1. Introduction

In practical engineering applications, mechanical equipment generally carries a variety of complex loads, and the various environments in which they continue to work are relatively harsh, including humidity, high pressure, and high temperature. The mechanical properties of this equipment will gradually decrease after a long time of work, and the equipment can even fail. The reason is that in the equipment there are crack defects and corrosion. Non-destructive testing (NDT) technology is significant because it can find these defects in time, which is conducive to ensuring the product quality of this equipment [

1,

2,

3]. The basis of NDT technology is modern science and technology, which is a comprehensive subject. It is usually used to judge the internal or surface structure, physical properties, and state parameters of the tested part. The judgment is usually based on changes in parameters such as sound, light, and magnetism caused by electromagnetic fields, and usually will not destroy the measured object [

4]. At present, the commonly used methods of NDT in engineering are mainly the following, such as magnetic particle testing (MT), ultrasonic testing (UT), eddy current testing (ECT), radiographic testing (RT), and penetration testing (PT). Among them, one of the most commonly used NDT techniques is ECT, because of its many characteristics, such as low requirements on the testing surface, no need for contact, fast testing speed, no need for coupling, easy operation, and no radiation to the human body. It plays an important part in some respects because of these advantages, such as testing and evaluating quality and structural integrity, and the detection objects are mainly metal materials, parts, and equipment [

5,

6,

7].

As one of the NDT methods, ECT technology is based on the principle of electromagnetic induction. It uses the magnetic field (MF) energy coupling between the measured object and the probe coil to detect the measured object. This technology is very suitable for testing the integrity of the test piece [

8]. When the conductivity, magnetic permeability, and distance between the measured object and the probe change, the corresponding magnetic field intensity will also change. The induced eddy currents induced within it change accordingly, ultimately leading to changes in the output signal of the probe [

9,

10]. As one of the core components in the eddy current testing system, the eddy current probe undertakes the task of generating the excitation magnetic field and picking up the information of the specimen [

11]. The optimization of the probe structure has always been a hot spot in the research of eddy current testing systems.

Cui et al. [

12] designed two structural excitation coil models for the detection of ferromagnetic plates, using rectangular coils to induce a directional propagating magnetic field in the plate. Xu et al. [

13] carried out research on the optimal design of the far-field eddy current sensor in riveting structure defect detection based on the far-field eddy current detection technology and designed a new type of flat far-field eddy current sensor from two aspects of signal enhancement and magnetic field suppression. The U-shaped probe can generate a uniform magnetic field within a certain space range, and with the increase in the magnetic field strength, the penetration depth becomes deeper [

14,

15,

16]. When the excitation coil is wound in dual excitation mode, the probe has a higher signal-to-noise ratio and is less affected by the lift-off effect [

17,

18]. Vyroubal conducted theoretical analysis by equating the sensor probe to a transformer model and obtained the relationship between the coil parameters of the probe and the sensitivity and linearity of the probe [

