Monitoring the Air Quality in an HVAC System via an Energy Harvesting Device

Abstract

1. Introduction

2. Materials and Methods

2.1. The Energy Harvesting Device

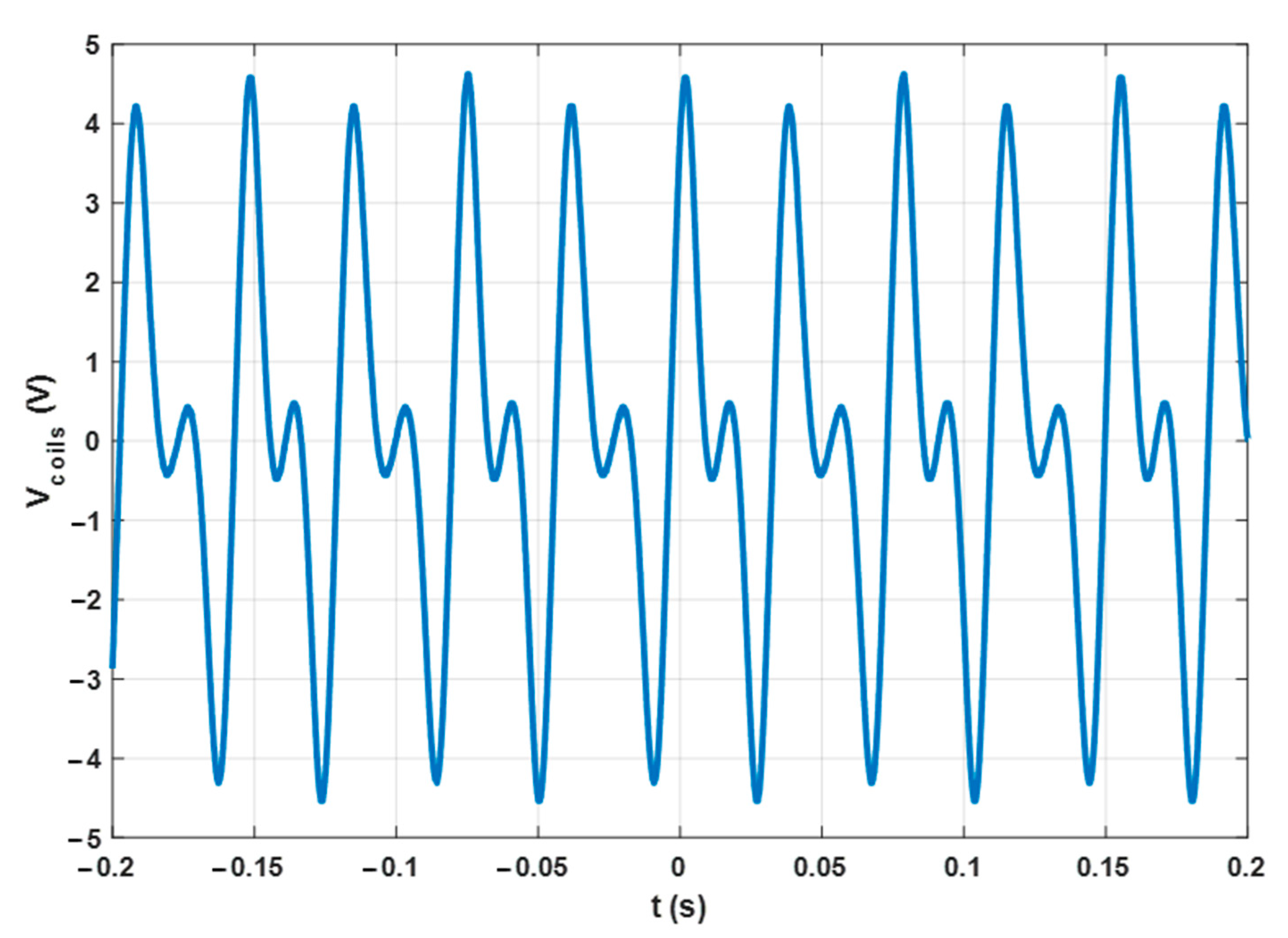

- The resulting force is the sum of , where is the weight of the system, is the fluid force due to the air flux, is the elastic restoring force, and is the force due to the electromagnetic coupling. These forces have a corresponding resulting momentum acting on the frame.

- represents the coupling between the mechanical and the electric parts. The current I in the coils obeys the following equation:where is the load resistance. Notice that the electromotive force can be written as , where is the magnetic flux across the coils, and is the vertical velocity of the coils.

- The current flowing in the coils induces a counteracting force on the frame , where is a constant depending on the strength of the permanent magnets and on the dimensions of the coils.

