with a surface plasmon resonance technique: Numerical investigation. Magnetochemistry 2022, 8, 31. [Google Scholar] [CrossRef]

- Ishtiak, K.M.; Imam, S.A.; Khosru, Q.M. BaTiO3—Blue Phosphorus/WS2 hybrid structure-based surface plasmon resonance biosensor with enhanced sensor performance for rapid bacterial detection. Results Eng. 2022, 16, 100698. [Google Scholar] [CrossRef]

- Tabassum, R.; Mishra, S.K.; Gupta, B.D. Surface plasmon resonance-based fiber optic hydrogen sulphide gas sensor utilizing Cu–ZnO thin films. Phys. Chem. Chem. Phys. 2013, 15, 11868–11874. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Sau, N.V.; Ngo, Q.M.; Eppe, G.; Tran, N.Q.; Anh, N.T.P. Enhanced sensitivity and detection of Near-Infrared refractive index sensor with plasmonic multilayers. Sensors 2021, 21, 7056. [Google Scholar] [CrossRef] [PubMed]

- Toloue, H.; Centeno, A. Numerical analysis on DNA-sensor based on copper-graphene surface plasmon resonance. In Proceedings of the 2015 International Conference on Smart Sensors and Application (ICSSA), Kuala Lumpur, Malaysia, 26–28 May 2015. [Google Scholar]

- Mumtaz, F.; Roman, M.; Zhang, B.; Abbas, L.G.; Ashraf, M.A.; Fiaz, M.A.; Dai, Y.; Huang, J. A simple optical fiber SPR sensor with ultra-high sensitivity for dual-parameter measurement. IEEE Photonics J. 2022, 14, 6852907. [Google Scholar] [CrossRef]

- Polat, K. Thin film photocatalyst made from Fe2O3/2D Graphene/Cu working in the visible region of the solar spectrum. Solid State Commun. 2020, 319, 11393. [Google Scholar] [CrossRef]

- Zhang, K.-K.; Wang, Y.-Y.; Wang, Q.; Wang, H.-Y.; Qian, Y.-Z.; Zhang, D.-Y.; Xue, Y.-Y.; Li, S.; Zhang, L. Sensitive monitoring of refractive index by surface plasmon resonance (SPR) with a gold α-iron (III) oxide thin film. Instrum. Sci. Technol. 2023, 51, 558–573. [Google Scholar] [CrossRef]

- Ahmed, A.M.; Shaban, M. Highly sensitive Au–Fe2O3–Au and Fe2O3–Au–Fe2O3 biosensors utilizing strong surface plasmon resonance. Appl. Phys. B 2020, 126, 57. [Google Scholar] [CrossRef]

- Augustine, S.; Joshi, A.G.; Yadav, B.K.; Mehta, A.; Kumar, P.; Renugopalakrishanan, V.; Malhotra, B.D. An emerging nanostructured molybdenum trioxide-based biocompatible sensor platform for breast cancer biomarker detection. MRS Commun. 2018, 8, 668–679. [Google Scholar] [CrossRef]

- Zakaria, R.; Mahbub, M.; Lim, C.S. Studies of surface plasmon resonance effect on different metallic layers of silver (Ag) and copper (Cu) with molybdenum trioxide (MoO3) for formaldehyde sensor. Results Opt. 2023, 11, 100374. [Google Scholar] [CrossRef]

- Pandey, A.K.; Hashemi, M. Plasmonic sensor based on molybdenum trioxide-MXene heterojunction for refractive index sensing. Arab. J. Sci. Eng. 2022, 47, 829–834. [Google Scholar] [CrossRef]

- Macis, S.; Aramo, C.; Bonavolontà, C.; Cibin, G.; D’Elia, A.; Davoli, I.; Lucia, M.D.; Lucci, M.; Lupi, S.; Miliucci, M.; et al. MoO3 films grown on polycrystalline Cu: Morphological, structural, and electronic properties. J. Vac. Sci. Technol. A 2019, 37, 021513. [Google Scholar] [CrossRef]

- Hsieh, C.-L.; Grange, R.; Pu, Y.; Psaltis, D. Bioconjugation of barium titanate nanocrystals with immunoglobulin G antibody for second harmonic radiation imaging probes. Biomaterials 2010, 31, 2272–2277. [Google Scholar] [CrossRef]