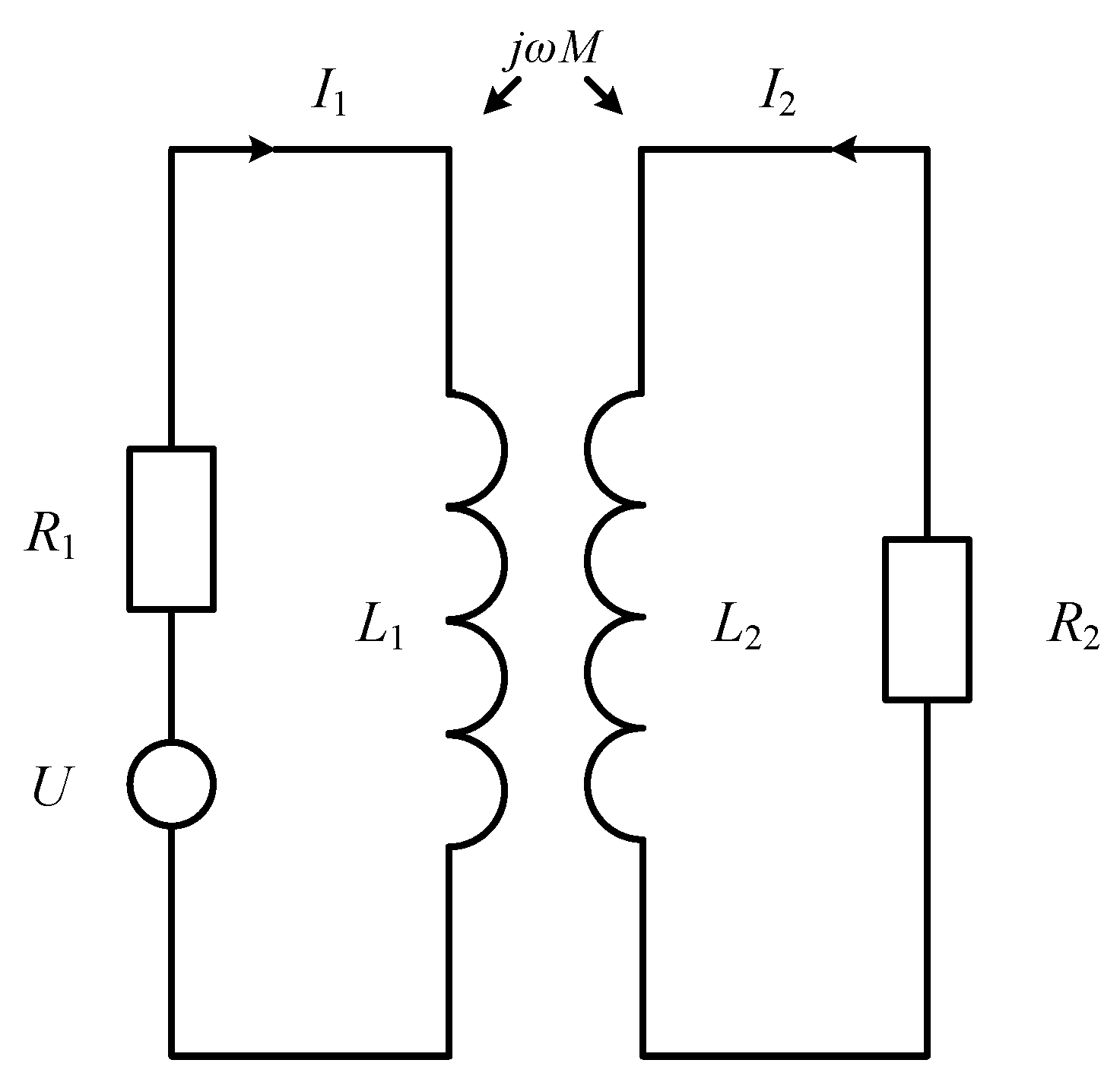

19]. Capobianco studied the effects of geometric parameters of the probe coil (inner-to-outer diameter ratio, turns, wire diameter), metal permeability, magnetic core diameter and height, and lift-off height on sensor sensitivity [