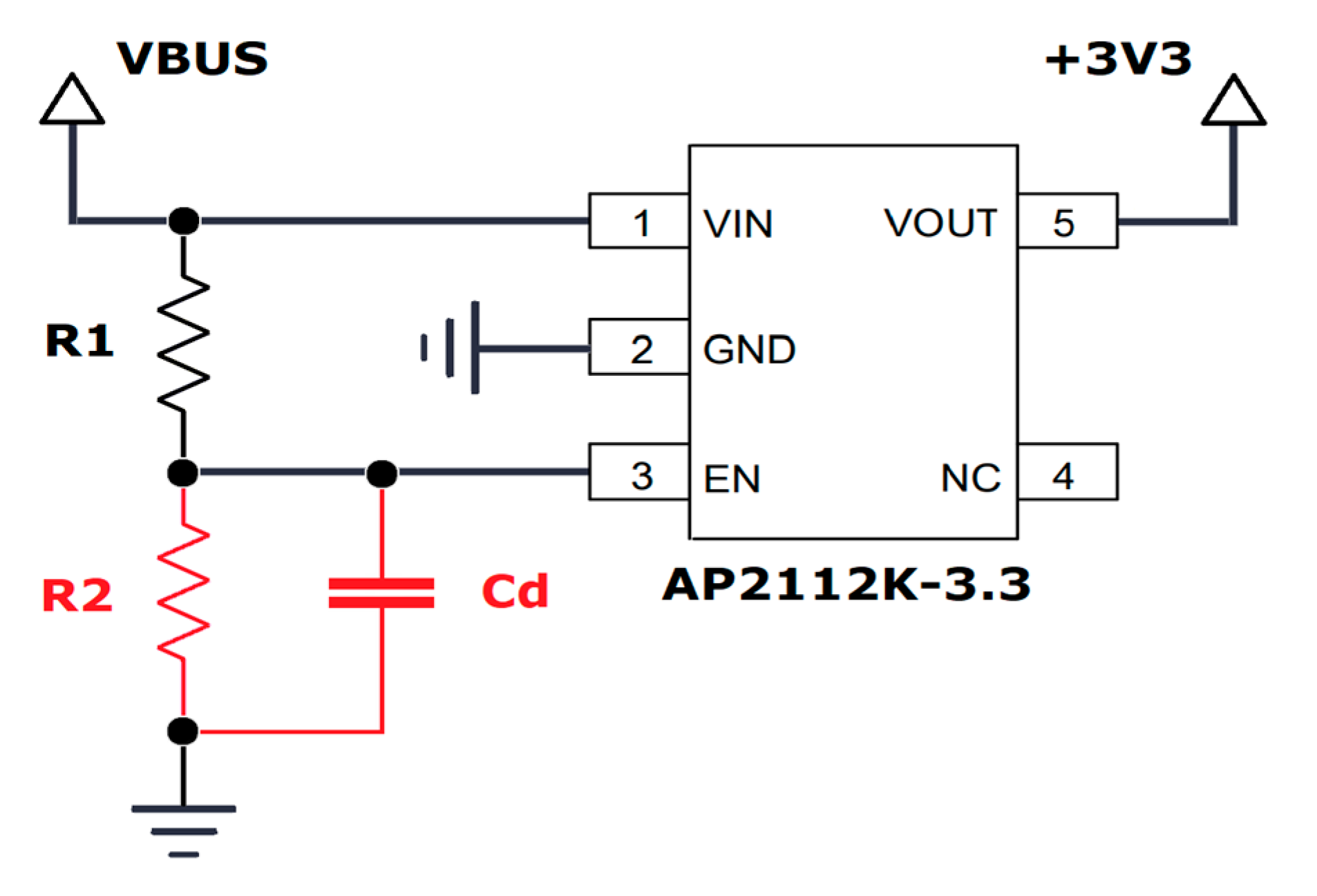

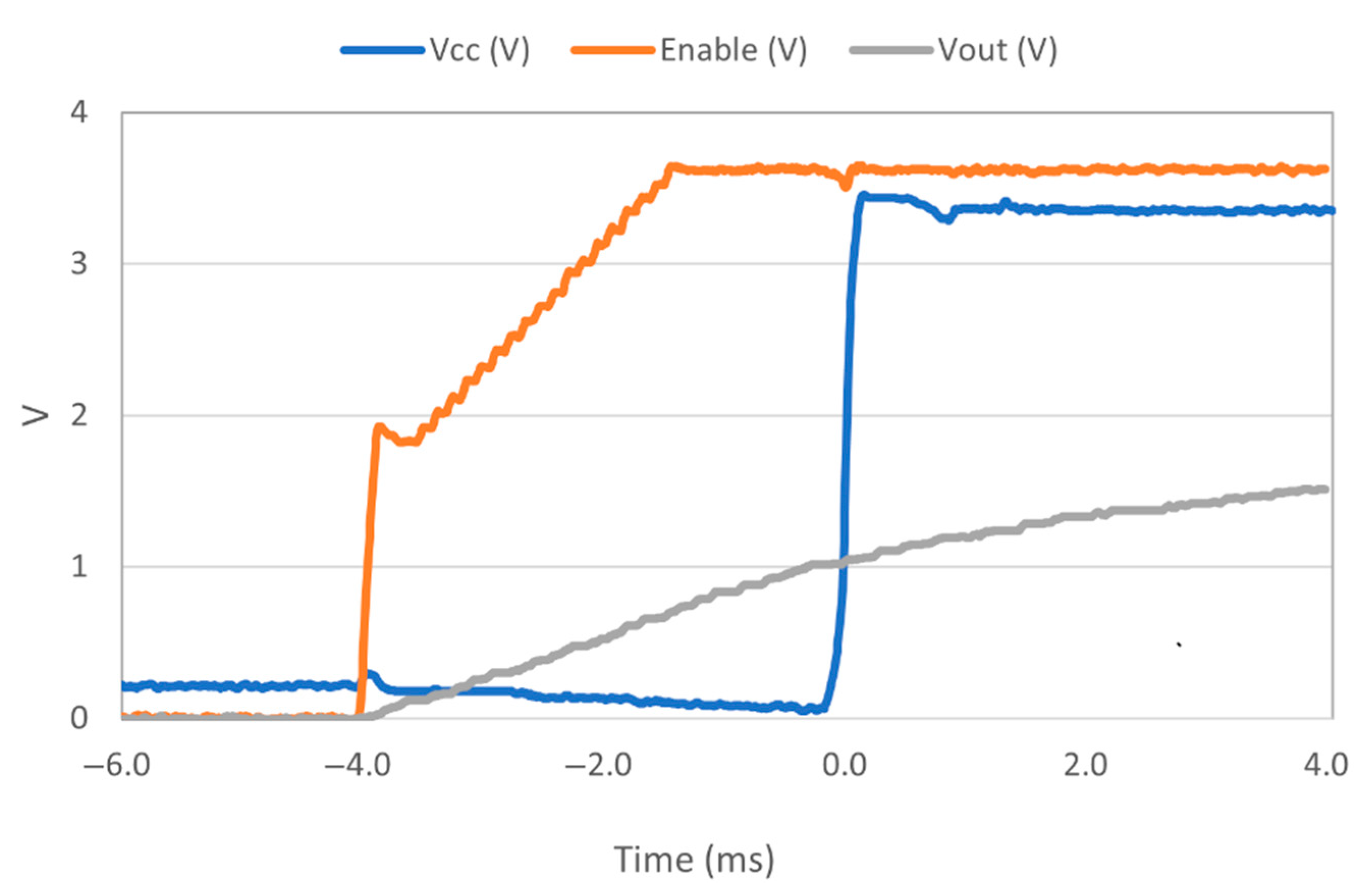

2.2. Architecture of the Sensor Node

2.3. Implementation Insights

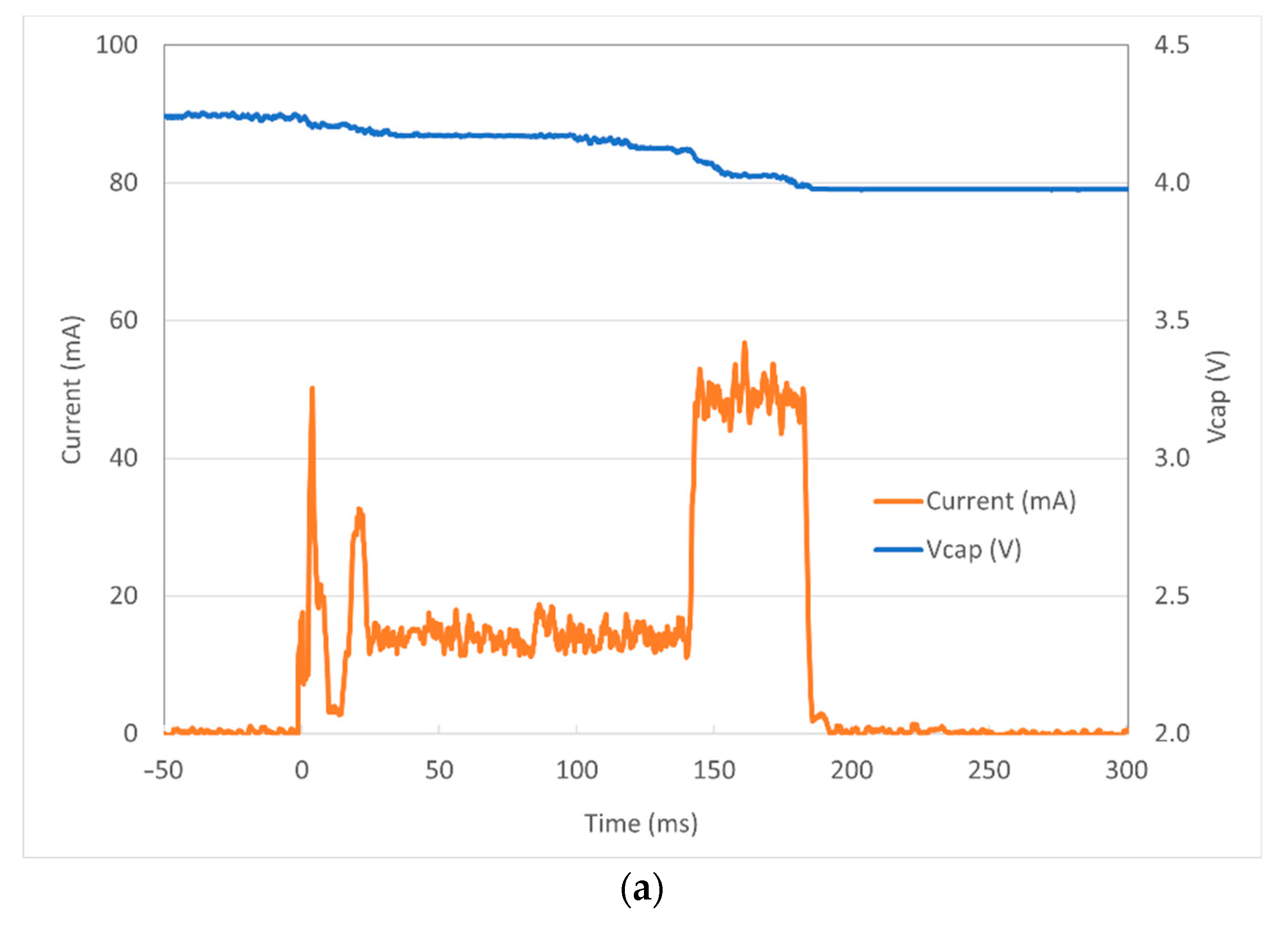