- Gläsel, H.-J.; Hartmann, E.; Hirsch, D.; Böttcher, R.; Klimm, C.; Michel, D.; Semmelhack, H.-C.; Hormes, J.; Rumpf, H. Preparation of barium titanate ultrafine powders from a monomeric metallo-organic precursor by combined solid-state polymerisation and pyrolysis. J. Mater. Sci. 1999, 34, 2319–2323. [Google Scholar] [CrossRef]

- O’Brien, S.; Brus, L.; Murray, C.B. Synthesis of monodisperse nanoparticles of barium titanate: Toward a generalized strategy of oxide nanoparticle synthesis. J. Am. Chem. Soc. 2001, 123, 12085–12086. [Google Scholar] [CrossRef] [PubMed]

- Ihlefeld, J.F.; Borland, W.; Maria, J.-P. Synthesis and properties of barium titanate thin films on copper substrates. MRS Online Proc. Libr. 2005, 902, 203. [Google Scholar] [CrossRef]

- Srivastava, A.; Das, R.; Prajapati, Y.K. Effect of perovskite material on performance of surface plasmon resonance biosensor. IET Optoelectron. 2020, 14, 256–265. [Google Scholar] [CrossRef]

- Fouad, S.; Sabri, N.; Jamal, Z.A.Z.; Poopalan, P. Enhanced sensitivity of surface plasmon resonance sensor based on bilayers of silver-barium titanate. J. Nano-Electron. Phys. 2016, 8, 04085. [Google Scholar] [CrossRef]

- Pal, A.; Jha, A. A theoretical analysis on sensitivity improvement of an SPR refractive index sensor with graphene and barium titanate nanosheets. Optik 2021, 231, 166378. [Google Scholar] [CrossRef]

- Mudgal, N.; Choure, K.K.; Saharia, A.; Agarwal, A.; Falaswal, M.K.; Sahu, S.; Singh, S.V.; Singh, G. Comparative assessment of fiber SPR sensor for sensitivity enhancement using BaTiO3 layer. Optoelectron. Adv. Mater. Rapid Commun. 2022, 16, 114–120. [Google Scholar]

- Setareh, M.; Kaatuzian, H. Sensitivity enhancement of a surface plasmon resonance sensor using blue phosphorene/MoS2 hetero-structure and barium titanate. Superlattices Microstruct. 2021, 153, 106867. [Google Scholar] [CrossRef]

- Sun, P.; Wang, M.; Liu, L.; Jiao, L.; Du, W.; Xia, F.; Liu, M.; Kong, W.; Dong, L.; Yun, M. Sensitivity enhancement of surface plasmon resonance biosensor based on graphene and barium titanate layers. Appl. Surf. Sci. 2019, 475, 342–347. [Google Scholar] [CrossRef]

- Singh, S.; Sharma, A.K.; Lohia, P.; Dwivedi, D.K. Theoretical analysis of sensitivity enhancement of surface plasmon resonance biosensor with zinc oxide and blue phosphorus/MoS2 heterostructure. Optik 2021, 244, 167618. [Google Scholar] [CrossRef]

- Kumar, A.; Yadav, A.K.; Kushwah, A.S.; Srivastava, S.K. A comparative study among WS2, MoS2 and graphene based surface plasmon resonance (SPR) sensor. Sens. Actuators Rep. 2020, 2, 100015. [Google Scholar] [CrossRef]

- El-Gohary, S.H.; Choi, M.; Kim, Y.L.; Byun, K.M. Dispersion curve engineering of TiO2/silver hybrid substrates for enhanced surface plasmon resonance detection. Sensors 2016, 16, 1442. [Google Scholar] [CrossRef] [PubMed]

- Hossain, M.B.; Tasnim, T.; Abdulrazak, L.F.; Rana, M.M.; Islam, M.R. A Numerical approach to design the kretschmann configuration based refractive Index graphene-MoS2 hybrid layers with TiO2-SiO2 nano for formalin detection. Photonic Sens. 2020, 10, 134–146. [Google Scholar] [CrossRef]

- Singh, S.; Prajapati, Y.K. TiO2/gold-graphene hybrid solid core SPR based PCF RI sensor for sensitivity enhancement. Optik 2020, 224, 165525. [Google Scholar] [CrossRef]