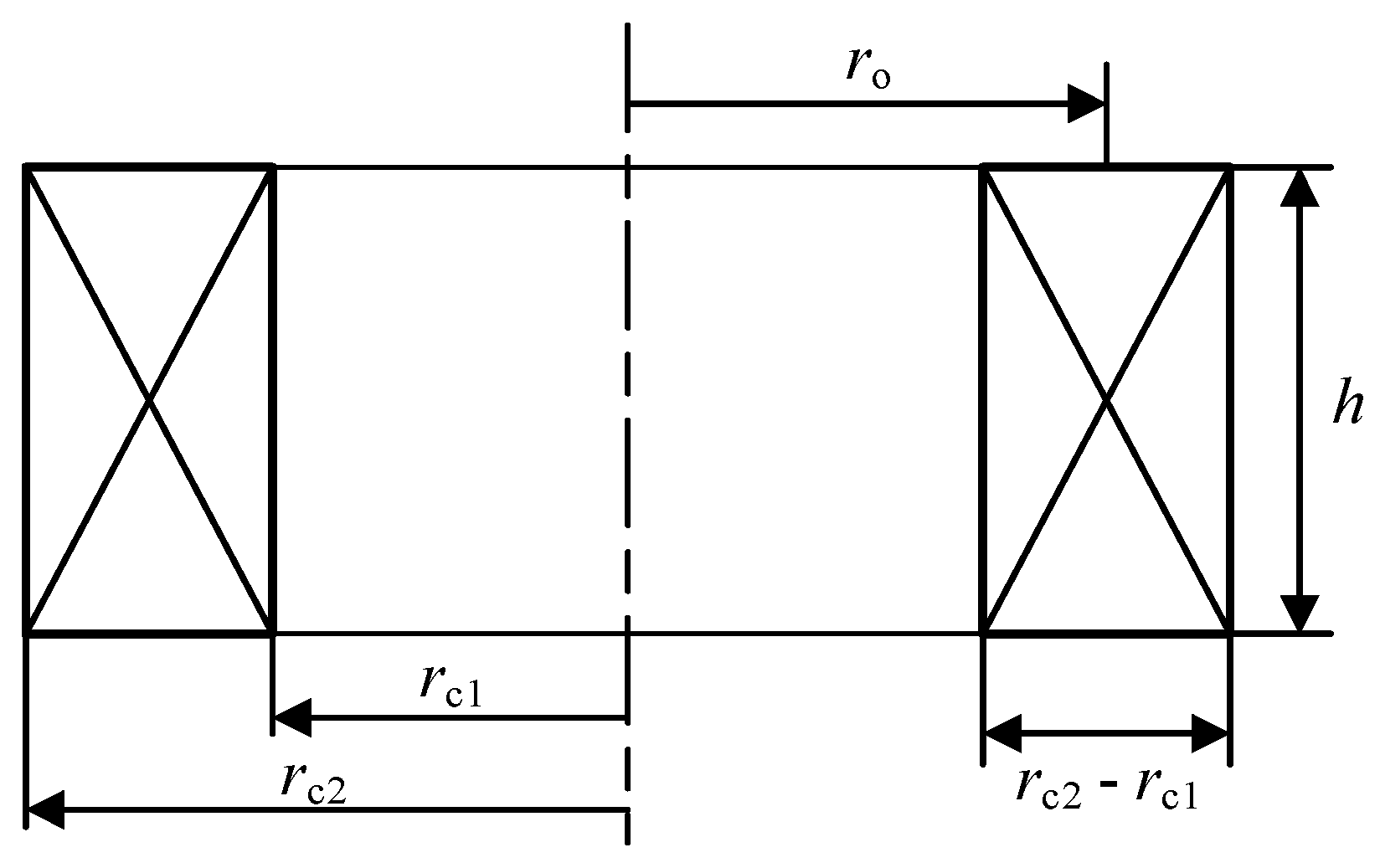

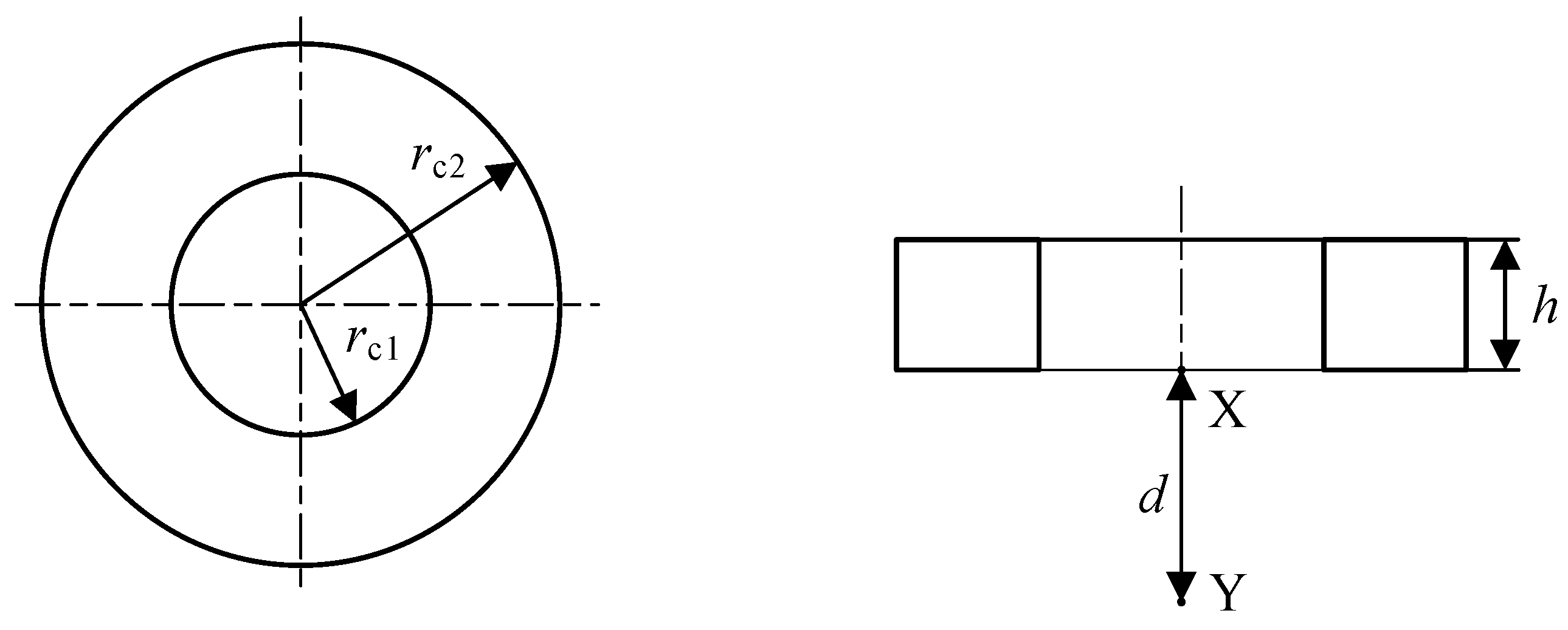

20]. Tomasz Chady optimized the working frequency and structure of the probe [

21]. Young-Kil Shin et al. analyzed a high-performance differential probe structure through finite element simulation and validated the theoretical analysis results through experiments [

22]. Chen et al. [

23] used ANSYS software to simulate and optimize the size of the rectangular coil and accordingly designed a rectangular-circular probe, which effectively suppressed the impact of lift-off. Gong et al. [