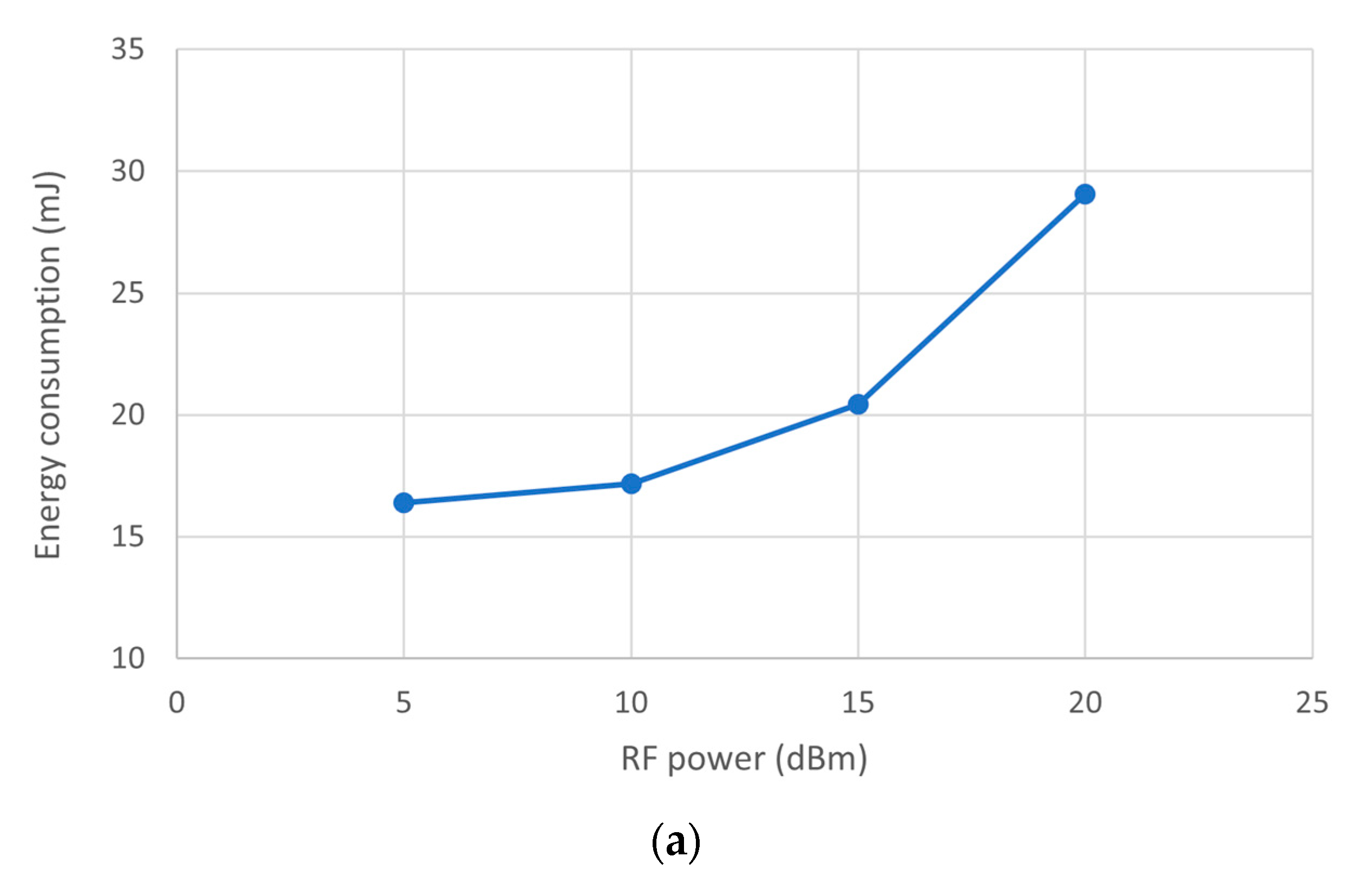

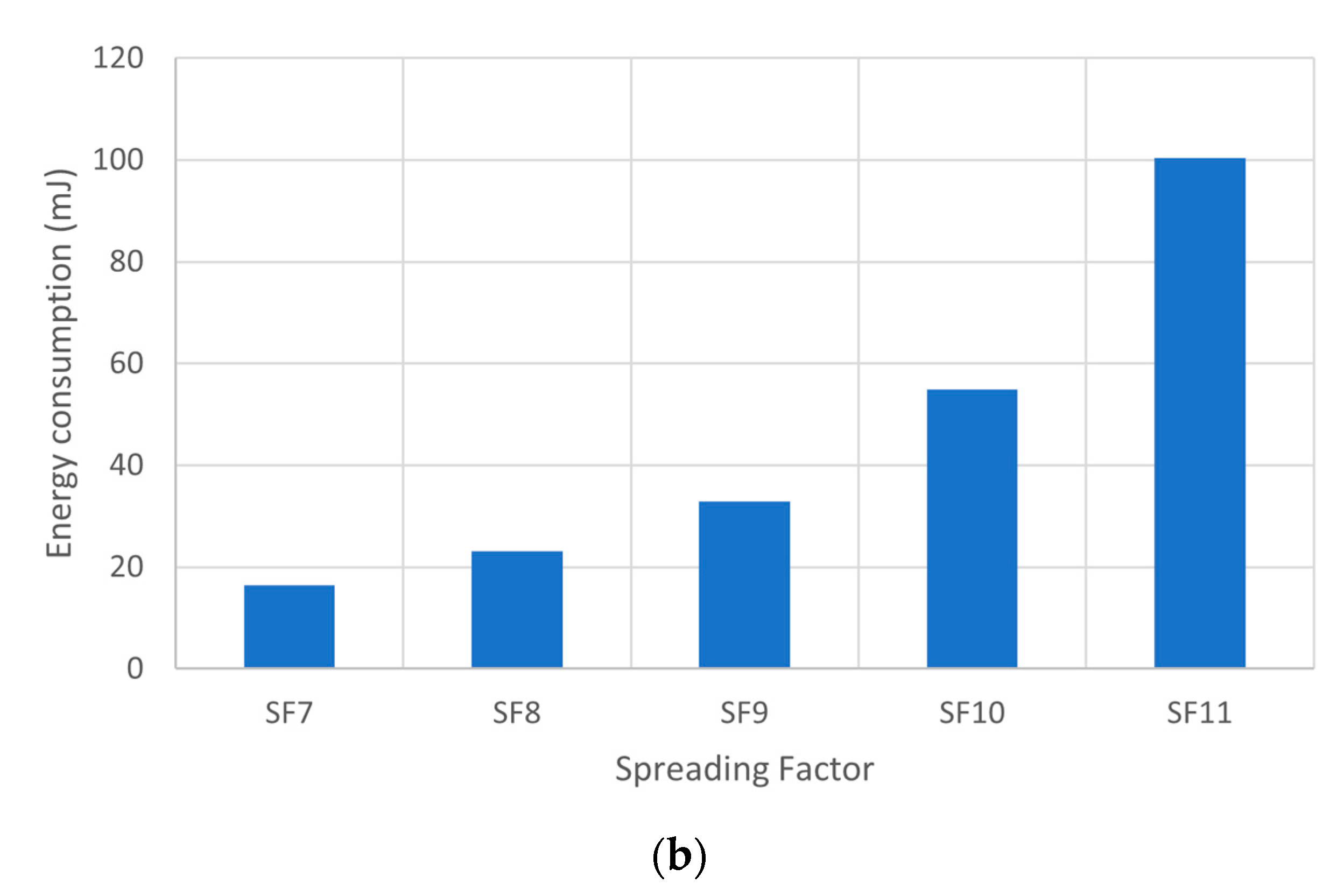

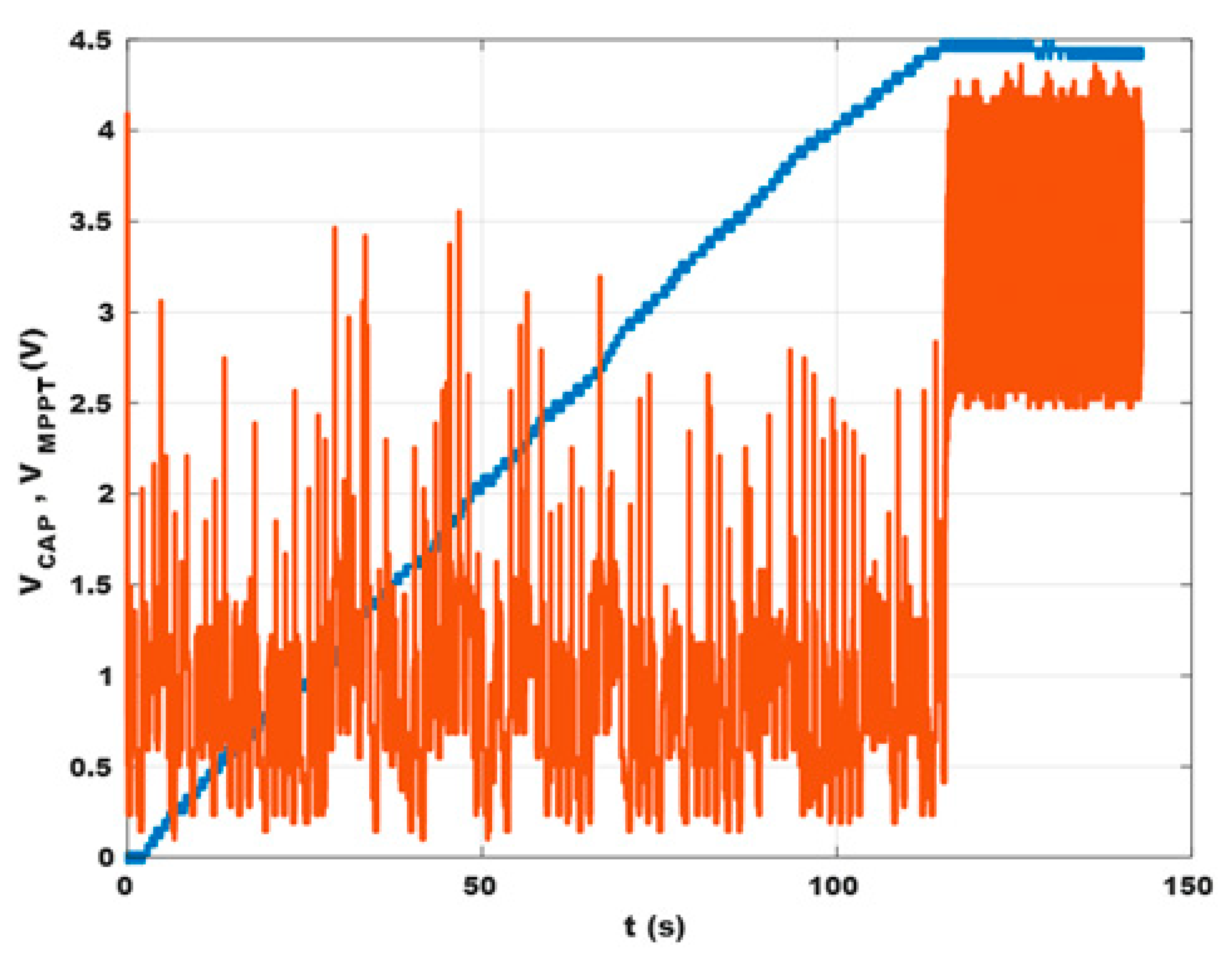

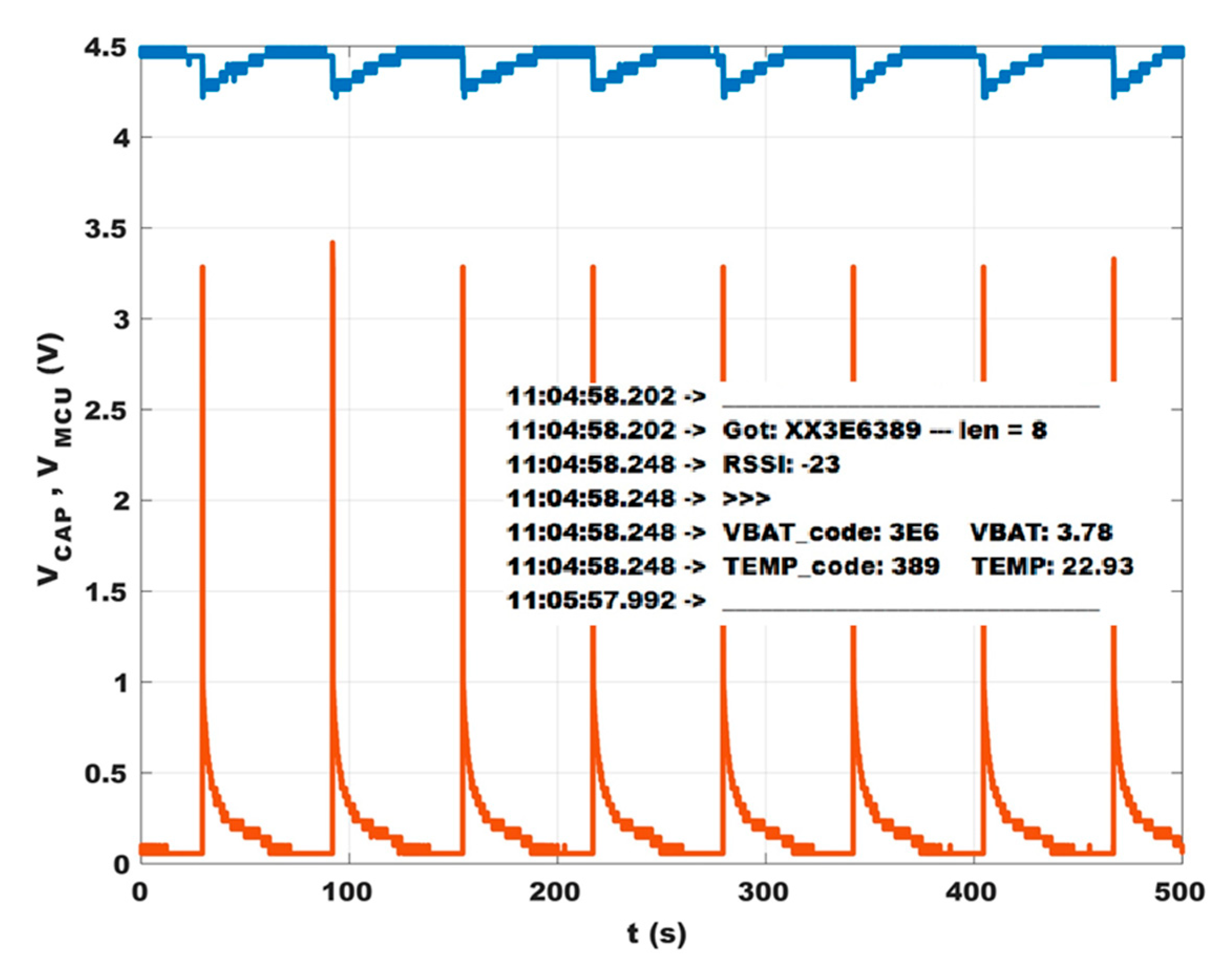

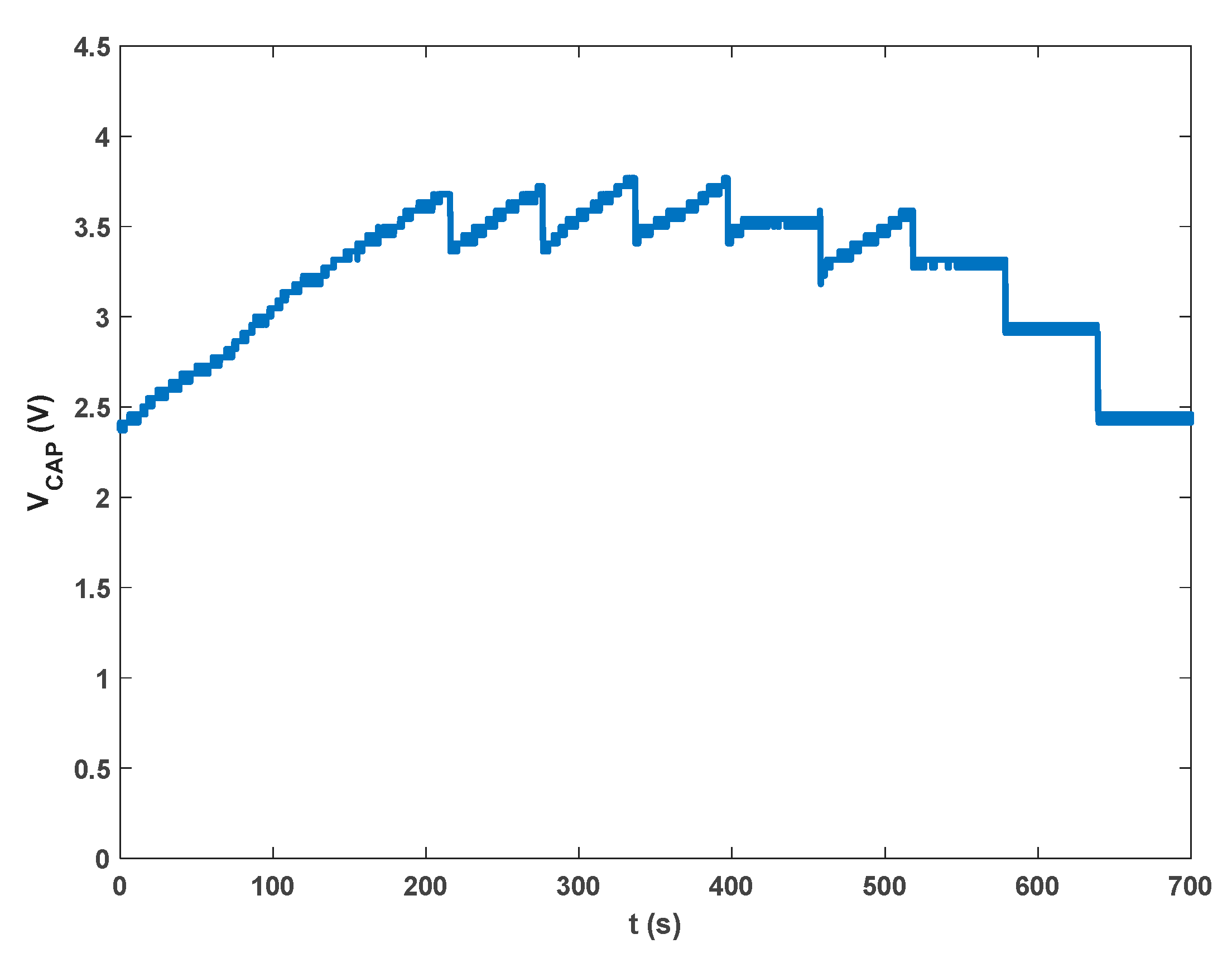

3. Measurement Results

4. Discussion and Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission—Energy. Energy Performance of Buildings Standards. Available online: https://energy.ec.europa.eu/ (accessed on 26 June 2023).

- U.S. Department of Energy. Residential Energy Consumption Survey (RECS). 2020. Available online: https://www.eia.gov/consumption/residential/data/2020/ (accessed on 26 June 2023).

- U.S. Department of Energy. Commercial Buildings Energy Consumption Survey (CBECS). 2018. Available online: https://www.eia.gov/consumption/commercial/data/2018 (accessed on 26 June 2023).