- Moznuzzaman, M.; Khan, I.; Islam, M.R. Nano-layered surface plasmon resonance-based highly sensitive biosensor for virus detection: A theoretical approach to detect SARS-CoV-2. AIP Adv. 2021, 11, 065023. [Google Scholar] [CrossRef]

- Raikwar, S.; Srivastava, D.K.; Saini, J.P.; Prajapati, Y.K. 2D- Antimonene based surface plasmon resonance sensor for improvement of sensitivity. Appl. Phys. A 2021, 127, 92. [Google Scholar] [CrossRef]

- Mostufa, S.; Akib, T.B.A.; Rana, M.M.; Islam, M.R. Highly sensitive TiO2/Au/Graphene layer-based surface plasmon resonance biosensor for cancer detection. Biosensors 2022, 12, 603. [Google Scholar] [CrossRef]

- Hajjaji, A.; Labidi, A.; Gaidi, M.; Ben-Rabha, M.; Smirani, R.; Bejaoui, A.; Bessais, B.; El Khakani, M.A. Structural, Optical and sensing properties of Cr-doped TiO2 thin films. Sens. Lett. 2011, 9, 1697–1703. [Google Scholar] [CrossRef]

- Wu, L.; Guo, J.; Wang, Q.; Lu, S.; Dai, X.; Xiang, Y.; Fan, D. Sensitivity enhancement by using few-layer black phosphorus-graphene/TMDCs heterostructure in surface plasmon resonance biochemical sensor. Sens. Actuators B. Chem. 2019, 249, 542–548. [Google Scholar] [CrossRef]

- Fouad, S.; Sabri, N.; Jamal, Z.A.Z.; Poopalan, P. Surface plasmon resonance sensor sensitivity enhancement using gold-dielectric material. Int. J. Nanoelectron. Mater. 2017, 10, 149–158. [Google Scholar] [CrossRef]

- Vahed, H.; Nadri, C. Ultra-sensitive surface plasmon resonance biosensor based on MoS2–graphene hybrid nanostructure with silver metal layer. Opt. Quant. Electron. 2019, 51, 20. [Google Scholar] [CrossRef]

- Yamamoto, M. Surface plasmon resonance (SPR) theory: Tutorial. Rev. Polarogr. 2002, 48, 209–237. [Google Scholar] [CrossRef]

- Kushwaha, A.S.; Kumar, A.; Kumar, R.; Srivastava, S.K. A study of surface plasmon resonance (SPR) based biosensor with improved sensitivity. Photonics Nanostructures Fundam. Appl. 2018, 31, 99–106. [Google Scholar] [CrossRef]

- Mohanty, G.; Akhtar, J.; Sahoo, B.K. Effect of Semiconductor on Sensitivity of a Graphene-Based Surface Plasmon Resonance Biosensor. Plasmonics 2015, 11, 189–196. [Google Scholar] [CrossRef]

- Ouyang, Q.; Zeng, S.; Jiang, L.; Hong, L.; Xu, G.; Dinh, X.-Q.; Qian, J.; He, S.; Qu, J.; Coquet, P.; et al. Sensitivity enhancement of transition metal Dichalcogenides/Silicon nanostructure-based surface plasmon resonance biosensor. Sci. Rep. 2016, 6, 28190. [Google Scholar] [CrossRef]

- Tiwari, R.; Singh, S.; Lohia, P.; Dwivedi, D.K. Sensitivity enhancement of platinum diselenide based SPR sensor using titanium dioxide as adhesion layer. In Advances in VLSI, Communication, and Signal Processing; Dhawan, A., Mishra, R.A., Arya, K.V., Zamarreño, C.R., Eds.; Lecture Notes in Electrical Engineering; Springer: Singapore, 2022; Volume 911, pp. 249–255. [Google Scholar]

- Lin, Z.; Chen, S.; Lin, C. Sensitivity improvement of a surface plasmon resonance sensor based on two-dimensional materials hybrid structure in visible region: A theoretical study. Sensors 2020, 20, 2445. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Pal, S.; Pal, N.; Mishra, V.; Prajapati, Y.K. High-performance bimetallic surface plasmon resonance biochemical sensor using a black phosphorus–MXene hybrid structure. Appl. Phys. A 2021, 127, 1–12. [Google Scholar] [CrossRef]