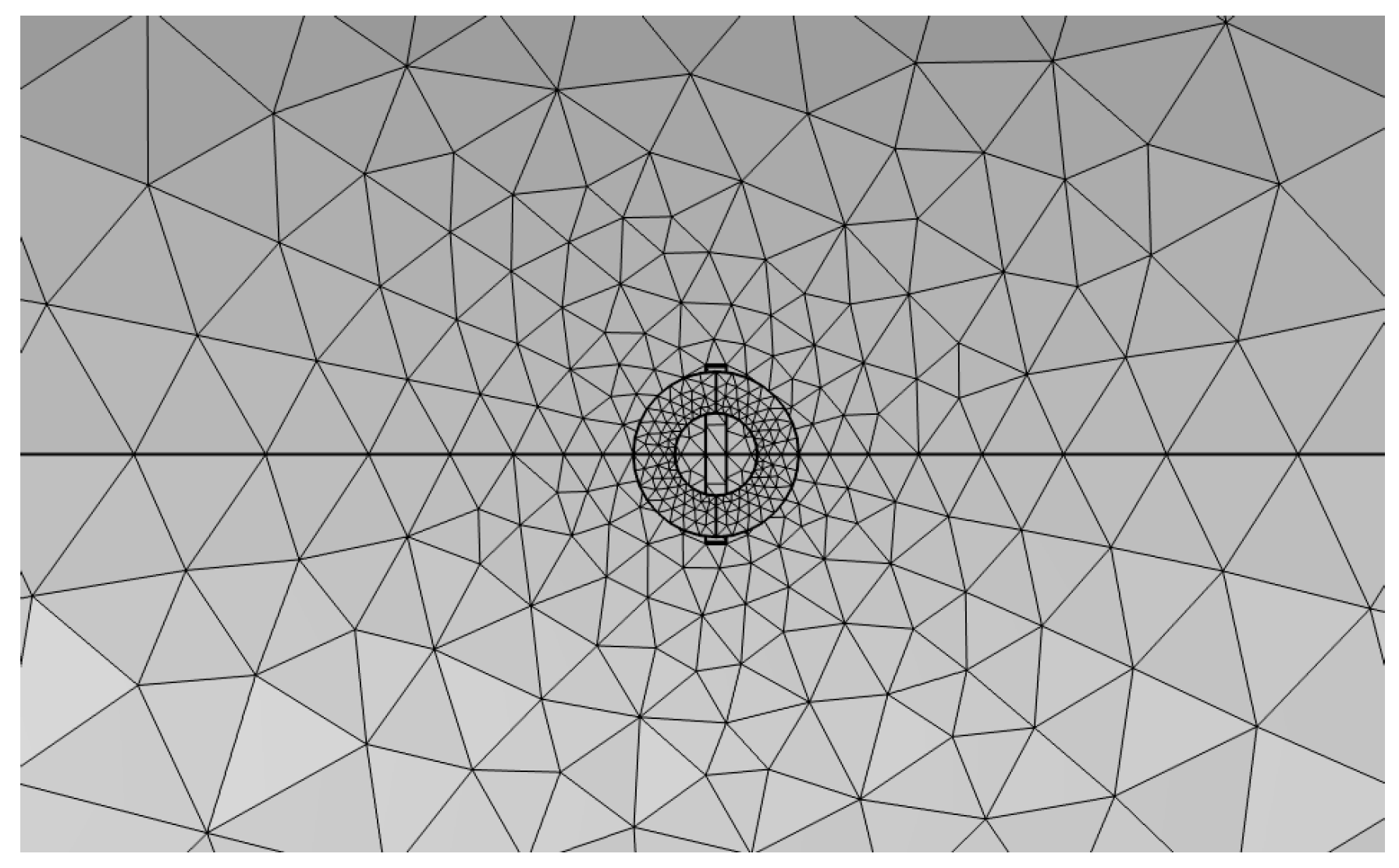

24] established a simulation model using the finite element method and analyzed the influence of pulse excitation parameters and excitation coil parameters on the detection sensitivity and resolution by taking the peak value of the differential signal as a feature. Yang et al. [

25] proposed and developed a new type of circular eccentric Bobbin probe, which has the functions of axial scanning and eccentric circumferential scanning, and can effectively detect information on small-diameter tube defects. Ahmed et al. [

26] proposed the ECECT simulation and hardware design, using the fuzzy logic technique for the development of the new methodology. The depths of the defect coefficients of the probe’s lift-off caused by the coating thickness were measured by using a designed setup. In this result, the ECECT gives an optimum correction for the lift-off, in which the reduction of error is only within 0.1% of its all-out value. Finally, the ECECT is used to measure lift-off in a range of approximately 1 mm to 5 mm, and the performance of the proposed method in non-linear cracks is assessed. Faraj et al. [

27] proposed a study on a hybrid giant magneto-resistance/infrared probe to minimize the influence of lift-off for detecting depth defects. The proposed method is verified experimentally, and the result shows that the impact of lift-off noise is highly reduced in the eddy current testing technique and enhances the sensor accuracy. The depth defect error caused by 1 mm lift-off is reduced to 7.20%.

Poletkin et al. [

28] derived sets of analytical formulas for the calculation of nine components of magnetic stiffness of corresponding force arising between two current-carrying circular filaments arbitrarily oriented in the space by using Babic’s method and the method of mutual inductance (Kalantarov–Zeitlin’s method). Dziczkowski et al. [

29] presented a practical way of using the method of evaluating the metrological properties of eddy current sensors. The idea of the proposed approach consists of employing a mathematical model of an ideal filamentary coil to determine equivalent parameters of the sensor and sensitivity coefficients of tested physical quantities.

It can be seen from the above research that the magnitude and distribution of magnetic induction in eddy current probes are closely related to the resolution and sensitivity of the probe. Most studies focus on the optimization of the probe shape or even the use of dual coils, and there are few studies on the geometric parameters of the probe. Based on this, this paper analyzes the source of affecting the performance of the probe, that is, the magnetic induction intensity, and uses finite element simulation software to construct coil models with different geometric structures. The detection performance of the probe is analyzed by observing the distribution of the magnetic field around the coil, and the theoretical analysis data and simulation data are compared and verified.