- Cetinkaya, O.; Zaghari, B.; Bulot, F.M.J.; Damaj, W.; Jubb, S.A.; Stein, S.; Weddell, A.S.; Mayfiel, M.; Beeby, S. Distributed Sensing with Low-Cost Mobile Sensors Toward a Sustainable IoT. IEEE Internet Things Mag. 2021, 4, 96–102. [Google Scholar] [CrossRef]

- Bulot, F.M.J.; Russell, H.S.; Rezaei, M.; Johnson, M.S.; Ossont, S.J.J.; Morris, A.K.R.; Basford, P.J.; Easton, N.H.C.; Foster, G.L.; Loxham, M.; et al. Laboratory comparison of low-cost particulate matter sensors to measure transient events of pollution. Sensors 2020, 20, 2219. [Google Scholar] [CrossRef] [PubMed]

- Touati, F.; Legena, C.; Galli, A.; Crescini, D.; Crescini, P.; Mnaouer, A.B. Renewable energy-harvested sensor systems for air quality monitoring. In Proceedings of the 2014 26th International Conference on Microelectronics (ICM), Doha, Qatar, 14–17 December 2014; IEEE: New York, NY, USA, 2014; pp. 160–163. [Google Scholar]

- Grossi, M. Energy Harvesting Strategies for Wireless Sensor Networks and Mobile Devices: A Review. Electronics 2021, 10, 661. [Google Scholar] [CrossRef]

- Panayanthatta, N.; Clementi, G.; Ouhabaz, M.; Costanza, M.; Margueron, S.; Bartasyte, A.; Basrour, S.; Bano, E.; Montes, L.; Dehollain, C.; et al. A Self-Powered and Battery-Free Vibrational Energy to Time Converter for Wireless Vibration Monitoring. Sensors 2021, 21, 7503. [Google Scholar] [CrossRef] [PubMed]

- Mishu, M.K.; Rokonuzzaman, M.; Pasupuleti, J.; Shakeri, M.; Rahman, K.S.; Binzaid, S.; Tiong, S.K.; Amin, N. An Adaptive TE-PV Hybrid Energy Harvesting System for Self-Powered IoT Sensor Applications. Sensors 2021, 21, 2604. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, H.; Yang, C.; Sun, H.; Yuan, Y. Vibration Energy Harvester Based on Bilateral Periodic One-Dimensional Acoustic Black Hole. Appl. Sci. 2023, 13, 6423. [Google Scholar] [CrossRef]

- Li, W.; Leng, B.; Hu, S.; Cheng, X. Improving the Output Efficiency of Triboelectric Nanogenerator by a Power Regulation Circuit. Sensors 2023, 23, 4912. [Google Scholar] [CrossRef]

- Wei, Y.; Duan, J.; Jing, H.; Yang, H.; Deng, H.; Song, C.; Wang, J.; Qu, Z.; Zhang, B. Scalable, Dual-Band Metasurface Array for Electromagnetic Energy Harvesting and Wireless Power Transfer. Micromachines 2022, 13, 1712. [Google Scholar] [CrossRef]

- Carter, J.; Rahmani, A.; Dibaj, M.; Akrami, M. Rainwater Energy Harvesting Using Micro-Turbines in Downpipes. Energies 2023, 16, 1660. [Google Scholar] [CrossRef]

- La Rosa, R.; Dehollain, C.; Livreri, P. Advanced Monitoring Systems Based on Battery-Less Asset Tracking Modules Energized through RF Wireless Power Transfer. Sensors 2020, 20, 3020. [Google Scholar] [CrossRef]

- La Rosa, R.; Dehollain, C.; Burg, A.; Costanza, M.; Livreri, P. An Energy-Autonomous Wireless Sensor with Simultaneous Energy Harvesting and Ambient Light Sensing. IEEE Sens. J. 2021, 21, 13744–13752. [Google Scholar] [CrossRef]

- Pop-Vadean, A.; Pop, P.P.; Latinovic, T.; Barz, C.; Lung, C. Harvesting energy and sustainable power source, replace batteries for powering WSN and devices on the IoT. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Baia Mare, Romania, 10–11 November 2016; IOP Publishing: Bristol, UK, 2017; Volume 200, p. 012043. [Google Scholar]

- Jiang, D.; Lian, M.; Xu, M.; Sun, Q.; Xu, B.B.; Thabet, H.K.; El-Bahy, S.M.; Ibrahim, M.M.; Huang, M.; Guo, Z. Advances in triboelectric nanogenerator technology—Applications in self-powered sensors, Internet of things, biomedicine, and blue energy. Adv. Compos. Hybrid Mater. 2023, 6, 57. [Google Scholar] [CrossRef]

- UN. The 17 Goals. Sustainable Development Goals. Retrieved 10 August 2022. Available online: https://sdgs.un.org/goals (accessed on 26 June 2023).

- Hosseinkhani, A.; Younesian, D.; Eghbali, P.; Moayedizadeh, A.; Fassih, A. Sound and vibration energy harvesting for railway applications: A review on linear and nonlinear techniques. Energy Rep. 2021, 7, 852–874. [Google Scholar] [CrossRef]

- Liu, L.; Guo, X.; Lee, C. Promoting smart cities into the 5G era with multi-field Internet of Things (IoT) applications powered with advanced mechanical energy harvesters. Nanoenergy 2021, 88, 106304. [Google Scholar] [CrossRef]

- Xia, L.; Ma, S.; Tao, P.; Pei, W.; Liu, Y.; Tao, L.; Wu, Y. A Wind-Solar Hybrid Energy Harvesting Approach Based on Wind-Induced Vibration Structure Applied in Smart Agriculture. Micromachines 2023, 14, 58. [Google Scholar] [CrossRef]

- Boccalero, G.; Olivieri, S.; Mazzino, A.; Boragno, C. Power harvesting by electromagnetic coupling from wind-induced limit cycle oscillations. Smart Mater. Struct. 2017, 26, 095031. [Google Scholar] [CrossRef]

- Olivieri, S.; Boccalero, G.; Mazzino, A.; Boragno, C. Fluttering conditions of an energy harvester for autonomous powering. Renew. Energy 2017, 105, 530–538. [Google Scholar] [CrossRef]

- Meeker, D. Finite Element Method Magnetics. Available online: www.femm.info (accessed on 26 June 2023).