- Islam, M.A.; Paul, A.K.; Hossain, B.; Sarkar, A.K.; Rahman, M.M.; Sayem, A.S.M.; Simorangkir, R.B.V.B.; Shobug, M.A.; Buckley, J.L.; Chakrabarti, K.; et al. Design and analysis of GO coated high sensitive tunable SPR sensor for OATR spectroscopic biosensing applications. IEEE Access 2022, 10, 103496–103508. [Google Scholar] [CrossRef]

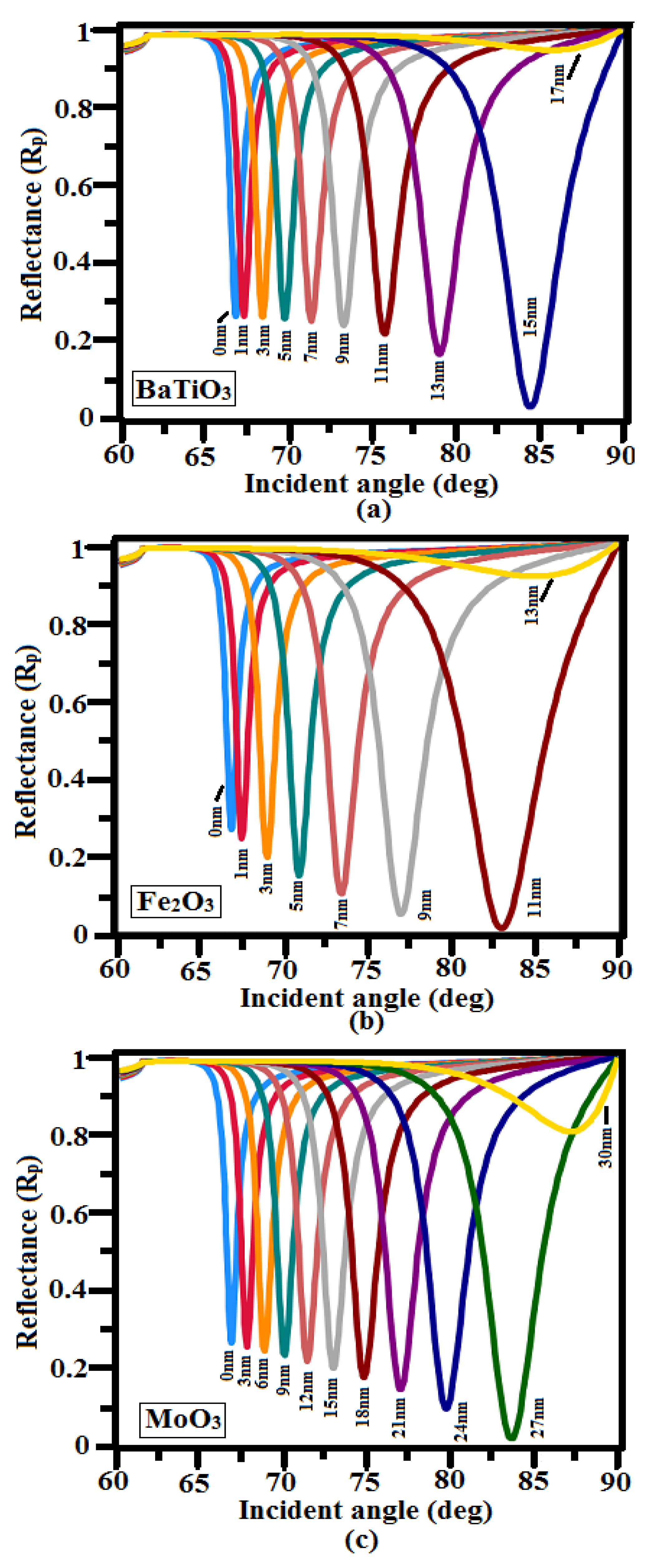