- Available online: www.supermagnete.it (accessed on 26 June 2023).

- Petrini, F.; Gkoumas, K. Piezoelectric energy harvesting from vortex shedding and galloping induced vibrations inside HVAC ducts. Energy Build. 2018, 158, 371. [Google Scholar] [CrossRef]

- Wang, J.; Tang, L.; Zhao, L.; Zhang, Z. Efficiency investigation on energy harvesting from airflows in HVAC system based on galloping of isosceles triangle sectioned bluff bodies. Energy 2019, 172, 1066. [Google Scholar] [CrossRef]

- Han, N.; Zhao, D.; Schluter, J.U.; Goh, E.S.; Zhao, H.; Jin, X. Performance evaluation of 3D printed miniature electromagnetic energy harvesters driven by air flow. Appl. Energy 2016, 178, 672. [Google Scholar] [CrossRef]

- Haidar, M.; Chible, H.; Boragno, C.; Caviglia, D.D. A Low Power AC/DC Interface for Wind-Powered Sensor Nodes. Energies 2021, 14, 1823. [Google Scholar] [CrossRef]

- Boccalero, G.; Boragno, C.; Caviglia, D.D.; Morasso, R. FLEHAP: A Wind Powered Supply for Autonomous Sensor Nodes. J. Sens. Actuator Netw. 2016, 5, 15. [Google Scholar] [CrossRef]

- Orfanos, V.A.; Kaminaris, S.D.; Papageorgas, P.; Piromalis, D.; Kandris, D. A Comprehensive Review of IoT Networking Technologies for Smart Home Automation Applications. J. Sens. Actuator Netw. 2023, 12, 30. [Google Scholar] [CrossRef]

- Semtech. What Is LoRa? Available online: https://www.semtech.com/lora/what-is-lora (accessed on 26 June 2023).

- MIOTY Alliance e.V. Mioty Technology. Available online: https://mioty-alliance.com/miotytechnology/ (accessed on 26 June 2023).

- LoRa Alliance. What Is LoRaWAN® Specification. Available online: https://lora-alliance.org/about-lorawan/ (accessed on 26 June 2023).

- AEM30940-RF-Vibration Energy Harvesting Datasheet, E-Peas Semiconductor. Available online: https://e-peas.com/wp-content/uploads/2022/09/e-peas-AEM30940-datasheet-RF-Vibration-energy-harvesting-09-22.pdf (accessed on 26 June 2023).

- Texas Instruments. TPS63900 1.8-V to 5.5-V, 75-nA IQ Buck-Boost Converter with Input Current Limit and DVS. Available online: https://www.ti.com/product/TPS63900?qgpn=tps63900 (accessed on 26 June 2023).

- Adafruit. Adafruit Feather M0 RFM96 LoRa Radio—433MHz—RadioFruit. Available online: https://www.adafruit.com/product/3179 (accessed on 26 June 2023).

- Microchip. SAM D21/DA1 Family Datasheet. Available online: https://ww1.microchip.com/downloads/en/DeviceDoc/SAM_D21_DA1_Family_DataSheet_DS40001882F.pdf (accessed on 26 June 2023).

- Semtech. SX1276/77/78/79—137 MHz to 1020 MHz Low Power Long Range Transceiver Datasheet. Available online: https://semtech.my.salesforce.com/sfc/p/#E0000000JelG/a/2R0000001Rbr/6EfVZUorrpoKFfvaF_Fkpgp5kzjiNyiAbqcpqh9qSjE (accessed on 26 June 2023).

- Overview of the Arduino IDE 1. Available online: https://docs.arduino.cc/software/ide-v1/tutorials/Environment (accessed on 26 June 2023).

- Texas Instruments. TPL5110 Nano-Powered System Timer with MOS Driver and Manual MOSFET Power ON. Available online: https://www.ti.com/product/TPL5110 (accessed on 26 June 2023).

- Diodes. AP2112 600 mA CMOS Ldo Regulator with Enable Datasheet. Available online: https://www.diodes.com/assets/Datasheets/AP2112.pdf (accessed on 26 June 2023).

- Arduino Forum. Arduino Zero without an External 32 khz Crystal. Available online: https://forum.arduino.cc/t/arduino-zero-without-an-external-32khz-crystal/625614/2, (accessed on 24 April 2023).

- CEPT/ERC Recommendation 70-03, 11 February 2022. Available online: https://docdb.cept.org/download/3700 (accessed on 25 June 2023).

- Boccalero, G.; Boragno, C.; Morasso, R.; Caviglia, D.D. A Sensor Node Driven by Air Flow. In Proceedings of the 2017 New Generation of CAS (NGCAS), Genova, Italy, 6–9 September 2017; pp. 21–24. [Google Scholar] [CrossRef]

- Microchip. MCP9700—Low-Power Linear Active Thermistor IC. Available online: https://www.microchip.com/en-us/product/MCP9700 (accessed on 26 June 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Boragno, C.; Aiello, O.; Caviglia, D.D. Monitoring the Air Quality in an HVAC System via an Energy Harvesting Device. Sensors 2023, 23, 6381. https://doi.org/10.3390/s23146381

Boragno C, Aiello O, Caviglia DD. Monitoring the Air Quality in an HVAC System via an Energy Harvesting Device. Sensors. 2023; 23(14):6381. https://doi.org/10.3390/s23146381

Chicago/Turabian StyleBoragno, Corrado, Orazio Aiello, and Daniele D. Caviglia. 2023. "Monitoring the Air Quality in an HVAC System via an Energy Harvesting Device" Sensors 23, no. 14: 6381. https://doi.org/10.3390/s23146381

APA StyleBoragno, C., Aiello, O., & Caviglia, D. D. (2023). Monitoring the Air Quality in an HVAC System via an Energy Harvesting Device. Sensors, 23(14), 6381. https://doi.org/10.3390/s23146381