| Oxide Layer | Refractive Index | Ref. |

|---|---|---|

| BaTiO3 | 2.4043 | [53] |

| Fe2O3 | 2.918 + 0.029i | [28] |

| MoO3 | 1.8233 + 0.00204i | [31] |

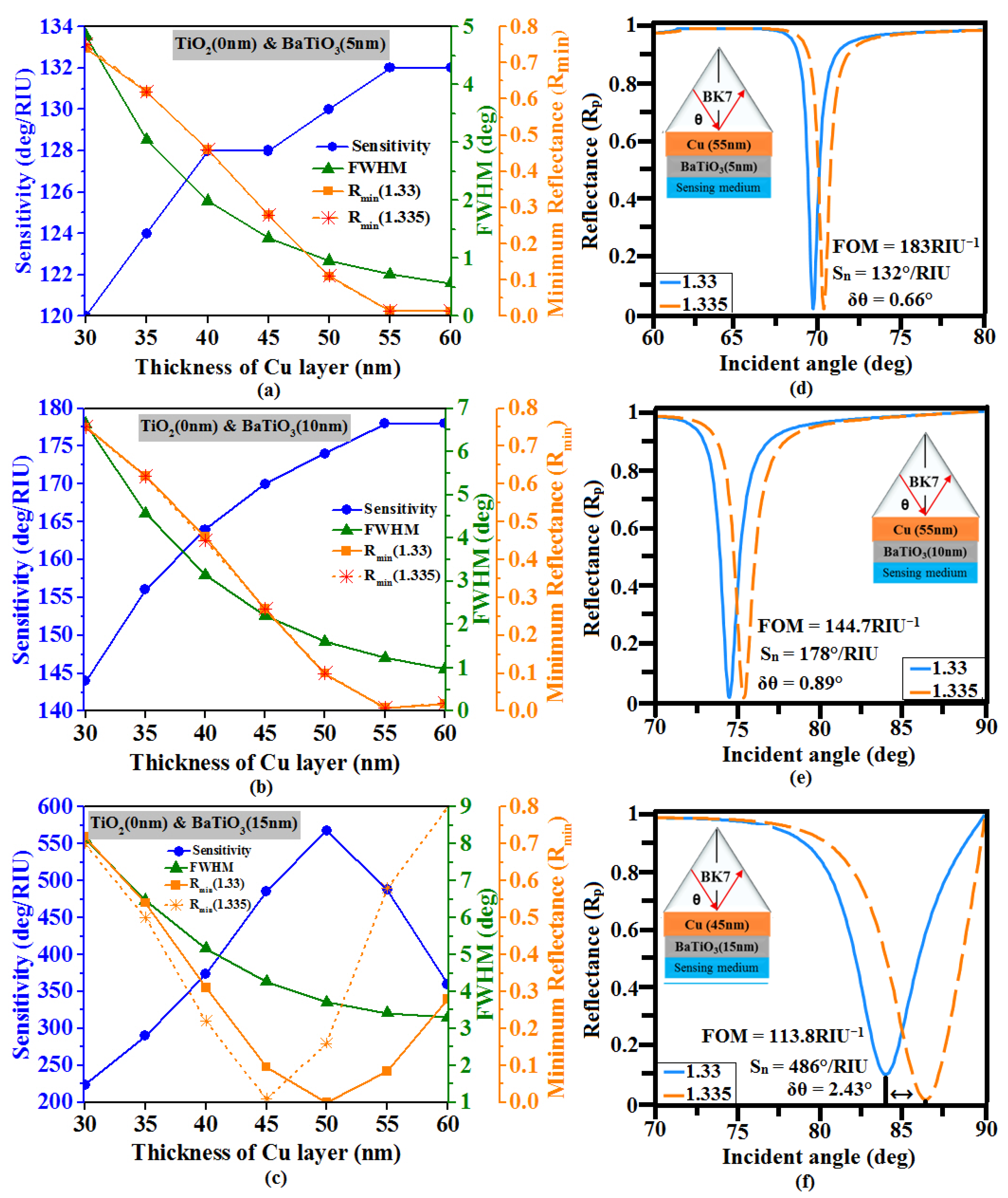

| Thickness of Oxide Layers (nm) | Thickness of TiO2 (nm) | Thickness of Cu (nm) | Rmin at ns | FWHM (deg) at ns | δθSPR (deg) at δns = 0.005 | Sn (°/RIU) | FOM (RIU−1) | ||

|---|---|---|---|---|---|---|---|---|---|

| 1.33 | 1.335 | 1.33 | 1.335 | ||||||

| BaTiO3 (5 nm) | 0 | 55 | 0.014 | 0.013 | 0.72 | 0.75 | 0.66 | 132 | 183 |

| BaTiO3 (10 nm) | 0 | 55 | 0.0097 | 0.0081 | 1.23 | 1.29 | 0.89 | 178 | 144.7 |

| BaTiO3 (15 nm) | 0 | 45 | 0.096 | 0.0095 | 4.27 | 4.65 | 2.43 | 486 | 113.8 |

| BaTiO3 (5 nm) | 5 | 55 | 0.0067 | 0.0061 | 0.69 | 0.71 | 0.66 | 132 | 191.30 |

| BaTiO3 (10 nm) | 5 | 55 | 0.0013 | 0.00053 | 1.15 | 1.21 | 0.90 | 180 | 156.5 |

| BaTiO3 (15 nm) | 5 | 45 | 0.026 | 0.031 | 4.03 | 4.49 | 2.76 | 552 | 136.97 |

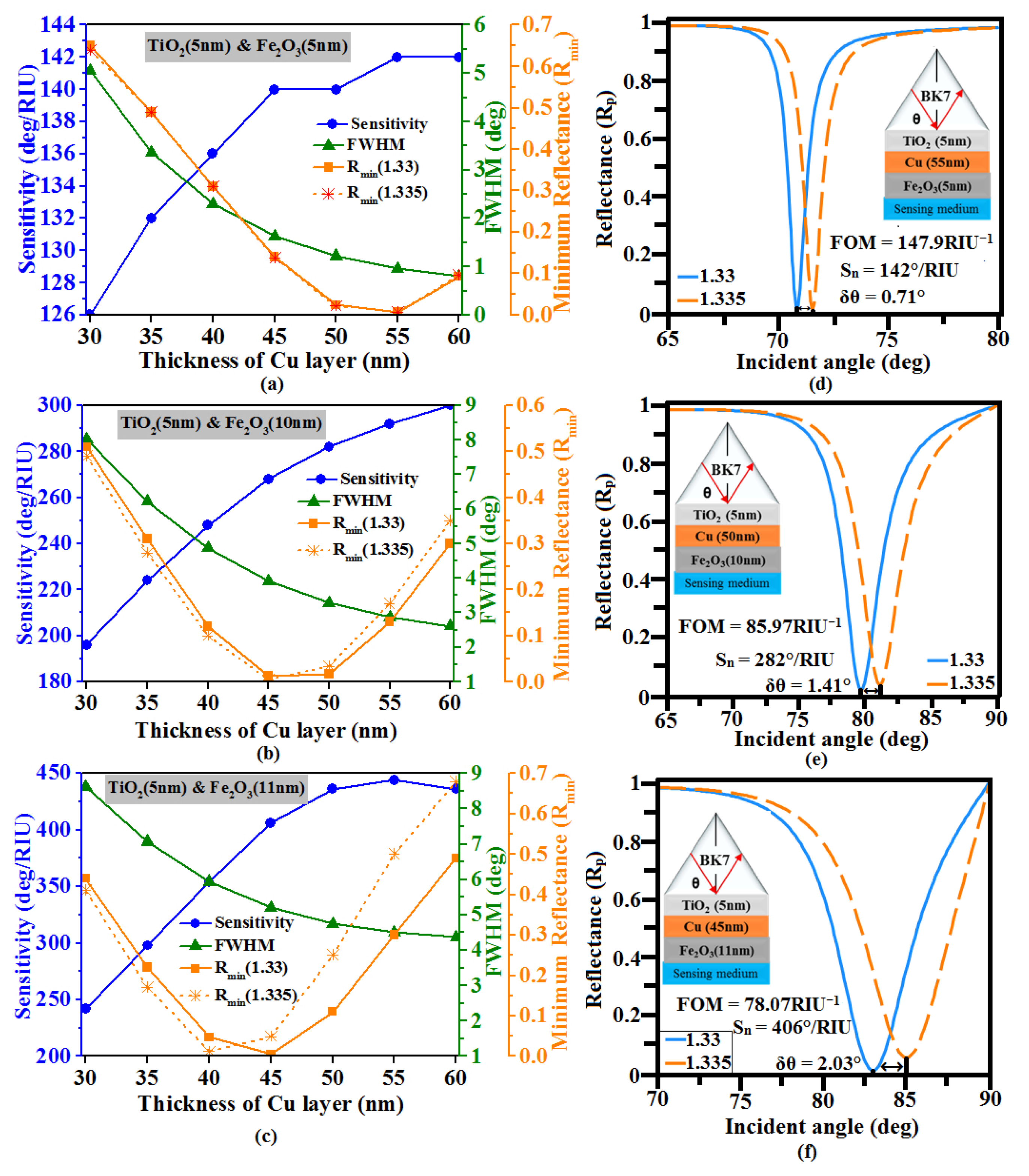

| Fe2O3 (5 nm) | 5 | 55 | 0.0062 | 0.0072 | 0.96 | 1.003 | 0.71 | 142 | 147.9 |

| Fe2O3 (10 nm) | 5 | 50 | 0.017 | 0.034 | 3.28 | 3.6 | 1.41 | 282 | 85.97 |

| Fe2O3 (11 nm) | 5 | 45 | 0.0043 | 0.049 | 5.2 | 5.78 | 2.03 | 406 | 78.07 |

| MoO3 (5 nm) | 5 | 55 | 0.0046 | 0.0042 | 0.58 | 0.6 | 0.59 | 118 | 203.4 |

| MoO3 (10 nm) | 5 | 55 | 0.0014 | 0.001 | 0.75 | 0.77 | 0.65 | 130 | 173.3 |

| MoO3 (27 nm) | 5 | 45 | 0.013 | 0.0022 | 3.68 | 4.18 | 1.93 | 386 | 104.89 |

| Ref. | λ (nm) | Configuration | Sensitivity (°/RIU) | FOM (RIU−1) | DA (deg−1) |

|---|---|---|---|---|---|

| [60] | 600 | SF11-Cu-WSe2 | 92 | - | - |

| [59] | 633 | CaF2-TiO2-Au-PtSe2 | 218 | 53.32 | 0.2466 |

| [49] | 633 | BK7-TiO2-Au-Mxene-Antimonene | 224.26 | 19.05 | 0.0849 |

| [61] | 633 | BK7-Cu-Ni-BP-Ti3C2Tx | 304.47 | 57.85 | 0.19 |

| [41] | 633 | FK51A-Ag-BaTiO3-BlueP/MoS2 | 347.82 | 60.52 | 0.174 |

| [62] | 632.8 | BK7-Cr-Ag-BaTiO3-Go | 372 | 88.11 | - |

| [19] | 633 | CaF2-Cu-Fe2O3-Antimonene | 398 | - | - |

| [18] | 633 | BK7-Cu-Ni-BP-Antimonene | 446 | 93.10 | 0.2 |

| proposed | 633 | BK7-TiO2-Cu-MoO3 | 386 | 104.89 | 0.2717 |

| proposed | 633 | BK7-TiO2-Cu-Fe2O3 | 406 | 78.07 | 0.1923 |

| proposed | 633 | BK7-TiO2-Cu-BaTiO3 | 552 | 136.97 | 0.2481 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muthumanikkam, M.; Vibisha, A.; Lordwin Prabhakar, M.C.; Suresh, P.; Rajesh, K.B.; Jaroszewicz, Z.; Jha, R. Numerical Investigation on High-Performance Cu-Based Surface Plasmon Resonance Sensor for Biosensing Application. Sensors 2023, 23, 7495. https://doi.org/10.3390/s23177495

Muthumanikkam M, Vibisha A, Lordwin Prabhakar MC, Suresh P, Rajesh KB, Jaroszewicz Z, Jha R. Numerical Investigation on High-Performance Cu-Based Surface Plasmon Resonance Sensor for Biosensing Application. Sensors. 2023; 23(17):7495. https://doi.org/10.3390/s23177495

Chicago/Turabian StyleMuthumanikkam, M., Alagu Vibisha, Michael Cecil Lordwin Prabhakar, Ponnan Suresh, Karupiya Balasundaram Rajesh, Zbigniew Jaroszewicz, and Rajan Jha. 2023. "Numerical Investigation on High-Performance Cu-Based Surface Plasmon Resonance Sensor for Biosensing Application" Sensors 23, no. 17: 7495. https://doi.org/10.3390/s23177495

APA StyleMuthumanikkam, M., Vibisha, A., Lordwin Prabhakar, M. C., Suresh, P., Rajesh, K. B., Jaroszewicz, Z., & Jha, R. (2023). Numerical Investigation on High-Performance Cu-Based Surface Plasmon Resonance Sensor for Biosensing Application. Sensors, 23(17), 7495. https://doi.org/10.3390/s23177495